Page 1

Dynamixel

Closer to Real,

A

User’s Manual 2006-06-14

X-12

Page 2

DYNAMIXEL

Contents

AX-12

1. Summary

1-1. Overview and Characteristics of AX-12 Page 2

1-2. Main Specifications Page 3

2. Dynamixel Operation

2-1. Mechanical Assembly Page 4

2-2. Connector Assembly Page 5

2-3. Dynamixel Wiring Page 6

3. Communication Protocol

3-1. Communication Overview Page 9

3-2. Instruction Packet Page 10

3-3. Status Packet Page 10

3-4. Control Table Page 12

4. Instruction Set and Examples

4-1. WRITE_DATA Page 19

4-2. READ_DATA Page 20

4-3. REG WRITE and ACTION Page 2 0

4-4. PING Page 21

4-5. RESET Page 22

4-6. SYNCWRITE Page 23

5. Example

Appendix

Page 30

Page 24

1

Page 3

DYNAMIXEL

AX-12

1. Dynamixel AX-12

1-1. Overview and Characteristics of AX-12

Dynamixel AX-12 The Dynamixel series robot actuator is a smart, modular actuator that incorporates a

gear reducer, a precision DC motor and a control circuitry with networking functionality,

all in a single package. Despite its compact size, it can produce high torque and is

made with high quality materials to provide the necessary strength and structural

resilience to withstand large external forces. It also has the ability to detect and act

upon internal conditions such as changes in internal temperature or supply voltage.

The Dynamixel series robot actuator has many advantages over similar products.

Precision Control Position and speed can be controlled with a resolution of 1024 steps.

Compliance Driving The degree of compliance can be adjusted and specified in controlling position.

Feedback Feedback for angular position, angular velocity, and load torque are available.

Alarm System The Dynamixel series robot actuator can alert the user when parameters deviate from

user defined ranges (e.g. internal temperature, torque, voltage, etc) and can also handle

the problem automatically (e.g. torque off)

Communication Wiring is easy with daisy chain connecti on, and it support communication speeds u p to

1M BPS.

Distributed Control Position, velocity, compliance, and torque can be set with a single command packet,

thus enabling the main processor to control many Dynamixel units even with very few

resources.

Engineering Plastic The main body of the unit is made with high quality engineering plastic which enables it

to handle high torque loads.

Axis Bearing A bearing is used at the final axis to ensure no efficiency degradation with high external

loads.

Status LED The LED can indicate the error status to the user.

Frames A hinge frame and a side mount frame are included.

2

Page 4

DYNAMIXEL

AX-12

1-2. Main Specifications

AX-12

Weight (g) 55

Gear Reduction Ratio 1/254

Input Voltage (V) at 7V at 10V

Final Max Holding Torque(kgf.cm) 12 16.5

Sec/60degree 0.269 0.196

Resolution 0.35°

Operating Angle 300°, Endless Turn

Voltage 7V~10V (Recommended voltage: 9.6V)

Max. Current 900mA

Operate Temperature -5 ~ +85℃℃

Command Signal Digital Packet

Protocol Type Half duplex Asynchronous Serial Communication (8bit,1stop,No Parity)

Link (Physical) TTL Level Multi Drop (daisy chain type Connector)

ID 254 ID (0~253)

Communication Speed 7343bps ~ 1 Mbps

Feedback Position, Temperature, Load, Input Voltage, etc.

Material Engineering Plastic

3

Page 5

DYNAMIXEL

AX-12

2. Dynamixel Operation

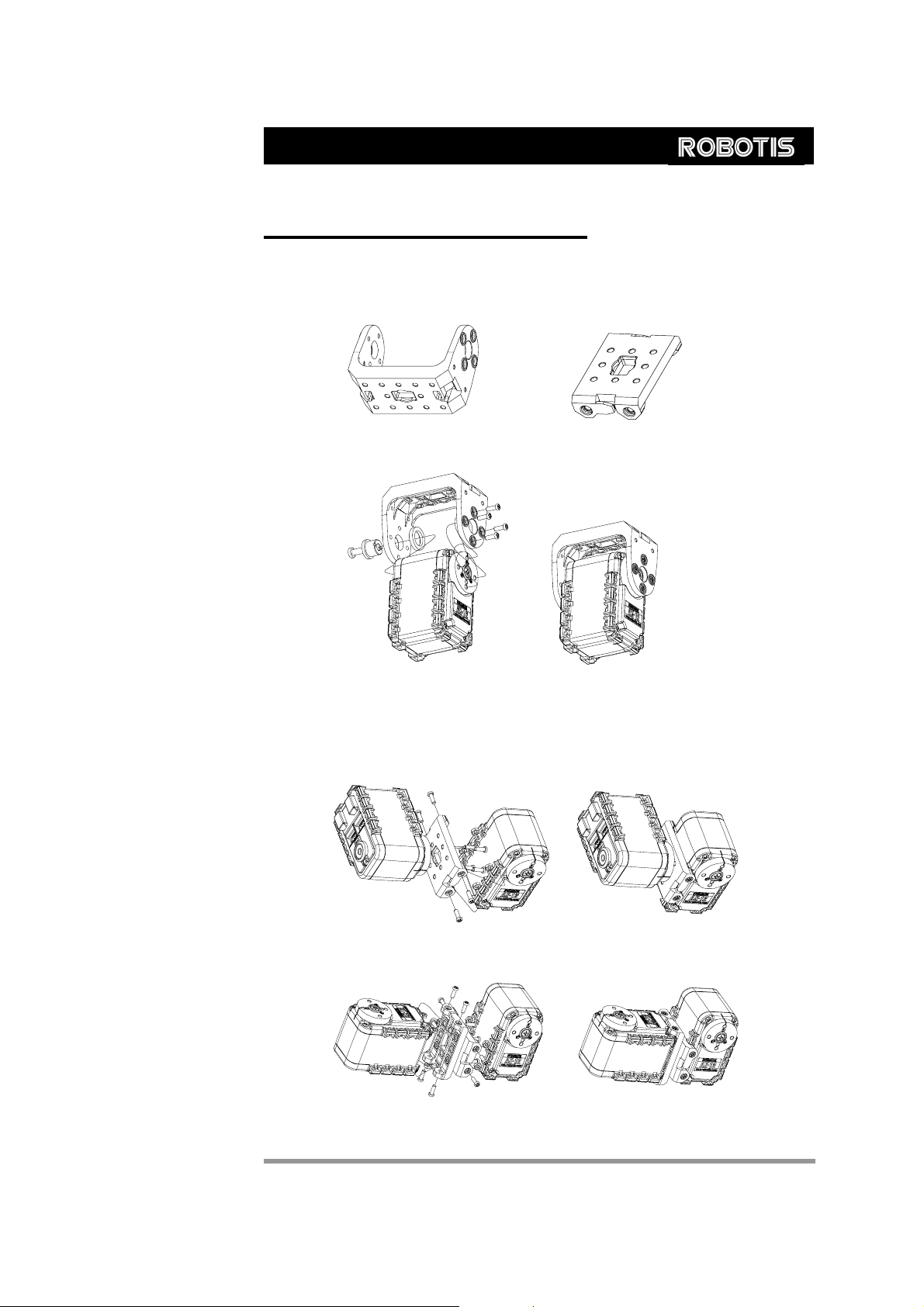

2-1. Mechanical Assembly

Frames Provided The two frames provided with AX-12 are shown below.

OF-12SH Installation The OF-12SH (hinge frame) can be installed on the AX-12 as the following.

OF-12S Installation The OF-12S (side mount frame) can be installed on the AX-12 as the following. The OF-

12S can be mounted on any of the three faces (left, right, or under side) of the AX-12

body as needed.

Horn2Body

Body2Body

OF-12SH OF-12S

Exploded view

Exploded view

Exploded view Assembled

Assembled

Assembled

4

Page 6

DYNAMIXEL

AX-12

2-2 . Connector Assembly

Assemble the connectors as shown below. Attach the wires to the terminals using the

correct crimping tool. If you do not have access to a crimping tool, solder the terminals to

the wires to ensure that they do not become loose during operation.

5

Page 7

DYNAMIXEL

AX-12

2-3. Dynamixel Wiring

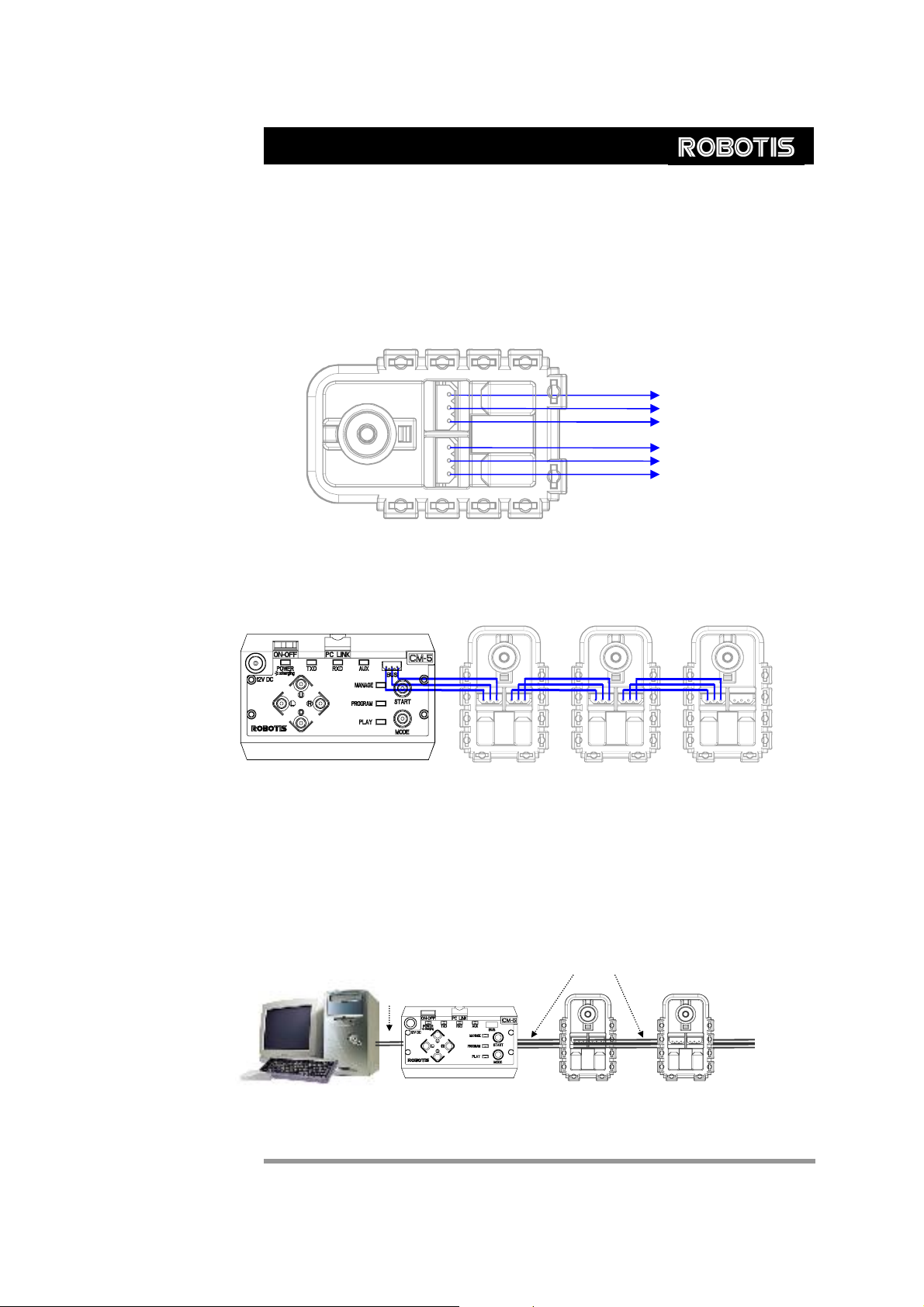

Pin Assignment The connector pin assignments are as the following. The two connectors on the

Dynamixel are connected pin to pin, thus the AX-12 can be operated with only one

connector attached.

