Page 1

Page 2

SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety should always be followed, including the

following:

Read all instructions before using this sewing machine.

DANGER

1. An appliance should never be left unattended when plugged in.

2. Always unplug this appliance from the electrical outlet immediately after using and before

cleaning.

3. Always unplug before checking and re-lamping. Contact the authorized retailer or service

center for repair in the event of failure if the machine is with 200mW, 300mW and 200mW

LED lamp, which is not user-replaceable.

WARNING

1. Do not allow to be used as a toy. Close attention is necessary when this appliance is

used by or near children.

2. Use this appliance only for its intended use as described in this manual. Use only the

attachments recommended by the manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working properly,

if it has been dropped or damaged, or dropped into water. Return the appliance to the

nearest authorized retailer or service center for examination, repair, electrical or

mechanical adjustment.

4. Never operate the appliance with any air openings block. Keep ventilation openings of the

sewing machine and foot control free from accumulation of lint, dust, and loose cloth.

5. Keep fingers away from all moving parts. Special care is required around the sewing

machine needle.

6. Always use the proper needle plate, a wrong needle plate can cause the needle to break.

7. Do not use bent needles.

8. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

9. Switch the sewing machine off ("O") when making any adjustments in the needle area,

such as threading needle, changing needle, threading bobbin, or changing presser foot,

and the light.

10.Always unplug sewing machine from the electrical outlet when removing covers, lubricating,

or when making any other user servicing adjustments mentioned in the instruction manual.

11.Never drop or insert any object into any opening.

12.Do not use outdoors.

13.Do not operate where aerosol spray products are being used or where oxygen is being

administered.

14.To disconnect, turn all controls to the off ("O") position, then remove plug from outlet.

15.Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

16.The sound pressure level under normal operating conditions is 75dB(A).

17.

Please turn off the machine or unplug when the machine is not operating properly.

-To reduce the risk of electrical shock:

-To reduce the risk of burns, fire, electrical shock, or injury to persons:

SAVE THESE INSTRUCTIONS

This sewing machine is intended for household use only.

1

Page 3

PLEASE READ BEFORE USING THIS MACHINE

For safe operation

1. Be sure to keep your eye on the needle while sewing. Do not touch the handwheel,

thread take-up lever, needle or other moving parts.

2. Remember to turn OFF the power switch and unplug the cord when:

Operation is completed.

Replacing or removing the needle or any other parts.

A power failure occurs during use.

Maintaining the machine.

Leaving the machine unattended.

3. Do not store anything on the foot controller.

4. Plug the machine directly into the wall.

For a longer service life

1. When storing this machine, avoid direct sunlight and high humidity locations. Do not use

or store the machine near a space heater, iron, halogen lamp, or other hot objects.

2. Use only neutral soaps or detergents to clean the machine. Benzene, thinner, and

scouring powder can damage the machine, and should never be used.

3. Do not drop or hit the machine.

4. Always consult this operation manual when replacing or installing any assemblies, the

presser feet, needle or other parts to assure correct installation.

For repair or adjustment

In the event a malfunction occurs or adjustment is required, first follow the troubleshooting

guide in the back of this operation manual to inspect and adjust the machine yourself. If the

problem persists, please consult your local authorized Baby Lock retailer.

For additional product information and updates, visit our website at

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection facilities.

Contact your local government for information regarding the collection systems available.

If electrical appliances are disposed of in landfills or dumps, hazardous substances can leak into the

groundwater and get into the food chain, damaging your health and well-being.

When replacing old appliances with new ones, the retailer is legally obligated to take back your old

appliance for disposal at least for free of charge.

www.babylock.com

2

Page 4

CONTENTS

CONTENTS

INSTRUCTIONS

SAFETY INSTRUCTIONS........................................................................................................................................1-2

CONTENTS ..............................................................................................................................................................3-4

ACCESSORIES...........................................................................................................................................................5

PRINCIPAL PARTS OF THE MACHINE ....................................................................................................................6

FOOT CONTROL ........................................................................................................................................................7

OPERATION BUTTONS .............................................................................................................................................8

START/STOP button ........................................................................................................................................8

Reverse button .................................................................................................................................................8

Auto-lock button................................................................................................................................................9

Needle position button .....................................................................................................................................9

FUNCTION BUTTONS ..............................................................................................................................................10

Stitch width adjustment button........................................................................................................................10

Stitch length adjustment button ......................................................................................................................11

FUNC selection button ...................................................................................................................................11

Key lock button ...............................................................................................................................................12

Bobbin winding button ....................................................................................................................................12

Elongation button............................................................................................................................................12

Mirror image button ........................................................................................................................................13

Twin needle button .........................................................................................................................................13

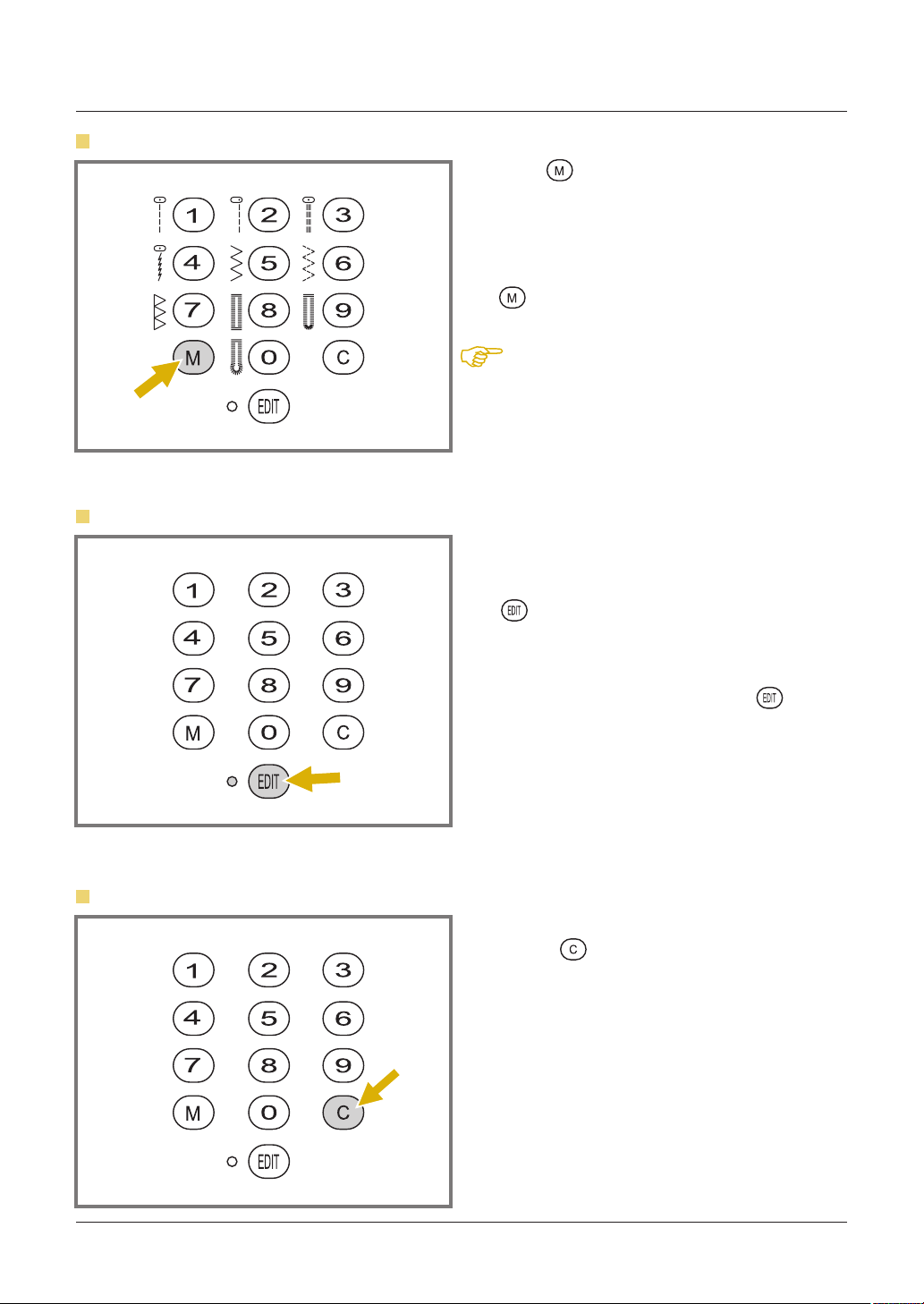

SELECTION BUTTONS ............................................................................................................................................14

Direct pattern selection and number buttons..................................................................................................14

Memory button................................................................................................................................................15

Edit button ......................................................................................................................................................15

Clear button ....................................................................................................................................................15

GETTING READY

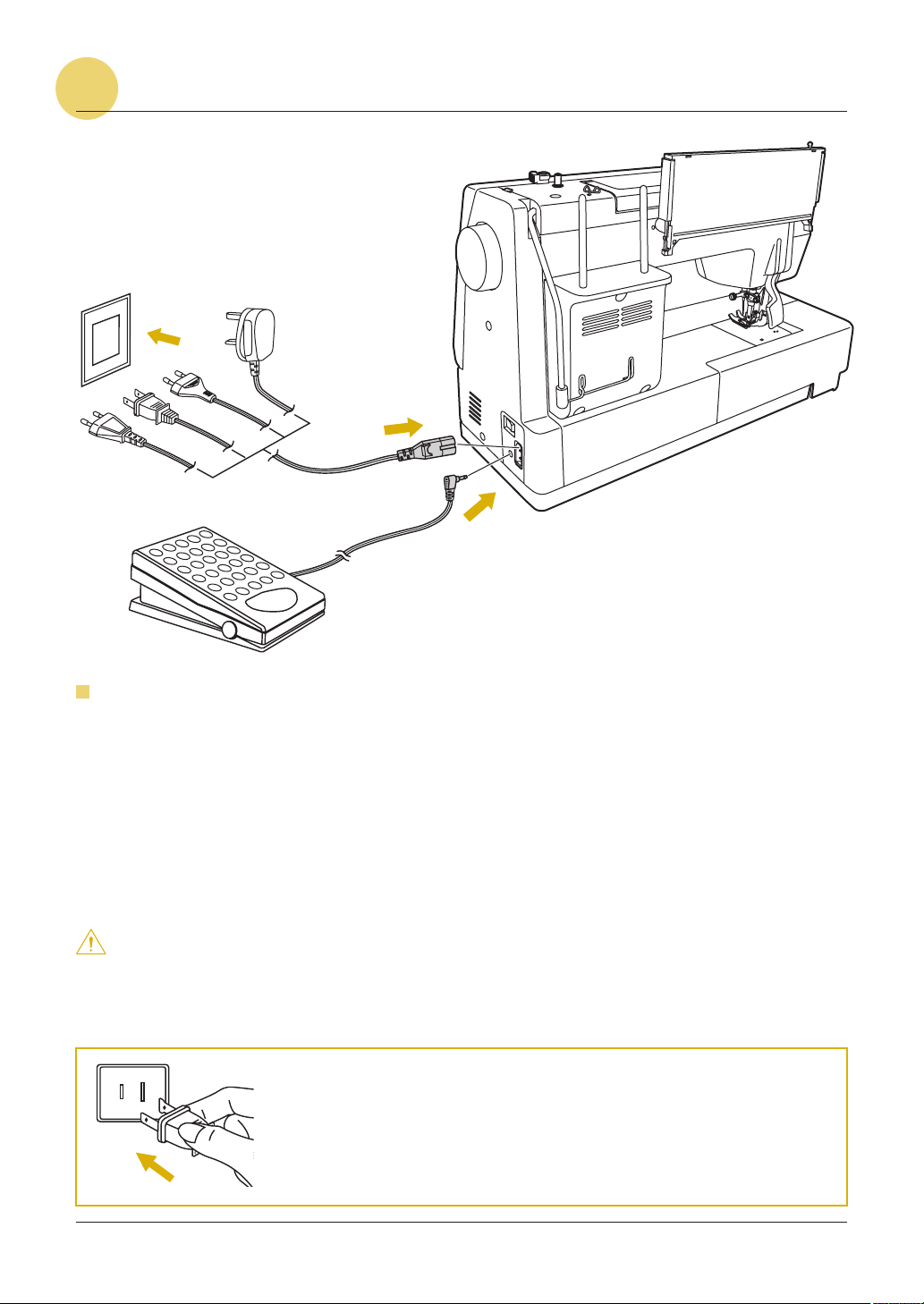

CONNECTING THE MACHINE TO THE POWER SOURCE....................................................................................16

Connecting the machine.................................................................................................................................16

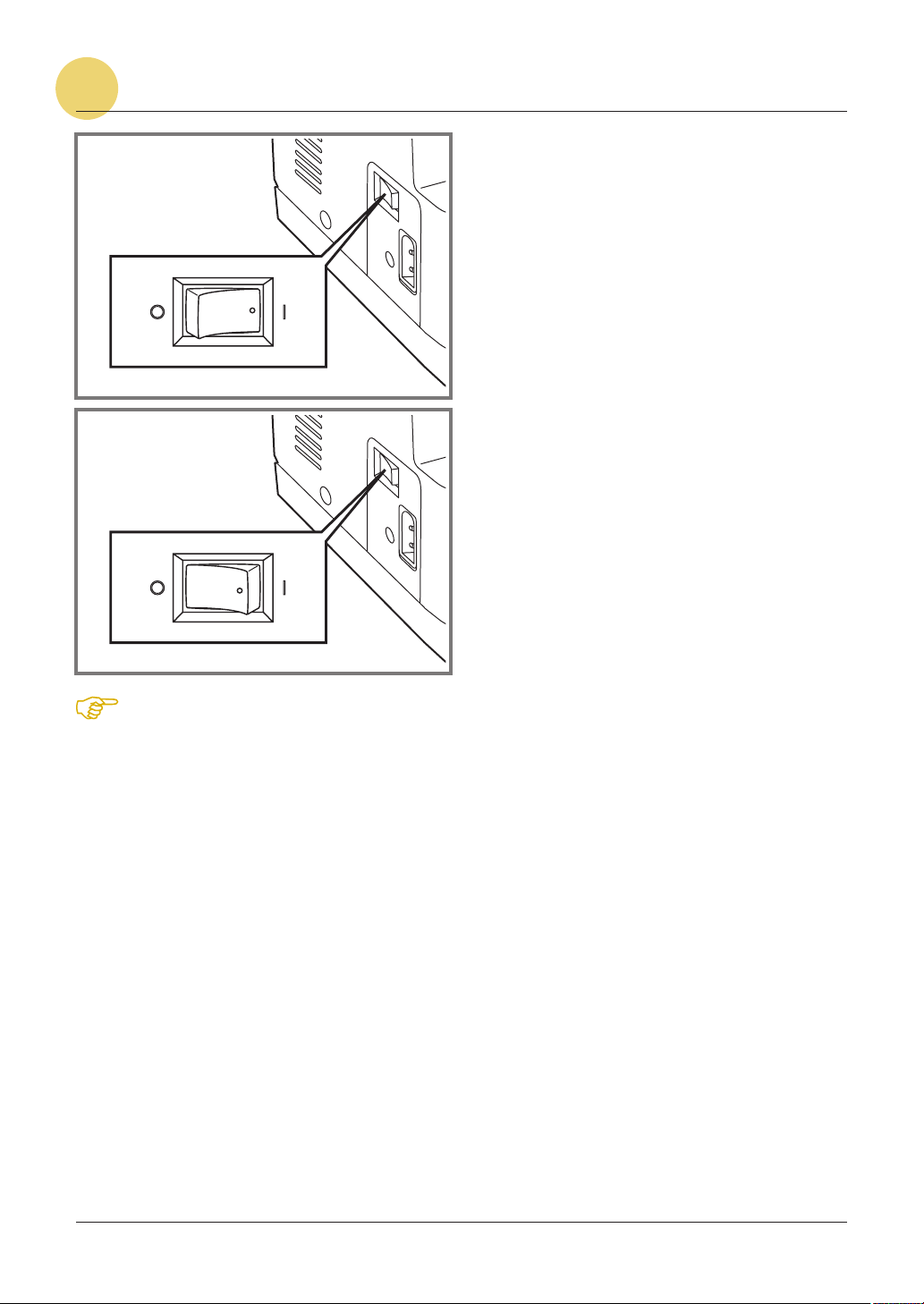

TURN MACHINE ON / OFF.......................................................................................................................................17

