Page 1

LUBRICA TION

RETURN

The rod on which the product holder slides, which is underneath the slicer, should be

lubricated weekly with several drops of oil. Machine without oiler . Lift up the machine and

oil the rod directly . After the lubrication have the carriage sliding 4 or 5 times.

Use oil SHELL ONDINA 15 or ESSO MARCOL 82.

Occasionally , the slice thickness plate slide rod should be coated lightly with lubricant.

Turn the slice thickness control fully counterclockwise when lubricating this slide rod

and then turn it fully clockwise when finished.

DO NOT lubricate the rod on which the last slice device slides.

It must be kept clean but not lubricated. The motor has sealed bearings and requires no

lubrication maintenance.

INSTALLATION

MAINTENANCE

SLICER

GB

AX-S9 Ultra

AX-S10 Ultra

AX-S12 Ultra

AX-SD12 Ultra

WEAR ADJUSTMENT

After several years of operation and many sharpenings of the blade it may become

necessary to have the slice thickness plate adjusted closer to the blade.

Dimension mm

AX-S9Ultra AX-S10Ultra AX-S12Ultra AX-SD12Ultra

E 330 360 390 470

F 280 280 320 365

G 410 410 450 500

H 360 360 420 455

L 590 590 600 630

Motor Data AX-S9Ultra AX-S10Ultra AX-S12Ultra AX-SD12Ultra

Volts 115

Hz 60

Ph 1

Amp 1,5 1,5 2,5 2,5

N/min 1750

Weight AX-S9Ultra AX-S10Ultra AX-S12Ultra AX-SD12Ultra

Net kg 12 13 18 24

Brut kg 15 16 22 29

Slicing capacity mm

AX-S9Ultra AX-S10Ultra AX-S12Ultra AX-SD12Ultra

A 140 140 150 200

B 190 190 220 270

C 170 170 210 235

A

B

INSTALLATION

UNP ACKING

Immediately after unpacking the slicer , check it for possible shipping damage. If this

machine is found to be damaged after unpacking, save the packing material and contact

the carrier within 15 days of delivery .

Prior to installation, test the elettrical service to assure that it agrees with the

specifications on the machine data plate 1 .

ELECTRICAL

WARNING: THIS MACHINE IS PROVIDED WITH THIS PLUG MUST BE

CONNECTED TO PROPERL Y GROUNDING PLUG, GROUNDED OUTLET . IF THE

RECEPT ACLE IS NOT THE PROPER GROUNDING TYPE, CONT ACT AN

ELECTRICIAN.

CLEANING

This machine must be thoroughly cleaned and sanitized after installation and before

being put into service.

