Page 1

Product

Instructions

25734

C O M M U N I C A T I O N S

Before attempting to connect or operate this product,

please read these instructions completely.

81-IN6215

06/01/07

Page 2

!

!

1. Read Instructions - All the safety and operating instructions

should be read before the unit is operated.

2. Retain Instructions - The safety and operating instructions

should be retained for future reference.

3. Heed Warnings - All warnings on the unit and in the operating

instructions should be adhered to.

4. Follow Instructions - All operating and user instructions should

be followed.

5. Electrical Connections - Only a qualied electrician should make

electrical connections.

6. Attachments - Do not use attachments not recommended by

the product manufacturer as they may cause hazards.

7. Cable Runs - All cable runs must be within permissible

distance.

8. Mounting - This unit must be properly and securely mounted to

a supporting structure capable of sustaining the weight of the

unit. Accordingly:

a. The installation should be made by a qualied installer.

b. The installation should be in compliance with local codes.

c. Care should be exercised to select suitable hardware to

install the unit, taking into account both the composition of

the mounting surface and the weight of the unit. Be sure to

periodically examine the unit and the supporting structure to

make sure that the integrity of the installation is intact. Failure

to comply with the foregoing could result in the unit separating

from the support structure and falling, with resultant damages

or injury to anyone or anything struck by the falling unit.

WARRANTY INFORMATION

Videolarm, Incorporated warrants that products sold hereunder

shall be t for the ordinary purpose for which said products

are intended and shall be free from defects in material and

workmanship for a period of two years from date of sale to

buyer. Videolarm makes no other warranty of any kind with

respect to this product, whether expressed or implied, including,

without limitation, the implied warranty of tness for a particular

purpose.

In the event of a breach of the above warranty, Videolarm shall,

at its option, repair or replace said product. This is Videolarm's

sole obligation under this warranty. In no event shall Videolarm

be liable for any incidental or consequential damages, as dened

in section 2-715 of the Uniform Commercial Code by a breach

of this warranty.

Videolarm shall repair or replace defective products upon shipment

of products prepaid to Videolarm, Inc., 2525 Park Central Blvd.,

Decatur, GA 30035.

SAFETY PRECAUTIONSIMPORTANT SAFEGUARDS

CAUTION

RISK OF

ELECTRIC SHOCK!

CAUTION: TO REDUCE THE RISK OF

ELECTRICAL SHOCK, DO NOT EXPOSE

COMPONENTS TO WATER OR MOISTURE.

The lightning ash with an arrowhead symbol,

within an equilateral triangle, is intended to alert the

user to the presence of non-insulated "dangerous

voltage" within the product's enclosure that may

be of sufcient magnitude to constitute a risk of

electric shock to persons.

The exclamation point within an equilateral

triangle is intended to alert the user to presence of

important operating and maintenance (servicing)

instructions in the literature accompanying the

appliance.

UNPACKING

Unpack carefully. Electronic components can be damaged if

improperly handled or dropped. If an item appears to have been

damaged in shipment, replace it properly in its carton and notify

the shipper.

Be sure to save:

1. The shipping carton and packaging material. They are the safest

material in which to make future shipments of the equipment.

2. These Installation and Operating Instructions.

SERVICE

If the unit ever needs repair service, the customer should contact

Videolarm (1-800-554-1124) for authorization to return and shipping

instructions.

TECHNICAL SUPPORT

If technical support is needed, Videolarm has set-up a 24 hour

technical support line for their customers.

Repairs made necessary by reason of accident, misuse or normal

wear shall be charged at Videolarm's standard rate. This warranty

gives you specic legal rights, and you may also have other rights

which vary from state to state.

24 HOUR TECHNICAL SUPPORT

1-800-554-1124

- 2 -

Page 3

!

!

ELECTRICAL SPECIFICATIONS (OUTDOOR ONLY):

Power 24VAC, Class 2 Only

52 watts at 24 VAC (accessories)

Heater: 50 watts

Blower: 2 watts

NOTE: This unit is designed for operation in an

upright position. Installing the unit upside

down may cause damage to the internal

equipment, and will void the warranty.

