Page 1

INSTALLATION

MAINTENANCE

SLICER AX-S12BA

INSTALLATION

UNPACKING

Immediatelyondeliveryunloading,please chekwhether machinepackagingiseventuallydeteriorated

and in this case make necessary reservetions on signing the delivery note. You will than check the

machineinsidepackagingand eventuallycontact immediatelythecarrier whenit isdamaged.

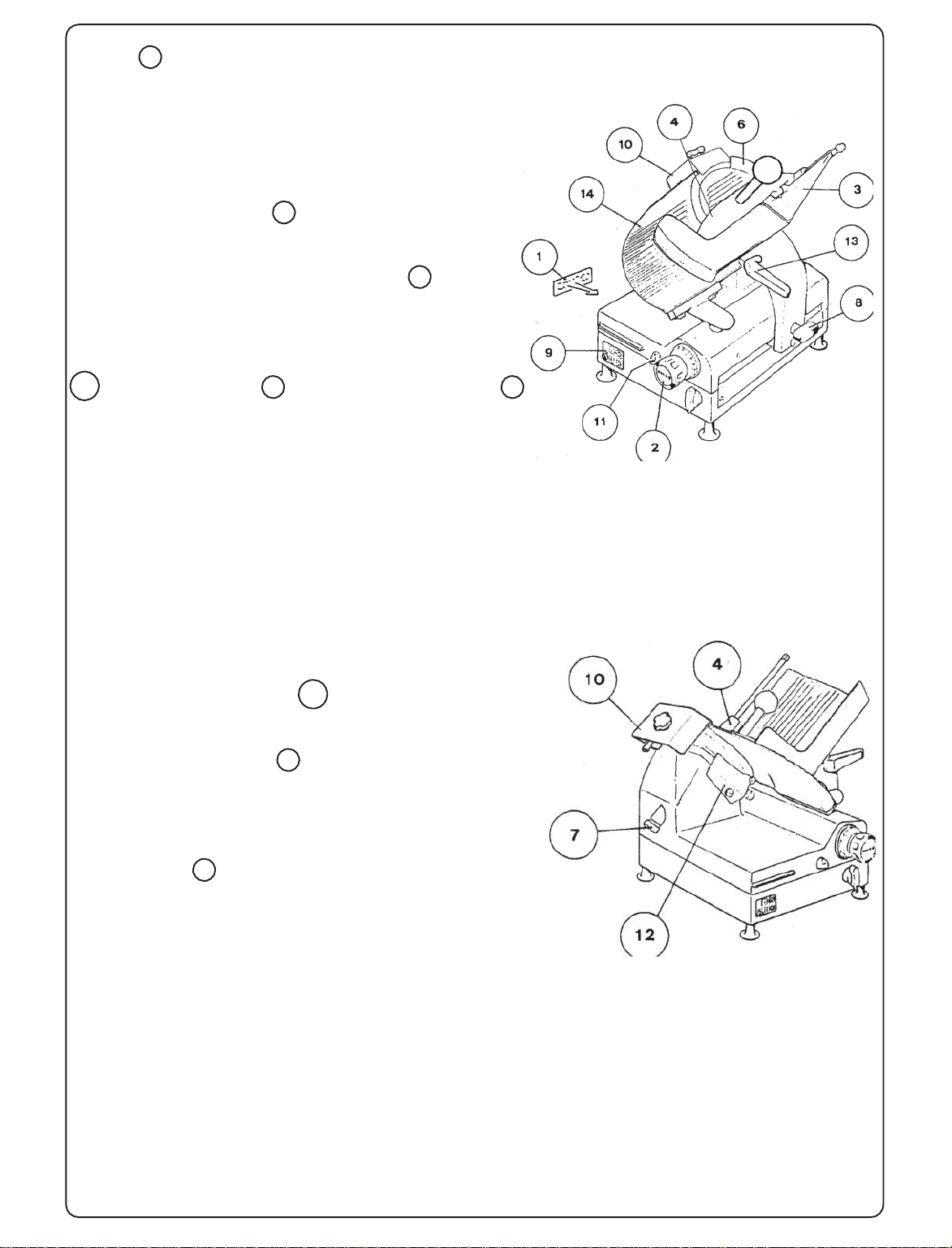

Priortoinstallation,testthe elettricalservicetoassurethatit isincompliancewiththespecificationson

the machine data plate 1 .