Wiring Connect the AX-2 actuators pin to pin as shown below. Many AX-12 actuators can be

controlled with a single bus in this manner.

Control Box “CM-5”

Main Controller To operate the Dynamixel actuators, the main controller must support TTL level half duplex

UART. A proprietary controller can be used, but the use of the Dynamixe l controller CM-5

is recommended.

PC LINK A PC can be used to control the Dynamixel via the CM-5 controller.

RS232

Level

TTL

Level

PC Dynamixels

CM-5

PIN1: GND

PIN2: VDD

PIN3: Data

PIN1: GND

PIN2: VDD

PIN3: Data

6

Page 8

DYNAMIXEL

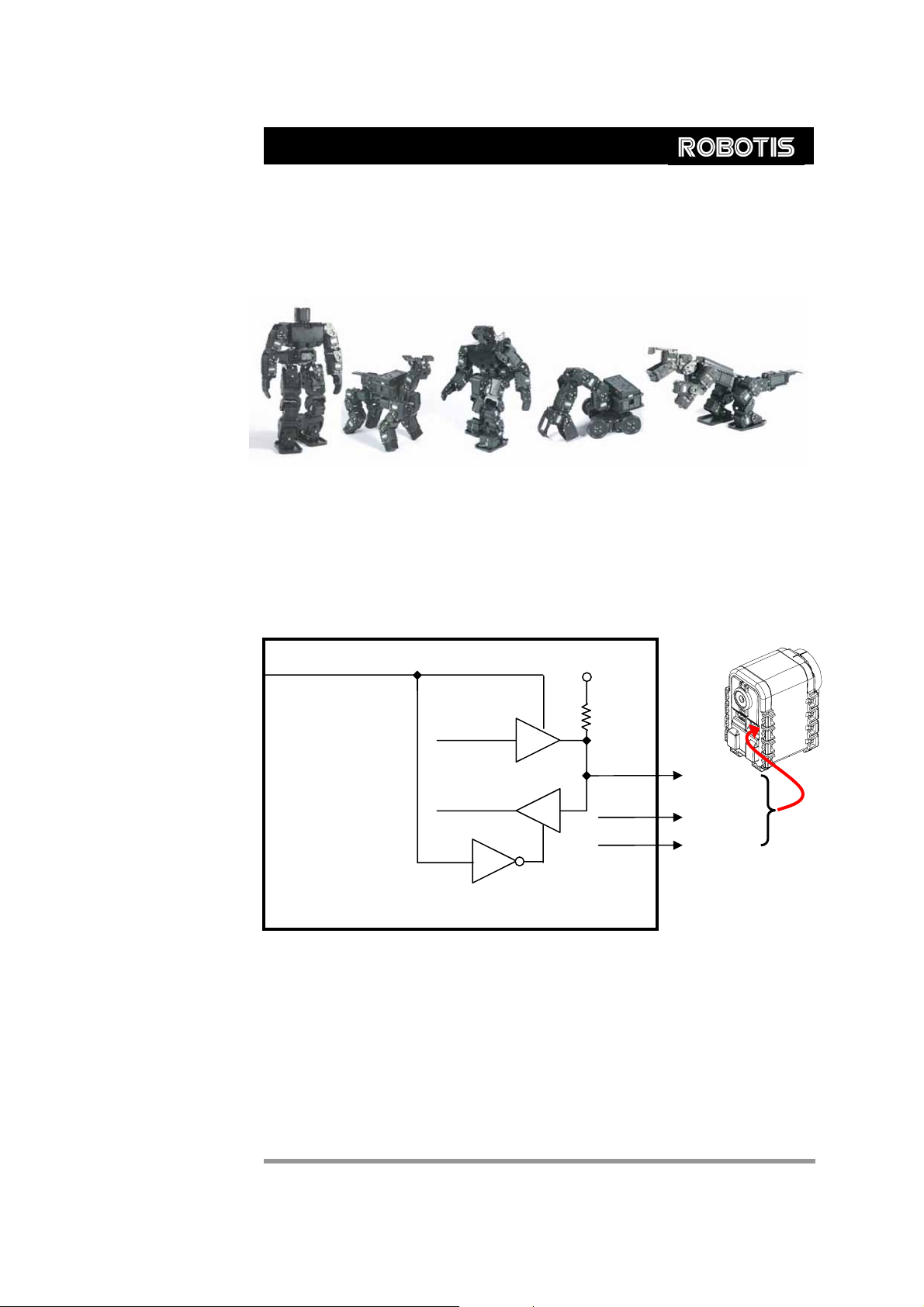

bioloid A robot can be built using only the CM-5 controller and a number of AX-12 actuators. An

Connection to UART To control the Dynamixel actuators, the main controller needs to convert its UART

AX-12

edutainment robotic kit named “Bioloid” is available which is based on the CM-5

controller and the AX-12 actuators.

An example of a robot built with Bioloid

For details, please refer to the Bioloid manual.

signals to the half duplex type. The recommended circuit diagram for this is shown

below.

DIRECTION_PORT

74HC126

TXD

74HC126

RXD

74HC04

CM-5 internal circuit (HALF DUPLEX UART)

The power is supplied to the Dynamixel actuator from the main controller through Pi n 1

and Pin 2 of the Molex3P connector. (The circuit shown above is presented only to

explain the use of half duplex UART. The CM-5 controller already has the above

circuitry built in, thus the Dynamixel actuators can be directly connected to it)

The direction of data signals on the TTL level TxD and RxD depends on the

DIRECTION_PORT level as the following.

5V

10K

DATA

9.6V

GND

DATA(PIN3)

VDD(PIN2)

GND(PIN1)

7

Page 9

r

DYNAMIXEL

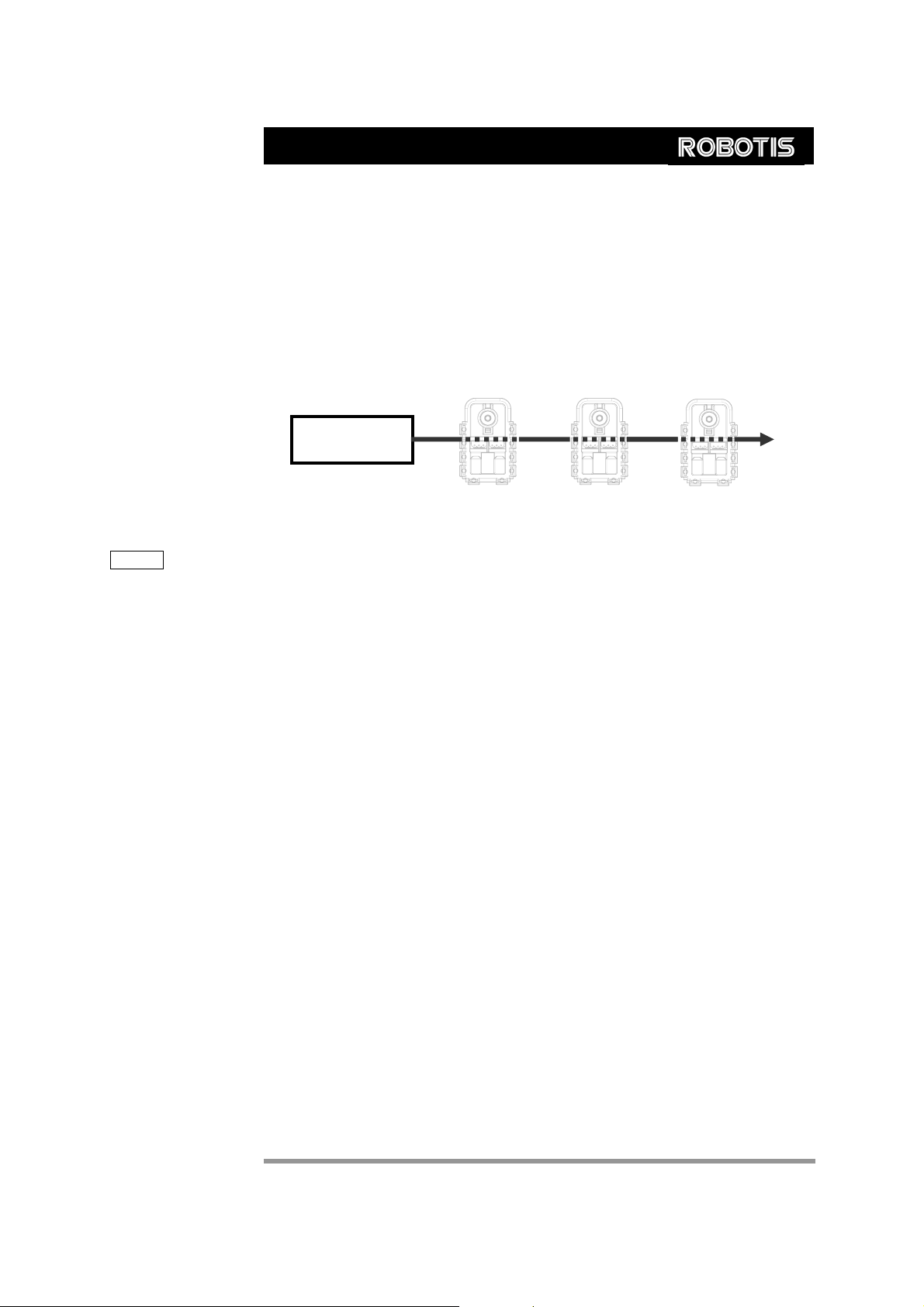

Half Duplex UART A multi-drop method of connecting multiple Dynamixel actuators to a single node is

Caution Please ensure that the pin assignments are correct when connecting the Dynamixel

Connection Status Verification

Inspection If the above operation was not successful, then check the co nnector pin assi gn ment and

AX-12

• When the DIRECTION_PORT level is High: the signal TxD is output as Data

• When the DIRECTION_PORT level is Low: the signal Data is input as RxD

possible by using the half duplex UART. Thus a protocol that does not allow multiple

transmissions at the same time should be maintained when controlling the Dynamixel

actuators.

Main

Controlle

[Multi Drop Link]

actuators. Check the current consumption when powering on. T he current consumption

of a single Dynamixel actuator unit in standby mode should be no larger than 50mA

When power is applied to the Dynamixel actuator, the LED blinks twice to confirm its

connection.

the voltage/current limit of the power supply.