2. Open the housing assembly box. Note there is a small roll

of Teon Tape that will be needed during installation, put it

aside. (Picture 2)

Teon Tape

Picture 2

GENERAL INSTRUCTIONS:

Tools Required: .100" Flat Head Screwdriver

Phillips Head Screwdriver

Be sure the bracket is properly and securely

mounted to a supporting structure capable of

rigidly holding the weight of the entire unit.

ASSEMBLING THE PRODUCT:

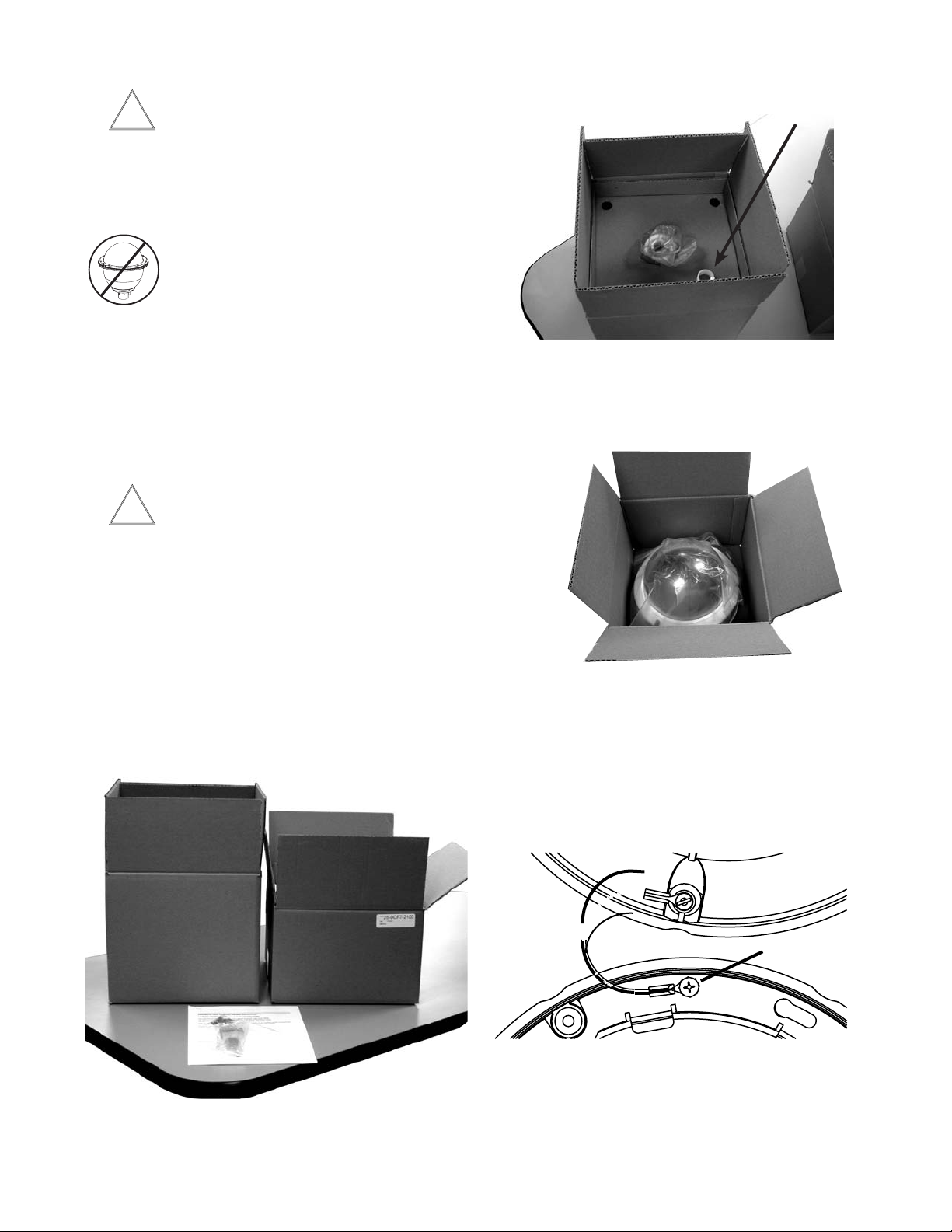

1. Remove the contents of the box onto a table. The larger

subassembly box is the housing assembly. The smaller

subassembly box is the dome assembly. (Picture 1)

