Page 1

®

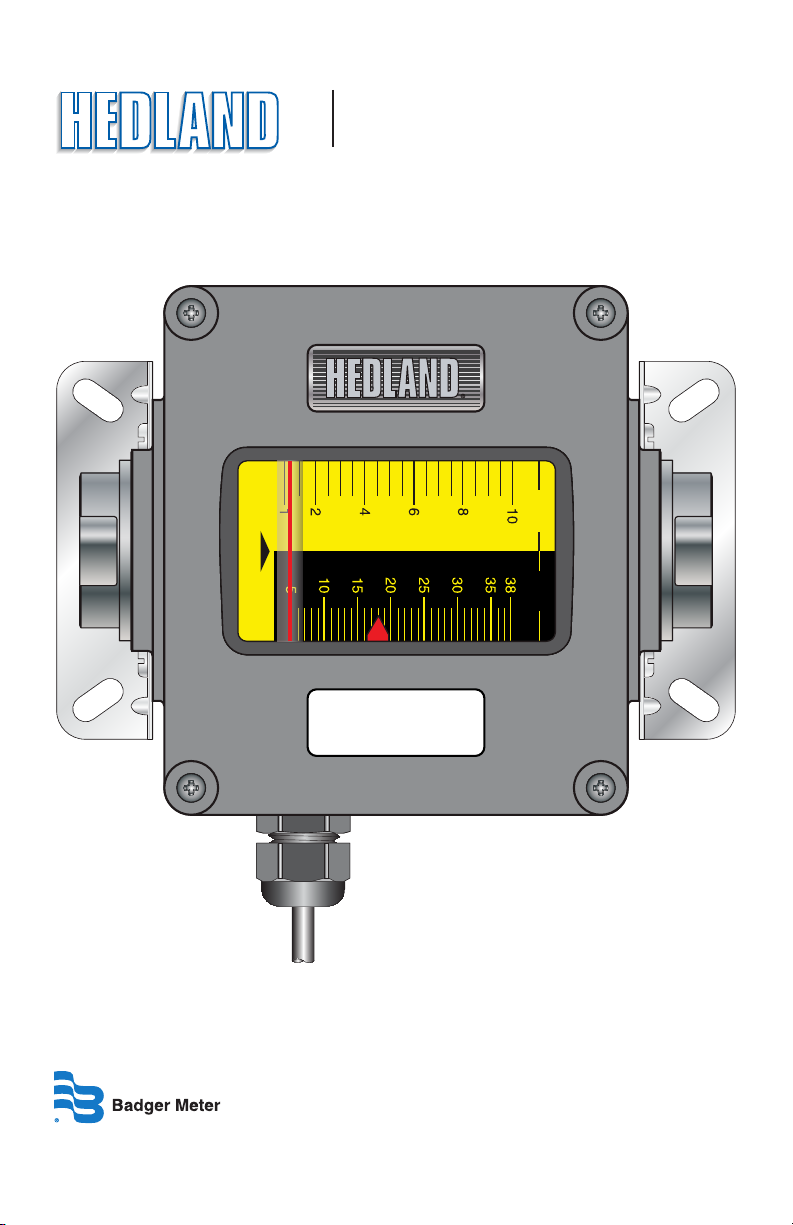

OIL

Flow-Alert

Flow Switch

GPM LPM

FORM #04-VAM-UM-00229 (September 2012)

FLOW-ALERT

FLOW SWITCH

6000 PSI / 414 BARS MAX

Installation & Operation Manual

Page 2

I INTRODUCTION

The Flow-Alert ow meter combines the rugged proven technology of a

direct reading, piston-type, variable area ow meter, coupled with electrical contacts utilized to signal at selected ow rates. This combination is

sealed against industrial contamination by a NEMA 12 and 13 (IP52/54)

rated enclosure.

This product provides a local ow indication and automatically signals the

operator or PLC if ow is too high or too low.

Uses of the Flow-Alert ow meter include: bearing lubrication, case drain

verication, gun drill cooling, pump ow conrmation, etc.

GPM LPM

OIL

FLOW-ALERT

FLOW SWITCH

6000 PSI / 414 BARS MAX

FIGURE 1 FLOWALERT FLOW METER

Page 2 Form #04-VAM-UM-00229 09/12

Page 3

II SPECIFICATIONS

Enclosure Rating

• NEMA 12 & 13

(equivalent to IP52 & 54)

Temperature Range

• -20 °F to +240 °F

(-20 °C to +116 °C)

Pressure Rating Aluminum/Brass

• Liquids (¼” to 1½”): 3500 psi

(241 bar) maximum with a 3:1

safety factor

• Gases (¼” to 1½”): 1000 psi

(69 bar) maximum with a 10:1

safety factor

Pressure Rating Stainless Steel

• Liquids (¼” to ½”): 6000 psi (414

bar) maximum with a 3:1 safety

factor

• Liquids (¾” to 1½”): 5000 psi (345

bar) maximum with a 3:1 safety

factor

• Gases (¼” to 1½”): 1500 psi (103

bar) maximum with a 10:1 safety

factor

Accuracy

• ±2% of full scale

Repeatability

• ±1%

Pressure Drop

• See Appendix for specic meter

information

Micro Switch

• Single (1) or double (2) switch,

pre-wired single-pole, doublethrow (SPDT), UL recognized and

CSA certied switch

• Type: SPDT

• Contact Rating VAC: 250 Volt,

10 Amp

• Contact Rating VDC: 125 Volt,

0.5 Amp

• Cable Single Switch: 34”, 4-wire,

#18 AWG, SO jacket

• Cable Dual Switch: 18”, 7-wire,

#16 AWG, SO jacket

Reed Switch

• Single (1) or double (2) reed

switch, pre-wired single -pole,

single-throw normally open

(SPST-NO); or single-pole,

single -throw normally closed

(SPST-NC); UL recognized and

CSA certied switch

• Type: SPST

• Contact Rating: (maximum, see

Figure 2)

