Page 1

Inline Liquid Flow Meter

VAM-UM-00551-EN-02 (November 2013)

User Manual

Page 2

Inline Liquid Flow Meter

Page ii November 2013

Page 3

User Manual

CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Materials of Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the Flow Meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the Test Kit Flow Meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Test Kit Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Test Procedures for Test Kit Flow Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Standard Test Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pump Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Tee Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Relief Valve in Separate Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Relief Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Removal of Dust Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Quick Re-Coupling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Test Kit Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Viscosity Eect (SUS/cSt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Density Eect (Specic Gravity). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Flow vs Pressure Drop* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Standard Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

High Temp Meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Test Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Page iii November 2013

Page 4

Inline Liquid Flow Meter

Page iv November 2013

Page 5

User Manual

INTRODUCTION

The Inline Liquid Flow Meter is a rugged industrial class inline flow rate indicator, offered in aluminum, brass or stainless

steel models to monitor a wide variety of liquids. Available in seven port sizes from 1/4" to 3" for flow ranges from 0.02…0.20

(0.1…0.75) through 20…300 gpm (100…1100 lpm), the meters are calibrated at 0.876 specific gravity for oil or other

petroleum-based fluids, 1.0 for water or other water-based fluids, or 1.18 for phosphate ester liquids.

The flow meter is equipped with a 360° rotatable guard/scale which allows the meter to be installed in any orientation

without regard to scale direction. Once the meter is permanently installed, the guard/scale can be rotated 360° to

optimize readability.

In addition, the unique spring-loaded design of this variable area flow meter decreases viscosity sensitivity and allows it

to be installed in any position, including inverted, without affecting accuracy. An optional inverted scale is available for

these applications.

The standard flow meter is a unidirectional device. If required, a reverse flow bypass option is available for the oil, phosphate

ester and water-based fluid models. Note that flow is measured in the forward direction only.

• Aluminum models are offered as a rugged, low cost flow meter for monitoring noncorrosive water-based or

petroleum-based fluids under operating pressures up to 3500 psi (241 bar).

• Brass meters are recommended for water monitoring applications or other systems where corrosion inhibitors

are not present.

• Stainless Steel is available for monitoring hydraulic systems operating at pressures up to 6000 psi (414

bar) or other corrosive caustic fluids, such as acetic acid. For further construction material information, see

"Fluid selection chart" on page 16.

Page 5 November 2013

Page 6

Inline Liquid Flow Meter

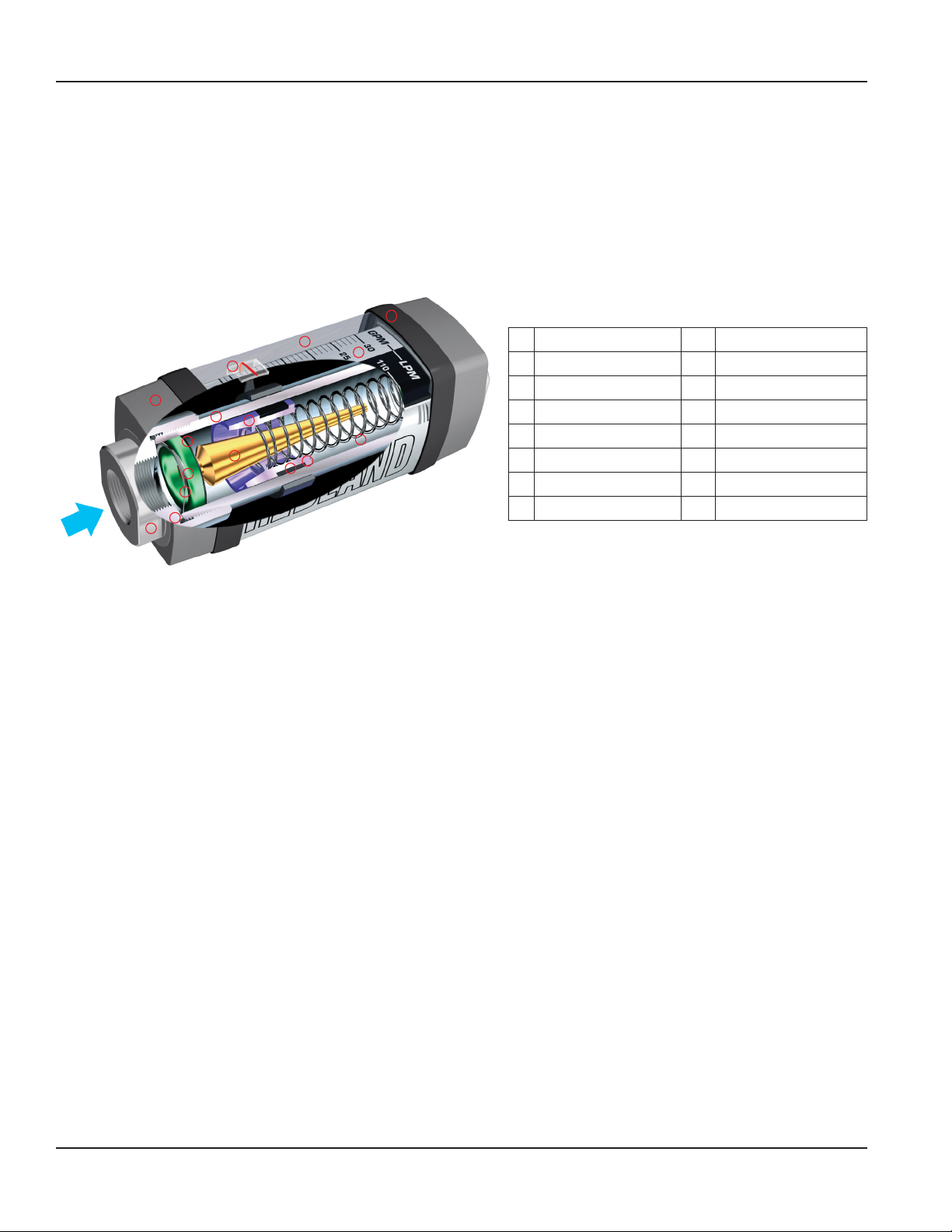

OPERATING PRINCIPLE

The Flow Meter is a variable area instrument. A sharp-edged Orifice, located within the Piston Assembly, forms an

