Page 1

Industrial Flow Computer

FC-5000 BTU Monitor

CTL-UM-02038-EN-03 (March 2019)

User Manual

Page 2

Industrial Flow Computer, FC-5000 BTU Monitor

CONTENTS

Scope of This Manual � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Unpacking and Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Safety Considerations� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Terminology and Symbols� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Safety Instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Safety Rules and Precautionary Measures � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Description � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Functions and Features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Flow Meter Input � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Digital Inputs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Relay Control Outputs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Power Supply� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Conguring the Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Display Information� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Installing the BTU Monitor� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Mounting Options� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

Wiring the BTU Monitor � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

Operator Interface� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

Keypad and Soft Keys � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

Scrolling � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

Control Panel Keys � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

Icon Functionality � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

Numeric Editing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

Alpha-Numeric Editing� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

Selection/Enumeration Editing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Conrmation Screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Navigating the Menus � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Menu Structure � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

Info/Sensor Data � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

System Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Basic Setup � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

Display � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

Resets � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

Passcode Setup � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 28

Units � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 29

Advanced Setup � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

Conguring a Flow Sensor � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

Page ii March 2019CTL-UM-02038-EN-03

Page 3

User Manual

Conguring a Temperature Sensor � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 34

Conguring Outputs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 35

Conguring Digital I/O � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 39

Conguring Fluid Properties � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 40

Conguring Communications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 41

Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

Modbus Interface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

Modbus Function Code Support� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

Modbus Register Map � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

BACnet Interface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

BACnet Map � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

Flow Sensor Types � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

Part Numbering Construction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 47

Replacement Parts/Accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 47

Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 48

Standards and Certications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

Agency Approval/Standards � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

EMI/EMC Compliance� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

Enclosure Protection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

March 2019 CTL-UM-02038-EN-03

Page iii

Page 4

Industrial Flow Computer, FC-5000 BTU Monitor

Page iv March 2019CTL-UM-02038-EN-03

Page 5

Scope of This Manual

SCOPE OF THIS MANUAL

This manual describes how to install and program the FC-5000 BTU Monitor� The

electronic version of this manual is available on our website

at www.badgermeter.com�

MPORTANTI

Read this manual carefully before attempting any installation or operation.

Keep the manual in an accessible location for future reference.

UNPACKING AND INSPECTION

Upon opening the shipping container, visually inspect the product and applicable

accessories for any physical damage such as scratches, loose or broken parts, or

any other sign of damage that may have occurred during shipment�

OTE:N If damage is found, request an inspection by the carrier’s agent within

48 hours of delivery and file a claim with the carrier� A claim for equipment

damage in transit is the sole responsibility of the purchaser�

SAFETY CONSIDERATIONS

Terminology and Symbols

Indicates a hazardous situation, which, if not avoided, will result in death or

serious personal injury�

Indicates a hazardous situation, which, if not avoided, could result in death or

severe personal injury�

Indicates a hazardous situation, which, if not avoided, could result in minor or

moderate personal injury or damage to property�

Please read the information in this manual in all cases where this symbol is used

in order to find out the nature of potential hazards, and any actions which have to

be taken to avoid them�

This symbol signifies that the FC-5000 BTU Monitor may be powered by a DC

power supply� Acceptable DC input voltage range is: 10…40V DC�

This symbol signifies that the FC-5000 BTU Monitor may be powered by an AC

power supply� Acceptable AC input voltage range is: 9…28V AC RMS (50…60 Hz)�

• Operating temperature is 32…130° F (0…55° C) with a maximum humidity

of 85% non-condensing� Always select a mounting location with proper

ventilation and environmental protection�

• Maximum operating altitude: 2000 meters (6561 feet)

• Pollution Degree 2: Only non-conductive pollution occurs except that

occasionally a temporary conductivity caused by condensation is to

be expected

• Over-Voltage Rating: CAT II

Page 5 March 2019 CTL-UM-02038-EN-03

Page 6

Safety Considerations

Safety Instructions

• LIFE SUPPORT APPLICATIONS: THE FC-5000 IS NOT DESIGNED FOR USE IN

LIFE SUPPORT APPLIANCES, DEVICES, OR SYSTEMS WHERE MALFUNCTION

OF THE PRODUCT CAN REASONABLY BE EXPECTED TO RESULT IN A PERSONAL

INJURY. CUSTOMERS USING OR SELLING THESE PRODUCTS FOR USE IN SUCH

APPLICATIONS DO SO AT THEIR OWN RISK AND AGREE TO FULLY INDEMNIFY

THE MANUFACTURER AND SUPPLIER FOR ANY DAMAGES RESULTING FROM

SUCH IMPROPER USE OR SALE.

• ELECTROSTATIC DISCHARGE INFLICTS IRREPARABLE DAMAGE TO

ELECTRONICS. BEFORE INSTALLING OR OPENING THE UNIT, INSTALLERS

MUST DISCHARGE THEMSELVES BY TOUCHING A WELL-GROUNDED OBJECT.

• THIS UNIT MUST BE INSTALLED IN ACCORDANCE WITH THE EMC

(ELECTROMAGNETIC COMPATIBILITY) GUIDELINES.

Safety Rules and Precautionary Measures

The manufacturer accepts no responsibility whatsoever if the following safety

rules and precaution instructions and the procedures as described in this manual

are not followed�

• Modifications of the BTU Monitor implemented without preceding written

consent from the manufacturer will result in the immediate termination of

product liability and warranty period�

• Installation, use, maintenance, and servicing of this equipment must be carried

out by authorized technicians�

• Check the mains voltage and information on the manufacturer’s nameplate

before installing the unit�

• Check all connections, settings and technical specifications of the various

peripheral devices with the BTU Monitor supplied�

• Never open the enclosure�

• Never touch the electronic components (ESD sensitivity)�

• Never expose the system to heavier conditions than allowed according to the

casing classification (see manufacturer’s nameplate)�

• If the operator detects errors or dangers, or disagrees with the safety

precautions taken, then inform the owner or the principal responsible�

• Adhere to the local labor and safety laws and regulations�

Page 6 March 2019CTL-UM-02038-EN-03

Page 7

Description

DESCRIPTION

The FC-5000 BTU Monitor is a microprocessor-driven device that is designed for

energy (BTU) and flow monitoring� The FC-5000 BTU Monitor is compatible with

the complete line of Badger Meter industrial flow meters and temperature sensors,

creating a solution to monitor hydronic energy usage, flow rates and totals� This

manual was written for firmware version 1�2�8�655�

Functions and Features

This product is designed with a focus on:

• Large display for easy viewing

• Ease-of-use with softkeys and a full numeric keypad

• Ruggedness for its application with a robust enclosure, keypad and

mechanical relays

• Info/Sensor Data Screen—view raw and calculated data, both to and from

the unit, including flow data, energy data, temperature readings and

output statuses

• User-friendly installation with quality plug-and-play terminals

• A wide range of outputs and functions for a broad fulfillment in

many applications

• User defined relay triggers for flow rates and totals, temperatures or energy

rates and totals

Flow Meter Input

The FC-5000 BTU Monitor accepts passive or active signal outputs� The input

circuit supports low and high frequency (0�5…3500 Hz) flow meters� A 12V DC

exitation terminal is available for flow meter sensors that require power�

Digital Inputs

The FC-5000 BTU Monitor control inputs allow the following functions:

• Unlatch Relays

• Reset Totalizers

• Unlatch Relays and Reset Totalizers

Page 7 March 2019 CTL-UM-02038-EN-03

Page 8

Description

Relay Control Outputs

The FC-5000 BTU Monitor has two relay outputs, either a mechanical Form C

switch or a solid state Form A switch� The product configuration determines which

switches are available� All control functions are always available by dedicated

relay outputs� Unneeded outputs may be left disconnected or disabled within the

firmware�

Relays can be used for alarm indication or as a totalizing output�

Form-C

• Can be powered directly from mains circuits rated up to 240V�

• Must be powered through circuits that are insulated from mains by at least

basic insulation�

• Connected sources of power need to be limited to 240V AC and fused at 5A

or less�

• Not suitable for connection to external circuits that are insulated from mains by

at least double insulation (SELV)�

Form A

• Located on TB4 and recommended to use, if configured as a high-rate,

totalizing output�

• Relay energizes (contact closes) with a minimum input current of 3 mA through

the input LED�

• The relay turns off (contact opens) with an input voltage of 0�8V or less�

Power Supply

The power supply used must be isolated from mains by double or reinforced

insulation (for instance, SELV power supply)�

The FC-5000 BTU Monitor operates on 10…40V DC or 9…28V AC supplied by any

suitable source that also meets the requirement listed above� Badger Meter has

power supplies available for the FC-5000 BTU Monitor�

Power Supply Part Numbers:

• 68334-001: includes wall mount (wall wart) power supply and various adapters

• 68334-002: power module that allows discrete power wiring

A power supply not sourced from the factory must be capable of supplying a

minimum of 8 Watts�

Conguring the Unit

The FC-5000 BTU Monitor is designed for many types of applications� See

“Advanced Setup” on page 32 for instructions on configuring your

FC-5000 BTU Monitor to your specific requirements�

All information is stored in EEPROM memory and will not be lost in the event of

power failure�

Page 8 March 2019CTL-UM-02038-EN-03

Page 9

Installing the BTU Monitor

Display Information

The FC-5000 BTU Monitor has a large transflective LCD with a bright LED backlight

that displays symbols and digits for measuring units, status information and

keyword messages� See “Units” on page 29�

INSTALLING THE BTU MONITOR

MOUNTING, ELECTRICAL INSTALLATION, STARTUP AND MAINTENANCE OF THIS

INSTRUMENT MAY ONLY BE CARRIED OUT BY TRAINED PERSONNEL AUTHORIZED BY

THE OPERATOR OF THE FACILITY. PERSONNEL MUST READ AND UNDERSTAND THIS

OPERATING MANUAL BEFORE CARRYING OUT ITS INSTRUCTIONS.

THE FC5000 BTU MONITOR MAY ONLY BE OPERATED BY PERSONNEL WHO ARE

AUTHORIZED AND TRAINED BY THE OPERATOR OF THE FACILITY. OBSERVE ALL

INSTRUCTIONS IN THIS MANUAL.

OBEY ALL SAFETY PRECAUTIONS MENTIONED IN “SAFETY CONSIDERATIONS” ON

PAGE 5.

