Page 1

CM-6001-TM Manual

SERIES 12

VARIABLE AREA FLOWMETERS

INSTALLATION, OPERATION &

SERVICE INSTRUCTIONS

15555 North 79th Place

Scottsdale, AZ 85260

tel: (480) 922-7446

fax: (480) 948-3610

Email: sales@cox-instruments.com

Web: www.cox-instruments.com

Page 2

Contents

Section Page

I USE AND MAINTENANCE…………………………………… 1

1-1. Purpose ………………………………………… 1

1-3. Models ………………………………………….. 1

1-6. Variations Within Models …………………….. 1

1-9. Description …………………………………….. 1

1-24. Specifications ………………………………….. 4

1-27. Preparation for Use …………………………… 4

1-29. Installation ……………………………………… 4

1-30. Operation ………………………………………. 5

1-38. Maintenance …………………………………… 6

1-40. Cleaning Tubes and Floats ………………….. 6

1-42. Parts Replacement ……………………………. 6

1-44. Replacing Tube Gaskets ……………………... 6

1-48. Replacing Valves ……………………………… 7

1-50. Shipment ……………………………………….. 8

1-52. Storage …………………………………………. 8

1-54. Trouble Shooting ……………………………… 8

1-55. Back Lighting Maintenance ………………….. 9

Flowmeter Model Conversion Key 10

II PARTS BREAKDOWN………………………………………... 13

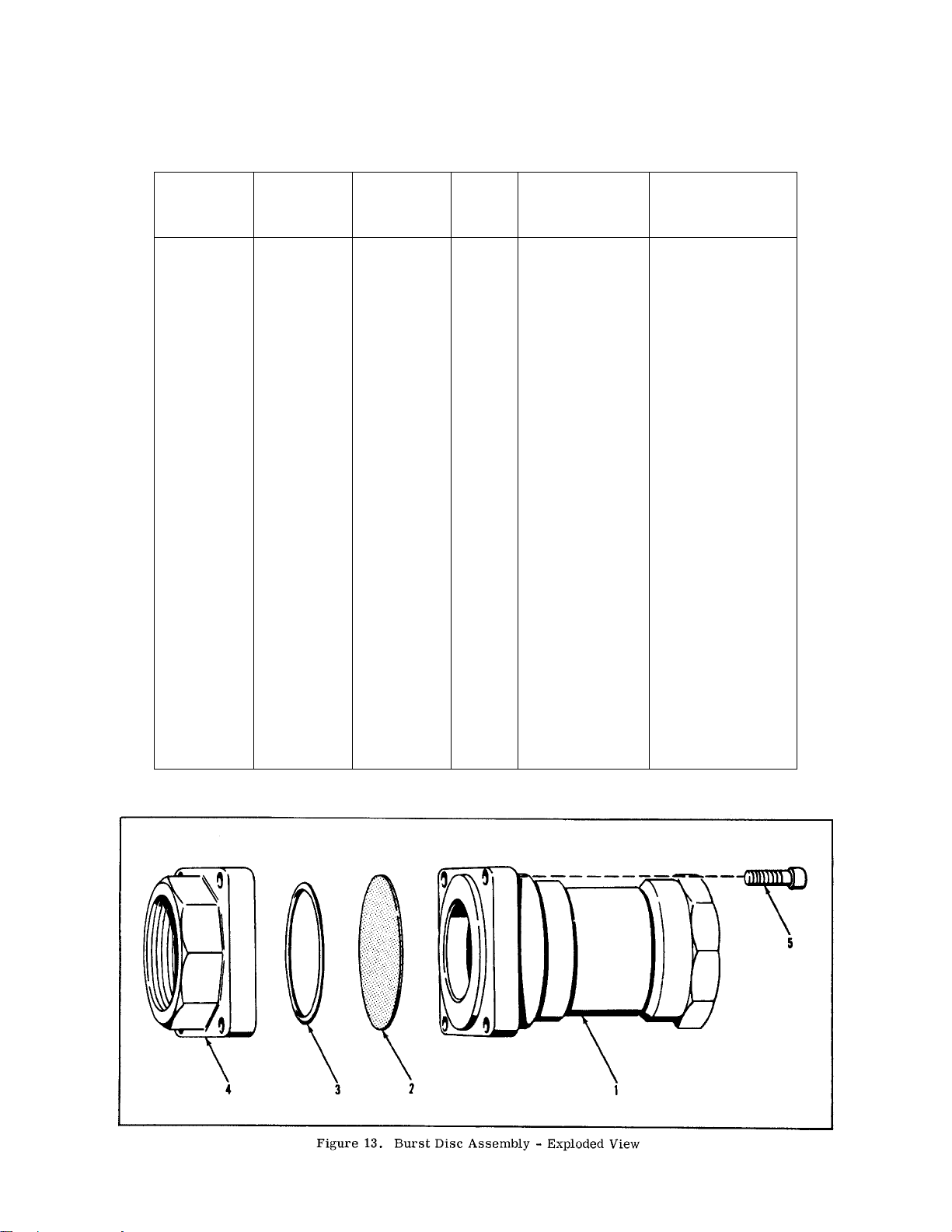

Figure 13. Burst Disc Assembly – Exploded View …… 13

Figure 14. Inlet Elbow Assembly …………………………. 13

Figure 15. Tube Assembly – Exploded View …………… 14

Figure 16. Worcester Valve and Handle Assembly ……. 15

Page 3

SECTION I

USE AND MAINTENANCE

Section I

Paragraphs 1-1 to 1-10

1-1. PURPOSE.

1-2. The Series 12 flowmeter is an instrument for the accurate

and continuous measurement of the rate of flow for liquids

and gases at nominal pressures.

1-3. MODELS.

1-4. The Series 12 flowmeter is available in three basic

models; Model 124, Model 129 and Model 120. (Refer to

Flowmeter Model Conversion Key, Page 9). Each model is

available as a single stage or multi-stage flowmeter. Each

stage consists of a matched tube and float with a calibrated

scale and necessary mounting connections. A multi-stage

flowmeter consists of two or more matched tubes and floats,

normally of the same model together with scales and mounting

connections, assembled into a steel shell.