annular opening with the contoured Metering Cone. The piston assembly carries a cylindrical PPS/Ceramic Magnet that

is magnetically coupled to an external Indicating Magnet which moves precisely in direct response to movement of the

piston. A calibrated Spring opposes flow in the forward direction.

The Hedland variable area flow meters are the most readable products in their class. Brightly colored indicators move over the

graduated, linear Flow Scale which contains bold, easy to read numeral and gauge marks. The enhanced resolution virtually

eliminates parallax problems associated with competitive, direct reading flow meters.

16

FLOW

15

5

13

14

1

8

9

10

11

12

3

2

4

7

6

1 Orifice 9 Spider Plate

2 Piston Assembly 10 Retaining Spring

3 Metering Cone 11 Pressure Seal

4 Internal Magnet 12 End Fitting

5 Flow Indicator 13 End Cap

6 Spring 14 Body

7 Flow Scale 15 Guard

8 Retaining Ring 16 Guard Seal/Bumper

Table 1: Meter components

SPECIFICATIONS

Temperature Range

• Standard: –20…240° F (–29…116° C)

• High temperature and hostile environment

◊ –20…400° F (–29…205° C) continuous

◊ 400…500° F (205…260° C) intermittent

• See "Flow vs Pressure Drop*" on page 18

Pressure Rating (3:1 safety factor)

• Aluminum/brass models: 3500 psi (241 bar) maximum

• Stainless steel models:

◊ 1/4" & 1/2" sizes: 6000 psi (414 bar) maximum

◊ 3/4" thru 1-1/2" sizes: 5000 psi (345 bar) maximum

Pressure Drop

• See "Application Information" on page 16 for specific

meter information

Accuracy

Repeatability

• ±1%

Threads

• SAE J1926/1, NPTF ANSI B2.2, BSPP ISO1179, Code 61

and Code 62: SAEJ518

Test Kit Pressure Gauge, Glycerin Dampened

• Aluminum/brass models: 0…3500 psi (0…240 bar)

• Stainless steel models: 0…6000 psi (0…400 bar)

Test Kit Load Valve

• 1/2", 3/4" and 1" sizes: needle valve

• 1-1/4" and 1-1/2" sizes: ball valve

• Produce ΔP up to 3500 psi (241 bar) PSID and 6000 psi

(414 bar) PSID

Dimensions

• See "Dimensions" on page 22

• ±2% of full scale

Page 6 November 2013

Page 7

Materials of Construction

Basic Flow Meters and Test Kits

User Manual

Meter Model Body Piston Cone

Spider

Plate

Spring Fasteners

Pressure

Seals

Guard

Retaining

Ring

Retaining

Spring

Indicator

& Internal

Magnet

2024-T351 Anodized

Oil Basic &

Test Kit

T303SS

Aluminum

C360 Brass

2024-T351

Anodized

1

T316SS T302SS T303SS Viton®Polycarbonate

SAE

1070/1090

Carbon

Steel

SAE

1070/1090

Carbon

Steel

PPS/Ceramic Buna N

Aluminum

2024-T351 Anodized

PE Basic &

Test Kit

T303SS

Aluminum

C360 Brass

2024-T351

Anodized

T316SS T320SS T303SS EPR Polycarbonate

SAE

1070/1090

Carbon

Steel

SAE

1070/1090

Carbon

Steel

PPS/Ceramic EPR

Aluminum

2024-T351 Anodized

WBF Basic &

Test Kit

Aluminum

C360 Brass

T303SS

1

2024-T351

Anodized

T316SS T302SS T303SS Viton®Polycarbonate T316SS T316SS PPS/Ceramic Buna N

Aluminum

Water Basic

Only

1

3" Models have Celcon® piston/piston ring

C360 Brass

T303SS C360 Brass

1

T316SS T302SS T303SS Viton®Polycarbonate T316SS T316SS PPS/Ceramic Buna N

API Oil/Caustic and Corrosive Liquids

Meter Model Body Piston Cone

Spider

Plate

Spring Fasteners

Pressure

Seals

Guard

Retaining

Ring

Retaining

Spring

Standard T316SS T316SS T316SS T316SS Viton®Polycarbonate T316SS T316SS PPS/Ceramic Buna N

Hostile

Environment

T316SS T316SS T316SS T316SS Viton

®

Cylindrical

Pyrex Glass

T316SS T316SS

Indicator

& Internal

Magnet

Indicator:

T415S

Magnet:

Teflon® Coated

Alnico 8

Guard

Seal/

Bumper

Guard

Seal/

Bumper

Scale

Support

6063-T6

Aluminum

6063-T6

Aluminum

6063-T6

Aluminum

6062-T6

Aluminum

Scale

Support

6063-T6

Aluminum

End

Caps

Nylon ST

Nylon ST

Nylon ST

Nylon ST

End

Caps

Nylon ST

T316SS T316SS T316SS

High Temp Flow

Meter

Model

1 3" Models have Celcon1 piston/piston ring

Body Piston Cone

2024-T351 Anodized Aluminum

C360 Brass

Oil

2024-T351 Anodized

T303SS

2024-T351 Anodized Aluminum

C360 Brass

PE

2024-T351 Anodized

T303SS

2024-T351 Anodized Aluminum

C360 Brass

WBF

2024-T351 Anodized

T303SS

C360 Brass

Wate r

T303SS C360 Brass

Aluminum

Aluminum

1

Aluminum

1

Spider

Plate

Spring Fasteners

Pressure

Seals

T316SS T302SS T303SS Viton

T316SS T320SS T303SS EPR

T316SS T302SS T303SS Viton

T316SS T302SS T303SS Viton

®

®

®

Guard

Cylindrical

Pyrex®

Glass

Cylindrical

Pyrex®

Glass

Cylindrical

Pyrex®

Glass

Cylindrical

Pyrex®

Glass

Retaining

Ring

Retaining

Spring

SAE

1070/1090

Carbon

Steel

1070/1090

Carbon

Steel

SAE

1070/1090

Carbon

Steel

1070/1090

Carbon

Steel

T316SS T316SS

T316SS T316SS

SAE

SAE

Indicator

& Internal

Magnet

Indicator:

Nickel-plated

Carbon Steel

Magnet: Teflon®

Coated Alnico 8

Indicator:

Nickel-plated

Carbon Steel

Magnet: Teflon®

Coated Alnico 8

Indicator:

Nickel-plated

Carbon Steel

Magnet: Teflon®

Coated Alnico 8

Indicator:

Nickel-plated

Carbon Steel

Magent: Teflon®

Coated Alnico 8

Guard

Seal/

Bumper

Buna N

EPR

Buna N

Buna N

Scale

Support

Scale:

Polymide

Scale

Support:

T316SS

Scale:

Polymide

Scale

Support:

T316SS

Scale:

Polymide

Scale

Support:

T316SS

Scale:

Polymide

Scale

Support:

T316SS

End Caps

2011-T3

Anodized

Aluminum

2011-T3

Anodized

Aluminum

2011-T3

Anodized

Aluminum

2011-T3

Anodized

Aluminum

Page 7 November 2013

Page 8

Inline Liquid Flow Meter

INSTALLATION

THIS PRODUCT SHOULD BE INSTALLED AND SERVICED BY TECHNICALLY QUALIFIED PERSONNEL TRAINED IN

MAINTAINING INDUSTRIAL CLASS FLOW INSTRUMENTATION AND PROCESSING EQUIPMENT.

READ INSTRUCTIONS THOROUGHLY BEFORE INSTALLING THE UNIT. IF YOU HAVE ANY QUESTIONS REGARDING

PRODUCT INSTALLATION OR MAINTENANCE, CALL YOUR LOCAL SUPPLIER FOR MORE INFORMATION.

OIL METERS ARE NOT RECOMMENDED FOR WATER MONITORING APPLICATIONS. IF METER IS TO BE SUBJECTED TO

BOTH OIL AND WATER, WATER METERS (BRASS) ARE SUGGESTED. CONSULT FACTORY FOR DETAILS.

THIS METER MAY CONTAIN RESIDUAL AMOUNTS OF TEST FLUID AT THE TIME OF SHIPMENT. THIS FLUID SHOULD BE

REMOVED PRIOR TO INSTALLATION AS THE FLUID MAY BE INCOMPATIBLE OR HAZARDOUS WITH SOME LIQUIDS OR

GASES. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN DAMAGE TO THE EQUIPMENT.

THIS STANDARD METER IS UNIDIRECTIONAL. ATTEMPTS TO FLOW FLUIDS IN THE OPPOSITE DIRECTION OF THE FLOW

ARROW WILL RESULT IN THE METER ACTING AS A CHECK VALVE, CREATING A DEADHEADING SITUATION. IF THE

DIFFERENTIAL PRESSURE MAGNITUDE IS GREAT ENOUGH, DAMAGE TO THE INTERNAL PARTS OF THE METER WILL

RESULT.

The inline flow meter is a simple device to install. However, the following measures are recommended for reliable, troublefree operation:

• Align pipe accurately. Piping should be accurately aligned and of correct length. The high pressure body of the flow meter

can withstand shock and flow/pressure pulsation. However, the piping should be firmly supported by external mounting

brackets, both upstream and downstream of the meter, to avoid any pipe flexing actions that could reduce meter life.

• Use rigid mounting. If the flow meter inlet or outlet are to be rigidly mounted, and the opposing port is to be connected to

flexible hose, the end connected with the flexible hose must be rigidly mounted.

• Use Teflon® tape for sealing NPT fitting.

• Install unions. Install a union near the inlet or outlet of the meter. This will facilitate quick, easy meter removal and

inspection during periodic maintenance procedures.

• Mount the meter either horizontally or vertically (flow arrow pointing to either side or straight up). If the meter must be

mounted inverted, special inverted scales are available from the factory.

• Ensure the fluid is traveling in the direction of the flow arrow (Figure 1).

• Use at least a 200 mesh (74 micron) filter. The meter will allow particulate to pass that would jam most valves and flow

controls. Systems that do not have filtration should be equipped with at least a 200 mesh (74 micron) filter. Most hydraulic

systems already have much finer filtration.

• Dirt, ferrous metal or sealing agents, such as Teflon® tape may lodge and cause malfunction. If the meter is jammed at a

fixed position, follow cleaning and maintenance instructions.

