Page 1

FLOW METERING EQUIPMENT

Installation and In struc tion

Man u al

Venturi Flow Meters

Models: SSL, SSM, LPL, VISSL VISSM, VILPL, CV, VBR

Page 2

I. Introduction

Preso Venturi ow meters are di erential pressure ow devices providing highly accurate and

repeatable measurements of liquids, gases, and steam. The Venturi restricts the ow at its throat and

measures the pressure di erence of the unrestricted ow and restricted ow. The Venturi's throat

can be designed to meet the ow mearurement application optimizing the Venturi's accuracy and

permanent pressure loss.

The Preso Venturi's design provides longer lasting accuracy and lower permanent pressure loss

than ori ce type meters, reducing maintenance and operating costs. The Preso Venturi can be built

to meet the highest pressure and temperature speci cations often limited in other ow meter

technologies. All models can also be supplied with RTDs and transmitters to provide an economical

mass ow measurement solution.

II. Speci cations

Applications: Liquids, gases and steam

SSL - Classical (Herschel) Design / VISSL - Insert Version

Pipe Sizes: ½ to 60 inches and larger (13 to 1524 mm)

Pressure & Temperature: Varies, dependent upon materials of construction

Pressure Loss: 6% of DP maximum

Turndown Ratio: 10:1

Process Connections: SSL; NPT, anged, butt weld, socket weld, grooved

VISSL; Insert ts between pair of anges

Instrument Connections: NPT, socket weld, anged

Accuracy: ±1% of reading uncalibrated; ±0.5% of reading calibrated

Standard Beta Ratios: 0.35, 0.49, 0.63 and 0.75;

exact sizing available to provide custom beta ratios

SSM - Hydraulic Shape Design (Nozzle Type) / VISSM - Insert Version

Pipe Sizes ½ to 60 inches and larger (13 to 1524 mm)

Pressure & Temperature: Varies, dependent upon materials of construction

Pressure Loss: 6% of DP maximum

Turndown Ratio: 10:1

Process Connections: SSM; NPT, anged, butt weld, socket weld, grooved

VISSM; Insert ts between pair of anges

Instrument Connections: NPT, socket weld, anged

Accuracy: ±1% of reading uncalibrated; ±0.5% of reading calibrated

Standard Beta Ratios: 0.35, 0.49, 0.63 and 0.75;

exact sizing available to provide custom beta ratios

Page 2 Form #4-20-23 11/10

Page 3

Speci cations (continued)

LPL - Low-Loss Design (Short Form) / VILPL - Insert Version

Pipe Sizes: ½ to 60 inches and larger (13 to 1524 mm)

Pressure & Temperature: Varies, dependent upon materials of construction

Pressure Loss: 3% of DP maximum

Turndown Ratio: 10:1

Process Connections: LPL; NPT, anged, butt weld, socket weld, grooved

VILPL; Insert ts between pair of anges

Instrument Connections: NPT, socket weld

Accuracy: ±3-5% of reading uncalibrated; ±0.5% of reading calibrated

Standard Beta Ratios: -10, -20, -38, -65;

exact sizing available to provide custom beta ratios

CV Series

Pipe Sizes: 2 to 16 inches and larger (51 to 406 mm)

Pressure: 300 PSIG (2070 kPa) maximum

Temperature: 250 °F (120 °C) maximum

Process Connections: NPT, butt weld, anged, grooved

Instrument Connections: NPT

Standard Beta Ratios: -38, -65

VBR Series

Pipe Sizes: ½ to 2 inches (13 to 51 mm)