1-5. Bypass valves are required for most multi-stage

flowmeters to bypass the lower stages when operating in the

higher flow ranges, thus maintaining a normal pressure drop

over the entire flow range.

NOTE

On a maximum stage standard flowmeter of

any model, the pressure drop through the

flowmeter will not exceed 6 psig, except for

flowmeters with bypass orifice sections

where the pressure drop is approximately 8

psig.

b. Orifice valve and calibrated auxiliary bypass

orifice to increase the capacity of a particular

flowmeter.

1-9. DESCRIPTION.

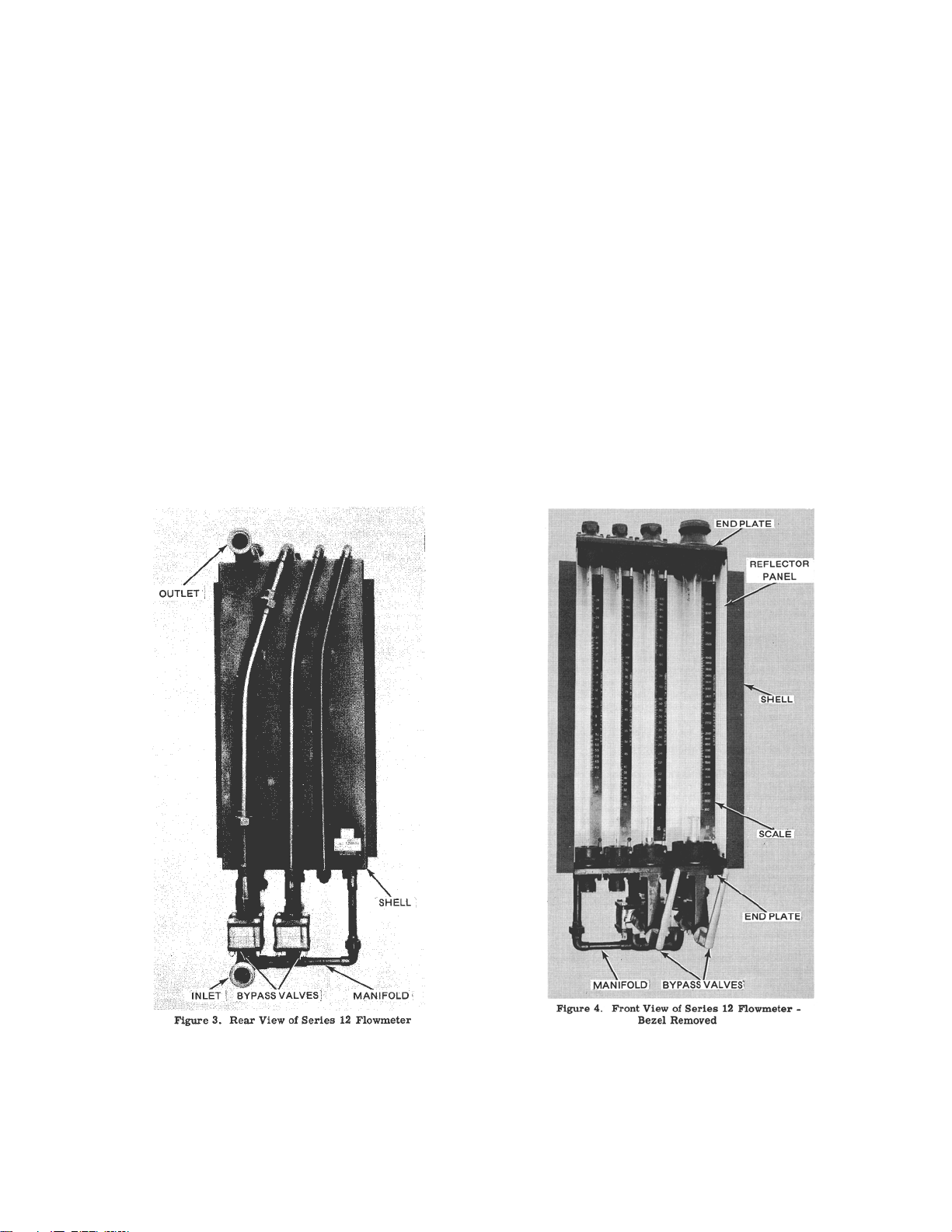

1-10. In multi-stage flowmeters the top of each glass tube is

connected with the bottom of the next larger tube by a

copper tube at the rear of the shell. This provides a

continuous passage from inlet at the lower end of the

first tube to the outlet at the top of the last tube (see fig.

3). Each tube is fitted with a metal float which

positions itself in the tube according to the rate of flow.

Since the pressure drop across the float is constant

throughout the range of any particular tube, any change

in rate of flow will result in a relocation of the float to a

position where the annulus area is such as to maintain

this constant pressure drop across the float. Since the

tube is of an expanded taper, an increase in flow will

result in a rise in the float position and inversely a

decrease in flow will result in a lowering of the float

position. When the maximum capacity of a tube is

approached, the increased rate of flow affects the float

in the next tube. This sequence is continued through all

tubes until one of the floats comes to rest within the

limits of its scale at which point the rate of flow is read.

Tubes are calibrated and scales are engine divided to

read in pounds per hour, gallons per minute or other

units to fit specific requirements.

1-6. VARIATIONS WITHIN MODELS.

1-7. Multi-stage flowmeters usually consist of tubes of the

basic model as in paragraph 1-4, but to meet certain

requirements, some multi-stage flowmeters have been

produced with intermixed size 40, 90, 100 and 140 tubes.

Other requirements have resulted in incorporating size 60

tubes intermixed with one or more of the standard Series 12.

To correctly identify any tube refer to the number etched near

the top of the tube. This number consists of the flowmeter

serial number, tube size, and model number. For example,

12001-47 indicates flowmeter serial number 12001-47 and

tube size seven in the Model 124-300 group.

1-8. Other variations within models are:

a. Fluorescent backlighting for each and

convenience in reading flow.

1

Page 4

Section I

Paragraphs 1-11 to 1-13

1-11. TUBES (fig. 2). Tubes are precision molded of

borosilicate glass with four float guides and tapered flutes

integral with the tube. The inner diameter across the guides is

the same from top to bottom but the inner diameter of the

tapered flutes expands logarithmically giving an increasing

flow area past the float as it rises. The guides confine the float

to the central axis of the tube and diminish swirls of fluid

passing through the tube. Tubes have flowmeter serial

number and tube size etched near the top of the tube.