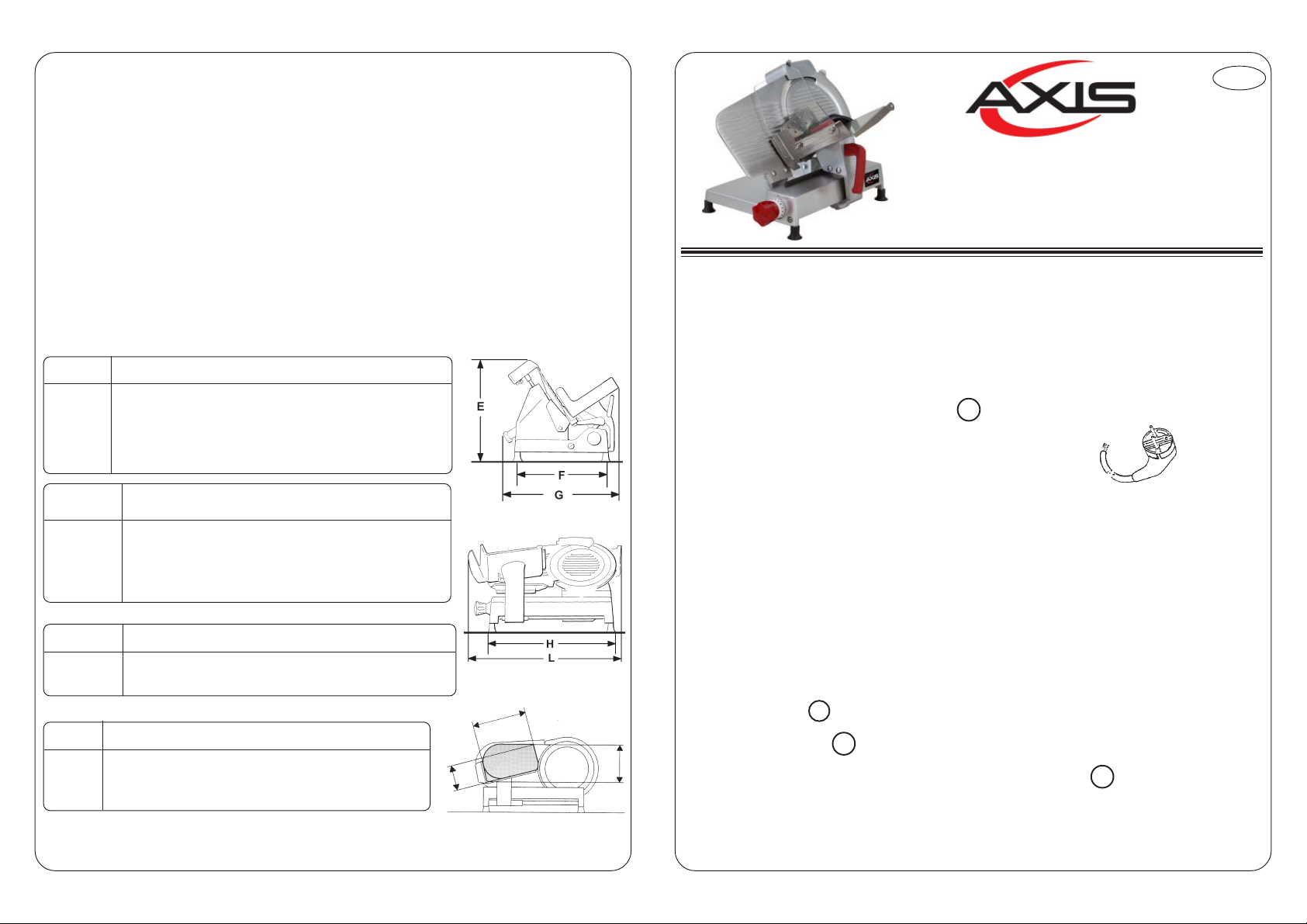

SAFETY

SAFETY DEVICES INCORPORA TED IN THIS SLICER MUST BE IN THEIR CORRECT

OPERA TING POSITIONS ANYTIME THE SLICER IS IN USE.

The blade cover 5 must be in position over the knife and secured by tightening

the hand knob.

The Iast slice device 4 must be used when slicing it keep your hands away from

C

the blade.

When the slicer is not running, the slicer thickness control 2 must be set on zero

(fuIly clockwise) to prevent the blade edge from being exposed. Always UNPLUG the

power cord before cleaning or moving the slicer.

PLEASE CALL AXIS EQUIPMENT FOR P ARTS & SER VICE FOR YOUR

SLICER A T: (514) 737-9701 / (888) 275-4538

Filename: Man_AX_S_Serie_Ultra_GB.PMD 03/02/15

Page 2

SLICING

PuII the product holder 3 toward you until

it stops and place the product to be sliced on

the product holder tray . Set the last slice

device 4 against the product and stwich on

the slicer by pressing the on-off stwich.

Adjust the slice thickness 7 by turning the

slice thickness control 2 .

The numbers on the slice thickness control

do not indicate actual measurements but

may be used for reference to duplicate slice

thickness.

Using the Iast slice device 4 handle push

the product holder 3 back and forth to slice. Always turn off the slicer and turn the

slice thickness control clockwise to zero when not slicing.

CLEANING

This machine must be thoroughly cleaned after each day’s operation or anytime it will

not be used for an extended period of time.

WARNING: UNPLUG MACHINE POWER CORD AND TURN THE INDEX KNOB FULL Y

CLOCKWISE BEFORE CLEANING THE SLICER.

Remove the slice deflector by removing its thumb screw.

Turnover product holder 3 . Pull the carriage up to its limit stop and rotate towards the

outside, by having the plate either removed or turned over , makes easier the cleaning of

remote spots otherwise difficult to be reached.

Using a mild soap and hot water solution and a clean cloth, wipe all surfaces of the slicer.

Thoroughly rinse it with another clean cloth and fresh water.

Remove the blade cover by removing the hand knob 5 .

With the hand knob removed, grasp the edge of the blade cover and carefully lift it straight

off the blade.

WARNING: THE SLICER BLADE IS VERY SHARP USE EXTREME CAUTION WHEN

WORKING NEAR THE BLADE.

CAREFULL Y wash both sides of the blade with the slice thickness control turned fully

clockwise. Wash the blade by wiping outward from the center . AL WA YS rinse the blade

thorougthly using fresh water and a clean cloth. Never use steel pads it clean the blade.

Wash and thoroughly rinse the removed components prior to reassembling them. DO

NOT wash any slicer components in a dishwasher .

MAINTENANCE

ATTENTION

Use protection gloves

ELECTRICAL SAFETY

When the slicer is running the eventual removal of the blade cover

electric power, causes the stop of the machine.

