Page 1

Precision Meters

Turbine Flow Meters

TUR-UM-00477-EN-01 (May 2014)

User Manual

Page 2

Precision Meters, Turbine Flow Meters

Page ii May 2014

Page 3

User Manual

CONTENTS

Description and Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Symbol Explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unpacking & Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Meter Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Use of Pipe Compound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cox Precision Ball Bearing Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Procedure for Cleaning a Turbine Meter after Water Calibration and/or Service . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Technical Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

K-Factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Linearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

K-Factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

20-Point Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

30-Point Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

UVC-Universal Viscosity Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Gas Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Dimensions (Liquid). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

AN End Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

NPT End Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Flange End Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hose Barb End Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Tri-Clamp End Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

High Pressure End Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Dimensions (Gas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

AN End Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Page iii May 2014

Page 4

Precision Meters, Turbine Flow Meters

NPT End Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Flange End Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Factors Aecting Linearity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Pickos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mounting for Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pressure Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Specic Gravity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Associated Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

LoFlo Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Page iv May 2014

Page 5

User Manual

DESCRIPTION AND USE

Cox Precision Turbine Flow Meters are a precisely manufactured and calibrated instruments used in accurate rate-of-flow and

total-flow measurement of all types of fluids, whether liquid or gas.

They also have many applications as sensors in process flow control.

The flow meter mounts directly in the flow line and consists of a cylindrically bored housing, a flow straightener and turbine

assembly, and magnetic or carrier frequency pickoffs, as shown in Figure 1.

On all Precision Flow Meters, the magnetic or carrier frequency pickoff is located directly above the turbine, near the

downstream end of the flow meter. The flow straightener and turbine assembly is retained in the housing by a snap ring and

can be easily removed for cleaning and further disassembly.

Figure 1: Turbine flow meter

Cox Precision Turbine Flow Meters are provided with flow straighteners at the downstream and upstream ends. The flow

straighteners diminish any turbulence created by the turbine. Other physical differences are illustrated in exploded views. See

Figure 2 and Figure 3.

Fluid passing through the meter causes the rotor and bearing to revolve at a speed directly proportional to fluid velocity.

As each rotor blade passes the pickoff, it varies the pickoff’s reluctance, producing an output signal. Since turbine speed is

directly proportional to fluid velocity, signal frequency is similarly proportional to the volumetric rate-of-flow. The output

signal can be fed into various types of instruments to indicate the rate-of-flow, such as indicators, frequency converters,

counters, recorders and controllers.

Cox uses two pickoff technologies, magnetic and carrier frequency (RF). The magnetic pickoff has a self-generating mV

frequency output. The RF carrier pickoff senses eddy current losses as the rotor blade passes the pickoff. It does not use an

internal permanent magnet and therefore eliminates magnetic drag on the rotor. This results in linear flow ranges up to 100:1

and repeatable operating flow ranges up to 150:1. The RF carrier pickoff requires a signal conditioner to generate an output. A

high level signal offers the advantage of high output signal to noise ratio over the entire range of the flow meter and permits

long distance signal transmission.

All Cox Precision Turbine Flow Meters are designed to provide a high frequency output voltage at the maximum of their

flow range. This high frequency signal improves resolution and standardized output permits several overlapping range flow

meters to be connected in series to one indicating instrument. Data concerning extended ranges, specific output voltage

and other frequency ranges is available from the Badger Meter Sales Department. As with any precision instrument, the full

capabilities of the Cox Precision Turbine Flow Meter can be realized only through close adherence to the installation and

maintenance instructions discussed in this manual.

Page 5 May 2014

Page 6

Precision Meters, Turbine Flow Meters

SAFETY INFORMATION

The installation of the Cox Precision Turbine Flow Meters must comply with all applicable federal, state, and local rules,

regulations, and codes.

Failures to read and follow these instructions can lead to misapplication or misuse of the Cox Precision Turbine Flow Meters,

resulting in personal injury and damage to equipment.

Safety Symbol Explanations

DANGER

INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED IS ESTIMATED TO BE CAPABLE OF CAUSING DEATH OR

SERIOUS PERSONAL INJURY.

INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED COULD RESULT IN SEVERE PERSONAL INJURY

OR DEATH.

INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED IS ESTIMATED TO BE CAPABLE OF CAUSING MINOR OR

MODERATE PERSONAL INJURY OR DAMAGE TO PROPERTY.

UNPACKING & INSPECTION

Upon opening the shipping container, visually inspect the product and applicable accessories for any physical damage such

as scratches, loose or broken parts, or any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier's agent withing 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

Page 6 May 2014

Page 7

User Manual

INSTALLATION

Meter Orientation

Cox Precision Turbine Flow Meters may be installed in any position without affecting performance. Be sure direction of flow is

in the direction of the arrow engraved on the flow meter body. Exception: Position gas service meters as calibrated.

Piping

Recommended layout for Cox Precision Turbine Flow Meters specifies a straight section of pipe or tube in the same size as the

flow meter and equal in length to 10 diameters on the upstream side, and a similar section equal in length to 5 diameters in

order to retard the formation of swirls in the liquid, which can cause incorrect flow meter output. If space prohibits the use

of these straight sections, use extreme care in arranging the piping to produce as straight and smooth a flow as possible.

Available Cox Flow Straighteners are listed in the Cox Flow Straighteners Product Data Sheet. Go to www.badgermeter.com.

Use of Pipe Compound

The 37-degree flared tube connections of Cox Precision Turbine Flow Meters DO NOT require any sealing compound or Teflon

tape, and none should be used. The use of these on adjacent piping should be held to a minimum in order to avoid coating

the bearings and rotor blades with compound, causing premature rotor failure and erratic performance.

OTE:N Copper conical seals or crush rings may be used, if necessary.

BLEED ALL AIR AND VAPOR FROM THE LIQUID AFTER INSTALLING OR REINSTALLING A FLOW METER.

START FLOW SLOWLY TO AVOID SENDING A “SLUG” OF HIGH VELOCITY AIR OR VAPOR THROUGH THE FLOW METER

AND CAUSING IT TO OVERSPEED. START REQUIRED FLOW AFTER FLOW METER IS FULL OF LIQUID. AERATED LIQUIDS

FLOWING THROUGH A FLOW METER WILL RESULT IN INCORRECT FLOW RATES.