NOTE

Tubes, floats, and scales are calibrated as a unit

and are not interchangeable. If a tube is broken,

a new tube, float, and scale must be ordered. An

unserviceable float can be replaced by fitting and

recalibrating a new float to the old tube.

Damaged scales can be replaced if flowmeter

serial number, tube number, and sizes are

furnished.

1-12. FLOATS (fig. 2). Floats are machined of a material

impervious to the fluid used and precisely fitted to the tube

making a matched assembly of float and tube. Floats are

provided with a short threaded stub extension for attachment

of a rod to facilitate removal or installation. Floats are etched

with the flowmeter serial number and tube size.

1-13. SCALES (fig. 4). Each tube with its float is accurately

calibrated and its scale graduated to agree with the calibration.

The 18-inch logarithmic type scale provides the same degree

of reading accuracy throughout the flow range. Scales are

made of plastic or aluminum and engraved with contrasting

figures. Scales are attached to adjustable support posts which

2

Page 5

are located in drilled holes in front corners of the tube packing

glands and secured by screws. Scales are aligned with tube

index line by adjusting the support posts. Packing glands are

drilled at each side permitting scales to be mounted on both

sides if desired.

1-14. TUBE MOUNTING (fig. 15). Tubes are fitted into

upper and lower end castings and are held in position by

packing glands. The glands are tightened against gaskets to

prevent leakage. The end caps mounted on lower and upper

end castings contain float stops with springs.

1-15. TUBE CONNECTIONS. End casting fittings extend

toward the back of the instrument and are connected in series

by copper tubing. Bottom fittings are provided with bypass

valves when required. The fluid enters a manifold assembly at

the bottom and is then distributed as governed by the position

of the bypass valves. Outlet is from the top of the last tube.

Section I

Paragraphs 1-14 to 1-21

1-18. A 2-inch orifice ball valve is provided, in flowmeters, to

divert a portion of the flow through the calibrated orifice

increasing the flow range of the instrument. Flowmeters

incorporating a bypass orifice are provided with a special inlet

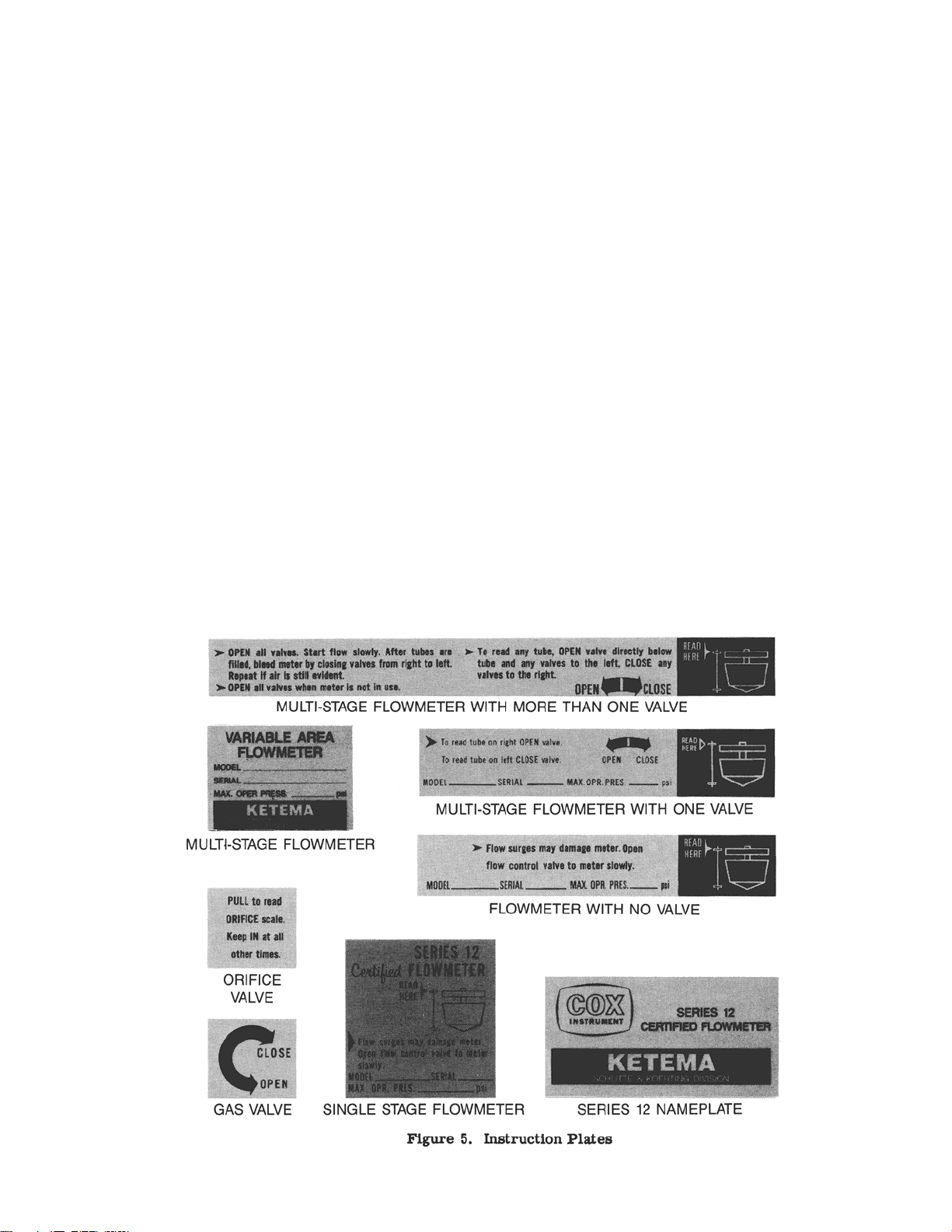

elbow to eliminate entrance effects.

1-19. INSTRUCTION PLATE. An instruction plate,

mounted behind the bezel window provides instructions for

operating the flowmeters and reading the position of the float.

