Page 1

Fluid Managment System

FMS-3 2.4 GHz RF High-End Software v3.4.1

FMS-UM-00138-EN-02 (July 2014)

User Manual

Page 2

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Page ii July 2014

Page 3

User Manual

CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

System Composition and Dataow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Certication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wall-Mounting The Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Keypad Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Master Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

System Version Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Settings Overview / Supervisor Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Initialization (INI) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Conguration (CNF) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Test Communication (DK) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Reports (REP) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Radio (RAD) Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Dispense Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

System Version Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Settings Overview / Supervisor Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Conguration (CNF) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Delete Prepared WOs (MET) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Reports (REP) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

190 (Internal Ticket Printer) Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

RF Communication Test (LNK) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Radio (RAD) Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Network Connect (CON) Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

System Override (SYS) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Dispense Keypad Menu Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Dispense Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Starting a Work Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

EPM-3 Rf Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Key Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

RF Mode (Standard Pre-Selection Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

AUTO Mode (Autonomous) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Electrical Override. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Changing the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Programming the EPM-3 RF Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Page iii July 2014

Page 4

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Installing And Launching The FMS Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

FMS Software Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Installing the FMS Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Installing the FMS Client . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Launching the FMS Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

FMS System Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Using The FMS Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Setting Up New Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Setting Up Tanks and Fluids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Setting Up Keypads and Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Initialize System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Test Comm Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Initialize All Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Initialize Changes Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Parts Department User Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Creating a New Work Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Work Order Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Tanks and Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Dispense Keypad Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Meter Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Worksheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Page iv July 2014

Page 5

User Manual

INTRODUCTION

The Badger Meter® Fluid Management System has been designed to control and monitor the consumption and inventory

balances of automotive fluid products with minimal installation and programming costs. Badger Meter has used its years of

expertise in the automated meter reading market to develop a modular control system using RF communications.

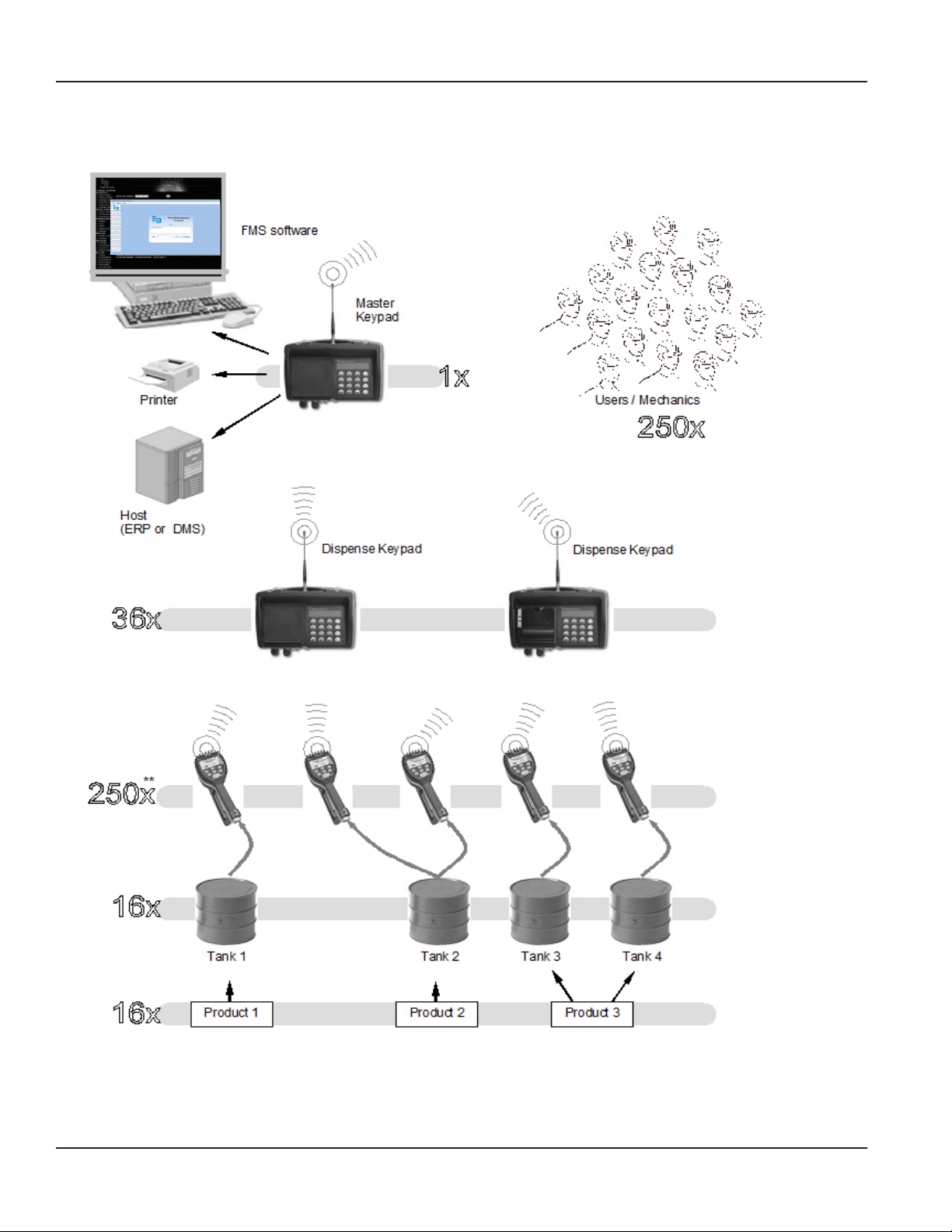

The high end system hardware consists of one Master Keypad and at least one Dispense Keypad as well as at least one radio

frequency (RF) electronic preset meter. The Master Keypad handles serial communication between the PC or a host server

(ERP system) and RF communication to the Dispense Keypads in the system. The system verifies the operator’s pin number

and validates the work order number, fluid quantities and the valid hose/meter.

The Master Keypad can communicate with up to 36 Dispense Keypads that can be positioned to support the workflow of the

facility the best way. Each Dispense Keypad can control up to 24 meters, for a total of 250 meters. The system supports up to

16 tanks and 16 fluids as a part of the system configuration. The system supports 250 unique operator IDs and pin numbers.

The system uses direct sequence spread spectrum RF technology to prevent communication problems with other equipment

in the facility. The RF system will look for a clear channel for transmission to insure that there is reliable communications at all

times. Communication distances are typically up to 100 meters, but can go up to 300 meters with unobstructed line-of-sight.

A remote antenna is available for situations where multiple buildings are involved in the installation.

The PC is used to configure the system, maintain system data and enter work orders. The service desk would use the PC to

enter a work order selecting the fluid and quantity required. The PC can stack as many work orders as required, limited only by

the disk storage space of the PC. There is no need to predetermine where the work is going to occur. This allows the flexibility

to service a vehicle at any open bay and select a meter when the work is going to be performed. When the work order is

going to be performed, the service personnel simply enters their pin number, work order and hose that is going to be used at

the Dispense Keypad.

There are a number of system utilization reports by user; fluid type, tank or meters available for the system’s management.

Optionally, the system can be connected with an ERP or DMS system via its RS232 interface. The real-time communication is

based on an open interface protocol (ASCII-code) and can be easily adapted to local conditions.

A unique, patented feature of the system is that the RF meter’s dispense trigger is locked until an authorization from the

keypad is received. After the dispense batch is completed, the user can top off if more fluid is required, the actual dispensed

amount is sent back to the keypad and the meter returns to the locked status. Additionally, the meter can be installed on

portable dolly systems offering control and monitoring of high-cost lubrication products.

Page 5 July 2014

Page 6

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

System Overview

Figure 1: System Overview

Page 6 July 2014

Page 7

System Composition and Dataow

Dispense Keypad

500

D

printer

R

Master Keypad

1200

D

FMS software

R

Host

R

printer

R

RS-232 Interface

User Manual

ispenses

S-232

ispenses

S-232

S-232

S-232

Computer

PC FMS

Figure 2: System Data Flow

Database

The main data streams:

1. The FMS software stores the conguration data into the database.

2. By using the Initialize System menu of the FMS software the conguration data is processed to the Master Keypad and

3. The FMS records all dispenses in the database.

Specications

Power Requirements 120V AC 50/60 Hz

RF Communications 2-way, 2.4…2.5 GHz Direct Sequence Spread Spectrum

RF Network Self-healing Mesh Network

Operating Temperature 14…140° F (–10…60° C)

Internal Printer Thermal printer Type FT190 (optional)

External Printer Epson LX300 or similar (optional)

nally via radio to all Dispense Keypads.

Page 7 July 2014

Page 8

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Certication

• Contains FCC ID: S4GEM35XB

• Contains IC: 8735A-EM35XB

• FCC CERTIFIED, PART 15, SUB-PART C

• CE0681 EC-R&TTE Certified

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may

not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

TO SATISFY FCC RF EXPOSURE REQUIREMENTS FOR MOBILE TRANSMITTING DEVICES, A SEPARATION DISTANCE OF 20

CM OR MORE SHOULD BE MAINTAINED BETWEEN THE ANTENNA OF THIS DEVICE AND PERSONS DURING OPERATION.

TO ENSURE COMPLIANCE, OPERATIONS AT CLOSER DISTANCES THAN THIS ARE NOT RECOMMENDED.

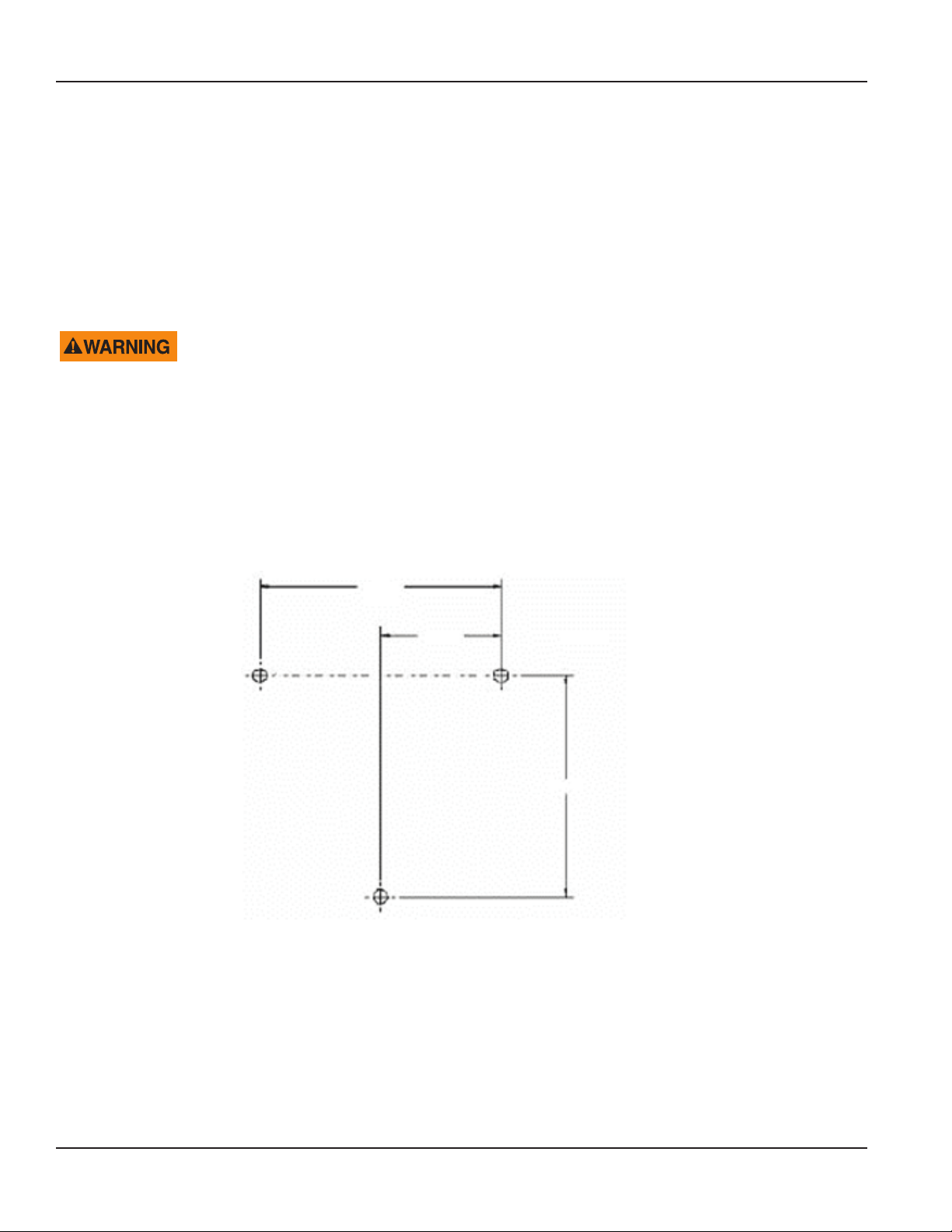

WALLMOUNTING THE KEYPAD

The keypad should be mounted upright with the antenna pointing upward, near a 120V AC electrical socket, to a structurally

sound wall through the two holes on the top of the keypad casing. Height on the wall should be at eye level. Care should be

taken to avoid mounting behind any steel objects (tool storage cabinets and metal chain linked fences) that may block the RF

communication signal. Care should also be taken to avoid direct, significant heat sources.

7-5/8”

3-3/16”

7-3/8”

Figure 3: Mounting Dimensions for Keypad

Page 8 July 2014

Page 9

Keypad Description

Internal printer

Type FT190

External printer port (RS-232)/

Bar Code Reader

Power supply

120V AC 50/60 Hz

Power supply

120V AC 50/60 Hz

External printer

(RS232)

Interface to FMS

software (RS232)

Host link

(RS232)

Dispense Keypad Master Keypad

User Manual

to

Figure 4: Keypad description

The SCROLL key selects options on the active display.

The HOME key returns the display to the default screen.

The BACKSPACE key deletes one character to the left of the cursor each time it is pressed.

The ENTER key completes the current action then displays the next screen.

The SPACE key adds a blank space to the right of the data just entered.

The Alphanumeric keys enter numbers and alpha characters (letters).

• To enter a number, press and release a key.

• To enter a letter, press and hold the key until the letter you want displays, then release the key.

Page 9 July 2014

Page 10

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Operation Modes

The configuration of the system is generally done by using the PC-based FMS Software. Only some special functions like the

operation modes are set at the Master Keypad.

RF System with PC Operation Mode

In this mode the PC is used to configure the system entities and install the network. The PC will be used to enter work orders

for processing and provide the queuing for future processing. When an operator processes a work order the PC will validate

the work order number and provide the fluid and amount to be dispensed. The results of the dispense will then be stored on

the PC.

RF System with Host Operation Mode

In this mode the PC is used to configure the system entities and install the network.

The host will be used to enter work orders for processing and provide the queuing for future processing. It will also store

the dispense results that have been completed. Dispense results can be additionally stored on the PC. When an operator

processes a work order the host will validate the work order number and provide the fluid and amount to be dispensed.

Standalone Mode

Work orders will not be validated; each entered work order will be accepted by the system. Data will be stored in the Master

Keypad’s memory.

