Page 1

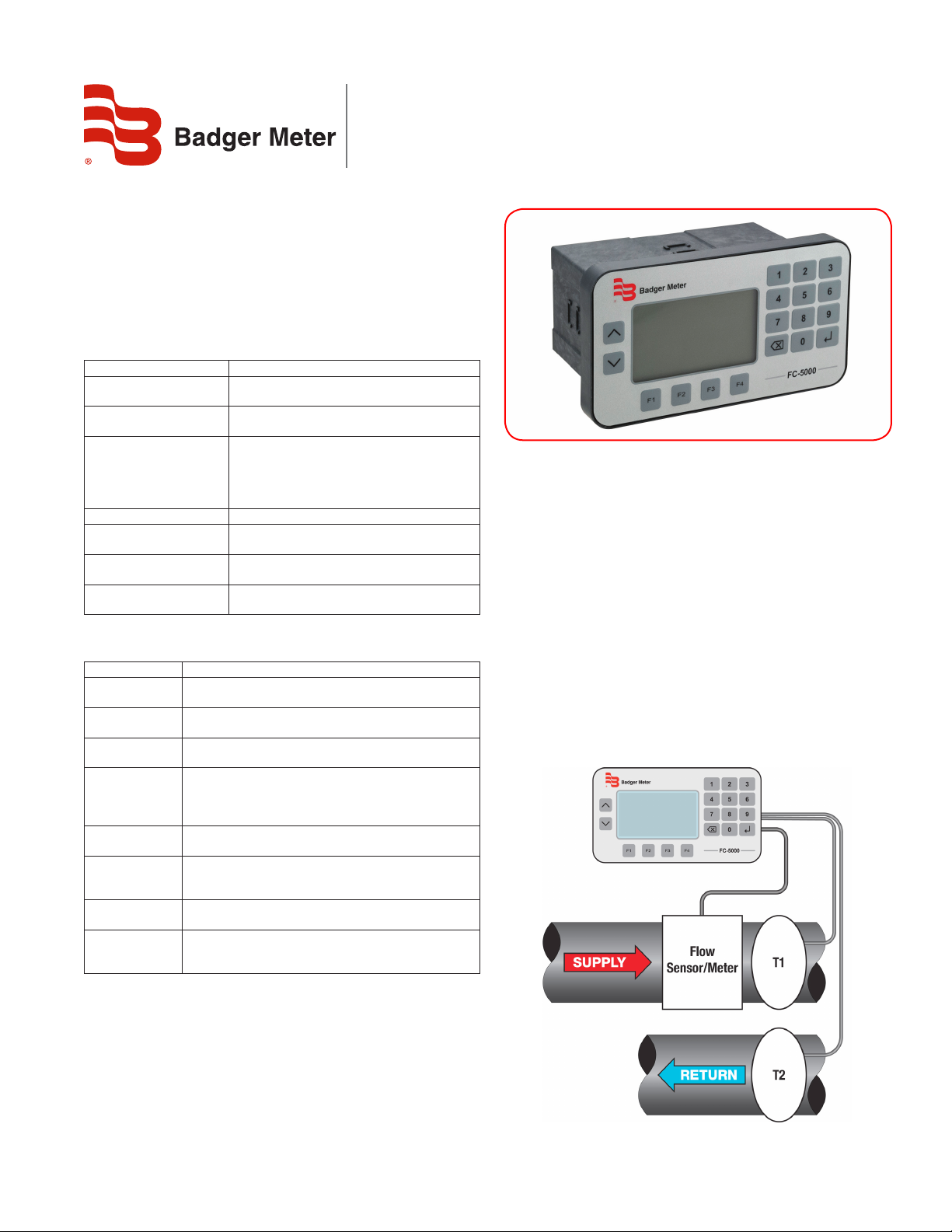

Industrial Flow Computer

FC-5000 BTU Monitor

DESCRIPTION

The Badger Meter® FC-5000 is a microprocessor-driven device

designed for energy/BTU and flow monitoring. The FC-5000 BTU

Monitor is compatible with the complete line of Badger Meter

industrial flow meters and temperature sensors, creating a solution

to monitor hydronic energy usage, flow rate and totals. Many years

of experience in the industrial market has allowed Badger Meter to

incorporate features indispensable in control operations.