8

Page 10

r

r

DYNAMIXEL

AX-12

3. Communication Protocol

3-1. Communication Overview

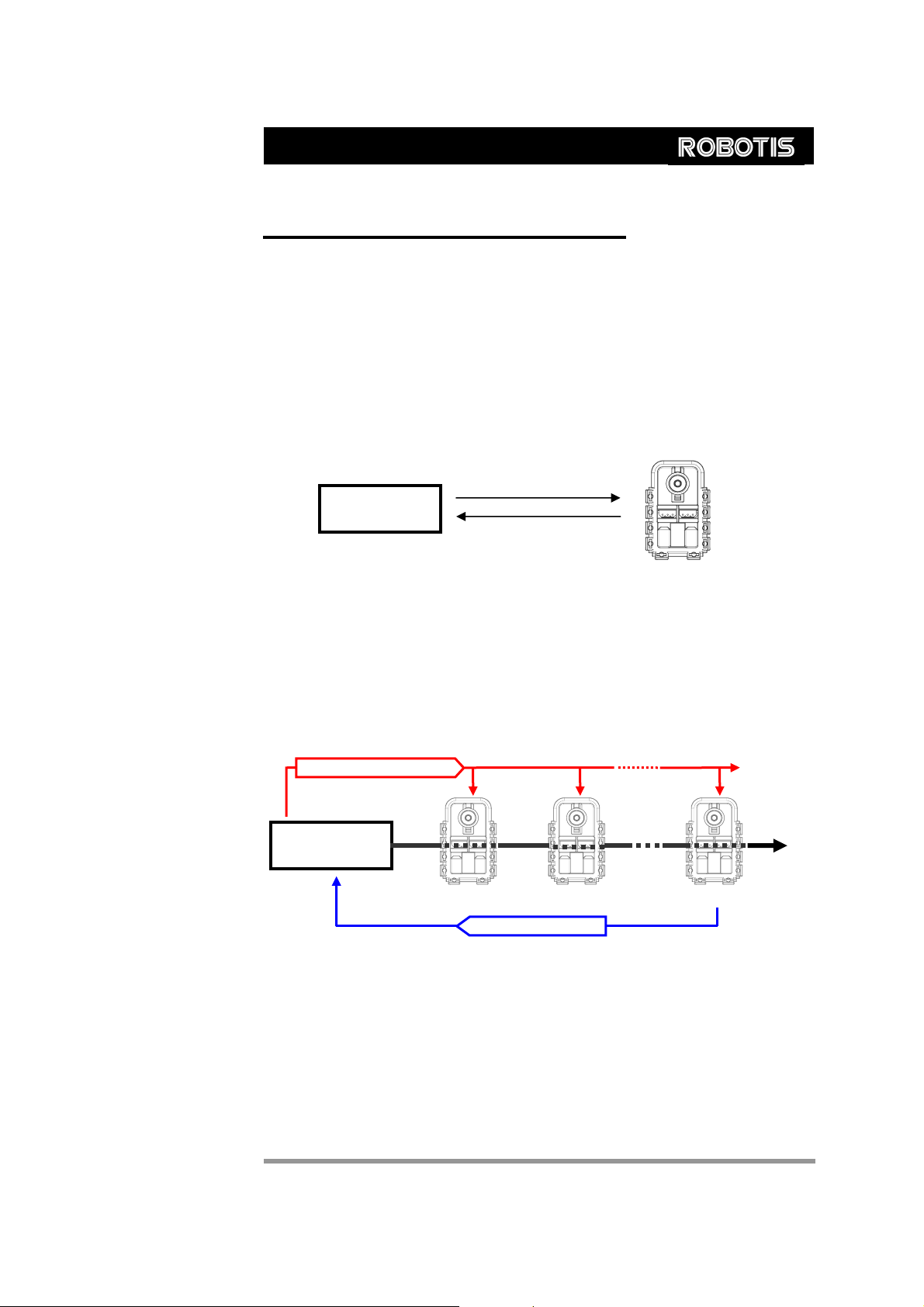

Packet The main controller communicates with the Dynamixel units by sending and receiving

data packets. There are two types of packets; the “Instruction Packet” (sent from the

main controller to the Dynamixel actuators) and the “Status Packet” (sent from the

Dynamixel actuators to the main controller.)

Communication For the system connectio n below, if the main controller sends an instruction packet with

the ID set to N, only the Dynamixel unit with this ID value will return its respective status

packet and perform the required instruction.

Unique ID If multiple Dynamixel units have the same ID value, multiple packets sent

Protocol The Dynamixel actuators communicate through asynchronous serial communication

Instruction Packet(ID=N)

Main

Controlle

simultaneously collide, resulting in communication problems. Thus, it is imperative that

no Dynamixel units share the same ID in a network node.

with 8 bit, 1 stop bit and no parity.

Main

Controlle

Instruction Packet

Status Packet

ID=0 ID=1 ID=N

Status Packet(ID=N)

9

Page 11

DYNAMIXEL

AX-12

3-2. Instruction Packet

The Instruction Packet is the packet sent by the main controller to the Dynamixel units

to send commands. The structure of the Instruction Packet is as the following.

Instruction Packet

0XFF 0XFF The two 0XFF bytes indicate the start of an incoming packet.

ID The unique ID of a Dynamixel unit. There are 254 available ID values, ranging from

Broadcasting ID ID 0XFE is the Broadcasting ID which indicates all of the conn ected Dynamixel units.

LENGTH The length of the packet where its value is “Number of parameters (N) + 2”

INSTRUCTION The instruction for the Dynamixel actuator to perform.

PARAMETER0…N Used if there is additional information needed to be sent other than the instruction itself.

CHECK SUM The computation method for the ‘Check Sum’ is as the following.

OXFF 0XFF ID LENGTH INSTRUCTION PARAMETER1 …PARAMETER N CHECK SUM

The meanings of each packet byte definition are as the following.

0X00 to 0XFD.

Packets sent with this ID apply to all Dynamixel units on the network. Thus packets sent

with a broadcasting ID will not return any status packets.

Check Sum = ~ (ID + Length + Instruction + Parameter1 + ... Parameter N)

If the calculated value is larger than 255, the lower byte is defined as the checksum

value.

~ represents the NOT logic operation.

3-3. Status Packet(Return Packet)

The Status Packet is the response packet from the Dynamixel units to the Main

Controller after receiving an instruction packet. The structure of the status packet is as

the following.

OXFF 0XFF ID LENGTH ERROR PARAMETER1 PARAMETER2… PARAMETER N CHECK SUM

10

Page 12

DYNAMIXEL

0XFF 0XFF The two 0XFF bytes indicate the start of the packet.

ID The unique ID of the Dynamixel unit returning the packet. The initial value is set to 1.

LENGTH The length of the packet where its value is “Number of parameters (N) + 2”

ERROR The byte repres enting errors sent from the Dynamixel unit. The meaning of each bit is

AX-12

The meanings of each packet byte definition are as the following.

as the following.

Bit Name Details

Bit 7 0 -

Set to 1 if an undefined instruction is sent or an action

Bit 6 Instruction Error

instruction is sent without a Reg_Write instruction.

Set to 1 if the specified maximum torque can't control the

Bit 5 Overload Error

applied load.

Bit 4 Checksum Error Set to 1 if the checksum of the instruction packet is incorrect.

Bit 3 Range Error Set to 1 if the instruction sent is out of the defined range.

Bit 2

Overheating

Error

Angle Limit

Bit 1

Error

Input Voltage

Bit 0

Error

PARAMETER0…N Used if additional information is needed.

CHECK SUM The computation method for the ‘Check Sum’ is as the following.

Check Sum = ~ (ID + Length + Instruction + Parameter1 + ... Parameter N)

If the calculated value is larger than 255, the lower byte is defined as the checksum

value. ~ represents the NOT logic operation.

Set to 1 if the internal temperature of the Dynamixel unit is

above the operating temperature range as defined in the

control table.

Set as 1 if the Goal Position is set outside of the range

between CW Angle Limit and CCW Angle

Limit.

Set to 1 if the voltage is out of the operating voltage range as

defined in the control table.

11

Page 13

DYNAMIXEL

3-4. Control

Table

EEPROM

Area

RAM

Area

AX-12

Address Item Acces s Initial Value

0(0X00) Model Num ber(L) RD

1(0X01) Model Num ber(H) RD

2(0X02) Version of Firmw are RD

3(0X03) ID RD,WR

4(0X04) Baud Rate RD,WR

5(0X05) Return Delay Time RD,WR

6(0X06) CW Angle Limit(L) RD,WR

7(0X07) CW Angle Limit(H) RD,WR

8(0X08) CCW Angle Limit(L) RD,WR

9(0X09) CCW Angle Limit(H) RD,WR

10(0x0A) (Reserved) 11(0X0B) the Highest Lim it T emperature RD,WR

12(0X0C) the Lowest Lim it Voltage RD ,WR

13(0X0D) the Highest Limit Voltage RD ,WR

14(0X0E) Max Torque(L) RD,WR

15(0X0F) Max Torque(H) RD,WR

16(0X10) Status Return Level RD,WR

17(0X11) Alarm LE D RD,WR

18(0X12) Alarm S hutdown RD,WR

19(0X13) (Reserved) RD,WR

20(0X14) Down Calibration(L) RD

21(0X15) Down Calibration(H) R D

22(0X16) Up Calibration(L) RD

23(0X17) Up Calibration(H) RD

24(0X18) Torque Enable RD,WR

25(0X19) LED RD,WR

26(0X1A) CW Com pliance Margin RD,WR

27(0X1B) CCW Com pliance Margin RD,WR

28(0X1C) CW Compliance Slope RD,WR

29(0X1D) CC W Compliance Slope R D ,WR

30(0X1E) G oal Pos ition(L) R D ,WR

31(0X1F) Goal Position(H) RD,WR

32(0X20) Moving Speed(L) RD,WR

33(0X21) Moving Speed(H) RD,WR

34(0X22) Torque Limit(L) RD,WR

35(0X23) Torque Limit(H) RD,WR

36(0X24) Present Position(L) RD

37(0X25) Present Position(H) RD

38(0X26) Present Speed(L) RD

39(0X27) Present Speed(H) RD

40(0X28) Present Load(L) RD

41(0X29) Present Load(H) RD

42(0X2A) Present Voltage RD

43(0X2B) Present Tem perature RD

44(0X2C) Registered Instruction RD,WR

45(0X2D) (Res erved) -

46[0x2E) Moving RD

47[0x2F) Loc k RD ,WR

48[0x30) Punch(L) RD,WR

49[0x31) Punch(H) RD,WR

12(0x0C)

0(0x00)

?

1(0x01)

1(0x01)

250(0xFA)

0(0x00)

0(0x00)

255(0xFF)

3(0x03)

0(0x00)

85(0x55)

60(0X3C)

190(0xBE)

255(0XFF)

3(0x03)

2(0x02)

4(0x04)

4(0x04)

0(0x00)

?

?

?

?

0(0x00)

0(0x00)

0(0x00)

0(0x00)

32(0x20)

32(0x20)

[Addr36]value

[Addr37]value

0

0

[Addr14] value

[Addr15] value

?

?

?

?

?

?

?

?

0(0x00)

0(0x00)

0(0x00)

0(0x00)

32(0x20)

0(0x00)

12

Page 14

DYNAMIXEL

Control Ta ble The Control Table contains information on the status and operation of the Dynamixel

RAM and EEPROM The data values for the RAM area will be set to the default initial values whenever the

Initial Value The Initial Value column on the right side of the control table shows the Factory Default

Address 0x00,0x01

Address 0x02

Address 0x03

Address 0x04

Speed (BPS) = 2000000 / (Address4 + 1)

Note A maximum Baud Rate error of 3% is within the tolerance of UART communication.

Caution The initial value of Baudrate is set to 1(1000000bps)

AX-12

actuator. The Dynamixel actuator is operated by writing values to its control table and its

status is checked by reading values off its control table.

power is turned on. However, the data values for the EEPROM area are non-volatile

and will still remain even after the power is turned off.

Values for the case of EEPROM area data, and shows the initial value when the power

is turned on for the case of RAM area data.

The following explains the meaning of data stored in each of the addresses in the

control table.

Model Number. For AX-12, this value is 0X000C (12).

Firmware Version.

ID. The unique ID number assigned to each Dynamixel actuators for identifying them.

Different IDs are required for each Dynamixel actuators that are on the same network.

Baud Rate. Determines the communication speed. The computation is done by the

following formula.