• Do not use thread locking compounds as thread sealant.

Page 8 November 2013

Page 9

User Manual

• Do not install the flow meter near turbulence producing fittings such as elbows, reducers, close coupled valves, etc. The

inline flow meter does not require flow straighteners or special lengths of straight inlet/outlet piping to stabilize turbulent

flow patterns. However, to assure maximum operational reliability, avoid installation of elbows, valves and/or reducers

immediately adjacent to the meter inlet.

• Do not install the meter near fast-acting valves. Fast-acting valves have the potential to create high magnitude hydraulic

pressure spikes. These spikes can damage the internal components of the meter, resulting in inaccuracies or malfunction.

• Do not allow unidirectional meters to be operated against the direction of the flow arrow. The standard flow meter is an

unidirectional flow meter. The piston acts as a check valve to block flow in the reverse direction. This causes an excessive

pressure differential, which can result in damage to internal meter components. The flow meter is also available in a

modified design, which offers a reverse flow bypass feature to accommodate bidirectional flow.

OTE:N Inline meters with a reverse flow bypass feature are available. Consult factory for details.

Installing the Flow Meter

1. Mount the meter so uid is traveling in the direction of the ow arrow.

Flow Direction

Arrow

GPM LPM

OIL

Figure 1: Flow direction arrow

2. Select a mounting location that is suitable for viewing and product service. To connect the ow meter into the piping

system, place an open-ended wrench onto the ow meter wrench ats adjacent to the pipe connection being installed.

DO NOT wrench on the opposite end of the ow meter or leakage may result.

Place wrench on meter ats on the same side

plumbing is being tightened

Never place wrench on meter ats opposite

plumbing being tightened

Figure 2: Installing the meter

3. After installation, rotate the meter by hand to view the ow scale.

Page 9 November 2013

Page 10

Inline Liquid Flow Meter

Rotate meter by hand to view ow scale

Never use wrench to rotate meter

body when viewing ow scale

Figure 3: Rotating the meter

Installing the Test Kit Flow Meter

1. Mount the VA High Pressure Test Kit Flow Meter so uid is traveling in the direction of the ow arrow. See Figure 1.

2. Install the test kit at any location in the hydraulic circuit that is suitable for viewing. To connect the test kit into the piping

system, place an open-ended wrench onto the test kit valve on the inlet side or on the test kit wrench at on the outlet

side adjacent to the pipe connection being installed. DO NOT wrench on the opposite end of the test kit or leakage may

result. See Figure 4.

Place wrench on valve body on the same side

plumbing is being tightened

Never place wrench on valve body opposite

plumbing being tightened

Figure 4: Installing the test kit

3. Or, use quick disconnect couplings for easy connections and to keep the test kit sealed and clean when not in use.

Diagrams illustrating Typical Test Placements for the test kits are located in the Test Procedures section beginning on

page 11.

4. After installation, rotate the meter by hand to view the ow scale.

Page 10 November 2013

Page 11

Rotate meter by hand to view ow scale

GPMxPSI

1714

LPMxbar

447 4.

LPMxbar

600

Never use wrench to rotate meter

body when viewing ow scale

Figure 5: Rotating the test kit

User Manual

OPERATION

General Information

See “Application Information” on page 16.

Test Kit Information

ALWAYS START WITH THE LOADING VALVE OPEN.

ALL TEST KITS ARE SHIPPED WITH THE LOADING VALVE IN THE CLOSED POSITION. THE LOADING VALVE MUST BE

OPENED FULLY BEFORE INITIATING FLOW AND TESTING OF THE HYDRAULIC CIRCUIT. TURN THE LOADING VALVE

HANDLE COUNTERCLOCKWISE TO THE FULLY OPEN POSITION. FAILURE TO OPEN THE LOADING VALVE FULLY CAN

RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT.

TEST PROCEDURES FOR TEST KIT FLOW METERS

THE INFORMATION IN THIS MANUAL IS FOR GENERAL APPLICATION ONLY. ANY INFORMATION FURNISHED BY THE

MANUFACTURER OF THE MACHINE’S HYDRAULIC COMPONENTS SHOULD BE

REQUIRE SPECIFIC TEST PROCEDURES.

FOLLOWED. SPECIFIC SYSTEMS MAY

General Information

The VA High Pressure Test Kits are designed to measure flow and pressure. Power measurements are derived from

the product of flow and pressure. When using a Test Kit, power can be calculated using the following formulas:

HP

=

HP

=

kW

=

Page 11 November 2013

Page 12

Inline Liquid Flow Meter

Standard Test Conditions

1. Install the Test Kit as described in one of the following test procedures:

a. Pump Test

b. Tee Test

c. Relief Valves in Separate Housings

d. Relief Valves

5. Open the loading valve fully by turning the handle counterclockwise.

6. Start the pump and adjust it to rated speed.

7. Open the Test Kit loading valve fully and proceed with the required test procedure.

8. The Test Kit will indicate ow and pressure.

Pump Test

See Figure 6.

A tee must be installed between the pump discharge port and the return line to the tank. Be sure the fluid path is only

through the pump, the hydraulic test unit, and back to the tank.

TEE

PUMP

IN

RELIEF

TANK

Figure 6: Pump test

OUT

1. Plug the line to the control valve.

2. Open the Test Kit loading valve fully to read maximum pump ow at zero pressure.

3. Close the loading valve to increase pressure from zero pressure to rated or maximum pump pressure to determine

pump condition.