OTE:N For a complete list of parts and accessories, refer to “Replacement Parts/

Accessories” on page 47�

Page 9 March 2019 CTL-UM-02038-EN-03

Page 10

Installing the BTU Monitor

Mounting Options

The FC-5000 BTU Monitor can be mounted on a wall, shelf or instrumentation

panel� Wall-mount units are shipped in a NEMA 4X enclosure, ready to mount�

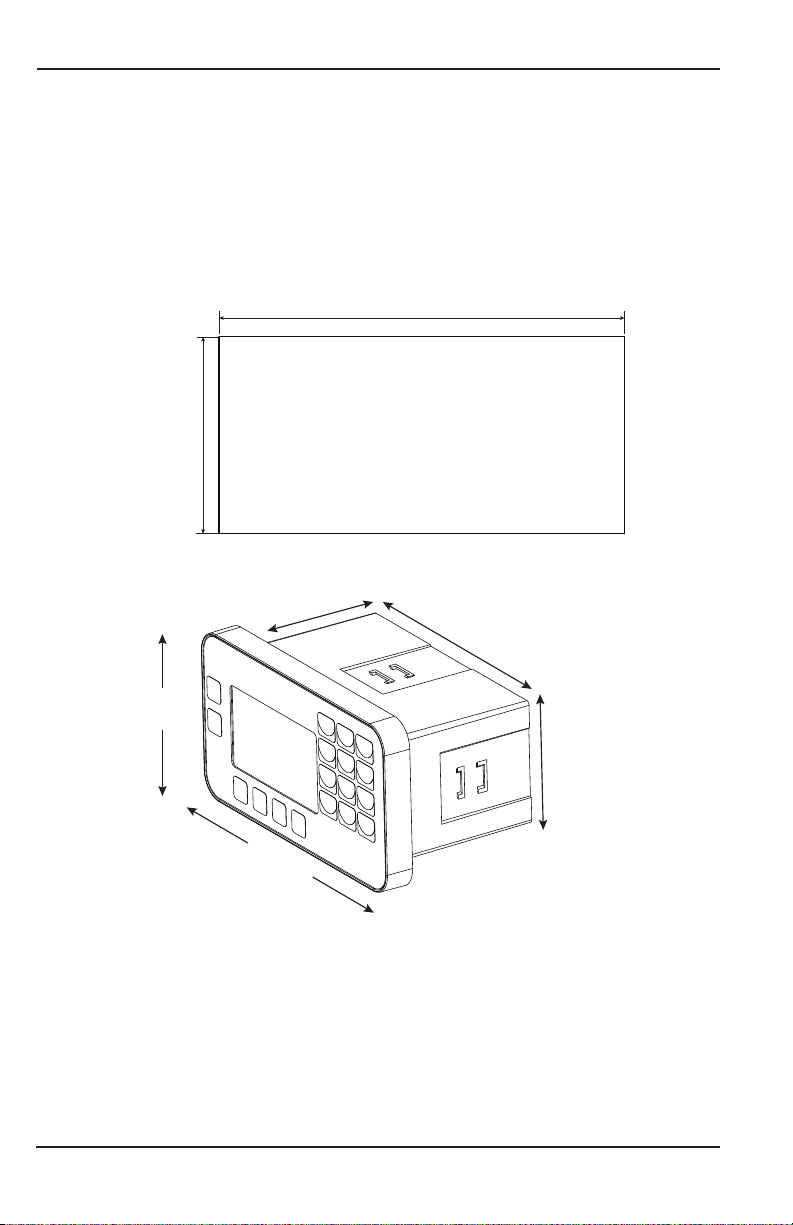

Panel-Mount Installations

OTE:N Mounting clips can accommodate a maximum panel thickness of

1�5 in� (38�1 mm)�

5.40 in.

(137.16 mm)

2.65 in.

(67.31 mm)

Figure 1: Panel cutout

3.07 in.

(78.00 mm)

Panel Cutout

5.38 in.

(136.65 mm)

3.50 in.

(89.00 mm)

2.54 in.

(64.52 mm)

6.22 in.

(158.00 mm)

Figure 2: Mounting dimensions

To install:

1� Measure and cut a mounting hole to the dimensions shown in Figure 1�

2� Verify that the gasket is secure inside the mounting bezel�

3� Insert the unit through the panel cutout�

4� Secure the unit to the panel with the provided mounting clips�

Page 10 March 2019CTL-UM-02038-EN-03

Page 11

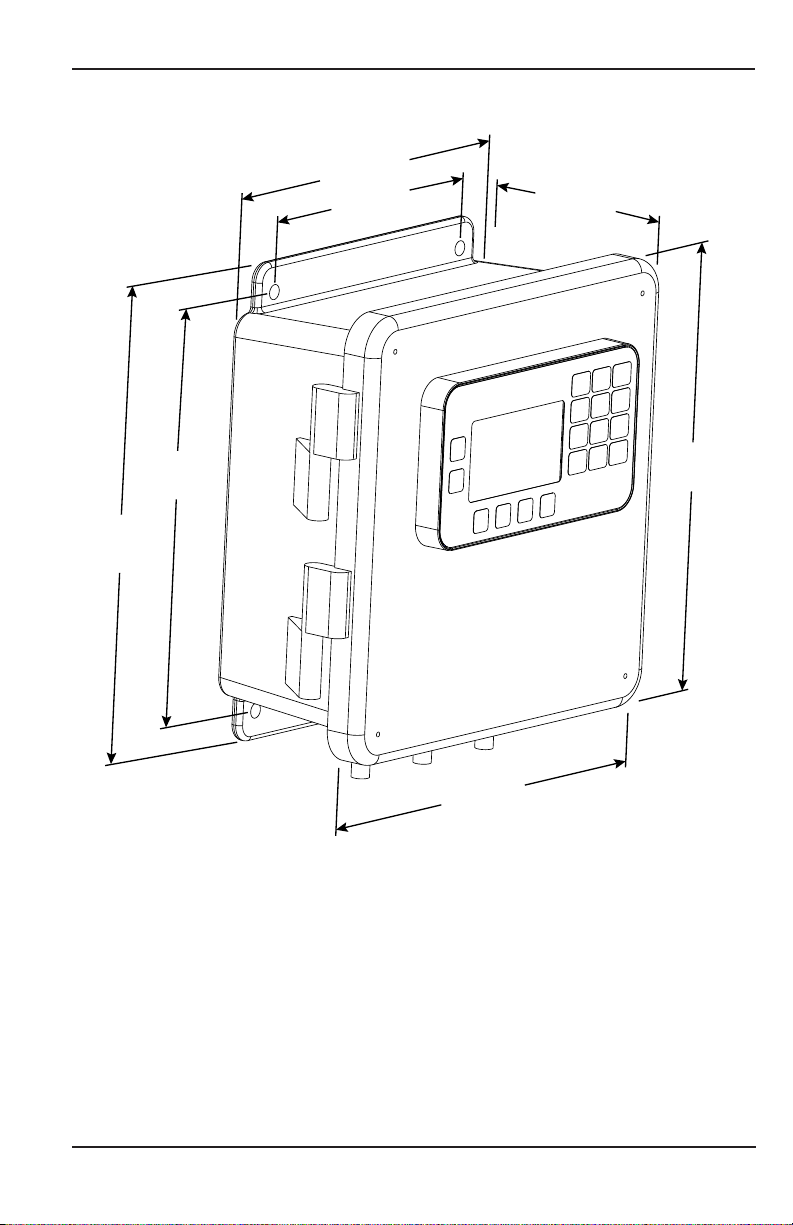

Wall-Mount Installations

8.00 in.

(203.20 mm)

6.00 in.

(152.40 mm)

Installing the BTU Monitor

4.88 in.

(123.95 mm)

8.75 in.

(222.25 mm)

9.65 in.

(242.83 mm)

9.38 in.

(238.25 mm)

Figure 3: FC-5000 BTU Monitor in an enclosure

9.38 in.

(238.25 mm)

To install the FC-5000 BTU Monitor on a wall, secure the enclosure to the wall with

four mounting screws (customer-supplied)�

Page 11 March 2019 CTL-UM-02038-EN-03

Page 12

Installing the BTU Monitor

Wiring the BTU Monitor

At installation, be sure to comply with the following requirements:

• Disconnect power to the unit before attempting any connection or service to

the unit�

• Avoid using machine power service for AC power� When possible, use a

dedicated circuit or a lighting circuit�

• Observe all local electrical codes�

• The unit must be wired with wires and/or cables with a minimum temperature

rating of 167° F (75° C)�

TO PREVENT ACCIDENTS, DO NOT APPLY POWER UNTIL ALL OTHER

CONNECTIONS HAVE BEEN COMPLETED.