Data Value for each Major Baud Rate

Adress4 Hex Set BPS Goal BPS Error

1 0X01 1000000.0 1000000.0 0.000%

3 0X03 500000.0 500000.0 0.000%

4 0X04 400000.0 400000.0 0.000%

7 0X07 250000.0 250000.0 0.000%

9 0X09 200000.0 200000.0 0.000%

16 0X10 117647.1 115200.0 -2.124%

34 0X22 57142.9 57600.0 0.794%

103 0X67 19230.8 19200.0 -0.160%

207 0XCF 9615.4 9600.0 -0.160%

13

Page 15

DYNAMIXEL

Address 0x05 Return Delay Time. The time it takes for the Status Packet to return after the Instruction

Address 0x06,0x07,0x08,0x09

Address 0x0B

Address 0x0C,0x0D

Address 0x0E,0x0F, 0x22,0x23

Address 0X10

AX-12

Packet is sent. The delay time is given by 2uSec * Address5 value.

Operating Angle Limit. Sets the Dynamixel actuator’s operating angle range. T he Goal

Position needs to be within the range of: CW Angle Limit <= Goal Position <= CCW

Angle Limit. An Angle Limit Error will occur if the Goal Position is set outside this range

set by the operating angle limits.

the Highest Limit Temperature. The upper limit of the Dynamixel actuator’s operating

temperature. If the internal temperature of the Dynamixel actuator gets higher than this

value, the Over Heating Error Bit (Bit 2 of the Status Packet) will return the value 1, and

an alarm will be set by Address 17, 18. The values are in Degrees Celsius.

the Lowest (Highest) Limit Voltage. The upper and lower limits of the Dynamixel

actuator’s operating voltage. If the present voltage (Address 42) is out of the specified

range, a Voltage Range Error Bit (Bit 0 of the Status Packet) will return the value 1,

and an alarm will be set by Address 17, 18. The values are 10 times the actual voltage

value. For example, if the Address 12 value is 80, then the lower voltage limit is set to

8V.

Max Torque. The maximum torque output for the Dynamixel actuator. When this value

is set to 0, the Dynamixel actuator enters the Free Run mode. There are t wo locations

where this maximum torque limit is defined; in the EEPROM (Address 0X0E, 0x0F) and

in the RAM (Address 0x22, 0x23). When the power is turned on, the maximum torque

limit value defined in the EEPROM is copied to the location in the RAM. The torque of

the Dynamixel actuator is limited by the values located in the RAM (Address 0x22,

0x23).

Status Return Level. Determines whether the Dynamixel actuator will return a Status

Packet after receiving an Instruction Packet.

Address16

0

1 Respond only to READ_DATA instructions

2

Returning the Status Packet

Do not respond to any instructions

Respond to all instructions

14

Page 16

DYNAMIXEL

Address 0X11

Address 0X12

This function operates following the “OR” logical operation of all bits. However, unlike

Address 0x14~0x17

AX-12

In the case of an instruction which uses the Broadcast ID (0XFE) the Status Packet will

not be returned regardless of the Address 0x10 value.

Alarm LED . If the corresponding Bit is set to 1, the LED blinks when an Error occurs.

Bit Function

Bit 7 0

Bit 6 If set to 1, the LED blinks when an Instruction Error occurs

Bit 5 If set to 1, the LED blinks when an Overload Error occurs

Bit 4 If set to 1, the LED blinks when a Checksum Error occurs

Bit 3 If set to 1, the LED blinks when a Range Error occurs

Bit 2 If set to 1, the LED blinks when an Overheating Error occurs

Bit 1 If set to 1, the LED blinks when an Angle Limit Error occurs

Bit 0 If set to 1, the LED blinks when an Input Voltage Error occurs

This function operates following the “OR” logical operation of all bits. For example, if the

value is set to 0X05, the LED will blink when an Input Voltage Error occurs or when an

Overheating Error occurs. Upon returning to a normal condition from an error state, the

LED stops blinking after 2 seconds.

Alarm Shutdown. If the corresponding Bit is set to a 1, the Dynamixel actuator’s torque

will be turned off when an error occurs.

Bit Function

Bit 7 0

Bit 6

If set to 1, torque off when an Instruction Error occurs

Bit 5

If set to 1, torque off when an Overload Error occurs

Bit 4

If set to 1, torque off when a Checksum Error occurs

Bit 3

If set to 1, torque off when a Range Error occurs

Bit 2

If set to 1, torque off when an Overheating Error occurs

Bit 1

If set to 1, torque off when an Angle Limit Error occurs

Bit 0

If set to 1, torque off when an Input Voltage Error occurs

the Alarm LED, after returning to a normal condition, it maintains the torque off status.

To recover, the Torque Enable (Address0X18) needs to be reset to 1.

Calibration. Data used for compensating for the differences between the

potentiometers used in the Dynamixel units. The user cannot change this data.

The following (from Address 0x18) is in the RAM area.

15

Page 17

DYNAMIXEL

AX-12

Address 0x18 Torque Enable. When the power is first turned on, the Dynamixel actuator enters the

Torque Free Run condition (zero torque). Setting the value in Address 0x18 to 1 enables

the torque.

Address 0x19

LED. The LED turns on when set to 1 and turns off if set to 0.

Address 0x1A~0x1D

Compliance Margin and Slope. The compliance of the Dynamixel actuator is defined

by setting the compliance Margin and Slope. This feature can be utilized for absorbing

shocks at the output shaft. The following graph shows how each compliance value

(length of A, B, C & D) is defined by the Position Error and applied torque.

CW

Goal Position

CCW

CCW

Y axis:Output Torque

A : CCW Compliance Slope(Address0x1D)

B : CCW Compliance Margin(Address0x1B)

C : CW Compliance Margin(Address0x1A)

D : CW Compliance Slope (Address0x1C)

E : Punch(Address0x30,31)

A

B

E

E

CD

X axis:Position Error

CW

Address 0X1E,0x1F

Goal Position Requested angular position for the Dynamixel actuator output to move to.

Setting this value to 0x3ff moves the output shaft to the position at 300°.

(Goal Position = 0x1ff)

150°

(Goal Position = 0x3ff)

300°

300~360°

Invalid Angle

0°

(Goal Position = 0)

16

Page 18

DYNAMIXEL

Address 0x20,0x21 Moving Speed. Sets the angular velocity of the output moving to the Goal Position.

Address 0x24,0x25

Address 0x26,0x27

Address 0x28,0x29

Load Direction = 0 : CCW Load, Load Direction = 1: CW Load

Address 0x2A

Address 0x2B

Address 0x2C

Address 0x2E

Address 0x2F

Address 0x30,0x31

Endless Turn If both values for the CW Angle Limit and the CCW Angle Limit are set to 0, an Endless

AX-12

Setting this value to its maximum value of 0x3ff moves the output with an angular

velocity of 114 RPM, provided that there is enough power supplie d (The lowest velocity

is when this value is set to 1. When set to 0, the velocity is the largest possible for the

supplied voltage, e.g. no velocity control is applied.)

Present Position. Current angular position of the Dynamixel actuator output.

Present Speed. Current angular velocity of the Dynamixel actuator output.

Present Load. The magnitude of the load on the operating Dynam ixel actuator. Bit 10 is

the direction of the load.

BIT 15~11 10 9876543210

Value 0 Load Direction Load Value

Present Voltage. The voltage currently applied to the Dynamixel actuator. The value is

10 times the actual voltage. For example, 10V is represented as 100 (0x64).

Present Temperature. The internal temperature of the Dynamixel actuator in Degrees

Celsius.

Registered Instruction. Set to 1 when an instruction is assigned by the REG_WRITE

command. Set to 0 after it completes the assigned instruction by the Action command.

Moving. Set to 1 when the Dynamixel actuator is moving by its own power.

Lock. If set to 1, only Address 0x18 to 0x23 can be written to and other areas cannot.

Once locked, it can only be unlocked by turning the power off.

Punch. The minimum current supplied to the motor during operation. The initial value is

set to 0x20 and its maximum value is 0x3ff.

Turn mode can be implemented by setting the Goal Speed. This feature can be used for

implementing a continuously rotating wheel.

17

Page 19

DYNAMIXEL

Goal Speed Setting

Range Each data has a valid minimum and maximum values. Write instructions made outside

AX-12

BIT 15~11 10 9876543210

Value 0 Turn Direction Speed Value

Turn Direction = 0 : CCW Direction Turn, Load Direction = 1: CW Direction Turn

of these valid ranges will return an error. The following table summarizes the data range

for each register. 16 bit data registers are indicated with two bytes (L) and (H). Both

bytes need to be written at the same time as one instruction packet.

Write

Address

3(0X03) ID 1 0

4(0X04) Baud Rate 1 0

5(0X05) Return Delay Time 1 0

6(0X06) CW Angle Limit 2 0

8(0X08) CCW Angle Limit 2 0

11(0X0B) the Highest Limit Temperature 1 0

12(0X0C) the Lowest Limit Voltage 1 50(0x32)

13(0X0D) the Highest Limit Voltage 1 50(0x32)

14(0X0E) Max Torque 2 0

16(0X10) Status Return Level 1 0

17(0X11) Alarm LED 1 0

18(0X12) Alarm Shutdown 1 0

19(0X13) (Reserved) 1 0

24(0X18) Torque Enable 1 0

25(0X19) LED 1 0

26(0X1A) CW Compliance Margin 1 0

27(0X1B) CCW Compliance Margin 1 0

28(0X1C) CW Compliance Slope 1 1

29(0X1D) CCW Compliance Slope 1 1

30(0X1E) Goal Position 2 0

32(0X20) Moving Speed 2 0

34(0X22) Torque Limit 2 0

44(0X2C) Registered Instruction 1 0

47(0X2F) Lock 1 1

48(0X30) Punch 2 0

Writing Item

Length

(bytes)

Min Max

253(0xfd)

254(0xfe)

254(0xfe)

1023(0x3ff)

1023(0x3ff)

150(0x96)

250(0xfa)

250(0xfa)

1023(0x3ff)

2

127(0x7f)

127(0x7f)

1

1

1

254(0xfe)

254(0xfe)

254(0xfe)

254(0xfe)

1023(0x3ff)

1023(0x3ff)

1023(0x3ff)

1

1

1023(0x3ff)

[Control Table Data Range and Length for Writing]

18

Page 20

DYNAMIXEL

AX-12

4. Instruction Set and Examples

The following Instructions are available.

4-1. WRITE_DATA

Function To write data into the control table of the Dynamixel actuator

Length N+3 (N is the number of data to be written)

Instruction 0X03

Parameter1 Starting address of the location where the data is to be written

Parameter2 1st data to be written

Parameter3 2nd data to be written

Parameter N+1 Nth data to be written

Example 1

Instruction Function Value

PING No action. Used for obtaining a Status Packet 0x01 0

READ DATA Reading values in the Control Table 0x02 2

W RITE DATA Writing values to the Control Table 0x03 2 ~

REG WRITE

ACTION

RESET

SYNC WRITE

Similar to WR ITE_DATA, but stays in standby

mode until the ACION instruction is given

Triggers the action registered by the

REG_WR ITE instruction

Changes the control table values of the

Dynamixel actuator to the Factory Default Value

settin g s

Us e d fo r c o n tro llin g ma n y D y na mixe l a c tu a to r s

at the same time

Setting the ID of a connected Dynamixel actuator to 1

Write 1 to address 3 of the control table. The ID is transmitted using the Broadcasting ID

(0xFE).

Number of

Parameter

0x04 2 ~

0x05 0

0x06 0

0x83 4~

19

Page 21

DYNAMIXEL

Instruction Packet : 0XFF 0XFF 0XFE 0X04 0X03 0X03 0X01 0XF6`

ID LENGTH INSTRUCTION PARAMETERS CHECKSUM

AX-12

Because it was transmitted with a Broadcast ID (0XFE), no status packets are returned.