1-20. SHELL. All tubes and fittings are mounted in a welded

steel shell. End castings are bolted to upper and lower

members. Shells are designed for flush panel mounting. A

bezel holding a safety glass window covers the front of the

instrument. A white enameled steel reflector panel is mounted

behind the tubes. Valve shafts extend through the bezel.

Handles are installed on the ends of the valve shafts.

1-16. The ball type bypass valve is manufactured by the

Worcester Valve Co. and is furnished in ¾, 1-1/4 and 2-inch

sizes.

1-17. The valve consists of a bronze body and ball with Buna

N seals to prevent leakage. One end of the handle assembly,

available in varying lengths, is connected to the valve by a

coupling while the bracket on the opposite end is connected to

the shell.

1-21. BURST DISC ASSEMBLY. A burst disc assembly can

be furnished to protect the flowmeter tube in installations

where the flowmeter might be subjected to excessive pressure

surges. This disc assembly is furnished as standard equipment

on any flowmeter incorporating a 48, 99, 109 or 148 size tube

and can also be ordered for any particular flowmeter. The disc

assembly is installed in a tee on the inlet side of the

3

Page 6

Section 1

Paragraphs 1-22 to 1-29

flowmeter and is designed to burst at a pressure lower than the

bursting pressure of the largest tube. The disc is rated to burst

at 85 psi. r 5 psi. This provides a bypass through which the

flow may be returned to the supply tank.

1-22. LIGHTS. Depending on size and number of stages

used, flowmeters can be equipped with explosion proof or

non-explosion proof fluorescent lights mounted behind the

tubes.

1-23. AIR CYLINDERS. Flowmeters can be equipped with

air cylinders to operate the bypass valves. Different cylinder

assemblies are used for 1-1/4 and 2-inch valves.

1-24. SPECIFICATIONS.

1-25. CAPACITY. Cox Variable Area Flowmeters Bulletin

CA 6001 provides information on the range and capacity for

all standard combinations of Series 12 Flowmeters.

1-26. MOUNTING DIMENSIONS. Cox Variable Area

Flowmeter Bulletin CA 6001 provides information on

mounting dimensions for all standard Series 12 Flowmeters.

1-27. PREPARATION FOR USE.

1-28. UNPACKING. Unpack instrument carefully. Parts of

this flowmeter are fragile and can be easily damaged. Check

all parts against packing slip to be sure that none are

discarded. Floats, 0.375-inch and larger, are packed

separately in a small container. Handle floats carefully.

Floats are fitted to the tubes with extreme accuracy and the

slightest damage may make them useless. Replace them in

original containers after checking until ready for their

installation.

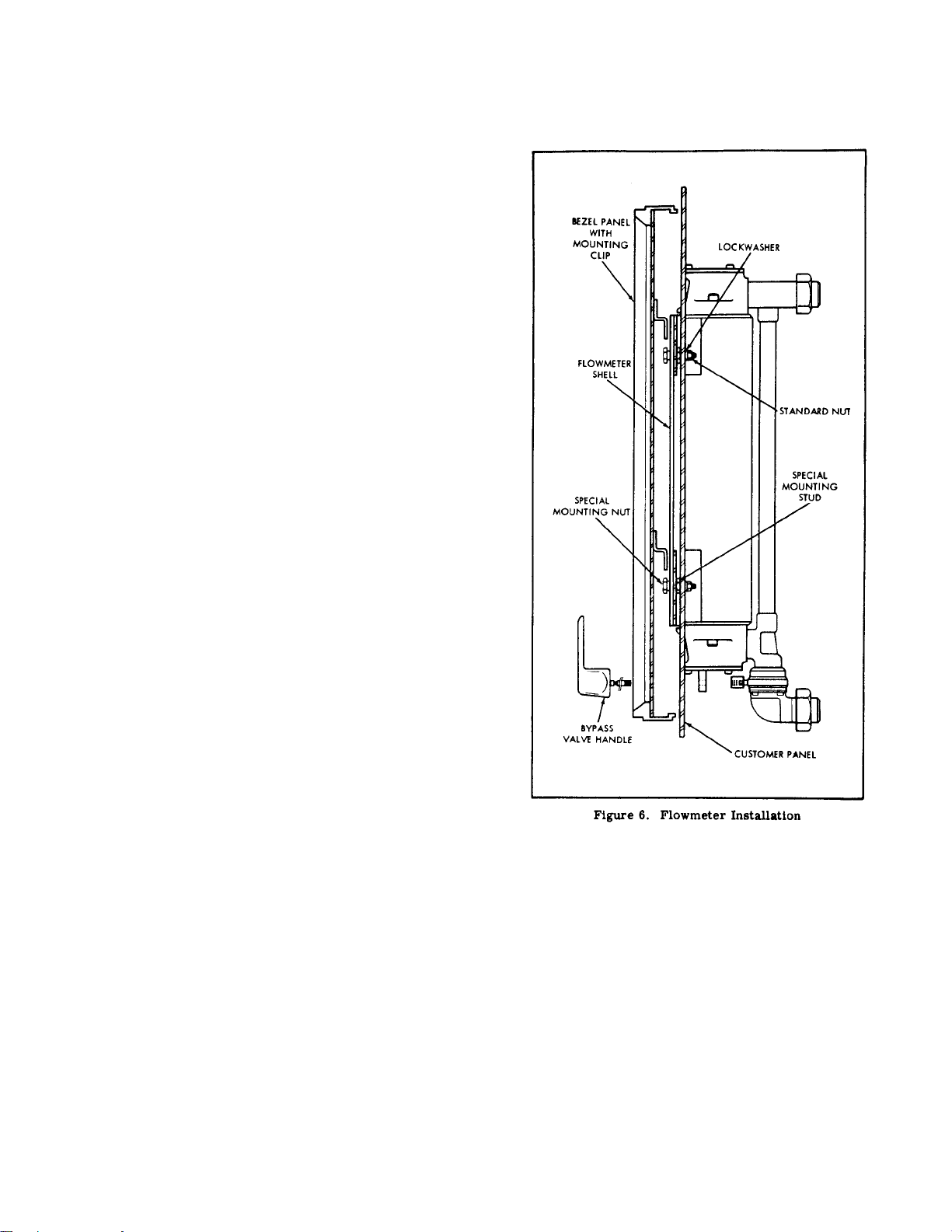

1-29. INSTALLATION (fig. 6).

a. Flowmeter should be mounted in a vertical position and as

free from vibration as possible. The maximum allowable

position is approximately 5q off the center vertical centerline.