Normally Open, 10 Watts;

Normally Closed, 5 Watts

• Voltage (maximum at switching):

Normally Open, 50 VDC;

Normally Closed, 50 VDC

• Current (maximum amps at

switching, resistive load):

Normally Open, 0.5 Amp;

Normally Closed, 0.5 Amps

• Initial Contact Resistance: 0.100

Ohms

• Cable: 15’ (4.6m), 4-wire, #22

AWG, PVC jacket

Form #04-VAM-UM-00229 09/12 Page 3

Page 4

Safe Operating Area for SPST (NO)

0.6

0.5

0.4

0.3

0.2

(DC Amps)

0.1

Operating Current

0.0

0 4 8 12 16 20 24 28 32 36 40 44 48

Operating Voltage

(VDC)

FIGURE 2 REED SWITCH POWER DISSIPATION

DIMENSIONS

Safe Operating Area for SPST (NC)

0.6

0.5

0.4

0.3

0.2

(DC Amps)

0.1

Operating Current

0.0

0 4 8 12 16 20 24 28 32 36 40 44 48

Operating Voltage

(VDC)

B

A

A

Nominal

Port Size

¼ (SAE 6)

½ (SAE 10)

¾ (SAE 12)

1 (SAE 16)

1¼ (SAE 20) 12.20

1½ (SAE 24) 12.20

B

LengthCLengthDLengthEWidthFWidthGWidthHWidthIDepthJOset

6.60

(168)

6.60

(168)

7.20

(183)

7.20

(183)

(310)

(310)

inches

(mm)

D

C

I

OIL

FLOW-ALERT

FLOW SWITCH

6000 PSI / 414 BARS MAX

K

FIGURE 3 CASE DIMENSIONS

5.27

(134)

5.27

(134)

5.27

(134)

5.27

(134)

10.68

(271)

10.68

(271)

6.41

(163)

6.41

(163)

7.04

(179)

7.04

(179)

11.65

(296)

11.65

(296)

6.00

(152)

6.00

(152)

6.00

(152)

6.00

(152)

7.63

(194)

7.63

(194)

3.23

(82)

3.23

(82)

3.60

(91)

3.60

(91)

4.84

(123)

4.84

(123)

GPM LPM

3.00

(76)

3.00

(76)

3.00

(76)

3.00

(76)

3.82

(97)

3.82

(97)

4.20

(107)

4.20

(107)

4.20

(107)

4.20

(107)

5.02

(128)

5.02

(128)

J

G

F

E

H

K

Hole

Dia.

2.94

(75)

2.94

(75)

2.94

(75)

2.94

(75)

4.50

(114)

4.50

(114)

1.51

(38)

1.51

(38)

1.27

(32)

1.27

(32)

2.20

(56)

2.20

(56)

.31

(8)

.31

(8)

.31

(8)

.31

(8)

.31

(8)

.31

(8)

TABLE 1 DIMENSIONAL INFORMATION

Page 4 Form #04-VAM-UM-00229 09/12

Page 5

III INSTALLATION

CAUTION

Caution - This product should be

installed and serviced by technically qualied personnel trained in

maintaining industrial class ow

instrumentation and processing

equipment.

CAUTION

Caution - Read instructions thoroughly before installing the unit. If

you have any questions regarding

product installation or maintenance, call your local supplier for

more information.

CAUTION

Caution - This meter may contain

residual amounts of test uid at the

time of shipment. This uid should

be removed prior to installation

as the uid may be incompatible

or hazardous with some liquids or

gases. Failure to follow these

WARNING

Warning - Disconnect electrical power before opening wiring

enclosure. Failure to follow these

instructions could result in serious

personal injury or death and/or

damage to the equipment.

WARNING

Warning - All wiring should be

installed in accordance with the

National Electrical Code® and must

conform to any applicable state and

local codes. Failure to follow these

instructions could result in serious

personal injury or death and/or

damage to the equipment.

CAUTION

Caution - Air/gas meters are NOT

oxygen cleaned. Use with oxygen

may cause hazardous or explosive

conditions that may cause serious

personal injury and/or damage to

the equipment.

CAUTION

Caution - This standard meter is

unidirectional. Attempts to ow uids in the opposite direction of the

ow arrow will result in the meter

acting as a check valve, creating a

deadheading situation. If the dierential pressure magnitude is great

enough, damage to the internal

parts of the meter will result.

Form #04-VAM-UM-00229 09/12 Page 5

Page 6

INSTALLATION RECOMMENDATIONS

The in-line ow meter is a simple device to install. However, the following

measures are recommended for reliable, trouble-free operation:

Do - Align pipe accurately. Piping

should be accurately aligned and

of correct length. The high pressure

body of the ow meter can withstand shock and ow/pressure pulsation. However, the piping should

be rmly supported by external

mounting brackets, both upstream

and downstream of the meter, to

avoid any pipe exing actions that

could reduce meter life.

Do - Use rigid mounting. If the ow

meter inlet or outlet are to be rigidly mounted, and the opposing port

is to be connected to exible hose,

the end connected with the exible

hose must be rigidly mounted.

Do - Use Teon® tape for sealing

NPT tting.

Do - Install unions. Install a union

near the inlet or outlet of the meter.

This will facilitate quick, easy meter

removal and inspection during periodic maintenance procedures.

Do - Mount the meter either

horizontally or vertically (ow arrow

pointing to either side or straight

up). If the meter must be mounted

inverted, special inverted scales are

available from the factory.

Do - Use at least a 200 mesh (74

micron) lter. The meter will allow particulate to pass that would

jam most valves and ow controls.

Systems that do not have ltration

should be equipped with at least

a 200 mesh (74 micron) lter. Most

hydraulic systems already have

much ner ltration.

Dirt, ferrous metal or sealing agents,

such as Teon® tape may lodge and

cause malfunction. If the meter is

jammed at a xed position, follow

cleaning and maintenance instructions.