Features Benefits

Large, backlit

graphical display

Integrated softkeys and

full numerical keypad

Sensor data display screen

Plug-and-play terminals Provides easier, user-friendly installation

User-programmable

relay configuration

User-programmable

scaled outputs

Robust enclosure, keypad

and mechanical relays

PROGRAMMABILITY

Features Programming Options

Fluid Properties

Digital I/O

Scaled Outputs

Relay Outputs

Display

Properties

Stored or

Custom Units of

Measure

Passcodes

Sensor Inputs

Provides enhanced viewing capabilities, near

and far from the device

Promotes intuitive navigation

and programming

Allows user to view raw and calculated flow

data, both to and from the device, including

flow data, energy usage and temperature

readings. Additionally, users can see relay,

output and digital I/O statuses

Enables alarms or totalizing output capabilities

for rates, totals and temperatures

Outputs transmit rate, total or temperature

data via dedicated output channels

Provides application ruggedness

Custom fluid characteristics can be stored for

calculations and reference.

Ability to reset relays, totals or both remotely via the 6

available I/O ports.

Fully configurable outputs that can be assigned to rates,

totals and temperature.

Fully configurable relays that can be assigned to rates,

totals and temperature as either a totalizing output or

alarm indication. Option to enable/disable

latching functionality.

Adjustable contrast and brightness for readability and

controlling power consumption.

Ability to select from a list of standardized units of

measure, or complete the customized option with labels

and quantity assignments.

User-defined passcodes to manage advanced

configuration parameters and reset functions.

Provides accurate and fast programming of flow and

temperature sensors with preprogrammed

selection lists.

OPERATION

Input signal—in the form of sine waves or pulses from open

collector transistors or dry contact closures—can be scaled to

any unit of measure for totalization and instantaneous

rate-of-flow indication. Energy rate and flow totals are examples

of parameters that can be viewed on the panel display or through

communications protocols such as BACnet or Modbus.

Two temperature sensor inputs can be configured to read RTDs

or thermistors and are fully customizable to adapt to application

needs. When used in conjunction with fluid flow, hydronic energy

rates and total usage are achieved, while conforming to

EN1434 standards.

Additionally, dedicated analog or frequency output channels

provide scaled outputs that are assignable to parameters such

as energy rate, total and temperature. A user defined damping

function can be applied for improved stability of the flow readings.

CTL-DS-02610-EN-02 (April 2019)

Product Data Sheet

Page 2

Industrial Flow Computer, FC-5000 BTU Monitor

FLEXIBILITY

• Non-volatile memory preserves all configured settings and

totalization values during power failure

• Low voltage AC/DC power

• Dynamic menu selection and programming reduces potential

programming errors

• Ability to restore to factory programmed settings

VIEWING CAPABILITIES

Quickly toggle views on the Home screen to switch between:

• Flow Rate

• Flow Total

• Energy/BTU Rate

• Energy/BTU Total

Figure 1: Single display

• Flow Rate and Flow Total

• Energy/BTU Rate and

Energy/BTU Total

ACCESSORIES

RTDs

Part No. Description

8RTD100 Replacement RTD Element

8RTD106B 1/4 in. NPT; BR; ADJ Depth; 6 in. Leads

8RTD116B 3/4 in. NPT; BR TW; 1-5/8 in. Depth; 1/2 in. Conduit Conn.

8RTD116S 3/4 in. NPT; SS TW; 1-5/8 in. Depth; 1/2 in. Conduit Conn.

8RTD125 3/4 in. NPT; SS TW; 2-1/2 in. Depth; 1/2 in. Conduit Conn.

8RTD140 3/4 in. NPT; SS TW; 4 in. Depth; 1/2 in. Conduit Conn.

8RTD160 3/4 in. NPT; SS TW; 6 in. Depth; 1/2 in. Conduit Conn.

Table 1: RTD part numbers

Thermistors

Part No. Description

8T106B 1/4 in. NPT; BR Thermistor; ADJ Depth

8T106S 1/4 in. NPT; SS Thermistor; ADJ Depth

8T116B 3/4 in. NPT; BR Thermowell; 1-5/8 in. Depth

8T116S 3/4 in. NPT; SS Thermowell; 1-5/8 in. Depth

8T125 3/4 in. NPT; SS Thermowell; 2-1/2 in. Depth

8T140 3/4 in. NPT; SS Thermowell; 4 in. Depth

8T160 3/4 in. NPT; SS Thermowell; 6 in. Depth

8T180 3/4 in. NPT; SS Thermowell; 8 in. Depth

67002 Replacement Thermistor Element

Table 2: Thermistor part numbers

Consult the factory or your local representative for availability,

pricing and delivery estimates for additional parts and accessories.