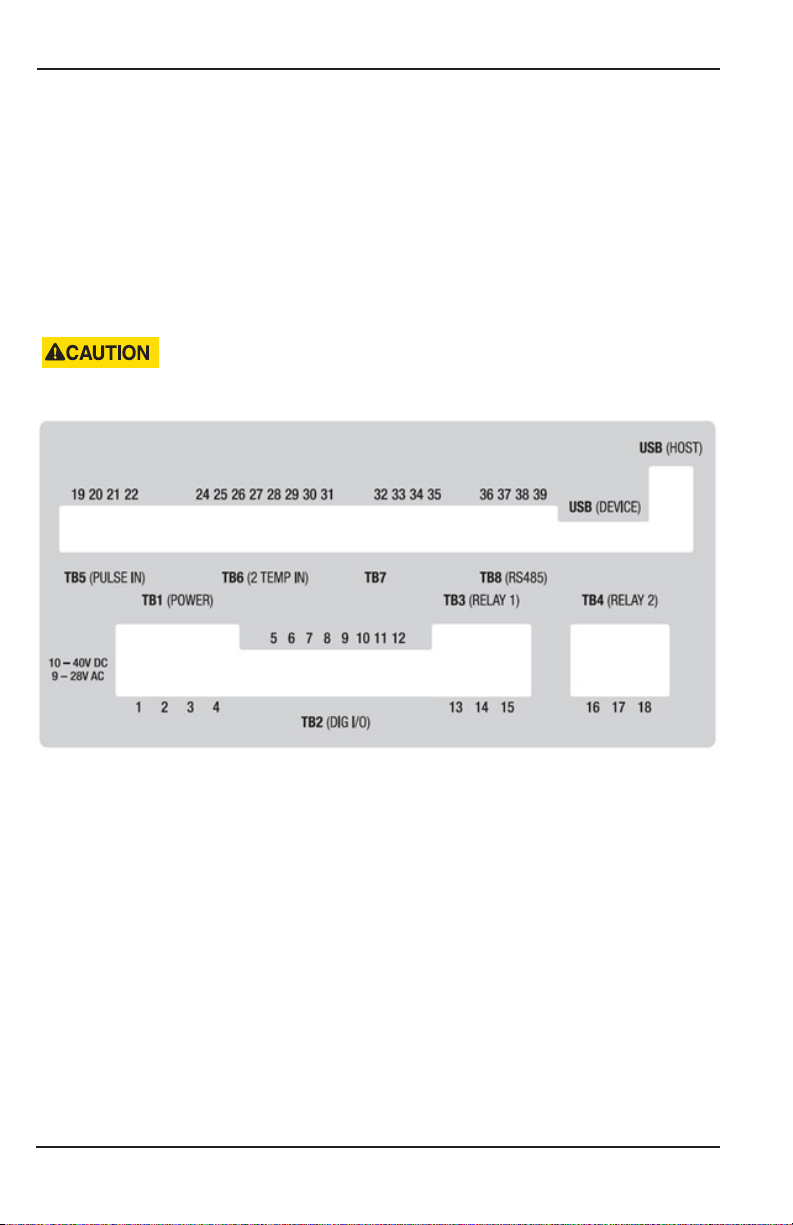

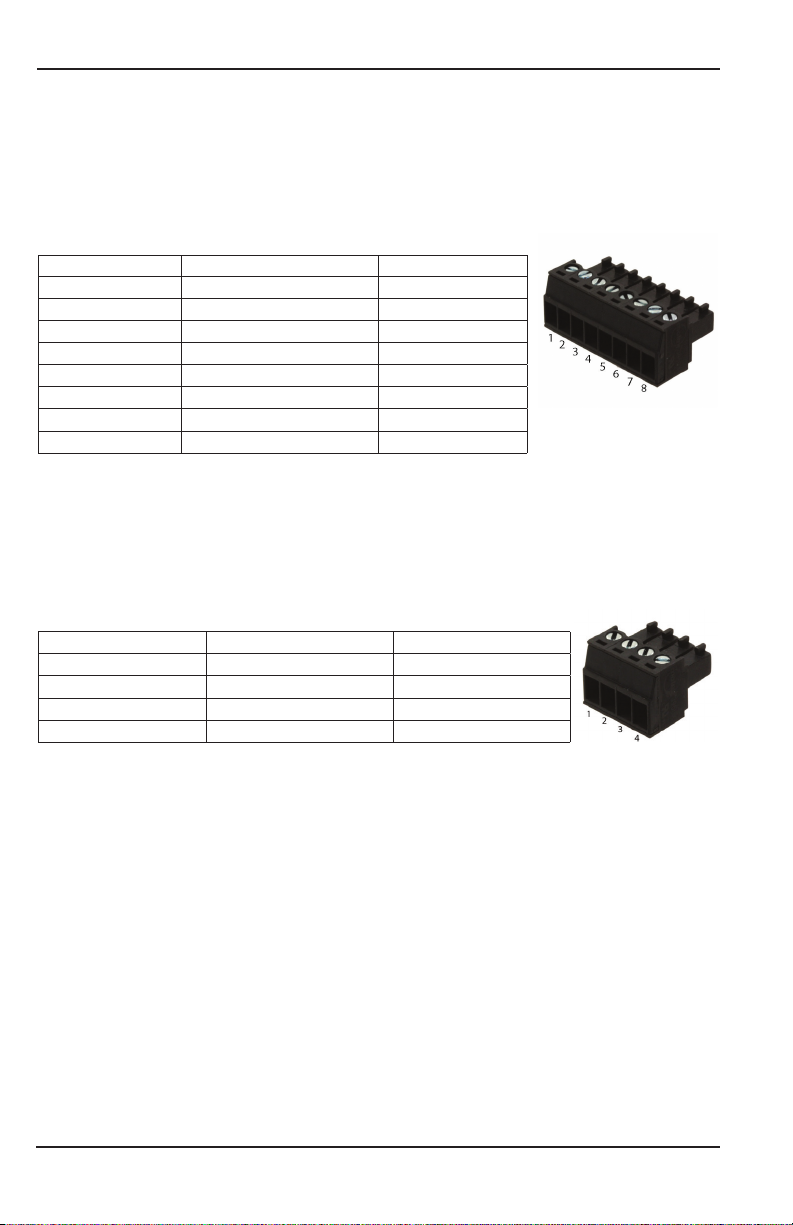

Terminal Connectors

Figure 4: Terminal connectors, analog out

OTE:N Terminal/pin descriptions shown on next page�

Page 12 March 2019CTL-UM-02038-EN-03

Page 13

Installing the BTU Monitor

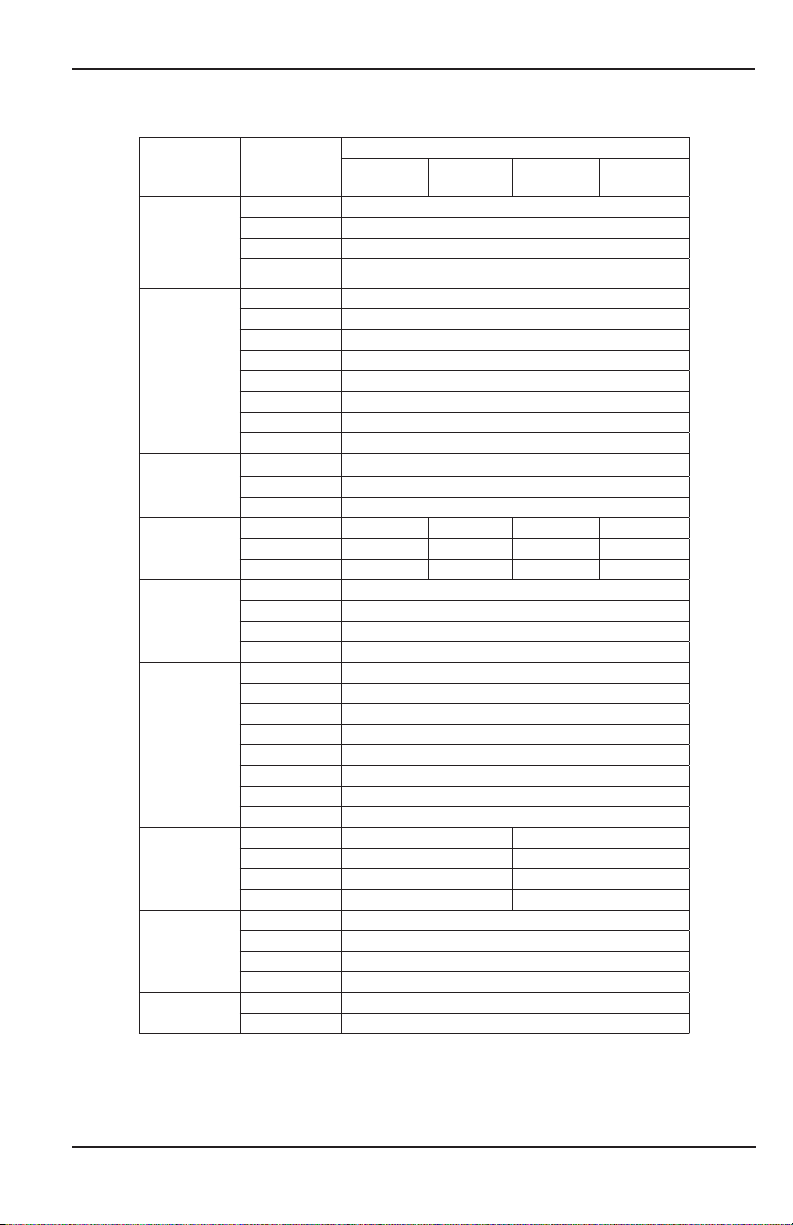

The plug-in connectors on the rear panel of the FC-5000 BTU Monitor are:

Terminal

Block

TB1

Power

TB2

Digital I/O

TB3

Relay 1

TB4

Relay 2

TB5

Pulse Input

TB6

Temperature

Inputs

TB7

Scaled

Outputs

TB8

Comms

USB

Connection

Pin

1 +

2 SHLD

3 -

4 I/O GND

5 PWR +

6 I/O 1

7 I/O 2

8 I/O 3

9 I/O 4

10 I/O 5

11 I/O 6

12 I/O GND

13 N�O�

14 COM

15 N�C�

16 N�O� X1 N�O� X1

17 COM N�C� COM N�C�

18 N�C� X2 N�C� X2

19 EXCI +

20 IN +

21 SNS GND

22 SHLD

24 EXCI 1 +

25 SENS 1 +

26 SENS 1 27 EXCI 1 28 EXCI 2 +

29 SENS 2 +

30 SENS 2 31 EXCI 2 32 OUT 1 OUT 1

33 OUT 2 OUT 2

34 OUT GND A GND

35 SHLD SHLD

36 SHLD

37 38 +

39 485 GND

Device Mini-B Receptacle (Used for Firmware Updates)

Host Type-A Receptacle (Not Used)

P1-FC6A-*

Configurations/Part Numbers

FC5-BM-

FC5-BM-

P1-FA6A-*

FC5-BM-

P1-AC6A-*

FC5-BM-

P1-AA6A-*

Page 13 March 2019 CTL-UM-02038-EN-03

Page 14

Installing the BTU Monitor

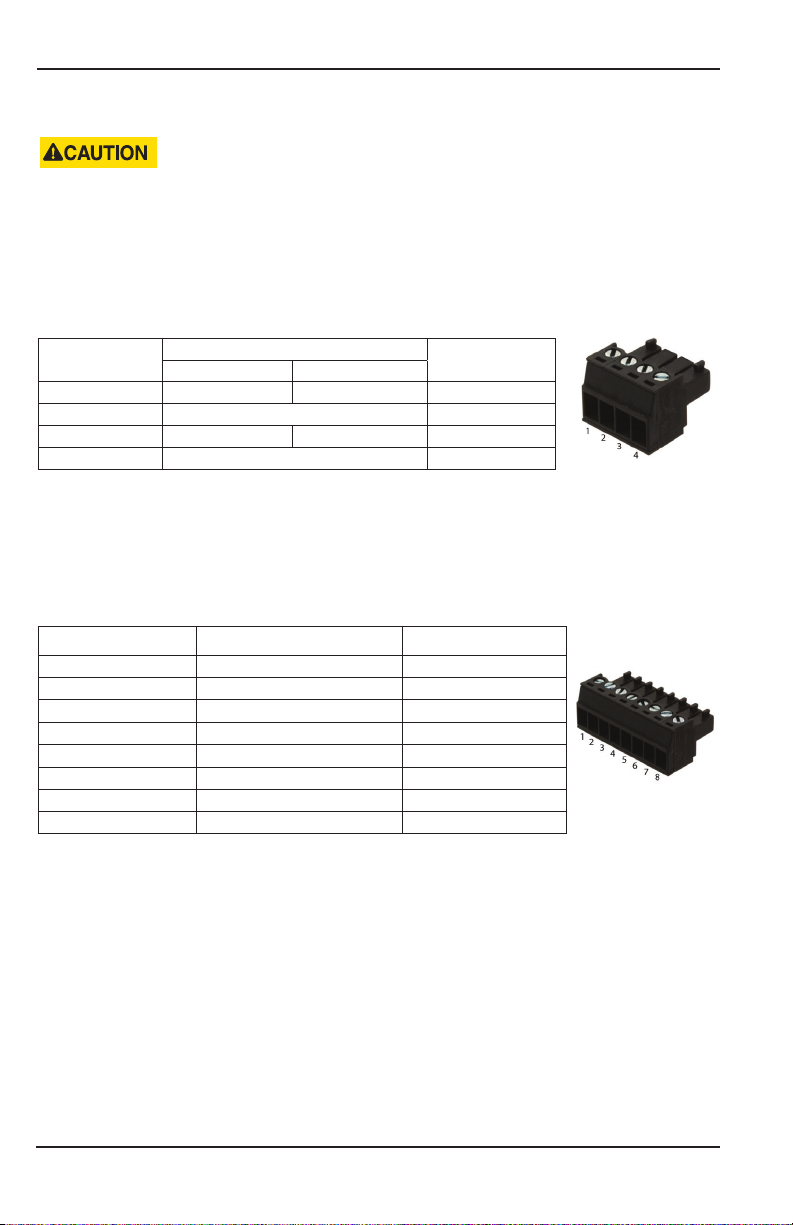

Power Input

THE FC5000 IS MICROPROCESSOR CONTROLLED. IT IS VERY IMPORTANT THAT THE

POWER SUPPLY BE FREE OF ELECTRICAL NOISE. AVOID USING POWER LINES THAT

FEED HEAVY LOAD ELECTRICAL DEVICES SUCH AS PUMPS AND MOTORS.

The FC-5000 BTU Monitor power input is internally fused and protected from

common line noise by a filtering network�

TB1 (POWER)

Connector Pin

1 Line (L) Positive (L+) 1

2 Shield (Chassis GND) 2

3 Neutral (N) Negative (L–) 3

4 Digital I/O GND 4

AC Power DC Power

Function

Table 1: Power input

Reference Pin

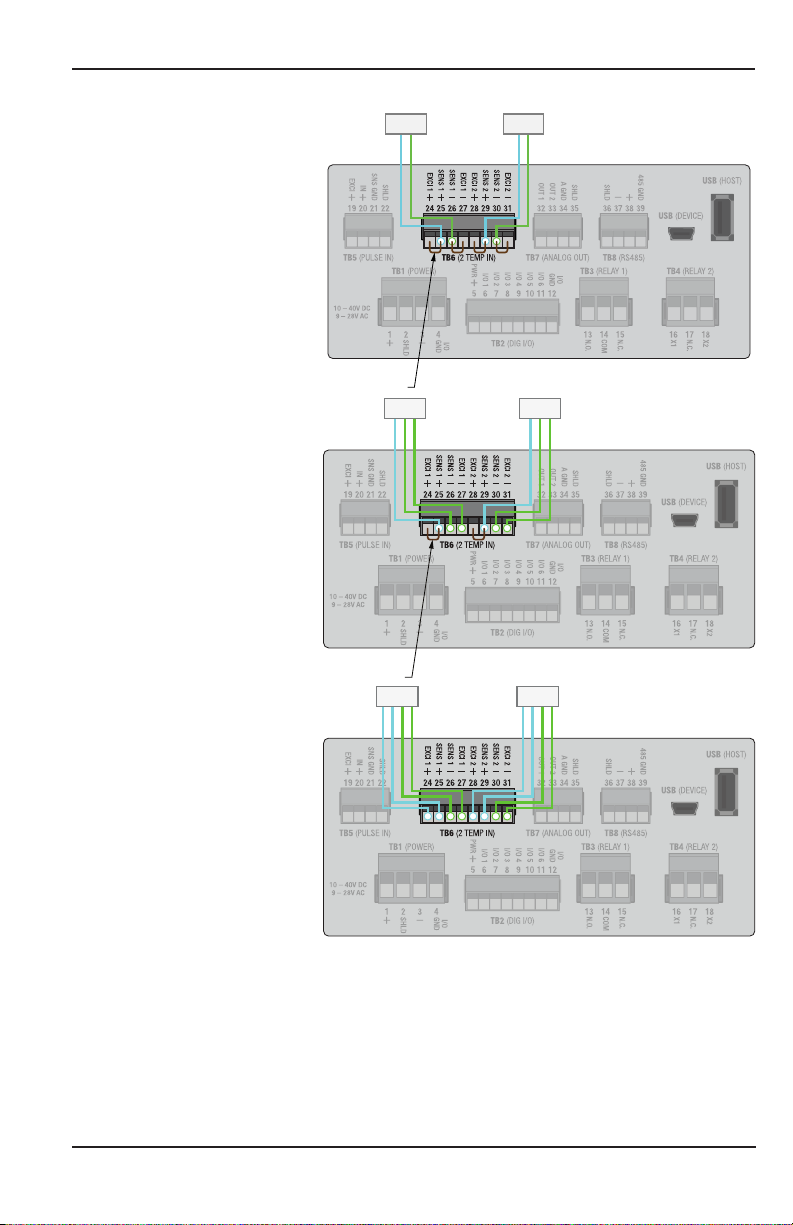

Temperature Inputs

Two temperature inputs allow the FC-5000 BTU Monitor to measure hydronic

energy usage with potentially varying temperature readings�

TB6 (2 TEMP IN)