OTE:N Each meter can only be associated to one Dispense Keypad. Only dispense and keypad supervisors can access each

of the Dispense Keypads.

Page 10 July 2014

Page 11

V3.00

- - - -

INI CNF DK REP

--:--

19/aug/2012

User Manual

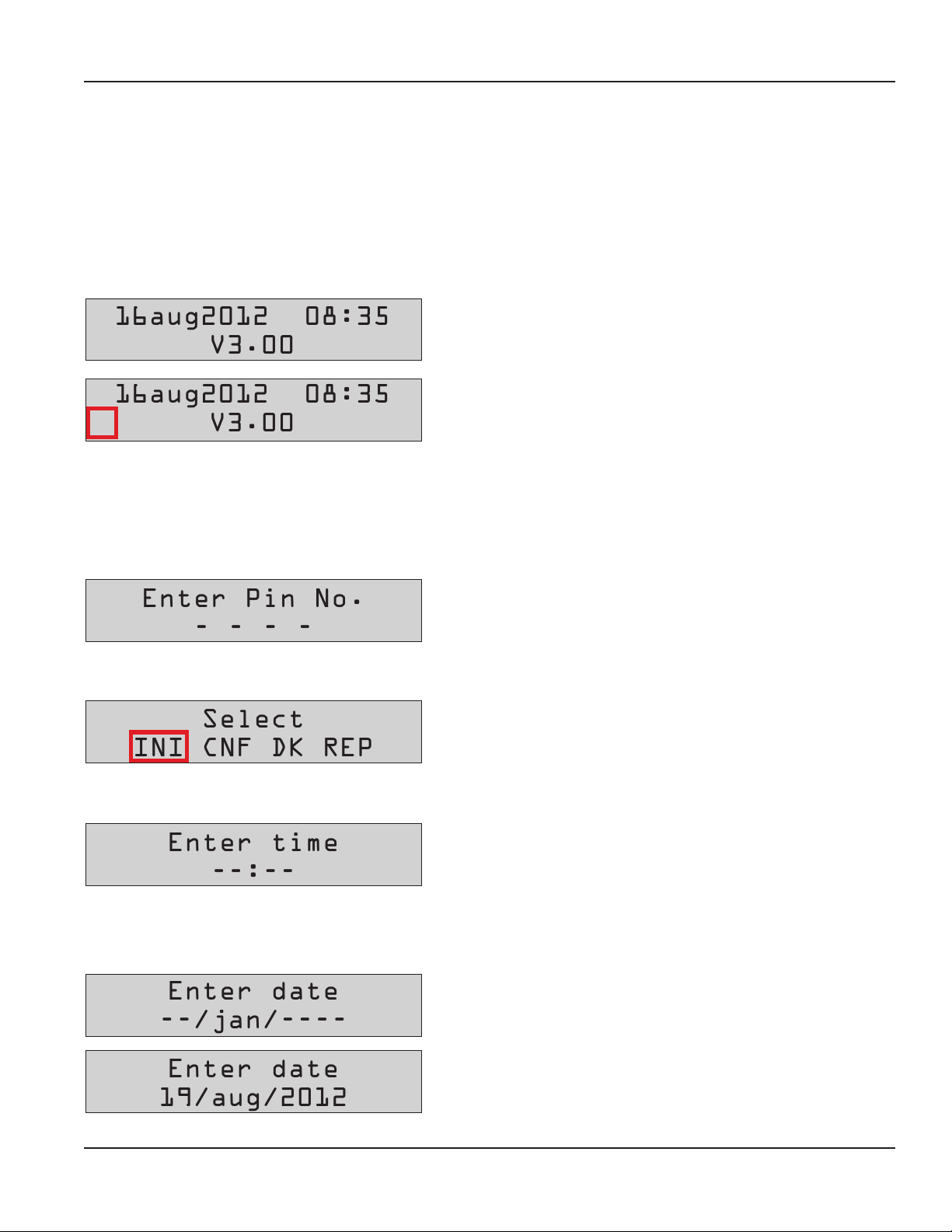

MASTER KEYPAD

The Master Keypad acts as the communications director for the RF communications. It handles all communications between

the Dispense Keypads and the PC or Host. There are no operator menus associated with the Master Keypad—only supervisor

menus for setting up the system or creating reports.

The remainder of this document shows only the actual display, not the entire keypad.

To gain access to the supervisor menus, the supervisor PIN has to be entered. The default PIN is 0001 at initial power-up.

System Version Screen

16aug2012 08:35

16aug2012 08:35

N

Settings Overview / Supervisor Menus

The following changes can only be made at the Master Keypad in the setup mode. All other settings can be changed by using

the FMS software.

Enter PIN Number

V3.00

Enter Pin No.

Initialization (INI) Menu

The standard screen shows the system date and software version

number. The display will alternate between the standard screen and

the Enter Pin Number screen. The Enter Pin Number screen is used to

access the supervisor menus.

OTE:N An "N" displayed in the lower left-hand corner of the system

version screen indicates a Radio Network error. See “Radio

Status” on page 17 to check the source of the error.

To access the setup mode:

Enter the supervisor PIN number and press ENTER.

The default PIN is 0001 at initial power-up.

The INI menu is used to set the system’s date and time.

Select

Set System Time

Enter time

Set System Date

Enter date

--/jan/----

Enter date

To change or set the system time:

1. Select the INI menu and press ENTER.

2. Use the numeric keys to set a 24-hour military time of day.

3. Press ENTER to save the setting and advance.

To change or set the system date:

1. Use the numeric keys to enter the two-digit day.

The cursor automatically moves to the month.

2. Press the SCROLL key to select a month.

3. Use the numeric keys to enter the four-digit year.

4. Press ENTER to save the setting.

Page 11 July 2014

Page 12

INI CNF DK REP

YES / NO

YES / NO

YES / NO

16-

YES / NO

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

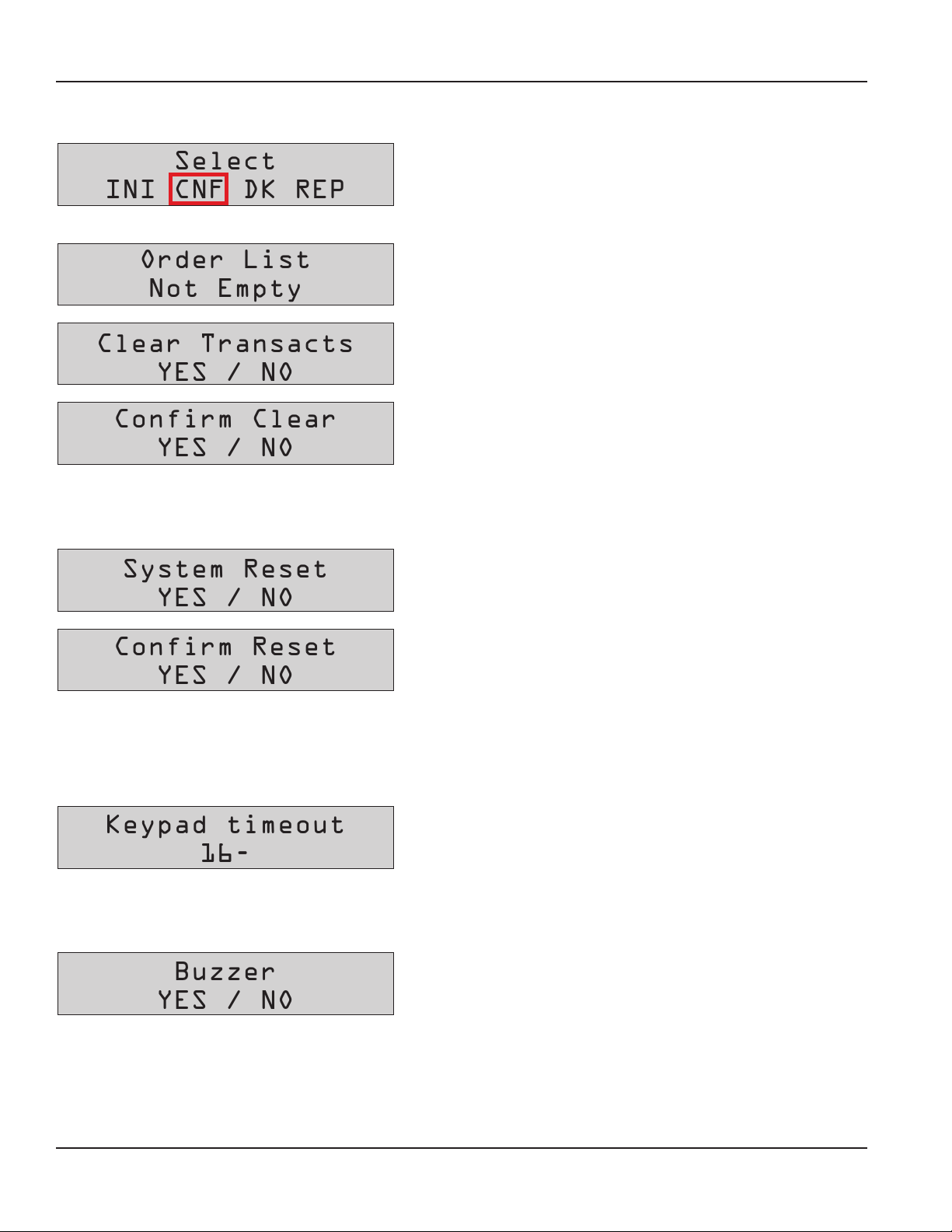

Conguration (CNF) Menu

Select

Order List

The CNF menu is used to set the system’s operation modes and

archiving methods.

If you see the message “Order List Not Empty," you have to clear the

transactions in the Master Keypad (CNF Menu).

Not Empty

Use the SCROLL key to move the cursor to either YES or NO and

Clear Transacts

Confirm Clear

press ENTER.

Use the Scroll key to move the cursor to either YES or NO and

press ENTER.

YES / NO

System Reset

The System Reset allows a supervisor to reset all configuration parameters to default values.

1. Use the SCROLL key to move the cursor to either YES or NO.

System Reset

a. If you select YES, the keypad asks you to Confirm Reset.

Confirm Reset

Keypad Timeout

• Timeout parameter corresponds to the time it takes to validate after all dispense order data has been entered. If the Enter

button is not pressed within the time allocated, the keypad display goes back to initial menu and the input data is erased.

• The Keypad Timeout is between zero to 255 seconds (0 = no timeout) and the default for this feature is 10 seconds.

b. If you select NO, the keypad advances.

3. Press ENTER.

1. Press the BACKSPACE key to erase the current setting.

Keypad timeout

2. Type in the new setting.

3. Press ENTER to advance.

Buzzer

This screen provides a user with the option to have a beep on every key entry. The default is YES.

1. Use the SCROLL key to move the cursor to YES or NO.

Buzzer

2. Press ENTER to advance.

Page 12 July 2014

Page 13

YES / NO

YES / NO

None Mem Print

YES / NO

User Manual

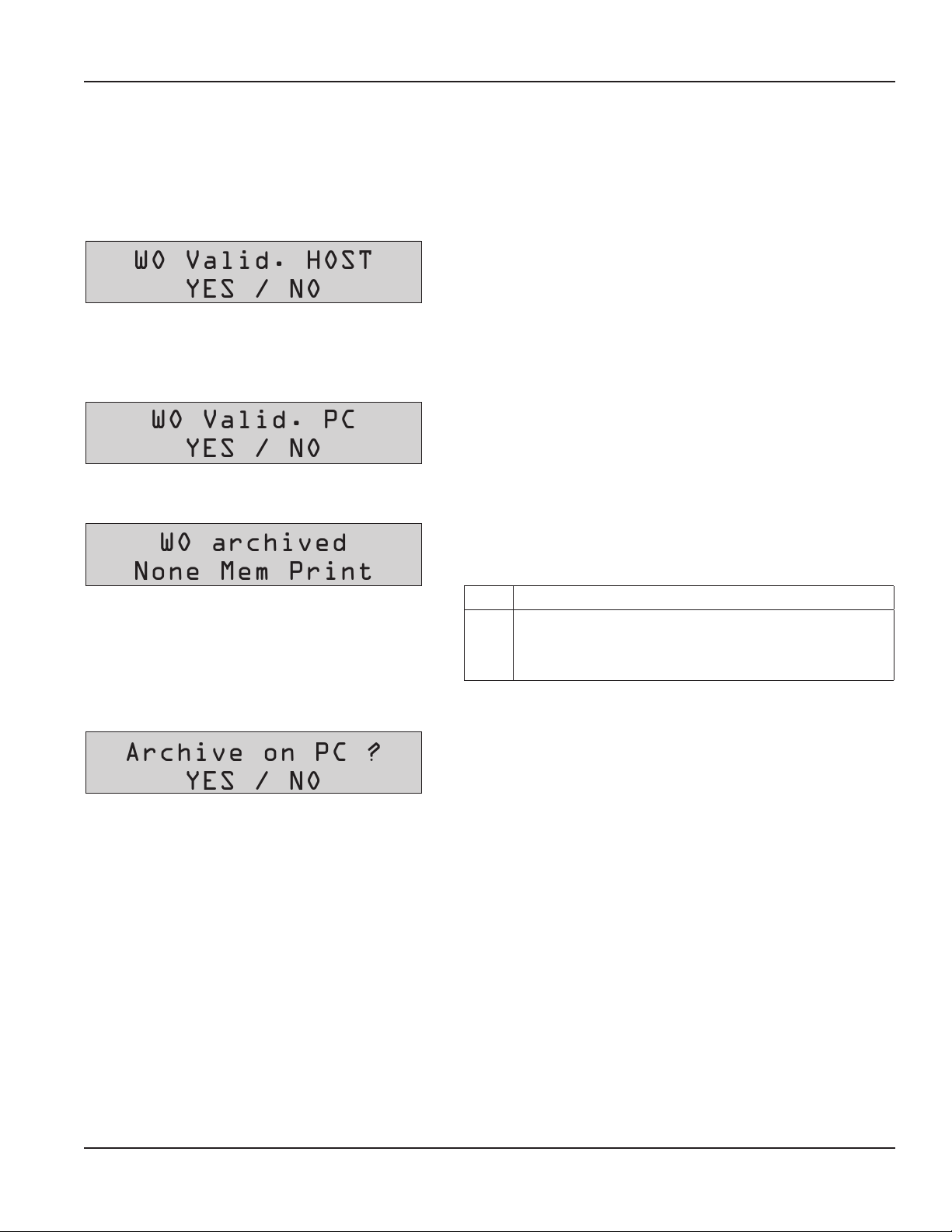

Work Order Validation

WO validation is used to define if a work order shall be validated by the system before processing it.

Host Validation (Host Operation Mode)

In this mode the work order number will be sent to the ERP (DMS) system. Only after validation from the system the meter will

unlock. Afterwards the dispense data will be sent to the ERP system.

1. Use the Scroll key to move the cursor to either YES or NO.

WO Valid. HOST

2. Press ENTER.

PC Validation (PC Operation Mode)

In this mode the work order number will be sent to the PC (FMS Software). Only after validation from the PC will the order

number is accepted.