A position greater than 5q would tend to introduce about a 1 to

2% error in accuracy. Install special mounting stud (longer

threaded portion first) into holes drilled in customer’s panel.

Secure in place with lockwasher and standard hex nut. Install

meter shell onto studs and secure in place with special nut

with shoulder toward panel.

b. Clean inside of instrument thoroughly. Wipe reflector with

a clean cloth. The red index line on scale must align with red

mark on tube. Loosen set screws holding scale support posts

in packing glands and adjust scales if necessary. Install bezel

with window on front of shell by engaging clips on inside of

bezel in special mounting studs.

c. To avoid strain and transmitting vibration to flowmeter,

flexible hoses or lines should be installed between flowmeter

and service lines. If inlet and outlet unions cannot be

separated by the fingers, use two wrenches. All tubing joints

are soft soldered and strain on them should be avoided. With

suitable adaptor, connect flexible lines to unions and service

piping. Use two wrenches to tighten. A shut-off valve should

be installed in discharge line beyond the flexible connection.

This will prevent possible drainage of the instrument when

device being checked is disconnected. When furnished, install

pressure blowout disc assembly in inlet line to flowmeter.

d. A 25 micron filter should be installed on the inlet side of

the flowmeter. This will keep the flowmeter clean and keep

floats from sticking and collecting dirt. Collecting dirt adds

weight to the float which in turn changes flow rate reading.

4

Page 7

Section I

Paragraphs 1-30 to 1-37

In addition, a thermometer should be installed as close to the

inlet of the flowmeter as possible. This will provide a

constant check to assure proper flow readings.

e. The flowmeters are calibrated on a Cox Liquid Calibrator

maintaining a 10-15 psig back pressure. Back pressure should

be provided in the installation to aid in purging air out of the

system and introducing float stability.

f. Remove fillister head screws holding end caps to upper end

castings and lift off caps. Remove floats from their container

and wipe them off thoroughly with a clean soft cloth. Notice

that floats are etched with the serial number of instrument and

tube size. Thread the float extractor rod to each float, insert

float in proper tube and lower to bottom of tube. Unscrew

rod. Use care to get floats in proper tube. Install end caps

with their “O” rings and tighten screws. Clearance on panel

cut-out should be provided in the top of any test stand to allow

for float removal.

CAUTION

Do not drop floats into tubes.

1-30. OPERATION.

valve is opened, the tubes below it are inoperative and

pressure drop is maintained at a minimum. All valves must be

opened when reading last tube.

1-35. READING THE SCALES. Scales are read opposite top

surface of float disc. On units equipped with an orifice, read

the scale on the right side of the largest tube when the orifice

valve is opened. Readings are accurate only when eye of

observer is at the same level as top of float. (See fig. 5.)

1-36. TEMPERATURE. Watch temperature of liquid during

test. Endeavor to keep it within plus or minus 3qF of value

marked on scale. Three degrees Fahrenheit temperature

change is equal to approximately 0.1% shift in flow rate.

1-37. PRESSURE BLOWOUT DISC ASSEMBLY. If a

flowmeter utilizing a pressure blowout disc assembly has been

subjected to excessive pressure surges causing the blowout

disc to burst, the following procedure must be followed before

resuming operation.

1. Shut down fuel supply to flowmeter

1-31. GENERAL. The instrument has been accurately

calibrated for a specific liquid or gas and the scales divided

accordingly. Variations in temperature or in specific gravity,

which are marked on edges of scales, will affect correctness of

readings.

1-32. LEAKAGE. The equipment to be tested is normally

connected to the outlet of the instrument. The connections

between flowmeter and equipment must be tight. Any leakage

in this line will result in high readings. If the equipment to be

tested is installed on the inlet side, leakage will result in low

readings.

1-33. EXPEL AIR. Open the bypass valves and provide

means to return the maximum flow to fuel supply tank. Open

supply line to flowmeter and set up rate of flow corresponding

to full scale reading on largest tube, open and close largest

tube valve and allow to remove air. Reduce flow within range

of next largest tube following a bypass valve and repeat

procedure until all air is expelled. Continue in a like manner

until flowmeter is completely purged of air.

CAUTION

Do not operate valves until flowmeter is filled

with liquid. Always leave valve in “OPEN”

position when flowmeter is not in use.

1-34. VALVES. In a multi-stage flowmeter, all valves must

be closed when reading flow in the smaller tubes. As each

5

Page 8

Section I

Paragraphs 1-38 to 1-44

2. Determine cause of excessive pressure surges

and correct if possible.

this reason the repairs and replacements considered

are limited to replacement tube gaskets, valve seals,

metering tubes, and repair of damaged copper tubing.

3. Replace ruptured blowout disc.

1-38. MAINTENANCE.

1-39. GENERAL. Periodic cleaning of tubes and floats is

necessary to remove all deposit of foreign matter. A regular

schedule of cleaning should be adhered to depending on nature

of liquid being used. Deposits on floats or tube walls which

restrict flow will result in high readings.

1-40. CLEANING TUBES AND FLOATS

a. Relieve pressure on instrument. Do not drain.

b. Remove fillister head screws holding end cap to upper end

castings.

c. Insert float extractor rod (fib. 7), thread it onto float, and

lift out float. Handle floats carefully to avoid damage.

d. With the proper size brush, clean tube thoroughly with

eight or ten strokes of brush for entire length of tube (fig. 8).

e. Drain and flush with clean fluid.

f. Wipe float with clean soft cloth to remove all dirt and gum

deposit. Do not polish float with any abrasive.

1-44. REPLACING TUBE GASKETS (fig. 9).

a. Relieve pressure on instrument.

b. Remove top end caps and floats.

c. Remove end caps from bottom end castings to

drain unit.

d. Remove bezel with window from front of

instrument.

e. Remove screw holding scale to lower support

post. Loosen screw holding upper support post and

pull down to remove scale and upper support post.

f. Remove socket head cap screws holding glands in

position. Slip glands toward center of tube, lift tube

slightly and remove from instrument. Notice

arrangement of tube gaskets when removing. Note

that one aluminum backing washer, then the four or

five Buna N gaskets (to make ½-inch thickness) go

on tube and are slipped into gland in that order, then

the second aluminum washer is placed on the gaskets.