Don’t - Use thread locking compounds as thread sealant.

Don’t - Install the ow meter near

turbulence producing ttings such

as elbows, reducers, close coupled

valves, etc. The in-line ow meter

does not require ow straighteners

or special lengths of straight inlet/

outlet piping to stabilize turbulent

ow patterns. However, to assure

maximum operational reliability,

avoid installation of elbows, valves

and/or reducers immediately adjacent to the meter inlet.

Do - Ensure the uid is traveling

in the direction of the ow arrow

(Figure 4 on page 8).

Page 6 Form #04-VAM-UM-00229 09/12

Page 7

Don’t - Install the meter near fastacting valves. Fast-acting valves

have the potential to create high

magnitude hydraulic pressure

spikes. These spikes can damage

the internal components of the

meter, resulting in inaccuracies or

malfunction.

3. See Figure 6. After installation,

rotate meter by hand to view

ow scale.

ELECTRICAL CONNECTIONS

Micro Switch

Equipped Models

Don’t - Allow unidirectional meters

to be operated against the direction of the ow arrow. The standard

ow meter is an unidirectional ow

meter. The piston acts as a check

valve to block ow in the reverse

direction. This causes an excessive

pressure dierential, which can

All meters (size ¼” to 1½”) are offered in single (1) switch or double

(2) switch models. The single switch

model is equipped with a 34” length

of 4-wire #18 AWG type SO jacketed

cable. The double switch model is

equipped with a 18” length of 7-wire

#16 AWG type SO jacketed cable.

result in damage to internal meter

components. The ow meter is

also available in a modied design,

which oers a reverse ow by-pass

feature to accommodate bi-directional ow.

NOTE: In-line meters with a reverse

ow by-pass feature are available. Consult factory for details.

INSTALLING THE FLOWALERT

1. See Figure 4. Mount the meter

so uid is traveling in the

direction of the ow arrow.

2. See Figure 5. Select a mounting

location that is suitable for

viewing and product service. To

connect the ow meter into the

piping system, place an open-

One Switch 4-Wire Cable

Red Normally Closed (NC)

Black Normally Open (NO)

White Common

Green Ground

Two Switch 7-Wire Cable

Switch 1

Red Normally Closed (NC)

Black Normally Open (NO)

White Common

Switch 2

Orange Normally Closed (NC)

Blue Normally Open (NO)

White/Black Common

Green Ground

TABLE 2 MICRO SWITCH

WIRE DESIGNATIONS

ended wrench onto the ow

meter wrench ats adjacent

to the pipe connection being

installed. DO NOT wrench on

the opposite end of the ow

meter or leakage may result.

Form #04-VAM-UM-00229 09/12 Page 7

Page 8

Flow Direction Arrows

OIL

FIGURE 4 FLOW DIRECTION ARROWS

GPM LPM

OIL

Flow-Al er t

Flow Sw it ch

3500 PSI/241 BARS MAX

GPM LPM

GPM LPM

OIL

Flow-A le rt

Flow S wi tc h

3500 PSI/24 1 BA RS MA X

Place wrench on transmitter ats on the same

side plumbing is being tightened

Place wrench on transmitter ats on the

same side plumbing is being tightened

GPM LPM

OIL

Flow-Al er t

Flow Sw it ch

3500 PSI/241 BARS MAX

GPM LPM

OIL

Flow-A le rt

Flow S wi tc h

3500 PSI/24 1 BA RS MA X

FIGURE 5 INSTALLING THE METER

Never place wrench on transmitter ats

opposite plumbing being tightened

FIGURE 6 ROTATING THE METER

Page 8 Form #04-VAM-UM-00229 09/12

Page 9

A 4-pin Brad Harrison® quickdisconnect plug is available upon

special order.

4-Pin Connector used with

SPDT Micro Switch

Red Normally Closed (NC)

Black Normally Open (NO)

White Common

Green Ground

TABLE 3 4PIN CONNECTOR

MICRO SWITCH

WIRE DESIGNATIONS

NOTE: If the factory supplied cable

is removed for hard wiring the meter,

switches must be connected with

0.187” × 0.020” insulated ag termi-

nals designed for the appropriate wire

gauge for the application.

REED SWITCH MODELS

Safe operation of the reed switch is

dependent on not exceeding the

maximum wattage for that switch.

For example the normally open

reed switch has a maximum power

rating of 10 Watts. If the switch is

to operate at 24 VDC the maximum

current is found by dividing the

wattage by the voltage.

All meters (size ¼” to 1½”) are

oered in single (1) switch or

double (2) switch models and come

equipped with a 4-pin Hirschmann

connector. All units are quipped

with a 15’ length of 4-wire #22 AWG

type PVC jacketed cable.

4-Pin Connector used with

SPST Reed Switch

Red Switch 1 Contact

Black Switch 1 Contact

White Optional Switch 2 Contact

Green Optional Switch 2 Contact

TABLE 4 4PIN CONNECTOR

REED SWITCH

WIRE DESIGNATIONS

ALL MODELS

The strain relief connection on the

outside of the enclosure is watertight. Be sure to consult local wiring

codes before applying power. Some

installations will require rigid conduit. By removing the black strain

relief connections from the outside

of the enclosure, a conduit connection is accessible.

W

I =

Form #04-VAM-UM-00229 09/12 Page 9

10

=

E

= 0.417A

24

Page 10

Wiring Congurations

IV OPERATION

WHITE

Power Line

Load

Load will turn ON when ow exceeds setpoint.

Load

Power Line

Load will turn OFF when ow exceeds setpoint.

BLACK

RED

Flow-Alert

WHITE

Flow-Alert

Power Line

Power Line

FIGURE 7 WIRING CONFIGURATION

FOR LOADS WITHIN

FLOWALERT CONTACT RATINGS

Relay

Coil

R

1

Power Line

Load will turn OFF when ow exceeds setpoint.

Power Line

Load will turn ON when ow exceeds setpoint.