Picture 1

3, Open the dome assembly box. Note there is a protection

lm on the dome. DO NOT REMOVE the lm until the

product is fully assembled and installed. This lm protects

the dome from scratches during installation. (Picture 3)

Picture 3

4. There is a safety lanyard that is attached to the inside of

housing assembly. Remove the phillips head screw on the

trim ring assembly and then attach the lanyard to the trim

ring with the phillips head screw.

5. The safety lanyard is now attached to the housing

(Picture 5).

the

Attach Lanyard

to Trim Ring

Picture 5

Listed on the following pages are the specic instructions

for each of the individual network cameras. See specic

instruction for the model that matches the unit you have.

- 3 -

Page 4

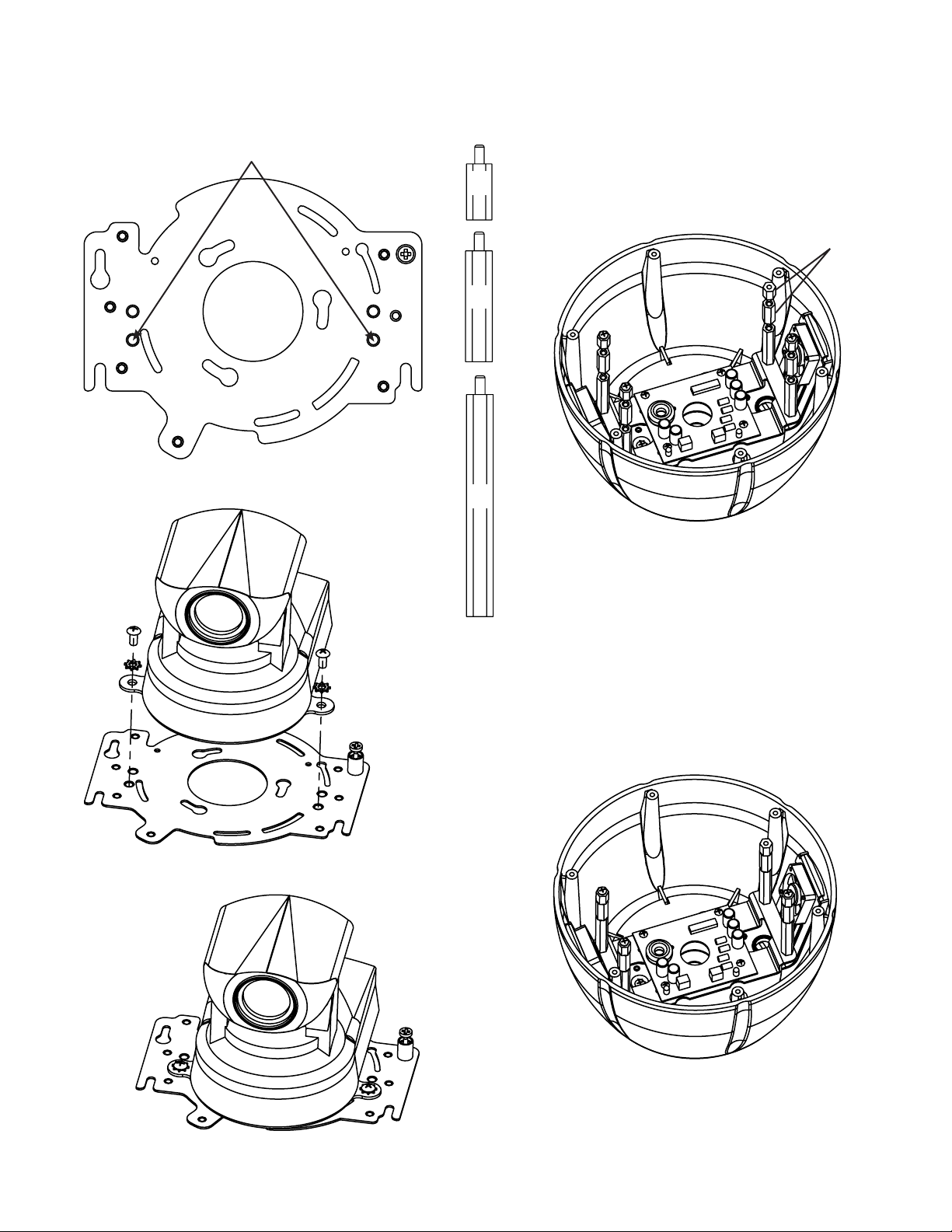

Installing the Axis 213 Camera

1. Install the camera onto the quick release bracket using

(2) 10-32 x 3/8” screws and star washers provided in the

packet.

Attach cameras using these (2) holes

½"

1"

2"

2. In the kit there are (8) aluminum spacers - (4) 1" and

(4) ½". Thread (2) spacers - (1) 1" and (1) ½" - on

top of each of the (4) 2" spacers that are already

located on the base bracket inside the housing.

½" + 1" spacers

3. Then start (3) 8-32x3/8” phillips head screws onto the

3½ inch spacers inside the housing. Be sure to place

the screws so that they line up with the (3) open slots

on the quick release bracket.

- 4 -

Page 5

Installing Axis 213 Camera (cont.)