The thin fairprene gasket is then placed in gland.

g. Attach extractor rod and carefully lower float until float

rests on lower stop. Detach rod.

h. Install end cap and tighten screws. Clean remaining stages

in order.

NOTE

Use extreme care at all times to avoid damage to

float. Any damage will affect calibration of any

tube and result in inaccurate readings. Also be

sure that floats are not interchanged.

1-41. ALIGNMENT OF SCALES. Check alignment of

scales when cleaning tubes. Red index line on scale should

align with red index line on tube. If out of line, loosen screws

holding scale support posts, align scale and tighten screws.

1-42. PARTS REPLACEMENT.

1-43. PERMISSIBLE OVERHAUL. Flowmeters

are assembled and calibrated by trained personnel

under exacting conditions and no general

disassembly is ever required or recommended. For

6

Page 9

This thin gasket can be held in position by coating with a thin

film of cup grease to prevent shifting while assembling gland

and tube. A tube stop washer is then installed as the last item

in the bottom gland only.

CAUTION

Do not use cup grease on flowmeters for oxygen

service.

g. To assemble, place tube in position with aligning mark

toward front. Slip glands into position and secure with cap

screws. Tighten screws evenly.

h. Install scale and upper support post. Install screw holding

scale to lower support post. Align mark on scale with mark on

tube and tighten support post set screws.

i. Install lower end caps and tighten fillister head screws.

j. Install floats using rod to carefully lower float onto bottom

stop.

Section I

Paragraphs 1-45 to 1-49

k. Install upper end caps and tighten fillister had screws.

l. Install bezel with window to front of instrument.

1-45. REPLACING BROKEN METERING TUBE. As all

tubes are calibrated with their floats, and scales graduated to

conform, replacement tubes are supplied with floats, scales,

and necessary gaskets. For removal and replacement of tubes

refer to paragraph 1-44. Damaged scales can be replaced by

giving tube size and serial number of the flowmeter. This

number is etched on tube near the stop and on the float shank.

1-46. REPLACING FLOAT STOPS. Float stops are rods

threaded on one end and screwed into end caps. Stops are

equipped with springs. To replace, grip stop in vise and

unscrew end cap and install new stop. Spring can be

unscrewed from old stop and installed on replacement. When

replacing float stop, the stop and end cap must be square.

1

-47. REPAIRS TO METAL TUBING AND FITTINGS. No

one except a repairman thoroughly experienced and competent

in making solder joints should be permitted to make repairs or

replacements on the metal tubing.

WARNING

If the vapor of the liquid used in this instrument

is highly volatile, the instrument must be

thoroughly cleaned before any heat is used in

disassembly.

remove manifold. Remove cap screws from the upper flange

of the valves to be replaced and withdraw valves.

b. See that seals and seats are in position on both faces, insert

valve between flanges and install cap screws on top and

bottom flanges. Tighten upper screws and pull screws in

lower flange up evenly. Tighten inlet union. Connect handle

assembly to valve, utilizing pin and coupling.

1-48. REPLACING VALVES.

a. Disconnect inlet tube union to first stage and loosen all cap

screws in lower flanges holding manifold to valves and

7

Page 10

Section I

Paragraphs 1-49 to 1-54

1-49. REPAIR OF VALVES. If the valve becomes worn or

defective, replacement parts may be purchased from the

manufacturer. See Section II for detailed parts lists.

1-50. SHIPMENT.

1-51. The flowmeter should never be shipped unless carefully

boxed and fully protected. Floats, 3/8 inch and larger, must be

removed from tubes and wrapped separately to prevent

damage.

TROUBLE POSSIBLE CAUSE REMEDY

READINGS TOO HIGH Temperature of fuel below

specifications.

Viscosity of fuel higher than specified.

Dirty floats or metering tubes.

Leaks in gaskets in tubes of higher

capacity than tube being read.

1-52. STORAGE.

1-53. If flowmeter is to be placed in storage, fill tube with oil

SAE-10 and open all valves.

CAUTION

For oxygen service flowmeters, clean with

Freon after storage.

1-54. TROUBLESHOOTING.

Correct temperature.

Use specified fuel if possible.

Clean (par. 1-40).

Replace gaskets (par. 1-44).

Leak between instrument and test unit (if

Check for and repair leakage.

on outlet side).

READINGS TOO LOW Temperature of fuel above

Correct temperature.

specifications.

Viscosity of fuel lower than specified.

Leaks through bypass valves.

Leak between instrument and test unit (if

Use specified fuel if possible.

Check valves are correct.

Check for and repair leakage.

on inlet side).

READING INACCURATE

(EITHER HIGH OR LOW)

Reading taken improperly.

Scales improperly set.

Eye must be on level with float top

(par. 1-35).

Align scale and tube red index lines

(par. 1-41).

FLOATS FLUCTUATE Pump surge reaches instrument.

Air in system.

Install surge trap or change pump.

Bleed air (par. 1-33).

FLOAT STICKS IN TUBE Tube or float dirty. Clean (par. 1-40).

EXCESSIVE PRESSURE DROP

Closed bypass valves.

Check and correct valves.

THROUGH INSTRUMENT

Float sticks.

Clean float (par. 1-40).

8

Page 11

Section I

Paragraph 1-55 – 1-55

1-55. BACK LIGHTING MAINTENANCE. Bulb

replacement is accomplished as follows:

a. Non-Explosionproof (See figures 10 and 11)

1. Disconnect power and electrical wires to shell

assembly.

2. Remove four (4) screws (10-32 x 3/8) holding shell

assembly to housing.

3. Slide out shell assembly.

4. Remove and replace defective fluorescent bulb (G.E.

P/N F20T12/D) and/or starter (G.E. P/N FS-2) as required.

5. Slide shell on housing and align.

6. Reinstall screws removed in second step.

7. Reconnect electrical wires disconnected in first step.

b. Explosionproof (See figures 10 and 12)

1. Disconnect power, conduit, and electrical wires to

shell assembly.