Pressure: 400 PSIG (2756 kPa) maximum

Temperature: 250 °F (120 °C) maximum

Process Connections: FNPT, socket/sweat

Instrument Connections: NPT

Standard Beta Ratios: -10, -20, -38, -65

Form #4-20-23 11/10 Page 3

Page 4

III. Installation

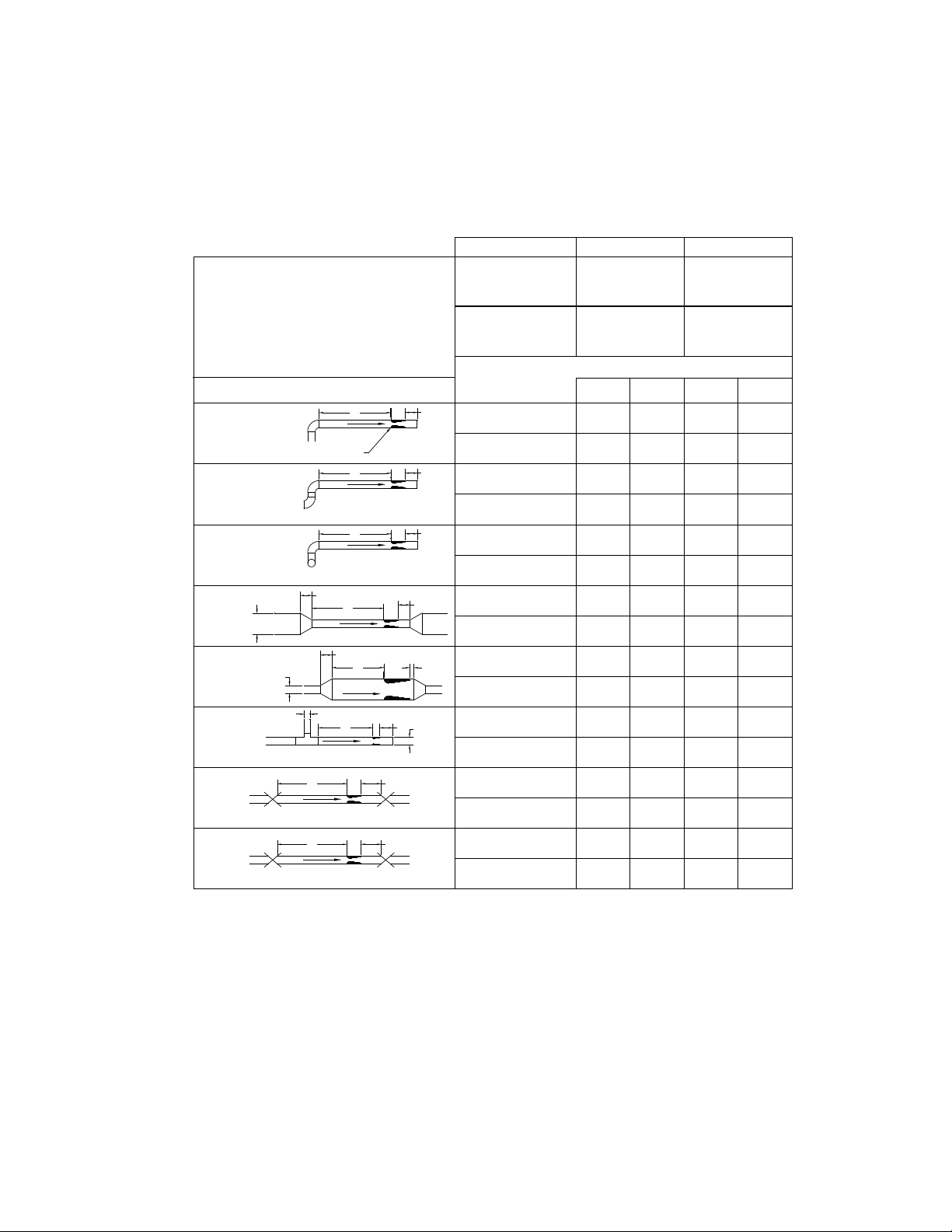

Straight Pipe Run Requirements - SSL, SSM, LPL, VISSL, VISSM, VILPL

As with most ow elements, proper operation and performance is dependent on the required

lengths of unrestricted upstream and downstream piping. The recommended minimum length

of the upstream side of the Venturi ow element depends on the type of tting at the start of the

straight run and the pipe con guration. A fully developed symmetrical ow pro le is achieved with

the minimum upstream and downstream lengths as shown in Figure 1.