ELECTRICAL

Warning:THIS MACHINE IS PROVIDEDWITHTHIS PLUG MUSTBE CONNECTED

TO PROPERLYGROUNDING PLUG, GROUNDED OUTLET. IF THE RECEPTACLE IS NOT THE

PROPERGROUNDINGTYPE,CONTACTANELECTRICIAN.

CLEANING

This machine musi be thoroughly cleaned and sanitized after installation and before being put into

service.

SAFETY

SAFETYDEVICESINCORPORATEDINTHISSLICERMUSTBEINTHEIR

CORRECTOPERATINGPOSITIONEVERYTIMETHESLICERISIN USE.

The blade cover 6 must bein position over theknife andsecured bytightening

thehand knob 7 .

TheIast slice device 4 must be used when slicing,it keeps your hands awayfrom the knife.

1/4

Page 2

When the siicer is not working, the slicer thickness

control 2 mustbesetonzero(fuIlyclockwise)toprevent

theblade edge from being exposed.

AlwaysUNPLUGthepowercordbeforecleaningormoving

theslicer.

SLICING

PuII the product holder 3 towards you until it stops

andplace theproduct tobe sliced on the productholder

tray. Place the last slice device against the product and

start the slicerbypressingthe on-off swtich 9 . Adjust the

slicethickness byturningthe slicethicknesscontrol. The

numbers on the slice thickness control donot indicate

precise measurement, but may be used for reference to

duplicateslicethickness.Usingeitherthecarriagehandle

13 orIastslice device 4 push the product holder 3

back and forth to slice. Always swtich-off the slicer and

turnthe slice thickness control clockwise to zero when

notslicing.

WARNING:Slicershouldnotbeoperatedbyuntrained

personnelorpersonsunder 18yearsofage.

CLEANING

Thismachinemustbe thoroughlycleanedaftereachday’s

operationor every time it willnot beused for an extended

period.

WARNING: UNPLUGMACHINE POWERCORD

AND TURN THE INDEX KNOB FULLY CLOCKWISE

BEFORECLEANINGTHE SLICER.

Removethe slicedeflector 12 byremoving itsthumb

screw.

Theproductholdercanberemovedforaneasycleaning

byunfastening its handle 8 .

Usingamildsoapandhotwatersolutionandacleancloth,

wipeall surfaces of theslicer.

Thoroughlyrinseitwithanothercleanclothandfreshwater.

Removethe bladecover byremoving

the hand knob 7 . With thehand knob removed,grasp

theedge of the blade cover andcarefully liftit straightoff

theknife.

WARNING:THE SLICERBLADEIS VERYSHARPUSE

EXTREME CAUTION WHEN WORKING NEAR THE

BLADE.

CAREFULLY wash both sides of the blade with the slice

thicknesscontrolturnedfullyclockwise. Washtheblade

by wiping outward from the center. ALWAYS rinse the

bladethoruogthlyusingfreshwaterandacleancloth.Never

use steel pads it clean the blade. Wash and thoroughly

rinse theremovedcamponentspriortoreassembling them.

DONOT washanyslicer componentsina dishwasher.