Load

Relay

Coil

Load

R

1

BLACK

BLACK

Flow-Alert

R1

Flow-Alert

R1

WHITE

WHITE

Power Line

Power Line

FIGURE 8 WIRING

CONFIGURATION FOR LOADS THAT

EXCEED FLOWALERT

CONTACT RATINGS

NOTE: Refer to the Appendix for appli-

cation information and uid charts.

MICRO SWITCH ADJUSTMENT

1. Remove cover screws and

front cover.

NOTE: On meters equipped with dual

micro switches, the right-side is the

decreasing ow switch; the left-side is

the increasing ow switch.

2. Loosen the screws securing

the switching roller and

latching rollers to the guide

bar. Turn each screw one full

turn maximum.

3. All rollers are secured as a set

to the spacer strip. Slide the

entire roller set until pointer is

at the desired setting.

NOTE: The spacer strip controls the

maximum distance between rollers.

This distance may be shortened when

the switching setting is close to the end

of the ow scale. Latching rollers may

also be removed if the switching setting is close to the end of the ow scale.

4. Make sure roller brackets are

ush against the guide bar.

Tighten roller screws.

5. For dual switch models,

repeat steps 1-4 for left-side

switch setting.

Page 10 Form #04-VAM-UM-00229 09/12

Page 11

6. Install the cover gasket and

front cover and secure with

screws. To properly seat the

cover gasket, tighten cover

screws in a crisscross pattern

as show in Figure 10.

Latching Roller

Spacer Strip

Switching Roller

Latching Roller

Pointer

Guide Bar

FIGURE 9 SNAP SWITCH

LPM

ADJUSTMENT

4

2

Reed Switch Adjustment for ¼”

Models

1. Loosen the screw securing

the switch assembly (Figure

11).

2. Slide the switch assembly

until the arrow pointers on

the switch band are aligned

with the desired ow rate

indicated on the scale.

3. Tighten the screw.

Reed Switch Adjustment for ¼” to

1½” Models

1. Remove cover screws and front

cover.

2. Loosen the screw securing the

switch assembly (Figure 12).

NOTE: On meters equipped with dual

switches, the right-side is the decreasing ow switch; the left-side is the

increasing ow switch.

GPM LPM

OIL

3. Slide the switch assembly until

the arrow pointer aligns with

the desired ow rate indicated

on the scale.

1

FLOW-ALERT

FLOW SWITCH

6000 PSI / 414 BARS MAX

3

4. Tighten the screw.

5. For dual switch models, repeat

steps 1-4 for left-side setting.

FIGURE 10 COVER SCREW

TIGHTENING SEQUENCE

6. Install the front cover and gasket. To properly seat the cover

gasket, tighten cover screws in

a crisscross pattern as shown in

Figure 10.

Form #04-VAM-UM-00229 09/12 Page 11

Page 12

Arrow Pointers

on Switch Band

GPM LPM

OIL

Screw

V. MAINTENANCE

WARNING

Warning - Disconnect electrical power before removing meter cover. Failure to follow these

instructions could result in serious

personal injury or death and/or

damage to the equipment.

SWITCH REPLACEMENT

Micro Switch (Figure 13)

FIGURE 11 REED SWITCH

ADJUSTMENT ¼” MODELS

GPM LPM

OIL

FIGURE 12 REED SWITCH

ADJUSTMENT FOR

¼” 1½” MODELS

DUAL SWITCH SHOWN

Arrow

Pointer

Screw

1. Disconnect cable connection

to the meter.

2. Remove screws securing cover

and remove cover.

3. Note the positions of the

colored wire connections on

the switch. Disconnect the

wires from the switch.

4. Remove the two mounting

bracket screws at the bottom

of the meter.

5. Remove mounting

bracket/switch assembly

from the meter. Remove the

two screws securing switch to

mounting bracket.

6. Install new switch to mounting

bracket using screws removed

in step 5.

7. Install wires to terminals on

switch as marked in step 3.

8. Install mounting bracket/

switch assembly to meter

using screws removed in step

4.

9. Install the front cover and

Page 12 Form #04-VAM-UM-00229 09/12

Page 13

gasket. To properly seat the

cover gasket, tighten cover

screws in a crisscross pattern

as shown in Figure 10 on page

10.

Reed Switch (Figure 14)

13. Install mounting brackets to

scale using scale mounting

screws. Do not fully tighten

yet.

14. Secure mounting brackets

using screws removed in step

4.

1. Disconnect the Hirschmann

connector and remove

connector from wires.

2. Remove screws securing cover

and remove cover.

3. Remove the two scale

mounting screws.

4. Remove the screws securing

the two mounting brackets

and remove the brackets.

5. Loosen the two slide bracket

screws.

6. Remove the switch mounting

screw and remove mounting

block/switch assembly from

slide bracket.

7. Remove the two mounting

screws securing switch to

mounting block and pointer.

Make note of switch position.

15. Tighten screws installed in

step 10.

16. Solder Hirschmann connector

to new switch wires.

NOTE: For ¼”, ½”, ¾” and 1” units, wire

should be cut to 5” length. For 1¼” and

1½” units, wire should be cut to 10”

length.

17. Install the front cover and

gasket. To properly seat the

cover gasket, tighten cover

screws in a crisscross pattern

as shown in Figure 10.

LPM

Mounting Bracket

Screws (Qty 2)

8. Install new switch to mounting

block and pointer using screws

Snap Switch

Screws (Qty 2)

removed in step 7.

9. Remove the strain relief.

10. Install mounting block/switch

assembly to slide bracket using

screw removed in step 6.

11. Tighten the slide bracket

screws.

12. Install strain relief.

Form #04-VAM-UM-00229 09/12 Page 13

FIGURE 13 MICRO SWITCH

REPLACEMENT

Page 14

Mounting

Mounting

Bracket

Reed

Switch

Scale

Mounting

Screw

GPM LPM

OIL

Bracket

Screws

Side

Bracket

Strain

Relief

Switch

Mounting

Screw

FIGURE 14 REED SWITCH

REPLACEMENT

Cartridge Cleaning (Figure 15)

1. Disconnect the meter cable.

2. Remove the meter from the

line. Remove excess piping

from meter.