4. The pump ow at rated pressure can now be checked against the pump manufacturer’s specications. A decrease in ow

from zero pressure to maximum pressure indicates the pump condition. A pump that delivers a constant low ow at zero

pressure and at maximum pressure suggests suction problems.

Tee Test

See Figure 7.

A tee must be installed between the pump and control valve and connected to the inlet of the Test Kit. The outlet port of the

Test Kit is connected to the tank. Pumps and relief valves can be isolated from the system and checked with the Tee Test.

1. Pump Test

a. Plug the line to the control valve.

Page 12 November 2013

Page 13

OUT

User Manual

HYDRAULIC

MOTOR

CONTROL

VALV E

TEE

PUMP

IN

RELIEF

TANK

Figure 7: Tee test

b. Open the Test Kit loading valve fully to read maximum pump flow at zero pressure.

c. Close the loading valve to increase pressure from zero pressure to rated or maximum pump pressure to determine

pump condition.

d. The pump flow at rated pressure can now be checked against the pump manu fac turer’s specifications. A decrease

in flow from zero pressure to maximum pressure indicates the pump condition. A pump that delivers a constant low

flow at zero pressure and at maximum pressure suggests suction problems.

2. Relief Valve Test

a. Put a control valve into a power output mode with the output flow blocked, such as a cylinder at the end of its stroke.

b. Close the Test Kit loading valve while viewing the pressure. Pressure will increase until the relief valve opens. Record

the pressure at this point. Repeat to check the relief valve adjustment.

Relief Valve in Separate Housing

1. Install the Test Kit in a Tee Test conguration to the line connecting the pump and relief valve. Plug any extra outlets.

2. Close the Test Kit loading valve and watch the pressure and ow.

a. Reconnect the control valve to the tee. Put a control valve into a power output mode with the output flow blocked,

such as a cylinder at the end of its stroke.

b. Close the Test Kit loading valve while watching the pressure. Pressure will increase until the relief valve opens. Record

the pressure at this point. Repeat to check the relief valve adjustment.

Relief Valves

Often relief valves will start to open before they reach their full pressure flow settings. This can be noted by comparing the

pressure and flow rate readings made in Step 3 under Tee Test. Any great decrease in flow rate from tests made in Step 3

under Tee Test indicates a faulty relief valve.

Page 13 November 2013

Page 14

Inline Liquid Flow Meter

MAINTENANCE

BEFORE ATTEMPTING TO REMOVE THE FLOW METER FROM THE LINE, CHECK THE SYSTEM TO CONFIRM THAT LINE

PRESSURE HAS BEEN REDUCED TO ZERO PSI. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS

PERSONAL INJURY OR DEATH AND/OR DAMAGE TO THE EQUIPMENT.

1. Remove the ow meter from the line. Remove excess piping from meter.

OTE:N It is not necessary to remove the transparent dust guard from the meter to remove the meter from the line. If you

choose to remove the dust guard assembly, see "Removal of Dust Guard" on page 14.

2. Thoroughly wipe o the entire ow meter surface using mild detergent or isopropyl alcohol.

DO NOT USE AROMATIC HYDROCARBONS, HALOGENATED HYDROCARBONS, KETONES OR ESTER BASED FLUIDS ON

POLYCARBONATE LENS. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN DAMAGE TO THE METER.

3. Remove the inlet cap from the ow meter, noting the sequence of disassembly for later reference (during reassembly).

4. The internal parts are secured with a retaining ring. Remove the retaining ring and the internal wetted parts from the

ow meter.

OTE:N If internal parts do not slide freely from flow meter, use a wooden dowel inserted into the outlet port of the meter to

push parts out.

5. Place all parts on a clean work surface. Clean and inspect all parts. Replace any that appear worn or damaged.

Check inlet port O-ring for damage and replace if required.

FIELD REPLACEMENT OF THE SPRING, METERING CONE AND/OR PISTON/MAGNET ASSEMBLY MAY RESULT IN CHANGES

TO THE CALIBRATION OF THE FLOW METER.

6. Reassemble spring, then piston/magnet assembly and retaining ring into ow meter.

7. Install metering cone/spider plate assembly, retaining spring, and secure with inlet cap.

8. Reinstall meter to the line.

Removal of Dust Guard

To remove the dust guard for cleaning or replacement, simply loosen the end fitting located at the bottom of the meter and

slide the end cap, dust bumper, and the dust guard off the bottom of the meter, taking care to avoid damaging the O-ring seal

between the end cap and the dust gland.

Quick Re-Coupling

This piston-type variable area flow meter is inherently less sensitive to shock and vibration than other variable area designs.

The unique magnetic coupling also eliminates the need for mechanical linkages that can wear or loosen over the functional

life of the meter.

However, on occasion, a pressure spike or extreme flow surge can cause the piston to move at such rapid speed that it

disconnects the piston magnet and the external indicator ring. If this occurs, use one of these procedures to re-couple the

magnet and the external indicator ring:

• If the system permits, simply change flow rate from “no flow” to “full flow” allowing the moving piston to magnetically recouple to the indicator ring.

• For rigorous cyclical applications where de-coupling may occur frequently, consult the technical services staff for further

recommendations.

Page 14 November 2013

Page 15

User Manual

Test Kit Maintenance

Load Valve

If the valve fails to load the system, remove the valve body and check for foreign material, worn parts or seals.

Flow

The absence of any flow reading may indicate a seized piston assembly. Remove any material that may be preventing the

piston to slide.

If the Test Kit still fails to indicate flow, it is recommended to return the Test Kit to the factory.