WO Valid. PC

1. Use the SCROLL key to move the cursor to either YES or NO.

2. Press ENTER.

WO Archive (Printout or Storing of the Work Order /Dispense Results)

1. Use the SCROLL key to move the cursor to your selection.

WO archived

2. Press ENTER.

Mem Data stored in an optional memory module.

Print After each dispense, the data will be printed out on the

external printer.

Each line displays one dispense.

Archive on PC (Archive of the Work Orders/Dispenses)

1. Use the SCROLL key to move the cursor to either YES or NO.

Archive on PC ?

2. Press ENTER.

All dispense results are stored on the PC (FMS Software). If the PC is currently not available, the data will be tagged as “not

sent” in the memory of the master. The data will be sent as soon as the PC is connected again.

Page 13 July 2014

Page 14

INI CNF DK REP

YES / NO

Press Enter

----------------

----

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

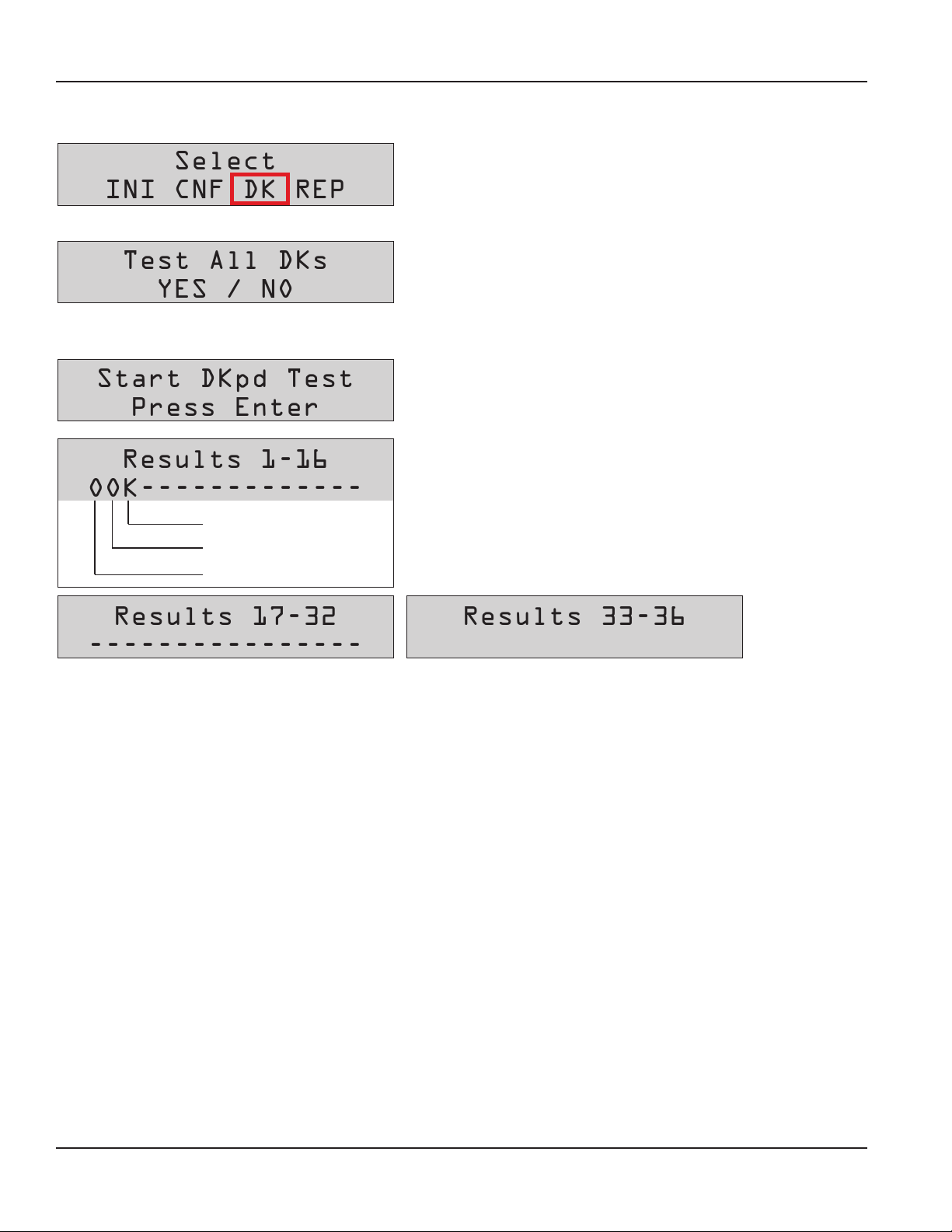

Test Communication (DK) Menu

Select

Test All DKs

Three Dispense Keypads are set up in the following example. Each "–" (dash) stands for a Dispense Keypad.

The DK menu is used to check the communication between

all keypads.

Use the Scroll key to move the cursor to either YES or NO and press

ENTER.

Press ENTER to begin the test.

Start DKpd Test

N=Network Error, T=Timeout

Results 1-16

OOK-------------

Keypad 3 - No Connection

Keypad 2 - Detected

Keypad 3 - Detected

Three Dispense Keypads are set up in this example.

In the following examples, each "–" (dash) stands for a

Dispense Keypad. Press ENTER to display these results.

Results 17-32

Results 33-36

Page 14 July 2014

Page 15

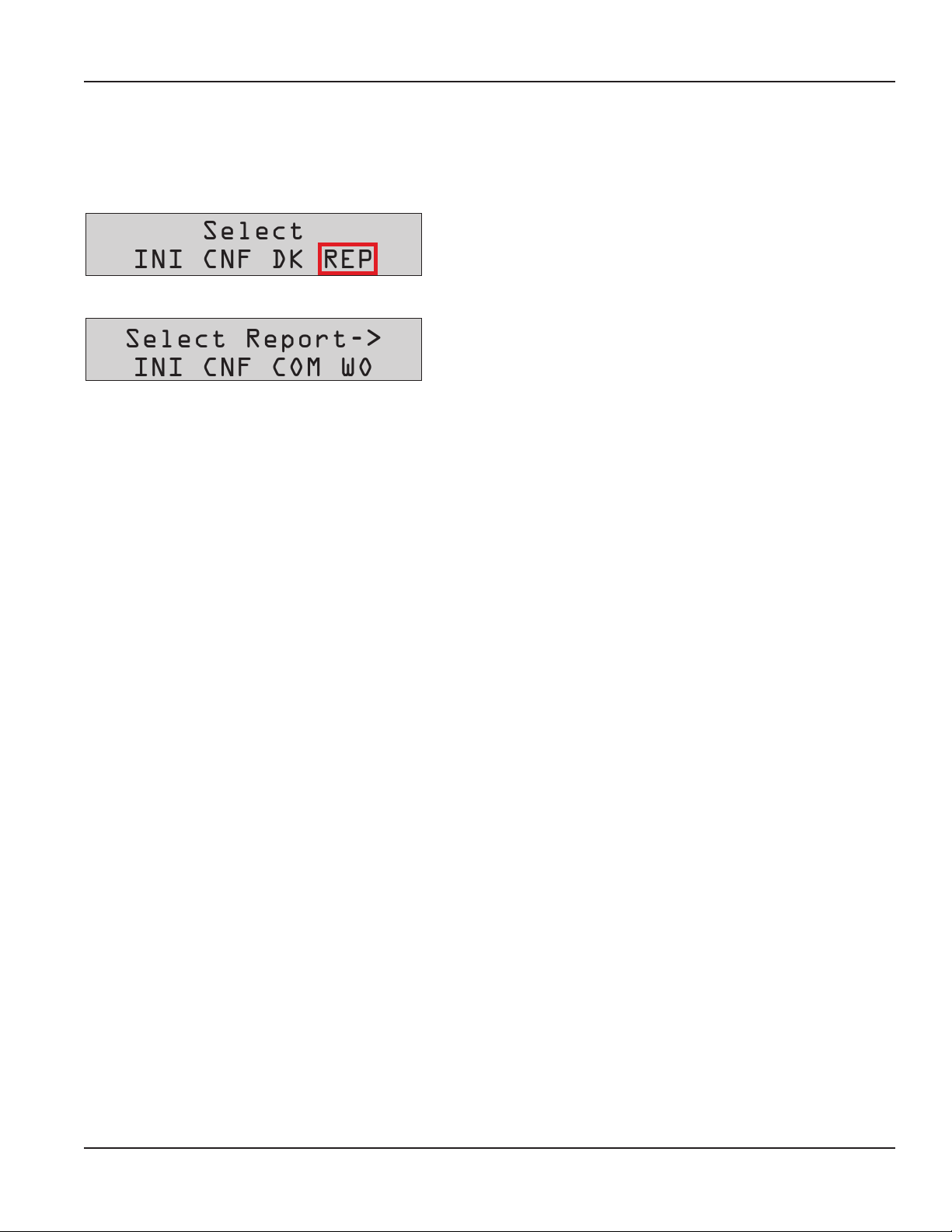

Reports (REP) Menu

INI CNF DK REP

INI CNF COM WO

• Connect a printer or a PC (Terminal program) to the serial printer port (RS232).

• Settings are 9600 Baud, Data Bits 8, Stop Bits 1, Parity ODD.

• Reports will automatically be stored in the data logger (RF memory) at the Master Keypad.

User Manual

Select

Select Report->

To use this feature you must the select External Printer option in

the CNF menu.

The REP menu is used to print reports to an external printer.

Use the SCROLL key to move the cursor to the report you want to print

and press ENTER.

The options are:

INI Initialization USR Sort list by user

CNF Configuration PRO Sort list by product

WO Sort list by work order HOS Sort list by hose (meter)

COM Display the

communication status

of hoses/meters.

TNK Sort list by tank

Page 15 July 2014

Page 16

ADR NWK PWR STA

00:0D:6F:00

01:80:A5:63

ADR NWK PWR STA

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Radio (RAD) Menu

The RAD menu screens are:

• Address (ADR) toggles the display between the Radio Address and the Radio Prefix screens.

• Network (NWK) allows you to select the Radio Network.

• Power (PWR) displays the radio’s transmit (Tx) output power.

• Status (STA) displays the Radio Network Status.

• Change Channel (CHA) allows you to select a different RF channel.

Select

1. Use the SCROLL key to move the cursor to REP.

Select

RAD ... ... ...

Select

ADR NWK PWR STA

Radio Address/Radio Prefix

Once you select ADR, you can use the Scroll key to toggle between the Radio Address and the Radio Prefix screens.

2. Press SCROLL two more times to move the cursor to the RAD

selection.

3. Press ENTER to display the RAD screen.

4. Use the SCROLL key to move the cursor to the information you

want to display.

5. Press HOME to go back to the default screens.

1. Use the SCROLL key to move the cursor to ADR.

Select

RADIO PREFIX

2. Press SCROLL again to display the Radio Prex screen.

3. Press ENTER to display the Radio Address screen.

RADIO ADDRESS

4. Press ENTER to return to the selection screen.

Radio Network

The Radio Network default is zero. You need to change this setting only if you have multiple RF FMS systems. All

RF Meter/Hose Radio Network settings must match the Master Keypad and Dispense Keypad settings.

1. Use the SCROLL key to move the cursor to NWK.

Select

2. Press ENTER to display the Radio Network screen.

3. Press ENTER to return to the selection screen.

RADIO NETWORK

0--

Page 16 July 2014

Page 17

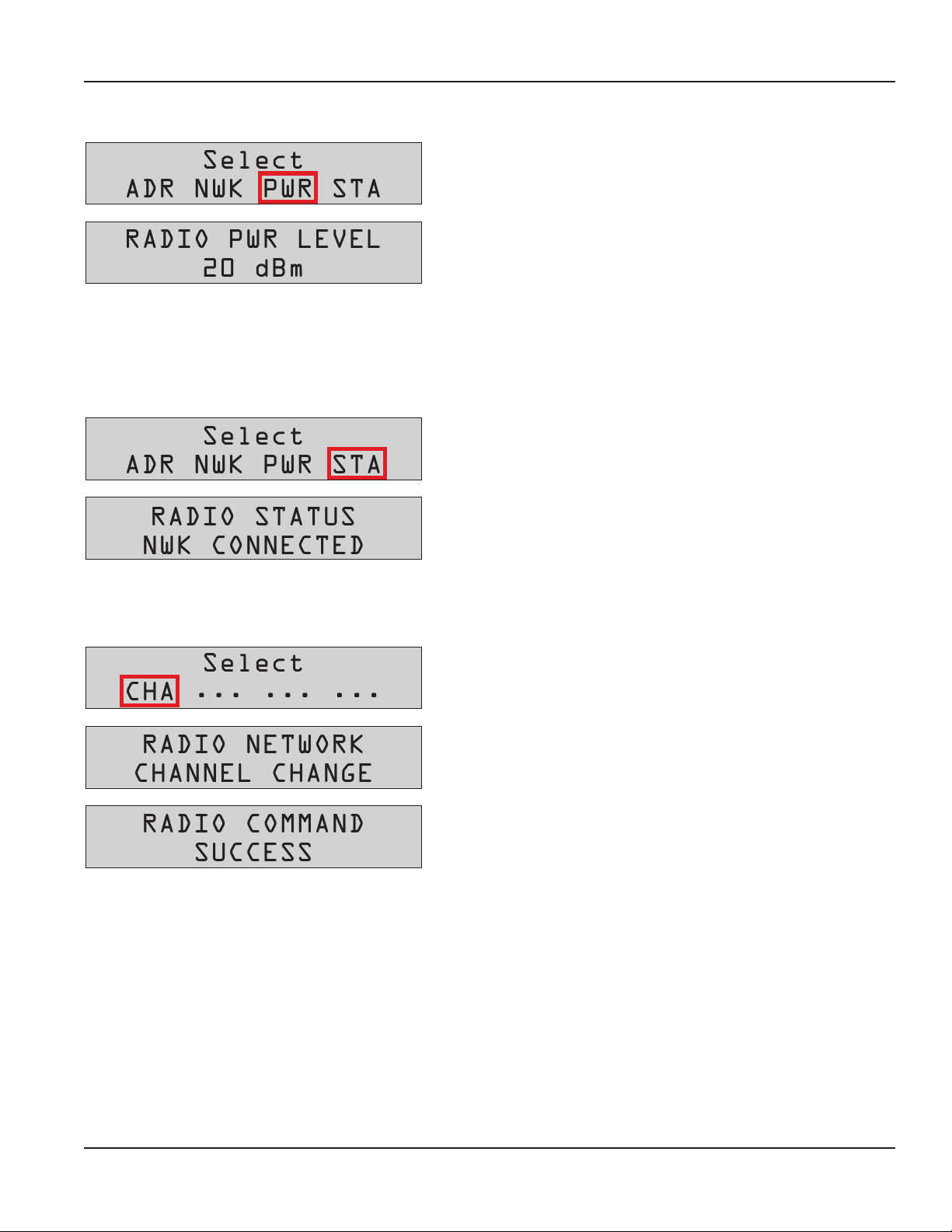

Radio Power

20 dBm

ADR NWK PWR STA

NWK CONNECTED

CHANNEL CHANGE

User Manual

Select

1. Use the SCROLL key to move the cursor to PWR.

ADR NWK PWR STA

2. Press ENTER to display the Radio Power Level screen.

3. Press ENTER to return to the selection screen.

RADIO PWR LEVEL

Radio Status

The Radio Status options are:

• NWK CONNECTED – The network is connected and operational.