WARNING

Warning - Before attempting to

remove the meter from the line,

check the system to conrm that

line pressure has been reduced

to zero PSI. Failure to follow these

instructions could result in serious

personal injury or death and/or

damage to the equipment.

NOTE: It is not necessary to remove the

aluminum housing from the meter to

remove it from the line.

3. Thoroughly wipe o the

entire meter surface using

mild detergent or isopropyl

alcohol.

CAUTION

Caution - Do not use aromatic

hydrocarbons, halogenated hydrocarbons, ketones or ester based

uids on polycarbonate lens. Failure

to follow these instructions could

result in damage to the meter.

4. Remove the inlet end

tting, retaining spring, and

metering cone/spider plate

assembly from the cartridge.

5. Gently push the cartridge

assembly towards the outlet

port while holding magnetic

indicator assembly in place.

6. The cartridge internal parts

are secured with a retaining

ring. Remove the retaining

ring and the remaining

internal parts from the

cartridge.

NOTE: If internal parts do not slide

freely from cartridge, use a wooden

dowel inserted into the outlet port of

the meter to push parts out.

7. Place all parts on a clean work

surface. Clean and inspect all

parts. Replace any that appear

worn or damaged.

8. Check inlet port O-ring

for damage and replace if

required.

Page 14 Form #04-VAM-UM-00229 09/12

Page 15

9. Reassemble spring, then

piston/magnet assembly and

retaining ring into cartridge.

10. Gently push cartridge

assembly into housing while

holding the magnetic ow

indicator in position.

11. Install metering cone/spider

plate assembly, retaining

spring, and secure with inlet

tting.

12. Reinstall meter to the line.

Reconnect electrical power.

[1] - BODY

[2] - CAP

[3] - CONE ASSEMBLY

[1]

[7]

[9]

[3]

[5]

[6]

[4]

[8]

[2]

LPM

FIGURE 15 CARTRIDGE

COMPONENTS

[4] - PISTON

[5] - INNER MAGNET

[6] - INDICATOR MAGNET

[7] - RETAINIGN RING

[8] - WAVE SPRING

[9] - METER SPRING

Quick Re-Coupling

This piston-type variable area ow

meter is inherently less sensitive

to shock and vibration than other

variable area designs. The unique

magnetic coupling also eliminates

the need for mechanical linkages

that can wear or loosen over the

functional life of the meter.

However, on occasion, a pressure

spike or extreme ow surge can

cause the piston to move at such

rapid speed that it disconnects the

piston magnet and the external

indicator ring. If this occurs, use one

of these procedures to re-couple

the magnet and the external indicator ring:

• If the system permits, simply

change ow rate from “no

ow” to “full ow” allowing

the moving piston to

magnetically re-couple to the

indicator ring.

• Remove cover and manually

re-attach external ow

indicator to internal magnet/

piston assembly.

• For rigorous cyclical

applications where decoupling may occur

frequently, consult the

technical services sta for

further recommendations.

Form #04-VAM-UM-00229 09/12 Page 15

Page 16

VI APPENDIX

APPLICATION

INFORMATION PNEUMATIC

APPLICATION

INFORMATION LIQUID

Viscosity Eect (SUS/cSt)

The design utilizes a precision

machined, sharp-edged orice and

biasing calibration spring that assures operating stability and accuracy over the wide viscosity range

common to many uids. Generally,

high ow models of each meter

size provide good accuracy over a

viscosity range of 40 to 500 SUS (4.2

to 109 cSt).

Density Eect

(specic gravity)

Any uid density change from

stated standards has a proportional

eect on meter accuracy. Special

scales can be supplied if actual specic gravity decreases accuracy beyond application limits. Corrections

for more or less dense uids can be

made to standard scales using the

following correction factor:

10.

Specic Gravity

for water/water-based meters

0 876.

Specic Gravity

NOTE: Pressure and temperature readings must be taken at the ow meter

inlet to ensure accurate correction

factors.

The pneumatic ow meter is oered

with a standard graduated dual

scale, calibrated for air in standard

cubic feet per minute (scfm) at 1.0

s.g. (70 °F @ 100 psi), and liter per

second (lps) at 1.0 s.g. (21 °C @ 6.9

bar).

PRESSURE

PRESSURE

SOURCE

GAUGE TEMP

FLOW

METER

AIR BLEED OFF

TO EQUIPMENT

ADJUSTABLE

VALVE

Conversion Chart

The Conversion Chart provides a

series of simplied mathematical

formulas to “correct” the graduated

scale for changes in pressure

(Table 1), temperature (Table 2),

and/or specic gravity (Table 3).

Special scales can be made to accommodate other pressures, temperatures and specic gravity.

The conversion chart can also be

used to “correct” (adjust) the Multipressure Flow Scale to indicate ow

rates in applications beyond the

parameters stated on the scale.

for petroleum-based meters

Page 16 Form #04-VAM-UM-00229 09/12

Page 17

To adjust Pressures beyond

(above or below) scale limits:

Step 1. Locate point at which the

brightly colored indicator line intersects the vertical 100 PSIG pressure

line.

Step 2. Divide this reading by the

Pressure Correction Factor (f1) indicated in the Conversion Chart.

To adjust for changes

in Temperature :

Step 1. Divide the 100 PSIG ow

rate reading by the Temperature

Correction Factor (f2).

To adjust for changes

in Specic Gravity:

Step 1. Establish the square root of

the new specic gravity.

Step 2. Divide the 100 PSIG ow

rate reading by the Specic Gravity

Correction Factor (f3).