Page 15 November 2013

Page 16

Inline Liquid Flow Meter

APPLICATION INFORMATION

Viscosity Eect (SUS/cSt)

The design uses a precision machined, sharp-edged orifice and biasing calibration spring that assures operating stability and

accuracy over the wide viscosity range common to many fluids. Generally, high flow models of each meter size provide good

accuracy over a viscosity range of 40…500 SUS (4.2…109 cSt).

Correction Factor

Fluid

Acetic Acid (Air Free) 1.06 0.909 0.971 C N R R R R C N R

Acetone 0.79 1.053 1.125 R R R R N R N R R

Alcohol Butyl (Butanol) 0.83 1.027 1.098 C C R R C R R R R

Alcohol Ethyl (Ethanol) 0.83 1.027 1.098 C C R R C R R N R

Ammonia 0.89 0.992 1.060 R C R R N R N C R

Benzine 0.69 1.127 1.204 C R R C R N N R R

Carbon Disulphide 1.26 0.834 0.891 R N R R R N N R R

Castor Oil 0.97 0.950 1.015 C R R C R N C C R

Cotton Seed Oil 0.93 0.970 1.037 C R R R R N R R R

Ethylene Glycol 50/50 1.12 0.884 0.945 R R R R R R R C R

Freon II 1.46 0.774 0.828 R R R R R N R R R

Gasoline 0.70 1.119 1.195 R R R R R N C R R

Glycerin 1.26 0.834 0.891 R R R R R R R C R

Kerosene 0.82 1.033 1.104 R R R R R N R R R

Liquid Propane (LPG) 0.51 1.310 1.400 R R R R R N N R R

Mineral Oil 0.92 0.976 1.042 R N R R R N R R R

Naphtha 0.76 1.074 1.147 R N R R R N C R R

Perchloroethylene 1.62 0.735 0.786 C N R R R N N N R

Petroleum Oil 0.876 1.000 1.068 R R R R R N R R R

Phosphate Ester 1.18 0.862 0.921 R R R R N R N R R

Phosphate Ester Base 1.26 0.833 0.891 R R R R N R N R R

Phosphoric Acid (Air Free) 1.78 0.701 0.749 N N R N R N R N R

Sea Water 1.03 0.922 0.985 N N C C N R R R R

Synthetic Petroleum Base 1.00 0.936 1.000 R C R R R N R R R

Water 1.00 0.936 1.000 N R R R N R R R R

Water Glycol 50/50 1.07 0.905 0.967 R R R R R N R R R

Water-in-oil 0.93 0.970 1.037 R R R R N R R R R

R–Recommended

N–Not Recommended

C–Consult Factory

Specific

Gravity

Oil Water

Table 2: Fluid selection chart

Aluminum

Brass

T16 SST

T303 SST

Viton®

EPR

Nylon

Polycarbonate

Pyrex®

Page 16 November 2013

Page 17

User Manual

Density Eect (Specic Gravity)

Any fluid density change from stated standards has a proportional effect on meter accuracy. Special scales can be supplied if

actual specific gravity decreases accuracy beyond application limits. Corrections for more or less dense fluids can be made to

standard scales using the following correction factors:

10.

Specific Gravity

0 876.

Specific Gravity

for water/water-based meters

for petroleum-based meters

7000

6000

5000

4000

3000

2000

1000

MAXIMUM OPERATING PRESSURE, PSI

0

0 100 200 300 400 500

Stainless Steel

Stainless Steel

TEMPERATURE DERATING CURVES

Brass

Aluminum

TEMPERATURE, DEGREES F

CONTINUOUS TEMPERATURE

INTERMITTENT TEMPERATURE

Figure 8: Pressure vs temperature

Page 17 November 2013

Page 18

Inline Liquid Flow Meter

Flow vs Pressure Drop*

1. The pressure drop curves are valid for uids with density and viscosity similar to factory test uids. Fluids, especially with

higher viscosity than these test uids, will yield a higher pressure drop through the ow meter and piping system per a

given ow volume.

2. A system must have adequate uidic horsepower available to move the system uid at a prescribed rate at a pressure

adequate to overcome all pressure reducing devices—including the ow meter

Petroleum Fluids

1/4"

.05-.50

.02-.20

PRESSURE DROP, PSI

1/2" Reverse Flow

0.2-2.0

PRESSURE DROP, PSI

0.1-1.0

.10-1.0

FLOW, GPM

PRESSURE DROP, PSI

0.5-5.0

FLOW, GPM

.20-2.0

1-1/4"/1-1/2"

5-50

3-30

FLOW, GPM

1-10

1-15

10-75

10-100

PRESSURE DROP, PSI

PRESSURE DROP, PSI

1/2"

0.1-1.0

0.2-2.0

0.5-5.0

0.2-2.0

FLOW, GPM

10-150

3/4"/1" Reverse Flow

2-20

1-10

0.5-5.0

FLOW, GPM

1-10

PRESSURE DROP, PSI

3-30

3.0"

1-15

4-40

3/4"/ 1"

PRESSURE DROP, PSI

10-200

FLOW, GPM

1-1/4"/1-1/2" Reverse Flow

PRESSURE DROP, PSI

3-30

2-20

FLOW, GPM

20-300

10-75

5-50

FLOW, GPM

10-100

3-30

4-40

10

0.5-5.0

5

0.2-2.0

0

0 10

5-50

1-10

10-150

Petroleum Test Kits

Reverse Flow

10-100

10-150

10-150

Standard

Test Kit

PRESSURE DROP, PSI

0.1-1.0

0.1-1.0

1/2"

