Page 1

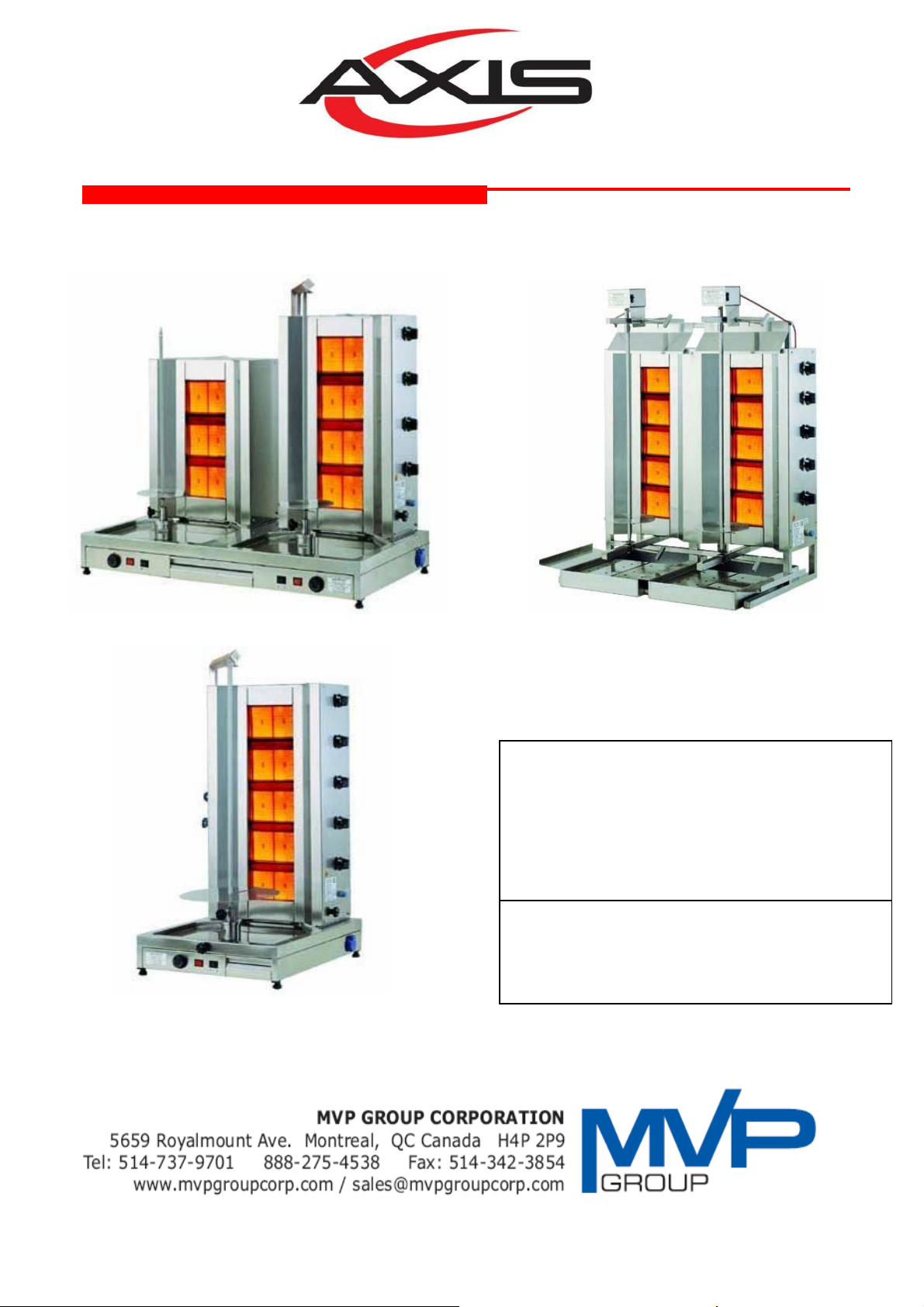

Döner-Grillmachine

SERIAL NR:

MANUFACTURER: OZTİİNOKS DÖNER MAKİNELERİ SAN. ve TİC.A.Ş.

ADDRESS: Cumhuriyet Mahallesi Eski Hadımköy Yolu No.:39/4 Büyükçekmece Istanbul/TURKEY

Oztiinoks is an Öztiryakiler group company.

Issued on: 23.05.2007

Tel.: 0090 212 886 78 00 (8 Lines) Fax : 0090 212 886 66 29

VER . 07.1

- 1009

INSTALLATION - USER -

MAINTENANCE MANUAL

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read the

installation, operation and maintenance

instructions thoroughly before installing or

servicing this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any

other appliance

YEAR OF

MANUFACTURE:

Page 2

TABLE OF CONTENTS

1 – PREFACE

1.1 – Use of Installation – Operation & Maintenance Manual

2 – INSTALLATION INSTRUCTIONS

2.1 – Technical Instructions for Gas Connections

2.2 – Installation of the Appliance

2.3 – Technical Specifications

2.3.1 – Table of Burners Depending on the Injector Type of Gas Used

2.3.2 – Technical Specifications of Gas Döner-Grillmachine

2.3.3 – Instructions for Gas Conversions

2.3.4 – Gas System Diagram

2.4 – Motor

2.5 – Gas Connection Diagram

2.5.1 – Döner-Grillmachine with Motor on Top

2.5.1 – Döner-Grillmachine with Motor on Top

3 – OPERATION AND MAINTENANCE INSTRUCTIONS

3.1 – Installing the Appliance

3.1.1 – Motor on Top Type Döner-Grillmachine

3.1.2 – Motor at Bottom Type Döner-Grillmachine

3.2 – Purpose of Use

3.3 – Warnings

3.4 – Operation

3.5 – Operation with Motor

3.5.1 – Döner-Grillmachine with Motor on Top

3.5.2 – Döner-Grillmachine with Motor at Bottom

3.6 – Operation without Motor

2.5.1 – Motor on Top Type Döner-Grillmachine

3.5.2 – Motor at Bottom Type Döner-Grillmachine

3.7 – Clean-Up

3.8 – Maintenance

3.9 – Economic Life of the Appliance

4 – WARRANTY

Page 3

1 - PREFACE

Thank you for preferring our product and for the confidence you showed in our

company - by purchasing Gas Döner-Grillmachine.

Being preferred in 86 countries professional kitchens, our products are manufactured

in compliance with the directives for appliances operated with gas.

Please read this User’s Manual carefully, in order to be able to achieve highest

efficiency throughout the economic life of the appliance.

• BEFORE CALLING OUR AUTHORIZED SERVICE STAFF PLEASE ENSURE

THAT ELECTRICAL INSTALLATION AND GAS INSTALLATION ARE

COMPLETED BY COMPETENT PERSONNEL IN LINE WITH LEGAL

REQUIREMENTS.

• IN CASES OF DOUBT AND UNCLEAR POINTS, PLEASE ASK OUR

NEAREST TECHNICAL SERVICE FOR MORE DETAILED INFORMATION.

• PLEASE REMEMBER THAT EXPENSES AND A HOURLY SERVICE FEE

MUST BE CHARGED IF AUTHORIZED SERVICE STAFF CALLED WITHOUT

MAKING PREPARATION BEFORE INSTALLATION ARE LEFT WAITING

UNNECESSARILY.

• WE HOPE THAT YOU WILL OBTAIN HIGHEST YIELD FROM OUR

PRODUCT PURCHASED.

1.1 – Use of Installation – Operation & Maintenance Manual

Dear customer please read this User’s Manual carefully in order to prevent your

appliance from damages, and to achieve maximum efficiency throughout the

economic life of the appliance.

Page 4

2 – INSTALLATION INSTRUCTONS

2.1 – Technical Instructions for Gas Connections

Initial installation and operation of the appliance must be carried out by an Authorized

Service in compliance with technical requirements and local directives related to gas

connections.

All gas connections of the appliance must comply with ISO 7 – 1 or ISO 228 – 1

standard.

AN ELECTRICAL AND GAS INSTALLATION COMPLYING WITH THE RELEVANT

LOCAL REGULATIONS MUST BE PRESENT AT THE FACILITY, BUILDING AND SIMILAR SITE

WHERE THE DÖNER-GRILLMACHINE WILL BE INSTALLED; NECESSARY PRECAUTIONS

MUST ALSO BE TAKEN TO ENSURE HEALTH AND MATERIAL SAFETY.

OTHERWISE OUR COMPANY WILL NOT BE RESPONSIBLE FOR THE

CONSEQUENCES.

!

2.2 – Installation of the Appliance

The appliance must be installed on a stable, even and balanced ground made of stainless

steel. This stainless steel surface must be in a form preventing fat from flowing down from the

surface and spilling The appliance should never be installed on a plastic or wooden surface. It

must be installed so that at least 20 cm distance is maintained between the appliance and the

wall, during its use.

Gas connections of the döner-grillmachine must be done in compliance with the regulations in

force.

The appliance should be operated under well ventilated conditions. The ventilation

system must be of non-flammable character, and the ventilation funnel must be free

of any obstruction.

2.3 – Technical Specifications

Öztiryakiler A.Ş. reserves the rights to use and to modify the technical specifications.

!

Power supply cords and gas connection hoses of the appliance installed by

!