Form #04-VAM-UM-00229 09/12 Page 17

Page 18

DETERMINE FLOW RATES USING DIFFERENT PRESSURES & TEMPERATURES

()

13

scfm actual

()

scfm indicated

=

fxfxf

2

Where f1 = Conversion Factor for Inlet Pressure

f2 = Conversion Factor for Inlet Pressure

f3 = Conversion Factor for Inlet Pressure

Table 1 - Pressure Correction Factor (f1) Operating Pressure

psig 25 50 75 100 125 150 175 200 225 250

BAR 1.7 3.5 5.2 6.9 8.6 10.4 12.1 13.8 15.5 17.2

kPa 172 345 517 689 862 1034 1207 1379 1551 1724

f

1.700 1.331 1.131 1.00 .902 .835 .778 .731 .692 .658

1

790 857

7 914

f

114 7

1

14 7=+..

psig

f

1

.

1 014=+

.

BAR

f

1

.

101 357=+

.

kPa

Table 2 - Temperature Correction Factor (f2)

ºF +10 +30 +50 +70 +90 +110 +130 +150 +170 +190

°C -12.2 -1.1 +9.9 +21.0 +32.1 +43 +54 +65 +76 +88

F

.942 .962 .981 1.00 1.018 1.037 1.055 1.072 1.090 1.107

2

C

273

F

460

f

2

+°

=

530

f

2

+°

=

293

Table 3 - Specic Gravity Correction Factor (f3)

fSpGr3 = ..

FIGURE 16 CONVERSION CHART

Page 18 Form #04-VAM-UM-00229 09/12

Page 19

LIQUIDS

Correction

Fluid

Acetic Acid (Air Free) 1.06 0.909 0.971 C N R R R R C N R

Acetone 0.79 1.053 1.125 R R R R N R N R R

Alcohol Butyl (Butanol) 0.83 1.027 1.098 C C R R C R R R R

Alcohol Ethyl (Ethanol) 0.83 1.027 1.098 C C R R C R R N R

Ammonia 0.89 0.992 1.060 R C R R N R N C R

Benzine 0.69 1.127 1.204 C R R C R N N R R

Carbon Disulphide 1.26 0.834 0.891 R N R R R N N R R

Castor Oil 0.97 0.950 1.015 C R R C R N C C R

Cotton Seed Oil 0.93 0.970 1.037 C R R R R N R R R

Ethylene Glycol 50/50 1.12 0.884 0.945 R R R R R R R C R

Freon II 1.46 0.774 0.828 R R R R R N R R R

Gasoline 0.70 1.119 1.195 R R R R R N C R R

Glycerin 1.26 0.834 0.891 R R R R R R R C R

Kerosene 0.82 1.033 1.104 R R R R R N R R R

Liquid Propane (LPG) 0.51 1.310 1.400 R R R R R N N R R

Mineral Oil 0.92 0.976 1.042 R N R R R N R R R

Naphtha 0.76 1.074 1.147 R N R R R N C R R

Perchloroethylene 1.62 0.735 0.786 C N R R R N N N R

Petroleum Oil 0.876 1.000 1.068 R R R R R N R R R

Phosphate Ester 1.18 0.862 0.921 R R R R N R N R R

Phosphate Ester Base 1.26 0.833 0.891 R R R R N R N R R

Phosphoric Acid (AIr Free) 1.78 0.701 0.749 N N R N R N R N R

Sea Water 1.03 0.922 0.985 N N C C N R R R R

Synthetic Petroleum Base 1.00 0.936 1.000 R C R R R N R R R

Water 1.00 0.936 1.000 N R R R N R R R R

Water Glycol 50/50 1.07 0.905 0.967 R R R R R N R R R

Water-in-oil 0.93 0.970 1.037 R R R R N R R R R

R - Recommended N - Not Recommended C - Consult Factory

Specic

Gravity

Factor

Oil Wat er

Brass

Aluminum

T316 SST

T303 SST

Viton®

EPR

Nylon

Polycarbonate

Pyrex®

FIGURE 17 FLUID SELECTION CHART LIQUIDS

Form #04-VAM-UM-00229 09/12 Page 19

Page 20

GASES

Fluid

Air 1.0 1.000 R R R R R R R R R

Argon (A) 1.38 1.175 R R R R R R R R R

Carbon Dioxide (CO2) 1.53 1.237 R R R R R R R R R

Freon 11 (CCI3F) 4.92 2.218 R R R R R R R R R

Freon 12 (CCI2F) 4.26 2.060 R R R R R R R R R

Helium (HE) 0.14 0.374 R R R R R R R R R

Hydrogen (H2) 0.07 0.265 R R R R R R R R R

Natural Gas 0.60 0.775

Specic

Gravity

Correc-

tion

Factor

Brass

Aluminum

T316 SST

T303 SST

Viton®

EPR

Nylon

Polycarbonate

C C R C R N C R R

Nitrogen (N2) 0.97 0.985 C C R R R R C R R

Oxygen (02) 1.10 1.049 R R R R R R R R R

Propane (C3H8) 1.57 1.253 R R R R R N N R R

R - Recommended N - Not Recommended C - Consult Factory

FIGURE 18 FLUID SELECTION CHART GASES

Pyrex®

Page 20 Form #04-VAM-UM-00229 09/12

Page 21

FLOW VS. PRESSURE DROP

1/2" Reverse Flow

0.2-2.0

PRESSURE DROP, PSI

0.1-1.0

PRESSURE DROP, PSI

PRESSURE DROP, PSI

0.5-5.0

FLOW, GPM

1/4"

.02-.20

3/4"/ 1"

1-10

.05-.50

.10-1.0

FLOW, GPM

2-20

FLOW, GPM

1-15

4-40

3-30

10

5

0.2-2.0

0

0 10

PRESSURE DROP, PSI

0.2-2.0

.20-2.0

5-50

1-10

0.5-5.0

3/4"/1" Reverse Flow

2-20

1-10

0.5-5.0

FLOW, GPM

PRESSURE DROP, PSI

PRESSURE DROP, PSI

3-30

1/2"