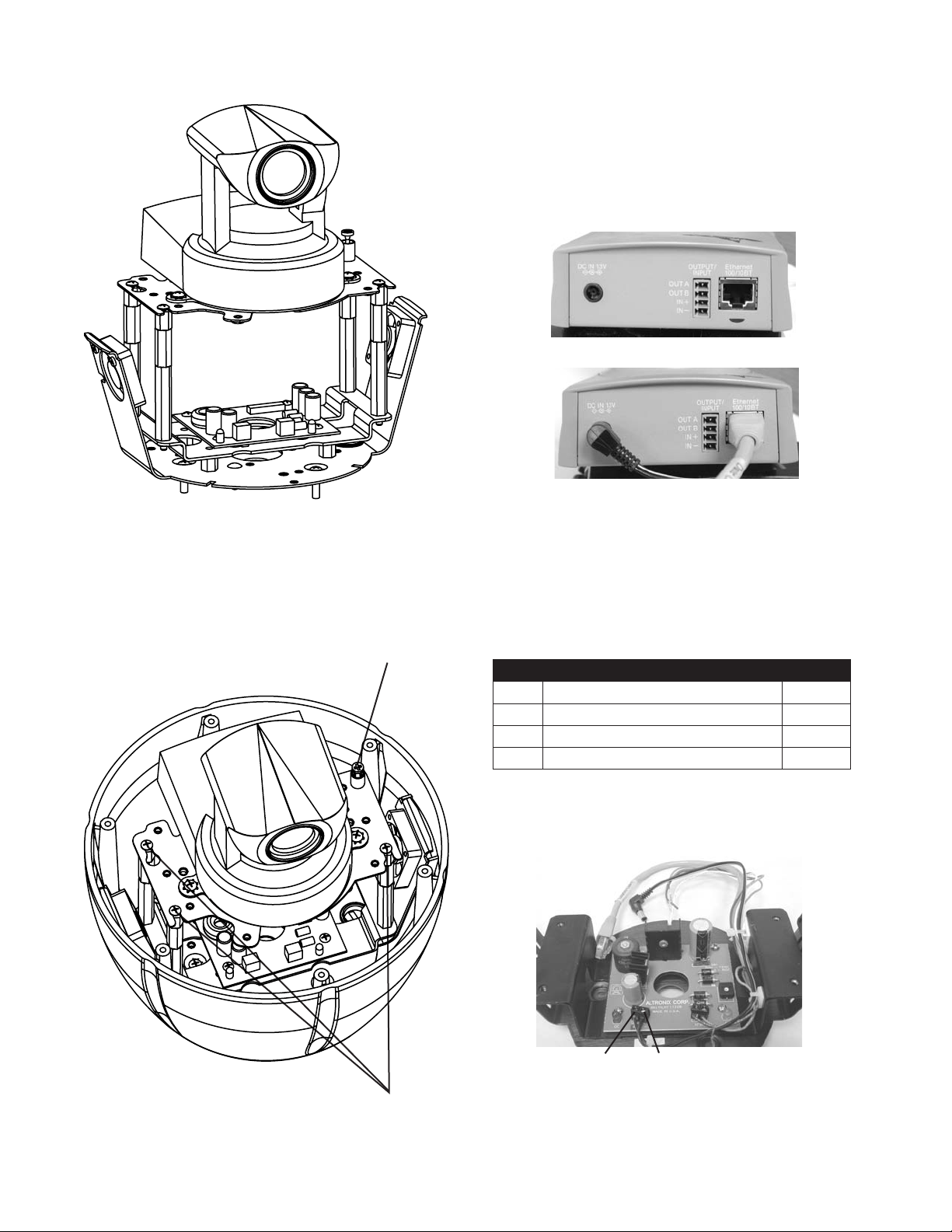

CAMERA POWER

Connect the power plug and the ethernet cable to the back

of the camera.

4. Mount the camera assembly in the housing, sliding

the (3) open screw slots over the (3) screws in the

housing. Slide the bracket forward then tighten the

captive screw on the bracket.

Captive Screw

CONTROL

RJ45 Ethernet Connector

ALARMS

1 Alarm 1 Blue

2 Alarm 2 Violet

3 Alarm 3 Gray

4 Common White

Power Connection - Reference

Only

(3) screws

in housing

+12 VDC -12 VDC

- 5 -

Page 6

Installing Axis 214 Camera

Attach cameras using these (3) holes

1"

3. Place (3) 8 x 32 x s Phillips head screws on the top

of the spacer as shown above. Be sure to place the

screws so that they line up with the open slots on the

mounting plate.

4. Slide the mounting plate with camera into position on

top of spacers. Secure 3 screws and captive fastener.

1. Install the AXIS 214 camera to the 2685 mounting

plate using the (3) 3mm x 12mm bolt and lock washers

provided.

2. The AXIS 214 camera requires 1” of spacing for optimal

position within the housing. Use the 4 (1”) spacers

provided in the packet.

- 6 -

Page 7

Installing Axis 231D/232D Camera

1. Install the camera onto the quick release bracket. Loosen

one of the screws on the bottom of the camera, see

diagram below.

Loosen screw

2. Place quick release bracket onto the bottom of the

camera, making sure that the (3) locking buttons line up

with the keyhole slots in the Q/R

bracket. Also make sure

the screw that

you loosened

up in the

previous

step lines

up with

the slot

located

next

to the

captive

insert.

Keyhole slots

Locking screw

Captive insert

Locking

buttons

4. When the locking buttons hit the end of the keyhole slots.

Tighten the locking screw. Then put the camera assembly

aside.

Locking screw

5. Since the 231D/232D camera operates on 24vac, the

power board that is located inside the housing is not

needed. The remove the power board, start by loosening

the screws on the terminal block and disconnect the

orange and red wires.

6. With a Phillips head screwdriver remove the (4) machine

screws holding the power board to the base bracket.

3. Turn the camera counter

clockwise.

Machine screws (4)

Base Bracket

- 7 -

Page 8

Installing Axis 231D/232D Camera (cont.)

7. Then start (3) 8-32x3/8” phillips head screws onto the (3) ½" spacers inside

the housing. Be sure to place the screws so that they line up with the (3)

open slots on the quick release bracket, the screws on the bottom of the

camera, see diagram below.