Page 5

2 – INSTALLATION INSTRUCTONS

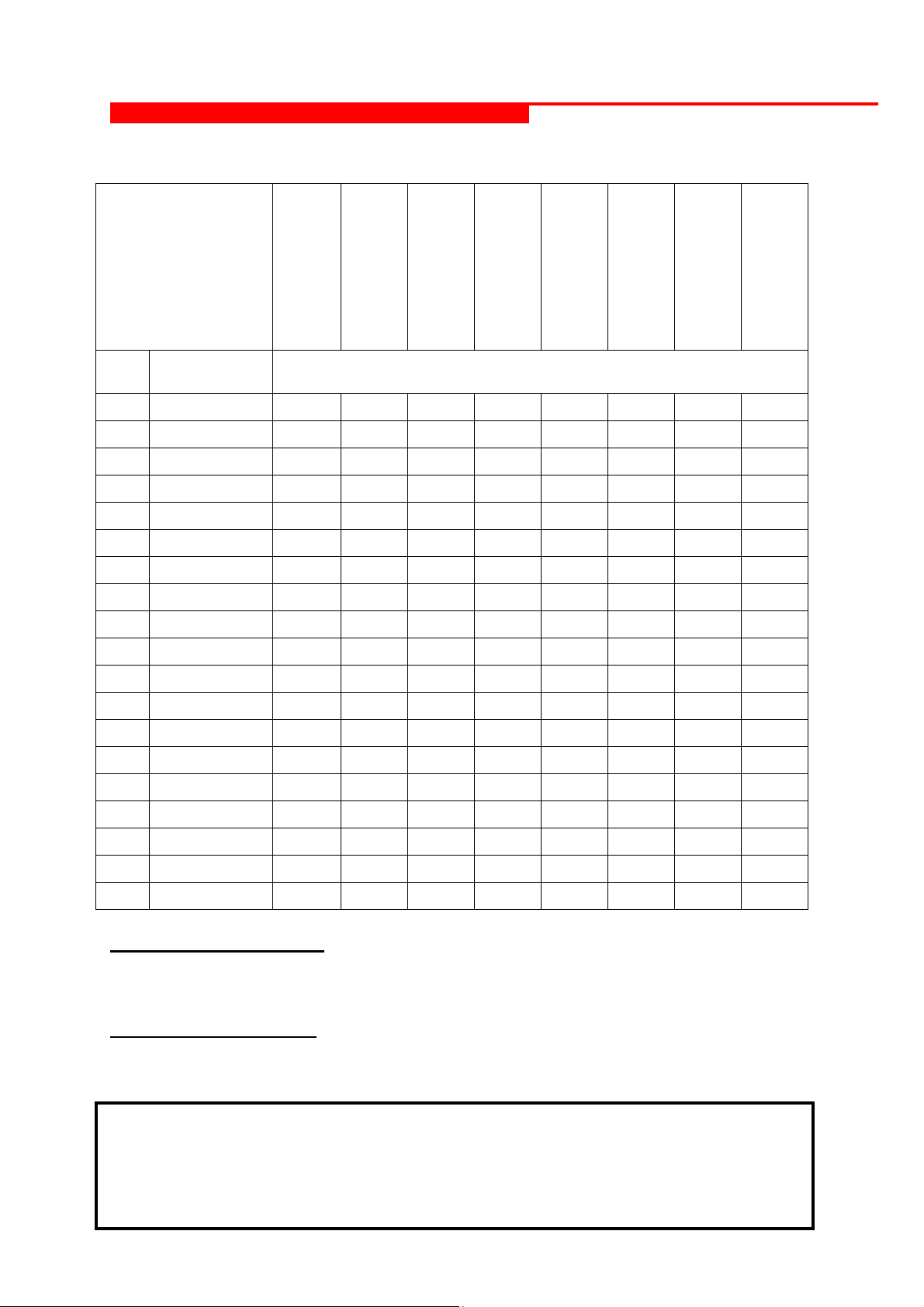

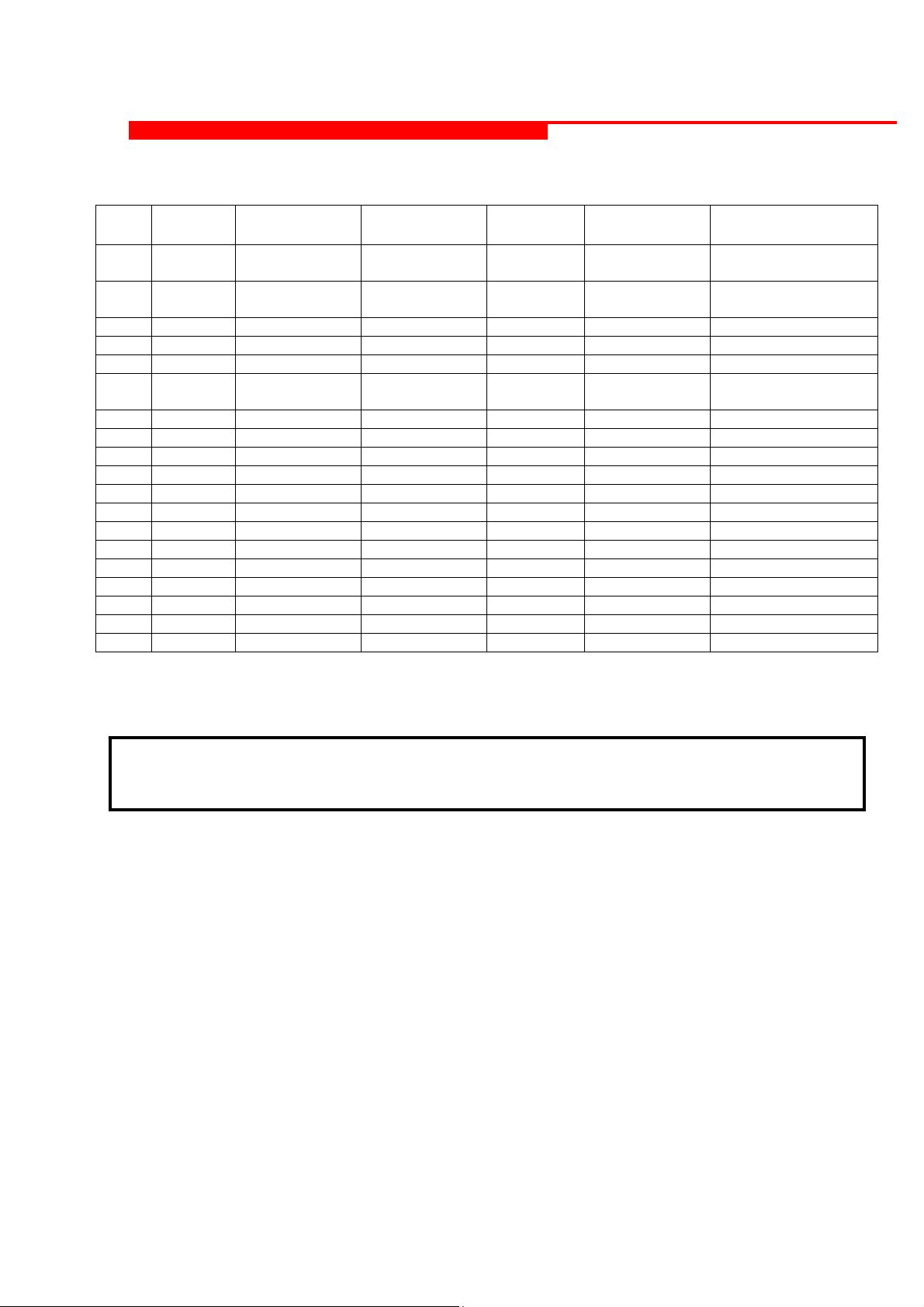

2.3.1 – Table of Burners Depending on the Injector Type of Gas Used

GAS TYPE

Pos

1 4G**

2 5G**

3 3GD*

4 4GD*

5 5GD*

6 55G**

7 44GD*

8 3GUD*

9 3GUD-W*

10 4GUD*

11 4GUD-W*

12 5GUD*

13 5GUD-W*

14 33GUD*

Machine

Type

G20 - 20 mbar

1,05 1,00 1,10 1,20 1,15 0,80 0,80 0,70

1,05 1,00 1,10 1,20 1,15 0,80 0,80 0,70

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,05 1,00 1,10 1,20 1,15 0,80 0,80 0,70

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

G20 - 25 mbar

G25 – 25 mbar

Burner Injector Diameter (mm)

G25 – 20 mbar

G25.1 – 25 mbar

G30 – 29 mbar

G31 – 37 mbar

G30 – 50 mbar

15 33GUD-W*

16 44GUD*

17 44GUD-W*

18 34GUD*

19 34GUD-W*

** Each burner capacity:

2 kW (natural gas) / gas valve by-pass injector Ø0.48 mm

2.4 kW (LPG) / gas valve by-pass injector Ø0.48 mm

* Each burner capacity:

3.25 kW / gas valve by-pass injector Ø0.65 mm

Nominal power of the appliance cannot be changed upon customer’s request.

Any modification made on valves and injectors, leaves the appliance out of

warranty coverage. Otherwise our company will not be responsible for the

consequences.

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

1,35 1,30 1,40 1,50 1,45 0,93 0,93 0,80

Page 6

2 – INSTALLATION INSTRUCTONS

2.3.2 – Technical Specifications of Gas Döner-Grillmachines

Poz.

01 4G

02 5G

03 3GD 9,75 40 kg 24 kg 736 mm 987x450x560 *

04 4GD 13 80 kg 27 kg 900 mm 1150x450x560 *

05 5GD 16,25 120 kg 45 kg 1060 mm 1312x600x600 *

06 55G

07 44GD 13 + 13 ( 90 + 90 ) kg 60 kg 900 mm 1150x900x560 *