2/4

Page 3

MAINTENANCE

ATTENTION

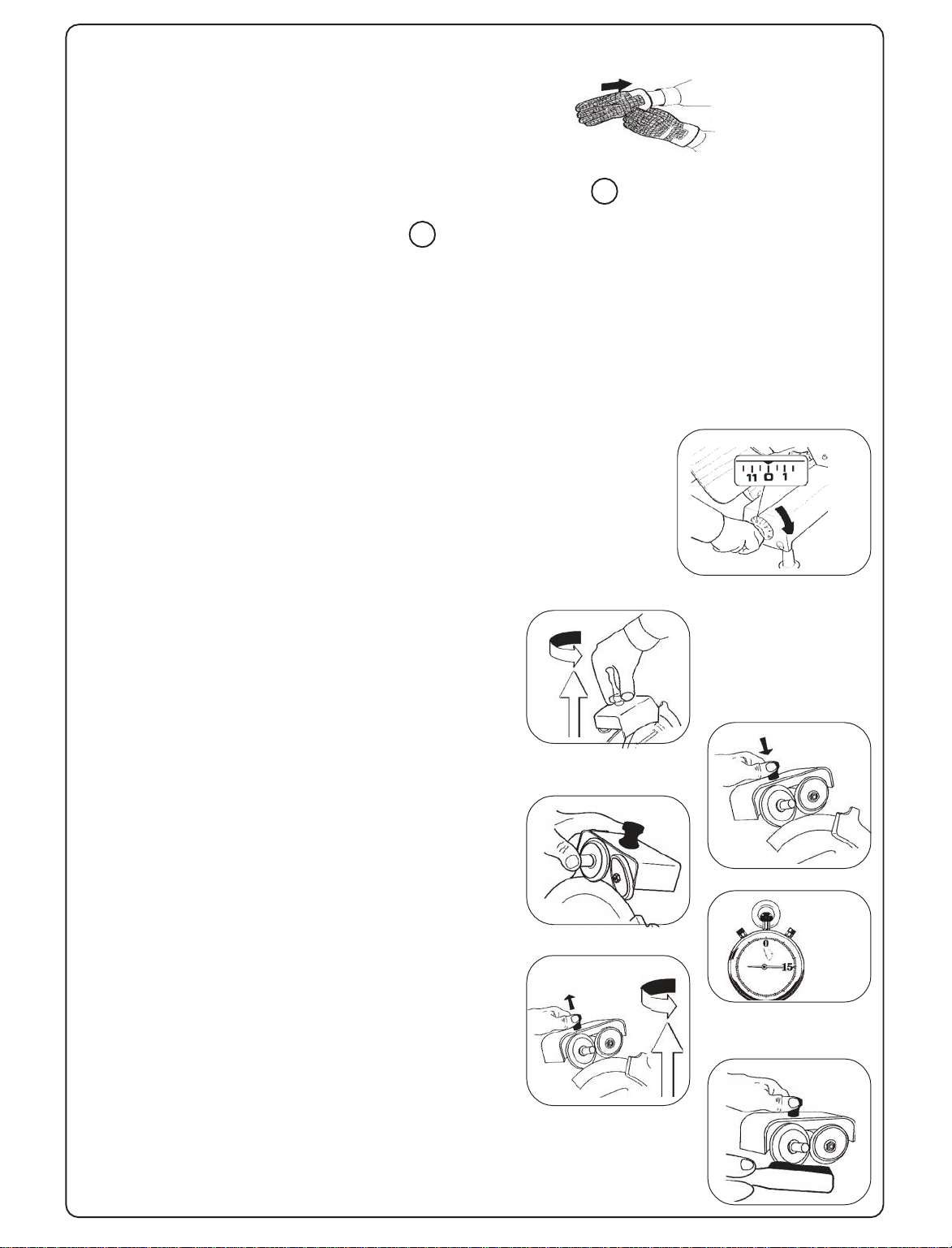

Use protection gloves

ELECTRICAL SAFETY

When theslicer is runningthe eventual removal of theblade cover 6 , or the default of electricpower,

causesthe stop of themachine.

To restartthe slicer press the on-off switch 9 .

SHARPENING OPERATION

Your slicerblade will providelongservice innormal deli,food store,or commercialkitchenuse.

However,inhighvolumeapplicationswhereitisapracticetosharpenthebladefrequently orevendaily,

theblade will be expended in a shorter time.

For a correct sharpening of the blade follow these

instructions:

1 Makesure thatthe machineis off.

2 Cleanthe bladeremovingany greasyresidue.

3 Rotatethe slicethickness control tozero to make

surethat the blade is coveredby theslice thickness

plate.

ATTENTION

During the sharpening operations, pay attention

to an accidental contact with the blade.

4 Fullyliftup and turnit by 180°thesharpenerdevice

5 Pressthe grinding wheel pushbuttonand putback

inits placethe sharpenerdevice.

180°

6 Sharpening: Press pushbuttonto start the machine

andstartthe automaticsharpeningoperation. After

10max.15secondspressthehoningstonebuttonand

pushthewheeltowards theblade.Afterafewseconds,

withthetwowheelsincontactwiththeblade, pressthe

stoppushbutton

7 Lift androtate of 180° the sharpenerandreset

it into its initial position

Cleaning of the grinding wheels

For an adequate sharpening the grinding wheel must

alwaysbecleaned.Removedirt and greasewith alcohol

byusingabrush.