Connector Pin Function Reference Pin

1 T1 Excitation (+) 24

2 T1 Sensor Input (+) 25

3 T1 Sensor Input (–) 26

4 T1 Excitation (–) 27

5 T2 Excitation (+) 28

6 T2 Sensor Input (+) 29

7 T2 Sensor Input (–) 30

8 T2 Excitation (–) 31

Table 2: Temperature inputs

OTE:N See Figure 5 on page 15 for a wiring diagram�

Page 14 March 2019CTL-UM-02038-EN-03

Page 15

Installing the BTU Monitor

Jumper Wire

2-Wire RTD or Thermistor

3-Wire RTD

4-Wire RTD

RTD RTD

Jumper Wire

RTDRTD

RTDRTD

OTE:N The wires in your application may not be the same color as the wires in the

diagram� The number of each color represents the number of a color of

wire that your application will have� For example, the 3-Wire RTD diagram

has two green wires and one blue wire� Your application may have two

yellow wires and one red wire� To wire the system you would wire the two

yellow wires the same way the green wires are in the diagram, and the

same with the red and blue wires�

Figure 5: RTD Wiring Diagram

Page 15 March 2019 CTL-UM-02038-EN-03

Page 16

Installing the BTU Monitor

Digital Inputs

The FC-5000 BTU Monitor has six independent channels available for digital input�

The channels accept TTL voltage signals in the 0…5V DC range� The control inputs

are triggered when the voltage signal on the pin is pulled low (active low)� Input

range for a logic low signal is 0…1V, logic high is 4…5V�

TB2 (DIG I/O)

Connector Pin Function Reference Pin

1 Excitation or Power 5

2 Input/Output 1 Signal 6

3 Input/Output 1 Signal 7

4 Input/Output 1 Signal 8

5 Input/Output 1 Signal 9

6 Input/Output 1 Signal 10

7 Input/Output 1 Signal 11

8 Ground or Neutral 12

Table 3: Digital inputs

Communications

The FC-5000 BTU Monitor comes with Modbus (RTU or ASCII) and BACnet

communication protocols� Signals are transmitted over an EIA-485 (RS-485)

physical layer�

TB8 (RS-485)

Connector Pin Function Reference Pin

1 Shield (Chassis GND) 36

2 Negative (–) 37

3 Positive (+) 38

4 Output Ground 39

Table 4: Communications input

Page 16 March 2019CTL-UM-02038-EN-03

Page 17

Installing the BTU Monitor

Scaled Outputs

The FC-5000 BTU Monitor has two scaled output channels for use in applications

requiring remote data collection and/or monitoring� The outputs are firmware

configurable, and can be tied to parameters such as rates, temperature or

totalizer values�

TB7 (FREQ OUT) or (ANALOG OUT)

Connector Pin Function Reference Pin

1 Output 1 Signal 32

2 Output 2 Signal 33

3 Output Ground 34

4 Shield (Chassis GND) 35

Table 5: Scaled output channels

ANALOG OUTPUT CONFIGURATIONS ARE DESIGNED TO PROVIDE A SOURCING

OUTPUT SIGNAL. THE RECEIVING DEVICE MUST NOT PROVIDE POWER TO

THE LOOP.

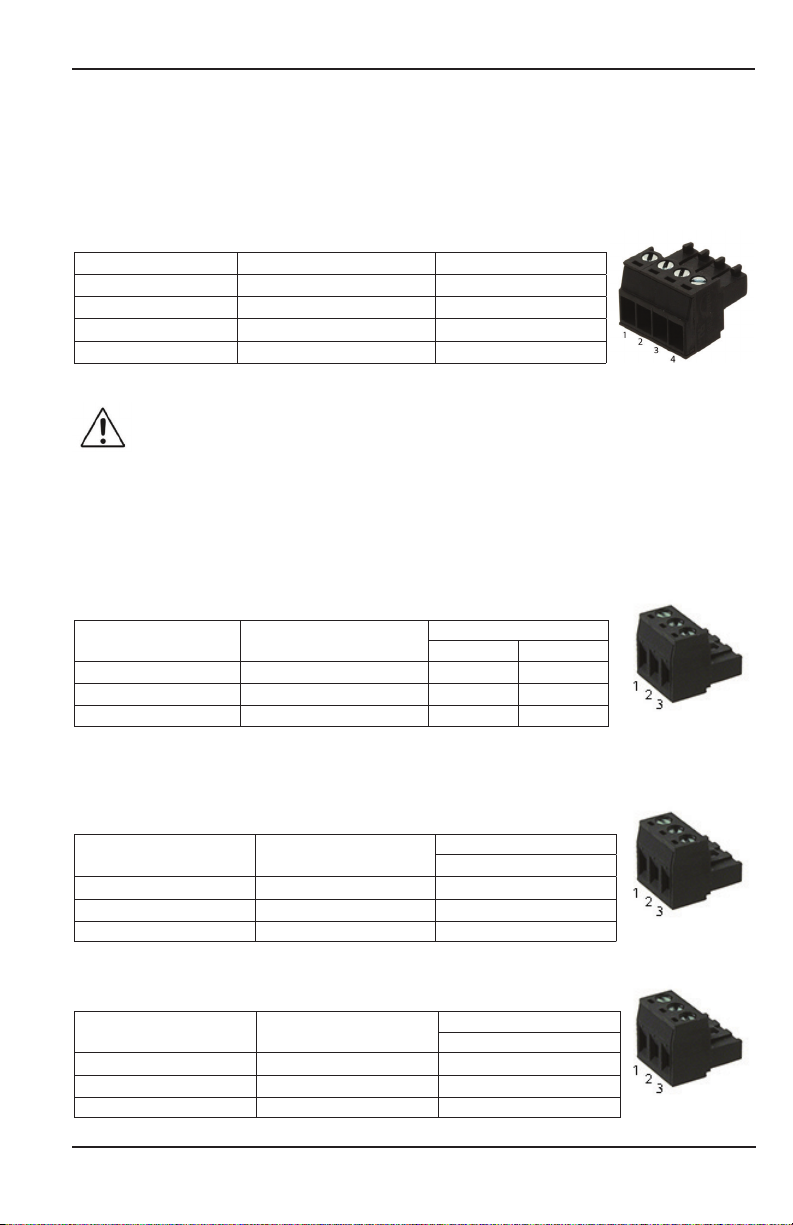

Relay Output Connectors

The FC-5000 BTU Monitor has either two Form C relay output terminals or one

Form C and one Form A terminal�

Two Form C

TB3 (RELAY 1) and TB4 (RELAY 2)

Connector Pin Function

1 Normally Open (N�O�) 13 16

2 Signal Common 14 17

3 Normally Closed (N�C�) 15 18

Table 6: Relay output connectors, relay option "C"

Reference Pin

Relay 1 Relay 2

One Form C and One Form A

TB3 (RELAY 1) - Form C

Connector Pin Function

1 Normally Open (N�O�) 13

2 Signal Common 14

3 Normally Closed (N�C�) 15

Figure 6: Form C Relay Output Connector

TB4 (RELAY 2) - Form A

Connector Pin Function

1 Connection Point 1 16

2 Not Used (No Contact) 17

3 Connection Point 2 18

Figure 7: Form A Relay Output Connector

Reference Pin

Relay 1

Reference Pin

Relay 2

Page 17 March 2019 CTL-UM-02038-EN-03

Page 18

Installing the BTU Monitor

Flow Sensor Input

The FC-5000 BTU Monitor is designed to accept pulses from open collector

transistors or dry contact closure transmitters�

Before making any connections:

• Always use shielded wire to protect the signal line from external noise (ground

shield to terminal #3)�

• Make sure the signal lines are not bundled with or touching power lines�

OTE:N In the table below, RF Pin refers to RF type pickups/amplifiers�

TB5 (PULSE IN)

Connector

Pin

1 Sensor Exitation (+) 19 A

2 Sensor Input (+) 20 C

3 Sensor Input/Common (–) 21 B

4 Shield (Chassis GND) 22 —

Function Reference Pin RF Pin

Table 7: Flow sensor input

Powering Radio Frequency (RF) Type Pickups

Radio Frequency (RF) type pickups require a power source to generate a radio

frequency field� Similar to magnetic pickups, as fluid velocity provides rotational

energy on the flow meter rotor, the field generated by the pickup is disturbed,

producing output pulses that are proportional to flow rate�

OTE:N Maximum current draw from the Excitation pin cannot exceed 200 mA� RF

style pickups will require a signal conditioning amplifier�

0…5V, 0…10V Configuration Source Voltage Configuration

From

Pickup/

Amplier

Table 8: Pickup configurations

From

Pickup/

Amplier

Page 18 March 2019CTL-UM-02038-EN-03

To

BTU

Monitor

Page 19

Operator Interface

OPERATOR INTERFACE

Keypad and Soft Keys

The keypad and soft keys are for programming, editing and changing views�

Scrolling

The screens can display up to four lines at a time� Some menus have more than

four items to display� To see the off-screen items, press UP/DOWN to scroll

through the entire list�

THE BTU MONITOR MAY BE OPERATED ONLY BY PERSONNEL WHO ARE AUTHORIZED

AND TRAINED BY THE FACILITY. OBSERVE ALL INSTRUCTIONS IN THIS MANUAL. OBEY

ALL SAFETY PRECAUTIONS MENTIONED IN “SAFETY CONSIDERATIONS” ON PAGE 5.