Figure 2: Dual display

EIA485 RS485 NETWORK

All FC-5000 BTU Monitors come equipped with an EIA-485 (RS-485) physical layer, and use BACnet or Modbus RTU protocols, selectable and

programmed in the firmware. Up to 255 FC-5000 products can be run on a single daisy-chain network and be individually queried for flow/

energy rate, positive flow/energy accumulator, supply temperature, return temperature and other information.

Figure 3: Daisy-chained units

Page 2 April 2019

CTL-DS-02610-EN-02

Page 3

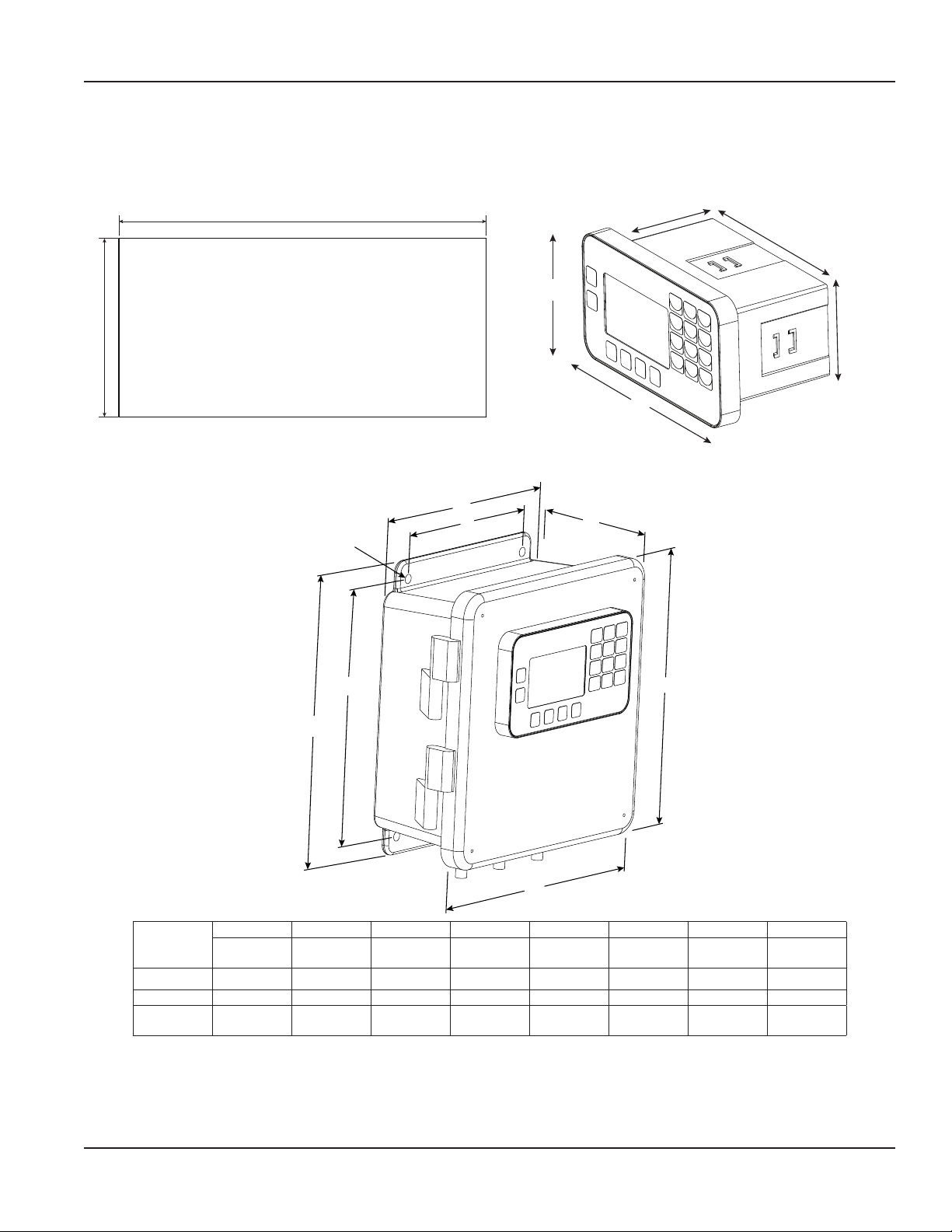

DIMENSIONS

Panel Mount Unit

Mounting clips can accommodate a maximum panel thickness of 1.5 in (38.1 mm).