• SERIAL ERROR – There is a radio communication error on the serial bus between the keypad and the radio.

1. Use the SCROLL key to move the cursor to STA.

Select

2. Press ENTER to display the Radio Status screen.

3. Press ENTER to return to the selection screen.

RADIO STATUS

Change Channel

The Change Channel option is used to select a different RF channel if the current channel is noisy.

1. Use the SCROLL key to move the cursor to CHA.

Select

CHA ... ... ...

2. Press ENTER to display the Radio Network screen.

3. Press ENTER to select a new channel.

RADIO NETWORK

RADIO COMMAND

4. The screen displays the radio command status.

SUCCESS

Page 17 July 2014

Page 18

- - - -

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

DISPENSE KEYPAD

The Dispense Keypads are responsible for the communication with the RF meters. The user starts a work order from the

keypad. After the dispense operation has been completed the keypad will receive the actual amount dispensed from the

meter. The Dispense Keypad then sends the dispense results to the Master Keypad.

The system can handle up to 36 Dispense Keypads. Up to 24 meters can be assigned to each keypad but each meter can only

be assigned to one Dispense Keypad.

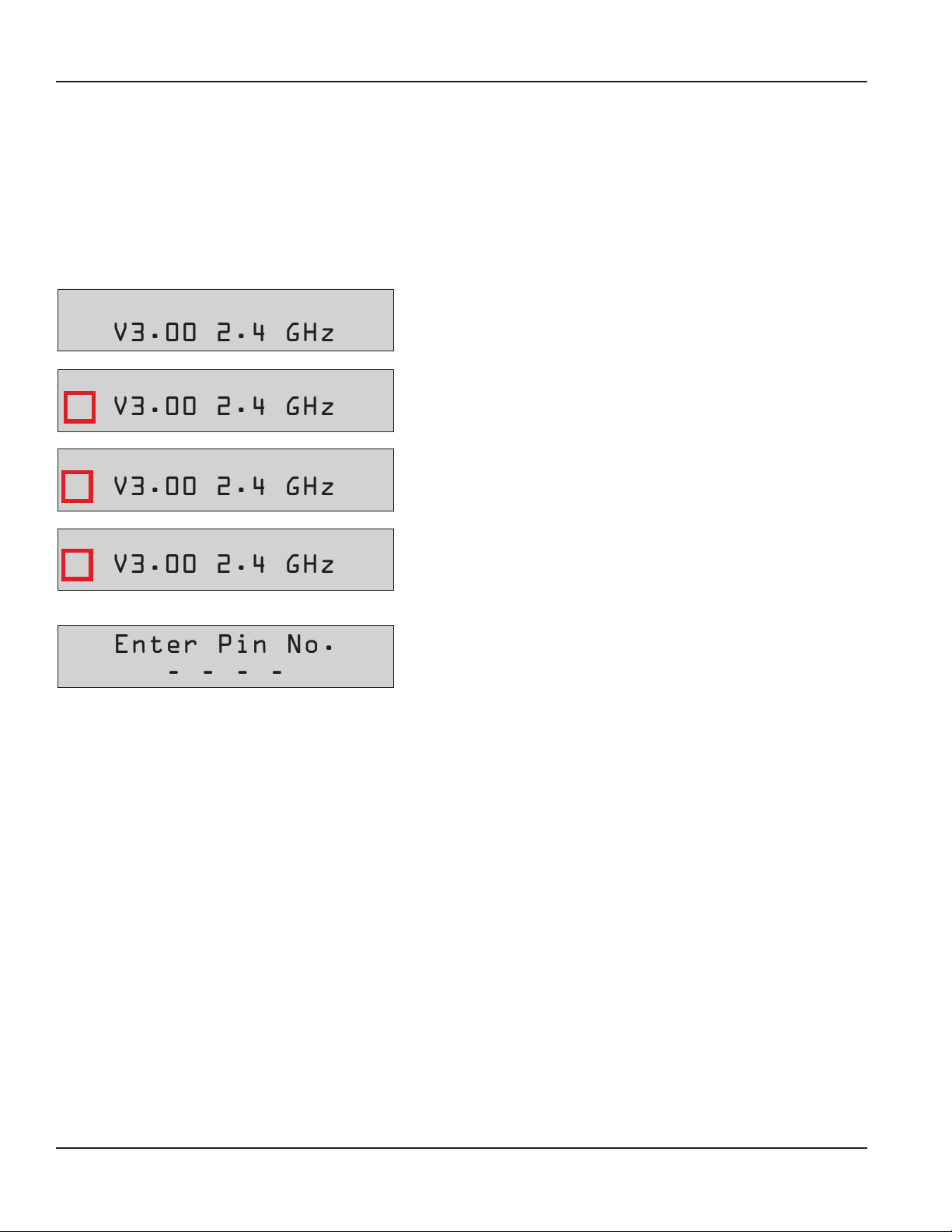

System Version Screen

The standard screen shows the system software version number. The

display will alternate between the standard screen and the Enter Pin

V3.00 2.4 GHz

V3.00 2.4 GHz

N

V3.00 2.4 GHz

M

V3.00 2.4 GHz

O

Number screen. The Enter Pin Number screen is used to access the

supervisor menus.

OTE:N An "N" displayed in the lower left-hand corner of the system

version screen indicates a Radio Network error. See “Radio

Status” on page 23 to check the source of the error.

OTE:N An "M" displayed in the lower left-hand corner of the system

version screen indicates that the Dispense Keypad has joined

an RF network, but cannot currently contact the Master

Keypad for WO authorization.

OTE:N An "O" displayed in the lower left-hand corner of the system

version screen indicates that the Dispense Keypad is in System

Override mode. See “System Override (SYS) Menu” on page 24

for details.

Enter a user PIN to start a work order or the supervisor PIN to enter the

Enter Pin No.

Settings Overview / Supervisor Menus

The following configuration options are only available at the Dispense Keypad.

The default value for the Supervisor PIN is 0001.

supervisor menus (the default PIN is 0001).

Page 18 July 2014

Page 19

Conguration (CNF) Menu

YES / NO

OFF PIN ALL

YES / NO

100_

User Manual

Select

The CNF menu is used to set the system’s operation modes and

archiving methods.

CNF MET REP 190

System Reset

Resets the system parameters to the original factory settings.

Mileage Type

Defines the unit for the Free Alphanumeric field (Defined in Global Keypad Settings)

Top Off Timer

Specifies the amount of time, how long user can make additional dispenses. Is the time allowed after a dispense is completed

before the meter will automatically lockout and send the dispense results back. (Defined in Global Keypad Setting)

Internal Printer

Enables the internal ticket printer. (Defined in Global Keypad Settings)

External Printer

Enables the external report printer port. (Defined in Global Keypad Settings)

Barcode Scanner

This menu will define the external Printer port as a Barcode Reader Port (RS232), if the External Printer is enabled the

Barcode Scanner menu will disappear.

Select YES to enable the Barcode Scanner.

Barcode Scanner

OFF Data can be entered with Keypad & Barcode Scanner

Scanner Lock

PIN Encoded

Encode Prefix #

Display Timeout

We recommend the following barcode scanners:

• Wall mounted: Datalogic Magellan 1000i

• Handheld: Datalogic Gryphon 4100

The scanner has to be programmed according to our specification. Null modem adapter has to be used between the keypad

serial port and the barcode scanner.

PIN PIN has to entered by Barcode Scanner

All All data has to be entered with Barcode Scanner

When PIN or All is selected you can choose an additional prefix

character. The prefix character will not be displayed and cannot be

entered on the keypad.

Choose the desired prefix, available characters are:

# $ % &´ ( ) * +, - Space / : ; < = > ? @ [ ] ^ ` { | } ! ” #

Defines the time, how long the scanned information will be shown on

the display in units of 1/10 second. For example, 100 = 1 second.

Page 19 July 2014

Page 20

YES / NO

YES / NO

YES / NO

YES / NO

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Buzzer

The buzzer beeps each time you press a button. You can turn off the sound. See Global Keypad Settings.

Auto Override

Activates the system Auto Override feature in all keypads so users can dispense WOs when the Master Keypad is not

operational. No supervisor intervention is required. Available with v3.X firmware only. After five failed MK communication

attempts, the Auto Override feature automatically puts the keypad in system override mode.

1. Use the SCROLL key to move the cursor to either YES or NO.

Auto Override

2. Press ENTER.

Batch Quantity Locked

With the Batch Quantity Locked, you cannot change the batch quantity

Batch Qty Locked

Hose ID First

Hose ID First

that was entered on the work order. If the work order has a batch

quantity of zero, you can change the batch quantity.

Used for HOST communication option only.

Selected product ID will be sent to the HOST.

Delete Prepared WOs (MET) Menu

Work orders that have been entered at a keypad are stored until they are picked up by the appropriate meter (by pressing

RESET at the meter). Meanwhile, the meter is locked for other dispenses.

Select

The MET menu is used to delete prepared work orders and release the

meter for new work orders.

CNF MET REP 190

1. Use the Scroll key to move the cursor to either YES or NO.

Init All Hoses

2. Press ENTER.

3. Press ENTER.

Reset All Hoses

Press Enter

Page 20 July 2014

Page 21

Reports (REP) Menu

INI CNF MET WO

USR PRO HOS TNK

INI CNF MET WO

• Connect a printer or a PC (Terminal program) to the serial printer port (RS232).

• Settings are 9600 Baud, Data Bits 8, Stop Bits 1, Parity ODD.

• Reports are automatically stored in the data logger (RF-memory) at the Master Keypad.

User Manual

Select

CNF MET REP 190

Select Report->

Select Report->

190 (Internal Ticket Printer) Menu

Use this menu to print the configuration and status reports from the internal printer FT 190 (optional).

Select

CNF MET REP 190

Select Report->

To use this feature, you must the select External Printer option in

the CNF menu.

The REP menu is used to print reports from an external printer.

Use the SCROLL key to move the cursor to the report you want to print

and press ENTER.

The options are:

INI Initialization USR Sort list by user

CNF Configuration PRO Sort list by product

MET Sort list by meter HOS Sort list by hose (meter)

WO Sort list by work order TNK Sort list by tank

To use this feature, you must the select Internal Printer option in

the CNF menu.

The 190 menu is used to print reports from an internal printer.

Use the SCROLL key to move the cursor to the report you want to print

and press ENTER.

The options are:

INI Initialization MET Sort list by meter

CNF Configuration WO Sort list by work order

Page 21 July 2014

Page 22

ADR NWK PWR STA

ADR NWK PWR STA

00:0D:6F:00

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

RF Communication Test (LNK) Menu

Select

The LNK Menu is used to check the quality of the RF communication

between the Master and Dispense Keypads.

LNK RAD SYS ...

The test performs a number of test communications and measures the quantity of lost transmissions. The Link Quality 10 is the

maximum you can achieve.

Start Link Test

Press Enter

Enter to Cancel

Radio (RAD) Menu

The RAD menu screens are:

• Address (ADR) toggles the display between the Radio Address and the Radio Prefix screens.

• Network (NWK) allows you to select the Radio Network.

• Power (PWR) displays the radio’s transmit (Tx) output power.

• Status (STA) displays the Radio Network Status.

• Network Connect (CON) connects the keypad to a new Master Keypad network.

Test in

Progress

Press Enter

Test Complete

Link Quality: 10

Select

1. Use the SCROLL key to move the cursor to REP.

Select

LNK RAD SYS ...

Select

Radio Address/Radio Prefix

Once you select ADR, you can use the Scroll key to toggle between the Radio Address and the Radio Prefix screens.

2. Press SCROLL two more times to move the cursor to the RAD

selection.

3. Press ENTER to display the RAD screen.

4. Use the SCROLL key to move the cursor to the information you

want to display.

5. Press HOME to go back to the default screens.

1. Use the SCROLL key to move the cursor to ADR.

Select

RADIO PREFIX

2. Press SCROLL again to display the Radio Prex screen.

Page 22 July 2014

Page 23

01:80:A5:63

3. Press ENTER to display the Radio Address screen.

ADR NWK PWR STA

20 dBm

ADR NWK PWR STA

NWK CONNECTED

RADIO ADDRESS

4. Press ENTER to return to the selection screen.

Radio Network

The Radio Network default is zero. You need to change this setting only if you have multiple RF FMS systems. All

RF Meter/Hose Radio Network settings must match the Master Keypad and Dispense Keypad settings.

User Manual

Select

1. Use the SCROLL key to move the cursor to NWK.

ADR NWK PWR STA

2. Press ENTER to display the Radio Network screen.

3. Press ENTER to return to the selection screen.

RADIO NETWORK

0--

Radio Power

1. Use the SCROLL key to move the cursor to PWR.

Select

2. Press ENTER to display the Radio Power Level screen.

3. Press ENTER to return to the selection screen.

RADIO PWR LEVEL

Radio Status

The Radio Status options are:

• NWK CONNECTED – The network is connected and operational.

• SERIAL ERROR – There is a radio communication error on the serial bus between the keypad and the radio.

• NWK DOWN – There is no network within the range of the Dispense Keypad.

• NWK LOST – The network connection is currently unavailable.

Select

RADIO STATUS

1. Use the SCROLL key to move the cursor to STA.

2. Press ENTER to display the Radio Status screen.

3. Press ENTER to return to the selection screen.

Page 23 July 2014

Page 24

ADR NWK PWR STA

CONNECTING

NWK CONNECTED

YES / NO

ON

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Network Connect (CON) Menu

The Network Connect forces the keypad to connect to a new Master Keypad network. This option is used when:

• Replacing the Master Keypad.

• Moving the Dispense Keypad if the Dispense Keypad does not automatically find the new network.

Select

Select

CON ... ... ...

RADIO NETWORK

RADIO STATUS

System Override (SYS) Menu

Select

LNK RAD SYS ...

System Override

1. Use the SCROLL key to move the cursor to CON.

2. Press ENTER to display the Radio Network screen.

3. Press ENTER to display the Radio Status screen.

4. The screen displays the radio connection status (NWK CONNECTED

or NWK DOWN).

The System Override Menu is used to override verification of the Master

Keypad.

1. Use the SCROLL key to move the cursor to YES.

2. Press ENTER.

System Override

The screen verifies that System Override is On.

Page 24 July 2014

Page 25

Dispense Keypad Menu Overview

Enter PIN No.

----

Enter WO No.