08 3GUD 9,75 50 kg 30 kg 736 mm 780x530x650

09 3GUD-W 9,75 50 kg 30 kg 736 mm 780x530x650

10 4GUD 13 90 kg 34 kg 900 mm 1070x530x650 **

11 4GUD-W 13 90 kg 34 kg 900 mm 1070x530x650 **

12 5GUD 16,25 130 kg 48 kg 1060 mm 1230x530x650 **

13 5GUD-W 16,25 130 kg 48 kg 1060 mm 1230x530x650 **

14 33GUD 9,75 + 9,75 ( 50 + 50 ) kg 58 kg 736 mm 780x1060x650

15 33GUD-W 9,75 + 9,75 ( 50 + 50 ) kg 58 kg 736 mm 780x1060x650

16 44GUD 13 + 13 ( 90 + 90 ) kg 68 kg 900 mm 1070x1060x650 **

17 44GUD-W 13 + 13 ( 90 + 90 ) kg 68 kg 900 mm 1070x1060x650 **

18 34GUD 9,75 + 13 ( 50 + 90 ) kg 64 kg 736mm/900mm 1070x1060x650 **

19 34GUD-W 9,75 + 13 ( 50 + 90 ) kg 64 kg 736mm/900mm 1070x1060x650 **

Product

Nr.

Power (KW)

8 ( NG )

9,6 ( LPG )

10 ( NG )

12 ( LPG )

10 + 10 ( NG )

12 + 12 ( LPG )

Meat Capacity

(Kg)

25 kg 23 kg 736 mm 987x400x560 *

40 kg 26 kg 900 mm 1150x400x560 *

( 40 + 40 ) kg 45 kg 900 mm 1150x800x560 *

Weight

(kg)

Skewer

length (mm)

Dimensions

(HxWxD)

2.3.3 – Instructions for Gas Conversions

PLEASE FOLLOW THE INSTRUCTIONS BELOW TO USE THE ROTISSERIE

APPLIANCE WITH A GAS TYPE VARYING FROM REGIONAL REQUIREMENTS!

• Gas conversions should only be carried out by staff qualified in gas conversion.

• Close the valves of the gas line or gas bottle supplying gas to the appliance.

• Disconnect gas connection of the appliance.

• Loosen the screws of the back panel and remove back panel of the appliance

• Demount and remove the tubes between the gas valve and the burners.

• By displacing its splint remove the connection, where the injectors on the

burner are attached.