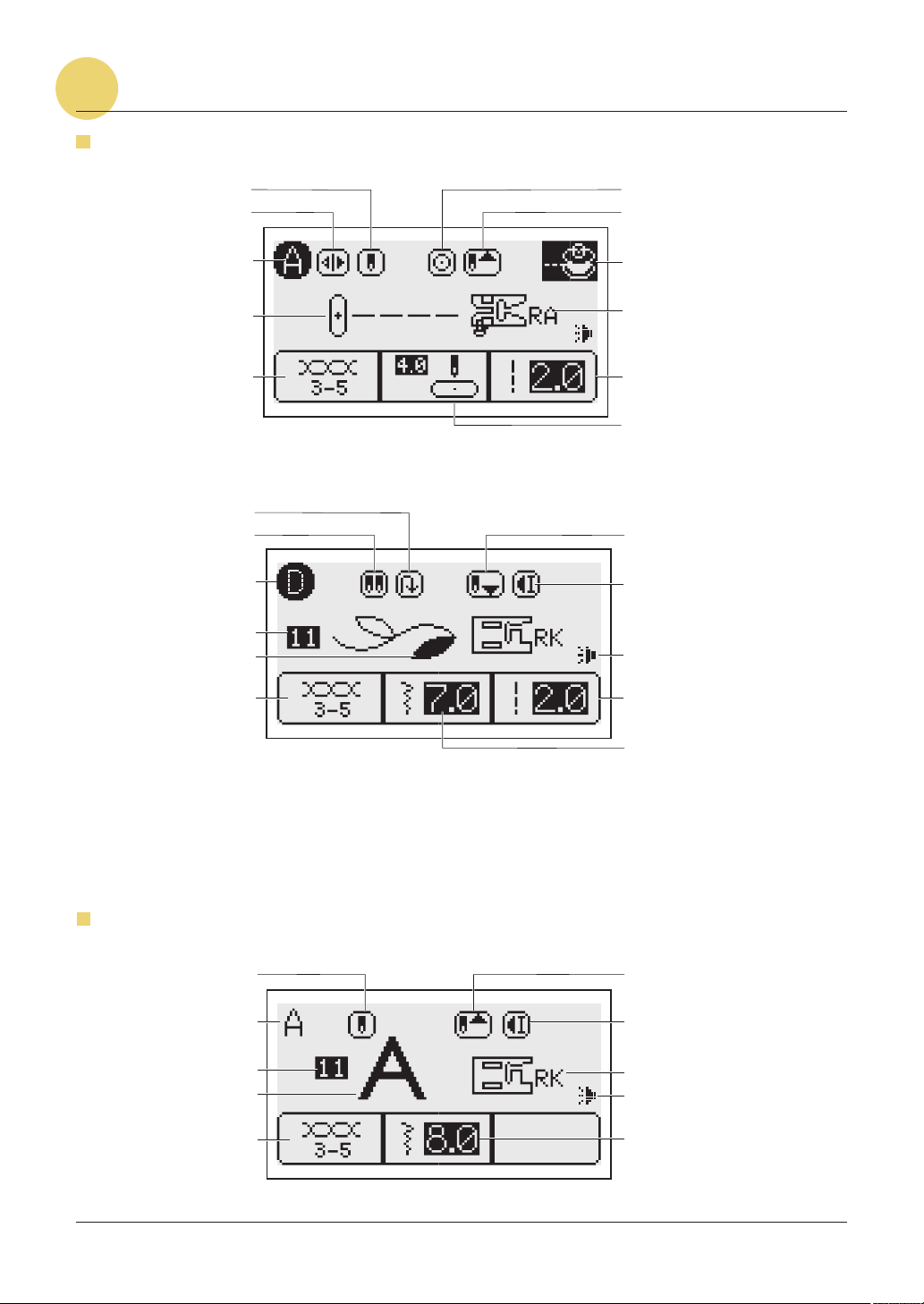

UNDERSTANDING THE LCD SCREEN..............................................................................................................18-19

LCD SCREEN BRIGHTNESS CONTROL ................................................................................................................19

WINDING THE BOBBIN............................................................................................................................................20

Bobbin winding ..........................................................................................................................................20-22

INSERTING THE BOBBIN...................................................................................................................................23-24

UPPER THREADING ...........................................................................................................................................25-27

Using the needle threader ..............................................................................................................................28

Using the net ..................................................................................................................................................29

Raising up the lower thread............................................................................................................................30

CUTTING THE THREAD...........................................................................................................................................31

REPLACING THE NEEDLE ......................................................................................................................................31

CHANGING THE PRESSER FOOT ..........................................................................................................................32

Attaching the presser foot holder....................................................................................................................32

Attaching the presser foot...............................................................................................................................32

Removing the presser foot .............................................................................................................................32

Type of presser foot chart...............................................................................................................................33

Two-step presser foot lifter ...................................................................................................

PRECISION DUAL-FEED QUILTING (PDQ )...........................................................................................................35

To engage the ..........................................................................................................................35

To disengage the .....................................................................................................................36

Fabric positioning ...........................................................................................................................................36

PDQ system

PDQ system

®

..........................34

SEWING BASICS

PATTERN CHART ...............................................................................................................................................37-38

MATCHING NEEDLE/ FABRIC/ THREAD ...............................................................................................................39

THREAD TENSION ...................................................................................................................................................40

LENGTH & WIDTH ADJUSTMENT ..........................................................................................................................41

Stitch width adjustment...................................................................................................................................41

Stitch length adjustment .................................................................................................................................41

PATTERN BALANCE ADJUSTMENT......................................................................................................................42

PRESSER FOOT PRESSURE ADJUSTMENT ........................................................................................................43

USEFUL FUNCTIONS...............................................................................................................................................44

Reverse ..........................................................................................................................................................44

Free arm sewing.............................................................................................................................................44

Installing the extension table ..........................................................................................................................45

To raise or drop the feed dogs .......................................................................................................................46

Attaching the knee lifter ..................................................................................................................................46

Knee lifter to raise / lower presser foot ...........................................................................................................46

3

Page 5

USEFUL SEWING TIPS ............................................................................................................................................47

Sewing corners...............................................................................................................................................47

Sewing on heavy fabric ..................................................................................................................................47

STITCHES

SELECTING STITCHES............................................................................................................................................48

BASIC STITCHING ...................................................................................................................................................49

Straight stitches and needle position..............................................................................................................49

Zigzag stitches ...............................................................................................................................................49

Stretch stitch...................................................................................................................................................50

BLIND HEM / LINGERIE STITCHING.......................................................................................................................51

OVERCASTING STITCHES......................................................................................................................................52

Using the overcasting foot ..............................................................................................................................52

Using the all purpose foot...............................................................................................................................52

ZIPPER INSERTION ............................................................................................................................................53-54

Inserting a centered zipper .............................................................................................................................53

Inserting a side zipper ....................................................................................................................................54

BUTTON SEWING ....................................................................................................................................................55

BUTTONHOLE STITCHING ................................................................................................................................56-59

Making a one-step buttonhole ...................................................................................................................56-59

Making a buttonhole on stretch fabrics...........................................................................................................59

BAR TACK STITCH .............................................................................................................................................60-61

EYELET STITCH .......................................................................................................................................................62

DARNING STITCH ...............................................................................................................................................63-64

To adjust the evenness of darning stitch ........................................................................................................64

NARROW HEMMING ...............................................................................................................................................65

QUILTING.............................................................................................................................................................66-69

Using the straight stitch needle plate..............................................................................................................66

Patchwork sewing...........................................................................................................................................66

Hand quilting stitch .........................................................................................................................................66

Decorative patchwork stitching.......................................................................................................................67

Free motion darning, embroidery & monogramming.................................................................................68-69

ATTACHING THE EDGE/ QUILTING GUIDE...........................................................................................................70

DECORATIVE TECHNIQUES

CORDING ..................................................................................................................................................................71

Single cording.................................................................................................................................................71

Triple cording..................................................................................................................................................71

FAGOTING ................................................................................................................................................................72

GATHERING ........................................................................................................................................................73-74

SATIN STITCH SEWING...........................................................................................................................................75

SCALLOP STITCH....................................................................................................................................................76

Scallop hem....................................................................................................................................................76

Scallop edging ................................................................................................................................................76

SMOCKING ...............................................................................................................................................................77

THE TWIN NEEDLE.............................................................................................................................................78-79

DECORATIVE PATTERNS

ELONGATION ...........................................................................................................................................................80

MIRROR IMAGE........................................................................................................................................................81

MEMORY FUNCTION ..........................................................................................................................................82-85

Combining patterns or letters ....................................................................................................................82-83

Adding patterns or letters ...............................................................................................................................83

Editing patterns...............................................................................................................

Clearing patterns or letters .............................................................................................................................84

Recalling and sewing the memorized pattern.................................................................................................85

................................84

APPENDIX

WARNING FUNCTIONS ...........................................................................................................................................86

Warning animation message display..............................................................................................................86

Instruction animation message display...........................................................................................................87

Unlock.............................................................................................................................................................87

Warning beeping sound..................................................................................................................................88

Beeping sound................................................................................................................................................88

MAINTENANCE ...................................................................................................................................................89-90

Cleaning the LCD screen ...............................................................................................................................89

Cleaning the sewing machine surface............................................................................................................89

Cleaning the hook .....................................................................................................................................89-90

TROUBLESHOOTING .........................................................................................................................................91-92

STITCH REFERENCE CHART ..........................................................................................................................93-102

4

Page 6

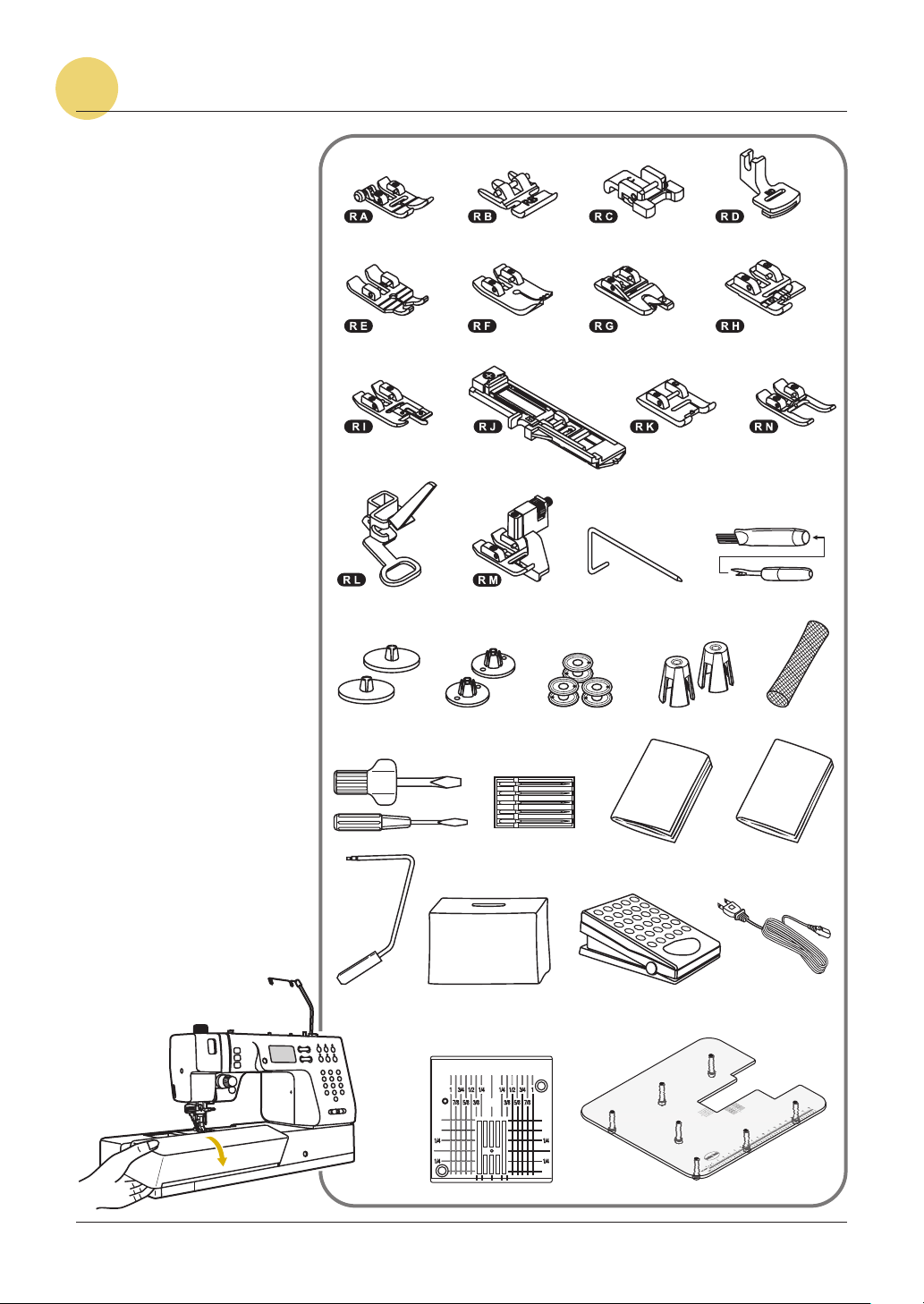

ACCESSORIES

ACCESSORIES

1. All purpose foot (RA)

2. Zipper foot (RB)

3. (RC)

Button sewing foot

4. Gathering foot (RD)

5. 1/4" inch quilting foot (RE)

6. Quilting foot (RF)

7. Hemmer foot (RG)

8. Cording foot (RH)

9. Overcasting foot (RI)

10.Buttonhole foot (RJ)

11.Satin stitch foot (RK)

12.Open toe foot (RN)

13.Darning/

Embroidery foot (RL)

14.Blind hem foot (RM)

15.

Edge/quilting guide

16.Brush/ Seam ripper

17.Spool cap (Large)(2X)

18.Spool cap (Small)(2X)

19.Bobbin (3X)

20.Cone holder (2X)

21.Net

22.Screwdriver (L & S)

23.Pack of needle

24.Instruction and

Reference Guide

25.Quick Reference Guide

26.Knee lifter

27.Soft cover

28.Foot control

29.Power cord

30.Straight stitch needle plate

31.Extension table

1 3 42

5

9 1110

17

18

22

27

6

7

8

12

1613 14

21

25

29

19

15

RG

20

2423

2826

30 31

0

5

Page 7

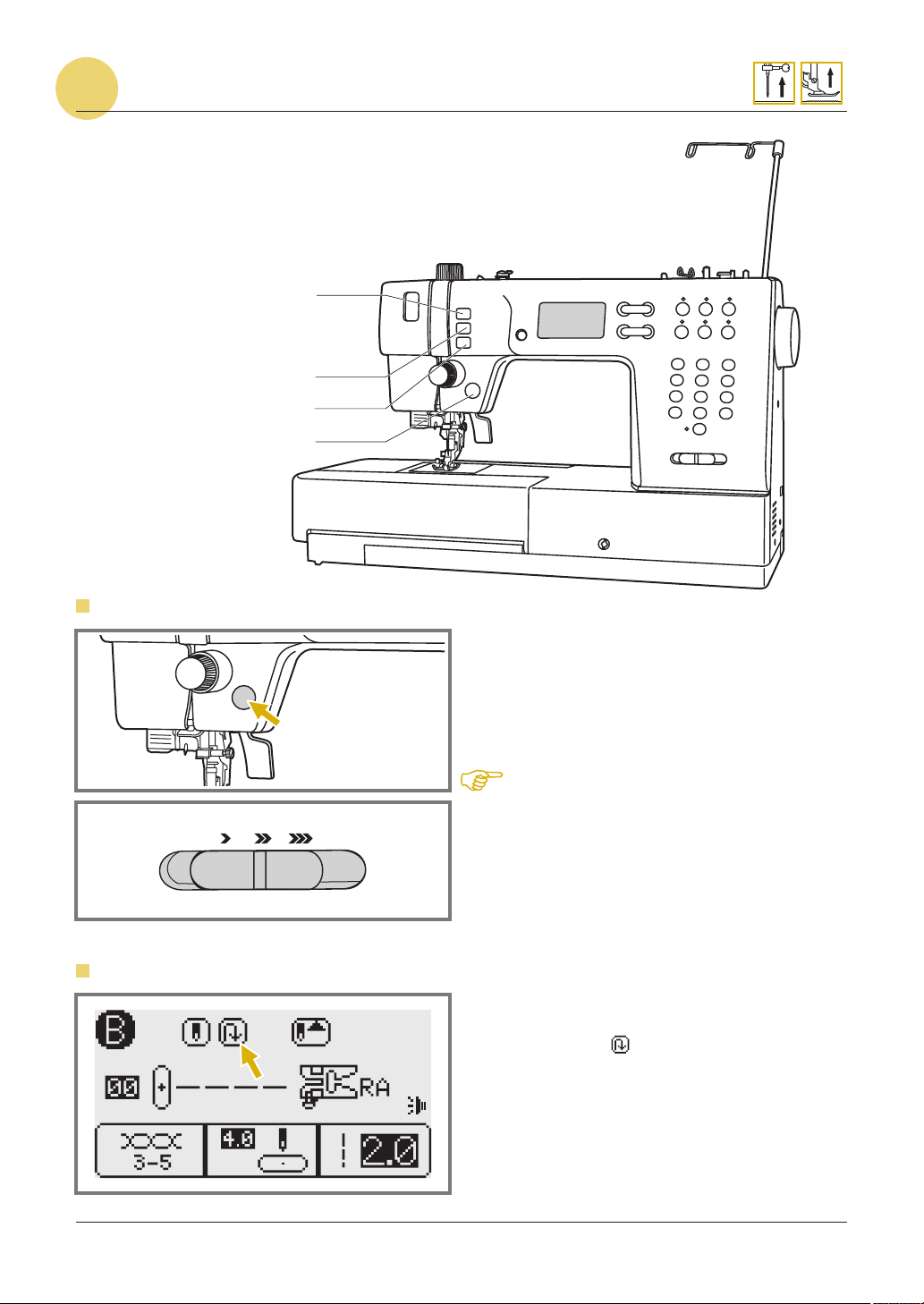

PRINCIPAL PARTS OF THE MACHINE

PRINCIPAL PARTS OF THE MACHINE

LCD screen

Bobbin thread guide

brightness control

LCD screen

Spool pins

Stitch pattern plate

Presser foot pressure dial

Operation buttons

Face plate

Tension dial

Thread cutter

Buttonhole lever

Needle threader

Needle plate

Sewing table and

accessory box

Drop feed lever

Retractable thread guide

Bobbin winder

Bobbin winder switch

and thread cutter

Function buttons

Selection buttons

Sewing speed controller

Knee lifter slot

Pattern adjustment dial

Handwheel

Main power switch

Foot control

connector

Power supply connector

Handle

Precision dual-feed

quilting (PDQ )