0.2-2.0

0.2-2.0

Reverse Flow

0.5-5.0

0.5-5.0

FLOW, GPM

1-10

1-10

Standard Test Kit

1-15

1-15

PRESSURE DROP, PSI

0.2-2.0

0.5-5.0

0.5-5.0

0.2-2.0

3/4" / 1"

1-10

1-10

Reverse Flow

2-20

2-20

FLOW, GPM

4-40

3-30

3-30

Standard Test Kit

4-40

5-50

PRESSURE DROP, PSI

1-1/4"/ 1-1/2"

5-50

3-30

3-30

FLOW, GPM

5-50

10-100

10-75

10-75

* The pressure drop curves are valid for fluids with density and viscosity similar to factory test fluids. Fluids, especially with

higher viscosity then these test fluids, will yield a higher pressure drop through the flow meter and piping system per a given

flow volume.

A system must have adequate fluidic horsepower available to move the system fluid at a prescribed rate at a pressure

adequate to overcome all pressure-reducing devices, including the flow meter.

Page 18 November 2013

Page 19

Phosphate Ester

FLOW, GPM

FLOW, GPM

FLOW, GPM

User Manual

1/2" Reverse Flow

PRESSURE DROP, PSI

0.2-2.0

0.1-1.0

0.5-5.0

FLOW, GPM

1/4"

0.10-1.0

PRESSURE DROP, PSI

FLOW, GPM

3/4"/ 1"

PRESSURE DROP, PSI

1-10

2-20

1-10

FLOW, GPM

1-15

0.20-2.0

.02-.20

6

.05-.50

4

2

0

0.50.0

5-50

4-40

3-30

6

4

2

0

0 1 2 3 54

0.5-5.0

0.2-2.0

3/4"/1" Reverse Flow

PRESSURE DROP, PSI

0.2-2.0

0.5-5.0

2-20

1-10

FLOW, GPM

PRESSURE DROP, PSI

1-1/4" / 1-1/2"

PRESSURE DROP, PSI

3-30

1/2"

3-30

0.5-5.0

FLOW, GPM

10-100

10-75

5-50

FLOW, GPM

4-40

1-15

1-10

0.2-2.0

4

0.1-1.0

2

0

0 1 2 2.5

10-150

1-1/4"/1-1/2" Reverse Flow

PRESSURE DROP, PSI

3-30

5-50

10-150

10-100

10-75

FLOW, GPM

Phosphate Ester Test Kits

1/2"

0.5-5.0

0.2-2.0

PRESSURE DROP, PSI

0.1-1.0

0.2-2.0

0.1-1.0

Reverse Flow

0.5-5.0

1-10

1-10

Standard Test Kit

1-15

1-15

PRESSURE DROP, PSI

0.2-2.0

0.2-2.0

3/4" / 1"

0.5-5.0

0.5-5.0

1-10

1-10

Reverse Flow

2-20

2-20

3-30

3-30

Standard Test Kit

4-40

4-40

5-50

PRESSURE DROP, PSI

1-1/4"/ 1-1/2"

5-50

3-30

3-30

5-50

Reverse Flow

10-75

10-75

10-100

10-100

10-150

10-150

Standard

Test Kit

Page 19 November 2013

Page 20

Inline Liquid Flow Meter

API Oil

Water-Based Fluids

PRESSURE DROP, PSI

1/4"

PRESSURE DROP, PSI

PRESSURE DROP, PSI

.10 -1.0

1/4"

3/4" / 1"

0.2-2.0

FLOW, GPM

2-20

FLOW, GPM

.20-2.0

.05-.50

.10-1.0

3-30

PRESSURE DROP, PSI

.20-2.0

4-40

1/2"

0.5-5.0

PRESSURE DROP, PSI

PRESSURE DROP, PSI

1-10

1/2"

0.2-2.0

1-1/4"/ 1-1/2"

3-30

1-15

0.1-1.0

0.2-2.0

0.5-5.0

FLOW, GPM

5-50

FLOW, GPM

PRESSURE DROP, PSI

1-10

10-75

3/4" / 1"

10-100

1-15

2-20

3-30

4-40

0.5-5.0

5-50

1-10

0.2-2.0

1/2" Reverse Flow

0.2-2.0

PRESSURE DROP, PSI

0.1-1.0

FLOW, GPM

0.5-5.0

FLOW, GPM

1-1/4"/ 1-1/2"

PRESSURE DROP, PSI

1-10

3-30

10-75

5-50

FLOW, GPM

1-15

10-100

3/4"/1" Reverse Flow

PRESSURE DROP, PSI

0.5-5.0

0.2-2.0

10-150

1-10

FLOW, GPM

PRESSURE DROP, PSI

2-20

FLOW, GPM

3-30

FLOW, GPM

3"

20-180

20-275

FLOW, GPM

4-40

1-1/4"/1-1/2" Reverse Flow

PRESSURE DROP, PSI

3-30

5-50

10-100

10-75

10-150

FLOW, GPM

Page 20 November 2013

Page 21

Water-Based Test Kits

User Manual

Water

PRESSURE DROP, PSI

PRESSURE DROP, PSI

0.1-1.0

0.1-1.0

1/4"

1/2"

0.2-2.0

0.2-2.0

Reverse Flow

0.5-5.0

0.5-5.0

FLOW, GPM

FLOW, GPM

1-10

1-10

Standard Test Kit

.10 -1.0

0.2-2.0

1-15

.20-2.0

.05-.50

1-1/4"/ 1-1/2"