---------------

Enter Hose

---

Fluid

Product Name

Quantity

----

Enter For

Dispense

CNF

System Reset

YES / NO

MET

REP

190

Mileage Type

KM / Miles

Topoff Timer

0----

Internal

Printer

Init All Hoses

YES / NO

Reset All Hoses

Press Enter

LNK

Select Report -

>

Select

FLU HOS TNK USE

Start Link Test

Press Enter

Test in

Progress

Test Complete

Link Quality:

Supervisor 0000

External

Printer

Enter PIN No.

----

Enter WO No.

---------------

Enter Hose

---

Fluid

Product Name

Quantity

----

Enter For

Dispense

CNF

System Reset

YES / NO

MET

REP

190

Mileage Type

KM / Miles

Topoff Timer

0----

Internal

Printer

Init All Hoses

YES / NO

Reset All Hoses

Press Enter

LNK

Select Report -

>

Select

INI CNF MET WO

Start Link Test

Press Enter

Test in

Progress

Test Complete

Link Quality:

Supervisor 0001

External

Printer

Pin Encoded

Hose RESET

Buzzer

Batch Qty

Locked

Hose ID First

Barcode Scanner

Sanner Locked

Display Timeout

Barcode menu disappears if the

Encode Prefix #

Available characters:

RAD

SYS

System Override

YES / NO

Select

ADR NET PWR STA

Select

CON ... ... ...

Auto Override

YES / NO

User Manual

# $ % &´ ( ) * + , Space / : ; < = > ? @ [

Page 25 July 2014

Page 26

-

- - - -

- - - -

- - - -

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

DISPENSE PROCESS

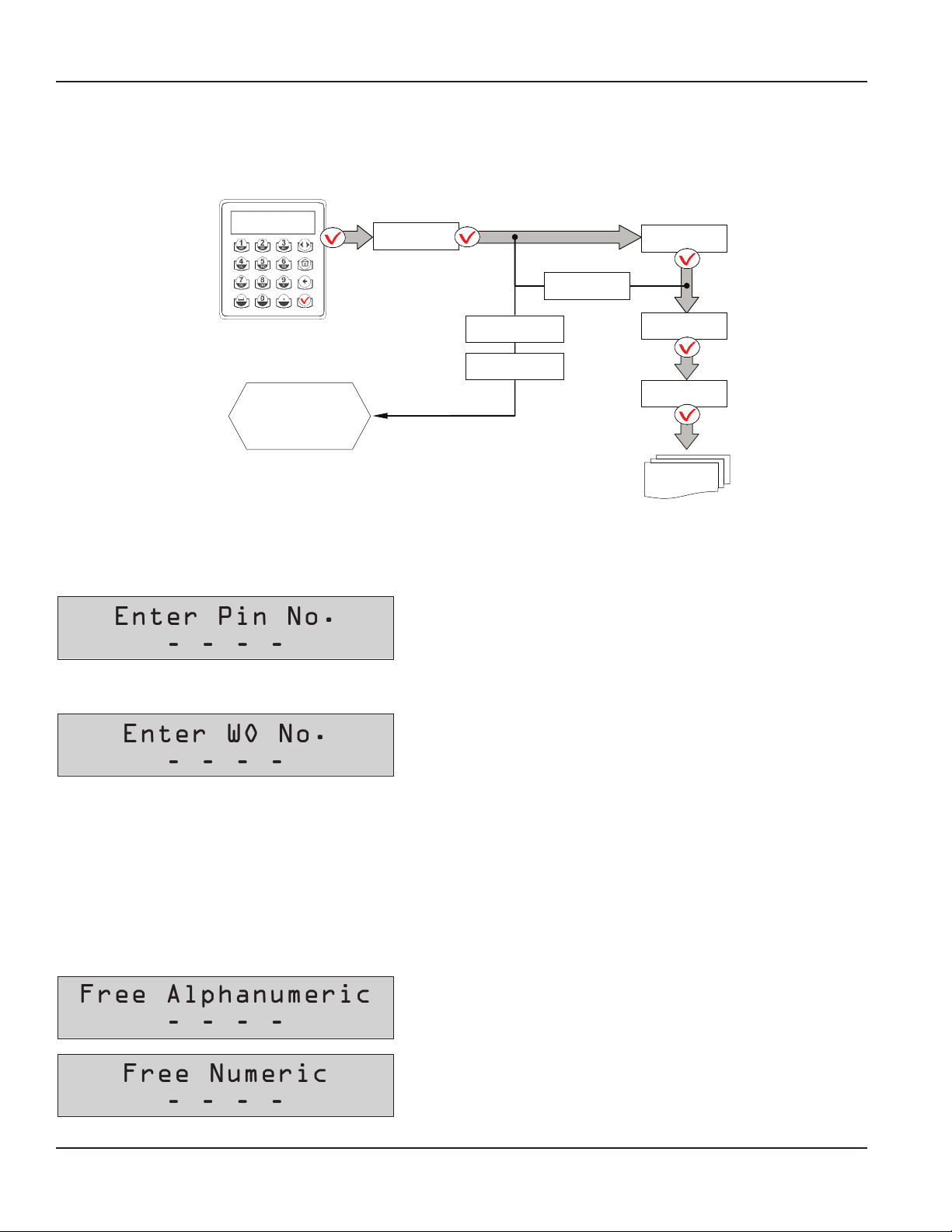

Schematic Overview

Enter PIN No.

----

External validation

By FMS Software (PC)

Or Host (DMS)

Enter WO No.

123A2--------

WO Valid Host

WO Valid. PC

YES / NO

YES / NO

Hos e ID First

YES / NO

Enter Hose

02-

Quantity

3.0-

Enter for

Dispense

Order stored in Dispense Keypad

until the meter RESET button is pressed.

Starting a Work Order

1. Enter your PIN number and press ENTER.

Enter Pin No.

To start a work order, the mechanics or users must enter their PIN to access the system.

2. Enter an alphanumeric number (max. 16 characters) and press

Enter WO No.

ENTER.

In the operation modes WO Validation HOST or WO Validation PC (see “Work Order Validation” on page 13) the entered WO

number will be compared with the numbers set in the system, which are defined in Global Keypad Settings.

Alphanumeric Keypad

To change from the numeric to the letter keypad, press the equivalent key for at least 3 seconds until the desired letter is

shown.

Additional Free Fields

These optional fields are only shown if they have been enabled (defined in Global Keypad Settings).

3. Enter alphanumeric characters and press ENTER.

Free Alphanumeric

Can be used, for example, for the licences plate number.

- - - -

4. Enter an alphanumeric number (max. 16 characters) and press

Free Numeric

Page 26 July 2014

ENTER.

Can be used, for example, for the actual mileage.

Page 27

- - -

Product Name

Dispense

User Manual

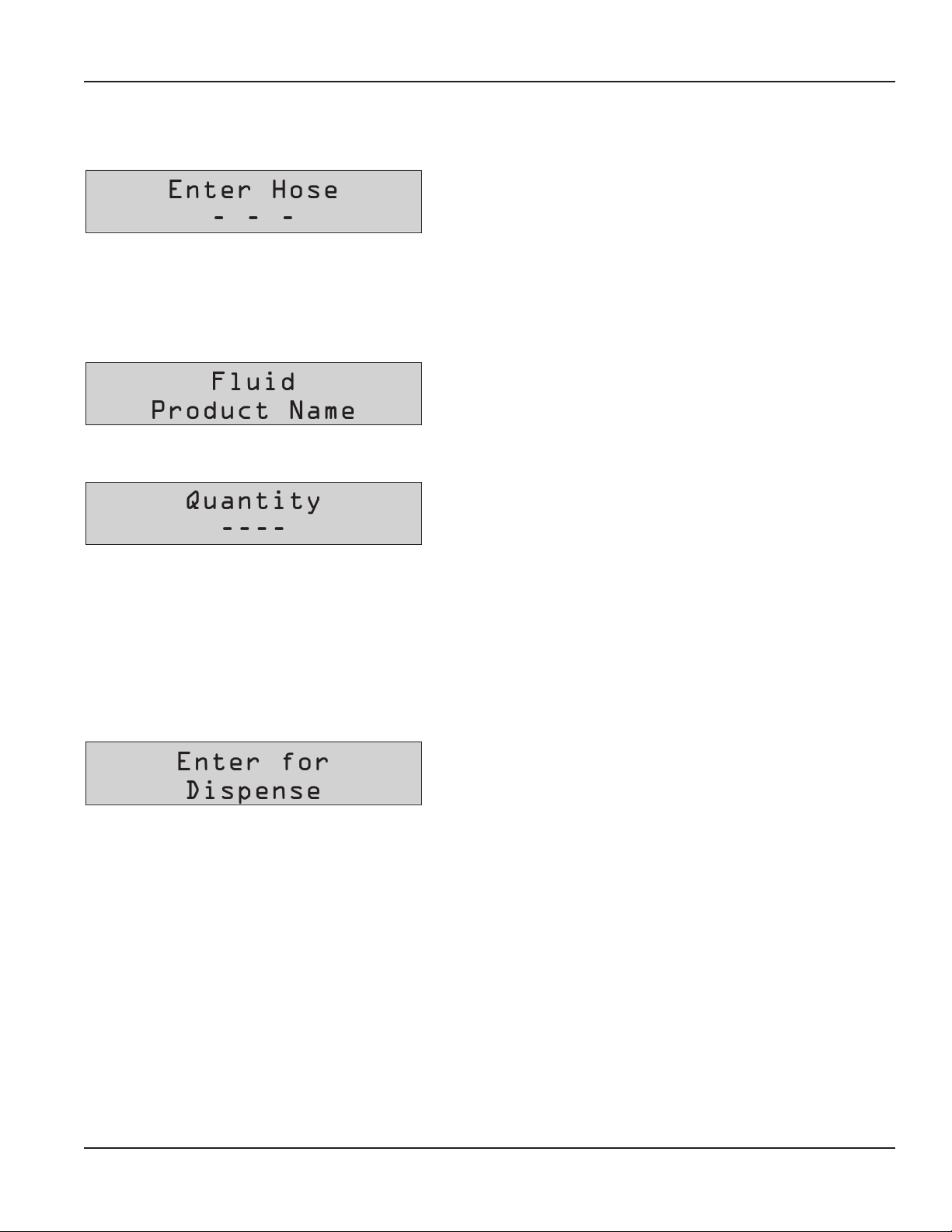

Meter Selection

Enter a preset meter (hose) ID for the product.

5. Enter a preset meter (hose) ID for the uid product you want and

Enter Hose

• Only meters that are assigned to the current keypad can be selected.

• In the operation modes WO Validation HOST or WO Validation PC the system will check if the product you entered is assigned to this work

order.

Display Fluid

press ENTER.

6. The chosen fluid type is displayed for three seconds.

Fluid

Product Quantity

Quantity

7. Enter the desired quantity and press ENTER.

----

Optionally, the quantity assigned to this WO is shown.

• The quantity can be chosen between 0.0…99.9 and 100…999 units of measure.

• The preselection can be made with one decimal place.

• For quantities more than 100 units of measure, the meter counts down toward zero.

• A quantity of 0.0 will deactivate the preselection on the RF meter. The RF meter will not latch and the user is required to hold the

trigger in the open position to dispense fluid. The user must press RESET on the RF meter to complete the dispense operation and

communicate the dispense order result to the keypad.

Dispense Confirmation

8. Press ENTER to dispense the uid.

Enter for

The work order is now ready for being picked up by the RF meter (see

RF Mode, Standard Preselection Mode) .

Page 27 July 2014

Page 28

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

EPM3 RF METER

The meter is equipped with RF communications to communicate dispense authorization and result information. Once a work

order has been set up, the operator simply pulls the trigger and the authorized amount of fluid for that meter will dispense.

The valve will automatically shut off when the full quantity has been dispensed. A Top Off feature allows additional quantities

to be dispensed and tracked after the valve closes. Upon completion of the dispense effort, the valve locks, prohibiting any

unauthorized dispense.

Key Description

The following keys (except for RESET and SHUT-OFF) are only active in the AUTO mode (or Manual mode).

10, 1, 0.1 Used to enter the dispense quantity to be used.

In operational mode it shows the five latest

dispensed amounts.

TOTAL Used to display the accumulated total of fluid

dispensed, as well as the resettable total when

held for 3 seconds.

AUTO Used to enter and exit the auto mode when RF

communications are not available.

RESET • Used to accept a dispense order from the

keypad.

• Used in normal operating mode (RF, manual

or auto) to clear the previously programmed

batch and to reset the meter.

• Used to reset the resettable total dispensed

while pressing the TOTAL button.

SHUTOFF

or

STOP

Used to stop the flow manually through an

electrical override.

Page 28 July 2014

Page 29

10 sec

02

Result stored in

Press the

Press the

The red button will STOP

a dispense at any time.

02

CLACK

02

User Manual

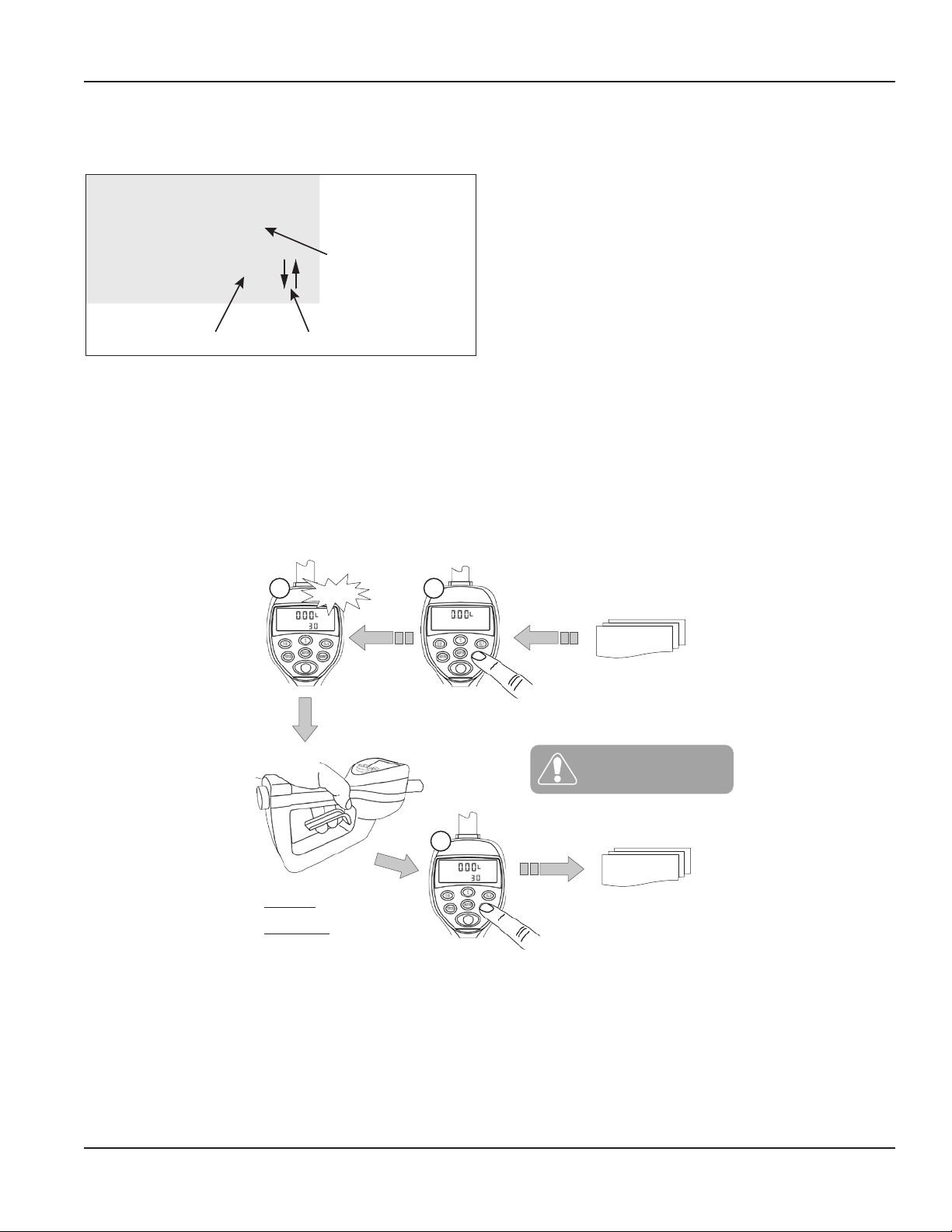

RF Mode (Standard Pre-Selection Mode)

Work Order Validation via the Dispense Keypad

When the battery pack is attached to the meter, the meter will

automatically enter the RF mode. The trigger is in a locked-out

0.00

7.2

L

Dispensed

Quantity

position and no oil can be dispensed until a dispense order is

received by the meter.