Presser foot lever

6

Page 8

FOOT CONTROL

FOOT CONTROL

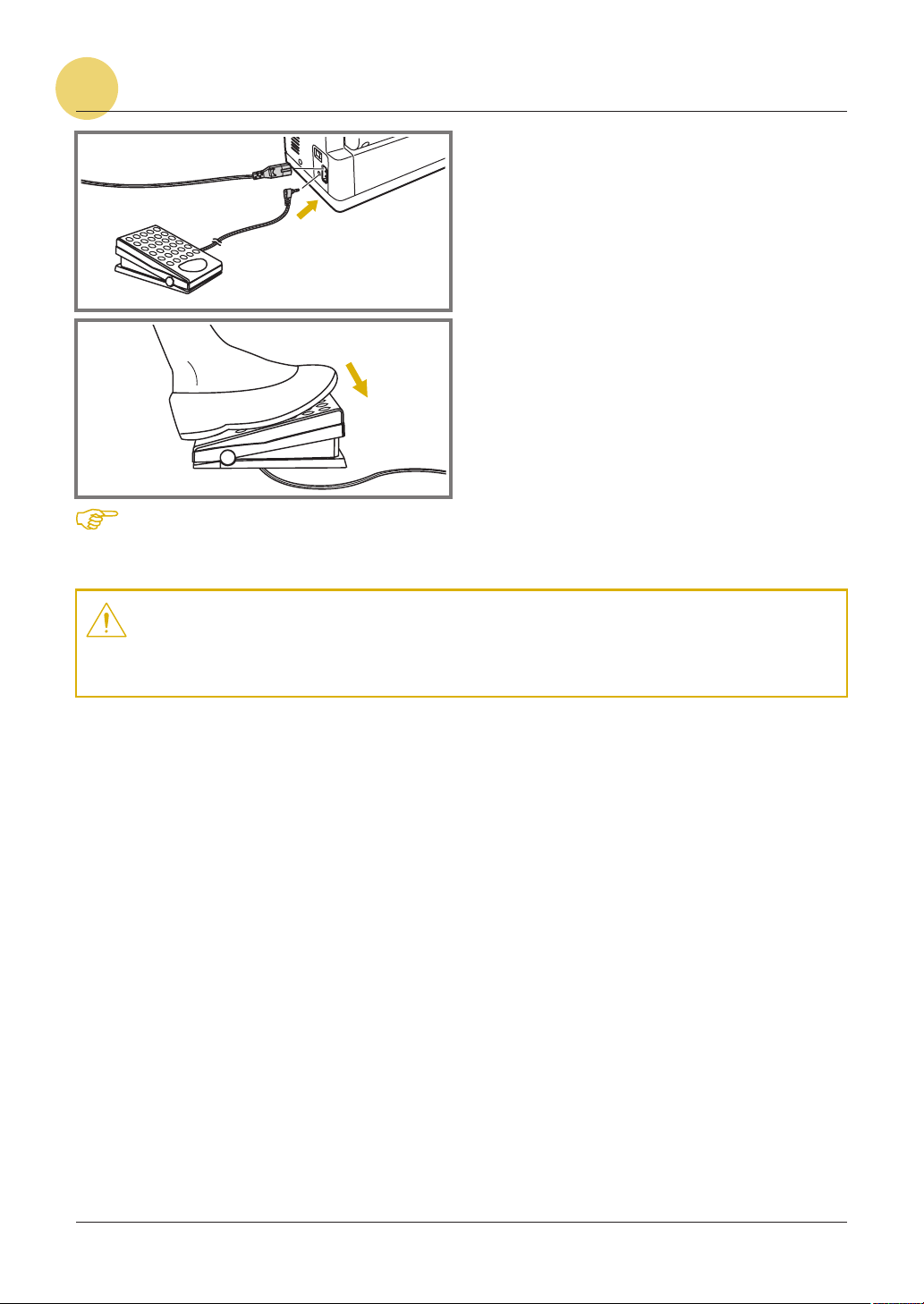

With the sewing machine turned off, insert the foot

control plug and the power supply cord into their

appointed connectors on the sewing machine.

Turn on the sewing machine, and then slowly

depress the foot control to start sewing.

Release the foot control to stop the sewing machine.

By tapping the foot control one time will allow the

needle to go up or down.

Note: The setting of the sewing speed controller will limit the maximum speed of the

machine when using the foot control.

Attention: Consult a qualified electrician if in doubt as how to connect the machine to

the power source. Unplug the power cord when the machine is not in use.

The appliance must be used with the foot control C-9001 manufactured by CHIEN HUNG

TAIWAN., LTD.

7

Page 9

OPERATION BUTTONS

OPERATION BUTTONS

Needle position button

Auto-lock button

Reverse button

START/STOP button

START/STOP button

Reverse button

The machine will start running when the

START/STOP button is pressed and will stop

when pressed the second time. The machine will

stitch slowly at the beginning of the sewing.

The sewing speed can be controlled by the

sewing speed controller.

Note: The Reverse and START/STOP

button functions will work at the same

time even when foot control is connected.

Use the sewing speed controller to adjust the

sewing speed.

To increase the speed, slide the lever to the

right; to decrease the sewing speed, slide the

lever to the left.

Select Group 2-B Patterns 00-06, 27-29 or Group

3-C Patterns 00-02, 04 and the machine will sew in

reverse. An arrow " " on the LCD screen display

appears while stitching in reverse. The machine

will sew forward after the button is released.

Select Group 2-B Patterns 07-26, 50-92, Group

3-C Patterns 03, 05-24 and Group 4-D Patterns

00-78 a reinforcement stitch sews at a low speed

and machine automatically stops if the reverse

button is pressed.

8

Page 10

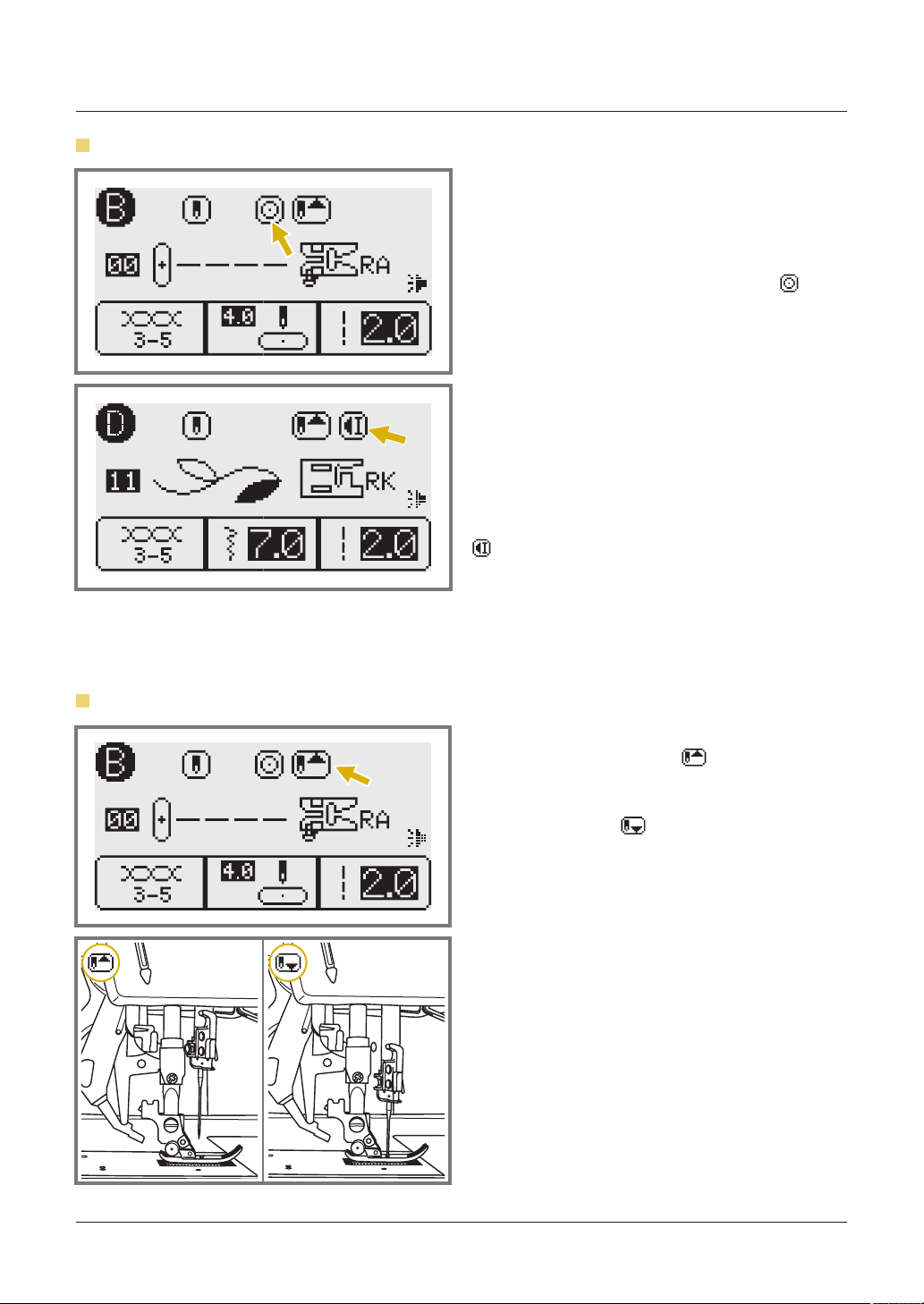

Auto-lock button

When the Group 2-B Patterns 00-05, 45 and

Group 3-C Patterns 01-02, 04, 18 are selected,

the machine will immediately sew 3 locking

stitches when the Auto-lock button is pressed,

then will automatically stop.

The LCD screen will display the figure " " until

the locking stitches stop.

To stop machine at the end of the current pattern or

to sew a single pattern (except Group 2-B Patterns

00-05, 27-49 and Group 3-C Patterns 00-02, 04, 18),

press the Auto-lock button, the machine will sew 3

locking stitches at the end of the current pattern and

automatically stop.

The LCD screen will display the Auto-stop figure

" " until the feature is cancelled.

The function will be cancelled if you press the

button once again or select another pattern.

Needle position button

Press the button so that the arrow, on the LCD

screen, will point upward " " and the needle

will stop in the highest position.

When you press the button so that the arrow

points downward " ", the machine will stop

with the needle in the lowest position.

Pressing the needle position button once will raise

or lower the needle.

Pressing the needle position button twice will sew

one stitch.

9

Page 11

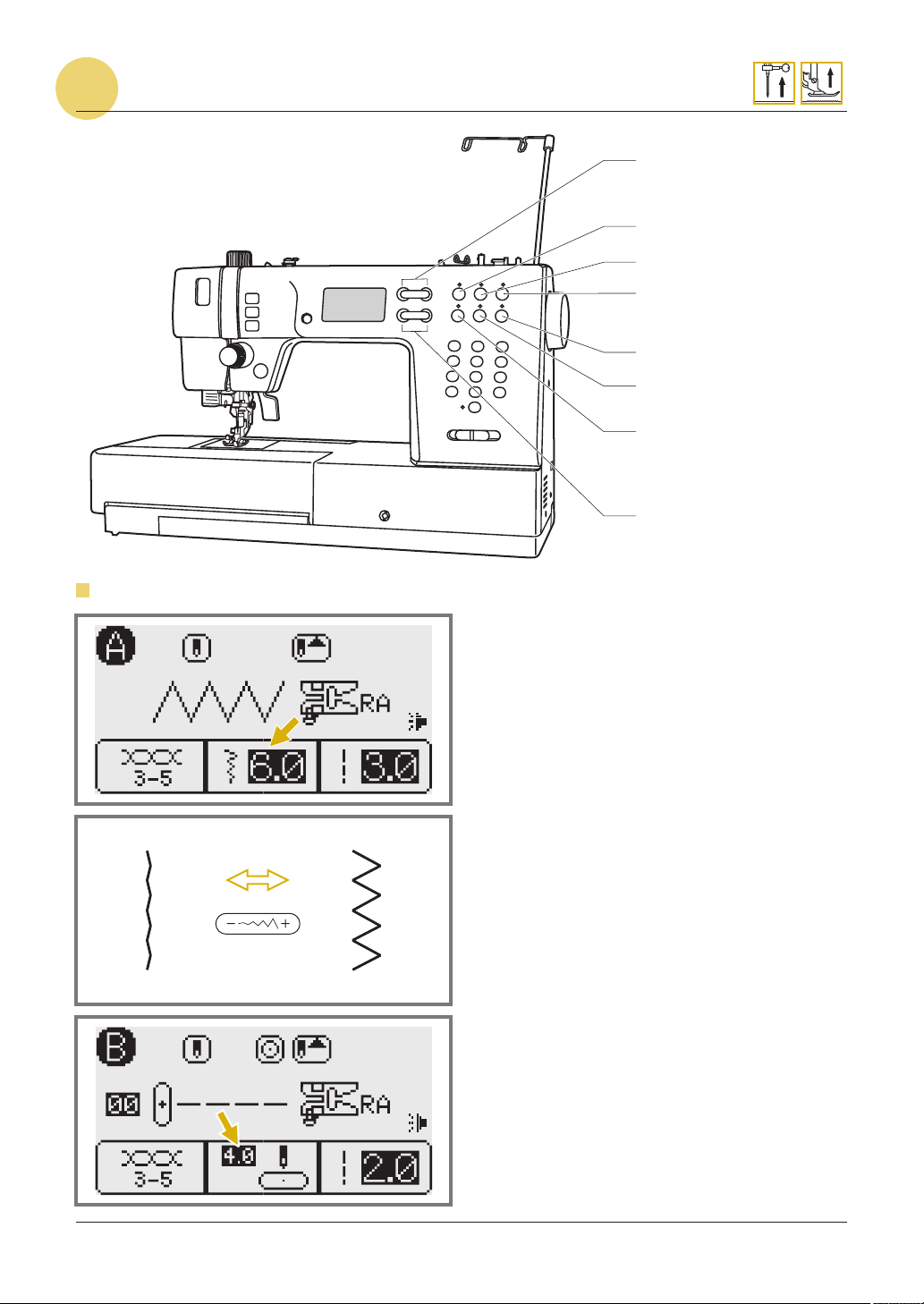

FUNCTION BUTTONS

FUNCTION BUTTONS

Stitch width adjustment buttons

Stitch width

adjustment buttons

FUNC selection button

Key lock button

Bobbin winding button

Twin needle button

Mirror image button

Elongation button

Stitch length

adjustment buttons

When you select a stitch, the machine will automatically set the recommended stitch width, which

will be indicated by numbers on the LCD screen.

The stitch width can be regulated by pressing the

stitch width adjustment buttons.

Certain stitches have a limited stitch width.

For a narrower stitch, press the left side of the

button "". For a wider stitch, press the right side

of button "+". The stitch width can be adjusted

between "0.0-8.0".

Certain stitches have a limited stitch width. (See

" " on page 93.)Stitch reference chart

When Group 2-B Patterns 00-05, 27-29 and

Group 3-C Patterns 00-02, 04, 18 and Group 4-D

Pattern 50 are selected, the needle position is

regulated by the stitch width adjustment buttons.

Pressing the "" button (left), will move the needle

to the left and pressing the "+" button (right), will

move the needle to the right. The numbers will be

changed from left position "0.0" to extreme right

position "8.0". The pre-set center needle position

will be indicated as "4.0".

10

Page 12

Stitch length adjustment button

FUNC selection button

When you select a stitch the machine will

automatically set the recommended stitch length

which will be indicated by numbers on the LCD

screen. The stitch length can be adjusted by

pressing the stitch length adjustment buttons.

For a shorter stitch, press the left side of the

button "". For a longer stitch, press the right

side of button "+". The stitch length can be

adjusted between "0.0-5.0".

Note:

Certain stitches have a limited stitch

length range.