4-2. READ_DATA

Function Read data from the control table of a Dynamixel actuator

Length 0X04

Instruction 0X02

Parameter1 Starting address of the location where the data is to be read

Parameter2 Length of the data to be read

Example 2

ID LENGTH INSTRUCTION PARAMETERS . CHECKSUM

Status Packet : 0XFF 0XFF 0X01 0X03 0X00 0X20 0XDB

ID LENGTH ERROR PARAMETER1 CHECKSUM

Reading the internal temperature of the Dynamixel actuator with an ID of 1

Read 1 byte from address 0x2B of the control table.

Instruction Packet : 0XFF 0XFF 0X01 0X04 0X02 0X2B 0X01 0XCC`

The returned Status Packet will be as the following.

The data read is 0x20. Thus the current internal temperature of the Dyna mixel actuator

is approximately 32°C (0X20).

4-3. REG_WRITE과 ACTION

4-3-1. REG_WRITE

Function The REG_WRITE instruction is similar to the WRITE_DATA instruction, but the

20

Page 22

DYNAMIXEL

Length N+3 (N is the number of data to be written)

Instruction 0X04

Parameter1 Starting address of the location where the data is to be written

Parameter2 1st data to be written

Parameter3 2nd data to be written

Parameter N+1 Nth data to be written

AX-12

execution timing is different. When the Instruction Packet is received the values are

stored in the Buffer and the Write instruction is under a standby status. At this time, the

Registered Instruction register (Address 0x2C) is set to 1. After the Action Instruction

Packet is received, the registered Write instruction is finally executed.

4-3-2. ACTION

Function Triggers the action registered by the REG_WRITE instruction

Length 0X02

Instruction 0X05

Parameter NONE

The ACTION instruction is useful when multiple Dynamixel actuators need to move

simultaneously. When controlling multiple Dynamixel actuator units, slight time delays

can occur between the 1st and last units to receive an instruction. The Dynamixel

actuator handles this problem by using the ACTION instruction.

Broadcasting The Broadcast ID (0XFE) is used when sending ACTION instructions to more than two

Dynamixel actuators. Note that no packets are returned by this operation.

4-4. PING

Function Does not com mand any operations. Used for requestin g a status packet or to check the

existence of a Dynamixel actuator with a specific ID.

Length 0X02

Instruction 0X01

Parameter NONE

21

Page 23

DYNAMIXEL

Example 3

Instruction Packet : 0XFF 0XFF 0X01 0X02 0X01 0XFB`

ID LENGTH INSTRUCTION CHECKSUM

ID LENGTH ERROR CHECKSUM

Regardless of whether the Broadcasting ID is used or the Status Return Level (Address

AX-12

Obtaining the status packet of the Dynamixel actuator with an ID of 1

The returned Status Packet is as the following

Status Packet : 0XFF 0XFF 0X01 0X02 0X00 0XFC

16) is 0, a Status Packet is always returned by the PING instruction.

4-5. RESET

Function Changes the control table values of the Dynamixel actuator to the Factory Default Value

settings

Length 0X02

Instruction 0X06

Parameter NONE

Example 4

Instruction Packet : 0XFF 0XFF 0X00 0X02 0X06 0XF7`

ID LENGTH INSTRUCTION CHECKSUM

The returned Status Packet is as the following

Status Packet : 0XFF 0XFF 0X00 0X02 0X00 0XFD

ID LENGTH ERROR CHECKSUM

Resetting the Dynamixel actuator with an ID of 0

Note the ID of this Dynamixel actuator is now changed to 1 after the RESET instruction.

22

Page 24

DYNAMIXEL

AX-12

4-6. SYNC WRITE

Function Used for controlling many Dynamixel actuators at the same time. The communication

time decreases by the Synch Write instruction since many instructions can be

transmitted by a single instruction. However, you can use this instruction only when the

lengths and addresses of the control table to be written to are the same. Also, the

broadcasting ID needs to be used for transmitting.

ID 0XFE

Length (L + 1) * N + 4 (L: Data length for each Dynamixel actuator, N: The number of Dynamixel

actuators)

Instruction 0X83

Parameter1 Starting address of the location where the data is to be written

Parameter2 The length of the data to be written (L)

Parameter3 The ID of the 1st Dynamixel actuator

Parameter4 The 1st data for the 1st Dynamixel actuator

Parameter5 The 2nd data for the 1st Dynamixel actuator

…

Parameter L+3 The Lth data for the 1st Dynamixel actuator

Parameter L+4 The ID of the 2nd Dynamixel actuator

Parameter L+5 The 1st data for the 2nd Dynamixel actuator

Parameter L+6 The 2nd data for the 2nd Dynamixel actuator

…

Parameter 2L+4 The Lth data for the 2nd Dynamixel actuator

….

Example 5

Dynamixel actuator with an ID of 0: to position 0X010 with a speed of 0X150

Setting the following positions and velocities for 4 Dynamixel actuators

Dynamixel actuator with an ID of 1: to position 0X220 with a speed of 0X360

Dynamixel actuator with an ID of 2: to position 0X030 with a speed of 0X170

Dynamixel actuator with an ID of 0: to position 0X220 with a speed of 0X380

Instruction Packet : 0XFF 0XFF 0XFE 0X18 0X83 0X1E 0X04 0X00 0X10 0X00 0 X50

0X01 0X01 0X20 0X02 0X60 0X03 0X02 0X30 0X00 0X70 0X01 0X03 0X20 0X02 0X80

0X03 0X12

No status packets are returned since the Broadcasting ID was used.

Data for the 1st Dynamixel actuator

Data for the 2nd Dynamixel actuator

23

Page 25

DYNAMIXEL

AX-12

5. Example

For the following examples, we assume a Dynamixel actuator with an ID of 1 in Rese t

status and that the Baud rate is 57142 BPS.

Example 6

Instruction Packet Instruction = READ_DATA, Address = 0x00, Length = 0x03

Communication ->[Dynamixel]:F F FF 01 04 02 00 03 F5 (LEN:008)

<-[Dynamixel]:FF FF 01 05 00

Status Packet Result Model Number = 116 (0x74) (for the case of DX-116) Firmware Version = 0x08

Example 7

Instruction Packet Instruction = WRITE_DATA, Address = 0x03, DATA = 0x00

Communication ->[Dynamixel]:FF FF 01 04 03 03

<-[Dynamixel]:FF FF 01 02 00 FC (LEN:006)

Status Packet Result NO ERROR

Example 8

Instruction Packet Instruction = WRITE_DATA, Address = 0x04, DATA = 0x01

Communication ->[Dynamixel]:FF FF 00 04 03 04

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 9

Reading the Model Number and Firmware Version of the Dynamixel actuator with

an ID of 1

74 00 08 7D (LEN:009)

Changing the ID to 0 for a Dynamixel actuator with an ID of 1

00 F4 (LEN:008)

Changing the Baud Rate of a Dynamixel actuator to 1M bps

01 F3 (LEN:008)

Resetting the Return Delay Time to 4 uSec for a Dynamixel actuator with an ID of

0

A Return Delay Time Value of 1 corresponds to 2uSec.

24

Page 26

DYNAMIXEL

Instruction Packet Instruction = WRITE_DATA, Address = 0x05, DATA = 0x02

Communication ->[Dynamixel]:FF FF 00 04 03 05

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

It is recommended to set the Return Delay Time to the minimum value allowed by the

Example 10

Instruction Packet Instruction = WRITE_DATA, Address = 0x08, DATA = 0xff, 0x01

Communication ->[Dynamixel]:FF FF 00 05 03 08

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 11

Instruction Packet Instruction = WRITE_DATA, Address = 0x0B, DATA = 0x50

Communication ->[Dynamixel]:FF FF 00 04 03 0B

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 12

Instruction Packet Instruction = WRITE_DATA, Address = 0x0C, DATA = 0x64, 0xAA

Communication ->[Dynamixel]:FF FF 00 05 03 0C

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

AX-12

02 F1 (LEN:008)

Main Controller.

Limiting the operating angle range to 0°~150° for a Dynamixel actuator w ith an ID

of 0

Since the CCW Angle Limit of 0x3ff corresponds to 300°, the angle 150° is represented

by the value 0x1ff

FF 01 EF (LEN:009)

Resetting the upper limit for the operating temperature to 80°C for a Dynamixel

actuator with an ID of 0

50 9D (LEN:008)

Setting the operating voltage to 10V ~ 17V for a Dynamixel actuator with an ID of 0

10V is represented by 100 (0x64), and 17V by 170 (0xAA).

64 AA DD (LEN:009)

25

Page 27

DYNAMIXEL

Example 13 Setting the maximum torque to 50% of its maximum possible value for a

Instruction Packet Instruction = WRITE_DATA, Address = 0x0E, DATA = 0xff, 0x01

Communication ->[Dynamixel]:FF FF 00 05 03 0E FF 01 E9 (LEN:009)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

To verify the effect of the adjusted Max Torque value, the po wer needs to be turned off

Example 14

Instruction Packet Instruction = WRITE_DATA, Address = 0x10, DATA = 0x00

Communication ->[Dynamixel]:F F FF 00 04 03 10 00 E8 (LEN:008)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

The Status Packet is not returned starting with the following instruction.

Example 15

Instruction Packet Instruction = WRITE_DATA, Address = 0x11, DATA = 0x04, 0x04

Communication ->[Dynamixel]:FF FF 00 05 03 11

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 16

Instruction Packet Instruction = WRITE_DATA, Address = 0x18, DATA = 0x01, 0x01

AX-12

Dynamixel actuator with an ID of 0

Set the MAX Torque value located in the ROM area to 0x1ff which is 50% of the

maximum value 0x3ff.

and then on.

Set the Dynamixel actuator with an ID of 0 to never return a Status Packet

Set the Alarm to blink the LED and Shutdown (Torque off) the actuator when the

operating temperature goes over the set limit

Since the Overheating Error is Bit 2, set the Alarm value to 0x04.

04 04 DE (LEN:009)

Turn on the LED and Enable Torque for a Dynamixel actuator with an ID of 0

26

Page 28

DYNAMIXEL

AX-12

Communication ->[Dynamixel]:FF FF 00 05 03 18

01 01 DD (LEN:009)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

You can verify the Torque Enabled status by trying to move the output of the actuator by

hand.

Example 17

Setting the Compliance Margin to 1 and Compliance Slope to 0x40 for a

Dynamixel actuator with an ID of 0

Compliance The Angle Error and Torque Output can be represented with the following graph.

Goal Position CW

CCW

CW

X:Angle Error

CCW

Even if the position deviates a little from the goal position in the CW direction, a large

amount of torque is generated in the CCW direction to compensate for this. However,

since inertia must be considered, a realistic implementation differs from this approach.

Considering this, the given conditions can be represented by the following graph.