DISASSEMBLY

Cox Precision Ball Bearing Type

1. Firmly hold ow meter and, using tweezers, carefully remove internal snap ring from the upstream end.

2. Use long nose pliers and grasp one vane of ow straightener and gently pull ow straightener and rotor assembly from

the body. Use slight twisting motion. Snug t at transition.

3. Press down on the hub to relieve spring pressure on C-washer and remove with tweezers or thin nosed pliers. Remove

hub, spring and spacer.

4. Carefully remove rotor from shaft.

5. Remove a snap ring from side of bearing and push bearing out of rotor.

OTE:N Models CLFA6 and CLFB6 must be returned to factory for bearing change.

CLEANING

Immerse all parts, except pickoff, in a clean, filtered solvent suitable for removing residue from the liquid the flow meter has

been used with. If necessary, use a soft bristle brush.

If there is foreign matter in the ball bearings, allow them to soak in the solvent for approximately 10 minutes and then dry

with filtered compressed air. Do not use excessive air pressure.

OTE:N Do not sonic clean bearings!

EXERCISE EXTREME CARE DURING THE CLEANING PROCESS SO THAT NONE OF THE PARTS ARE DROPPED,

SCRATCHED OR DAMAGED IN ANY WAY. NO ATTEMPT SHOULD BE MADE TO FURTHER POLISH ANY OF THE PARTS,

ESPECIALLY THE ROTOR.

Page 7 May 2014

Page 8

Precision Meters, Turbine Flow Meters

Procedure for Cleaning a Turbine Meter after Water Calibration and/or Service

OTE:N When cleaning flow meters, keep the body, sleeve and pickoff together. Sleeve is fitted to body and pickoff has a

protruding pin. Replacement pickoffs are supplied with a nut and have no protruding pin.

1. Remove the meter from the line and let all excess water drip out.

2. Fill the meter with alcohol (at least 50% Isopropyl, Ethyl or Methyl) and let it stand for 5 minutes.

3. Discard the alcohol and let the meter dry for 2 minutes.

4. Fill the meter with MIL-C-7024 Type 2 calibration uid (or similar solvent) and let it stand for 1 minute.

5. Discard the calibration uid and ush the meter with an approved uorocarbon solvent, such as Isotron.

OTE:N If this procedure is not possible, the turbine meter should always remain filled with water when not in use, to prevent

internal wetted parts from being exposed to air.

CLFC6, CLFD6, CLFE6, CLFF6

1. Body *

2. C-washer

3. Hub *

4. Spring *

5. Spacer

6. Bearing retainer ring *

7. Bearing

CLFC6, CLFD6, CLFE6

CLFB6, CLFA6

CLFF6

Figure 2: Cox Precision LoFlo turbine flow meter

8. Rotor *

9. Straightener assembly *

10. Body retaining ring

* Replaceable at factory level only.

OTE:N Order parts by name and basic number shown, followed by flow meter

size designation. For example, order a bearing for a CLFF6 flow meter

as bearing #1400-63. Flow meter serial number must be provided when

ordering parts.

CLFB6, CLFA6

1. Body *

2. C-washer

3. Hub *

4. Spring *

5. Spacer

8. Rotor *

9. Straightener assembly *

10. Body retaining ring

Figure 3: Cox precision turbine flow meter

DO NOT INTERCHANGE FLOW METER PARTS OTHER THAN BEARINGS AND RETAINING RINGS. THIS PRECAUTION IS

NECESSARY TO PRESERVE LINEARITY AND REPEATABILITY.

Page 8 May 2014

Page 9

REASSEMBLY

Reassembly is the reverse of disassembly except for the following:

• On Precision Turbine Flow Meters where shaft bearings are provided with a

retainer, always install with the retainer flange facing upstream.

• Inspect rotor for markings as shown in Figure 4 to indicate flow direction before

assembly.

• Flow meters having broached slots in the body for flow straightener vanes

should be carefully assembled.

• Align straightener vanes with the slots and push gently until the assembly

is seated.

User Manual

Figure 4: Scribed lines

Page 9 May 2014

Page 10

Precision Meters, Turbine Flow Meters

TROUBLESHOOTING

Issue Possible Cause Remedy

Meter indicates higher flow than actual. Cavitation. Increase back pressure.

Meter indicates high flow. Dirt blocking flow area rotor. Clean meter; add filter.

Meter indicates low flow. Dirt dragging rotor. Clean meter; add filter.

Meter indicates low flow. Worn bearing. Replace bearing; recalibrate when

required.

Meter indicates low flow. Viscosity higher than calibrated. Change temperature; change fluid;

recalibrate meter.

Erratic system indication; meter alone

works well.

Indicator shows flow when shut off.

Mechanical vibration causes rotor to

oscillate without turning.

No flow indication. Full flow of fluid

opened into dry meter. Impact of fluid

on rotor causes bearing separation.

Erratic indication at low flow; good

indication at high flow.

No flow indication. Faulty pickoff. Replace pickoff; recalibrate as

System works perfectly, except

indicates lower flow over entire range.

Meter indicating high flow. Upstream

piping at meter smaller than meter.

Opposite effects as above. Viscosity lower than calibrated. Change temperature; change fluid;

Mass flow indication wrong. Turbine

meter is volumetric; density correction

is electronic; must change with

temperature.

Erratic or wrong indication of flow. Loose pickoff. Tighten pickoff.

Indicates high flow two hours after

installing new bearing.

Cannot reach maximum flow rate;

meter selection was with Delta-P at 0.75

sp. gr., now using on 1.0 sp. gr. Delta-P

is proportional to specific gravity.

Does not repeat at low flows. Repeats at

high flows.

Ground loop is shielding. Ground shield one place only. Watch for

internal electronic instrument grounds.

Mechanical vibration. Isolate meter; use potted pickoff.

Fluid shock. New bearing failed. Move meter to position where it is full

of fluid at start-up.

Low instrument sensitivity. 10

mV rms turbine signal is being

lowered by loading of electronics or

instrumentation cannot sense low level

signals.

Bypass flow, leak. Eliminate bypass valves, leak. Faulty

Fluid jet impingement on rotor. Critical

in gas.

Wrong fluid density. Critical in gas. Check fluid, electronics.

Bearing wear-in; small meters critical. Recalibrate. 20…30 min. run-in is

High pressure drop. Install larger meter.