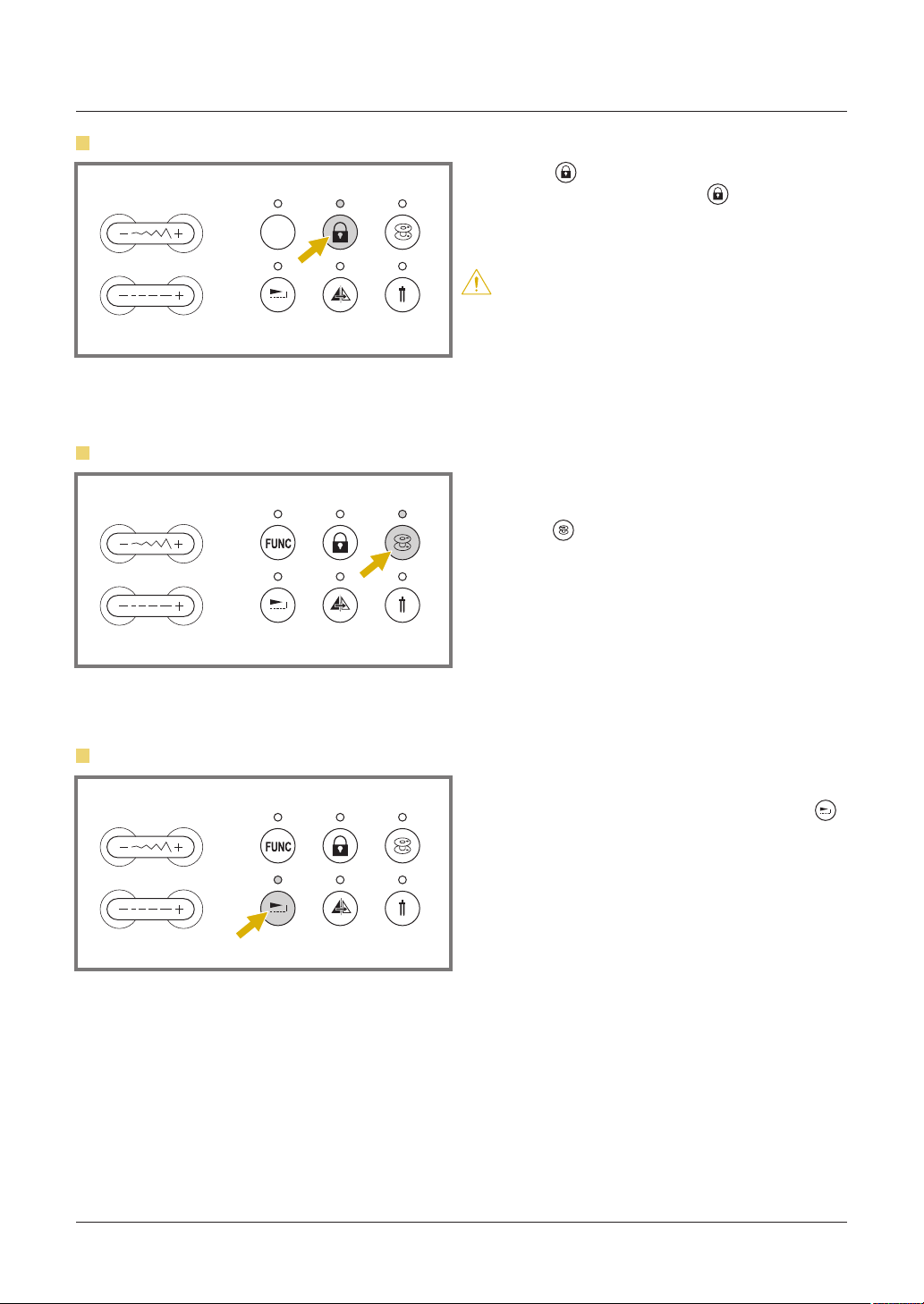

The LCD screen will be set at direct mode A when

you turn on the machine. By pressing the " "

button, the LED light will turn on. LCD screen

enters the pattern group screen automatically.

Press the numbered button corresponding to the

group of stitches. For example : Press FUNC, then

2 for group B. Then press the 2 digit pattern

number from group B on the stitch chart.

FUNC

Direct mode stitch selection (Group 1-A)Select pattern from the numbered buttons or

" ", and then 1 to reenter direct selection.

Utility and decorative pattern mode (Group

2-B)- Press " ", then 2, and then pattern

number by using the numbered buttons.

Quilt pattern mode (Group 3-C)- Press " ",

then 3, and then pattern number by using

the numbered buttons.

Decorative pattern mode (Group 4-D)- Press

" ", then 4, and then pattern number by

using the numbered buttons.

Block letter mode - Press " ", then 5, and

then pattern number by using the numbered

buttons.

Script letter mode - Press " ", then 6, and

then pattern number by using the numbered

buttons.

11

Page 13

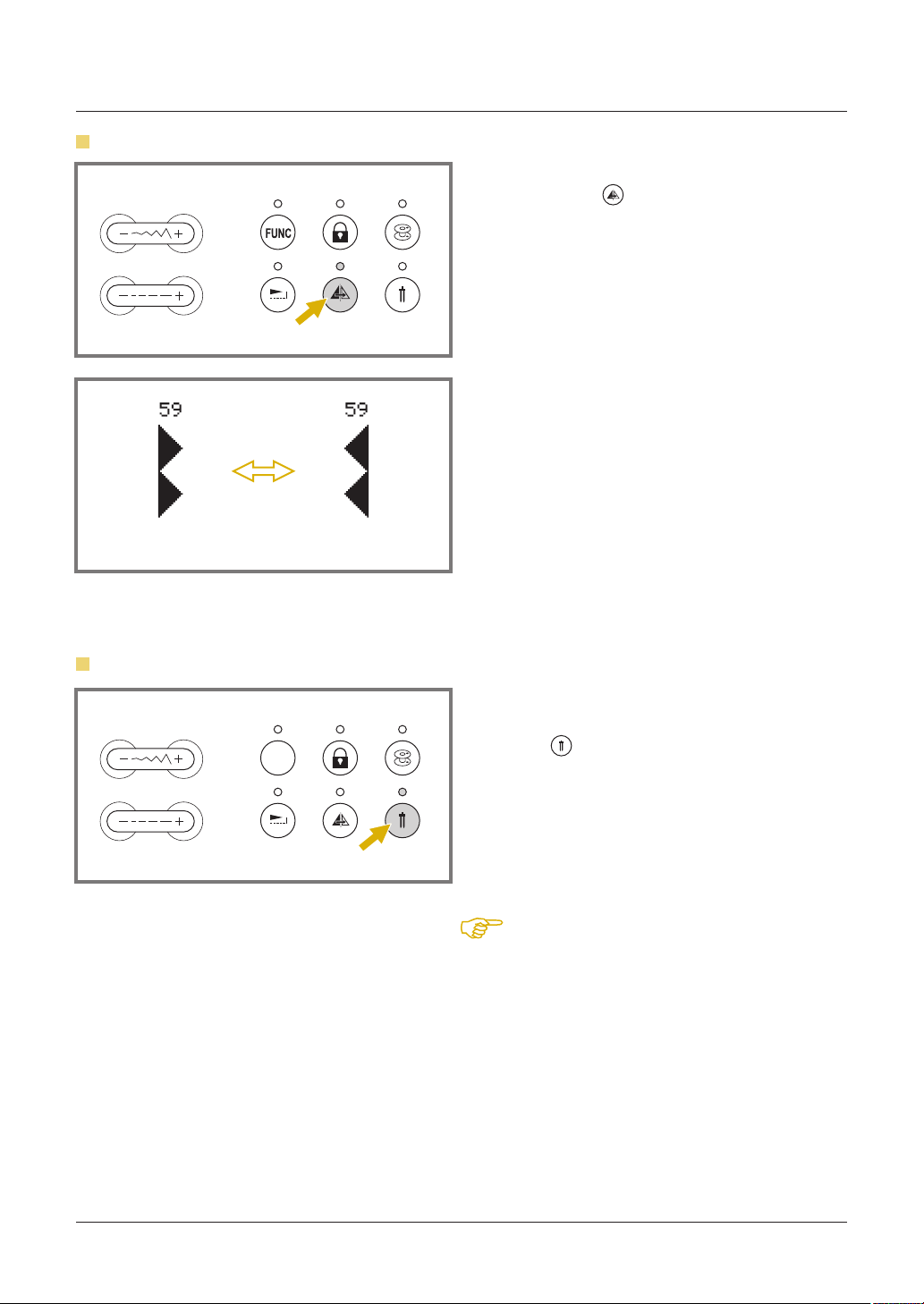

Key lock button

FUNC

Bobbin winding button

Press the " " button to lock the Function and

Selection buttons. Press the " " button again

to unlock. Lock buttons to prevent stitch settings

from accidentally being changed.

Attention: While the key lock button is locked

the Function and Selection buttons cannot be

operated.

Put the empty bobbin on the bobbin winder shaft.

Push the bobbin winder switch to the left.

Press the " " button to wind the bobbin.

The LED light will be on while the bobbin is

winding.

Bobbin can wind in any operation mode.

Elongation button

Group 2-B Patterns 58-75 can be elongated up to

five times its normal length by pressing the " "

button, the LED light will turn on.

Combine different stitches in this group : change

width or length for a greater variety of patterns.

12

Page 14

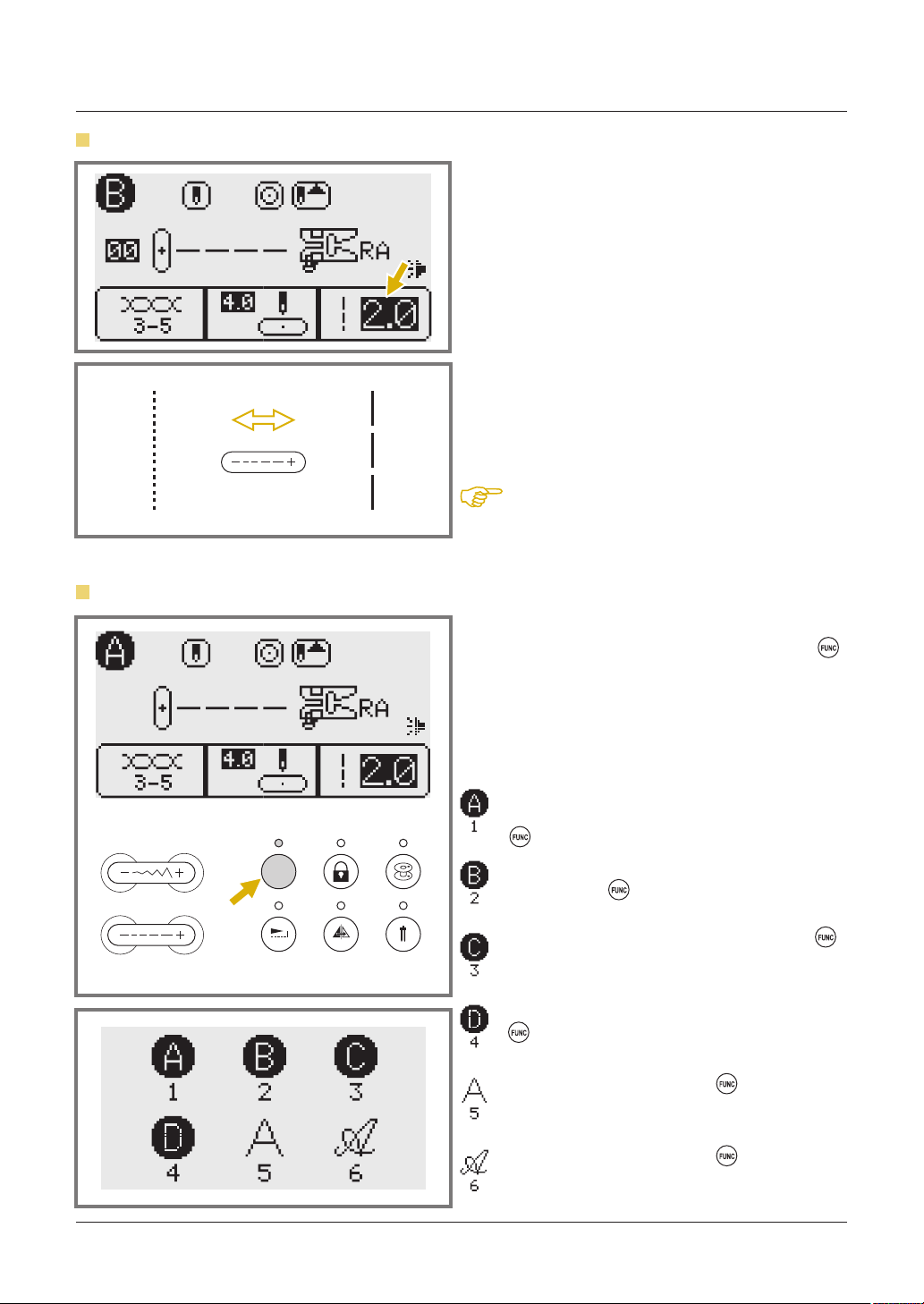

Mirror image button

Pattern can be mirror imaged along a vertical axis

by pressing the " " button except for patterns

30-49 from the Group 2-B Patterns.

LED light will turn on. The machine will continue

to sew the reflected pattern until the mirror image

button is pressed again or the pattern is changed.

Mirror imaging the pattern appears on the LCD

screen.

A - Normal

B - Mirror imaged

A

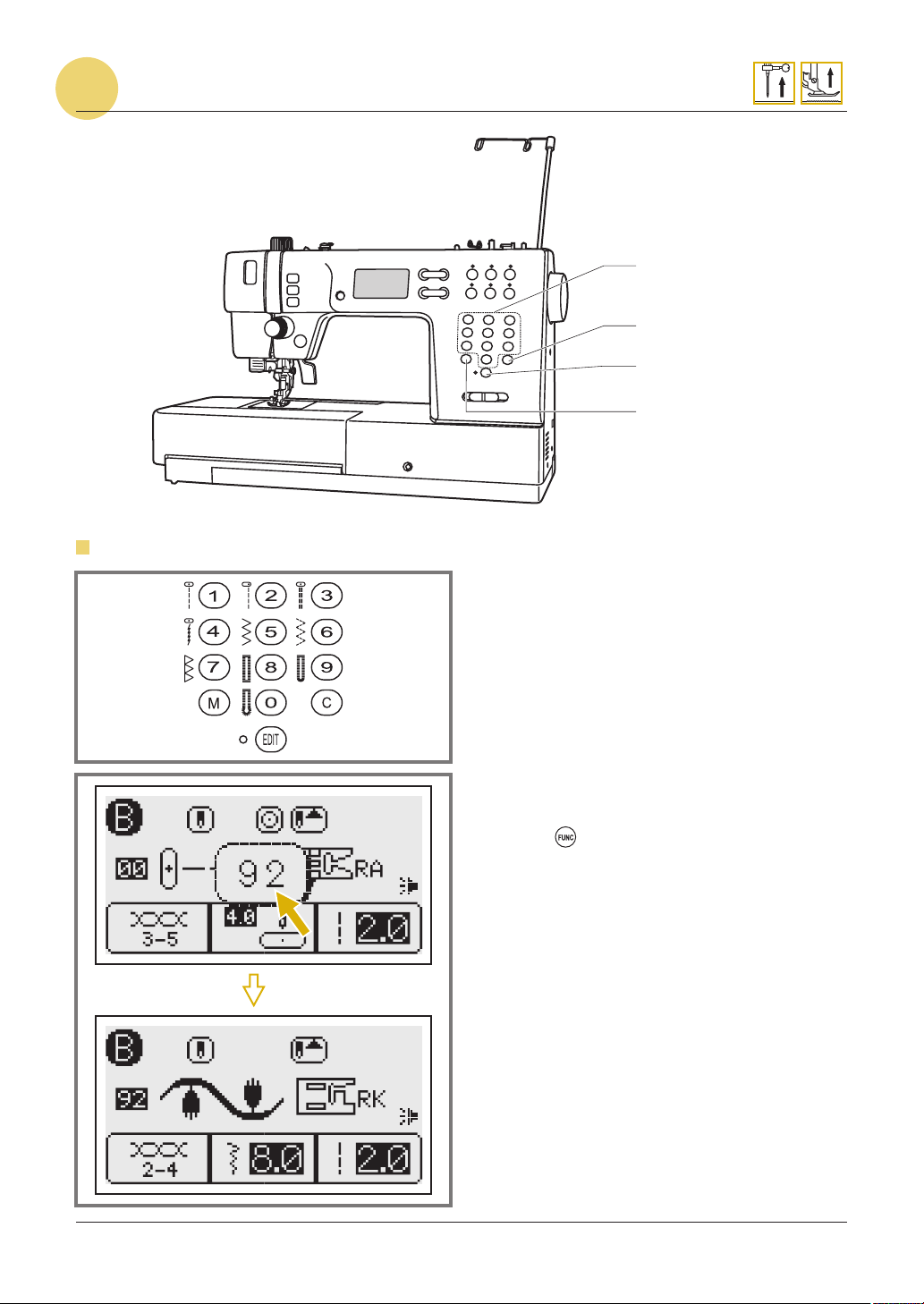

Twin needle button

FUNC

B

Patterns can be sewn in two parallel lines of the

same stitch with the twin needle.