(3) 8-32 x 3/8"screws

8. Locate the connector block,

which is included with the

camera. Then located the

connector block bracket,

which is included with the

housing. Attach the block

to the bracket as shown

in the following diagram.

Use the M3 screws

and washers that are

located in the housing

packet.

9. Attach the connector

block assembly to the

housing using (1) 632x3/8” screw and star

washer located in the

housing packet.

10. Make wiring connections to connector block assembly per

camera instructions.

Wiring Connections

POWER

1 Camera Power (24VAC) Red

2 Camera Power (24VAC) Orange

CONTROL

RJ45 Ethernet Connector

ALARMS

1 Alarm 1 Blue

2 Alarm 2 Violet

3 Alarm 3 Gray

4 Common White

- 8 -

Page 9

Installing Axis 231D/232D Camera

(cont.)

11. To manage the input cable running from the connector

block to the camera use the (2) cable tie mounts and

cable ties that are located in the housing packet.

Cable Tie Mounts

13. Attach the

camera

assembly to

the housing by

sliding the (3)

open screw

slots over the

screws in the

housing. Slide

the bracket

forward, and

the tighten the

captive screw

on the bracket.

Captive screw

Cable Ties

12. Now grab the camera assembly and connector the RJ45

cable and the input cable to the camera.

Open screw slots

FOR REFERENCE ONLY

- 9 -

Page 10

Installing Axis 233 Camera

1. Note the position of the mounting holes on the camera

bracket (see diagram below).

Camera Bracket Mounting holes

Mounting holes for housing

2. Since the 233 camera operates on 24vac, the power

board that is located inside the housing is not needed.

The remove the power board, start by loosening the

screws on the terminal block and disconnect the

orange and red wires.

4. Now remove the Base Bracket.

3. With a Phillips head screwdriver remove the (4) machine

screws holding the power board to the base bracket.

Remove the power board.

Machine screws (4)

5. Now attach (4) 1” spacers (located in the packet that

came with the housing) to the base bracket.

Attach (4) 1" spacers

1"

Base Bracket

- 10 -

Page 11

Installing Axis 233 Camera (cont.)

6. Mount the Axis 233 camera bracket and Q/R plate (Quick

Release plate) as shown.

Keyhole SlotsQuick Release

(Q/R) plate

Keyhole Slots

7. Place the Quick Release plate onto the bottom of the

camera,

Make sure that the locking

screws on the AXIS 233

camera line up with

the keyhole slots

on the Q/R plate.

Slide the

camera into

the keyhole

slots by

targeting

the locking

screw(s).

Keyhole Slots

Locking Screw

8. Turn the camera counter-clockwise.

9. When the locking

buttons hit the end

of the keyhole

slots, tighten

the locking

screw.

- 11 -

Page 12

INSTALLING THE HOUSING ASSEMBLY:

!

REMOVING AND ATTACHING THE DOME ASSEMBLY:

Be sure the bracket is properly and securely

mounted to a supporting structure capable of rigidly

holding the weight of the entire unit.

NOTE: This unit is designed for operation in an

upright position. Installing the product upside

down may cause damage to the internal

equipment, and will void the warranty.

1. This unit includes a 1½" NPT housing for a standard 1½"

NPT pipe. The housing can be used with other brackets

designed with 1½" male pipe threads, such as the UNI-WMB1

wall mount brackets.

2. Attach the housing coupling (Figure 3).

NOTE: Pipe threads should be clean and rust free.

Use the Teon™ tape included with

the housing on the threads.

Add thread

sealing tape

1. Attach the dome assembly to the housing top by lining

up the three pins with the three keyhole slots. Insert the

dome assembly into the housing and then rotate the dome

assembly clockwise. Then tighten the (3) screws on the front

of the dome assembly.

Figure 3

3. Mount the housing assembly to the mounting bracket

and housing coupling. A safety cable is included with

the housing to temporarily hold it while making wiring

connections. Loop the safety cable over one of the set

screws on the housing coupling and make the appropriate

connections using the (2) screw-down connectors supplied.