System resolution readability. Increase resolution, for example:

Table 1: Troubleshooting

Amplify signal.

necessary.

solenoid valves.

Change piping.

recalibrate meter.

required to stabilize friction.

1 out of 100 = 1%

1 out of 1000 = 0.1%

Page 10 May 2014

Page 11

=

(

× 60)÷

=

. −

User Manual

TECHNICAL TERMS

Several terms, such as K-Factor and linearity, are used to indicate turbine flow meter performance.

K-Factor

“K” is a letter used to denote the cycles per gallon factor of a flow meter. This factor is a fixed value used in resolving or

totalizing the pulse count output of a flow meter. It results from the equation:

Cycles per second/Gallons per second = Cycles per gallon (K)

Repeatability

The maximum deviation from the corresponding data points taken from repeated tests under identical conditions.

Linearity

This is defined as the deviation from the mean calibration factor (K) and is expressed as being within a certain tolerance. Cox

Precision Turbine Flow Meters are linear to ± 0.5% over the range shown.

CALIBRATION DATA

K-Factor

The calibration data supplied with a Cox Precision Turbine Flow Meter is shown in Figure 6.

Correct application of a Cox Precision Turbine Flow Meter requires consideration of many important factors. Because of

the wide variation of possible applications, detailed data for liquid flow models only is given in this manual. For special

requirements—such as those outside the range of –300…350° F, those with extremely corrosive liquids, gases and other

unusual conditions—consult the Badger Meter Sales Department.

20-Point Calibration

Calibration at twenty flow rates (10 up-scale and 10 down) between minimum and maximum flow range, is available for

application where ± 0.25% accuracy or better is required. With this calibration complete data on signal output, pressure drop,

K-Factor and deviation from linearity is supplied.

30-Point Calibration

This is the same as the 20-point, with 10 extra points to cover the longer range of the carrier type meters.

UVC-Universal Viscosity Curve

A 10-point calibration is made at each of four viscosities if curves of “K” versus Hertz were made. In between, viscosities cannot

be determined (see right side of Figure 5). Replot as “K” versus Hertz divided by centistokes. A single curve is drawn through all

data points. Other viscosity curves can now be determined. Use only over 10:1 range for viscosity effects.

Gas Calibrations

When performed at the Flow Dynamics facility, a curve of ACFM vs. Hertz is supplied.

Pressure Rating

The standard LoFlo and Precision Flow Meters are rated 2500…5000 psi operating pressure. They have a 4:1 pressure safety

factor. Flange flow meters are rated for service pressure according to ANSI ratings for the flanges used.

Operation at temperatures above 200° F will decrease the connection rating because of lowered stress capabilities of

the metal.

Liquid Formula Gas Formula

= × 3600 × 8.328 × . .

Figure 5: Calculating flow rates in different units

Page 11 May 2014

Page 12

Certificate

of Calibration

Customer Name:

HONG KONG EVERBLOOMING INTL CO LTD

Report #

CX35874 - X14892

Customer Address:

Sooner Air Freight Int’l Ltd Unit 7,Corp Square, 8 Lam Lok Street KLN BAY Hong Kong

Customer PO #

13EB0205COX

Model #

NRPC 12

Cal Date:

2/21/2013

Serial #

X14892

Customer Re-Cal Date:

Signal:

PULSE (Collect Raw Data)

Lab Temp:

72.1 Deg F

Calibration Procedure:

FDP-002

Lab Relative Humidity:

27.3%

Calibration Tech:

Luis

Fluid Specifications:

MIL-C-7024 T2

Specific Gravity:

0.76

Temperature (F):

80

Viscosity (CSTKS):

1.12

Notes, Adjustments & Repairs

Test Point #

Frequency

Flow Rate

Roshko #

Strouhal #

Meter Temp

Viscosity

Density

Flow Rate

Hz

GPM

Hz/cstk

pul/gal

Deg. F

cStks

g/cc

LPM

1

10.5941

0.23290

10.1597

2729.48

72.223

1.0428

0.7662

0.88161

2

10.5995

0.23292

10.1649

2730.62

72.223

1.0428

0.7662

0.88169

3

16.4760

0.35749

15.8004

2765.43

72.224

1.0428

0.7666

1.35326

4

16.4773

0.35751

15.8017

2765.55

72.224

1.0428

0.7666

1.35331

5

23.0864

0.49779

22.1398

2782.83

72.229

1.0428

0.7665

1.88435

6

23.0878

0.49790

22.1411

2782.42

72.229

1.0428

0.7665

1.88474

7

31.8261

0.68334

30.5241

2794.65

72.239

1.0427

0.7665

2.58671

8

31.8233

0.68336

30.5214

2794.30

72.244

1.0427

0.7665

2.58681

9

45.9753

0.98154

44.0817

2810.58

72.207

1.0430

0.7665

3.71553

10

45.9764

0.98158

44.0913

2810.53

72.224

1.0428

0.7665

3.71569

11

65.0253

1.38527

62.2155

2816.58

71.909

1.0452

0.7665

5.24383

12

65.0929

1.38719

62.2802

2815.61

71.909

1.0452

0.7665

5.25109

13

92.3185

1.97035

88.2532

2811.37

71.782

1.0461

0.7665

7.4586

14

92.7150

1.97801

88.7088

2812.52

71.909

1.0452

0.7665

7.4876

15

126.727

2.71355

121.228

2802.25

71.876

1.0454

0.7665

10.2719

16

126.986

2.71960

121.429

2801.72

71.829

1.0458

0.7665

10.2948

17

172.915

3.72060

165.032

2788.63

71.567

1.0478

0.7668

14.084

18

173.020

3.72232

165.100

2789.03

71.539

1.0480

0.7668

14.0905

19

249.704

5.39233

238.001

2778.54

71.382

1.0492

0.7668

20.4122

20

250.070

5.39867

238.304

2779.35

71.347

1.0494

0.7668

20.4362

21

353.158

7.64305

335.772

2772.47

71.032

1.0518

0.7669

28.9321

22

353.580

7.65082

336.141

2772.96

71.016

1.0519

0.7669

28.9615

23

487.881

10.5643

462.716

2770.99

70.694

1.0544

0.7669

39.9901

24

488.960

10.5857

464.180

2771.49

70.824

1.0534

0.7669

40.0714

25

724.643

15.6740

686.287

2773.97

70.499

1.0559

0.7669

59.3325

26

725.055

15.6826

685.830

2774.01

70.321

1.0572

0.7669

59.3651

27

986.019

21.3207

976.576

2775.36

76.755

1.0098

0.7669

80.7077

28

993.053

21.4722

982.275

2775.43

76.571

1.0111

0.7668

81.281

29

1406.85

30.3943

1390.06

2777.71

76.414

1.0122

0.7668

115.055

30

1412.22

30.5055

1393.71

2778.13

76.245

1.0134

0.7668

115.476

I certify the accuracy of this Calibration Report:

Andrew Yee

Calibration Engineer

Name Title Signature

Standard #

Description

Serial #

ReCal Date

FDI-180

30 GPM Liquid Prover

NA

8/12/2013

Precision Meters, Turbine Flow Meters

15555 North 79th Place • Scottsdale, AZ 85260 • Phone: (480) 948 -3789 • Fax: (480) 948 -3610 • sales@flow-dynamics.com

Calibration Results (Initial Calibration)

www.badgermeter.com

Standards Used in Calibration

The instrument referenced above was calibrated using standards traceable to the National Institute of Standards and Technology. Calibration reports for references

maintained by Badger Meter, Inc. are available upon request to the customer of this calibration report. The volumetric flow rates reported are within a best

uncertainty of +/- .037% of reading (Represents an expanded uncertainty using a coverage factor, k =

calibration equipment only and does not apply to the UUT ( Unit Under Test).

Badger Meter, Inc. Flow Dynamics calibration services are accredited by NVLAP (Lab Code 200668-0) to ISO/IEC 17025:2005 (NIST Handbook 150) and are

compliant to ANSI/NCSLZ540-1-1994; Part 1. This certificate is not an endorsement by NVLAP, NIST or an agency of the federal government.

The results reported relat

Badger Meter, Inc..

e only to the item(s) calibrated as described above. This report may not be reproduced, except in full, without the written approval of

Report #:CX35874 - X14892

Figure 6: Calibration certification

Page 12 May 2014

2, at an approximate level of confidence of 95%) and applies to

Doc Nbr: CRF-002 Rev: F

Page 1 of 1

Page 13

User Manual

Torque Rating

When using Precision Flow Meters with AN end fittings at high pressure, tighten the fittings to the torque values in Table 2.

Size Minimum Torque (Dry)

All CLF Meters 270 in-lb

8-4, 8-6, 08 450 in-lb

10 650 in-lb

12 900 in-lb

16 1200 in-lb

20 1400 in-lb

24 1600 in-lb

32 1800 in-lb

Table 2: Torque values

Materials

Materials listed in Table 3 are recommended and used for most turbine flow meter applications. For unusual requirements—

such as those outside the range of –300…350° F or those with extremely corrosive liquids—consult the Badger Meter

Sales Department.

Part Type

Bearing Hybrid ceramic

Body 316

C-Washer 302

Hub 303

Locknut CRS (plated)

Pickoff 304

Spacer 303

Spring 302

Snap Ring 303

Straightener Assembly 316

Rotor 17-4 SS

Table 3: Materials per part

Dimensions

• See “Dimensions (Liquid)” on page 14 for tube sizes and mounting dimensions of liquid Precision Turbine Flow Meters.

• See “Dimensions (Gas)” on page 18 for tube sizes and mounting dimensions of gas Precision Turbine Flow Meters.

Page 13 May 2014

Page 14

Precision Meters, Turbine Flow Meters

DIMENSIONS LIQUID

Dimension B specifies the most common pickoff type. Actual size may vary depending on pickoff choice. Consult factory

for details.

AN End Fitting

B

Size

A

End Fitting

in. (mm)

A

in. (mm)

HEX BODY

Figure 7: AN end fitting

B (RF)

in. (mm)

SQUARE BODY

B (MAG)

in. (mm)

in. (mm)

8-4 0.50 (12.70) 2.45 (62.23) 3.20 (81.28) 2.70 (68.58) 1.12 (28.45) Square Body

8-6 0.50 (12.70) 2.45 (62.23) 3.20 (81.28) 2.70 (68.58) 1.12 (28.45) Square Body

8 0.50 (12.70) 2.45 (62.23) 3.30 (83.82) 2.80 (71.12) 1.12 (28.45) Square Body

10 0.625 (15.88) 2.72 (69.08) 3.30 (83.82) 2.80 (71.12) 1.25 (31.75) Square Body

12 0.75 (19.05) 3.25 (82.55) 3.40 (86.36) 2.90 (73.66) 1.25 (31.75) Square Body

16 1.00 (25.40) 3.56 (90.42) 3.50 (88.90) 3.00 (76.20) 1.63 (41.40) Hex Body

20 1.25 (31.75) 4.06 (103.1) 3.60 (91.44) 3.10 (78.74) 1.88 (47.75) Hex Body

24 1.50 (38.10) 4.59 (116.6) 3.80 (96.52) 3.30 (83.82) 2.25 (57.15) Hex Body

32 2.00 (50.80) 6.06 (153.9) 4.00 (101.6) 3.50 (88.90) 2.75 (69.85) Hex Body

Table 4: AN end fitting dimensions

NPT End Fitting

B

C

SQUARE BODY

B (MAG)

in. (mm)

C

in. (mm)

Size

A

End Fitting

in. (mm)

A

in. (mm)

HEX BODY

Figure 8: NPT end fitting

B (RF)

in. (mm)

8-4 0.50 (12.70) 2.70 (68.58) 3.20 (81.28) 2.70 (68.58) 1.12 (28.45) Square Body

8-6 0.50 (12.70) 2.70 (68.58) 3.20 (81.28) 2.70 (68.58) 1.12 (28.45) Square Body

8 0.50 (12.70) 2.70 (68.58) 3.30 (83.82) 2.80 (71.12) 1.12 (28.45) Square Body

10 0.75 (19.05) 3.29 (83.57) 3.30 (83.82) 2.80 (71.12) 1.25 (31.75) Square Body

12 0.75 (19.05) 3.29 (83.57) 3.40 (86.36) 2.90 (73.66) 1.25 (31.75) Square Body

16 1.00 (25.40) 3.78 (96.01) 3.50 (88.90) 3.00 (76.20) 1.63 (41.40) Hex Body

20 1.25 (31.75) 4.23 (107.4) 3.60 (91.44) 3.10 (78.74) 1.88 (47.75) Hex Body

24 1.50 (38.10) 4.67 (118.6) 3.80 (96.52) 3.30 (83.82) 2.25 (57.15) Hex Body

32 2.00 (50.80) 5.89 (149.6) 4.00 (101.6) 3.50 (88.90) 2.75 (69.85) Hex Body

Table 5: NPT end fitting dimensions

Page 14 May 2014

Page 15

Flange End Fitting

A

B

ASME B16.5 FLANGES

DASH NUMBER

5.00

3.2

1/2"