5. Remove and replace defective fluorescent bulb (G.E.

P/N F15T12/CW) and/or starter (G.E. P/N FS-2) as required.

Maintenance instructions for this operation are printed on the

cap inside face.

6. Reinstall the cap removed in the fourth step.

7. Slide shell assembly on flowmeter housing and align.

8. Reinstall screws removed in second step.

9. Reconnect electrical wires and conduit disconnected in

first step.

2. Remove four (4) screws (10-32 x 3/8) holding shell

assembly to flowmeter housing.

3. Slide out shell assembly.

4. Remove upper cap (end opposite conduit connection)

by turning cap counter-clockwise.

9

Page 12

Section I

FLOWMETER MODEL CONVERSION KEY

MODEL SHELL NO. TUBE NUMBERS

124-200

124-201

124-202

124-203

124-204

124-205

124-206

124-207

8

14

15

3

4

5

6

7

141

141-142

141-142-143

141-142-143-144

141-142-143-144-145

141-142-143-144-145-146

141-142-143-144-145-146-147

141-142-143-144-145-146-147-148

RECOMMENDED

SAFE WORKING

PRESSURE (psig)

200

200

160

14

110

95

70

65

124-208

124-209

124-210

124-211

124-212

124-213

124-214

124-215

124-216

124-217

124-218

124-219

124-220

124-221

124-222

124-223

124-224

124-225

124-226

124-227

124-228

124-229

14

10

8

2

3

4

5

6

9

1

2

4

5

6

9

1

3

4

6

2

3

5

142

142-143

142-143-144

142-143-144-145

142-143-144-145-146

142-143-144-145-146-147

142-143-144-145-146-147-148

143

143-144

143-144-145

143-144-145-146

143-144-145-146-147

143-144-145-146-147-148

144

144-145

144-145-146

144-145-146-147

144-145-146-147-148

145

145-146

145-146-147

145-146-147-148

200

160

140

110

95

70

65

160

140

110

95

70

65

140

110

95

70

65

110

95

70

65

10

124-230

124-231

124-232

124-233

124-234

11

12

146

2

4

3

146-147

146-147-148

147

147-148

95

70

65

70

65

Page 13

FUEL

(120 – 200

to 120 – 222)

FLOWMETER MODEL CONVERSION KEY – CONTINUED

OIL

(120 – 240

to 120 – 261)

GASES

(120 – 277

to 120 – 294)

SHELL

NO. TUBE NUMBERS

Section I

RECOMMENDED

SAFE WORKING

PRESSURE (psig)

LIQUIDS GASES

120-200

120-201

120-202

120-203

120-204

120-205

120-206

120-207

120-208

120-209

120-210

120-211

120-212

120-213

120-214

120-215

120-216

120-217

120-218

120-219

120-220

120-240

120-241

120-242

120-243

120-244

120-245

120-246

120-247

120-248

120-249

120-250

120-251

120-252

120-253

120-254

120-255

120-256

120-257

120-258

120-259

120-277

120-279

120-280

120-281

120-282

120-283

120-284

120-285

120-286

120-287

120-288

120-289

120-290

120-291

120-292

120-293

10

11

12

12

12

8

8

8

1

3

3

8

1

3

3

9

2

2

9

2

2

3

3

61

65

102

102-105

102-105-108

102-105-108*

103

103-106

103-106-109

103-106-109*

104

104-107

104-107*

105

105-108

105-108*

106

106-109

106-109*

107

107*

108

108*

270

260

210

140

75

75

175

110

65

65

170

95

95

140

75

75

110

65

65

95

95

75

75

180

170

140

90

50

-

115

70

50

-

110

60

-

90

50

-

70

50

-

60

-

50

-

120-221

120-222

FUEL

(129 – 200

to 129 – 234)

129-200

129-201

129-202

129-203

129-204

129-205

129-206

129-207

129-208

129-209

129-210

* 2-inch orifice valve

** No. 1 shell used

120-260

120-261

OIL

(129 – 240

to 129 – 271)

129-240

129-241

129-242

129-243

129-244

129-245

129-246

129-247

129-248

120-294

GASES

(129 – 277

to 129 – 304)

129-277

129-279

129-280

129-281**

129-282

129-283

129-284

129-285

129-286**

129-287

129-288

13

13

SHELL

NO.

8

8

8

14

2

3

5

5

8

14

2

4

4

109

109*

TUBE NUMBERS

61

65

91

91-93

91-93-95

91-93-95-97

91-93-95-97-99

91-93-95-97-99*

92

92-94

92-94-96

92-94-96-98

92-94-96-98*

65

65

RECOMMENDED

SAFE WORKING

PRESSURE (psig)

LIQUIDS GASES

270

260

210

175

140

90

65

65

210

170

110

75

75

50

-

180

170

140

115

90

60

50

-

140

110

70

50

-

11

Page 14

Section I

FUEL

(129 – 200

to 129 – 234)

FLOWMETER MODEL CONVERSION KEY – CONTINUED

RECOMMENDED

OIL

(129 – 240

to 129 – 271)

GASES

(129 – 277

to 129 – 304)

SHELL

NO.

TUBE NUMBERS

SAFE WORKING

PRESSURE (psig)