• Install appropriate type of injectors for the gas type to be used, on burner

connections.

• Install the splint and the connection back and tighten.

Page 7

2 – INSTALLATION INSTRUCTONS

• Re-mount the tubes between the gas valve and the burners. (Smear gearing of

the connection, where the collar on the tube and the tube are mounted to the

gas valve, with gas paste against gas leakage.)

•

• Change the labels of the appliance according to the gas conversion type.

• Connect the appliance to appropriate type of gas according to the gas

conversion.

• Check all connections for gas leakage. (Tests have to be carried out using

leakage spray or foam. Never check gas leakage with an open fire source like

match, lighter etc.)

• After the gas leakage test carry out combustion test for the appliance.

• If the heat of the appliance is not sufficient set the gas adjustment injector (by-

pass) on the gas valve appropriately using a screwdriver. (Since the by-pass

injector is opened into the gas flow path, do never remove the by-pass injector

during operation. Since the settings of the appliance are done by default as to

requested gas pressure; if gas conversion will not be carried out, these settings

should never be changed by the user. Re-mount the back panel if no problem

exists.

• If you follow these instructions you can use your appliance safely with the gas

type converted.

2.3.4 – Gas System Diagram

1 – Burner

2 – Burner connection

3 – Burner injector

4 - Splint

5 – Ring

6 – Burner collar

7 – Gas tube (Ø8X1)

8 – Gas valve

9 – Thermo-element

10 – Gas ramp (Ø16x1.5)

11 – Gas pressure control connection

12 – Natural gas connection collar

13 – Propane connection collar

14 – Gas valve button

15 – Gas valve nut

16 – Gas valve by-pass injector

17 – Gas valve collar

18 – Gas valve clamp

19 – Clamp screw

20 - Gas tube counter nut

Page 8

2 – INSTALLATION INSTRUCTONS

14

15

17

5

8

14

GAS SYSTEM DIAGRAM

15

Page 9

2 – INSTALLATION INSTRUCTONS

2.4 – Motor

Electrical motors used in döner-grillmachine can be operated two-ways (right/left). By

the electrical motor used in döner-grillmachine, each side of the skewered meat can

be grilled homogenously, and also the appliance is operated using less human effort.

* Do not clean the electrical motor with water. In döner-grillmachines with motor on

top, wipe the frame of the motor with a moist cloth, and then wipe it dry.

(In döner-grillmachine with motor at the bottom, the motor is shielded with a cover. Do

not operate the appliance without cover. Do not use water for cleaning. )

* Do not drop down the electrical motor.

* Protect the cord of the electrical motor from contacting directly with fire.

* In döner-grillmachine with motor on top, use the Heat Cap (5) being an original part

of the appliance, in order to protect the motor from excessive heat during operation.

(Figure 1-b)

* Check the electrical cord of the appliance before each operation. Cords affected by

heat or cut due to incorrect operation may cause leakage current.

By following instructions stated above, maximum efficiency is achieved with the motor

of the product.

Motor Technical Specifications:

- 220 Volt (AC) NPE ~ / 50 Hz

- 1 rpm

3,7 W

Rotisserie

Guide

Rotisserie Guide

Thisapplianceisequippedwithathree‐prong(grounding)plugforyour

protection against shock hazardand should be plugged directly into a

properly grounded three‐prong receptacle. Do not cut or remove the

groundingprongfromthisplug

WARNING

ElectricalGroundingInstructions

Switch

Plug

Motor Cord

Motor Fixing Plate

Mount Opening

Page 10

2 – INSTALLATION INSTRUCTONS

2.5 – Gas Connection Diagram

2.5.1 – Döner-Grillmachine with Motor on Top

Figure 1 - a

1 - Motor

17 – Motor Plate

18 – Skewer Guide

5 - Heat Cap

6 - Skewer

8 - Guard Grating

10 - Burner

11 - Disc

12 - Splint

14 - Fat Tray

Figure 1 - b

Gas Valve &

Gas valve button

By-Pass Injector

Gas Connection &

Pressure Gauge Connection

2 - Motor Cord

16 – Counter-Arm

3 - Upper Slide

4 - Cord Holder

7 -Gas Valve Button &

Gas Valve

9 - Thermoelement

13 - Gas Connection &

Pressure Gauge

Connection

15 - Lower Slide

Page 11

g (

2 – INSTALLATION INSTRUCTONS

2.5.2. Döner-Grillmachine with Motor at Bottom

Figure 2 - a

1 - Telescopic Skewer Support

2 - Skewer

4 - Telescopic Skewer

Support Holding Arm

5 - Telescopic Skewer Support

Fixing Screw

7 - Disc

11 - Splint

12 - Skewer Fixing Screw

22 - Rotisserie Guide

18 - Thermostat

19 - Thermostat Switch

20 - Motor Switch

Figure 2 - b

Gas valve &

Gas valve button

By-Pass Injector

Gas Connection &

Pressure Gauge

23 - Frame

3 - Burner

6 - Thermoelement

8 - Guard Grating

9 - Gas Valve Button &

Gas Valve

10 - Gas Connection &

Pressure Gauge

Connection

13 - Frame Moving Arm

14 - Telescopic Rail

16 - Power Plu

21 –Bottom Plate

17 - Fat Drawer

230

The parts shown with numbers (18) – (19) are only present in appliances with code (W).

In appliances with code W, the bottom plates (21) are equipped inside with a heating system

preventing fat accumulated from freezing.