Product Data Sheet

A

Wall Mount Unit

B

Panel Cutout

H

C

D

A

E

B

D

F

C

G

E

B

A

A B C D E F G H

Height

in. (mm)

Width

in. (mm)

Depth

in. (mm)

Width

in. (mm)

Height

in. (mm)

Width

in. (mm)

Height

in. (mm)

Hole Dia.

in. (mm)

Panel Cutout 2.65 (67.31) 5.40 (137.16) — — — — — —

FC-5000 Unit 3.50 (89.00) 6.22 (158.00) 3.07 (78.00) 5.38 (136.65) 2.54 (64.52) — — —

Wall Mount

Unit

9.38 (238.25) 9.38 (238.25) 4.88 (123.95) 8.00 (203.20) 9.56 (242.83) 6.00 (152.40) 8.75 (222.25) 0.31 (7.87)

CTL-DS-02610-EN-02

Page 3 April 2019

Page 4

Industrial Flow Computer, FC-5000 BTU Monitor

SPECIFICATIONS

Input range: 10…40V DC and 9…28V AC RMS (50…60 Hz)

Power Supply

Flow Meter Input

Temperature Inputs

Scaled Outputs

Digital I/O

Calculations

Maximum power consumption: 8 Watts (power supply must provide 8 watts at minimum)

Isolated from power ground

Over-voltage, transient and reverse polarity protected

Input Range: 0.3 Hz…10 kHz

One (1) independent channel

Configurable as square wave 0…30V pulse with 2.5V threshold

Configurable as sine wave, zero-centered with 45 mV threshold

Configurable debounce

Excitation Output 12V DC source

Voltage

Impedance Pullup to 12V DC

VDC Current ±50 mA, short circuit current

Response 100 µs/3.5 ms min pulse (high/low speed)

Two (2) independent channels

RTD Specifications

Thermistor Specifications

Two (2) independent channels

Isolated from power ground

Over-voltage, transient and reverse polarity protected

Output is multiplexed on the process out pins

Analog Output (option A)

Frequency Output (option F)

Six (6) independent channels

Isolated from power ground

Over-voltage, transient and reverse polarity protected

0…30V as input

Debounce

0…5V, TTL, 200 ms 90-10% step response, driving < 0.1 uF

Flow Calculation

BTU Calculation Meets EN 1434 requirements

Low: –0.3…1.85V DC

High: 2.5…25V DC

50 µA/1000 µA Excitation current source

2, 3 and 4-wire

compatible

Callendar-Van Dusen coefficients

Type II Thermistors or customizable calibration configuration

Steinhart-Hart coefficients

Configurable to 0…5V, 0…10V or 4…20 mA

Uncertainty: ±0.1% of reading

16-bit resolution (0…10V and 4…20 mA), 15-bit resolution (0…5V)

200 ms, 90-10% step response

Sourcing analog output signal

TTL, 1…4000 Hz, square wave

Uncertainty: ±0.01% reading

Resolution: 0.01 Hz

Uncertainty: ± 0.01%

Adjustable FIR/IIR filtering

Platinum, 100 and 1000 Ohm RTDs

Optional two-point or customizable

calibration configuration

Page 4 April 2019

CTL-DS-02610-EN-02

Page 5

Configuration Option "C" Two (2) Form C Mechanical Relays

Configuration Option "A" One (1) Form C Mechanical Relay and One (1) Form A Solid State Relay

Isolated coil drivers

Over-voltage, transient and reverse polarity protected

Load Resistive

Rated Carry Current 5 A (N.C. or N.O.)