RF COMBatch Size

1. Press the RESET button on the meter to enable it to receive a dispense order provided by the Dispense Keypad. The trigger

will unlock.

2. Pull the trigger to begin the dispensing of uid. The valve will automatically lock in place, even though the trigger will fall

back to the closed position. The ow will automatically shut o when the programmed amount has been dispensed.

3. To top o, pull the trigger to dispense uid and release when the desired amount has been reached.

4. Press the RESET button when nished. The total quantity will be transmitted to the keypad and the meter will return to a

locked-out position. The meter is now ready to receive the next dispense order from the keypad.

10 sec

Preselection: Pull the trigger until it

latches and RELEASE the trigger.

No preselection (0 liter): Pull and HOLD

the trigger. The trigger won´t latch.

Order stored in

Dispense Keypad

RESET button

Dispense Keypad

RESET button

Page 29 July 2014

Page 30

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

AUTO Mode (Autonomous)

MPORTANTI

This function allows unauthorized dispenses. The dispense information will not be associated to any mechanic or operator.

• The total dispensed quantity will be stored under the general work order number (999999).

• The AUTO sign at the display’s lower left corner indicates the manual mode.

Enter the AUTO Mode

To enter the AUTO Mode:

1. Press and hold the TOTA L button.

2. Press the following buttons one after the other: 10, 1, 0.1, AUTO.

You can use this same button sequence to return to RF mode.

The solenoid will now unlock and the meter may be used as a normal preselection meter.

3. Press the AUTO button to enter the preselection.

Reset to Standard Mode

To return the meter to the standard preselection mode, press the RESET button and start a communication with the assigned

dispense (see “Network Connect (CON) Menu” on page 24 and “RF Mode (Standard Pre-Selection Mode)” on page 29.

If the communication was successful (no “F02” error code) the meter will lockout and fall back in the preselection mode. The

total quantity, which has been dispensed during the AUTO mode, will be automatically transmitted to the Master Keypad. It

will be assigned to Misc. WO-Number (default 999999), with the user named as “???”. The dispense result will be marked with

the Status 16 for manual dispense.

Electrical Override

In case of an emergency or to interrupt a batch, the meter is equipped with an electrical override. This option automatically

closes the valve in the meter, stopping the flow immediately. The display will begin to flash because the meter does not sense

any flow. Batching can be continued after an override, even if the meter is in the middle of a programmed batch and the

display continues to flash.

1. Press the red SHUTOFF button to activate the electrical override. This button can only be used when the valve is open.

2. Press the RESET button to cue up the next batch and stop the display from ashing.

Page 30 July 2014

Page 31

Changing the Battery

When the batteries need changing, a progression of warnings appears on the meter screen.

First Warning

The Low Battery icon appears in the lower left corner of the display. That means the

batteries are low and need to be changed when the icon appears.

Second Warning

The Battery icon flashes. The battery power is too low and meter functions are disabled.

The battery compartment is located in the lower case on the backside of the trigger guard.

1. Position the unit face down.

2. Unscrew the two screws. Remove the battery door to expose the batteries.

3. Replace the old batteries with 4 AA alkaline batteries.

OTE:N Battery polarity markings are inside battery compartment.

4. Dispose of used batteries properly, according to local regulations.

User Manual

OTE:N Changing the batteries does not affect any of the programmed values

or totals.

Programming the EPM-3 RF Meter

The units of measurement and scale factor can be changed. For instructions, see the EPM-3 RF Meter Installation and Operation

Manual.

Page 31 July 2014

Page 32

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

INSTALLING AND LAUNCHING THE FMS SOFTWARE

The system configuration is done by using this FMS Software. Only some special functions like the operation modes are set at

the Master Keypad.

The software provides the ability to set work orders, and assign a product and a quantity to it.

All dispense results will be collected and saved in a work order list (W.O. Report). Several filters are available to select the

desired information. The result can be exported to a semicolon separated value (CSV) file format.

System Requirements

• P4 1.6 GHz or greater

• 1 GB RAM minimum

• XP, Vista, or Windows® 7, Server 2003, Server 2008 Required (will not run on Windows 2000 or earlier) 64 and 32bit compatible

FMS Software Description

Before beginning the installation, please be sure your Windows user profile has the appropriate rights to install the software

properly (particularly Windows XP).

Insert the setup CD ROM into your CD ROM drive.

If the Installer does not launch itself after a short period, open it manually by double clicking on your CD Drive in your My

Computer folder. Select the AutoMenu.exe file.

The installer menu will appear:

The installer menu provides several options:

• Server – installs the server and all server

components. This will be the location

where all the master keypad is plugged

in, data is stored and where the client

machine will go to access and update

work orders, tank levels, etc.

• Client – installs the client and all client

components. This will have to be

installed on every machine you would

like to run the software on

• Exit closes the installer

Page 32 July 2014

Page 33

User Manual

Installing the FMS Server

1. Select Install Server.

If the .NET 4.0 Framework or SQL Compact Edition is already installed, they will be skipped. If the .Net 4.0 Framework is not

installed, the installer will appear.

2. Click ACCEPT.

If the SQL Compact Edition is not installed, the installer will appear.

3. Click ACCEPT.

The Framework and/or SQL Compact Edition installation will take several minutes. The screens appear in the following order:

Page 33 July 2014

Page 34

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

After the prerequisites are installed, the FMS Server Setup Wizard appears:

1. Click NEXT.

1. Select the installation folder you want the Server installed

to.

The default folder is HIGHLY recommended.

2. Click NEXT.

3. Click NEXT to conrm the installation.

Page 34 July 2014

Page 35

User Manual

During the installation, a screen similar to this one displays,

showing the installation progress:

When the installation is complete, a screen similar to this

one displays.

4. Click CLOSE to exit the installer.

Page 35 July 2014

Page 36

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Installing the FMS Client

1. Select Install Client.

The .NET 4.0 Framework installer will appear here if the Client is being installed on a machine without it. The Client will also

install the SQL Compact Edition if it is not installed.

2. Click ACCEPT.

After the prerequisites are installed, the FMS Client Setup Wizard screen appears:

1. Click NEXT.

Page 36 July 2014

Page 37

User Manual

2. Select the installation folder you want the Client installed

to.

The default folder is HIGHLY recommended.

3. Click NEXT.

4. Click NEXT to conrm the installation.

When the installation is complete, a screen similar to this

one displays.

5. Click CLOSE to exit the installer.

Page 37 July 2014

Page 38

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Launching the FMS Software

To launch the software, click on the FMS Client icon on your desktop

Before you can begin, you first need to tell the Client application the IP address where the server resides.

1. Enter the IP address of the FMS server.

For the Client installed on the server, the IP address should be 127.0.0.1.

For the Client not installed on the server, enter the IP address assigned to the

server.

FMS System Conguration

2. Enter the 4-digit system password and click the OK button.

The system admin password is initially set to 0000.

Page 38 July 2014

Page 39

User Manual

USING THE FMS SOFTWARE

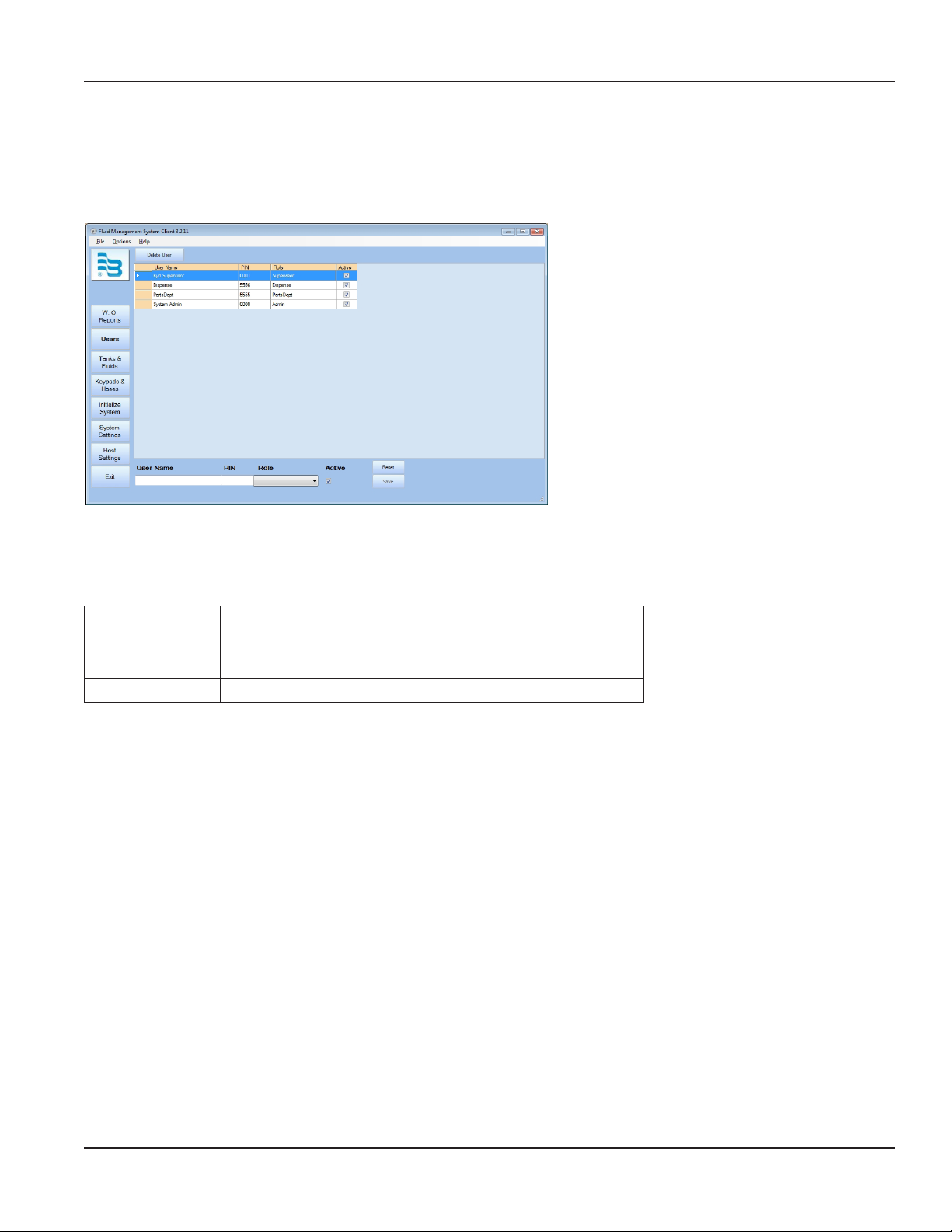

Setting Up New Users

The default names and pins may be changed at any time by highlighting the text, deleting it, and entering the appropriate

text. To save changes made, click the SAVE button.

1. To add a new user, click the RESET button.

The information will clear from the text boxes.

2. Enter a user name, new pin (cannot duplicate

any currently used pin number), and assign a

role.

If you wish to set up a user having multiple roles,

you will need to create a user and pin number for

each role.

New User Roles

The choices for role selection are System Admin, Supervisor, Parts Dept, and Dispense. These choices will allow the user to do

the following:

System Admin Make changes to all levels of the software, from the PC only.

Supervisor Make changes at the keypad only.

Parts Dept Enter work orders at the PC.

Dispense Enter a work order id at dispense keypad to complete dispense..

Active or Inactive Users

Only users who have an Active status will be allowed to access their respective duties.

To make a user active or inactive:

1. Select the user's name.

2. Check the Active box.

3. Click SAVE.

Users with multiple roles will require a unique password for each role.

Deleting a User

To delete a user:

1. Select the user's name.

2. Click the DELETE USER button in the top left-hand corner.

3. Confirm your request to delete the user.

Page 39 July 2014

Page 40

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

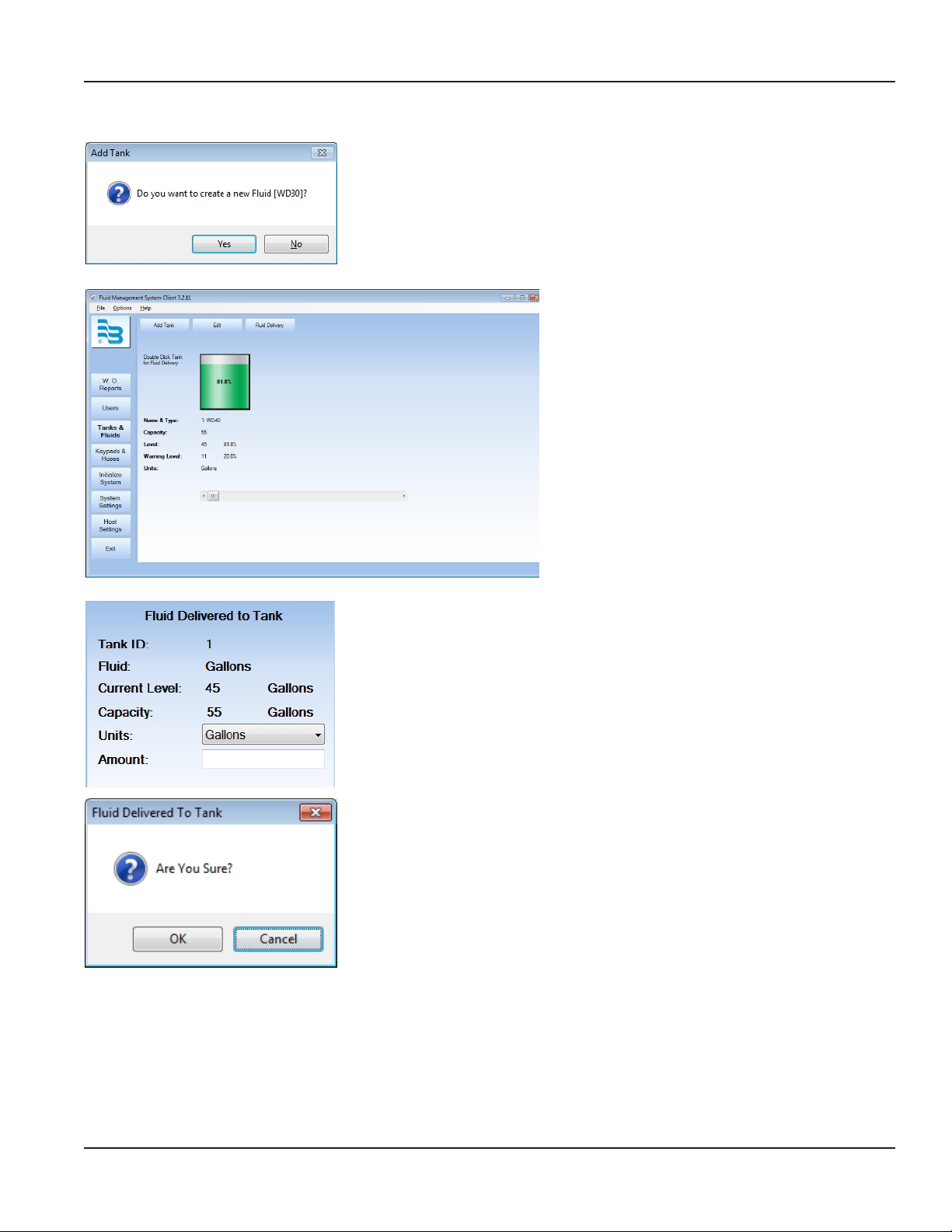

Setting Up Tanks and Fluids

Using the software, you can track and monitor tank levels based off work orders. To track this, you first need to add a tank and

its corresponding fluid.