CW Goal Position

CCW

Output Torque

CCW

CW

Angle(Position)

A

B

D C

A : CCW Compliance Slope (Address0x1D) = 0x40 (about 18.8°)

B : CCW Compliance Margin (Address0x1B) = 0x01 (about 0.29°)

C : CW Compliance Margin (Address0x01A) = 0x01 (about 0.29°)

D : CW Compliance Slop e (Address0x1C) = 0x40 (about 18.8°)

27

Page 29

DYNAMIXEL

Instruction Packet Instruction = WRITE_DATA, Address = 0x1A, DATA = 0x01, 0x01, 0x40, 0x40

Communication ->[Dynamixel]:FF FF 00 07 03 1A 01 01 40 40 59 (LEN:011)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

The Compliance Slope takes effect with discrete steps of 2

Example 18

Instruction Packet Instruction = WRITE_DATA, Address = 0x1E, DATA = 0x00, 0x02, 0x00, 0x02

Communication ->[Dynamixel]:F F FF 00 07 03 1E 00 02 00 02 D3 (LEN:011)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 19

Instruction Packet ID=0, Instruction = REG_WRITE, Address = 0x1E, DATA = 0x00, 0x00

ID=1, Instruction = REG_WRITE, Address = 0x1E, DATA = 0xff, 0x03

ID=0xfe(Broadcasting ID), Instruction = ACTION,

Communication ->[Dynamixel]:F F FF 00 05 04 1E 00 00 D8 (LEN:009)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

->[Dynamixel]:FF FF 01 05 04 1E FF 03 D5 (LEN:009)

<-[Dynamixel]:FF FF 01 02 00 FC (LEN:006)

->[Dynamixel]:FF FF FE 02 05 FA (LEN:006)

<-[Dynamixel]: //No return packet against broadcasting ID

Status Packet Result NO ERROR

AX-12

n

(n is integer). Thus any

Compliance value between 0x11 and 0x20 has identical effects.

Position the output of a Dynamixel actuator with an ID of 0 to 180° with an angular

velocity of 057RPM

Set Address 0x1E (Goal Position) to 0x200 and Address 0x20 (Moving Speed) to 0x200.

Position the output of a Dynamixel actuator with an ID of 0 to 0° and Position the

output of a Dynamixel actuator with an ID of 1 to 300°, and initiate the movement

at the same time.

If the WRITE_DATA is used, the movement of the two actuators cannot be initiate at the

same time, thus the REG_WRITE and ACTION instructions should be used instead.

28

Page 30

DYNAMIXEL

Example 20

Instruction Packet Instruction = WRITE_DATA, Address = 0x2F, DATA = 0x01

Communication ->[Dynamixel]:FF FF 00 04 03 2F

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Once locked, the only way to unlock it is to remove the power.

<-[Dynamixel]:FF FF 00 02 08 F5 (LEN:006)

Example 21

Instruction Packet Instruction = WRITE_DATA, Address = 0x30, DATA = 0x40, 0x00

Communication ->[Dynamixel]:FF FF 00 05 03 30

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

AX-12

Lock all addresses except for Address 0x18 ~ Address0x23 for a Dynamixel

actuator with an ID of 0

Set Address 0x2F (Lock) to 1.

01 C8 (LEN:008)

If an attempt is made to access any locked data, an error is returned.

->[Dynamixel]:FF FF 00 05 03 30 40 00 87 (LEN:009)

Range Error

Set the minimum power (Punch) to 0x40 for a Dynamixel actuator with an ID of 0

40 00 87 (LEN:009)

29

Page 31

DYNAMIXEL

AX-12

Appendix

Half duplex UART Half duplex UART is a serial communication protocol where both TxD and RxD cannot

be used at the same time. This method is generally used when many devices need to

be connected to a single bus. Since more than one device are connected to the same

bus, all the other devices need to be in input mode while one device is transmitting. The

Main Controller that controllers the Dynamixel actuators sets the communication

direction to input mode, and only when it is transmitting an Instruction Packet, it

changes the direction to output mode.

Return Delay Time The time it takes for the Dynamixel actuator to return the Status Packet after receiving

an Instruction Packet. The Default Value is 160 uSec and can be changed via the

Control Table at Address 5. The Main Controller needs to change the Direction Port t o

input mode during the Return Delay Time after sending an instruction packet.

Tx,Rx Direction For Half Duplex UART, the transmission ending timing is important to change the

direction to receiving mode. The bit definitions within the register that indicates

UART_STATUS are as the following

TXD_BUFFER_READY_BIT: Indicates that the transmission DATA can be loaded into

the Buffer. Note that this only means that the SERIAL TX BUFFER is empty, and does

not necessarily mean that the all the data transmitted before has left the CPU.

TXD_SHIFT_REGISTER_EMPTY_BIT: Set when all the Transmission Data has

completed its transmission and left the CPU.

The TXD_BUFFER_READY_BIT is used when one byte is to be transmitted via the

serial communication channel, and an example is shown belo w.

TxDByte(byte bData)

{

while(!TXD_BUFFER_READY_BIT); //wait until data can be loaded.

SerialTxDBuffer = bData; //data load to TxD buffer

}

RS485 Direction Output Duration

Instruction Packet Status Packet

Return Delay Time

30

Page 32

DYNAMIXEL

The following is an example program that sends an Instruction Packet.

LINE 1 DIRECTION_PORT = TX_DIRECTION;

LINE 2 TxDByte(0xff);

LINE 3 TxDByte(0xff);

LINE 4 TxDByte(bID);

LINE 5 TxDByte(bLength);

LINE 6 TxDByte(bInstruction);

LINE 7 TxDByte(Parameter0); TxDByte(Parameter1); …

LINE 8 DisableInterrupt(); // interrupt should be disa ble

LINE 9 TxDByte(Checksum); //last TxD

LINE 10 while(!TXD_SHIFT_REGISTER_EMPTY_BIT); //Wait till last data bit has been sent

LINE 11 DIRECTION_PORT = RX_DIRECTION; //Direction change to RXD

LINE 12 EnableInterrupt(); // enable interrupt again

Please note the important lines between LINE 8 and LINE 12. Line 8 is necessary since

Byte to Byte Time The delay time between bytes when sending an instruction packet. If the delay time is

AX-12

When changing the direction, the TXD_SHIFT_REGISTER_EMPTY_BIT must be

checked.

an interrupt here may cause a delay longer than the return delay time and corruption to

the front of the status packet may occur.

over 100ms, then the Dynamixel actuator recognizes this as a communic ation problem

and waits for the next header (0xff 0xff) of a packet again.

Byte To Byte Time

The following is the source code of a program (Example.c) that accesses the Dynamixel

actuator using the Atmega 128.

31

Page 33

DYNAMIXEL

C Language Example : Dinamixel access with Atmega128

/*

* The Example of Dynamixel Evaluation with Atmega128

* Date : 2005.5.11

* Author : BS KIM

*/

/*

* included files

*/

#define ENABLE_BIT_DEFINITIONS

//#include <io.h>

#include <inttypes.h>

#include <avr/io.h>

#include <avr/interrupt.h>

#include <avr/signal.h>

#define cbi(REG8,BITNUM) REG8 &= ~(_BV(BITNUM))

#define sbi(REG8,BITNUM) REG8 |= _BV(BITNUM)

typedef unsigned char byte;

typedef unsigned int word;

#define ON 1

#define OFF 0

#define _ON 0

#define _OFF 1

//--- Control Table Address --//EEPROM AREA

#define P_MODEL_NUMBER_L 0

#define P_MODOEL_NUMBER_H 1

#define P_VERSION 2

#define P_ID 3

#define P_BAUD_RATE 4

#define P_RETURN_DELAY_TIME 5

#define P_CW_ANGLE_LIMIT_L 6

#define P_CW_ANGLE_LIMIT_H 7

#define P_CCW_ANGLE_LIMIT_L 8

#define P_CCW_ANGLE_LIMIT_H 9

#define P_SYSTEM_DATA2 10

#define P_LIMIT_TEMPERATURE 11

#define P_DOWN_LIMIT_VOLTAGE 12

#define P_UP_LIMIT_VOLTAGE 13

#define P_MAX_TORQUE_L 14

#define P_MAX_TORQUE_H 15

#define P_RETURN_LEVEL 16

#define P_ALARM_LED 17

#define P_ALARM_SHUTDOWN 18

#define P_OPERATING_MODE 19

#define P_DOWN_CALIBRATION_L 20

#define P_DOWN_CALIBRATION_H 21

#define P_UP_CALIBRATION_L 22

#define P_UP_CALIBRATION_H 23

#define P_TORQUE_ENABLE (24)

#define P_LED (25)

#define P_CW_COMPLIANCE_MARGIN (26)

#define P_CCW_COMPLIANCE_MARGIN (27)

#define P_CW_COMPLIANCE_SLOPE (28)

#define P_CCW_COMPLIANCE_SLOPE (29)

#define P_GOAL_POSITION_L (30)

#define P_GOAL_POSITION_H (31)

#define P_GOAL_SPEED_L (32)

#define P_GOAL_SPEED_H (33)

#define P_TORQUE_LIMIT_L (34)

#define P_TORQUE_LIMIT_H (35)

#define P_PRESENT_POSITION_L (36)

#define P_PRESENT_POSITION_H (37)

#define P_PRESENT_SPEED_L (38)

#define P_PRESENT_SPEED_H (39)

#define P_PRESENT_LOAD_L (40)

#define P_PRESENT_LOAD_H (41)

#define P_PRESENT_VOLTAGE (42)

#define P_PRESENT_TEMPERATURE (43)

AX-12

#define P_REGISTERED_INSTRUCTION (44)

#define P_PAUSE_TIME (45)

#define P_MOVING (46)

#define P_LOCK (47)

#define P_PUNCH_L (48)

#define P_PUNCH_H (49)

//--- Instruction --#define INST_PING 0x01

#define INST_READ 0x02

#define INST_WRITE 0x03

#define INST_REG_WRITE 0x04

#define INST_ACTION 0x05

#define INST_RESET 0x06

#define INST_DIGITAL_RESET 0x07

#define INST_SYSTEM_READ 0x0C

#define INST_SYSTEM_WRITE 0x0D

#define INST_SYNC_WRITE 0x83

#define INST_SYNC_REG_WRITE 0x84

#define CLEAR_BUFFER gbRxBufferReadPointer = gbRxBufferWritePointer

#define DEFAULT_RETURN_PACKET_SIZE 6

#define BROADCASTING_ID 0xfe

#define TxD8 TxD81

#define RxD8 RxD81

//Hardware Dependent Item

#define DEFAULT_BAUD_RATE 34 //57600bps at 16MHz

////// For CM-5

#define RS485_TXD PORTE &= ~_BV(PE3),PORTE |= _BV(PE2)

#define RS485_RXD PORTE &= ~_BV(PE2),PORTE |= _BV(PE3)

/*

////// For CM-2

#define RS485_TXD PORTE |= _BV(PE2); //_485_DIRECTION = 1

#define RS485_RXD PORTE &= ~_BV(PE2);//PORT_485_DIRECTION = 0

*/

//#define TXD0_FINISH UCSR0A,6 //This bit is for checking TxD Buffer

//#define TXD1_FINISH UCSR1A,6

#define SET_TxD0_FINISH sbi(UCSR0A,6)

#define RESET_TXD0_FINISH cbi(UCSR0A,6)

#define CHECK_TXD0_FINISH bit_is_set(UCSR0A,6)

#define SET_TxD1_FINISH sbi(UCSR1A,6)

#define RESET_TXD1_FINISH cbi(UCSR1A,6)

#define CHECK_TXD1_FINISH bit_is_set(UCSR1A,6)

#define RX_INTERRUPT 0x01

#define TX_INTERRUPT 0x02

#define OVERFLOW_INTERRUPT 0x01

#define SERIAL_PORT0 0

#define SERIAL_PORT1 1

#define BIT_RS485_DIRECTION0 0x08 //Port E

#define BIT_RS485_DIRECTION1 0x04 //Port E

#define BIT_ZIGBEE_RESET PD4 //out : default 1 //PORTD

#define BIT_ENABLE_RXD_LINK_PC PD5 //out : default 1

#define BIT_ENABLE_RXD_LINK_ZIGBEE PD6 //out : default 0

#define BIT_LINK_PLUGIN PD7 //in, no pull up

void TxD81(byte bTxdData);

void TxD80(byte bTxdData);

void TxDString(byte *bData);

void TxD8Hex(byte bSentData);

void TxD32Dec(long lLong);

byte RxD81(void);

void MiliSec(word wDelayTime);

void PortInitialize(void);

void SerialInitialize(byte bPort, byte bBaudrate, byte bInterru

byte TxPacket(byte bID, byte bInstruction, byte bParameterLength);

byte RxPacket(byte bRxLength);

void PrintBuffer(byte *bpPrintBuffer, byte bLength);

//PORT_485_DIRECTION = 1

//PORT_485_DIRECTION = 0

in CPU is empty or not.

pt);

32

Page 34

DYNAMIXEL

// --- Gloval Variable Number --volatile byte gbpRxInterruptBuffer[256];

byte gbpParameter[128];

byte gbRxBufferReadPointer;

byte gbpRxBuffer[128];

byte gbpTxBuffer[128];

volatile byte gbRxBufferWritePointer;

int main(void)

{

byte bCount,bID, bTxPacketLength,bRxPacketLength;

PortInitialize(); //Port In/Out Direction Definition

RS485_RXD; //Set RS485 Direction to Input State.