The parts shown with numbers (1) – (4) – (5) are not present in the appliances coded with 3.

Page 12

3 – OPERATION AND MAINTENANCE INSTRUCTIONS

3.1 – Installing the Appliance

3.1.1 – Motor on Top Type Döner-Grillmachine (Figure 1 – b)

After installing the appliance in compliance with the regulations mentioned in the

User’s Manual of the motor on top type of döner-grillmachines the fat tray and the

motor (Figure 1–b) are inserted, making the appliance ready for use. In these types of

appliances, unscrew upper and lower slide arms for the meat grilling. The distance

between the skewer (6) with meat on, and the burners is adjusted with the help of

these arms.

Make the gas connections at values as specified on appliance label and plug the

electrical cord in. Your appliance is ready for use.

3.1.2 – Motor at Bottom Type Döner-Grillmachine (Figure 2 – b)

Frame

Bottom

Table

Rail Synchronisation

Spindle

Rail Fixing Screws

and Connection

Openings

Rail Mechanism

Page 13

3 – OPERATION AND MAINTENANCE INSTRUCTIONS

Before operating the motor at bottom type döner-grillmachine, the frame (23) and

bottom plate (21) must be installed first.

In order to fix your appliance with bolts follow the instructions below:

• Install the bottom plate of the appliance as described in the User’s

Manual.

• Place the frame onto the bottom plate, so that the connection openings on

the rail mechanism coincide with the connection points on the bottom

plate.

(The frame where the burners are connected is equipped with a rail

mechanism. Four openings for bolt connections - two being on the right two

being on the left - are present on this mechanism. )

• Holding the rail mechanism, push the frame forward. Doing this the frame

moves closer to the skewer, but the rail mechanism is stationary. Pass

the bolts through the connection openings on the rail mechanism, and

screw them onto the mounting openings on the bottom plate. Then screw

all bolts using a wrench and fix the frame on the bottom plate.

• Make the gas connections at values as specified on appliance label and

plug the electrical cord in. Your appliance is ready for use.

The skewer (2) being located in a fixed position; the distance between the meat and

the burners is set by moving the frame where the burners are bound to back and forth

by a special rail mechanism. When doing this, consider that the appliance might be

heated up, and use the frame moving arm (13) to move the frame (23) back and forth.

If your döner-grillmachine is of a type with telescopic skewer supporter, this supporter

must be installed as shown in Figure 2-b.

In the motor at bottom type (W) coded döner-grillmachines, the bottom plate is

equipped with a resistance. This enables both to prevent the fat from freezing, and

cause it flow into the fat tray, and to keep and to serve the meat located above of the

bottom plate hot. During operation, this fat tray should be checked periodically and

evacuated if filled with fat. Otherwise overflowing fat may spill, both impairing hygiene

conditions and creating a slippery surface that might cause accident and serious

injury.

In such type of döner-grillmachines, the resistance is controlled via a thermostat and a

switch using to start the thermostat (Figure 2-b 18-19).

With the help of the thermostat, the meat can be kept at desired temperature.

An additional accessory device operating at 230 V to be connected to the side plug on

your appliance can also be used. (for example electrical meat slicing machine)

For rotisserie ovens with motor on top and at bottom, please read point 3.-5.

before inserting the rotisserie where the meat is skewered to the rotisserie

oven!

Page 14

3 – OPERATION AND MAINTENANCE INSTRUCTIONS

3.2 – Purpose of Use

This döner-grillmachine was designed and manufactured to grill any kind of döner meat for

commercial purposes, and cannot be used for different purposes.

3.3 – Warnings

* Before starting the appliance remove all protective PVC films and any other packaging

material, from the appliance.

* Do not leave the appliance unattended when operating.

* The appliance should only be operated under a chimney hood.

* The appliance should only operated by persons, who have read the user’s manual and

maintenance manual and are trained about the operation of the appliance.

* This appliance should only be operated on a stable, levelled surface made of stainless steel.

* Gas connections must be checked for gas leakage.

* The appliance should be operated under well ventilated conditions. The ventilation system

must be of non-flammable character, and the ventilation funnel must be free of any

obstruction.

* When changing the location of the appliance, it must be turned off and cooled down.

* If the appliance is operated without motor (for motor on top type of döner-grillmachines) use

the original skewer turning arm, which can be mounted to the top of the skewer, to rotate the

meat.

* If gas odour is smelled, turn the gas valves of the appliance and all other gas valves off, and

ventilate the room. Call authorized service as soon as possible.

* Do never check gas leakage using a match or lighter. Check it using a gas leakage spray or

foam.

* All gas valves, main gas valves and power supplies must be turned off, after the operation

and in cases of emergency.

* The appliance should not be used beyond its purpose of use.

* The appliance should not be moved and jolted when operating.

* Beware from spilling of fat, when operating the appliance. Any spilled fat should be cleaned

up immediately. Otherwise accidents and serious injuries might arise from the slippery surface

caused by spilled fat.

* Do not hit and tilt the appliance when carrying it.

* Do not locate any flammable material near the appliance. Do not operate the appliance near

easily flammable materials.

* If the appliance has to be located near to a wall, dividing wall, kitchen furniture, decorative

coating etc., these must definitely be of non-flammable material. Otherwise these must be

coated with non-flammable heat insulation material, and the fire protection instructions must

be strictly followed.

* Leave 20 cm gap between the location, where the appliance will be operated and the wall.