6

7

2

5

4

3

, or the default of

1

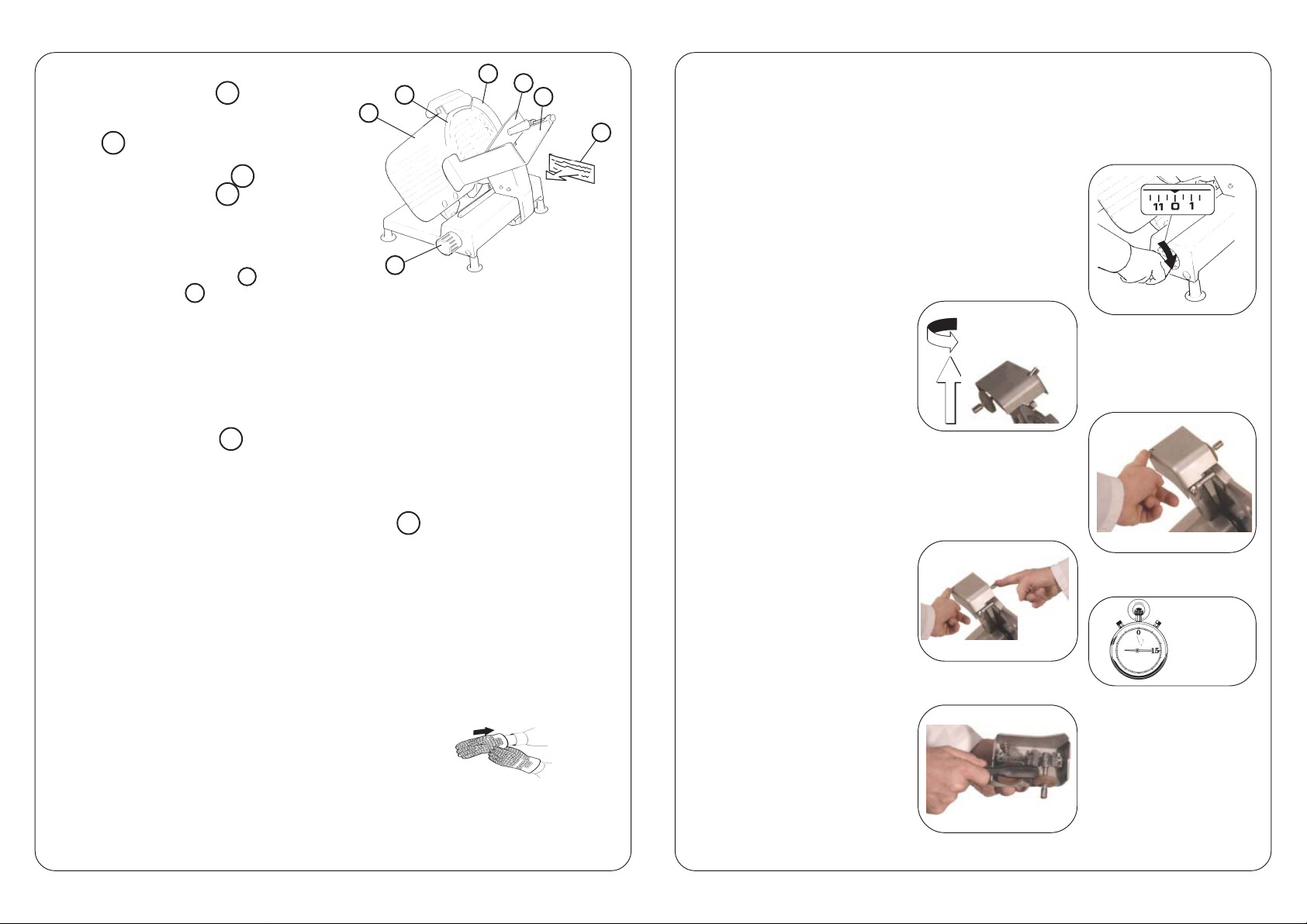

SHARPENING OPERA TION

Your slicer blade will provide long service in normal deli, food store, or commercial

kitchen use.

However, in high volume applications where it is a practice to sharpen the blade frequently

or even daily , the blade will be expended in a shorter time.

For a correct sharpening of the

blade follow these instructions:

Make sure that the machine off.

1

Clean the blade removing any

2

greasy residue.

Rotate the slice thickness control

3

to zero to make sure that the blade

is covered by the slice thickness

plate.

ATTENTION: During the sharpening operations, pay

attention to an accidental

contact with the blade.

Slip off completely the sharpener

4

and spin it 180 degrees.

Sharpening: Press the

5

sharpening wheel for about 10-15

seconds, then press

simultaneously also the grinding

stone for two seconds.

Contemporaneously loosen the

two grindstones.

Lift and rotate 180 degrees the

6

sharpener and reallocate it into

its initial position.

Cleaning of the grinding wheels

For an adequate sharpening the

grinding wheel must always be

clean. Remove dirt and grease with

alcohol and using a brush.

180°

STOP

Loading...

Loading...