1-15

PRESSURE DROP, PSI

PRESSURE DROP, PSI

0.2-2.0

0.2-2.0

3/4" / 1"

0.5-5.0

0.5-5.0

1/2"

1-10

10-150

Reverse Flow

2-20

1-10

FLOW, GPM

0.5-5.0

FLOW, GPM

2-20

3-30

3-30

1-10

4-40

Standard

Test Kit

0.1-1.0

3"

4-40

0.2-2.0

1-15

5-50

PRESSURE DROP, PSI

PRESSURE DROP, PSI

1-1/4" / 1-1/2"

3-30

3-30

3/4" / 1"

15-150

Reverse Flow

10-75

5-50

10-75

5-50

FLOW, GPM

3-30

2-20

FLOW, GPM

10-100

10-100

4-40

Standard

0.5-5.0

0.2-2.0

10-150

10-150

Test Kit

5-50

1-10

Caustic and Corrosive Liquids

PRESSURE DROP, PSI

PRESSURE DROP, PSI

PRESSURE DROP, PSI

1/4"

3/4" / 1"

3-30

FLOW, GPM

2-20

10-75

5-50

FLOW, GPM

.10 -1.0

3-30

10-100

4-40

0.5-5.0

.20-2.0

0.1-2.0

10-100

PRESSURE DROP, PSI

5-50

FLOW, GPM

1/2"

0.5-5.0

1-15

1-10

0.2-2.0

PRESSURE DROP, PSI

FLOW, GPM

1-1/4"/ 1-1/2"

10-100

1-10

PRESSURE DROP, PSI

3-30

5-50

10-75

FLOW, GPM

FLOW, GPM

Page 21 November 2013

Page 22

Inline Liquid Flow Meter

DIMENSIONS

Standard Meter

E

A

C

E

F

B

D

A

Nominal Port

Size

B

Length

in. (mm)

C

Width

in. (mm)

D

Depth

in. (mm)

E

Offset

in. (mm)

F

Flats

in. (mm)

1/4" (SAE 6) 4.80 (122) 1.68 (43) 1.90 (48) 0.82 (21) 0.88 (22)

1/2" (SAE 10) 6.60 (168) 2.07 (53) 2.40 (61) 1.04 (26) 1.25 (32)

3/4" (SAE 12) 7.20 (183) 2.48 (63) 2.85 (72) 1.24 (32) 1.50 (38)

1" (SAE 16) 7.20 (183) 2.48 (63) 2.85 (72) 1.24 (32) 1.75(44)

1-1/4" (SAE 20) 12.20 (310) 4.12 (105) 4.72 (120) 2.06 (52) 2.75 (70)

1-1/2" (SAE 24) 12.20 (310) 4.12 (105) 4.72 (120) 2.06 (52) 2.75 (70)

3.125

4.12

(104.6)

2.06

(52.3)

1.563

(39.7)

(79.4)

4.44

(112.8)

2.65

(67.3)

0.719

(18.3)

1.438

(36.5)

5/8-11 UN-2B

Typ. (4 pl)

5.75

(146.0)

4.50

(114.3)

Across Flats

3" Ports

6.00

(152.4)

4.18

(106.3)

4.50

(114.3)

Across Flats

2.44

(61.9)

15.8

(401.3)

Figure 9: 1-1/2 inch; C62 Flange

Inches (mm)

Figure 10: 3 inch; SAE, NPTF, BSPP

Inches (mm)

16.18

(411)

Figure 11: 3 inch; C61 Flange

Inches (mm)

16.18

(411)

Page 22 November 2013

Page 23

High Temp Meter

User Manual

DC

B

Test Kit

E

GPM LPM

30

25

20

15

10

5

3

OIL

C

A

A

Nominal

Port Size

B

Length

in. (mm)

C

Width

in. (mm)

D

Flats

in. (mm)

1/4" (SAE 6) 6.60 (168) 2.01 (53) 1.25 (32)

1/2" (SAE 10) 6.60 (168) 2.01 (53) 1.25 (32)

3/4" (SAE 12) 7.20 (183) 2.48 (63) 1.50 (38)

1" (SAE 16) 7.20 (183) 2.48 (63) 1.75 (44)

1-1/4" (SAE 20) 12.20 (310) 4.20 (105) 2.75 (70)

115

100

80

60

40

20

10

A

F

1-1/2" (SAE 24) 12.20 (310) 4.20 (105) 2.75 (70)

A

Nominal

Port Size

D

1/2" (SAE 10) 6.60 (168) 9.60 (245) 2.07 (53) 2.40 (61) 1.04 (26) 1.25 (32)

B

Length

in. (mm)

B1

Length

in. (mm)

C

Width

in. (mm)

D

Depth

in. (mm)

E

Offset

in. (mm)

F

Flats

in. (mm)

3/4" (SAE 12) 7.20 (183) 10.70 (272) 2.48 (63) 2.85 (72) 1.24 (32) 1.50 (38)

1" (SAE 16) 7.20 (183) 10.70 (272) 2.48 (63) 2.85 (72) 1.24 (32) 1.75 (44)

1-1/4" (SAE 20) 12.20 (310) 20.50 (521) 4.12 (105) 4.72 (120) 2.06 (52) 2.75 (70)

1-1/2" (SAE 24) 12.20 (310) 20.50 (521) 4.12 (105) 4.72 (120) 2.06 (52) 2.78 (70)

B

B

1

(Ref. Dim.)

Page 23 November 2013

Page 24

HEDLAND is a registered trademarks of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2013 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-04 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412 Legacy Document Number: 04-VAM-UM-00223

Loading...

Loading...