8-4

5.00

3.2

1/2"

8-6

5.00

3.3

1/2"

8

5.50

3.3

1/2"

10

5.50

3.4

3/4"

12

5.50

3.5

1"

16

6.00

3.6

1-1/4"

20

6.00

3.8

1-1/2"

24

6.50

4.0

2"

32

A

B

C

BODY

MS33658 END FITTING

DASH NUMBER

3.18

3.2

1.12

SQUARE

- 8

8-4

3.18

3.2

1.12

SQUARE

- 8

8-6

3.18

3.3

1.12

SQUARE

- 8

8

3.24

3.3

1.25

HEX

- 10

10

3.25

3.4

1.25

HEX

- 12

12

3.56

3.5

1.63

HEX

- 16

16

4.50

3.6

1.88

HEX

- 20

20

5.00

3.8

2.25

HEX

- 24

24

6.50

4.0

2.75

HEX

- 32

32

A

2X FLANGES

(PER ASME B16.5)

B

Figure 9: Flange end fitting

User Manual

ØC

Size

A

in. (mm)

B (RF)

in. (mm)

B (MAG)

in. (mm)

C—150# Flange

in. (mm)

C—300# Flange

in. (mm)

C—600# Flange

in. (mm)

8-4 5.00 (127.0) 3.20 (81.28) 2.70 (68.58) 3.50 (89) 3.75 (95) 3.75 (95)

8-6 5.00 (127.0) 3.20 (81.28) 2.70 (68.58) 3.50 (89) 3.75 (95) 3.75 (95)

8 5.00 (127.0) 3.30 (83.82) 2.80 (71.12) 3.50 (89) 3.75 (95) 3.75 (95)

10 5.50 (139.7) 3.30 (83.82) 2.80 (71.12) 3.50 (89) 3.75 (95) 3.75 (95)

12 5.50 (139.7) 3.40 (86.36) 2.90 (73.66) 3.88 (99) 4.62 (117) 4.62 (117)

16 5.50 (139.7) 3.50 (88.90) 3.00 (76.20) 4.25 (108) 4.88 (124) 4.88 (124)

20 6.00 (152.4) 3.60 (91.44) 3.10 (78.74) 4.62 (117) 5.25 (133) 5.25 (133)

24 6.00 (152.4) 3.80 (96.52) 3.30 (83.82) 5.00 (127) 6.12 (155) 6.12 (155)

32 6.50 (165.1) 4.00 (101.6) 3.50 (88.90) 6.00 (152) 6.50 (165) 6.50 (165)

Table 6: Flange end fitting dimensions

Hose Barb End Fitting

B

A

End Fitting

in. (mm)

C

Size

8-4 0.50 (12.70) 3.18 (80.77) 3.20 (81.28) 2.70 (68.58) 1.12 (28.45) Square body

8-6 0.50 (12.70) 3.18 (80.77) 3.20 (81.28) 2.70 (68.58) 1.12 (28.45) Square body

8 0.50 (12.70) 3.18 (80.77) 3.30 (83.82) 2.80 (71.12) 1.12 (28.45) Square body

10 0.625 (15.88) 3.24 (82.30) 3.30 (83.82) 2.80 (71.12) 1.25 (31.75) Hex body

12 0.75 (19.05) 3.25 (82.55) 3.40 (86.36) 2.90 (73.66) 1.25 (31.75) Hex body

16 1.00 (25.40) 3.56 (90.42) 3.50 (88.90) 3.00 (76.20) 1.63 (41.40) Hex body

20 1.25 (31.75) 4.50 (114.3) 3.60 (91.44) 3.10 (78.74) 1.88 (47.75) Hex body

24 1.50 (38.10) 5.00 (127.0) 3.80 (96.52) 3.30 (83.82) 2.25 (57.15) Hex body

32 2.00 (50.80) 6.50 (165.1) 4.00 (101.6) 3.50 (88.90) 2.75 (69.85) Hex body

2X MS33658 END FITTINGS

Figure 10: Hose barb end fitting

A

in. (mm)

B (RF)

in. (mm)

Table 7: Hose barb end fitting dimensions

HEX BODY

SQUARE BODY

B (MAG)

in. (mm)

C

in. (mm)

Page 15 May 2014

Page 16

A

2X TRI-CLAMP END FITTINGS

(PER ASME BPE)

C

B

A

B

C

ASME BPE END FITTING

DASH NUMBER

3.56

3.2

1.50

1/2"

8-4

3.56

3.2

1.50

1/2"

8-6

3.56

3.3

1.50

1/2"

8

3.56

3.3

1.77

1-1/4"

10

3.56

3.4

1.77

1-1/4"

12

3.56

3.5

1.99

1-1/2"

16

4.59

3.6

2.17

1-1/2"

20

4.59

3.8

2.38

1-1/2"

24

6.06

4.0

3.18

2"

32

A

B

HEX BODY

SQUARE BODY

A

B

BODY

SQUARE

SQUARE

SQUARE

SQUARE

SQUARE

HEX

HEX

HEX

HEX

(Compliant with AS4375)

Precision Meters, Turbine Flow Meters

Tri-Clamp End Fitting

Figure 11: Tri-clamp end fitting

Size

End Fitting

in. (mm)

8-4 0.50 (12.70) 3.56 (90.42) 3.20 (81.28) 2.70 (68.58) 1.50 (38.10)

8 0.50 (12.70) 3.56 (90.42) 3.30 (83.82) 2.80 (71.12) 1.50 (38.10)

10 1.25 (31.75) 3.56 (90.42) 3.30 (83.82) 2.80 (71.12) 1.77 (44.96)

12 1.25 (31.75) 3.56 (90.42) 3.40 (86.36) 2.90 (73.66) 1.77 (44.96)

16 1.50 (31.80) 3.56 (90.42) 3.50 (88.90) 3.00 (76.20) 1.99 (50.55)