SerialInitialize(SERIAL_PORT0,1,RX_INTERRUPT);//RS485

SerialInitialize(SERIAL_PORT1,DEFAULT_BAUD_RATE,0); //RS232

gbRxBufferReadPointer = gbRxBufferWritePointer = 0; //RS485

sei(); //Enable Interrupt -- Compiler Function

TxDString("\r\n [The Example of Dynamixel Evaluation with

//Dynamixel Communication Function Execution Step.

// Step 1. Parameter Setting (gbpParameter[]). In case of no parameter

// Step 2. TxPacket(ID,INSTRUCTION,LengthOfParameter); --Total

// Step 3. RxPacket(ExpectedReturnPacketLength); -- Real RxPacket

// Step 4 PrintBuffer(BufferStartPointer,LengthForPrinting);

bID = 1;

TxDString("\r\n\n Example 1. Scanning Dynamixels(0~9). -- Any Key to

for(bCount = 0; bCount < 0x0A; bCount++)

{

bTxPacketLength = TxPacket(bCount,INST_PING,0);

bRxPacketLength = RxPacket(255);

TxDString("\r\n TxD:"); PrintBuffer(gbpTxBuffer,bTxPacketLength);

TxDString(", RxD:"); PrintBuffer(gbpRxBuffer,bRxPacketLength);

if(bRxPacketLength == DEFAULT_RETURN_PACKET_SIZE)

{

TxDString(" Found!! ID:");TxD8Hex(bCount);

bID = bCount;

}

}

TxDString("\r\n\n Example 2. Read Firmware Version. -- Any Key to

gbpParameter[0] = P_VERSION; //Address of Firmware Version

gbpParameter[1] = 1; //Read Length

bTxPacketLength = TxPacket(bID,INST_READ,2);

bRxPacketLength =

TxDString("\r\n TxD:"); PrintBuffer(gbpTxBuffer,bTxPacketLength);

TxDString("\r\n RxD:"); PrintBuffer(gbpRxBuffer,bRxPacketLength);

if(bRxPacketLength == DEFAULT_RETURN_PACKET_SIZE+gbpParameter[1])

{

TxDString("\r\n Return Error : ");TxD8Hex(gbpRxBuffer[4]);

TxDString("\r\n Firmware Version : ");TxD8Hex(gbpRxBuffer[5]);

}

TxDString("\r\n\n Example 3. LED ON -- Any Key to Continue.");

gbpParameter[0] = P_LED; //Address of LED

gbpParameter[1] = 1; //Writing Data

bTxPacketLength = TxPacket(bID,INST_WRITE,2);

bRxPacketLength = RxPacket(DEFAULT_RETURN_PACKET_SIZE);

TxDString("\r\n TxD:"); PrintBuffer(gbpTxBuffer,bTxPacketLength);

TxDString("\r\n RxD:"); PrintBuffer(gbpRxBuffer,bRxPacketLength);

Initializing(RxInterrupt)

Initializing(None Interrupt)

RxBuffer Clearing.

ATmega128,GCC-AVR]");

instruction(Ex. INST_PING), this step is not

needed.

TxPacket Length is returned

Length is returned

Continue."); RxD8();

Continue."); RxD8();

RxPacket(DEFAULT_RETURN_PACKET_SIZE+gbpParameter

[1]);

RxD8();

AX-12

TxDString("\r\n\n Example 4. LED OFF -- Any Key to Continue.");

gbpParameter[0] = P_LED; //Address of LED

gbpParameter[1] = 0; //Writing Data

bTxPacketLength = TxPacket(bID,INST_WRITE,2);

bRxPacketLength = RxPacket(DEFAULT_RETURN_PACKET_SIZE);

TxDString("\r\n TxD:"); PrintBuffer(gbpTxBuffer,bTxPacketLength);

TxDString("\r\n RxD:"); PrintBuffer(gbpRxBuffer,bRxPacketLength);

TxDString("\r\n\n Example 5. Read Control Table. -- Any Key to

gbpParameter[0] = 0; //Reading Address

gbpParameter[1] = 49; //Read Length

bTxPacketLength = TxPacket(bID,INST_READ,2);

bRxPacketLength =

TxDString("\r\n TxD:"); PrintBuffer(gbpTxBuffer,bTxPacketLength);

TxDString("\r\n RxD:"); PrintBuffer(gbpRxBuffer,bRxPacketLength);

if(bRxPacketLength == DEFAULT_RETURN_PACKET_SIZE+gbpParameter

{

TxDString("\r\n");

for(bCount = 0; bCount < 49; bCount++)

{

TxD8('[');TxD8Hex(bCount);TxDString("]:");

}

}

TxDString("\r\n\n Example 6. Go 0x200 with Speed 0x100 -- Any Key to

gbpParameter[0] = P_GOAL_POSITION_L; //Address of Firmware Version

gbpParameter[1] = 0x00; //Writing Data P_GOAL_POSITION_L

gbpParameter[2] = 0x02; //Writing Data P_GOAL_POSITION_H

gbpParameter[3] = 0x00; //Writing Data P_GOAL_SPEED_L

gbpParameter[4] = 0x01; //Writing Data P_GOAL_SPEED_H

bTxPacketLength = TxPacket(bID,INST_WRITE,5);

bRxPacketLength = RxPacket(DEFAULT_RETURN_PACKET_SIZE);

TxDString("\r\n TxD:"); PrintBuffer(gbpTxBuffer,bTxPacketLength);

TxDString("\r\n RxD:"); PrintBuffer(gbpRxBuffer,bRxPacketLength);

TxDString("\r\n\n Example 7. Go 0x00 with Speed 0x40 -- Any Key to

gbpParameter[0] = P_GOAL_POSITION_L; //Address of Firmware Version

gbpParameter[1] = 0x00; //Writing Data P_GOAL_POSITION_L

gbpParameter[2] = 0x00; //Writing Data P_GOAL_POSITION_H

gbpParameter[3] = 0x40; //Writing Data P_GOAL_SPEED_L

gbpParameter[4] = 0x00; //Writing Data P_GOAL_SPEED_H

bTxPacketLength = TxPacket(bID,INST_WRITE,5);

bRxPacketLength = RxPacket(DEFAULT_RETURN_PACKET_SIZE);

TxDString("\r\n TxD:"); PrintBuffer(gbpTxBuffer,bTxPacketLength);

TxDString("\r\n RxD:"); PrintBuffer(gbpRxBuffer,bRxPacketLength);

TxDString("\r\n\n Example 8. Go 0x3ff with Speed 0x3ff -- Any Key to

gbpParameter[0] = P_GOAL_POSITION_L; //Address of Firmware Version

gbpParameter[1] = 0xff; //Writing Data P_GOAL_POSITION_L

gbpParameter[2] = 0x03; //Writing Data P_GOAL_POSITION_H

gbpParameter[3] = 0xff; //Writing Data P_GOAL_SPEED_L

gbpParameter[4] = 0x03; //Writing Data P_GOAL_SPEED_H

bTxPacketLength = TxPacket(bID,INST_WRITE,5);

bRxPacketLength = RxPacket(DEFAULT_RETURN_PACKET_SIZE);

TxDString("\r\n TxD:"); PrintBuffer(gbpTxBuffer,bTxPacketLength);

TxDString("\r\n RxD:"); PrintBuffer(gbpRxBuffer,bRxPacketLength);

TxDString("\r\n\n Example 9. Torque Off -- Any Key to Continue.");

gbpParameter[0] = P_TORQUE_ENABLE; //Address of LED

gbpParameter[1] = 0; //Writing Data

bTxPacketLength = TxPacket(bID,INST_WRITE,2);

bRxPacketLength = RxPacket(DEFAULT_RETURN_PACKET_SIZE);

TxDString("\r\n TxD:"); PrintBuffer(gbpTxBuffer,bTxPacketLength);

TxDString("\r\n RxD:"); PrintBuffer(gbpRxBuffer,bRxPacketLength);

TxDString("\r\n\n End. Push reset button for repeat");

RxD8();

Continue."); RxD8();

RxPacket(DEFAULT_RETURN_PACKET_SIZE+gbpParameter

[1]);

[1])

TxD8Hex(gbpRxBuffer[bCount+5]);TxD8(' ');

Continue."); RxD8();

Continue."); RxD8();

Continue."); RxD8();

RxD8();

33

Page 35

DYNAMIXEL

while(1);

}

void PortInitialize(void)

{

DDRA = DDRB = DDRC = DDRD = DDRE = DDRF = 0; //Set all port to

PORTB = PORTC = PORTD = PORTE = PORTF = PORTG = 0x00; //PortData

cbi(SFIOR,2); //All Port Pull Up ready

DDRE |= (BIT_RS485_DIRECTION0|BIT_RS485_DIRECTION1); //set output

DDRD |=

PORTD &= ~_BV(BIT_LINK_PLUGIN); // no pull up

PORTD |= _BV(BIT_ZIGBEE_RESET);

PORTD |= _BV(BIT_ENABLE_RXD_LINK_PC);

PORTD |= _BV(BIT_ENABLE_RXD_LINK_ZIGBEE);

}

/*

TxPacket() send data to RS485.

TxPacket() needs 3 parameter; ID of Dynamixel, Instruction byte,

TxPacket() return length of Return packet from Dynamixel.

*/

byte TxPacket(byte bID, byte bInstruction, byte bParameterLength)

{

byte bCount,bCheckSum,bPacketLength;

gbpTxBuffer[0] = 0xff;

gbpTxBuffer[1] = 0xff;

gbpTxBuffer[2] = bID;

gbpTxBuffer[3] = bParameterLength+2;

gbpTxBuffer[4] = bInstruction;

for(bCount = 0; bCount < bParameterLength; bCount++)

{

gbpTxBuffer[bCount+5] = gbpParameter[bCount];

}

bCheckSum = 0;

bPacketLength = bParameterLength+4+2;

for(bCount = 2; bCount < bPacketLength-1; bCount++) //except

{

bCheckSum += gbpTxBuffer[bCount];

}

gbpTxBuffer[bCount] = ~bCheckSum; //Writing Checksum with Bit

RS485_TXD;

for(bCount = 0; bCount < bPacketLength; bCount++)

{

sbi(UCSR0A,6);//SET_TXD0_FINISH;

TxD80(gbpTxBuffer[bCount]);

}

while(!CHECK_TXD0_FINISH); //Wait until TXD Shift register empty

RS485_RXD;

return(bPacketLength);

}

/*

RxPacket() read data from buffer.