Control Panel Keys

OTE:N Always press (ENTER) to save a new value�

The numbered keys are used to enter or change parameter values�

In editing mode, BACKSPACE deletes the character to the left of the

cursor� While navigating, BACKSPACE moves to a previous

menu selection�

Depending on the current screen, ENTER:

• Saves the current value and ends the editing session

• Advances deeper into the menu structure

• Toggles enumerations

The UP/DOWN keys:

• Toggle the display views on the home screen

• While editing, use UP/DOWN to advance the cursor to the right or left

• In the menu structure, scroll through the menus and parameters

The F1-F4 function keys are soft keys that change

function to whichever icon is present above them�

See “Icon Functionality” on page 20�

Table 9: Control panel keys

Page 19 March 2019 CTL-UM-02038-EN-03

Page 20

Operator Interface

Icon Functionality

Depending on the task being performed, one or more of the following icons may

appear on the screen� To activate an icon, press the Function key (F1, F2, F3 or F4)

directly under the icon, where applicable�

Icon Function

Display the Home screen or cancel an edit (if you press the button without saving first)

Display the menu structure

Create a custom label (name) for a unit of measure

Return to Setup menu

Cycle through alpha characters

Enter a decimal point

Cycle through special characters

Reveal raw and calculated info/sensor data for the BTU Monitor

Clear the selected value or cancel edit (press twice, consecutively)

Enter conversion factor for custom unit of measure

Change selected value to positive ( + ) or negative ( – )

Set totalizer rollover point

Appears on Home screen for various events� Refer to “Troubleshooting” on page 43 for

details�

Table 10: Icon functionality

Page 20 March 2019CTL-UM-02038-EN-03

Page 21

Numeric Editing

On-screen

instruction

Move cursor

to the right

Existing

Value

Move cursor

to the left

New

Value

FC-5000

Operator Interface

Delete

character

to the left

OR

Return to

previous

menu

Save value

Return to

parent setup

screen

Alpha-Numeric Editing

On-screen

instruction

Move cursor

to the right

Existing

value

Move cursor

to the left

New

value

Return to

parent

setup

screen

Cycle

through

letters

Make entry

positive or

negative

Add a

decimal

point

Clear entire new value or

cancel edit (press twice, consecutively)

Figure 8: Numeric editing

Cycle

through

Clear entire new value or

cancel edit (press twice, consecutively)

special

characters

Figure 9: Alpha-numeric editing

Delete

character

to the left

OR

Return to

previous

menu

Save value

Page 21 March 2019 CTL-UM-02038-EN-03

Page 22

Operator Interface

Selection/Enumeration Editing

OTE:N Depending on the menu, the selection during an enumeration style edit

may appear different�

Save/Select

Move up or

down in

menu

Return to

parent setup

screen

Create a

custom

label

Enter

conversion

factor

Figure 10: Selection editing

Set totalizer

rollover point

Conrmation Screen

No

Figure 11: Confirmation screens

Page 22 March 2019CTL-UM-02038-EN-03

Yes

Page 23

Operator Interface

Navigating the Menus

The Home screen display shows rates and totals, either separately or

simultaneously� Status and alarm messages or alarm icons appear on the display

when appropriate�

Press UP/DOWN to toggle views on the Home screen:

• Flow Rate

• Flow Total

• Energy/BTU Rate

• Energy/BTU Total

Figure 12: Single display

• Flow Rate and Flow Total

• Energy/BTU Rate and

Energy/BTU Total

Figure 13: Dual display

Press F1 to enter the Main menu to access Setup and System Information, or press

F2 to enter the INFO/SENSOR DATA menu�

Page 23 March 2019 CTL-UM-02038-EN-03

Page 24

Operator Interface

Menu Structure

The available menu items depend on the BTU Monitor configuration� Each menu

item is explained in detail in the following pages�

HOME

SCREEN

MAIN MENU

DISPLAY

Language

Contrast

Brightness

Temperature Units

Energy Rate Units

Energy Total Units

SYSTEM

INFORMATION

Function

Part Number (P.N.)

Serial Number (S.N.)

MFG Date

Logic Board

Power Board

Starttime

UNITS

Flow Rate Units

Flow Total Units

Vendor

Model

Version

Uptime

Ontime

SETUP

ADVANCED

SETUP

SENSOR INPUT

Flow Sensor Type

Flow Sensor Calibration

Flow Sensor Properties

Temperature Sensor 1 Type

Temperature Sensor 1 Calibration

Temperature Sensor 2 Type

Temperature Sensor 2 Calibration

SCALED OUTPUT

Output 1 Mode

Output 1 Settings

Output 2 Mode

Output 2 Settings

DIGITAL I/O

Disabled

Reset Relay 1

Reset Relay 2

Reset Flow Total

Reset R1/Flow Total

Reset R2/Flow Total

Reset Energy Total

Reset R1/Energy Total

Reset R2/Energy Total

RELAY OUTPUT

Relay 1 Mode

Relay 2 Settings

Relay 2 Mode

Relay 2 Settings

Figure 14: Menu structure

Page 24 March 2019CTL-UM-02038-EN-03

RESETS

Reset Flow Total

Reset Energy Total

Reset Faults

Reset Defaults

PASSCODE SETUP

Setup Menu Passcode

Reset Menu Passcode

FLUID PROPERTIES

Fluid ID

Heat Transfer Fluid

Communications

Network Type

*Network settings vary

based on the Network

Type that is selected

Page 25

Info/Sensor Data

INFO/SENSOR DATA

The FC-5000 BTU Monitor features a quick method to view measured data

transmitting to and from the device� You can use the data for informational

purposes or for troubleshooting� The type of data displayed can include raw input

frequency, relay status or calculated data, such as flow rate�

Item Description

FLOW FREQ Raw frequency of the flow sensor

FLOW COUNT Raw pulse count of the flow sensor

FLOW RATE Calculated flow rate of the flow sensor

FLOW TOT Calculated flow total of the flow sensor

ENERGY RATE Calculated energy rate

ENERGY TOT Calculated energy total

TEMP 1

TEMP 2

DELTA T The difference between TEMP 1 and TEMP 2

DENSITY Density of the fluid (Programmed)

SP HT Specific heat of the fluid (Programmed)

RELAY 1 ENERGIZED/OFF status of relay 1

RELAY 2 ENERGIZED/OFF status of relay 2

D-I/O 1 ENABLED/DISABLED status of digital I/O port 1

D-I/O 2 ENABLED/DISABLED status of digital I/O port 2

D-I/O 3 ENABLED/DISABLED status of digital I/O port 3

D-I/O 4 ENABLED/DISABLED status of digital I/O port 4

D-I/O 5 ENABLED/DISABLED status of digital I/O port 5

D-I/O 6 ENABLED/DISABLED status of digital I/O port 6

Displays the calculated temperature and raw resistance (ohms) value of

temperature sensor 1�

Displays "NO SENSOR" if no sensor is connected�

Displays the calculated temperature and raw resistance (ohms) value of

temperature sensor 2�

Displays "NO SENSOR" if no sensor is connected�

To return to the home screen, press BACKSPACE or F1 (home)�

Figure 15: Info/sensor data screen

Page 25 March 2019 CTL-UM-02038-EN-03

Page 26

System Information

SYSTEM INFORMATION

The System Information menu contains build information specific to the

configuration of the unit�

To view your system information, navigate to System Information from

the Main menu�

Item Description

VENDOR Manufacturer of the product

MODEL Product family/series

FUNCTION For factory/diagnostic purposes only

P�N� Configured part number

S�N� Serial number

MFG DATE The original manufacture/build date

VERSION Loaded firmware version

LOGIC BRD For factory/diagnostic purposes only

POWER BRD For factory/diagnostic purposes only

UPTIME Time, in seconds, since last power-on session start

ONTIME Total lifetime power-on, in seconds

STARTTIME Ontime at start of power-on session

Table 11: System information menu

Figure 16: System information screen

Page 26 March 2019CTL-UM-02038-EN-03

Page 27

Basic Setup

BASIC SETUP

Display

Use this menu to change the display settings for Language, Contrast or Brightness�

1� Navigate to Display from the main menu�

2� Press UP/DOWN to scroll through the available display parameters, then

press ENTER�

3� Scroll through available options, then press ENTER to select and save

your changes�

Figure 17: Display configuration screen

Resets

Use this menu to reset Totalizers, Faults, Defaults and latched relays:

1� Navigate to Resets from the main menu�

OTE:N If a passcode was configured, enter the passcode, then press ENTER to

access this menu�

2� Press UP/DOWN to scroll through the available reset options, then

press ENTER�

3� On the conrmation screen press ENTER to conrm the reset�

Figure 18: Resets menu

Page 27 March 2019 CTL-UM-02038-EN-03

Page 28

Basic Setup

Clearing a Latched Relay

To clear a relay that latches after a trigger:

1� Navigate to the main menu�

2� Press UP/DOWN to scroll to UNLATCH R1 or UNLATCH R2, then press ENTER�

Passcode Setup

Enabling Passcodes

FC-5000 units are shipped without passcode protection enabled� You can enable a

unique password for the Setup Menu and the Reset Menu� To enable a passcode:

1� Navigate to SETUP > PASSCODE SETUP�

2� Press UP/DOWN to scroll to the passcode you want to enable, then

press ENTER�

Figure 19: Enable passcode screen

3� Enter a numeric passcode from 4 to 8 digits in length, then press ENTER�

4� On the conrmation screen, press ENTER again to conrm the passcode�

OTE:N An asterisk ( * ) appears next to each passcode if it is enabled�

Figure 20: Asterisk indicates enabled passcode

Page 28 March 2019CTL-UM-02038-EN-03

Page 29

Basic Setup

Disabling a Passcode

1� Navigate to SETUP > PASSCODE SETUP�

2� Press UP/DOWN to scroll to the passcode you want to delete, then press

F4 (clear)�

3� On the conrmation screen, press ENTER to conrm removal of the passcode�

Forgotten Passcodes

If you have forgotten your passcode, call Badger Meter customer service and they

will be able to assist you in resetting the passcode�

1� Navigate to System Information from the main menu�

2� Locate and write down the valves shown for "STARTTIME" and "S�N�

(Serial Number)"�

3� Call Badger Meter customer service� See “Troubleshooting” on page 43 for

contact information�

Units

Use the UNITS menu to configure units of measure, display precision (resolution)

and radix (comma or decimal point)� You can configure these settings for each

Parameter Unit: Flow (Rate and Total), Temperature and Energy (Rate and Total)�

1� Navigate to SETUP > UNITS�

2� Press UP/DOWN to scroll through the available parameter units�

3� Scroll to Unit of Measure, Display Precision or Radix, then press ENTER to

activate the drop-down menu for that setting�

Unit of Measure

The Unit of Measure setting determines the engineering unit and/or time interval

for calculated measurements of the selected parameter unit�

1� Press UP/DOWN to scroll through the available units of measure, then press

ENTER to select and save the new setting�

OTE:N For most rate measurements, all options are available in time intervals of

seconds (S), minutes (M), hours (H) and days (D)�

For any of the Flow parameters (Rate or Total), the available units are:

Unit Description Unit Description

US GAL US Gallon M

IG Imperial Gallon AC-FT Acre Feet

MG US Million Gallons BBL Oil Barrels [42 US Gallons]

MIG Imperial Million Gallons FBBL Liquid Barrels [31�5 US Gallons]

L Liters US OZ US Ounces

ML Million Liters I OZ Imperial Ounces

3

FT

Cubic Feet CUST Custom

Table 12: Flow units

3

Cubic Meters

Page 29 March 2019 CTL-UM-02038-EN-03

Page 30

Basic Setup

For Energy Rate the available units are:

Unit Description Unit Description

kBTU/H Thousand BTU per Hour Ton (RT) 12,000 BTU/H

BTU/MIN BTU per Minute J/S Joules per Second

KW Kilowatts CUST Custom

Table 13: Energy rate units

For Energy Total the available units are:

Unit Description Unit Description

BTU British Thermal Unit MWH Megawatt Hour

kBTU 1000 BTU KJ Kilojoule

MMBTU Million BTU TON(RT)-H 12,000 BTU/H Hour

KWH Kilowatt Hour CUST Custom

Table 14: Energy total units

For Temperature the available units are:

Unit Description Unit Description

°F Degrees Fahrenheit °C Degrees Celsius

K Kelvin R Rankine

Table 15: Temperature units

Creating Custom Units for Rate or Total Measurement

1� Follow the procedure outlined in “Unit of Measure” on page 29 to enter the

Unit of Measure menu for a parameter�

2� Press UP/DOWN to choose CUST, then press ENTER�

OTE:N The display populates with additional icons that need to be modified for

custom units�

3� Press F2 (custom label)� Use the soft keys in conjunction with the numeric

keypad and UP/DOWN to create a custom label, then press ENTER�

OTE:N See Table 9 on page 19 and Table 10 on page 20 for button functionality�

4� On the conrmation screen, press ENTER to conrm the new custom unit� The

new label displays in the selection list�

5� Press F3 (conversion) to assign a conversion factor for this custom unit� The

number entered will be a factor related to the specic parameter�

◊ FLOW RATE: GAL/MIN

◊ FLOW TOTAL: GALLONS (GAL)