20 1.50 (31.80) 4.59 (116.6) 3.60 (91.44) 3.10 (78.74) 2.17 (55.12)

24 1.50 (31.80) 4.59 (116.6) 3.80 (96.52) 3.30 (83.82) 2.38 (60.45)

32 2.00 (50.80) 6.06 (153.9) 4.00 (101.6) 3.50 (88.90) 3.18 (80.77) 2.00 (50.80)

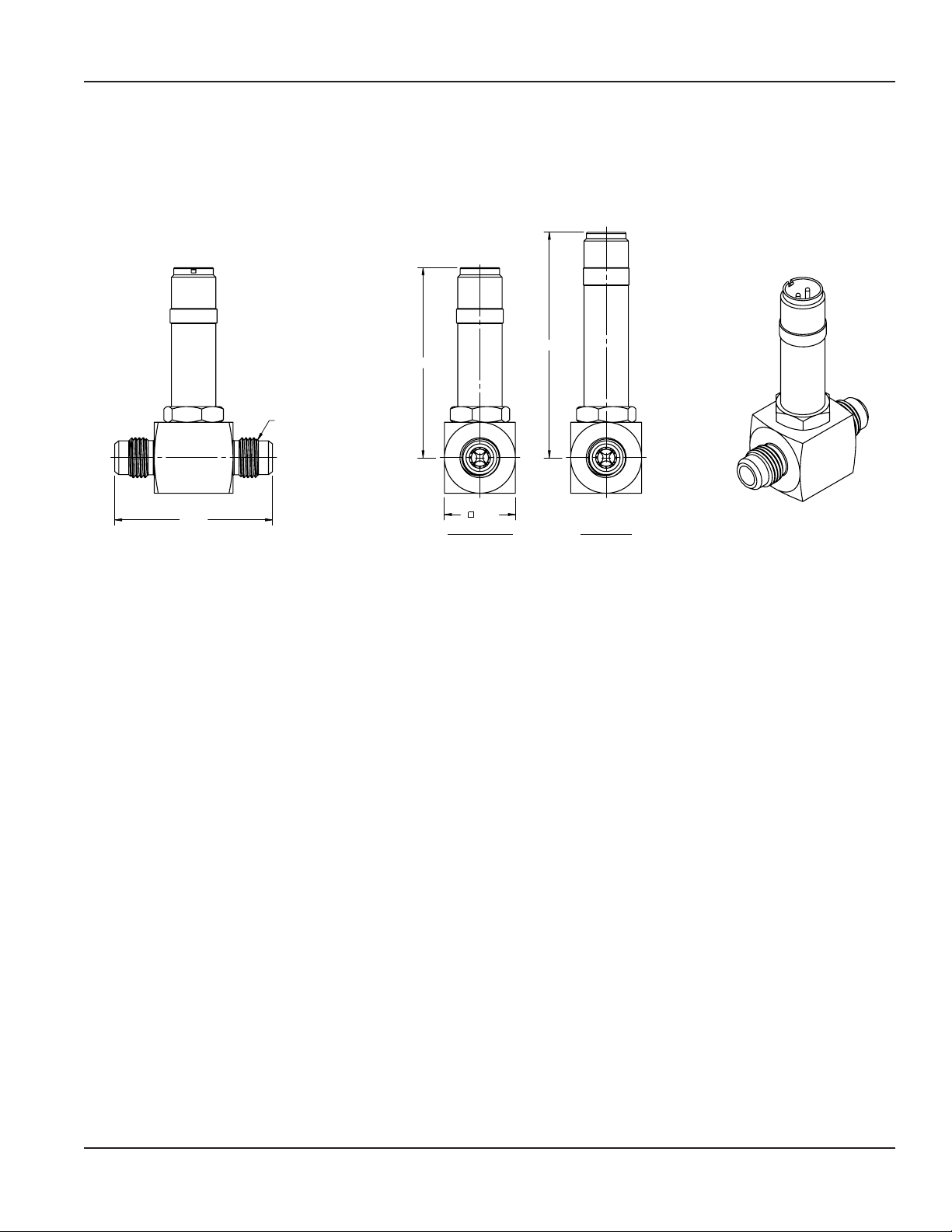

High Pressure End Fitting

Size

End Fitting

in. (mm)

8-4 0.50 (12.70) 3.25 (82.55) 3.20 (81.28) 2.70 (68.58) 1.12 (28.45) Square body

8-6 0.50 (12.70) 3.25 (82.55) 3.20 (81.28) 2.70 (68.58) 1.12 (28.45) Square body

8 0.50 (12.70) 3.50 (88.90) 3.30 (83.82) 2.80 (71.12) 1.12 (28.45) Square body

10 0.625(15.88) 4.00 (101.6) 3.30 (83.82) 2.80 (71.12) 1.25 (31.75) Square body

12 0.75 (19.05) 4.50 (114.3) 3.40 (86.36) 2.90 (73.66) 1.50 (38.10) Square body

16 1.00 (25.40) 4.75 (120.7) 3.50 (88.90) 3.00 (76.20) 1.63 (41.40) Hex body

20 1.25 (31.75) 5.50 (139.7) 3.60 (91.44) 3.10 (78.74) 1.88 (47.75) Hex body

24 1.50 (38.10) 6.00 (152.4) 3.80 (96.52) 3.30 (83.82) 2.25 (57.15) Hex body

32 2.00 (50.80) 7.00 (177.8) 4.00 (101.6) 3.50 (88.90) 2.75 (69.85) Hex body

A

in. (mm)

in. (mm)

B (RF)

in. (mm)

B (MAG)

in. (mm)

Table 8: Tri-clamp end fitting dimensions

Figure 12: High pressure end fitting

A

B (RF)

in. (mm)

Table 9: High pressure end fitting dimensions.

B (MAG)

in. (mm)

C

in. (mm)

Clamp Size

in. (mm)

0.75(19.05)8-6 0.50 (12.70) 3.56 (90.42) 3.20 (81.28) 2.70 (68.58) 1.50 (38.10)

1.50 (38.10)

C

in. (mm)

Page 16 May 2014

Page 17

LoFlo

The dimension from the center of bore to top of pickoff represents the most common pickoff types. Length may vary

depending on pickoff choice. Consult factory for details.

OTE:N Dimensions below are shown in inches.