Press the " " button, LED light will turn on, and

the machine automatically reduces the maximum

width for the twin needle sewing by 2mm.

When using some straight stitches and the

needle position is set below 2.0, the width will

automatically move to 2.0mm.

Press the button again to return to single needle

sewing.

Note: Group 1-A pattern 0, 8, 9 and

Group 2-B patterns 27-49 cannot be used

with twin needle function.

13

Page 15

SELECTION BUTTONS

SELECTION BUTTONS

Direct pattern selection and number buttons

Direct pattern selection

Press the numbered button to the right of the utility

pattern shown when the mode button (FUNC) is

set at the direct mode (1-A).

Direct pattern selection

and number buttons

Clear button

Edit button

Memory button

Number buttons

To select a pattern other than direct mode 1-A :

Press the " " button and enter the number of

pattern group (see page 11). Then press the two

numbers of the desired pattern from the stitch

chart.

For example: For Group 2-B press FUNC then

button 2. Press 92.

14

Page 16

Memory button

Edit button

Press the " " button to enter the memory mode.

Select up to 8 memories for storing combinations

of characters and decorative stitches.

Up to 20 patterns can be combined in each memory.

Use the stitch width"+"and""button to scroll

through the pattern combination memorized. Press

the " " button again to exit the memory mode.

See page 82 for details.

Note: Direct Patterns, Group 2-B patterns

27-49 and Group 3-C pattern 00 cannot be

memorized.

If you wish to modify the pattern settings in the

memory mode, use the stitch width "+" or ""

button to select the pattern to be modified. Press

the " " button to enter the editing mode , the

LED light will turn on.

Manual setting function of the stitch width, stitch

length, mirror and Auto-lock for these memorized

patterns can be changed. Press the " " button

again to exit the editing mode. See page 84 for

details.

Clear button

When combining characters or decorative patterns,

press the " " button to clear or erase one

character or pattern. See page 84 for details.

15

Page 17

CONNECTING THE MACHINE TO THE POWER SOURCE

CONNECTING THE MACHINE TO THE POWER SOURCE

Connecting the machine

Before connecting the power supply, make sure that the voltage and the frequency shown on the

machine is conforming to your electrical power.

Place the machine on a stable table.

1. Connect the power cord to the machine by inserting the plug into the power supply connector.

2. Connect the power cord plug to the electrical outlet.

3. Insert foot control plug into the foot control connector on machine.

* 001.The appliance must be used with foot control C-9

Caution: Never leave machine unattended when plugged in.

Always unplug this machine from the electrical outlet immediately after using and before

maintenance.

Polarized plug information

This appliance has a polarized plug (one blade wider than the other), to

reduce the risk of electrical shock; this plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician. Do not modify the

plug in any way. (For U.S.A. only)

16

Page 18

TURN MACHINE ON/ OFF

TURN MACHINE ON/ OFF

Turn on the machine

Press the right side of the main power switch on

the right side of the machine, the

ON (" I ") .

The lamp comes on when the machine is turn on.

Turn off the machine

When you are finished using the machine, turn it

off. In addition, before transporting the machine to

another location, be sure to turn it off.

1. Make sure the machine is not sewing.

2. Press the left side of the main power switch on

the right of the machine, the power switch is

OFF ("O") .

The lamp goes off when the machine is turn off.

3. Unplug the power supply cord from the power

supply jack.

power switch is

Note: If a power outage occurs while the machine is being operated, turn off the machine

and unplug the power supply cord.

When restarting the machine, follow the necessary procedure to correctly operate the

machine.

17

Page 19

UNDERSTANDING THE LCD SCREEN

UNDERSTANDING THE LCD SCREEN

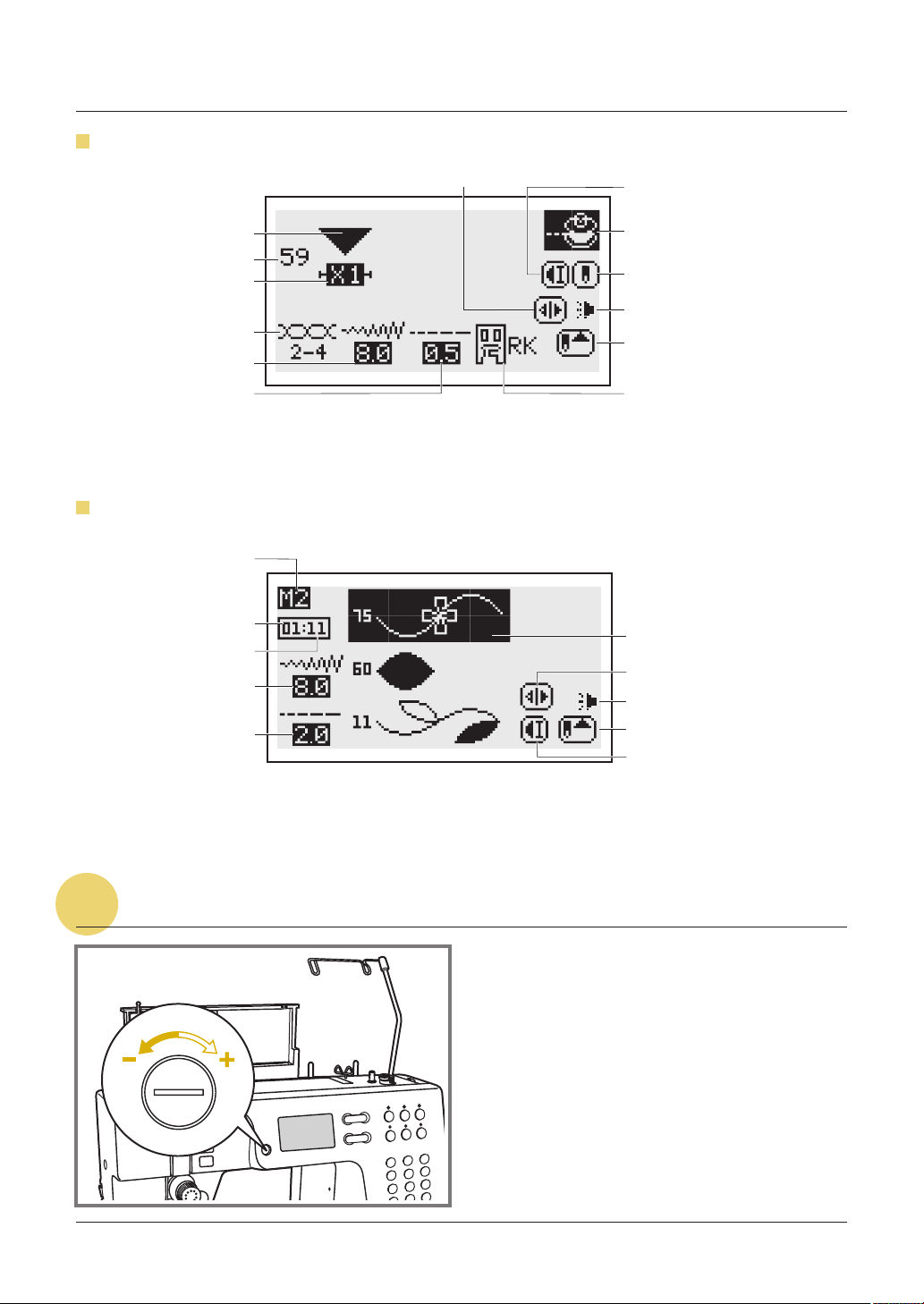

Pattern

Single needle

Mirror

Group mode

Pattern

Tension

Reverse

Twin needle

Group mode

Pattern number

Pattern

Tension

Auto-lock

Needle up position

Bobbin winding

Suggested presser foot

and identification letters

Stitch length

Needle position

Needle down position

Auto-stop

Sound on

Stitch length

Alphabet

Single needle

Group mode

Alphabet number

Pattern

Tension

Stitch width

Needle up position

Auto-stop

Suggested presser foot

and identification letters

Sound on

Stitch width

18

Page 20

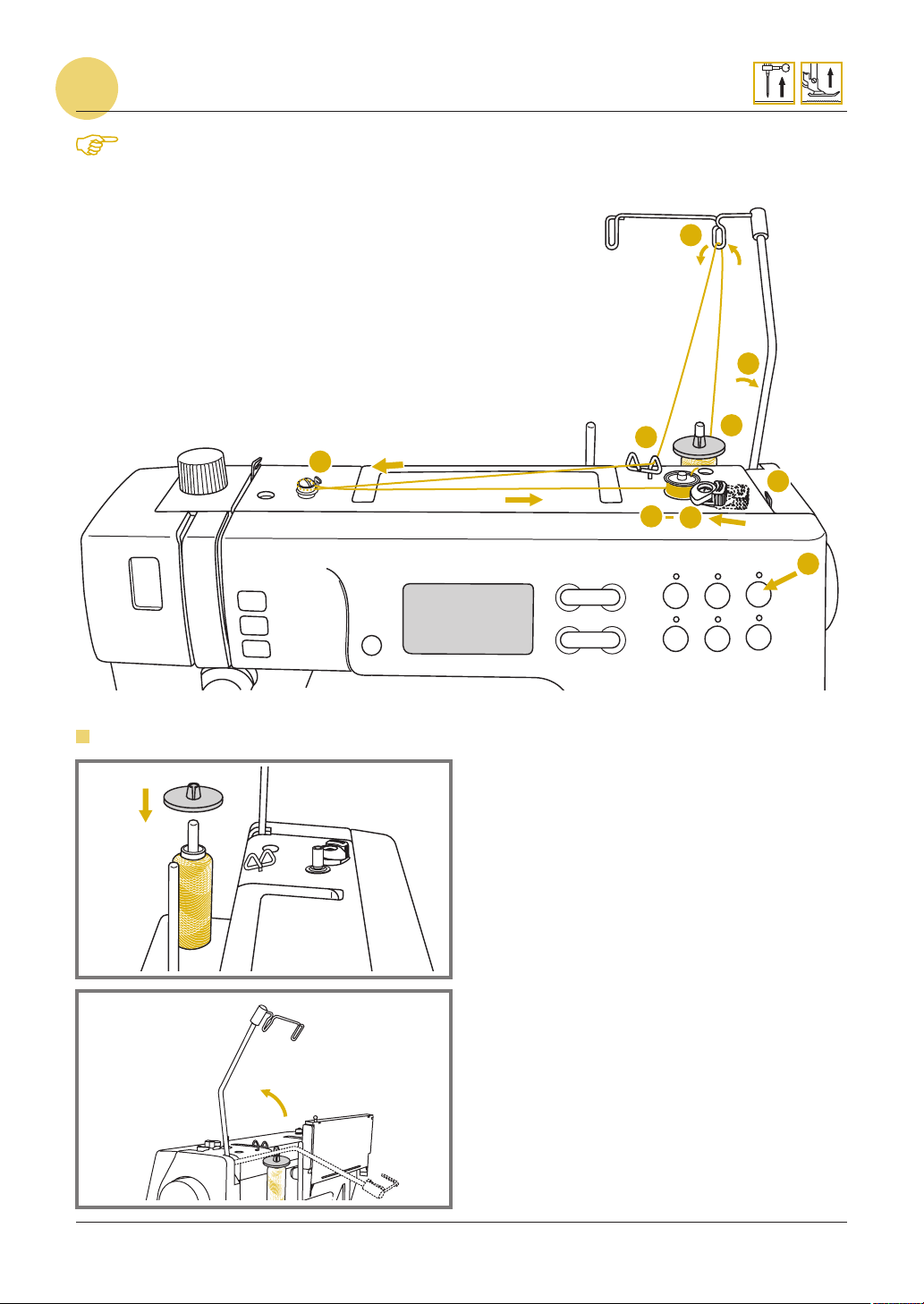

Elongation

Pattern

Pattern number

Magnification

Tension

Stitch width

Stitch length

Memory

Memory number

Number of

current pattern

Total number of patterns

Stitch width

Stitch length

Mirror

Auto-stop

Bobbin winding

Single needle

Sound on

Needle up position

Suggested presser foot

and identification letters

Pattern to edit

Mirror

Sound on

Needle up position

Auto-stop

LCD SCREEN BRIGHTNESS CONTROL

LCD SCREEN BRIGHTNESS CONTROL

The LCD screen brightness control dial is located

at the left of LCD screen. Use this to dial adjust

the sharpness of the LCD .

If no indication is shown on the screen after

switching on the power, adjust the LCD screen

brightness with the dial.

LCD screen brightness : Turn the dial to the

toward the "+"

LCD screen darkness : Turn the dial to the left

toward the "".

19

screen

right

.

Page 21

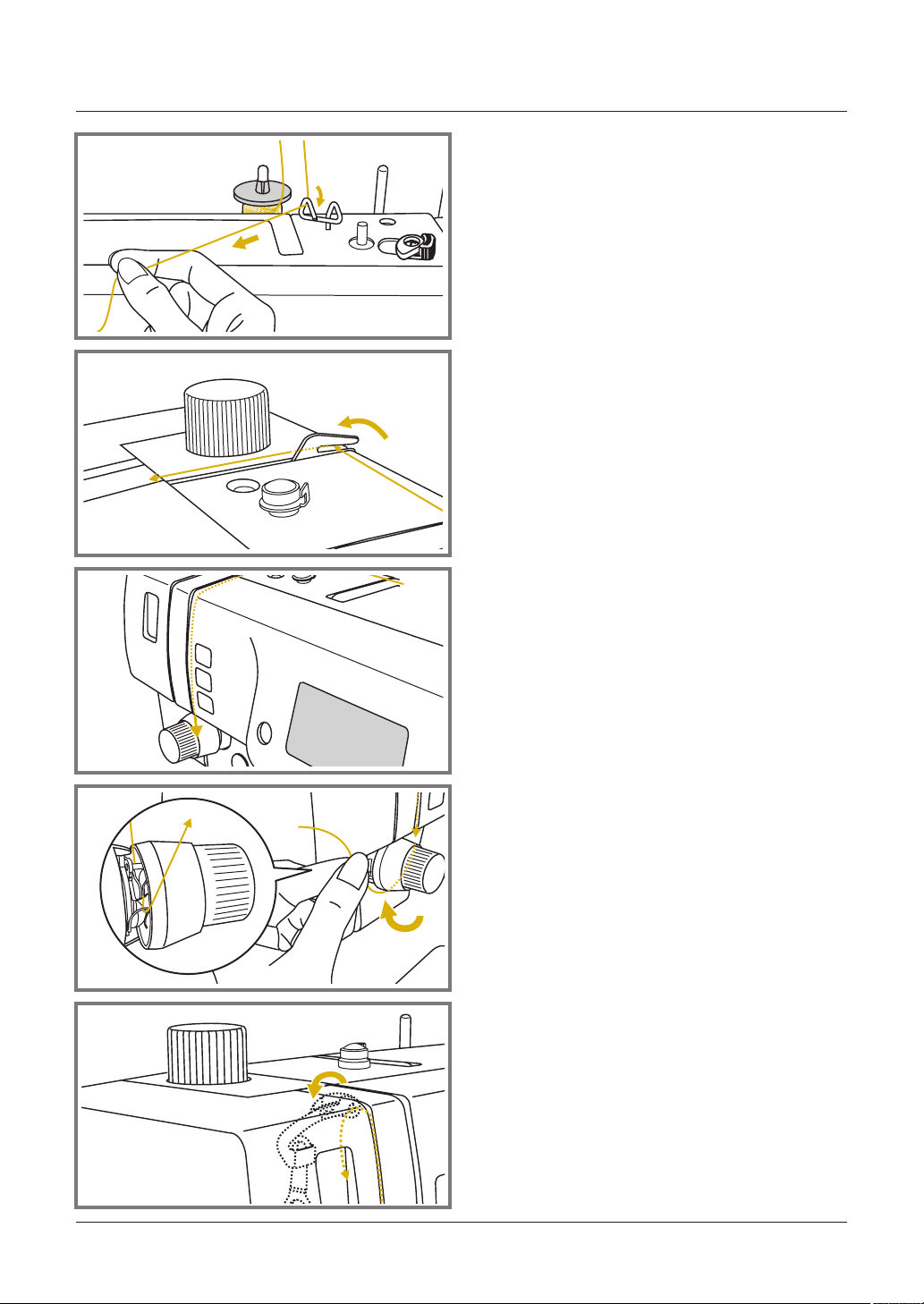

WINDING THE BOBBIN

WINDING THE BOBBIN

Note: Due to the independent bobbin winder motor, you can wind the bobbin during sewing.

Follow the steps for "Winding The Bobbin" except place the thread for the bobbin through

the thread guide opening not in use being careful not to tangle thread.

3

2

Bobbin winding

4

1

5

12

6

7

8

1. Place the spool of thread and spool cap onto the

spool pin. For smaller spools of thread, use the

small spool cap.