INSTALLATION DISTURBANCE

A

Single elbow

Two elbows in the same plane

Two elbows in dierent planes

≤ 2D

Reducer

≥ 0.5D

Expander

Tee connection with dierent diameters

Venturi

A

A

1.5 to 3D

A

1D to 2D

A

d or D

AB

A

B

MODEL

SSL / VISSL – Classical

SSM / VISSM – Nozzle

LPL / VILPL – Low-Loss

B

B

B

B

B

D

A

B

A

B

A

B

A

B

A

B

A

B

A

THROAT SIZE

–1

–2

–3

–4

–10

–20

–38

–65

Minimum Recommended Pipe Diameters

–1

–10

4

222 2

8

333 3

15

4

6

2

8

3

8

3

6

–2

–20

4

8

15 15

4

2

3

33

6

BETA RATIO

0.35

0.49

0.63

0.75

0.35

0.49

0.62

0.81

–3

–38

45

9

4

66

2

88

33

88

6

–4

–65

10

20

10

10

4

7

2

3

3

Globe / Gate valve fully opened

A

Globe / Gate valve partially opened

B

B

A

B

3

12

3333

3

12

14

3

3

18

FIGURE 1

Venturi Pipe Diameter Recommendations

SSL, SSM, LPL, VISSL, VISSM and VILPL Models

NOTES:

1. For upstream and downstream lengths equal to one half the values shown, add 2 percent to the accuracy

value.

2. Any ow conditioner shall be installed in the straight length between the primary element and the

upstream distance, or the tting closest to the element. The straight lengths between tting and

conditioner shall be at least 5D and the length between conditioner and Venturi meter shall be at least 8D.

3. For other ttings, con gurations, consult Preso.

4. Reference - ISO-5167, "Flow Measurement Engineering Handbook", R.W. Miller.

Page 4 Form #4-20-23 11/10

Page 5

Straight Pipe Run Requirements - CV, VBR

Preso CV and VBR Model Venturi elements can be installed in any position with minimal straight

pipe run requirements. The recommended minimum lengths for these models are 5 pipe diameters

upstream and 2 pipe diameters downstream.