3.2

2.7

2X AN END FITTINGS

(PER AS4395)

User Manual

2.22

1.00

MAG PICKOFF

Figure 13: LoFlo meter dimensions

RF PICKOFF

Page 17 May 2014

Page 18

A

B

D

HEX BODY

SQUARE BODY

A

B

D

HEX BODY

SQUARE BODY

Precision Meters, Turbine Flow Meters

DIMENSIONS GAS

Dimension B specifies the most common pickoff type. Actual size may vary depending on pickoff choice. Consult factory

for details.

AN End Fitting

Figure 14: AN end fitting

Size

End Fitting

in. (mm)

8-4 0.50 (12.70) 2.45 (62.23) 2.80 (71.12)

8-6 0.50 (12.70) 2.45 (62.23) 2.80 (71.12)

8 0.50 (12.70) 2.45 (62.23) 2.80 (71.12)

10 0.625 (15.88) 2.72 (69.08) 2.80 (72.12) 1.25 (31.75) Square Body 4.30 (109.2)

12 0.75 (19.05) 3.25 (82.55)

16 1.00 (25.40) 3.56 (90.42)

20 1.25 (31.75) 4.06 (103.1)

24 1.50 (38.10) 4.59 (116.6)

32 2.00 (50.80) 6.06 (153.9) 3.50 (88.90) 2.75 (69.85) Hex Body 5.70 (144.8)

NPT End Fitting

A

in. (mm)

B

in. (mm)

2.90 (73.66) 1.25 (31.75) Square Body

3.00 (76.20) 1.63 (41.40) Hex Body

3.10 (78.74) 1.88 (47.75) Hex Body

3.30 (83.82) 2.25 (57.15) Hex Body

Table 10: AN end fitting dimensions

C

in. (mm)

1.12 (28.44) Square Body

1.12 (28.44) Square Body

1.12 (28.44) Square Body

D

in. (mm)

4.20 (106.7)

4.20 (106.7)

4.20 (106.7)

4.40 (111.8)

4.70 (119.4)

4.90 (124.5)

5.20 (132.1)

Figure 15: NPT end fitting

Size

End Fitting

in. (mm)

A

in. (mm)

B

in. (mm)

C

in. (mm)

D

in. (mm)

8-4 0.50 (12.70) 2.70 (68.58) 2.80 (71.82) 1.12 (28.44) Square Body 4.20 (106.7)

8-6 0.50 (12.70) 2.70 (68.58) 2.80 (71.82) 1.12 (28.44) Square Body 4.20 (106.7)

8 0.50 (12.70) 2.70 (68.58) 2.80 (71.82) 1.12 (28.44) Square Body 4.20 (106.7)

10 0.75 (19.05) 3.29 (83.57) 2.80 (71.82) 1.25 (31.75) Square Body 4.30 (109.2)

12 0.75 (19.05) 3.29 (83.57) 2.90 (73.66) 1.25 (31.75) Square Body 4.40 (111.8)

16 1.00 (25.40) 3.78 (96.01) 3.00 (76.20) 1.63 (41.40) Hex Body 4.70 (119.4)

20 1.25 (31.75) 4.23 (107.4) 3.10 (78.74) 1.88 (47.75) Hex Body 4.90 (124.5)

24 1.50 (38.10) 4.67 (118.6) 3.30 (83.82) 2.25 (57.15) Hex Body 5.20 (132.1)

32 2.00 (50.80) 5.89 (149.6) 3.50 (88.90) 2.75 (69.85) Hex Body 5.70 (144.8)

Table 11: NPT end fitting dimensions

Page 18 May 2014

Page 19

Flange End Fitting

A

2X FLANGES

(PER ASME B16.5)

AN-4 PRESSURE TAP FITTING

(PER AS4395)

B

C

D

User Manual

Figure 16: Flange and fitting

Size

A

in. (mm)

B#

in. (mm)

C#

in. (mm)

D

150# Flange

in. (mm)

D

300# Flange

in. (mm)

D

600# Flange

in. (mm)

8-4 5.00 (127.0) 2.80 (71.12) 4.10 (104.1) 3.50 (89) 3.75 (95) 3.75 (95)

8-6 5.00 (127.0) 2.80 (71.12) 4.10 (104.1) 3.50 (89) 3.75 (95) 3.75 (95)

8 5.00 (127.0) 2.80 (71.12) 4.30 (109.2) 3.50 (89) 3.75 (95) 3.75 (95)

10 5.50 (139.7) 2.80 (72.12) 4.40 (111.8) 3.50 (89) 3.75 (95) 3.75 (95)

12 5.50 (139.7) 2.90 (73.66) 4.50 (114.3) 3.88 (99) 4.62 (117) 4.62 (117)

16 5.50 (139.7) 3.00 (76.20) 4.80 (121.9) 4.25 (108) 4.88 (124) 4.88 (124)

20 6.00 (152.4) 3.10 (78.74) 5.00 (127.0) 4.62 (117) 5.25 (133) 5.25 (133)

24 6.00 (152.4) 3.30 (83.82) 5.20 (132.1) 5.00 (127) 6.12 (155) 6.12 (155)

32 6.50 (165.1) 3.50 (88.90) 5.70 (144.8) 6.00 (152) 6.50 (165) 6.50 (165)

Table 12: Flange end fitting dimensions

Page 19 May 2014

Page 20

Precision Meters, Turbine Flow Meters

Stouhal Number

7000

6500

6000

5500

5000

4500

Figure 17: Typical linearity curve for a size 20 flow meter

UVC Plot, Three Viscosities

0.7 cStk

4.2 cStk

25.5 cStk

4000

1 10 100 1,000 10,000

Roshko Number

Figure 18: UVC plot

Page 20 May 2014

Page 21

= 1200 �1.0/1.5 = 980

User Manual

FACTORS AFFECTING LINEARITY

There are many factors affecting the linearity of turbine flow meters. The following enumerates some of these factors and

their effect.

Size

The size of the meter selected is determined by the flow range required and the fluid characteristics. Standard flow ranges are

listed in the Product Data Sheet. Where range requirements fall between listed ranges, it may be necessary to use two meters

or a meter can be ordered for the specific range required. Overspeeding to meet a required flow capacity results in lowered

operating life. Going to a larger meter size to avoid overspeeding will result in the non-linear range at the lower flow rates.