These are the fields of information required to add a tank:

Tank ID The Tank ID field automatically displays the next available sequential ID number. You can also select

available tank IDs from the drop-down menu.

Units The Units field specifies the units of measurement that you use to track the tank level. The choices are

Gallons, Liters, Pints and Quarts.

Fluid The Fluid field specifies the type of fluid in the tank. You can also select existing fluids from the

drop-down menu.

Capacity The Capacity field specifies the total amount of fluid that may be stored in that tank. Enter a numeric

value that corresponds to the capacity of the tank (the value will be in the units you previously

identified).

Level The Level field specifies the current level of fluid in the tank.

Warning Level The Warning Level field specifies the fluid level at which you would like a warning message emailed to a

particular person. A warning message will appear on any running client screen when a completed work

order brings the tank level down to, or below, the warning level setpoint.

To use this feature, click the check box and enter either a nominal value or percentage (the other value

with self-propagate after you enter the first value).

Auto Email Check the Auto Email checkbox to bring up a screen to specify email settings for the warning message.

When the tank reaches the specified Warning Level, this email will be sent to the email recipient.

Multiple recipients can be defined. Enter a semicolon ( ; ) between each e-mail address.

OTE:N This is not a required field. This option will not run if email settings are not activated. See “Email

Settings” on page 46.

To set up a tank:

1. Click on the ADD TANK button.

2. In the Units eld, select a unit of measure from the drop-down menu.

3. In the Fluid eld, enter a uid name in the text box or select a uid from the

drop-down menu.

4. In the Capacity eld, enter the total number of units (gallons, liters, pints or

quarts) of uid that may be stored in the tank.

5. In the Warning Level eld, enter the uid level at which to trigger a warning

message.

6. To specify the email setting for the warning message, check the box next to

Auto Email, then select Email Options.

7. Enter the email address of the recipient.

8. Type a message.

9. Click SAVE to close this screen and return to the Add Tank screen.

10. Click SAVE again to save your changes and exit the Add Tank screen.

OTE:N If the fluid you entered was not in the drop-down list, you will be asked if

you want to create a new fluid when you exit this screen.

Page 40 July 2014

Page 41

Creating a New Fluid

User Manual

11. If the uid you entered during the Add Tank procedure was not in the drop-

down list, click YES if you want to create a new uid.

The new fluid will now appear in the Fluid Type drop-down list.

After you set up a tank and fluid(s), the software

displays graphical representation of the tank

level, including:

• the percentage of fluid remaining in the tank.

• the tank information that was entered in the

previous step.

To change the information, click on EDIT.

To add a new tank, click on ADD TANK and

repeat the process explained in “Setting Up Tanks

and Fluids” on page 40.

To track when fluid is added to the tank, click on

FLUID DELIVERY.

You can edit the amount of fluid added and the units in which it was added

(gallons, liters, pints, and quarts).

After entering the information, click SAVE to save your changes.

You will be asked to verify your changes.

When the verification screen appears, click OK.

Page 41 July 2014

Page 42

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

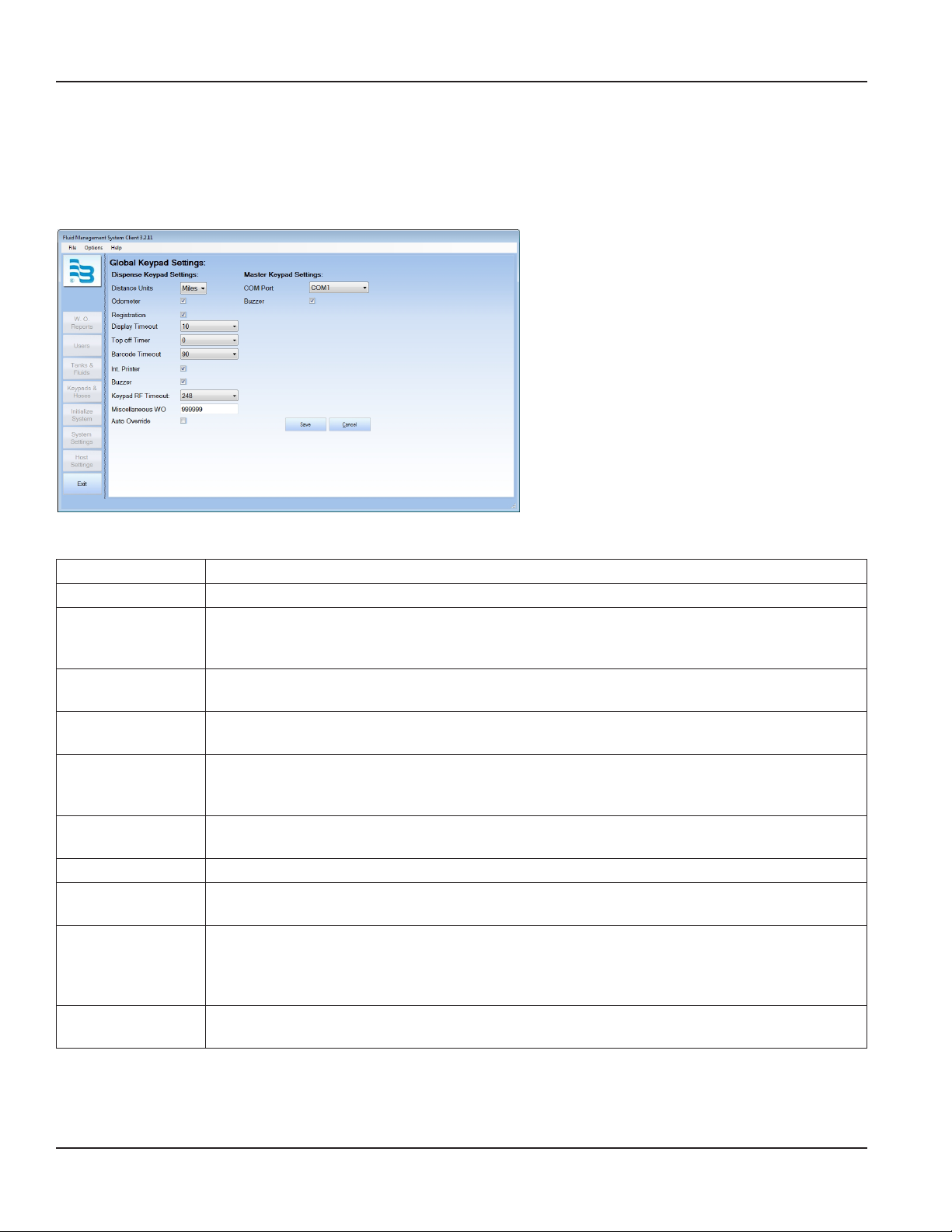

Setting Up Keypads and Hoses

Adding keypads and hoses allows you to build out your entire system and send work orders to the appropriate stations.

Global Keypad Settings

Before starting, make sure your Global Keypad Settings are configured correctly.

1. Click the SETTINGS button.

2. Change any settings according to the

“Dispense Keypad Settings” and “Master Keypad

Settings” tables below.

3. Click SAVE to save your changes or CANCEL

to discard the changes and return to the Main

screen.

Dispense Keypad Settings

Distance Units Specifies the units (miles or kilometers) of odometer readings for each WO.

Odometer To request that mileage be tracked, check the Odometer checkbox.

Registration To request that the car registration number be tracked, check the Registration checkbox. This

allows the system users to enter the car registration number in the Pending WO and save it to the

Completed WO.

Display Timeout Sets how long (in minutes) a PIN will be able to sit idle before timing out and forcing the user to log

back in.

Top off Timer Sets the time that the user is allowed to keep the meter open after the allotted amount of fluid has

been dispensed (timer is in seconds).

Barcode Timeout The amount of time in increments of 10 ms to display the entered parameter on the screen after

the barcode scanner input is entered. A value of 100 will equal 1000 ms or 1s of display time. This

timeout is only used when the barcode scanner feature is selected on the keypad.

Int. Printer If you have an optional internal printer connected to the keypad, select the checkbox next to the Int.

Printer field.

Buzzer To activate the key click buzzer, check the box next to the Buzzer field.

Keypad RF Timeout Sets how long (in minutes) a PIN will be able to sit idle before timing out and forcing the user to log

back in.

Miscellaneous WO A configurable numeric input that allows the user to define what number a miscellaneous work

order gets. This would be used in the event any fluid needs to be dispensed independent of a system

work order. The miscellaneous work order number along with the user ID number will be in the work

order report. To change, simply highlight the number, delete, and enter a new number.

Auto Override Activates System Auto Override feature in all keypads so users can dispense WOs when the Master

Keypad is not operational. No supervisor intervention is required. Available with v3.X firmware only.

Page 42 July 2014

Page 43

User Manual

Master Keypad Settings

COM Port Select the COM port on the PC for the serial connection to the Master Keypad. To change, simply

click on the drop down and select the appropriate COM port.

Buzzer To activate the key click buzzer, check the box next to the Buzzer field.

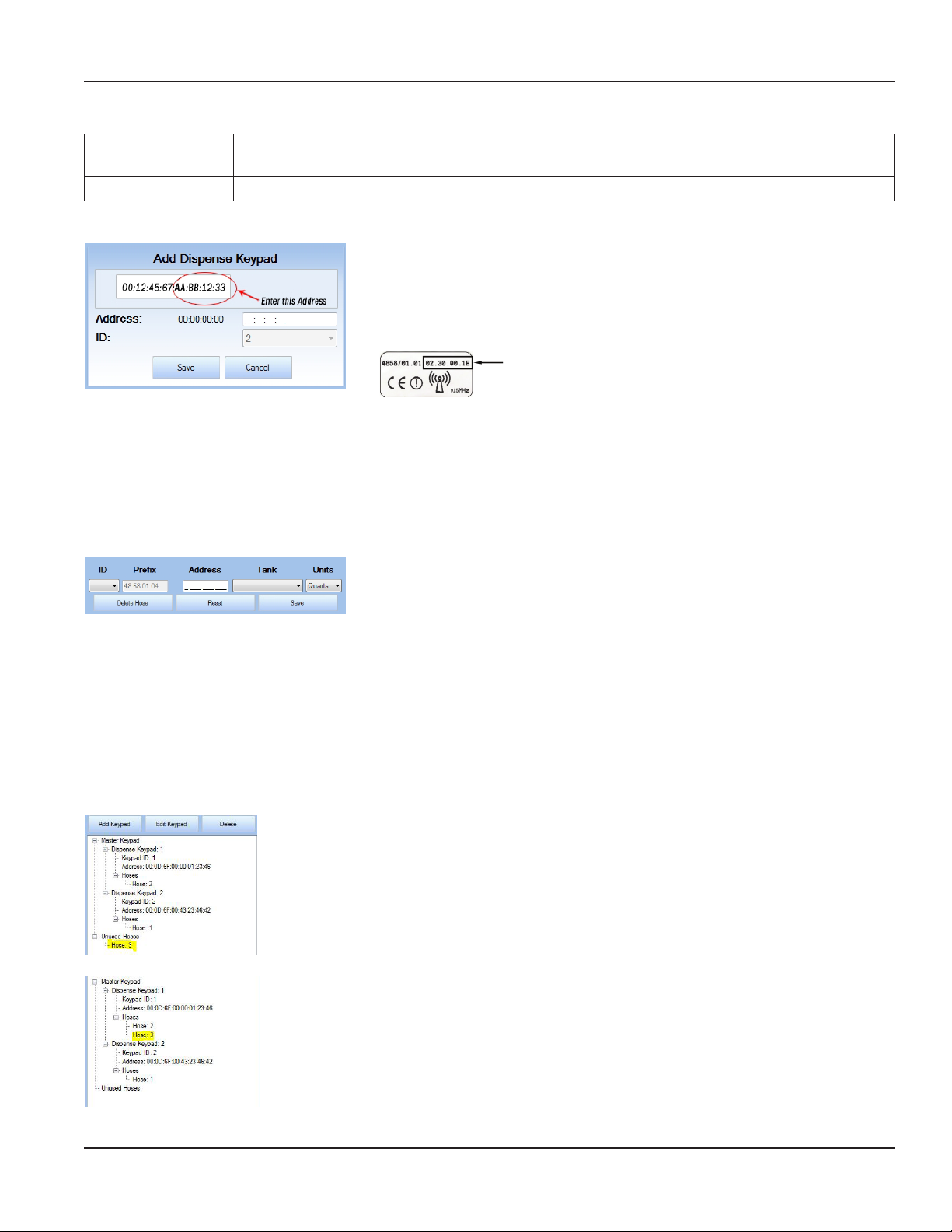

Adding a Dispense Keypad

1. From the Keypad and Hoses screen, click ADD KEYPAD.

2. Enter the Dispense Keypad address found on the back of the keypad. Use only

the last 8 characters as shown here:

Keypad address

3. The ID eld automatically displays the next available sequential number.

4. Click SAVE.

Adding Hoses

Once you have added a keypad, you can begin adding hoses associated with it. You can also enter hoses not associated with

any keypad. You can drag and drop hoses to a keypad or between keypads.