LIQUIDS GASES

129-211

129-212

129-213

129-214

129-215

129-216

129-217

129-218

129-219

129-220

129-221

129-222

129-223

129-224

129-225

129-226

129-227

129-228

129-229

129-230

129-231

129-232

129-233

129-234

129-249

129-250

129-251

129-252

129-253

129-254

129-255

129-256

129-257

129-258

129-259

129-260

129-261

129-262

129-263

129-264

129-265

129-266

129-267

129-268

129-269

129-270

129-271

129-289

129-290

129-291

129-292

129-293

129-294

129-295

129-296

129-297

129-298

129-299

129-300

129-301

129-302

129-303

129-304

10

11

12

12

12

13

13

8

1

3

5

5

9

1

3

3

9

2

4

4

2

2

3

3

93

93-95

93-95-97

93-95-97-99

93-95-97-99*

94

94-96

94-96-98

94-96-98*

95

95-97

95-97-99

95-97-99*

96

96-98

96-98*

97

97*

97-99

97-99*

98

98*

99

99*

175

14

90

65

65

170

110

75

75

140

90

65

65

110

75

75

90

90

65

65

75

75

65

65

115

90

60

50

-

110

70

50

-

90

60

50

-

70

50

-

60

-

50

-

50

-

50

-

12

* 2-inch orifice valve

Page 15

SECTION II

PARTS BREAKDOWN

Section II

Parts Breakdown

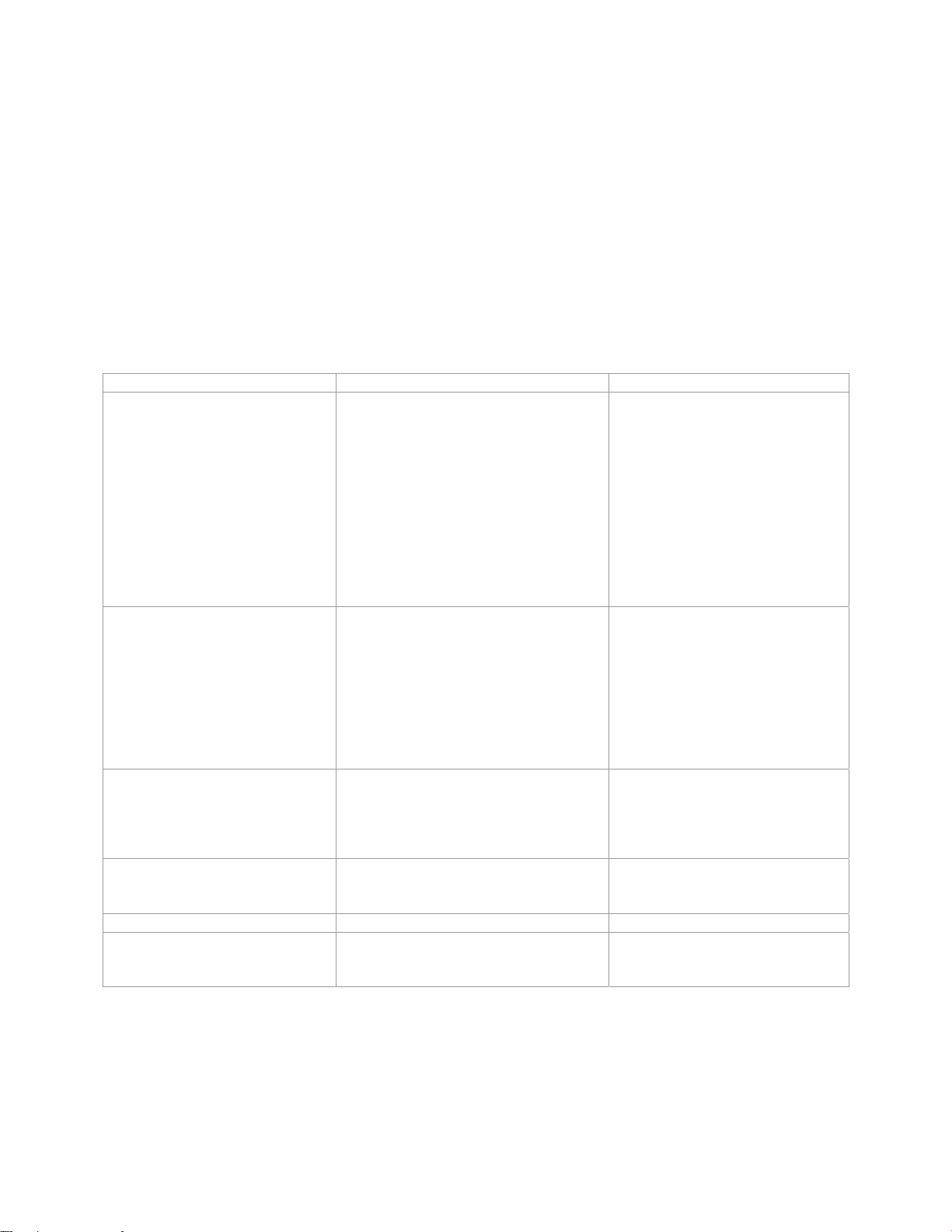

FIGURE

AND

INDEX NO.

13-

-1

-2

-3

-4

-5

14-

-1

-2

PART

NUMBER DESCRIPTION

25861

25862

85309

AN6230-8

25867A

5 / 16-24 x 1

36638

36634

No Number

No Number

AN6230-4

AN6230-13

BURST DISC ASSEMBLY

STRAINER ASSY

BLOWOUT DISC

“O” RING

THREADED END FLANGE

SOCKET HEAD SCREW

INLET ELBOW ASSY, 2-inch

INLET ELBOW ASSY, 3-inch

INLET ELBOW, 2-inch

INLET ELBOW, 3-inch

“O” RING, 2-inch elbow

“O” RING, 3-inch elbow

QTY

PER

ASSY

1

1

1

1

1

4

1

1

1

1

1

1

13

Page 16

Section II

Parts Breakdown

14

Page 17

Section II

Parts Breakdown

FIGURE

AND

INDEX NO. DESCRIPTION

16-1

-2

-3

-4

-5

-6

WORCESTER VALVE*

ROLL PIN

COUPLING

PIN

BRACKET

HANDLE ASSEMBLY

WITHOUT LIGHT SHELL

WITHOUT LIGHT SHELL

WITHOUT LIGHT SHELL

WITH LIGHT SHELL

WITH LIGHT SHELL

WITH LIGHT SHELL

FLOWMETER

SHELL

1

2

3 thru 7

1

2

3 thru 7

* Teflon Seal Kits available. When ordering, specify valve size.

PART NUMBER

3/4 –inch valve 1-1/4-inch valve 2-inch valve

411TB-3/4

3/16”x1-1/8”

48467-3/4

703563

48458

3-82900C-9

4-82900C-9

6-82900C-9

7-82900C-9

8-82900C-9

10-82900C-9

411TB-1-1/4

3/16”x1-1/8”

48467-1-1/4

703563

48458

3-82900C-9

4-82900C-9

6-82900C-9

7-82900C-9

8-82900C-9

10-82900C-9

411TB-2

3/16”x1-1/8”

48468-2

703563

48458

--

-5-82900C-9

--

-9-82900C-9

090804

15

Page 18

Loading...

Loading...