Maximum Switching Voltage 250V AC, 30V DC

Minimum Permissible Load 10 mA at 5V DC

Relay Outputs

Form C Relay

Coil Rating 5…24V DC

Life Expectancy 5,000,000 operations

Switching Speed On (0.25 ms), Off (0.02 ms)

Current Rating (IO) 1 A

Form A Relay

(N.O. SPST)

Network Types/Communication

Protocols

Maximum Output Voltage (VO) 60V

Output On-Resistance (R

Output Withstand Voltage (V

) 0.5 Ohms (Ω) @ IF = 5 mA, IO = 1 A

(ON)

) 60-65V @ VF = 0.8V, IO = 250 µA, TA = 77° F (25° C)

O(OFF)

Modbus RTU, Modbus ASCII and BACnet

Physical Layer EIA-485 (RS-485)

Network Communications

Baud Rates 1200…115.2K

4-wire interface/half duplex

Over-voltage/ESD Protection

Isolated from power ground

USB (HOST) Type-A Receptacle | Currently not supported

USB Communications

USB (DEVICE) Mini-B Receptacle (used for field updates)

Over-voltage/ESD/transient protected

Keypad Membrane overlay, domed tactile response keys

Display/User interface

Display 128 × 64 pixel LCD graphical display, LED backlit

Protected from EMI/RFI

Keypad interface is protected from ESD

Pollution Degree 2

Altitude Restriction Up to 2000 m (6561 ft)

Environmental Ratings

Over-Voltage Rating Category II (CAT II)

Ambient Temperature Range 32…130° F (0…55° C)

Storage Temperature Range –40…160° F (–40…70° C)

Humidity 0…85%, non-condensing

Weights (Approx.)

Panel Mount 1.25 lb (0.57 kg)

Wall Mount (Including Unit) 4.54 lb (2.06 kg)

Operator Functions Unlatch Relays, Reset Totalizers, Unlatch Relays and Reset Totalizers

Maximum Displayed Digits

Rates: Max 8 (7 with decimal)

Totals: Max 9 (8 with decimal)

Resolution/Display Precision Configurable, 0…4

Parameters

Volumetric Flow Rate Units

Seconds (S), Minute (MIN), Hour

(H), Day (D)

US Gallons (US GAL), Imperial Gallons (I GAL), Mega US Gallons (US MGAL), Mega

Imperial Gallons (I MGAL),

Liters (L), Mega Liters (ML), Cubic Meters (M3), Cubic Feet (FT3),

Acre Feet (AC-FT), Oil Barrels (OBBL), Liquid Barrels (LBBL),

Volumetric Flow Total Units

US Ounces (US OZ), Imperial Ounces (I OZ),

Custom (user-specified)

Energy Units kBTU, BTU, KW, TONS (RT), Custom (user-defined)

Temperature Units ° F (Fahrenheit), ° C (Celsius), R (Rankine) or K (Kelvin)

Product Data Sheet

CTL-DS-02610-EN-02

Page 5 April 2019

Page 6

Industrial Flow Computer, FC-5000 BTU Monitor

PART NUMBERING CONSTRUCTION

Badger Meter

FC5

BM

-

P1

-

-

6 A

FC-5000 BTU Monitor

FUNCTION

BTU Monitor BM

SENSOR INPUTS

One Pulse / Two Temperature P1

SCALED OUTPUTS

Two Analog Outputs A

Two Frequency Outputs F

RELAY OUTPUTS

One Form C Relay / One Form A Relay A

Two Form C Relays C

DIGITAL INPUTS/OUTPUTS

Six Programable Inputs/Outputs 6

COMMUNICATIONS

EIA-485(RS-485); Modbus; BACnet; USB A

MOUNTING METHOD

Panel Mount P

Wall Mount | Includes NEMA 4X (IP67) Rated Enclosure W

-

Page 6 April 2019

CTL-DS-02610-EN-02

Page 7

INTENTIONAL BLANK PAGE

Product Data Sheet

CTL-DS-02610-EN-02

Page 7 April 2019

Page 8

Industrial Flow Computer, FC-5000 BTU Monitor

Control. Manage. Optimize.

Trademarks appearing in this document are the property of their respective entities. Due to continuous research, product improvements and enhancements, Badger Meter reserves

the right to change product or system specications without notice, except to the extent an outstanding contractual obligation exists. © 2019 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 19-07 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11

Loading...

Loading...