2. Undo the safety cable and twist the housing onto the

housing coupling. Secure all (3) setscrews provided on the

housing coupling (Figure 4).

Set screws

Figure 4

2. Remove the protective

lm from the dome.

3. Clean the outside of

the dome.

Chart A Wiring Color Code

Power and Control Inputs

(Outside of housing)

POWER

1 Camera Power (24 VAC) Red

2 Camera Power (24 VAC) Orange

3 Accessory Power (24 VAC) Yellow

4 Accessory Power (24 VAC) Green

Separate Power Supplies for Camera and Accessory Power

Camera: 25 watts (VA), 24 VAC, Class 2 Only

Accessory: 27 wattts (VA), 24 VAC, Class 2 Only

CONTROL

RJ45 Ethernet Connector

ALARMS

1 Alarm 1 Blue

2 Alarm 2 Violet

3 Alarm 3 Gray

4 Common White

- 12 -

Page 13

22

90

20 18

13016225143501252510830

Maximum distance from transformer to housing

Total vA consumed

Wire Gauge

24 VAC Wiring Distances

The following are the recommended maximum distances for 24VAC wit h a

10% voltage drop. (10% is generally the maximum allowable voltage drop

for AC-powered devices.)

6530

56

90 143 228 362 576

3550

POWER WIRING

Two plug-in wall transformers are included with the housing.

Use one to provide power for the heater and blower in the

housing, and the other for the camera. Determine where

the transformers will be located, then run two sets of power

wires into the wall mount bracket (Four total power wires).

Use the chart below to determine the correct gauge of wire

needed based on the length of the run and the 30vA power

line.

The unit is setup with (2) individual power inputs.

1. Accessory Power (yellow and green wire)

2. Camera Power (red and orange)

If you wish to provide a single power transformer it is recommended that:

1. Be certain that you know the total power consumption of the

housing Heaters (25 watts) + Blowers (2 watts) + camera/pan-tilt

(not supplied)

CONNECTING THE TRANSFORMERS (Figure 2)

Determine which transformer will be attached to the camera.

Attach the red and orange wires to the terminal points on the

transformer .

For the transformer which will be used for the heater and

blower, attach the yellow and green wires to the terminal

points.

NOTE: You may attach wires to either terminal, however MAKE

SURE THAT THE TRANSFORMERS ARE ATTACHED TO THE PROPER

CONNECTION ON THE HOUSING.

Accessory

Power

Green

Yellow

Accessory

Power

Camera

Power

Camera

Power

Orange

Red

213 = 24 watts @ 13Vdc

214 = 14 watts @ 12Vdc

231D/232D = 25 watts @ 24Vdc

2. Check the supplied wiring chart to be sure that you have the

proper gauge wire for the distance that you intend to run your

power wires.

3. Bring power to the 3 and 4 position of the power connector (yellow

and green wire)

4. Two jumpers are provided in the housing packet. Jumper from

the 1st position to the 3rd position and from the 2nd position to the

4th position of the terminal block. Be careful not to short between

the yellow and green wires.

Add 2

jumpers for

single power

input

One Power Supply for both Camera and Accessory Power

52 watts (VA), 24 VAC, Class 2 Only

NOTE: In this combination, run power to the camera connector,

then run jumper wires (not provided) to the accessory

side of the connector.

- 13 -

Page 14

16

4

Exploded View for Replacement Parts

9

8

7

5

Replacement Parts List

Part Number Description

1 RPFD7015 Lower Trim Ring

2 FD7T Tinted Replacement Capsule

FD7C Clear Replacement Capsule

3 RPFD703 Dome Clamping Bracket

4 RPFD072 24 Vac Heater

5 RPFD080 (12 Vdc) Blower (Used In 24v Housings)

6 RPFD060 Camera Bracket

7 RPRH707 Connection Pcb

8 RPFD040 Housing Hardware

9 RPFD709 Housing Top

16 RPFD711 Pendant Mount Bracket

- 14 -

6

3

2

1

Loading...

Loading...