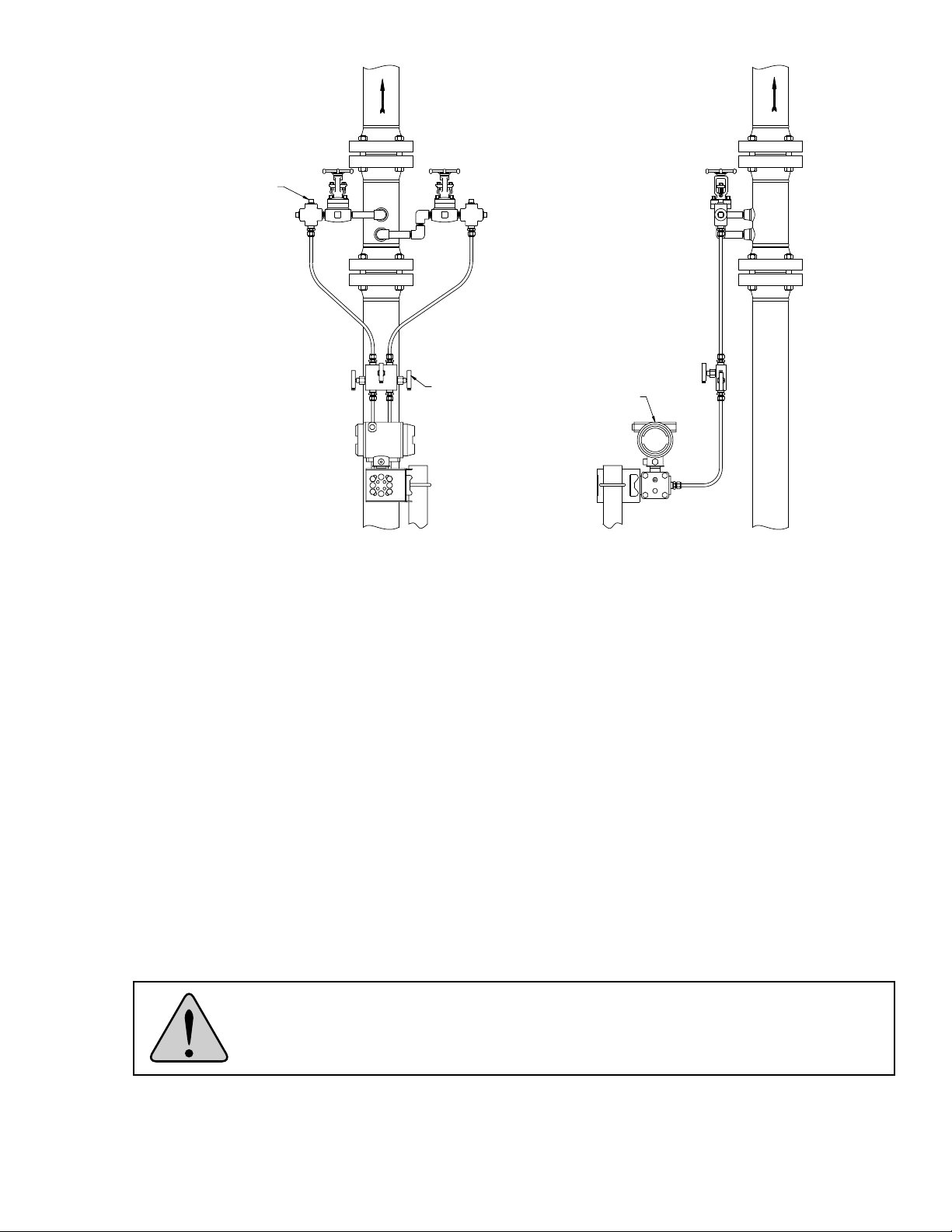

Selecting a Mounting Location

The primary Venturi station can be installed in any position on vertical or horizontal lines. However,

on horizontal liquid lines where the risk of gas/gas entrapment in the meter tubing is prevalent, it

is recommended to install the element with the connections below the horizontal center line. For

horizontal air or gas lines, it is recommended to install the element with the connection above the

horizontal centerline. For steam lines, to protect the transmitter, it is recommended to install the

element so that the connections are in the horizontal centerline on meters with the instrument

taps in the same plane. See Figure 5 for meters with instrument taps that are not in the same

plane. Make sure that the ow arrow or the indicated inlet is correctly oriented. Other positions are

acceptable provided proper venting of the secondary element is accomplished and di erences in

tap line elevations are considered.

Vertical installations may introduce a slight hydrostatic head e ect, which must be considered

when zeroing a transmitter. The use of a 3-valve manifold is recommended particularly for zeroing

a transmitter.

Before installation of any Venturi element, inspect for damage, particularly at the sealing surfaces.

Any damage should be reported to Preso as soon as possible. Each ow element has an arrow

indicating the required direction of ow. Failure to properly orient the Venturi element according

to the direction of ow will cause improper results.

For Venturi elements supplied with lifting rings, the installer should take care to ensure the

connections are in the desired position for their application. Thus, supplied lugs location may not

be appropriate for all applications and may require other means of lifting.

WARNING:

Never exceed the maximum pressure or temperature recommended for the measured

process. Exceeding proper pressure or temperature ratings can lead to personal injury

or equipment damage. The process piping anges should be identical to those on the

Venturi. The process temperature and pressure should never exceed those for which

the element has been designed.

Form #4-20-23 11/10 Page 5

Page 6

HI

LO

Flow

Top View

DP Transmitter or

Direct Read Gage

3-Valve Manifold

HI

LO

Side View

Notes:

1. ф = 1 in / ft (80 mm/m) for water;

2 to 4 in / ft (160 to 320 mm/m) for more viscous uids

2. Minimize all lead line lengths

Flow

Up to -45°

Front View

FIGURE 2

Typical Horizontal Installation for Liquid

DP Transmitter or

Direct Read Gage

Flow

Notes:

1. ф = 1 in / ft (80 mm/m)

2. Minimize all lead line lengths

Top View

Side View

HI

LO

3-Valve Manifold

HI

LO

FIGURE 3

Typical Horizontal Installation for Gas

Page 6 Form #4-20-23 11/10

Page 7

Flow

HI

LO

Filling Crosses

(Fill with water

to same level)

DP Transmitter or

Direct Read Gage

DP Transmitter or

Direct Read Gage

By-pass

Valve

Side View Front View

FIGURE 4

Typical Horizontal Installation for Steam

HI

Filling Crosses

(Fill with water

to same level)

Flow

By-pass

Valve

Side View

Front View

FIGURE 5

Optional Horizontal Installation for Steam

(Instrument Taps Not in the Same Plane)

NOTE: Please see instructions in Selecting a Mounting Location section on page 4 for additional

information.