◊ ENERGY RATE: BTU/MIN

◊ ENERGY TOTAL: BTU

◊ TEMPERATURE: ° F (Fahrenheit)

6� Press ENTER to save the change�

7� On the conrmation screen, press ENTER to conrm the change�

OTE:N For example, if making a custom unit for Energy Rate and 2 is programmed

as a conversion factor, the custom unit is equivalent to 2 BTU/MIN� If 0�5 is

entered, the custom unit is equivalent to 0�5 BTU/MIN�

Page 30 March 2019CTL-UM-02038-EN-03

Page 31

Basic Setup

Display Precision

The Display Precision setting determines the resolution of a value, indicated by the

number of digits after the decimal place, for the selected parameter unit�

1� Press UP/DOWN to scroll to DISPLAY PRECISION, then press ENTER�

2� Scroll through the available options (0…4), then press ENTER to select and

save the change�

Radix

The Radix parameter determines if a period or comma is used to represent a

decimal place for the selected parameter unit�

1� Press UP/DOWN to scroll to RADIX, then press ENTER�

2� Scroll through available options (decimal point or comma), then press ENTER

to select and save the change�

Page 31 March 2019 CTL-UM-02038-EN-03

Page 32

Advanced Setup

ADVANCED SETUP

Use the ADVANCED SETUP menu to configure flow meters, temperature sensors,

outputs, relays and communication�

Conguring a Flow Sensor

Flow Sensor Type

See "Flow Sensor Types" on page 46 for more details on flow type selection for

Badger Meter products� Use this menu to select the flow meter that the device is

connected to�

1� Navigate to SETUP > ADVANCED SETUP > SENSOR INPUTS�

2� Press UP/DOWN to scroll to FLOW SENSOR TYPE, then press ENTER�

3� Scroll through the available sensor types, then press ENTER to select and save

the new settings�

The ow sensor types are shown in Table 16�

Option Description

NO SENSOR/

DISABLED

SINE:

K-FACTOR

PULSE:

K-FACTOR

PULSE:

K-FACTOR

PULLUP

PULSE:

DEBOUNCE

K-FACTOR

PULSE:

DIC

Page 32 March 2019CTL-UM-02038-EN-03

Disables the sensor input in the firmware

• Frequency input channel

◊ Examples: Mag pick-offs, Low level signals (~100 mV)

• Single K-Factor entry

• Pulse input channel

◊ Any pulse producing sensor

◊ Examples: TTL, RF carriers w/ amplifier

• Single K-Factor entry

• Active sensor: No pullup resistor

• Pulse input channel

◊ Any pulse producing sensor

◊ Examples: TTL, RF carriers w/ amplifier

• Single K-Factor entry

◊ Pulses per unit of volume

• Passive sensor: Pullup resistor to 12V for excitation

• Unique to products with raw reed switches

• Pulse input channel

◊ Any pulse producing sensor coupled with a reed switch

◊ Example: Industrial Oval Gear

• Single K-Factor entry

◊ Pulses per unit of volume

• Passive sensor: Pullup resistor to 12V for excitation

• Unique to the Data Industrial (DIC) product line

• Pulse input channel

◊ Any pulse producing sensor

◊ Examples: TTL, RF carriers w/ amplifier

• K & Offset values entered

◊ K = unit of volume per pulse

• Active sensor: No pullup resistor

Table 16: Flow sensor types

Page 33

Advanced Setup

Flow Sensor Calibration

Use this menu to change the calibration settings (K-factor, offset and low flow

cutoff) for the selected Flow Meter Type�

1� Navigate to SETUP > ADVANCED SETUP > SENSOR INPUTS�

2� Press UP/DOWN to scroll to FLOW SENSOR CAL, then press ENTER�

3� Scroll to and edit each option, as necessary� The options include:

Option Description

K-FACTOR A singular K-factor entry point�

OFFSET Used to apply an offset to sensor input calibration

LOW FLOW

CUTOFF

The point at which the display reads zero� Represented in configured unit of measure

Table 17: Flow sensor calibration options

Flow Sensor Properties

Use this menu to change flow meter damping� Damping is a smoothing

coefficient� As the number increases, averaging becomes greater� As the number

decreases, it approaches the raw reading� Valves range from 0…10�

1� Navigate to SETUP > ADVANCED SETUP > SENSOR INPUTS�

2� Press UP/DOWN to scroll to FLOW SENSOR PROP, then press ENTER�

3� Press ENTER to select the DAMPING option and edit it�

OTE:N Each time you press ENTER, the value (0…10) will increase� If the value is

10, pressing ENTER again will restart the list at 0�

Page 33 March 2019 CTL-UM-02038-EN-03

Page 34

Advanced Setup

Conguring a Temperature Sensor

Temperature Sensor Type

Use this menu to select the temperature sensor type the device is connected to�

1� Navigate to SETUP > ADVANCED SETUP > SENSOR INPUTS�

2� Press UP/DOWN to scroll to either temperature sensor, then press ENTER�

OTE:N In most applications, Temperature Sensor 1 is used for the supply line, and

Temperature Sensor 2 is used for the return line�

3� Scroll through the available sensor types, the press ENTER to select and save

the new setting�

The temperature sensor types are shown in Table 18�

OTE:N TCR is the temperature coefficient of resistance�

Option Description

NO SENSOR/DISABLED No sensor� Disables the input in the firmware

2-WIRE RTD: PT100 (385) 2-Wire RTD; 100 Ohm; Platinum; 0�0385 TCR

2-WIRE RTD: CUSTOM 2-Wire RTD; Custom Calibration

3-WIRE RTD: PT100 (385) 3-Wire RTD; 100 Ohm; Platinum; 0�0385 TCR

3-WIRE RTD: CUSTOM 3-Wire RTD; Custom Calibration

4-WIRE RTD: PT100 (385) 4-Wire RTD; 100 Ohm; Platinum; 0�0385 TCR

4-WIRE RTD: CUSTOM 4-Wire RTD; Custom Calibration

4-WIRE RTD: PT1000 (385) 4-Wire RTD; 1000 Ohm; Platinum; 0�0385 TCR

2-PT RTD: CUSTOM Platinum RTD with 2-point calibration

THERMISTOR: DI TYPE Data Industrial thermistor configuration

THERMISTOR: CUSTOM Custom Thermistor

Table 18: Temperature sensor types

Temperature Sensor Calibration

Use this menu to change calibration settings for the respective Temperature

Sensor Type�

OTE:N This menu is only available when a custom temperature sensor type

is selected�

1� Navigate to SETUP > ADVANCED SETUP > SENSOR INPUTS�

2� Press UP/DOWN to scroll to the temperature sensor calibration setting for the

respective temperature sensor type, then press ENTER�

3� Scroll to and edit each option, as necessary�

Page 34 March 2019CTL-UM-02038-EN-03

Page 35

Advanced Setup

The calibration setting options are described below� The settings that appear on

the device are relative to the sensor type and will only show if a sensor type

is chosen�

Temperature

Sensor Type

2, 3 and

4-Wire RTDs

2-PT RTD:

Custom

Thermistor

Option Description

ALPHA COEFF

Callendar-Van Dusen coefficientsBETA COEFF

DELTA COEFF

OHMS: LOW Resistance (Ω) at 0° C / Resistance (Ω) at "TEMP: LOW"

TEMP: LOW Temperature at "OHMS: LOW" (° C)

OHMS: HIGH Resistance (Ω) at temperature "TEMP: HIGH"

TEMP: HIGH Temperature at "OHMS: HIGH" (° C)

OFFSET Temperature calibration offset

COEFF A

Steinhart-Hart coefficientsCOEFF B

COEFF C

Table 19: Temperature sensor calibration descriptions

OTE:N The temperature sensor calibration for Temperature Sensor 2 includes an

adjustment field "TEMP 2 ADJ (° F)"� Changing this setting will increase or

decrease the temperature variance by the value entered, in

degrees Fahrenheit�

Conguring Outputs

Scaled Outputs: Output Mode

Use this menu to change the mode of one or both scaled outputs� The mode

defines the behavior of the output�

1� Navigate to SETUP > ADVANCED SETUP > SCALED OUTPUTS

2� Press UP/DOWN to scroll to an output mode, then press ENTER�

3� Scroll through the available modes, then press ENTER to select and save

the setting�

The Output Mode options will vary based on device conguration�

Device Configuration Option Description

Frequency Output

FC5-BM-**-F***-*

Analog Output

FC5-BM-**-A***-*

NO OUTPUT/DISABLED Disables Output

PULSE: TOTAL Sends pulse(s)-per-total unit of measure

PULSE: RATE Sends pulse(s)-per-rate unit of measure

NO OUTPUT/DISABLED Disables Output

ANALOG: 0…5V

ANALOG: 0…10V

ANALOG: 4…20 mA

Table 20: Output mode options

0…5V output signal, scaled to an

output source

0…10V output signal, scaled to an

output source

4…20 mA output signal, scaled to an output

source

Page 35 March 2019 CTL-UM-02038-EN-03

Page 36

Advanced Setup

Scaled Outputs: Output Settings

Use this menu to change the output settings for the respective output mode�

1� Navigate to SETUP > ADVANCED SETUP > SCALED OUTPUTS�

2� Press UP/DOWN to scroll to the applicable output settings, then press ENTER�

3� Scroll to and edit each option, as necessary�

a� If using the frequency output configuration

Output Mode Option Description

Parameter assignment of the output

(such as rate, total or temperature)

Minimum parameter value associated with

output minimum

Maximum parameter value associated with

output maximum

Maximum frequency output value

Parameter assignment of the output

(such as rate, total or temperature)

(Read Only) Number of transmitted pulses

Table 21: Frequency output settings

PULSE: RATE

PULSE: TOTAL

OUTPUT SOURCE

SCALE MINIMUM

SCALE MAXIMUM

MAXIMUM

FREQUENCY

OUTPUT FREQ (Read Only) Real-time output frequency

OUTPUT SOURCE

SCALING FACTOR Units of measure transmitted, per pulse

SCALED PULSE

COUNT

b� If using the analog output configuration

Option Description

OUTPUT SOURCE

ANALOG FULL SCALE Maximum value associated with output maximum

ANALOG LOW SCALE Minimum value associated with output minimum

Parameter assignment of the output

(such as rate, total or temperature)

Table 22: Analog output settings

Relay Outputs: Relay Mode

Use this menu to change the mode of one or both relay outputs� The mode

defines the behavior of the output�

1� Navigate to SETUP > ADVANCED SETUP > RELAY OUTPUTS.