Spool cap should be close in size to the thread

spool, however should not be any smaller. If the

spool cap is smaller than thread spool, thread

may get caught in the slit on end of spool and

cause damage.

1

2. Bring the hinged thread guide up and forward

into the upright position.

2

20

Page 22

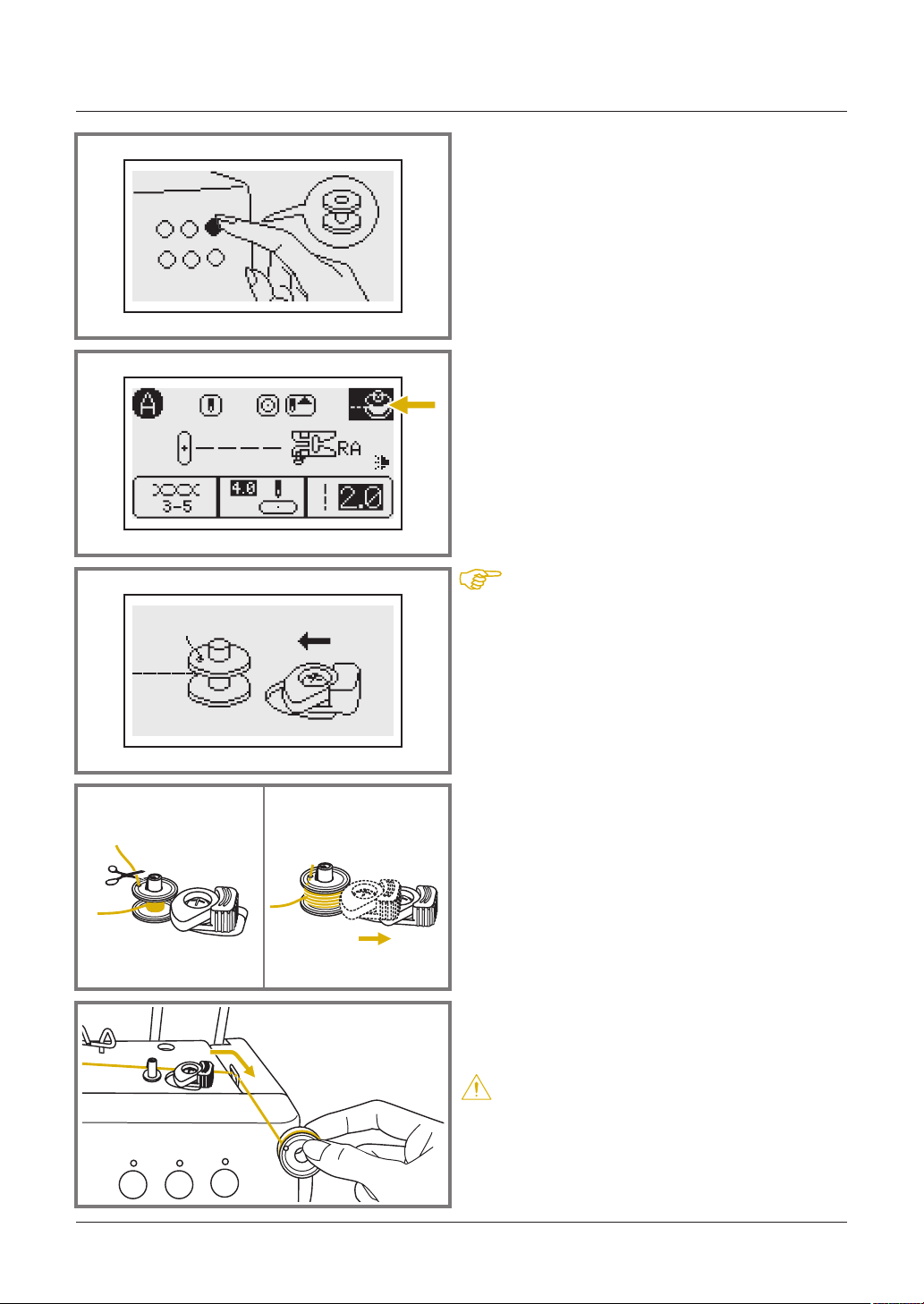

3. Place the thread through the thread guide

above the spool of thread from back to front.

3

4. Place the thread through the appropriate

thread guide opening for the spool pin that is

being used.

4

5. Pass the thread clockwise around the bobbin

winder tension discs as illustrated.

5

6. Place the thread end through one of the inner

holes in the bobbin as illustrated and place

the empty bobbin on the bobbin winder shaft.

6

7. While holding the thread tail securely in one

hand, push the bobbin winder switch to the

left.

7

21

Page 23

8. Press the bobbin winding button.

8

9. When the bobbin winder switch is pushed to

the left and bobbin winder button is pressed,

the LCD screen will display the animation of

the bobbin winding.

9

Note: When the bobbin winder button is

pushed without pushing the bobbin winder

switch to the left, the following screen is

displayed for a few seconds.

10

11

10.After the bobbin has wound a few turns stop

the machine and cut the thread near the hole

of the bobbin.

Continue winding the bobbin until it is full. The

motor stops automatically when the bobbin is

full.

11.Remove the bobbin then cut the thread on

the thread cutter.

Attention: Since this machine is equipped

with an independent bobbin winder the sewing

speed controller does not effect the winding

speed. Keep fingers clear of the needle area

while winding the bobbin.

22

Page 24

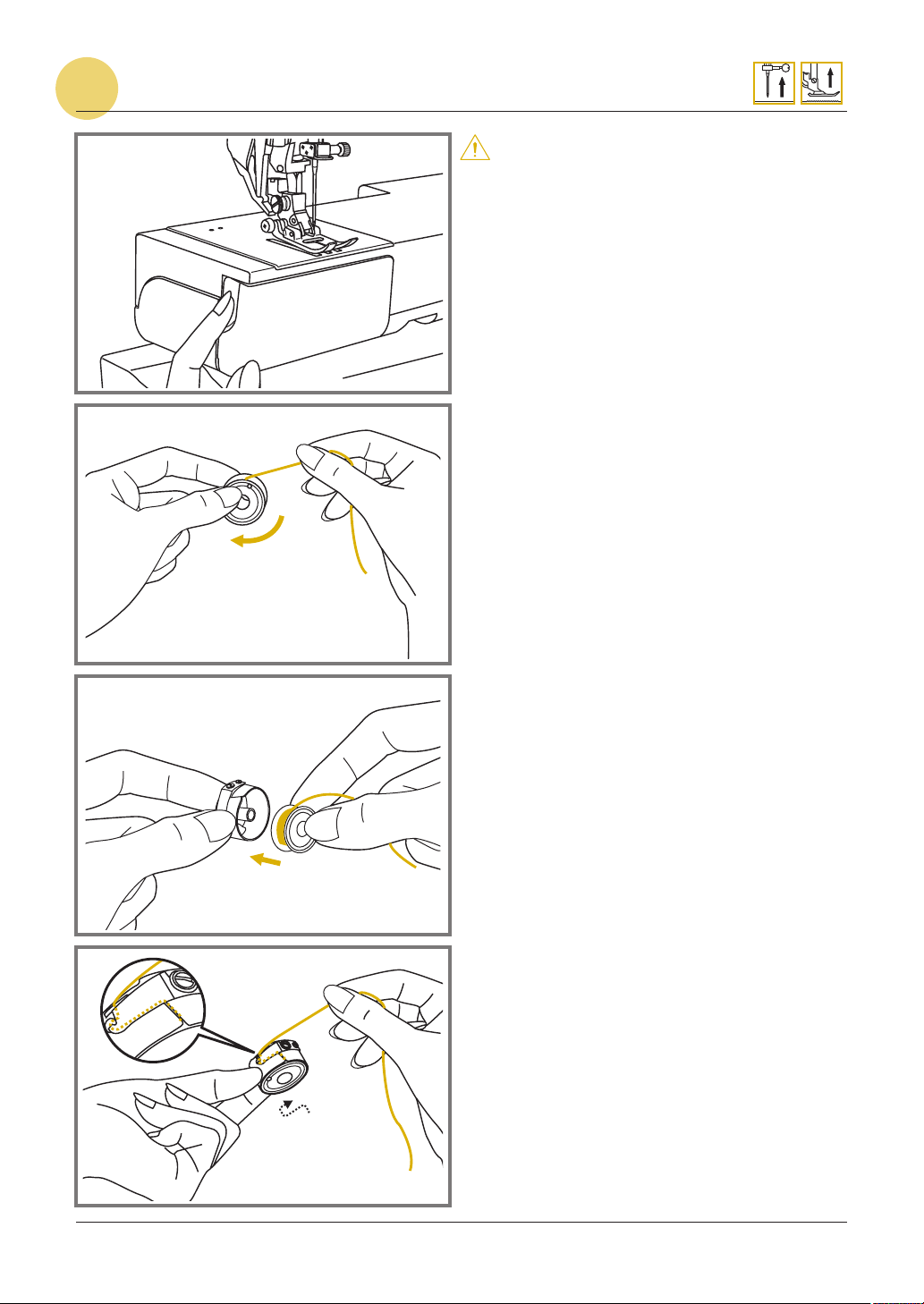

INSERTING THE BOBBIN

INSERTING THE BOBBIN

1

Attention: Turn power switch OFF ("O")

before inserting or removing the bobbin.

Press the needle position button to raise the

needle before inserting or removing the

bobbin.

1. Open the hinged cover.

2. It is important to be sure that the bobbin is

turning in a clockwise direction (arrow).

2

3. Hold the bobbin case with one hand. Insert the

bobbin so that the bobbin turns in a clockwise

direction.

3

4. Pull the thread through the slot, to the left and

then right until it enters the delivery eyelet

under the tension spring.

4

23

Page 25

INSERTING THE BOBBIN

INSERTING THE BOBBIN

5

5. Pull the bobbin thread through the metal hook

using a clockwise motion.

6. Hold the bobbin case by the hinged latch.

Insert the bobbin case fully into the shuttle

race and release the latch.

6

7. Close the hinged cover.

7

24

Page 26

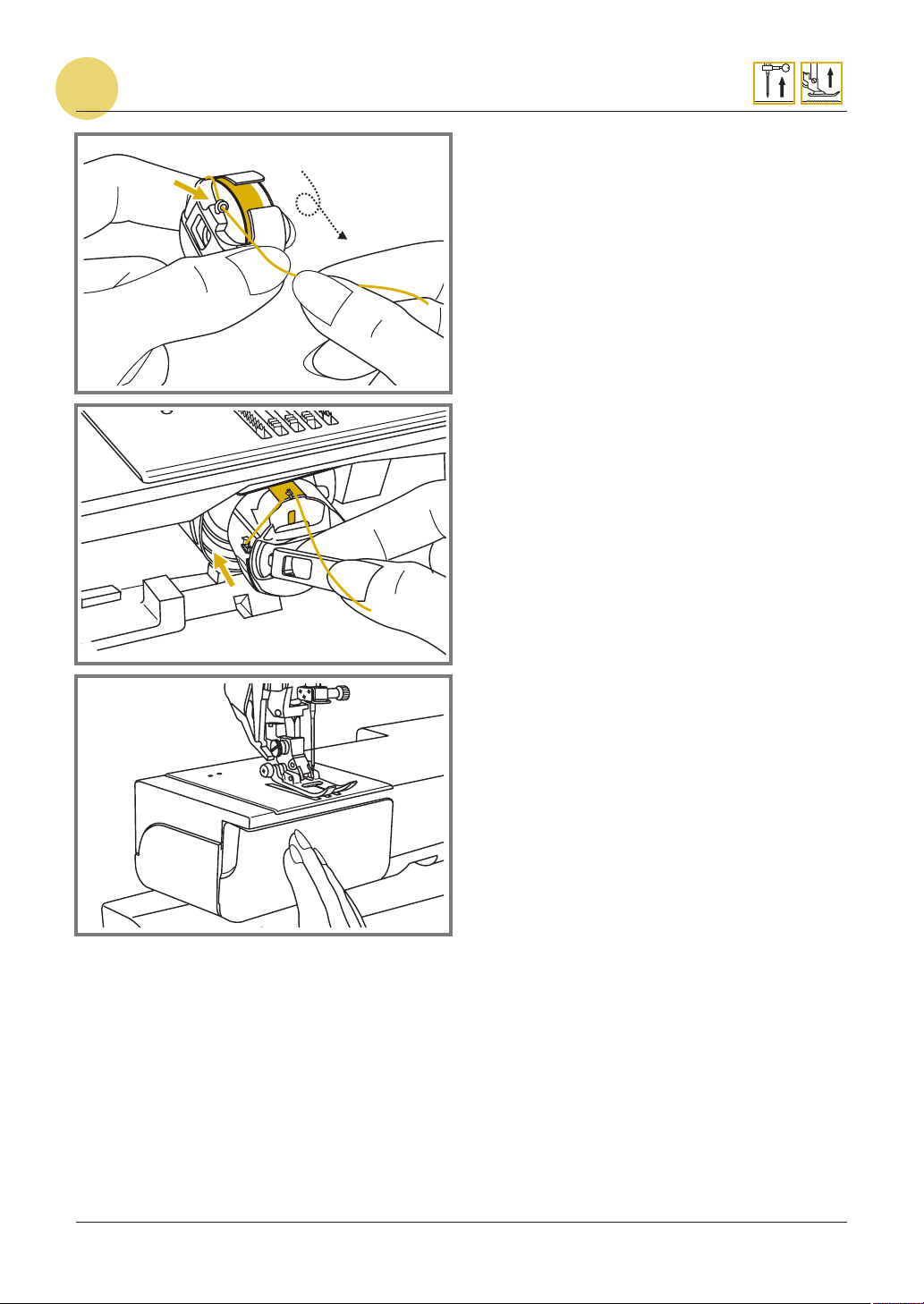

UPPER THREADING

2

1

3

4

5

UPPER THREADING

7

6

8

9

10

Note: It is important to thread the machine correctly. Improper threading could result in

several sewing problems.

Before threading the machine, raise the needle

to its highest point and raise the presser foot

to release the tension discs.

1. Slide the spool of thread onto the spool pin so

the thread unwinds clockwise from the thread

spool. Then position the spool cap on the spool

1

pin to secure the spool of thread.

2. Place thread in the thread guide above the

spool of thread.

2

25

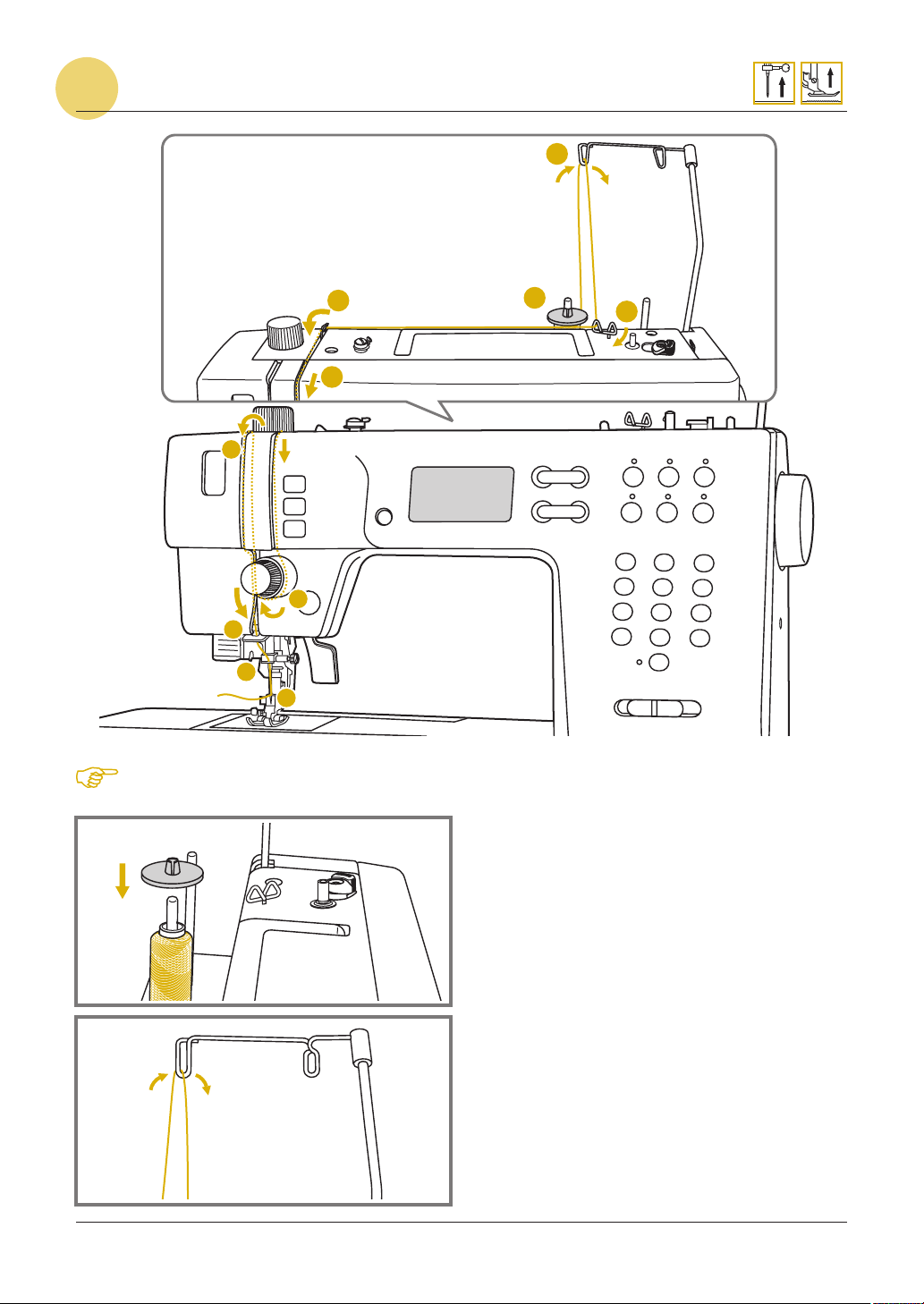

Page 27

3. Place the thread through the appropriate

thread guide opening for the spool pin that is

being used.