180°

STOP

Page 4

GLM 300

A

170

B

210

C

240

D

210

¾

DEFINITIONS

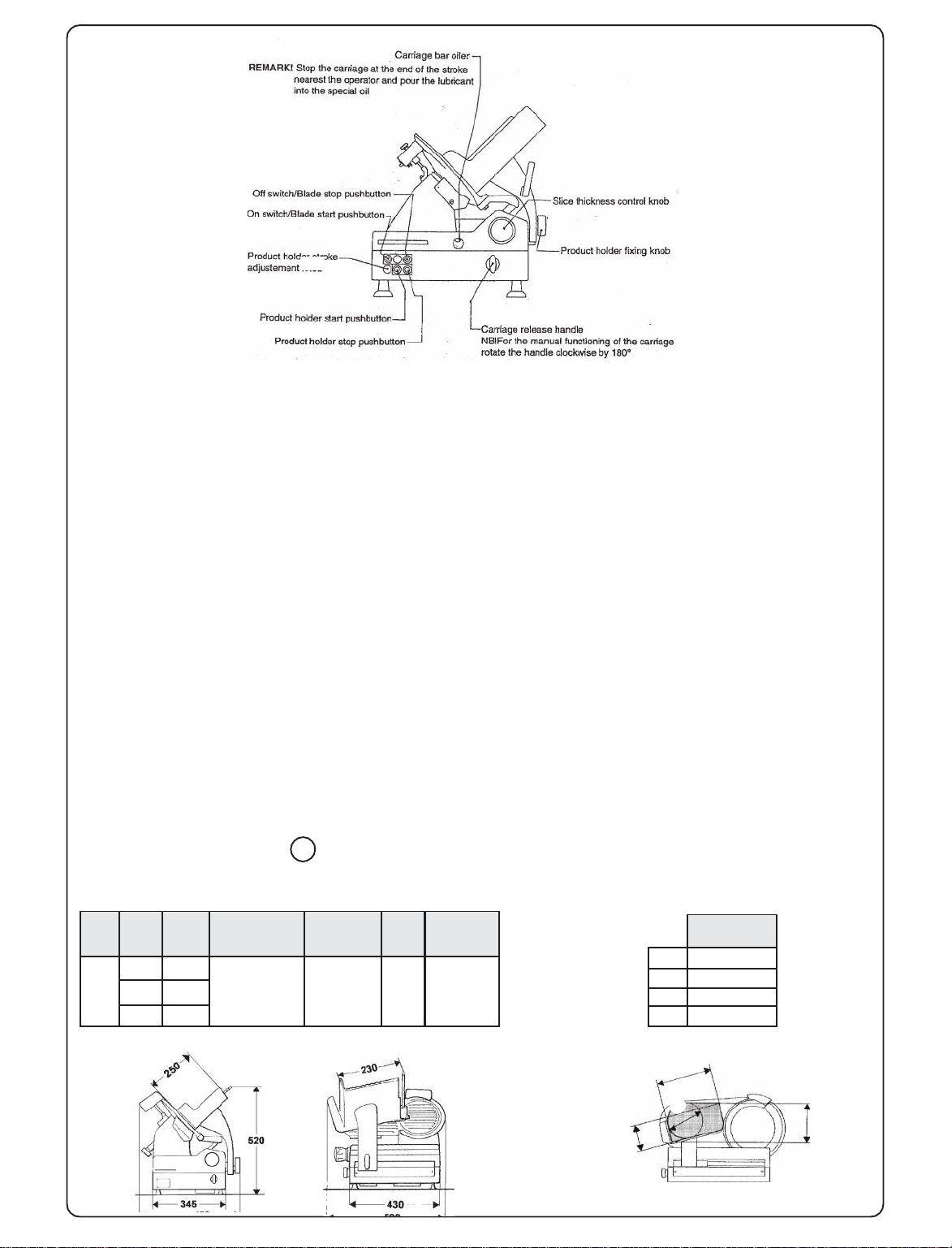

MANUAL OPER ATION

Ro tat e th e AU T O/MANUA L selecto r carriag e releas e handl e b y 1800,clockwise