2� Press UP/DOWN to scroll to an output mode, then press ENTER�

3� Scroll through the available modes, then press ENTER to select and save

the setting�

Option Description

NO RELAY/DISABLED Disables output

TOTALIZER Totalizer output

ALARM: HIGH On/Off function, energized at the high set point

ALARM: LOW On/Off function, energized at the low set point

ALARM: RANGE On/Off function, energized beyond high and low set points

MANUAL On/Off function of manual operation

Table 23: Relay mode options

Page 36 March 2019CTL-UM-02038-EN-03

Page 37

Advanced Setup

Relay Outputs: Relay Settings

Use this menu to change the relay settings for the respective relay mode�

1� Navigate to SETUP > ADVANCED SETUP > RELAY OUTPUTS�

2� Press UP/DOWN to scroll to the applicable relay setting, then press ENTER�

3� Scroll to and edit each option, as necessary�

OTE:N Alarm icons "R1" and "R2" will appear in the upper right section of the

Home Screen to provide a local indication when a relay condition has been

met and when the relay has be energized�

Output Mode Option Description

OUTPUT SOURCE Parameter assignment (e�g� Flow Total or Energy Total)

TOTALIZER

ALARM: HIGH

ALARM: LOW

SCALING FACTOR Pulse(s) transmitted per unit of measure

UNITS Converts output unit of measure

PULSE WIDTH Time between the rising and falling edges of a single pulse

OUTPUT SOURCE Parameter assignment (such as Flow Rate or Temperature)

HIGH SETPOINT

HYSTERESIS HI

SET DELAY

RELEASE DELAY

LATCHING

OUTPUT SOURCE Parameter assignment (such as Flow Rate or Temperature)

LOW SETPOINT

HYSTERESIS LO

SET DELAY

RELEASE DELAY

LATCHING

Instructs the device to energize the relay if this value reached/

exceeded� This value is linked to the OUTPUT SOURCE and its unit

of measure (for example, Flow Rate in GPM)

Creates a window/zone below the HIGH SETPOINT value where

the relay remains in an energized state

Time in seconds that will elapse before the relay energizes, if the

HIGH SETPOINT value is reached/exceeded

Time in seconds that the relay will remain energized, if the

HYSTERESIS HI value is reached/exceeded

Leaves the relay in an energized state until it is manually cleared

on the device, either through the keypad interface or through

the Digital I/O channels

Instructs the device to energize the relay if this value reached/

exceeded� This value is linked to the OUTPUT SOURCE and its unit

of measure (for example, Flow Rate in GPM)

Creates a window/zone above the LOW SETPOINT value where

the relay remains in an energized state

Time in seconds that will elapse before the relay energizes, if the

LOW SETPOINT value is reached/exceeded

Time in seconds that the relay will remain energized, if the

HYSTERESIS LO value is reached/exceeded

Leaves relay in an energized state until it is manually cleared on

the device, either through the keypad interface or through the

Digital I/O channels

Page 37 March 2019 CTL-UM-02038-EN-03

Page 38

Advanced Setup

Output Mode Option Description

OUTPUT SOURCE Parameter assignment (such as Flow Rate or Temperature)

HIGH SETPOINT

HYSTERESIS HI

LOW SETPOINT

ALARM: RANGE

HYSTERESIS LO

SET DELAY

RELEASE DELAY

LATCHING

MANUAL OVERRIDE

Instructs the device to energize the relay if this value reached/

exceeded� This value is linked to the OUTPUT SOURCE and its unit

of measure (for example, Flow Rate in GPM)

Creates a window/zone below the HIGH SETPOINT value, where

the relay remains in an energized state

Instructs the device to energize the relay if this value reached/

exceeded� This value is linked to the OUTPUT SOURCE and its unit

of measure (for example, Flow Rate in GPM)

Creates a window/zone above the LOW SETPOINT value, where

the relay remains in an energized state

Time in seconds that will elapse before the relay energizes, if

either setpoint value is reached/exceeded

Time in seconds that the relay will remain energized, if either

hysteresis value is reached/exceeded

Leaves relay in an energized state until it is manually cleared on

the device, either through the keypad interface or through the

Digital I/O channels

Bypasses any programmed triggers to trigger the relay, which

will remain triggered until deactivated

Table 24: Relay settings

Page 38 March 2019CTL-UM-02038-EN-03

Page 39

Advanced Setup

Conguring Digital I/O

The FC-5000 BTU Monitor has remote reset capabilities for relays and totalizers

through any one of six different channels�

All six channels are input-only and can be configured for any combination of

the following�

Option Description

DISABLED The I/O channel will have no function

RESET: RELAY 1 Resets latch on Relay 1

RESET: RELAY 2 Resets latch on Relay 2

RESET: ALL RELAYS Resets latches on Relays 1 and 2

RESET: FLOW TOTAL Resets Flow Total

RESET: ENERGY TOTAL Resets Energy Total

RESET: RELAY 1 AND FLOW TOTAL Resets latch on Relay 1 and resets Flow Total

RESET: RELAY 2 AND FLOW TOTAL Resets latch on Relay 2 and resets Flow Total

RESET: RELAY 1 AND ENERGY TOTAL Resets latch on Relay 1 and resets Energy Total

RESET: RELAY 2 AND ENERGY TOTAL Resets latch on Relay 2 and resets Energy Total

RESET: FLOW/ENERGY TOTALS Resets Flow Total and Energy Total

RESET: ALL RELAYS AND ALL TOTALS Resets Relay 1, Relay 2, Flow Total and Energy Total

Table 25: Channel options

Figure 21: Digital I/O menu

1� Navigate to SETUP > ADVANCED SETUP > DIGITAL I/O�

2� Press UP/DOWN to scroll to any of the six input channels�

3� Press ENTER repeatedly until the desired function appears� Each time ENTER is

pressed, the channel toggles through the available functions�

To disable any channel, simply highlight the digital I/O channel, and press ENTER

until DISABLED appears�

Page 39 March 2019 CTL-UM-02038-EN-03

Page 40

Advanced Setup

Conguring Fluid Properties

The Fluid Properties menu configures the device for the fluid medium that is

being measured�

Figure 22: Fluid properties menu

Fluid ID

Use this menu to enter a user-defined text entry for naming or identification�

1� Navigate to SETUP > ADVANCED SETUP > FLUID PROPERTIES�

2� Press UP/DOWN to select FLUID ID, then press ENTER�

3� Use the soft keys and numeric keypad to enter the desired name, then press

ENTER to save�

4� On the conrmation screen, press ENTER to conrm any changes�

Heat Transfer Fluid

Use this menu to select from a list of pre-programmed fluid types� A custom

option is available�

1� Navigate to SETUP > ADVANCED SETUP > FLUID PROPERTIES�

2� Press UP/DOWN to select HEAT TRANSFER FLUID, then press ENTER�

3� Scroll through the available options, then press ENTER to save the change�

Option Description

WATER Water only�

20% PROPYLENE GLYCOL 20% Propylene Glycol / 80% water mixture

30% PROPYLENE GLYCOL 30% Propylene Glycol / 70% water mixture

50% PROPYLENE GLYCOL 50% Propylene Glycol / 50% water mixture

CUSTOM FLUID Custom fluid (requires additional settings)

Table 26: Heat Transfer Fluid options

Page 40 March 2019CTL-UM-02038-EN-03

Page 41

Advanced Setup

Creating a Custom Heat Transfer Fluid

If CUSTOM FLUID is selected, the polynomials for Specific Heat and Density must

be programmed� These settings will not appear unless CUSTOM FLUID is selected

as a fluid type�

1� Navigate to SETUP > ADVANCED SETUP > FLUID PROPERTIES�

2� Press UP/DOWN to scroll to SP HEAT POLY or DENSITY POLY, then press ENTER�

3� Scroll to and edit each selection, as necessary�

The options include:

Polynomial Curve Option Description

C3

Specific Heat

SP POLY (BTU/LB F)

Density

DENSITY POLY (LB/GAL)

C2

C1

C0

B3

B2

B1

B0

Table 27: Custom fluid options

Polynomial curve coefficients for

specific heat

Polynomial curve coefficients for

density

4� Make sure the settings for both specic heat and density are programmed

The polynomial equations for specific heat and density are as follows:

• SP HT = (C3)x3 + (C2)x2 + C1)x + (C0)

• DENSITY = (B3)x3 + (B2)x2 + (B1)x + (B0)

Where "x" is the inlet temperature value (TEMPERATURE1 or TEMP1)�

Conguring Communications

The Communications menu configures the device to communicate to other

systems via Modbus or BACnet�

The available communication settings vary based on Network Type�

Figure 23: Modbus communications menu Figure 24: BACnet communications menu

1� Navigate to SETUP > ADVANCED SETUP > COMMUNICATIONS�

2� Press UP/DOWN to scroll to NETWORK TYPE, then press ENTER�

3� Scroll through the available options, then press ENTER to select save

the change�

Page 41 March 2019 CTL-UM-02038-EN-03

Page 42

Advanced Setup

4� Press BACKSPACE to return to the COMMUNICATIONS menu�

5� Scroll to and edit each option, as necessary� The options are:

Modbus RTU and Modbus ASCII

Settings Options

BAUD RATE 1200, 2400, 4800, 9600, 14400, 19200, 28800, 34800, 57600 or 115200

PARITY No Parity, Odd Parity or Even Parity

STOP BIT No Stop Bit, One or Two Stop Bit

SLAVE ADDRESS 1…255

DEVICE NAME User-defined ID

Table 28: Modbus settings

BACnet

Settings Options

BAUD RATE 1200, 2400, 4800, 9600, 14400, 19200, 28800, 34800, 57600 or 115200

MSTP ADDRESS

MAX MASTER

DEVICE INSTANCE 1…4,294,967,295

DEVICE NAME User-defined ID

1…255

Table 29: BACnet settings

Page 42 March 2019CTL-UM-02038-EN-03

Page 43

Troubleshooting

TROUBLESHOOTING

This section lists common problems that may be encountered with the BTU

Monitor, the possible causes and the recommended remedies� Most problems are

due to improper wiring and/or programming procedures� The problem may also

be in the flow meter, valve, pump or other piece of equipment�

Be sure that all other equipment is functioning properly� The FC-5000 BTU Monitor

is extensively tested at the factory before shipment� However, the unit may get

damaged during transit or installation� If after all possible remedies have been

tried and the problem persists, contact your local representative or Badger Meter�

Problem Possible Causes Remedies

Unit has power

but display does

not light up

Transmitter is

connected but

the FC-5000

does not count

Valve does

not close at

setpoints

Counter

accumulates too

many counts

Some of the

keys on the

control panel are

not operational

DISPLAY

OVERRUN error

1� Incorrect power wiring 1� Re-check power wiring

1� Incorrect transmitter wiring or

broken wire

2� Transmitter is defective

3� No sensory type selected

4� Wrong scale factor

5� Low frequency input must be

on terminal #7

6� Meter is defective, rotor

not turning

1� Relay output is not

properly connected

2� Relay is defective

3� Valve components are defective

1� Wrong scale factor

2� Electrical noise causing extra

pulses�

3� Excessive vibration�

1� Broken switch behind

control panel

2� Function not available on

this model

3� Problem with internal

components

1� There are more than 8 digits in

the display

1� Check wiring diagrams

2� Replace parts or entire unit

3� Select a sensor type� See “Flow Sensor

Type” on page 32

4� Check scale factor calculation� For

example, if programmed 0�001 instead of

0�100, unit will wait for 100 pulses before

decrementing one count

5� Verify connection

6� Disassemble meter, check rotor, replace

if defective

1� Reconnect relay wiring

2� Contact factory for replacement

3� Check and replace valve components�

1� Check scale factor calculation

2� Check wiring� Make sure power lines are

not touching or close to pulse signal line�

Always use shielded cable

3� Dampen vibration

1� Replace the BTU Monitor

2� See “Operator Interface” on page 19

3� Return the BTU Monitor to the factory

for repair

4� Cycle the power to the BTU Monitor

1� Check that the unit of measure you

entered will not result in a readout

greater than 8 digits

2� Check the display precision and reduce

it, if possible

Page 43 March 2019 CTL-UM-02038-EN-03

Page 44

Troubleshooting

Problem Possible Causes Remedies

Alarm

notification from

the Home screen

"R1" and/or "R2"

appear on home

screen

"TSENSERR"

displayed on

home screen

"DISABLED"

displays on

home screen

1� The rate or total values

indicated on the Home Screen

are in an overrun condition

(value exceeds 8 digits)

2� There is a negative value

associated with Energy Rate,

where T1>T2

3� Temperature sensor 1 and/or

2 is congured in the unit, but

there is no sensor

hardware detected

1� Relay 1 and/or Relay 2

are latched

2� Relay 1 and/or 2 are energized

1� Temperature sensors

not congured

2� Temperature sensor

disconnected

1� Flow sensor type setting set to

"NO SENSOR/DISABLED"

Table 30: Troubleshooting

1� Change the unit of measure associated

with the parameter (see “Unit of Measure”

on page 29) or reset the totalizer (see

“Resets” on page 27)

2� Rewire the temperature sensors on the

unit or swap sensors in the application

3� Make sure that the temperature sensors

are appropriately wired to the unit

1� See “Clearing a Latched Relay” on

page 28

2� The programmed alarm conditions are

met� Check process or programming

1� Congure temperature sensor� See

“Configuring a Temperature Sensor” on

page 34

2� Check wiring to TB6

1� Congure a ow sensor� See “Configuring

a Flow Sensor” on page 32

THERE ARE NO FIELDREPLACEABLE PARTS INSIDE. OPENING THE UNIT WILL VOID ALL

WARRANTIES.