Bearings

The rotor in a standard meter is mounted on ball bearings. The function of rolling friction in regard to linear operating range

is nil and can be disregarded. Where ball bearings cannot be used because of fluid characteristics, a sleeve or bushing type

bearing is available at the expense of a reduced linear range. Due to the inherent character of increased friction, the linear

operating range may be sharply curtailed in the lower capacity meters.

Pickos

Magnetic pickoffs affect the linear range of a meter, due to magnetic drag on the rotor. Since the turning force available is a

function of the total mass flow, the low capacity meters will be more affected at the minimum flow rate than the high capacity

meters. Replacement pickoffs should have the same part number as original equipment, otherwise the linear range can

be affected.

Fluids

There are two types of fluids: compressible and incompressible. Considering only the incompressible (liquids), there are three

factors that affect the linear flow range. They are lubricity, density and viscosity.

Lubricity

This is not a measurable quantity. It is that property of a liquid which determines the friction within the bearing and affects

the life of the bearing as well as the linear operating range. Lack of lubricity can cause erratic action, especially at the low end

of the flow range.

Density

Turbine flow meters are designed to operate over the standard frequency range with liquids of 1.0 specific gravity (H2O).

If a liquid of 1.5 specific gravity is used, it will have a 50% increase in driving force available at a given frequency. Also, the

differential pressure of the meter is increased a like amount. This increased differential pressure can reduce the life of the

bearing. Reduction of maximum operating frequency to maintain design pressure drop will result in reduced bearing life. The

maximum frequency can be approximately calculated as shown by the following example:

Figure 19: Calculating maximum frequency

Page 21 May 2014

Page 22

Precision Meters, Turbine Flow Meters

Viscosity

In a turbine meter, the one factor that affects the linear range the greatest is viscosity. The skin friction (viscous affect of

the boundary layers) on the blades of the rotor and adjacent surfaces, is known to be a function of the Reynolds number

(a dimensionless parameter). At a sufficiently low Reynolds number, the boundary layer is completely laminar. At a high

Reynolds number, the boundary layer is turbulent. In the transition region, there is a gradual change from laminar to

turbulent flow. At low viscosities, the Reynolds number is high, so that at the minimum operating frequency the flow is still

turbulent. As the viscosity is increased, the Reynolds number decreases and the meter (at the same minimum frequency) is

operating in the transition region. At this point, the drag actually decreases and the K-Factor (cycles per gallon) increases.

A further increase in viscosity and the Reynolds number decreases to a point where the flow is completely laminal and the

K-Factor decreases. In effect, as the viscosity increases, the range in which the flow is turbulent decreases. In low capacity flow

meters, the viscosity effect may be of such an order that the entire flow range will be in the laminar flow region.

Mounting for Calibration

Turbine flow meters are calibrated with the axis horizontal and the pickoff on top. Flow meters with ball bearings may be

mounted in any attitude with nil affect on the linearity range or calibration. Pipe configuration, such as valves, tees and

elbows immediately preceding the meter, can produce swirl in the fluid with erroneous results. A minimum of 10 diameters

of tubing the same size as the meter is recommended. For maximum precision, external flow straighteners are available for all

size meters.

Pressure Drop

Pressure drop across turbine flow meters is substantially constant for a given gravimetric flow rate, but varies in approximate

proportion to the square of the volumetric flow rate. This variation is proportional to a liquid’s density. The values shown

under range characteristics are based on a liquid specific gravity of 0.760 and a viscosity of 1 centistoke.

Specic Gravity

Changes in the specific gravity of a liquid in a linear shift in gravimetric calibration can be plotted as a function of specific

gravity. These changes have no measurable effect on the volumetric flow rate but will cause a shift in the pressure drop across

the flow meter.

Pressure

Pressure changes have no measurable effect on volumetric flow rates.

Temperature

Large temperature changes cause an area change within the flow meter. Higher temperature will result in decreased fluid

velocity while depressed temperature will result in increased fluid velocity. This change will cause a variation of the K-Factor

that is supplied with the turbine flow meter. Turbine flow meters calibrated at one temperature and operated at another

require correction of their K-Factor. Cox Precision Turbine Flow Meters can operate from –350…500° F, and up to 800° F using

a special high temperature pickoff.

Associated Equipment

Electrical leads from the flow meter to remote associated equipment should be carefully chosen to be compatible with

the flow meter output and the impedance values of the components used. Distance between flow meter and associated

equipment is then a negligible factor. Use good quality coaxial cable or twisted pairs, with or without shielding, as required

by environmental factors. If a shielded lead is required, it must not be grounded at the flow meter since neither pin of the

standard pickoff is grounded. Ground at some other point to eliminate ground loops in the associated equipment.

Filtration

Filtration is recommended as follows:

• LoFlo meters, meter sizes 84 through 08, and flange sizes 84, 86, 8 and 10 flow meters should have filters with a rating of

25…40 microns.

• Size 10 through 32 and flange sizes 12 through 48 flow meters should have filters with a rating of 40…75 microns.

Page 22 May 2014

Page 23

User Manual

RECALIBRATION

• Recalibration is not necessary following a cleaning operation or the replacement of bearings, snap rings, springs

or spacers.

• Recalibrate the flow meter if the rotor hub, or rotor and flow straightener assembly is replaced.

• Flow meters may be recalibrated by the user if the facilities are available, or they may be returned to the factory. Yearly

calibration is recommended.

• When the flow meter is set up for recalibration, allow the fluid to circulate for 5 minutes before beginning the

calibrating runs.

LOFLO REPLACEMENT PARTS

Figure 20: Model CLFA6 Figure 21: Model CLFB6 Figure 22: Models CLFC6…CLFF6

1100 – Flow is through 0.03

1300 – Rotor is angled blade

1400 – Bearing is staked into rotor.

(Factory replace)

1100 – Flow is through swirl slot.

Tube is press fit over slot.

1300 – Rotor has straight blades.

1400 – Bearing is staked into rotor.

(Factory replace)

1100 – Flow is through swirl slots. No tube over slots.

1300 – Rotor has straight blades.

1400 – Bearing is held with snap rings. (Field replace)

Page 23 May 2014

Page 24

Control. Manage. Optimize.

COX INSTRUMENTS is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous

research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an

outstanding contractual obligation exists. © 2014 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-04 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412 Legacy Document Number: CH-4001

Loading...

Loading...