* Operational gas pressure values of the appliance are labelled on the appliance. Do nor

operate the appliance at a gas pressure other than the specified level.

* If the appliance is operated with LPG, the distance between the device and LPG cylinder

should be minimum 50 cm.

During grilling consider that the meat is hot, heavy and fatty and do not remove

the meat from the appliance until the meat is completely finished!

!

Page 15

3 – OPERATION AND MAINTENANCE INSTRUCTIONS

Push and turn the gas valve left and after keeping the gas valve pressed for 5 sec.,

push the igniter, and repeat this operation until seeing the flame on the burner, release

the gas valve after 10 sec when burner is lit, and turn the gas valve right to shut the

appliance off. If the burner does not light within 10-15 seconds, turn the valve off, and

wait for a short while before retrying. Gas valves are equipped with thermo-elements.

Therefore when lighting the burner first, keep the gas valve button pressed until the

thermo-element heats up (around 10 seconds). Otherwise, thermo-elements not

heated up enough will not allow gas flow and combustion will not occur. When the

thermo-couples are heated up, stop pressing the buttons.

By repeating the procedure mentioned above following the same order, all burners of

the appliance can be started. If for any external reason, the flame expires, the thermoelements cease the gas flow.

Each of the burners is controlled by independent gas valves. Gas valves have two

different cooking operation settings - low and full levels. Döner meat can be grilled or

kept warm, using these settings as required.

Full Level Setting:

Gas valve button is labelled with a large flame indicator. For operating at full level, set

the valve to this position, which will enable meat grilling.

Low Level Setting:

Gas valve button is labelled with a small flame indicator. For operating at low level set

the valve to this position, which will keep the meat warm.

After the operation is finished always turn all gas valves, main gas valves and

power connections off.

Page 16

3 – OPERATION AND MAINTENANCE INSTRUCTIONS

3.5 – Operation with Motor

3.5.1 – Döner-Grillmachine with Motor on Top

Operating your appliance with motor will enable both a homogenous meat grilling and

depending less on manual operation.

Please follow the following procedure to operate your appliance with motor.

(Figure 1-b)

- Unscrew (T) shaped arms of upper (3) and lower slides (15) Depending on the

diameter size of the meat, move these arms to the best position where the meat

can easily be skewered. Remove T shaped upper slide (3) arm completely.

When doing this counter-arm (16) must be located above upper slide arm (3).

Then, pass the T shaped upper slide arm through the mounting opening above

of the motor shield (17), and install it together with the motor (1) and screw.

When holding the motor in correct position with your hands, screw the counterarm (16) and the motor shield (17).

- Insert the bottom end of the skewer (6) with meat on, to the conical guide

located above lower slide (15), and tighten T shaped arm.

- Then move the top end of the skewer (6) closer towards the skewer guide.

Raise the snatching tube on the skewer guide up, and insert the skewered meat

into the skewer guide and snatch the tube.

- After doing this, ensure that both the bottom slide (15) and the upper slide (3)

are aligned.

- Then pass the motor cable (2) through cord holders, in order to protect the

cable from the heat generated during operation. (Use the heat cap (5) to protect

the cable from heat during operation)

- Your appliance is ready for use with motor. Plug electrical cord of the motor in,

and start it using the switch on it.

When operating with motor always ensure that cords are kept away from

heat sources. For this reason, never attach the motor cord on cord holders

when operating.

!

Page 17

3 – OPERATION AND MAINTENANCE INSTRUCTIONS

3.5.2 – Döner-Grillmachine with Motor at Bottom

Operating your appliance with motor will enable both a homogenous meat grilling and

depending less on manual operation.

Please follow the following procedure to operate your appliance with motor.

(Figure 2-b)

• Unscrew the fixing screw (5) of the telescopic skewer supporter. By doing t his,

the telescopic skewer supporter (1) will be raised up by a spring mechanism.

• Unscrew the skewer fixing screw (12).

• Insert the lower end (2) of the skewer with meat on, onto the skewer guide (22).

• Tighten the skewer fixing screw (12).

• Pushing the telescopic skewer supporter holding arm (4) down, insert the upper

side of the skewer with meat on (2) into the guide located on this arm.

• Tighten the fixing screw (5) of the telescopic skewer supporter.

• Your appliance is ready for use with motor. You can start the motor by plugging

the electrical cord of the motor in and using the motor switch (20) located on the

bottom plate (21).

NOTE: THOSE APPLIANCES HAVING A 3-DIGIT PRODUCT CODE ARE NOT EQUIPPED

WITH A TELESCOPIC SKEWER SUPPORTER. TAKING THIS INTO ACCOUNT FOLLOW

THE INSTRUCTIONS BELOW FOR THESE APPLIANCES:

• Unscrew the skewer fixing screw (12).

• Insert the lower end (2) of the skewer with meat on, onto the skewer guide (22).

• Tighten the skewer fixing screw (12).

• Your appliance is ready for use with motor. You can start the motor by plugging

the electrical cord of the motor in and using the motor switch (20) located on the

bottom plate (21).

3.6 – Operation without Motor

3.6.1 – Motor on Top Type Döner-Grillmachine

If the appliance will be operated without motor, use the hygienic skewer turning arm,

which is used for rotating the skewer and is mountable to the top of the skewer. (For a

hygienic, safe and less human power consuming grilling operation, operating the oven

with motor is recommended).

Please follow the following procedure to operate your appliance without motor.