Form #4-20-23 11/10 Page 7

Page 8

LO

HI

LO

HI

3-Valve

Manifold

Flow

DP Transmitter or

Direct Read Gage

Front View

FIGURE 6

Typical Vertical Installation for Liquid

DP Transmitter or

Direct Read Gage

LO

Flow

HI

3-Valve Manifold

Side View

LO

HI

Flow

Front View

Side View

FIGURE 7

Typical Vertical Installation for Gas

Page 8 Form #4-20-23 11/10

Page 9

Filling Crosses

(Fill with water

to same level)

Flow

Flow

Line Installation

LO

HI

3-Valve

Manifold

Front View

DP Transmitter or

Direct Read Gage

FIGURE 8

Typical Vertical Installation for Steam

LO

HI

Side View

All anged Venturi ow elements require a gasket between the process line connection and the

mating ange. Select gaskets that match the pressure rating of the Venturi anges and resist corrosive

attack of the process uid.

Before completing the bolting process, be sure that the gaskets are properly centered so that

protrusion into the pipe opening is minimized. Misalignment may cause added ow turbulence.

However, performance e ects are typically minimal depending upon the application. Bolt the

element in line with suitable hardware using recommended bolt torques for the type and class

rating of the anges.

Torque all models per ANSI ange ratings.

Tighten the ange bolts in a progressive "star" pattern to avoid localized stress on the gaskets.

CAUTION:

Do not exceed speci ed torque!

Form #4-20-23 11/10 Page 9

Page 10

Di erential Pressure Connections

The high pressure connection is always on the upstream side of the ow direction arrow and the

low pressure connection on the downstream side. Fittings used must be able to withstand the

process temperature and pressure conditions, as well as provide proper corrosion resistance. Refer

to appropriate secondary instrument instructions for connections to the seondary instrument high

and low ports. All tting threads should be coated with a process compliant thread sealant prior to

tightening. Once tightened, torque mark all ttings for future reference.

Secondary

Instruments

Transmitter

3-Valve Manifold

Flow

Primary

Element

FIGURE 9

Secondary Instrument Illustration

Direct Read Gage

(Gage shown with

optional by-pass)

Page 10 Form #4-20-23 11/10

Page 11

NOTES

Form #4-20-23 11/10 Page 11

Page 12

FLOW METERING EQUIPMENT

Limited Warranty and Disclaimer

Preso Flow Metering Equipment, Division of Racine Federated Inc. warrants to the end pur chas er, for

a period of one year from the date of shipment from the fac to ry, that all flow meters manufactured

by it are free from defects in materials and workmanship. This warranty does not cover products

that have been dam aged due to misapplication, abuse, lack of main te nance, modi ed or improper

in stal la tion. Preso’s obligation under this war ran ty is limited to the repair or re place ment of a

defective prod uct, at no charge to the end purchaser, if the product is in spect ed by Preso and found

to be defective. Repair or re place ment is at Preso’s discretion. A return goods au tho ri za tion (RGA)

number must be obtained from Preso before any product may be re turned for warranty repair

or re place ment. The product must be thoroughly cleaned and any process chem i cals removed

before it will be ac cept ed for return.

The purchaser must determine the applicability of the product for its desired use and assumes

all risks in connection there with. Preso assumes no responsibility or liability for any omissions or

errors in con nec tion with the use of its products. Preso will under no circumstances be liable for

any in ci den tal, con se quen tial, con tin gent or special dam ag es or loss to any person or prop er ty

arising out of the failure of any product, com po nent or accessory.

All expressed or implied warranties, including the implied warranty of mer chant abil i ty and the

implied war ran ty of tness for a particular purpose or ap pli ca tion are ex press ly dis claimed

and shall not apply to any products sold or services rendered by Preso.

The above warranty supersedes and is in lieu of all other warranties, either ex pressed or implied

and all other ob li ga tions or li a bil i ties. No agent or rep re sen ta tive has any au thor i ty to alter the

terms of this war ran ty in any way.

8635 Washington Avenue • Racine, WI 53406-3738 USA

Tel: 262-639-6770 • Fax: 262-417-1148

Toll Free: 800-632-7337

www.preso.com • info@preso.com

©2010 Racine Federated Inc.

PRESO is a registered trademark of Racine Federated Inc.

UL is a registered trademark of Underwriters Laboratories.

All rights reserved.

Printed in USA

Form #4-20-23 04/10

Loading...

Loading...