3

4. Guide the thread into the pre-tension thread

guide pulling the thread through the pretension spring as illustrated.

4

5. Pull the thread downward from the thread guide.

5

6. Draw the thread down through the right slot

and around the tension dial from the right to

left. Pull the thread up to insert it between the

tension disks and under the wire loop of the

check spring.

6

7. Bring the thread up through the left slot and

then into the slotted eye of the take-up lever

from right to left. Continue by bringing the

thread back down through the left slot.

7

26

Page 28

8. Pass the thread behind the flat, horizontal thread

guide and then through the thread guide above

the needle.

8

9. Insert the end of the thread through the eye of

the needle from front to back or use the needle

threader to thread the needle. ( See next page

for needle threader instructions.)

9

10.Place the thread under the foot and pull out

approximately 15 cm (6 inches) of thread to

the back of the machine.

10

27

Page 29

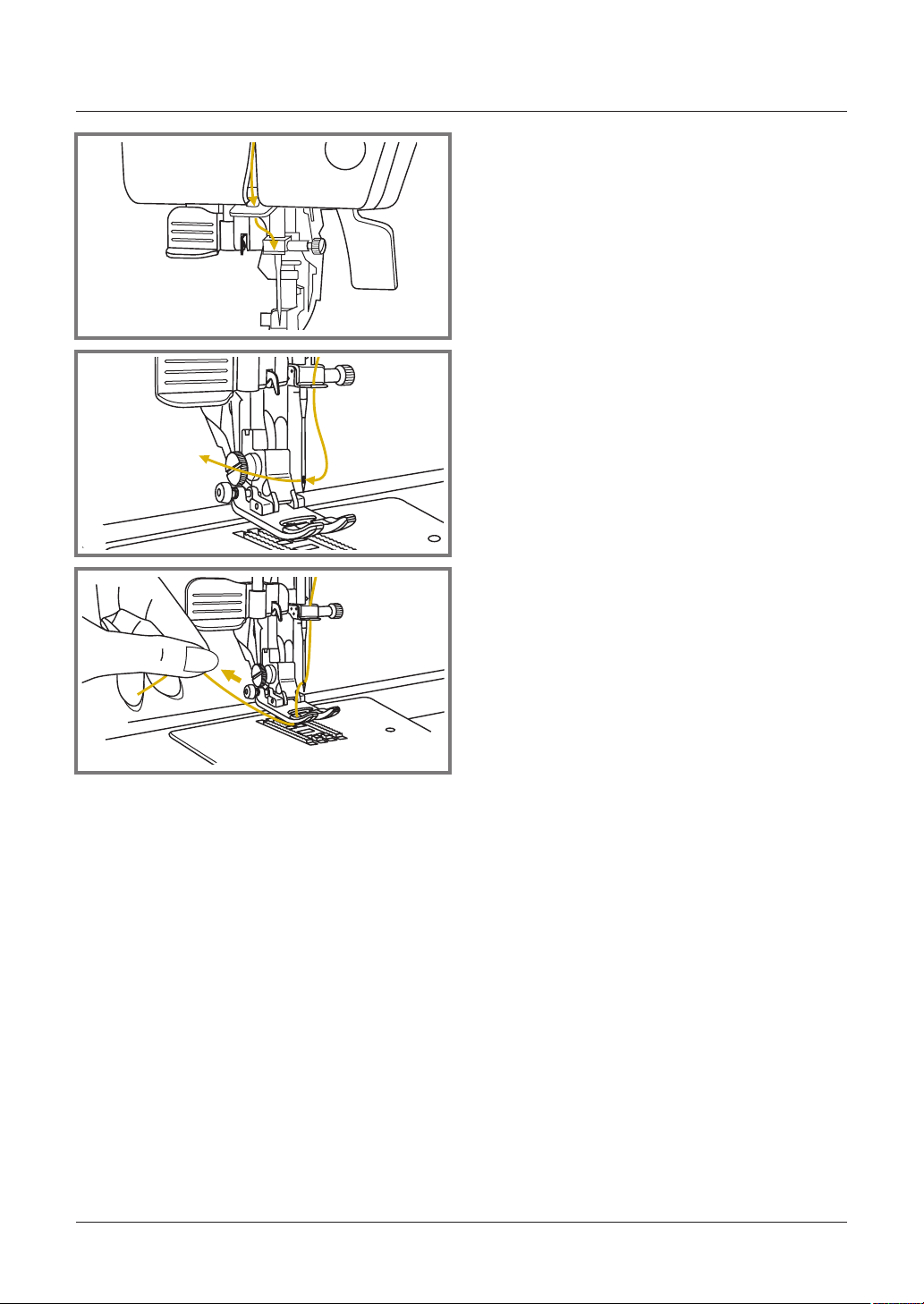

Using the needle threader

1

Attention: Turn power switch to the OFF

position ("O").

Raise the needle to its highest position and

lower the presser foot.

1. Lower the needle threader lever slowly and

draw the thread through the thread guide as

illustrated and then to the right.

2. Pivot the needle threader into the threading

position so the hook pin passes through the

needle eye.

2

3. Pass the thread in front of the needle to catch

the hook of the threader.

3

4. Hold the thread loosely and return the threader

to its original position. The hook will turn and

pull the thread through the needle eye forming

a loop.

Pull the loop of thread through the needle eye.

4

28

Page 30

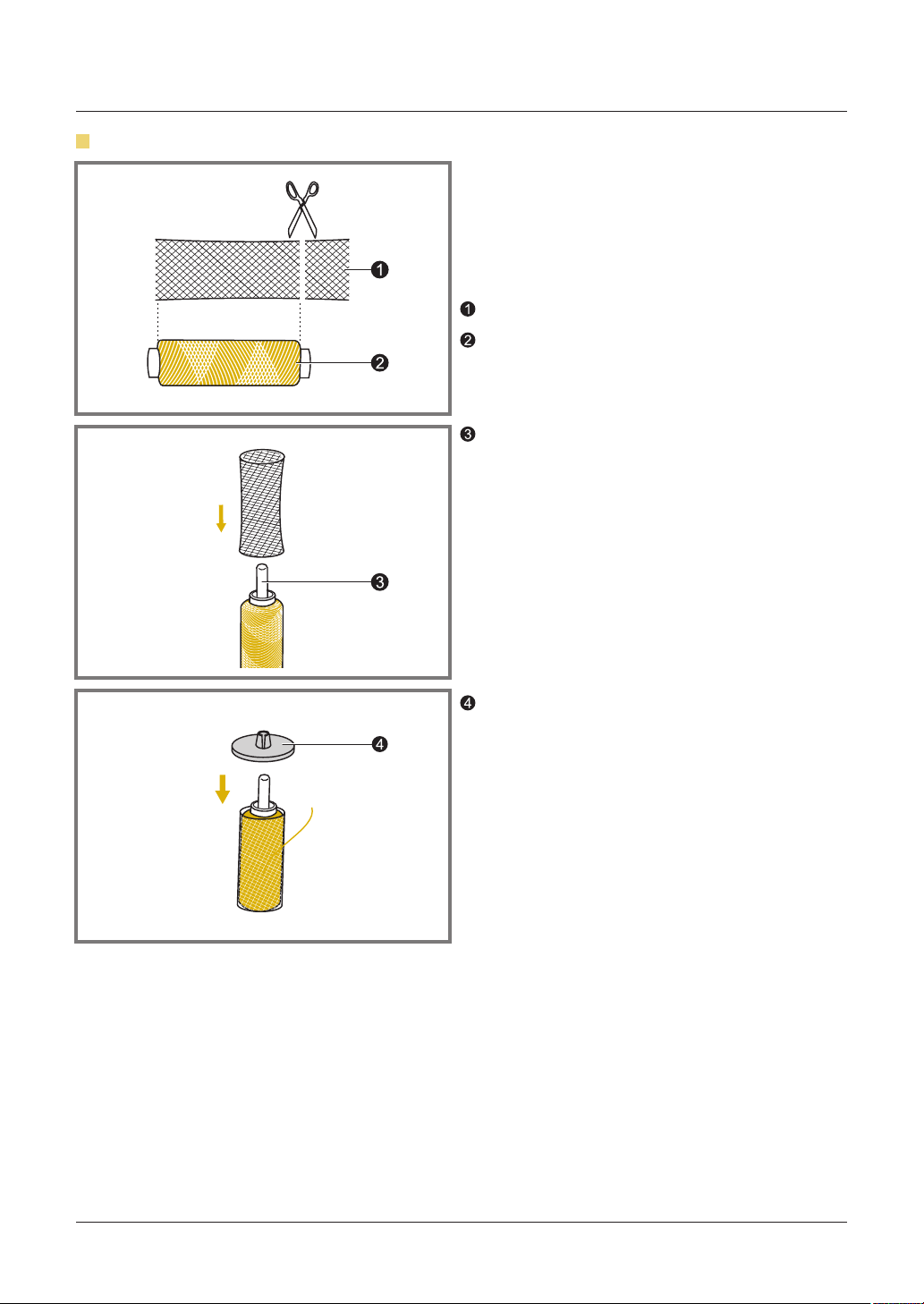

Using the net

1

If using special threads which wind quickly off

the thread spool, attach a net to the spool before

using.

* Cut the net to match the size of the spool.

NET

Thread spool

Spool pin

2

Spool cap

3

29

Page 31

Raising up the lower thread

1

1. Hold the upper thread with the left hand. Turn

the handwheel towards you (counterclockwise)

lowering, then raising the needle.

2. Gently pull on the upper thread to bring the

bobbin thread up through the needle plate

hole. The bobbin thread will come up in a loop.

2

3. Pull both threads to the back under the presser

foot.

3

30

Page 32

CUTTING THE THREAD

CUTTING THE THREAD

Raise the presser foot. Remove the fabric, draw

the threads to the left side of the face cover and

cut using the thread cutter.

The threads are cut at the proper length to start

the next seam.

REPLACING THE NEEDLE

REPLACING THE NEEDLE

Attention: Turn power switch to OFF. (

when replacing the needle !

Change the needle regularly, A bent or damaged

needle can cause skipped stitches, damage fabric,

and break while sewing.

To check the needle, place the flat side of the

needle on a flat surface. Discard any damaged

or bent needles.

Before changing the needle, use the handwheel

to raise the needle to its highest position.

A. Loosen the needle clamp screw and remove

the damaged needle.

B. With the flat side of the needle facing the back,

insert a new needle up as far as it will go.

C. Securely tighten the needle clamp screw.

"O")

31

Page 33

CHANGING THE PRESSER FOOT

CHANGING THE PRESSER FOOT

Attaching the presser foot holder

a

b

Attaching the presser foot

a

b

d

c

e

Attention: Turn power switch to OFF ( )

when carrying out any of the following

operations!

Raise the presser foot bar (a).

Position the presser foot holder (b) in place and

attach as illustrated.

Lower the presser foot holder (b) until the notch

(c) is directly above the pin (d).

Lower the presser foot holder (b) and the presser

foot (e) will engage automatically.

"O"

Removing the presser foot

Raise the presser foot.

Press down on the front of the presser foot by hand.

The foot will disengage.

32

Page 34

Type of presser foot chart

(double needle is being suggested for certain stitches for more creativity)

PRESSER FOOT

RA

All purpose foot

with PDQ

RB

Zipper foot

with PDQ

Buttonhole foot

RH

Cording foot

with PDQ

APPLICATION

General sewing,

Patchwork stitches,

Decorative

stitching,

Smocking,

Fagoting, etc.

Inserting zippers

Buttonhole sewing

Cording

NEEDLE NEEDLE

PRESSER FOOT

APPLICATION

Satin stitch sewing,

Decorative stitching.

RK

Satin stitch foot

Open toe foot

with PDQ

Quilting

Quilting foot

with PDQ

Darning

Free embroidery

Monogramming

RL

Darning/

Embroidery foot

RI

Overcasting foot

with PDQ

RM

Blind hem foot

with PDQ

RG

Hemmer foot

with PDQ

Overcasting

Blind hem stitching

Narrow hemming

Gathering

RD

Gathering foot

Button sewing

RC

Button sewing foot

Quilt and patchwork

sewing

RE

1/4" inch quilting foot

with PDQ

33

Page 35

Two-step presser foot lifter

1

2

1. The presser foot lever raises and lowers your

presser foot.

2. When sewing several layers or thick fabrics,

the presser foot can be raised a second stage

for easy positioning of the work.

34

Page 36

®

PRECISION DUAL-FEED QUILTING (PDQ )

PRECISION DUAL-FEED QUILTING (PDQ )

The system feeds fabric from the top and bottom simultaneously to ensure matching of

PDQ

®

checked, striped or plaid fabrics. When sewing light or difficult materials such as silk or rayon

fabrics, the system prevents seam puckering.

PDQ

To engage the PDQ system

Raise the presser foot.

Lower the PDQ mechanism slowly.

Swing the PDQ mechanism forward under the

back of the presser foot until it is engaged and

stays in the lowered position.

Attention: PDQ

mechanism

Only use presser feet with the back opening when engaging the

.

35

Page 37

To disengage the PDQ system

Raise the presser foot.

Pull down PDQ mechanism and swing it to

the rear to disengage.

Push PDQ mechanism up.the

the

Fabric positioning

Place fabric flat on top of needle plate and position

the fabric under presser foot.

While holding the thread tails with left hand turn

handwheel with right hand to insert the needle

into the fabric. Lower the presser foot and make

3-4 stitches.

Place hands on each side of the presser foot

and gently guide the fabric while sewing.

36

Page 38

PATTERN CHART

PATTERN CHART

On the chart below the portion marked in gold shows a single unit of each pattern.

Patterns

Group 1-A Patterns ( -10Direct Patterns)

Group 2-B Patterns-93

Group 3-C Patterns-25

37

Page 39

Group 4-D Patterns-79

Alphabets

38

Page 40

MATCHING NEEDLE/ FABRIC/ THREAD

MATCHING NEEDLE/ FABRIC/ THREAD

NEEDLE, FABRIC, THREAD SELECTION GUIDE

NEEDLE SIZE

9-11 (70-75) Lightweight fabrics-thin cottons,

voile, serge, silk, muslin, interlocks,

cotton knits, tricot, jerseys, crepes,

woven polyester, shirt & blouse

fabrics.

12-14 (80-90) Medium weight fabrics-cotton, satin,

sailcloth, double knits, lightweight

woollens.

14 (90)

16 (100)

Note:

- In general, fine threads and needles are used for sewing fine fabrics, and thicker threads

are used for sewing heavy fabrics.

- Always test thread and needle size on a small piece of fabric which will be used for actual

sewing.

- Use the same thread for needle and bobbin.

Medium weight fabrics-cotton duck,

woolen, heavier knits, terrycloth,

denims.

Heavyweight fabrics-canvas, woolens,

quilted fabrics, denims, upholstery

material (light to medium).

FABRICS

Light-duty thread in cotton, nylon,

polyester or cotton wrapped polyester.

Most threads sold are medium size

and suitable for these fabrics and

needle sizes. Use polyester threads

on synthetic materials and cotton

on natural woven fabrics for best

results. Always use the same

thread on top and bottom.

Heavy duty thread.

THREAD

39

Page 41

THREAD TENSION

THREAD TENSION

Tight Loose

- Basic thread tension setting: "4"

- To increase the tension, turn the dial to the next number up. To reduce the tension, turn the dial

to the next number down.

- Proper setting of tension is important to good sewing.

- There is no single tension setting appropriate for all the stitch functions and fabrics.

- 90% of all sewing will be between "3" and "5" ("4" is basic setting).

- For all decorative sewing you will always obtain a nicer stitch and less fabric puckering when the

upper thread appears slightly on the bottom side of your fabric.

1

2

3

Wrong

side

Upper thread

Bobbin thread

Wrong

side

Upper thread

Bobbin thread

Wrong

side

Upper thread

Bobbin thread

Surface

Surface

Surface

1. Normal thread tension for straight stitch sewing.

2. Upper thread tension is too loose for straight

stitch sewing. Turn dial to higher number to

tighten the upper tension.