(Figure 1-b)

- Unscrew (T) shaped arms of upper (3) and lower slides (15) Depending on the

diameter size of the meat, move these arms to the best position where the meat

can easily be skewered.

- Insert the bottom end of the skewer with meat on to the conical guide located

above lower slide (15), and tighten T shaped arm.

- Then, pass the upper end of the skewer with meat on through the ring located

above the upper slide (3), and tighten the T shaped arm of the upper slide (3).

Page 18

3 – OPERATION AND MAINTENANCE INSTRUCTIONS

- After doing this, ensure that both the bottom slide (15) and the upper slide (3)

are aligned.

- Mount the original skewer turning arm to the top of the skewer, and rotate the

skewer using this arm. Doing this, higher hygiene and safety will be maintained

by enabling you to avoid the contact with the hot and fatty meat.

3.6.2 – Motor at Bottom Type Döner-Grillmachine

Since using a skewer turning arm is not possible with these types of appliances, it is

recommended to operate the appliance with motor. If the motor of your appliance has

a failure and immediate service response is not necessary, operate the appliance after

unplugging the electrical cord supplying power to the motor of the appliance. Call

authorized service as soon as possible for replacing the motor of your appliance.

Follow the procedure below, to operate your appliance without motor for a short

period of time: (Figure 2-b)

• Unscrew the fixing bolt (5) of the telescopic skewer supporter. By doing this, the

telescopic skewer supporter (1) will be raised up by the spring mechanism.

• Unscrew the skewer fixing screw (12).

• Insert the lower end (2) of the skewer with meat on, onto the skewer guide (22).

• Do not tighten the skewer fixing screw (12). Otherwise you will not be able to

rotate the skewered meat.

• Pushing the telescopic skewer supporter holding arm (4) down, insert the upper

side of the skewer (2) with meat on into the guide located on this arm.

• Tighten the fixing screw (5) of the telescopic skewer supporter.

• Your appliance is ready for use without motor. Unplug the appliance from power

supply during operation without motor.

NOTE: THOSE APPLIANCES HAVING A 3-DIGIT PRODUCT CODE ARE NOT

EQUIPPED WITH A TELESCOPIC SKEWER SUPPORTER. TAKING THIS INTO

ACCOUNT FOLLOW THE INSTRUCTIONS BELOW FOR THESE APPLIANCES:

• Unscrew the skewer fixing screw (12).

• Insert the lower end (2) of the skewer with meat on, onto the skewer guide (22).

• Do not tighten the skewer fixing screw (12). Otherwise you will not be able to

rotate the skewered meat.

• Your appliance is ready for use without motor. Unplug the appliance from power

supply during operation without motor.

Page 19

3 – OPERATION AND MAINTENANCE INSTRUCTIONS

3.7 – Clean-Up

For a longer and hygienic life of use, please clean your appliance up after daily

operation. Do never use rubbing powders and abrasive chemicals for the clean-up of

the appliance.

Use liquid soap dissolved in some amount lukewarm water. Then wipe the appliance

using a sponge immersed in soap water, and wipe it dry using a dry cloth.

Carry out the clean-up after the appliance is cooled down completely and not

operating. Never allow the motor and other electrical parts of the appliance contact

with water. Never allow the electrical parts (if any), the motor and burner parts contact

with water. Do not wash the appliance immersing into water. Do not use pressure

water for cleaning.

3.8 – Maintenance

In order to check gas leakage, and whether the appliance is functioning properly, the

appliance must be serviced at least every 6 (six) months at manufacturers site or an

authorized service, depending on the way the appliance is used and depending on the

location. If the appliance is not functioning properly call authorized service

immediately, and do not operate the appliance until it is fixed as necessary. If in such

cases functional parts of the appliance have to be replaced, these should be replaced

with original spare parts.

3.9 – Economic Life of the Appliance

If the appliance used in line with the instructions given in the User’s Manual, its

economic life is 10 (ten) years.

Page 20

4 – WARRANTY

The warranty starts with the initial installation and operation of the appliance. The

warranty of the appliance is 6 (six) months against workmanship and material faults,

provided that it is installed and operated as instructed within the User’s Manual.

Any failure arising from violation of the methods or conditions specified in the User’s

Manual and its operation beyond the purpose of use, and those failures arising from

the interference of unauthorized persons/entities to the appliance, shall annul the

service warranty.

Installation should be carried out by authorized service personnel and the service

should be informed about the location change of the appliance.

The failures within the scope of warranty, how and where these will be eliminated, and

the way and place of maintenance is determined by the manufacturer.

-If the information on the warranty deed or information label on the appliance are

scraped, rubbed or changed, then the warranty shall no longer valid.

The warranty covers only maintenance and repairing of material or workmanship

failure within the valid warranty period. Failures and parts within the scope of the

warranty are repaired and replaced without any charge. Used parts replaced will be

kept by the manufacturer.

Use or repair of the appliance with non-original parts shall also annul the warranty of

the appliance.

Any damage and failure arising from loading, unloading, shipment operations beyond

the responsibility of the manufacturer are not subject to the warranty. Similarly,

damages and failures caused by external factors during the operation of the appliance

are not covered by the warranty.

The consumer must apply to the technical service to be designated by the dealer

where the appliance is purchased.

SERVICE UNDER WARRANTY CAN ONLY BE RENDERED IF IS THE WARRANTY

CARD / INVOICE ARE PRESENTED.

!

Page 21

Loading...

Loading...