To add hoses, fill in the information at the bottom right-hand corner of the Keypad

and Hoses screen:

1. Enter the hose ID found on a tag on the meter.

2. Enter the hose Address.

3. Enter the Tank the uid will be dispensed from.

4. Enter the dispenser Units of measure of the meter.

5. Click SAVE.

After the hose is added, it will appear under the Unused Hoses section or under the selected keypad.

Associating an Unused Hose with a Keypad

To associate an unused hose with a keypad:

1. Drag and drop the hose from the Unused Hoses section to the keypad section.

OR

2. Move it manually by selecting the hose(s) from the list on the right and

assigning them to keypads using the drop-down next to the Move Hoses to:

eld.

To delete a hose, select it on the left and click the DELETE HOSE button.

Page 43 July 2014

Page 44

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

System Settings

To change system settings, select the System Settings tab on the left-hand side. A screen similar to the one below appears:

1. Change any settings according to the tables

below.

2. Click SAVE to save your changes or CANCEL

to discard the changes and return to the Main

screen.

System Settings Fields

Location Location is set as a factory default and cannot be changed by the user.

Skip Failed DK in Init The system can be configured to skip a keypad that it cannot communicate with and

continue with the initialization process. To activate this, check the box next to Skip Failed DK

in Init.

Decimal Point Select a period or comma as the decimal point.

Firmware Version Select the firmware version your master and Dispense Keypad is using. Version 1x can

support 99 meters, version 2x and version 3x for 2.4 GHz radios can support up to 250

meters.

Auto Log Off If you would like the software to automatically log off the PC user after a specified period of

time, check the box next to Auto Log Off and chose the time (in minutes) you would like the

PC user to remain idle before being logged off.

Email Completed WO Work Orders may be emailed or printed upon completion. To set this up, check the box next

Print Completed WO

to the corresponding text. There are two buttons in the Functions section.

Use the Printer Settings button to select a printer that is available on your network. Use the

Page Setup to set up paper formatting information. Enter text that you want to appear on

the printout in the work order message box. Make the appropriate changes, then click SAVE

to save your changes and exit the printer settings. The CLEAR button will reset all of the

information on the form.

Allow Users to Delete WOs To allow dispense users to delete work orders, check the box next to the

Allow Users to Delete WOs field.

Allow Users Fluid Delivery To allow dispense users to enter a fluid delivery, check the box next to the

Allow Users Fluid Delivery field.

* Auto Override Enables the Dispense Keypad to automatically enter System Override mode when

communication is lost to the Master Keypad.

* Available for v3.x firmware only.

Page 44 July 2014

Page 45

System Settings – Functions Options

Log Viewer

Use the Log Viewer to display system activity logs based on the parameters you choose.

1. From the System Settings screen,

select LOG VIEWER.

2. Check the boxes next to the options you want

to display. The options are:

• Server

• Client

• Details

• INIT

• Error

• Date Range

3. Click Submit.

4. At this point, you can click the EXPORT button

to save the le.

User Manual

Printer Settings

1. From the System Settings screen, select PRINTER SETTINGS.

2. Click SELECT PRINTER and chose a printer.

3. Click PAGE SETUP to set up paper formatting information.

4. Enter text that you want to appear on the printout into the Work Order Message

box.

5. Click SAVE to save your changes and exit the printer settings. .

Page 45 July 2014

Page 46

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Email Settings

To configure the software to send an email on the completion of a work order, enter the SMTP settings for your email server.

Contact your local system administrator for information on your email server.

1. From the System Settings screen,

select EMAIL SETTINGS.

2. Enter the SMTP Server, Port, User Name and

Password.

3. Enter the email address of the recipient.

4. Enter your email address in the From line, the

subject, and any header or footer text you

would like.

5. Enter the work order message you would like

to have in the email.

6. Click SAVE to save your settings.

System Settings – Save to File Options

The FMS Software lets you set up and save pending work orders, completed work orders, and everything in the database. To

use this option, click on the corresponding buttons under Save to File. Browse to the destination folder or file, and click OK.

It is highly recommended that you save your system configuration using the Save to File function.

Page 46 July 2014

Page 47

User Manual

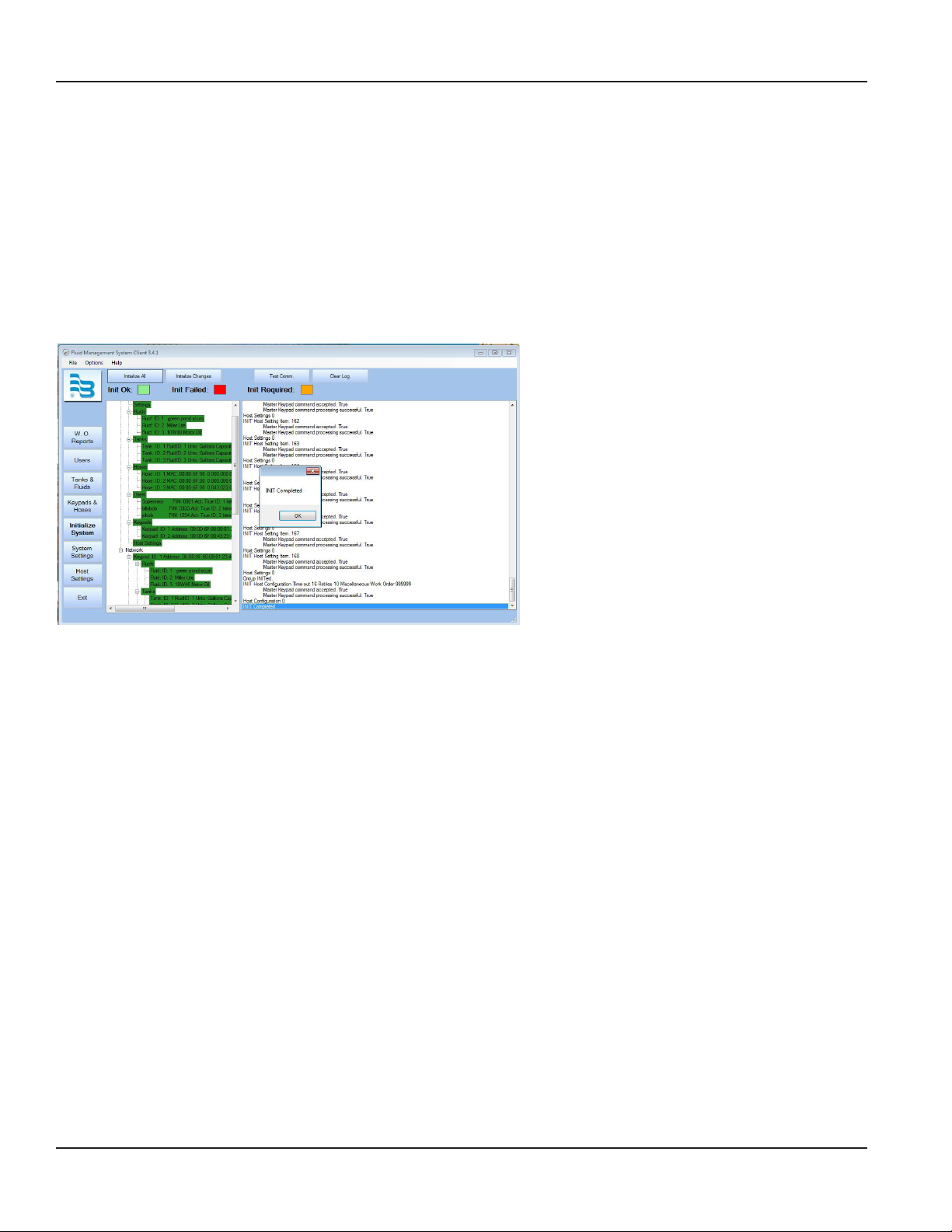

INITIALIZE SYSTEM

Test Comm Option

The Test Comm option checks that the serial

cable is connected to the Master Keypad and the

correct communication port has been selected.

1. To test the serial communication between the

Master Keypad and PC, click the

TEST COMM button.

2. Upon completion, a Test Passed screen

displays.

After the system is configured you will need to initialize the system before using. The first time you select the Initialize System

option, you will see a screen similar to the one this:

All items highlighted are color-coded to indicate

their initiation status:

• Orange indicates an initialization is required.

• Green indicates the items have

been initiated.

• Red indicates that the initialization

process failed.

Page 47 July 2014

Page 48

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

Initialize All Option

The Initialize All option initializes all parts of the system. This is the option to use for the first initialization.

Initialize Changes Option

The Initialize Changes option initializes only the changes made since the last initialization.

After clicking the appropriate button, you will be reminded that everything currently on the keypads will be erased. Click YES

to continue or NO to go back. The initialization process may take several minutes. Upon completion, a Request Completed

screen displays.

After the system is initialized, if changes are made to the system configuration it will be necessary to initialize those changes

before the system can be used. You will not be allowed to make changes to the system if there are pending work orders.

To initialize only the changes, click the INITIALIZE

CHANGES button. Any items that are highlighted

in red did not initialize properly and it will be

necessary to determine what is wrong. All custom

settings initiated by the supervisor user will

be erased.

On the right-hand side is the log of all Master

Keypad communications during an initialization

or communications test. To clear this log, click the

CLEAR LOG button.

Page 48 July 2014

Page 49

PARTS DEPARTMENT USER MENU

Creating a New Work Order

User Manual

The parts department user can enter work

orders, view work order reports, and enter a fluid

delivery, if enabled.

Upon login, the screen to the left displays:

To enter a new work order:

1. Click on the WORK ORDER option.

Work Order Reports

2. Enter a work order number in the Work Order

ID eld.

3. Enter a Quantity and type of Fluid to be

dispensed in the respective elds.

4. Click SAVE.

Optionally, a zero quantity can be entered in the

quantity and the dispense user can select the

quantity at the keypad. Work Orders are stored on

the PC until requested by a dispense user. Work

orders can be deleted by selecting them and

clicking the DELETE key.

To see if a work order has been completed by

other personnel, click on the W.O. REPORTS

option. If no work orders have been completed,

the screen to the left displays:

Page 49 July 2014

Page 50

Fluid Managment System, FMS-3 2.4 GHz RF High-End Software v3.4.1

The columns across the top show:

• the work order ID number assigned,

• date and time the fluid was dispensed,

• the quantity of fluid actually dispensed,

• the quantity that was preset on the work order,

• the user who dispensed the fluid,

• the type of fluid dispensed,

• the hose the fluid was dispensed from,

• the status of the work order, and

• whether the work order has been reviewed.

The default view shows all work orders that

have been completed on that day. If you have a

work order completed you will see it listed in the

screen to the left:

Reviewing a Work Order

To mark a work order as reviewed, check the box below Reviewed and press ENTER.

Locating a Work Order

To locate a work order, you may search by user, work order ID, hose ID, fluid type, or date range.

To search, enter your criteria in the appropriate text boxes and click NEW SEARCH. To clear the search criteria, click RESET.

Changing the Unit of Measure

At the bottom of the screen, there are total fluid numbers and records counts. This will sum the total amount of fluid that has

been dispensed for the records currently appearing on the search. You may change the unit that the fluid is summed in by

selecting the drop-down menu next to Unit and choosing from Liters, Gallons, Pints, and Quarts.

Page 50 July 2014

Page 51

Deleting Old Work Orders

Exporting Work Orders to a CSV File

User Manual

To delete old work orders:

1. Click the DELETE button.

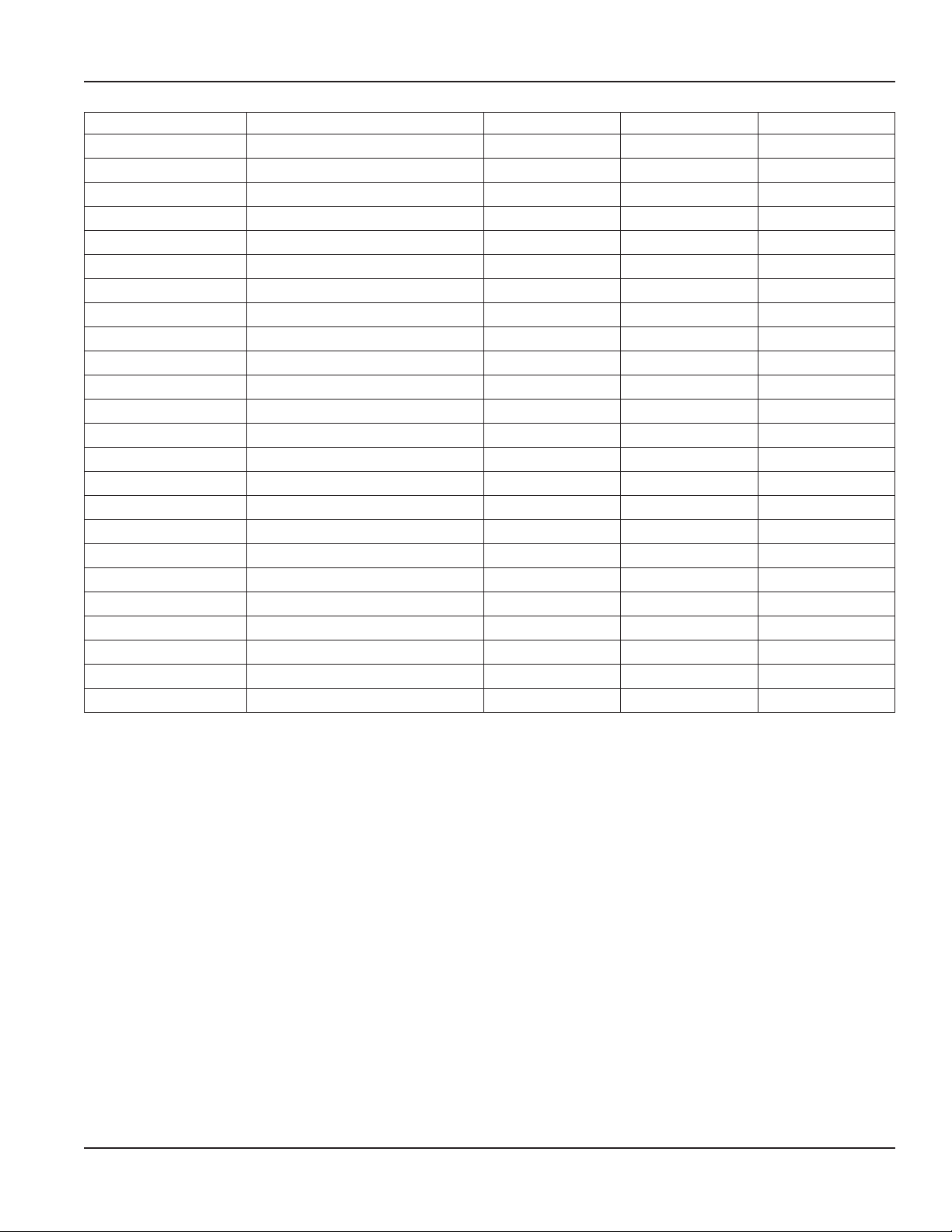

2. On the pop-up screen, select either the date