3. Upper thread tension is too tight for straight

stitch sewing. Turn dial to lower number to

reduce the upper tension.

4

Wrong

side

Upper thread

Bobbin thread

Surface

4. Thread tension for zigzag and decorative

sewing should be slightly looser on the upper

thread stitching for the fabric to lay flat and to

avoid puckering of fabric.

40

Page 42

LENGTH & WIDTH ADJUSTING

LENGTH & WIDTH ADJUSTING

Stitch width adjusting

For a narrower stitch, press the left side of the

button "". For a wider stitch, press the right side

of button "+". The stitch width can be adjusted

between "0.0-8.0".

Certain stitches have a limited stitch width. (See

" " on page 93.)Stitch reference chart

Stitch length adjusting

For a shorter stitch, press the left side of the

button "". For a longer stitch, press the right

side of button "+". The stitch length can be

adjusted between "0.0-5.0".

Note:

Certain stitches have a limited stitch

length range.

41

Page 43

PATTERN BALANCE ADJUSTMENT

PATTERN BALANCE ADJUSTMENT

If the decorative stitch patterns, numbers or manual buttonhole stitch are uneven when

you sew on a particular fabric, adjust them with the pattern adjustment dial. Use a coin to

turn the dial slightly towards the "+" or "".

The pattern adjustment dial normally should be in

the horizontal position.

Adjusting distorted stretch stitch patterns

A. When Patterns are too compressed, correct

by turning the dial in the direction of "".

B. Correct setting.

C. When Patterns are too drawn out, correct by

turning the dial in the direction of "+".

Adjusting distorted letters or numbers

A. When the letters or numbers are overlap, turn

the dial to "".

B. Correct setting.

C. When the patterns are too drawn out, correct

by turning the dial to "+".

Adjusting the stitch density for buttonhole

A. Buttonhole is too dense, correct by turning the

dial to "".

B. Correct setting.

C. Buttonhole is less dense, correct by turning

the dial to "+".

Note: Always test sew the pattern on a piece of fabric that is the same as the fabric used for

your project.

42

Page 44

PRESSER FOOT PRESSURE ADJUSTMENT

PRESSER FOOT PRESSURE ADJUSTMENT

The presser foot pressure dial is on the top of

the face plate.

The presser foot pressure of the machine has

been preset and usually requires no particular

readjustment.

The foot pressure dial should be set near "1" for

regular sewing. Adjust the pressure between "0"

and "2" for heavyweight or thicker fabrics. Set

the pressure between "1" and "2" for lightweight

or fine fabrics and applique stitching.

43

Page 45

USEFUL FUNCTIONS

USEFUL FUNCTIONS

Reverse

Reverse stitching is used to secure the threads

at the beginning and at the end of a seam.

Press the reverse button and sew 4-5 stitches.

The machine will sew forward when the button is

released.

Free arm sewing

Free-arm sewing is convenient for sewing

tubular areas such as pant hems and cuffs.

44

Page 46

Installing the extension table

1

1. Take out the extension table and seven

extension table feet from the packaging.

Remove the screws from each of the feet with

the large slotted screwdriver.

Place one of the feet under one of the holes in

the and tighten the top screw

extension table

with the .

Repeat for the remaining feet.

2. Pull the sewing table and accessory box off by

sliding it to the left.

large slotted screwdriver

2

3. Keeping the extension table level, slide it up

against the sewing machine.

To adjust the height of the extension table,

turn the rubber knobs under each of the feet to

the proper height.

Attention: Do not move the sewing machine

while the extension table is attached, otherwise

damage and/or injury may occur.

3

45

Page 47

b

a

To raise or drop the feed dogs

a

With the sewing table off the machine, the feed

dog adjustment lever is located at the base of

the free-arm in the front of the machine.

Sliding the lever to the " " (b) will lower the

feed dog, for example during button sewing. If

you wish to continue sewing normally, slide the

lever to the " " (a) in order to raise the feed

dogs.

b

a

b

Attaching the knee lifter

The knee lifter is extremely helpful when sewing

applique, patchwork and quilting since it allows

you to handle the fabric while your knee controls

the presser foot.

Match the ribs on the knee lifter with the notches

in the knee lifter socket and insert the knee lifter.

Knee lifter to raise / lower presser foot

Move the knee lifter to the right to raise the presser

foot. Release the knee lifter to lower the presser

foot.

Note: Turn the handwheel one complete

cycle to return the feed dog to the raised

position.

Attention: Do not touch the knee lifter while

sewing, otherwise the fabric will not be fed

correctly.

46

Page 48

USEFUL SEWING TIPS

2

3

USEFUL SEWING TIPS

Sewing corners

2

1

4

Sewing on heavy fabric

1. Stop the sewing machine when

you reach a corner.

2. Lower the needle into the

5

fabric manually or by pressing

the needle up/down button till

needle is in down position.

3. Raise the presser foot.

4. Use the needle as a pivot and

turn the fabric.

5. Lower the presser foot and

resume sewing.

The black button on the left side

of the presser foot will lock the

presser foot in a horizontal

position if you push it in before

lowering the presser foot.

Cardboard or

thick fabric

This ensures even feeding at the

beginning of a seam and helps

when sewing multiple layers of

fabric such as sewing over

seams when hemming jeans.

When you reach the point of an

increased thickness, lower the

needle and raise the presser foot.

Press the toe of the presser foot

and push in the black button,

then lower the foot and continue

sewing.

The black button releases automatically after sewing few stitches.

You also can place another piece

of fabric with the same thickness

at the back of the seam.

Or support the presser foot while

feeding by hand and sewing

toward the folded side.

47

Page 49

SELECTING STITCHES

SELECTING STITCHES

Using the selection buttons

Ten of the most frequently used utility stitches can quickly be selected with the selection buttons.

Select the desired stitch from those shown on the stitch pattern plate.

When the sewing machine is turned on, the straight stitch (center needle position) is automatically

selected.

1. Determine the stitch that you wish to use.

* Refer to Pattern Chart on page 37.

2. Determine which presser foot should be used with the selected stitch.

The presser feet can be stored inside the accessory compartment.

* For details on the stitches that can be sewn with a twin needle, refer to "Stitch Reference

Chart" beginning on page 93.

3. Attach the correct presser foot for the selected stitch.

* For details, refer to "Changing the Presser Foot" on page 32.

4. Turn on the sewing machine.

* The straight stitch (center needle position) is shown selected within the LCD.

5. Press the " " button and the pattern group screen will automatically appear on the LCD screen.

6. Press the numbered button corresponding to the desired group of stitches that you wish to use.

(e.g. press 2 for group "B")

7. Press the 2 digit pattern number from the selected group on the stitch pattern plate.

Note: When a stitch is selected, the icon for the presser foot that should be used appears

in the screen. Check that the correct presser foot is attached before starting to sew. If the

wrong presser foot is installed, turn off the sewing machine, attach the correct presser foot,

and then select the desired stitch again.

48

Page 50

BASIC STITCHING

BASIC STITCHING

Straight stitches and needle position

RA

Changing the needle position

This setting can be applied only to patterns 1-4

from Group 1-A, Group 2-B Patterns 00-05, 27-29,

Group 3-C Patterns 00-02, 04, 18 and Group 4-D

Pattern 50.

The pre-set position is "4.0", center position.

When you press the "" stitch width adjustment

button, the needle position will move to the left.

When you press the "+" stitch width adjustment

button, the needle position will move to the right.

The LCD screen width illustration indicates the

position of needle and number for easy reference.

Changing the stitch length

To shorten the stitch length, press the "" stitch

length adjustment button. For a longer stitch length,

press the "+" stitch length adjustment button.

Generally speaking, the thicker the fabric, thread

and needle, the longer the stitch should be.

Zigzag stitches

RA RK

Adjusting the stitch width

The maximum zigzag stitch width for zigzag stitching is "8.0"; however, the width can be reduced on

any patterns. The width increases as you press the

"+" stitch width adjustment button from "0.0-8.0".

Note: Some stitches have a limited stitch

width range.

Adjusting the stitch length

The density of zigzag stitches increase as the

setting of stitch length approaches "0.0". Neat

zigzag stitches are usually achieved at "1.0-2.5".

Zigzag stitches with a short length (approximately

0.4) are referred to as a satin stitch. The cutout on

the underside of the RK satin stitch foot is designed

to accom

modate dense stitch formation.

49

Page 51

Stretch stitch

RA

Straight stretch stitch

Straight stitch

04 05

Stretch stitches assure you of a stitch that is strong

and flexible and will give with the fabric without

breaking. The flexibility of the straight stretch stitch

makes it ideal for seaming heavy, knit or easy to

ravel fabrics.

These stitches can also be used as a bold,

decorative top stitch.

Straight stretch stitch is used to add triple

reinforcement to stretch and hardwearing seams.

Use it to sew stress areas such as the crotch

seams in pants or the sleeve underarm area.

Triple zigzag stretch stitch is suitable for medium

08

to heavyweight stretch fabrics in any area you

would normally use a zigzag stitch or decorative

rickrack trim.

Note: Reinforce points that will be subject

to strain such as inseams and attaching

sleeves.

50

Page 52

BLIND HEM/ LINGERIE STITCH

BLIND HEM/ LINGERIE STITCH

RM

5mm

Wrong side Wrong side

1

Overcasting

stitches

2

1.0~5.0

3

b

2.5~6.0

5mm

a

RM

16:

Blind hem/ lingerie for firm fabrics

19:

Blind hem for stretch fabrics

20:

Blind hem for stretch fabrics

Note: It takes practice to sew blind hems.

Always make a sewing test first.

1. Fold the fabric as illustrated with the wrong

side facing up.

2. Attach the blind hem foot.

Place the fabric under the foot.

Turn the handwheel towards you by hand until

the needle swings fully to the left. It should

just pierce the fold of the fabric. If it does not,

adjust the stitch width or guide on the presser

foot accordingly.

3. Adjust the guide (b) by turning the knob (a) so

that the guide just rests against the folded

edge of the fabric and the needle just barely

catches the fold as you sew.

4. Sew slowly, guiding the fabric carefully along

the edge of the guide.

1.0~3.0

3.5~6.0

4

5. Turn the fabric over.

Note: If the stitches are too visible on the

right side of the fabric, decrease the width

of the stitch or move the guide to the right.

If the stitches are not catching the fold of

the fabric, increase the width or move the

guide to the left.

5

51

Page 53

OVERCASTING STITCHES

OVERCASTING STITCHES

Using the overcasting foot

RI

2.0~3.0

5.0~7.0

2

1. Change the presser foot to the overcasting foot.

2. Sew the fabric with the fabric edge against the guide of the overcasting foot.

Attention: The overcasting foot should be used to sew with group 2-B patterns 06 and 09

only and do not set the stitch width narrower than "5.0". It is possible that the needle could hit

the presser foot and break when sewing other patterns and width.

Using the all purpose foot

1

2.0~3.0

2.5~4.5

2

1. Change the presser foot to the all purpose foot.

2. Sew the overcasting along the edge of the fabric so that the needle drops over the edge of the

fabric on the right side.

52

Page 54

ZIPPER INSERTION

ZIPPER INSERTION

RB

1.5~3.0

Inserting a centered zipper

3mm

(1/8")

1 2

4.0

Attention: Zipper foot should be used for

sewing with the centered needle position

straight stitch only. It is possible that the

needle could hit the presser foot and break

when sewing other patterns.

1. Baste the zipper opening on the garment.

2. Press open the seam allowance. Place the

zipper face down on the seam allowance with

the teeth against the seam line. Baste the

zipper tape.

3. Attach the zipper foot. Attach the left side of

the presser foot pin to the presser foot holder

when sewing the right side of the zipper.

4. Attach the right side of the presser foot pin to

the presser foot holder when sewing the left

side of the zipper.

3

5

4

5. Stitch left side of the zipper from bottom to top.

6. Stitch across the lower end and right side of

zipper. Remove the basting stitches and press.

6

53

Page 55

ZIPPER INSERTION

ZIPPER INSERTION

Inserting a side zipper

3mm

(1/8")

1. Baste the zipper opening on the garment.

2. Fold the garment back to the left seam allowance.

Turn under the right seam allowance to form a

3mm (1/8 inch) fold.

1

3

2

3. Attach the zipper foot. Attach the left side of

the presser foot pin to the presser foot holder

when sewing the right side of the zipper.

Attach the right side of the presser foot pin to

the presser foot holder when sewing the left

side of the zipper.

4. Stitch the left side of the zipper from bottom to

top.

4

5. Turn the fabric right side out, stitch across the

lower end and right side of zipper.

6. Stop about 5cm (2 inches) from the top of

zipper. Remove the basting and open the

zipper. Stitch the remainder of the seam.

5 6

54

Page 56

BUTTON SEWING

BUTTON SEWING

RC

2.5~4.5

1. Select the pattern 43 from the Group 2-B

Patterns to get the button sewing stitch.

Change the presser foot to the button sewing

foot "RC" and lower feed dogs.

1

2. Position the fabric under the foot. Place the

button in the desired position, lower the presser

2.5~4.5

3

2

4

foot lever.

3. Adjust the stitch width to "2.5-4.5" according to

the distance between the two holes of the button.

4. Turn the handwheel counterclockwise to check

that the needle goes cleanly into the left and

right holes of the button.

Note: Sew at a slow speed to avoid hitting

the button.

5. Hold the end of the upper thread gently, and

begin sewing. Once sewing is completed, the

machine automatically sews reinforcement

stitches, then stops.

Note: Repeat this procedure to attach the

button more securely.

With scissors, cut the upper and bobbin threads

at the beginning of the stitching, pull the upper

5

thread at the end of the stitching to the wrong

side of the fabric, and then tie it with the bobbin

thread.

6. For 4-hole buttons, sew the two holes towards

the front. Then, raise the presser foot, move

the fabric so that the needle goes into the back

two holes, and then sew them in the same way.

Note: If a shank is required, place a needle

or straight pin on top of the button and sew.

6

55

Page 57

BUTTONHOLE STITCHING

BUTTONHOLE STITCHING

Making a one-step buttonhole

Recommended

0.3~1.0

0.3~1.0

0.3~1.0

0.3~3.0

1.0~3.0

3.0~7.0

2.5~7.0

5.5~7.0

2.5~7.0

2.5~7.0

30 :

For horizontal holes on blouses or shirts

made from thin or medium fabric.

31:

For thin or medium fabric.

32 :

For thin or medium fabric.

33 :

For horizontal buttonholes on thick fabrics.

34:

For suits or overcoats.

35:

For jeans or trousers.

36:

For thick coats.

37:

For bound button holes.

38:

For jeans or stretch fabric with a coarse

weave.

39:

For stretch fabric.

RJ

Note: Before sewing a buttonhole on your project, practice on a scrap piece of the same

type of fabric.

2.0~3.0

3.5~7.0

1. Mark the position of the buttonholes on the

fabric.

The maximum buttonhole length is 3cm (1 3/16

inch). (Total of diameter + thickness of button.)

1

2. Attach the buttonhole foot, then extend the

button guide plate and insert the button. The

size of the buttonhole is determined by the

button inserted in the button plate.

The upper thread should be passed through

the needle opening in the buttonhole foot, then

the thread placed under the foot as illustrated.

2

56

Page 58

3. Select the buttonhole stitch.

Adjust the stitch width and the stitch length to

the desired width and density.

Position the fabric under the presser foot with

the front end of the buttonhole mark aligned

with the center line on the buttonhole foot.

3

4. Pull the buttonhole lever all the way down and

position it behind the bracket on the

buttonhole foot.

PUSH

4

Note: When you start to sew any buttonhole pattern before the buttonhole lever is

lowered, the LCD screen will show the

animated warning message to remind you

to lower the buttonhole lever.

5. While lightly holding the end of the upper

thread, start sewing.

Note: Gently guide the fabric by hand.

Before stopping, the machine will auto-

PUSH

matically sew a reinforcement stitch after

the buttonhole is sewn.

5

57

Page 59

31

30

32 33

34 35 36

37

38

39

6

6. Buttonholes are sewn from the front of the

presser foot to the back, as shown.

7. Raise the presser foot and cut thread. To

restart the same buttonhole at the beginning,

raise the presser foot to return to the starting

position. After sewing the buttonholes, raise the

buttonhole lever all the way up to its original

position for other sewing.

7

58

Page 60

Note: If the buttonhole lever is in the down

position and a stitch other than a buttonhole

is selected an animated warning message

to raise the lever will appear on the LCD

screen when the START/STOP button or

foot control is pressed.

8. Cut the center of the buttonhole being careful

not to cut any buttonhole stitches on either

side. Use a pin as a stopper at the bartack to

prevent the stitching from being cut.

8

Making a buttonhole on stretch fabrics

When sewing buttonholes on stretch fabric, hook gimp thread under the buttonhole foot.

1. Attach the buttonhole foot and hook the gimp

thread onto the back spur of the presser foot.

Bring the two gimp thread ends parallel to the

front of the foot and insert them into the

grooves, then temporarily tie them there.