0.2-2.0

0.1-1.0

1-1/4"/1-1/2"

3-30

4-40

1-10

0.5-5.0

FLOW, GPM

10-100

10-75

5-50

FLOW, GPM

1-1/4"/1-1/2" Reverse Flow

PRESSURE DROP, PSI

3-30

1-15

10-150

10-150

10-100

10-75

5-50

FLOW, GPM

PETROLEUM FLUIDS

Form #04-VAM-UM-00229 09/12 Page 21

Page 22

1/4"

FLOW, GPM

PRESSURE DROP, PSI

FLOW, GPM

FLOW, GPM

0.10-1.0

0.20-2.0

1/2"

1-15

1/2" Reverse Flow

0.2-2.0

0.5-5.0

0.1-1.0

1/4"

.02-.20

6

.05-.50

4

FLOW, GPM

2-20

FLOW, GPM

2

0

3-30

0.50.0

4-40

6

4

2

0

0 1 2 3 54

3/4"/1" Reverse Flow

PRESSURE DROP, PSI

0.2-2.0

0.5-5.0

0.5-5.0

PRESSURE DROP, PSI

5-50

0.2-2.0

1-10

1-1/4" / 1-1/2"

PRESSURE DROP, PSI

3-30

4-40

3-30

2-20

PRESSURE DROP, PSI

3/4"/ 1"

PRESSURE DROP, PSI

1-10

1-15

1-10

0.5-5.0

5-50

FLOW, GPM

10-75

FLOW, GPM

10-100

1-10

PRESSURE DROP, PSI

4

0.1-1.0

2

0

0 1 2 2.5

0.2-2.0

10-150

1-1/4"/1-1/2" Reverse Flow

10-75

5-50

3-30

10-150

10-100

PHOSPHATE ESTER

.10-1.0

.20-2.0

1/2"

1-10

1-15

0.5-5.0

0.2-2.0

PRESSURE DROP, PSI

PRESSURE DROP, PSI

3/4" / 1"

FLOW, GPM

4-40

3-30

2-20

FLOW, GPM

PRESSURE DROP, PSI

FLOW, GPM

1-1/4"/ 1-1/2"

10-75

5-50

3-30

PRESSURE DROP, PSI

FLOW, GPM

A.P.I. OIL

Page 22 Form #04-VAM-UM-00229 09/12

10-100

Page 23

PRESSURE DROP, PSI

1/4"

.10 -1.0

0.2-2.0

.05-.50

.20-2.0

PRESSURE DROP, PSI

1/2"

0.5-5.0

1-15

1-10

0.1-1.0

0.2-2.0

PRESSURE DROP, PSI

3/4" / 1"

5-50

4-40

3-30

2-20

0.5-5.0

0.2-2.0

1-10

PRESSURE DROP, PSI

0.2-2.0

FLOW, GPM

1/2" Reverse Flow

0.5-5.0

0.1-1.0

FLOW, GPM

PRESSURE DROP, PSI

1-10

1-1/4"/ 1-1/2"

5-50

3-30

FLOW, GPM

10-150

10-100

10-75

FLOW, GPM

1-15

3/4"/1" Reverse Flow

PRESSURE DROP, PSI

0.5-5.0

0.2-2.0

2-20

1-10

FLOW, GPM

WATERBASED FLUIDS

PRESSURE DROP, PSI

FLOW, GPM

3"

20-180

20-275

FLOW, GPM

4-40

3-30

1-1/4"/1-1/2" Reverse Flow

PRESSURE DROP, PSI

5-50

3-30

10-100

10-75

10-150

FLOW, GPM

Form #04-VAM-UM-00229 09/12 Page 23

Page 24

1/4"

.10 -1.0

.20-2.0

1/2"

1-15

1-10

PRESSURE DROP, PSI

PRESSURE DROP, PSI

3/4" / 1"

1/4"

FLOW, GPM

3-30

2-20

FLOW, GPM

.10 -1.0

0.2-2.0

4-40

0.5-5.0

.20-2.0

.05-.50

0.2-2.0

5-50

1-10

WATER

PRESSURE DROP, PSI

PRESSURE DROP, PSI

0.5-5.0

1-1/4"/ 1-1/2"

5-50

3-30

1/2"

0.5-5.0

0.1-1.0

0.2-2.0

FLOW, GPM

10-150

10-100

10-75

FLOW, GPM

1-15

1-10

0.2-2.0

PRESSURE DROP, PSI

FLOW, GPM

PRESSURE DROP, PSI

FLOW, GPM

1-1/4"/ 1-1/2"

3/4" / 1"

PRESSURE DROP, PSI

3-30

2-20

FLOW, GPM

4-40

0.5-5.0

0.1-2.0

1-10

PRESSURE DROP, PSI

3-30

10-100

10-75

5-50

FLOW, GPM

CAUSTIC AND CORROSIVE LIQUIDS

Page 24 Form #04-VAM-UM-00229 09/12

Page 25

25

1/4"

20

15

1-10

2-20

10

5

PRESSURE DROP, PSI

0.5-5

0

0 105 15 20 25 30

FLOW, SCFM

3-30

20

1/2"

15

10

5-50

3-25

10-100

5

PRESSURE DROP, PSI

0

0 5025 75 100 125 150

FLOW, SCFM

15-150

20

3/4" / 1"

15

10

3-25

5

10-100

15-150

5-50

PRESSURE DROP, PSI

0

0 10050 150 200 250

FLOW, SCFM

AIR / COMPRESSED GASES

25

1/4"

20

15

10

5

PRESSURE DROP, PSI

0

0 105 15 20 25 30

FLOW, SCFM

20

3/4" / 1"

15

10

3-25

5

10-100

5-50

PRESSURE DROP, PSI

0

0 10050 150 200 250

FLOW, SCFM

2-20

15-150

25-250

3-30

25-250

30

25

1-1/4"/ 1-1/2"