If a repair or evaluation from the factory is required, call your local representative

or the factory to obtain a Return Material Approval (RMA)�

The shipping address, RMA number and any other required information will be

provided to send the unit to an appropriate location�

Company Website www�badgermeter�com

Customer Service Email indorders@badgermeter�com

Customer Service Number (877) 243–1010

Table 31: Contact information

Page 44 March 2019CTL-UM-02038-EN-03

Page 45

Modbus Interface

MODBUS INTERFACE

Modbus Function Code Support

The FC-5000 BTU Monitor supports access through all four of the Modbus data

types� Both single and multiple write-access commands are supported for register

and coil data types� For multiple register writes, the command must initiate on

a valid parameter address and end on last register of a valid parameter address�

Multiple register writes that start in the middle of a multiple register parameter or

do not end on the last register of a multiple register parameter are not supported�

The table below lists the supported function codes�

Description Function Code Subcode

Read Coils 01 —

Read Discrete Inputs 02 —

Read Holding Registers 03 —

Read Input Registers 04 —

Write Single Coil 05 —

Write Single Register 06 —

Diagnostic – Return Query Data 08 00

Write Multiple Coils 15 —

Write Multiple Registers 16 —

Report Slave ID 17 —

Table 32: Supported Modbus function codes

Modbus Register Map

Register Name

FLOW RATE 0×0000 — Float Read Only Register

FLOW TOTAL 0×0002 — Float Read Only Register

FLOW TOTAL PRECISION 0×0004 — Double Read Only Register

ENERGY RATE 0×0100 — Float Read Only Register

ENERGY TOTAL 0×0102 — Float Read Only Register

ENERGY TOTAL PRECISION 0×0104 — Double Read Only Register

TEMPERATURE 1 0×0200 — Float Read Only Register

TEMPERATURE 2 0×0202 — Float Read Only Register

FLUID DENSITY 0×0400 — Float Read Only Register

SPECIFIC HEAT 0×0402 — Float Read Only Register

Register

Address

Table 33: Modbus register map

Coil

Addr.

Data Type Read/Write Access Type

Page 45 March 2019 CTL-UM-02038-EN-03

Page 46

BACnet Interface

BACNET INTERFACE

BACnet Map

Object Description BACnet Object ID BACnet Object Type

FLOW RATE 2 Analog Value

FLOW TOTAL 3 Analog Value

FLOW TOTAL PRECISION 4 Large Analog Value

ENERGY RATE 11 Analog Value

ENERGY TOTAL 12 Analog Value

ENERGY TOTAL PRECISION 13 Large Analog Value

TEMPERATURE 1 14 Analog Value

TEMPERATURE 2 15 Analog Value

FLUID DENSITY 16 Analog Value

SPECIFIC HEAT 17 Analog Value

Table 34: BACnet register map

FLOW SENSOR TYPES

The table below lists the Badger Meter products suitable for use with the

FC-5000 BTU Monitor�

Meter Technology Product Line Output Type Flow Sensor Input

Impeller Impeller

Oval Gear Oval Gear Reed Switch Pulse PULSE: DEBOUNCE K-FACTOR

OP Meters

Positive Displacement

Recordall

Blancett

Cox

Turbine

Turbo

Flo-tech

Vision Frequency PULSE: K-FACTOR PULLUP

Square Wave

Frequency

Unscaled Pulse PULSE: DEBOUNCE K-FACTOR

Scaled Pulse PULSE: DEBOUNCE K-FACTOR

Unscaled Pulse PULSE: DEBOUNCE K-FACTOR

Scaled Pulse PULSE: DEBOUNCE K-FACTOR

MAG Pickup SINE: K-FACTOR

MAG Pickup with

K-Factor Scaler

MAG Pickup SINE: K-FACTOR

MAG Pickup with

K-Factor Scaler

RF Pickup PULSE: K-FACTOR

Unscaled Pulse PULSE: DEBOUNCE K-FACTOR

Scaled Pulse PULSE: DEBOUNCE K-FACTOR

MAG Pickup SINE: K-FACTOR

MAG Pickup with

K-Factor Scaler

Table 35: Badger Meter flow sensors

PULSE: DIC

PULSE: K-FACTOR

PULSE: K-FACTOR

PULSE: K-FACTOR

Page 46 March 2019CTL-UM-02038-EN-03

Page 47

PART NUMBERING CONSTRUCTION

Part Numbering Construction

Badger Meter

FC5-BM-P1

-

6 A

FC-5000 BTU Monitor

FUNCTION

BTU Monitor BM

SENSOR INPUTS

One Pulse / Two Temperature P1

SCALED OUTPUTS

Two Analog Outputs A

Two Frequency Outputs F

RELAY OUTPUTS

One Form C Relay / One Form A Relay A

Two Form C Relays C

DIGITAL INPUTS/OUTPUTS

Six Programable Inputs/Outputs 6

COMMUNICATIONS

EIA-485(RS-485); Modbus; BACnet; USB A

MOUNTING METHOD

Panel Mount P

Wall Mount | Includes NEMA 4X (IP67) Rated Enclosure W

REPLACEMENT PARTS/ACCESSORIES

Part Number Description

68334-001 P/S Plug; 100-264V AC ln; 24V DC out

68334-002 P/S Module; 85-264V AC ln; 24V DC out

809041 Panel mounting clips (2)

68788-001 Wall-mount enclosure kit

68231-002 Terminal connector kit

Consult factory for other parts/accessories�

-

Page 47 March 2019 CTL-UM-02038-EN-03

Page 48

Specications

SPECIFICATIONS

Input range: 10…40V DC and 9…28V AC RMS (50…60 Hz)

Maximum power consumption: 8 Watts

Power Supply

Flow Meter Input

Temperature

Inputs

Scaled Outputs

Digital I/O

(power supply must provide 8 watts at minimum)

Isolated from power ground

Over-voltage, transient and reverse polarity protected

Input Range: 0�3 Hz…10 kHz

One (1) independent channel

Configurable as square wave 0…30V pulse with 2�5V threshold

Configurable as sine wave, zero-centered with 200 mV amplitude and 45 mV

threshold

Configurable debounce

Excitation Output 12V DC source

Voltage

Impedance Pullup to 12V DC

VDC Current ±50 mA, short circuit current

Response 100 µs/3�5 ms min pulse (high/low speed)

Two (2) independent channels

RTD Specifications

Thermistor Specifications

Two (2) independent channels

Isolated from power ground

Over-voltage, transient and reverse polarity protected

Output is multiplexed on the process out pins

Analog Output

(option A)

Frequency Output

(option F)

Six (6) independent channels

Isolated from power ground

Over-voltage, transient and reverse polarity protected

0…30V as input

Debounce

0…5V, TTL, 200 ms 90-10% step response, driving < 0�1 uF

Low: –0�3…1�85V DC

High: 2�5…25V DC

50 µA/1000 µA Excitation current source

Platinum, 100 and 1000 Ohm

2, 3 and 4-wire

compatible

Callendar-Van Dusen coefficients

Type II Thermistors or customizable calibration

configuration

Steinhart-Hart coefficients

Configurable to 0…5V, 0…10V or 4…20 mA

Uncertainty: ±0�1% of reading

16-bit resolution (0…10V and 4…20 mA), 15-bit

resolution (0…5V)

200 ms, 90-10% step response

Sourcing analog output signal

TTL, 1…4000 Hz, square wave

Uncertainty: ±0�01% reading

Resolution: 0�01 Hz

RTDs

Optional two-point or

customizable

calibration configuration

Page 48 March 2019CTL-UM-02038-EN-03

Page 49

Specications

Calculations

Relay Outputs

Network

Communications

USB

Communications

Display/User

interface

Environmental

Ratings

Weights (Approx.)

Operator

Functions

Flow Calculation

BTU Calculation Meets EN 1434 requirements

Configuration Option "C" Two (2) Form C Mechanical Relays

Configuration Option "A"

Isolated coil drivers

Over-voltage, transient and reverse polarity protected

Load Resistive

Rated Carry Current 5 A (N�C� or N�O�)

Form C Relay

Form A Relay

(N�O� SPST)

Network Types/

Communication Protocols

Physical Layer EIA-485 (RS-485)

Baud Rates 1200…115�2K

4-wire interface/half duplex

Over-voltage/ESD Protection

Isolated from power ground

USB (HOST) Type-A Receptacle | Currently not supported

USB (DEVICE) Mini-B Receptacle (used for field updates)

Over-voltage/ESD/transient protected

Keypad

Display 128 × 64 pixel LCD graphical display, LED backlit

Protected from EMI/RFI

Keypad interface is protected from ESD

Pollution Degree 2

Altitude Restriction Up to 2000 m (6561 ft)

Over-Voltage Rating Category II (CAT II)

Ambient Temperature Range 32…130° F (0…55° C)

Storage Temperature Range –40…160° F (–40…70° C)

Humidity 0…85%, non-condensing

Panel Mount 1�25 lb (0�57 kg)

Wall Mount (Including Unit) 4�54 lb (2�06 kg)

Unlatch Relays, Reset Totalizers, Unlatch Relays and Reset Totalizers

Maximum Switching Voltage 250V AC, 30V DC

Minimum Permissible Load 10 mA at 5V DC

Coil Rating 5…24V DC

Life Expectancy 5,000,000 operations

Switching Speed On (0�25 ms), Off (0�02 ms)

Current Rating (IO) 1 A

Maximum Output

Voltage (VO)

Output On-Resistance

(R(ON))

Output Withstand

Voltage (VO(OFF))

Uncertainty: ± 0�01%

Adjustable FIR/IIR filtering

One (1) Form C Mechanical Relay and

One (1) Form A Solid State Relay

60V

0�5 Ohms (Ω) @ IF = 5 mA, IO

= 1 A

60-65V @ VF = 0�8V, IO = 250

µA, TA = 77° F (25° C)

Modbus RTU, Modbus ASCII and BACnet

Membrane overlay, domed tactile response

keys

Page 49 March 2019 CTL-UM-02038-EN-03

Page 50

Specications

Parameters

Maximum Displayed Digits

Resolution/Display Precision Configurable, 0…4

Volumetric Flow Rate Units

Seconds (S), Minute (MIN),

Hour (H), Day (D)

Volumetric Flow Total Units

Energy Units

Temperature Units

Rates Max 8 (7 with decimal)

Totals Max 9 (8 with decimal)

US Gallons (US GAL), Imperial Gallons (I GAL),

Mega US Gallons (US MGAL), Mega Imperial

Gallons (I MGAL), Liters (L), Mega Liters (ML),

Cubic Meters (M3), Cubic Feet (FT3), Acre Feet

(AC-FT), Oil Barrels (OBBL), Liquid Barrels (LBBL),

US Ounces (US OZ), Imperial Ounces (I OZ),

Custom (user-specified)

kBTU, BTU, KW, TONS (RT),

Custom (user-defined)

° F (Fahrenheit), ° C (Celsius), R (Rankine) or K

(Kelvin)

Page 50 March 2019CTL-UM-02038-EN-03

Page 51

Standards and Certications

STANDARDS AND CERTIFICATIONS

Agency Approval/Standards

• CE Marked for Low Voltage Directive and RoHS

• CSA Marked per Class C225286 and C225206, Process Control Equipment

• CSA C22�2 No� 61010-1-12, General requirements

• CAN/CSA-C22�2 No� 61010-1-12 Safety requirements for electrical equipment

for measurement, control and laboratory use� Part 1: General requirements—

Tri-national standard with UL 61010-1 and ANSI/ISA-61010-1 (82�02�01)

EMI/EMC Compliance

Conducted and Radiated Emissions per