RxPacket() need a Parameter; Total length of Return Packet.

RxPacket() return Length of Return Packet.

*/

byte RxPacket(byte bRxPacketLength)

{

#define RX_TIMEOUT_COUNT2 3000L

#define RX_TIMEOUT_COUNT1 (RX_TIMEOUT_COUNT2*10L)

unsigned long ulCounter;

byte bCount, bLength, bChecksum;

byte bTimeout;

input direction first.

initialize to 0

the bit RS485direction

(BIT_ZIGBEE_RESET|BIT_ENABLE_RXD_LINK_PC|BIT_ENA

BLE_RXD_LINK_ZIGBEE);

Length of parameters.

//Length(Paramter,Instruction,Checksum)

0xff,checksum

Inversion

AX-12

bTimeout = 0;

for(bCount = 0; bCount < bRxPacketLength; bCount++)

{

ulCounter = 0;

while(gbRxBufferReadPointer == gbRxBufferWritePointer)

{

if(ulCounter++ > RX_TIMEOUT_COUNT1)

{

bTimeout = 1;

break;

}

}

if(bTimeout) break;

gbpRxBuffer[bCount] =

}

bLength = bCount;

bChecksum = 0;

if(gbpTxBuffer[2] != BROADCASTING_ID)

{

if(bTimeout && bRxPacketLength != 255)

{

TxDString("\r\n [Error:RxD Timeout]");

CLEAR_BUFFER;

}

if(bLength > 3) //checking is available.

{

if(gbpRxBuffer[0] != 0xff || gbpRxBuffer[1] != 0xff )

{

TxDString("\r\n [Error:Wrong Header]");

CLEAR_BUFFER;

return 0;

}

if(gbpRxBuffer[2] != gbpTxBuffer[2] )

{

TxDString("\r\n [Error:TxID != RxID]");

CLEAR_BUFFER;

return 0;

}

if(gbpRxBuffer[3] != bLength-4)

{

TxDString("\r\n [Error:Wrong Length]");

CLEAR_BUFFER;

return 0;

}

for(bCount = 2; bCount < bLength; bCount++) bChecksum +=

if(bChecksum != 0xff)

{

TxDString("\r\n [Error:Wrong CheckSum]");

CLEAR_BUFFER;

return 0;

}

}

}

return bLength;

}

/*

PrintBuffer() print data in Hex code.

PrintBuffer() needs two parameter; name of Pointer(gbpTxBuffer,

*/

void PrintBuffer(byte *bpPrintBuffer, byte bLength)

{

byte bCount;

for(bCount = 0; bCount < bLength; bCount++)

{

TxD8Hex(bpPrintBuffer[bCount]);

TxD8(' ');

}

TxDString("(LEN:");TxD8Hex(bLength);TxD8(')');

}

gbpRxInterruptBuffer[gbRxBufferReadPointer++];

gbpRxBuffer[bCount];

gbpRxBuffer)

34

Page 36

DYNAMIXEL

}

/*

Print value of Baud Rate. /*

*/ TXD81() send data to USART 1.

void PrintBaudrate(void) */

{ void TxD81(byte bTxdData)

TxDString("\r\n

TxDString(" RS485:");TxD32Dec((16000000L/8L)/((long)UBRR0L+1L) );

} /*

TXD32Dex() change data to decimal number system

*/

/*Hardware Dependent Item*/ void TxD32Dec(long lLong)

#define TXD1_READY bit_is_set(UCSR1A,5)

#define TXD1_DATA (UDR1) long lTmp,lDigit;

#define RXD1_READY bit_is_set(UCSR1A,7) bPrinted = 0;

#define RXD1_DATA (UDR1) if(lLong < 0)

{

#define TXD0_READY bit_is_set(UCSR0A,5) lLong = -lLong;

#define TXD0_DATA (UDR0) TxD8('-');

#define RXD0_READY bit_is_set(UCSR0A,7) }

#define RXD0_DATA (UDR0) lDigit = 1000000000L;

for(bCount = 0; bCount < 9; bCount++)

/* {

SerialInitialize() set Serial Port to initial state. lTmp = (byte)(lLong/lDigit);

Vide Mega128 Data sheet about Setting bit of register. if(lTmp)

SerialInitialize() needs port, Baud rate, Interrupt value. {

TxD8(((byte)lTmp)+'0');

*/ bPrinted = 1;

void SerialInitialize(byte bPort, byte bBaudrate, byte bInterrupt) }

{ else if(bPrinted) TxD8(((byte)lTmp)+'0');

if(bPort == SERIAL_PORT0) lLong -= ((long)lTmp)*lDigit;

{ lDigit = lDigit/10;

UBRR0H = 0; UBRR0L = bBaudrate; }

UCSR0A = 0x02; UCSR0B = 0x18; lTmp = (byte)(lLong/lDigit);

if(bInterrupt&RX_INTERRUPT) sbi(UCSR0B,7); // RxD interrupt enable /*if(lTmp)*/ TxD8(((byte)lTmp)+'0');

UCSR0C = 0x06; UDR0 = 0xFF; }

sbi(UCSR0A,6);//SET_TXD0_FINISH; // Note. set 1, then 0 is read

} /*

else if(bPort == SERIAL_PORT1) TxDString() prints data in ACSII code.

{ */

UBRR1H = 0; UBRR1L = bBaudrate; void TxDString(byte *bData)

UCSR1A = 0x02; UCSR1B = 0x18; {

if(bInterrupt&RX_INTERRUPT) sbi(UCSR1B,7); // RxD interrupt enable while(*bData)

UCSR1C = 0x06; UDR1 = 0xFF; {

sbi(UCSR1A,6);//SET_TXD1_FINISH; // Note. set 1, then 0 is read TxD8(*bData++);

} }

} }

/* /*

TxD8Hex() print data seperatly. RxD81() read data from UART1.

ex> 0x1a -> '1' 'a'. RxD81() return Read data.

*/ */

void TxD8Hex(byte bSentData) byte RxD81(void)

{ {

byte bTmp; while(!RXD1_READY);

return(RXD1_DATA);

bTmp =((byte)(bSentData>>4)&0x0f) + (byte)'0'; }

if(bTmp > '9') bTmp += 7;

TxD8(bTmp); /*

bTmp =(byte)(bSentData & 0x0f) + (byte)'0'; SIGNAL() UART0 Rx Interrupt - write data to buffer

if(bTmp > '9') bTmp += 7; */

TxD8(bTmp); SIGNAL (SIG_UART0_RECV)

} {

gbpRxInterruptBuffer[(gbRxBufferWritePointer++)] = RXD0_DATA;

/*

TxD80() send data to USART 0.

*/

void TxD80(byte bTxdData)

{

while(!TXD0_READY);

TXD0_DATA = bTxdData;

RS232:");TxD32Dec((16000000L/8L)/((long)UBRR1L+1

L) ); TxDString(" BPS,");

TxDString(" BPS");

//(UCSR1A_Bit5)

AX-12

{

while(!TXD1_READY);

TXD1_DATA = bTxdData;

}

{

byte bCount, bPrinted;

}

35

Page 37

DYNAMIXEL

Connector Company Name : Molex

Pin Number: 4

Model Number

Temperature range : -40°C to +105°C

Contact Insertion Force-max : 14.7N (3.30 lb)

Contact Retention Force-min : 14.7N (3.30 lb)

Female Connector

Male Connector

AX-12

Molex Part Number Old Part Number

Male 22-03-5045 5267-03

Female 50-37-5043 5264-03

www.molex.com or www.molex.co.jp for more detail information

Pin No.1

36

Page 38

DYNAMIXEL

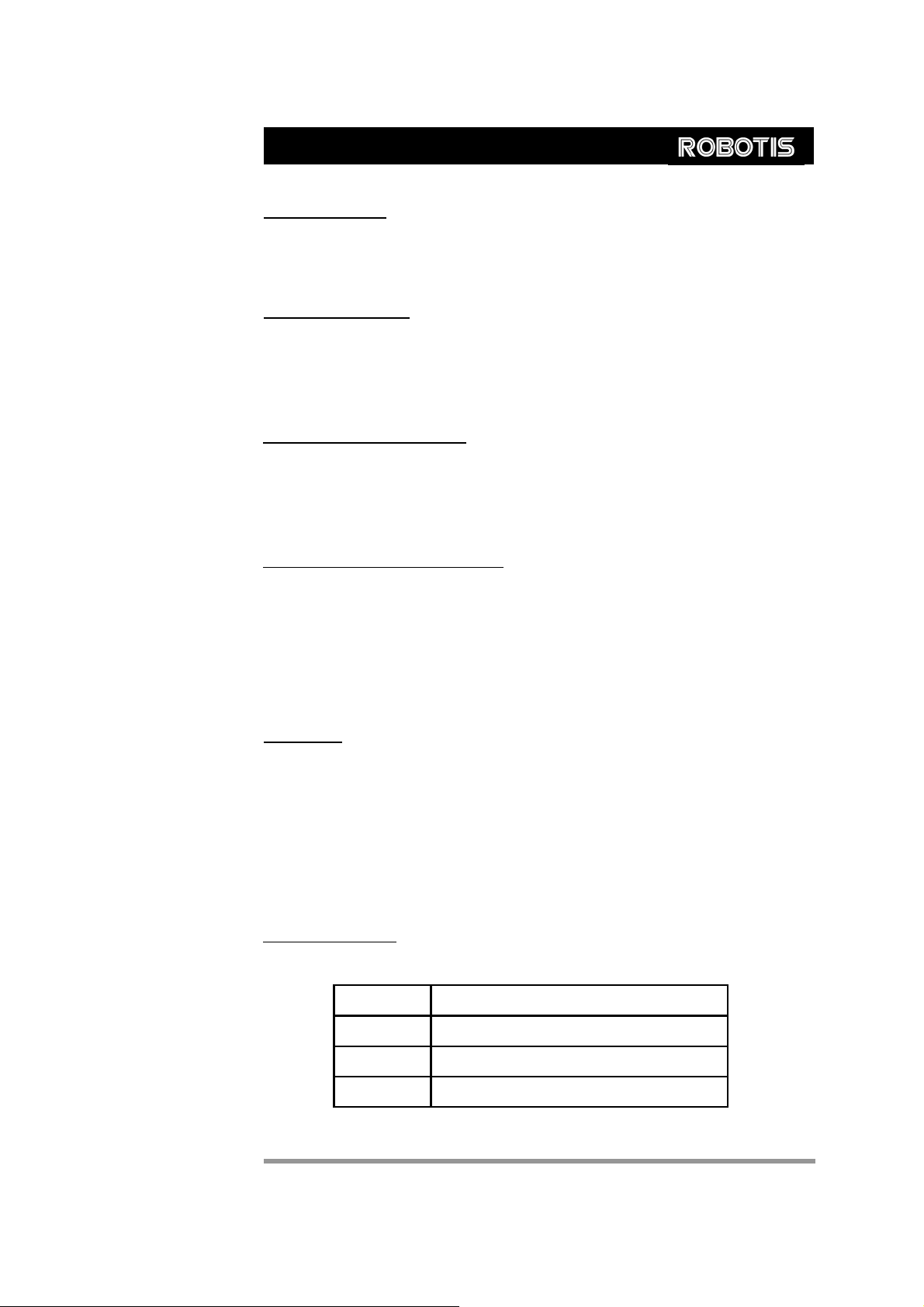

Dimension

CM-5 Dedicated AX-12 control box. Able to control 30 AX-12 actuators.

AX-12

6 push buttons (5 for selection, 1 for reset)

Optional installable wireless devices available

Battery compartment (AA x 8) with recharging capability (when connected to an external

SMPS)

CM-5

37

Loading...

Loading...