100-1000

20

15

10

5

PRESSURE DROP, PSI

0

0 400200 600 800 1000

40-400

20-200

80-800

60-600

FLOW, SCFM

20

1/2"

15

10

5-50

3-25

10-100

5

PRESSURE DROP, PSI

0

0 5025 75 100 125 150

FLOW, SCFM

30

1-1/4"/ 1-1/2"

25

100-1000

20

15

10

5

PRESSURE DROP, PSI

0

0 400200 600 800 1000

40-400

20-200

80-800

60-600

FLOW, SCFM

15-150

AIR / CAUSTIC AND CORROSIVE GASES

Form #04-VAM-UM-00229 09/12 Page 25

Page 26

NOTES

Page 26 Form #04-VAM-UM-00229 09/12

Page 27

®

Badger Meter Warranty

Flow-Alert Flow Switch

PRODUCTS COVERED

The Badg er Meter warrant y shall apply to th e Hedland Flow-

Alert Flow Switch (“Product”).

MATERIALS AND WORKMANSHIP

Badger M eter warrants th e Product to be fre e from defect s in

material s and workmanshi p for a period of 12 months f rom the

original purchase date.

PRODUCT RETURNS

Produc t failures must be p roven and verifi ed to the satisfa ction

of Badger Meter. The Badger Meter obligation hereunder

shall be li mited to such repair a nd replacement a nd shall be

conditi oned upon Badge r Meter receivi ng written noti ce of any

assert ed defect with in 10 (ten) days after its di scovery. If the

defec t arises and a valid c laim is received wi thin the Warranty

Period, at its option, Badger Meter will either (1) exchange

the Produ ct with a new, used or re furbished Pro duct that is

at least fu nctionally e quivalent to the or iginal Product , or (2)

refund t he purchase price o f the Product. DO N OT RETURN

ANY PRODU CT UNTIL YOU HAVE CALL ED THE BADGER METE R

CUSTOMER SE RVICE DEPARTMENT AND O BTAINED A RE TURN

AUTHORIZATION.

Produc t returns must be sh ipped by the Custom er prepaid F.O.B.

to the near est Badger Mete r factory or dis tribution cente r. The

Customer shall be responsible for all direct and indirect costs

associated with removing the original Product and reinstalling

the repaired or replacement Product. A replacement Product

assumes the remaining warranty of the original Product or

ninet y (90) days from the date of r eplacement, wh ichever

provides longer coverage.

LIMITS OF LIABILITY

This warranty shall not apply to any Product repaired or

altered b y any Product other t han Badger Mete r. The fore going

warrant y applies only to t he extent that th e Product is

install ed, service d and operated st rictly in accorda nce with

Badger Meter instructions. The warranty shall not apply and

shall be vo id with respect t o a Product expos ed to conditions

other than those detailed in applicable technical literature

and Inst allation and Ope ration Manuals (IO Ms) or which have

been subj ect to vandalis m, negligence, ac cident, acts of G od,

improper installation, operation or repair, alteration, or other

circumstances which are beyond the reasonable control of

Badger Meter.

With resp ect to produc ts not manufac tured by Badger Me ter,

the warra nty obligatio ns of Badger Mete r shall in all respec ts

conform a nd be limited to the wa rranty exte nded to Badger

Meter by th e supplier.

THE FOREG OING WARRANTIE S ARE EXCLUSIVE AND IN LI EU OF

ALL OTHER E XPRESS AND IMPLIED WARR ANTIES WHATSOEV ER,

INCLUDIN G BUT NOT LIMITED TO IM PLIED WARRANTIES O F

MERCHANTABI LITY AND FITNES S FOR A PARTICULAR PURP OSE

(except war ranties of title).

Any descri ption of a Produc t, whether in wri ting or made orall y

by Badge r Meter or its agent s, specific ations, sample s, models,

bulletins, drawings, diagrams, engineering sheets or similar

material s used in connect ion with any Custome r’s order are for

the sole p urpose of identi fying the Prod uct and shall not b e

construed as an express warranty. Any suggestions by Badger

Meter or it s agents regard ing use, applicat ion or suitabili ty

of the Prod uct shall not be con strued as an expr ess warranty

unless con firmed to be suc h, in writing, by Ba dger Meter.

EXCLUSION OF CONSEQUENTIAL

DAMAGES AND DISCLAIMER OF OTHER

LIABILITY

Badger M eter liabilit y with respect to b reaches of the fore going

warrant y shall be limite d as stated herein . Badger Meter

liabilit y shall in no event ex ceed the contrac t price. BADGER

METER SHA LL NOT BE SUBJECT TO AN D DISCLAIMS: (1) ANY

OTHER OBL IGATIONS OR LIABILI TIES ARISING OUT O F BREACH

OF CONTR ACT OR OF WARRANT Y, (2) ANY OBLIGATIO NS

WHATSOEVE R ARISING FROM TORT CL AIMS (INCLUDING

NEGLIGENCE AND STRICT LIABILITY) OR ARISING UNDER

OTHER THE ORIES OF LAW WITH R ESPECT TO PRODUC TS

SOLD OR SERV ICES RENDERED BY BAD GER METER, OR A NY

UNDERTAKIN GS, ACTS OR OMISSI ONS RELATING THERE TO,

AND (3) ALL CONSEQU ENTIAL, INCIDE NTAL AND CONTI NGENT

DAMAGES WHATSOEVER.

04-VAM-UM-00229 09/12 Badger Meter Warranty

Page 28

Trademarks appearing in this document are the property of their respective entities.

Due to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2012 Badger Meter, Inc. All rights reserved.

info@hedland.com | www.hedland.com | www.badgermeter.com

Phone: 262-639-6770 | Fax: 262-639-2267

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-04 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | Rm 501, N° 11 Longyue Apartment | N° 180 Longjin Rd, Jiuting Songjiang District | Shanghai, China | 201615 | +86-21-5763 5412

Loading...

Loading...