Pus h th e on switch/blad e star t pushbutton

Adjus t th e thicknes s yo u wan t b y turnin g th e slic e thicknes s contro l knob

Actuat e th e carri ag e by you r hand

Pus h th e off switch/blad e sto p pushbutton

AU T OM ATIC OPER ATION

Ro tat e th e AU TO/MANUA L selecto r carriag e releas e handl e b y 1800, counterclockwise

Pus h th e on switch/blad e star t pushbutton

Adjus t th e thicknes s yo u wan t b y turnin g th e slic e thicknes s contro l knob

Pus h th e produc t holde r star t pushbutton

Adjus t th e lengt h of th e strok e by turnin g th e produc t holde r strok e adjustment

Pus h th e produc t holde r sto p pushbutto n to en d carriag e movement

Pus h th e off switc h bIad e sto p pushbutton

LUBR IC A TIO N

Th e ro d o n whic h th e

produc t holde r

slides , whic h is underneat h th e slice r, shoul d b e lubricated

weekl y wit h severa l dro ps o f oil . Sto p th e carriag e at th e en d of th e strok e neares t th e operato r position

an d pou r th e Iubrican t int o th e specia l oile r. D O NO T us e vege tabl e oil . Occasionall y, th e slic e thickness

plat e slid e rod shoul d be coate d Iightl y wit h lubricant . Tur n th e slic e thicknes s contro l full y counterclockwise

whe n Iubricatin g this slid e ro d an d the n tur n it full y clockwis e whe n finished . D O NO T lubricat e th e ro d on

which the

last slice device slides.

It must be kept clean but not lubricated. The motor has sealed

bearing s an d require s no Iubricatio n maintenance.

WEAR ADJUSTMENT

Afte r several , year s of operatio n an d man y sharpening s o f th e

blad e

it ma y becom e necessar y to have

the slice

thickness plate 14

adjusted closer to the blade.

Motors electrical data

WVH z

Phase N°

Service

A

IP

Degree of

Protection

230

50

220

60

390

120

60

1~

S1733

Slicing capacity m m

Page 5

AFFETTASALUMI AUTOMATICHE A GRAVITÀ

AUTOMATIC GRAVITY FEED SLICERS

TRANCHEURS AUTOMATIQUES POUR CHARCUTERIE

AUTOMATISCHE SCHWERKRAFTAUFSCHNITTMASCHINEN

AX-S12BA

PEZZI DI RICAMBIO

SPARE PARTS LIST

Page 6

07 - 07 - 04

1

D 5851 n.4

V 634515

P 5017 n.4

C 6778

n.4

D 0135X

I 1926

B 1870

M 7023

D 5806

V 620615 n.2

S 7568

P 7404

V 6065

S 7612

S 7539

V 6285

P 8006

A 5446

n.2

M 0802

B 1317

C 4813

V 6065

V 625315

E 1409A

P 4621 n.2

T 1025

V 6460X

V 6461X

S 8907

n.2

D 0167

R 6840

A 5446

n.2

A 5470 n.2

V 705616

V 8017

R 6520X

S 9112

M 0810

B 5033

S 8910

S 8907

MOD.

dal/from Ser.Nr.

fino al/to Ser.Nr.

C 6784

A 5470

C 8006 n.2

GLMATIC 300

V 8085 n.4

n.2

P 3303A

P 1034

B 6009 n.4

M 7016 n.2

R 6840

C 8006

R 6520X

n.2

n.2

V 6460X n.2

P 3302A

C 4814

S 7523 n.2

B 5032

A 5404X

n.2

Page 7

M 8260

I 3780

M 8051

D 0153X

-120V/60Hz-1

THERMAL PROT.

n.2

C 5833

120V/60Hz

P 2014

V 8052

S 7512

V 8048

MOD.

dal/from Ser.Nr.

fino al/to Ser.Nr.

16 - 09 - 08

GLM300 “ETL”

2

C 3654 n.2

R 6512X n.4

D 0155X n.2

B 5096

R 6520X

V 6460X

C 3263

R 4031

V 7023

T 1763

D 0101

S 9265

C 6024

n.2

P 3536

V 804501

P 2017

S 3234

P 8620

C 3264

V 6450X

n.2

n.4

P 8626

P 8057

n.2

n.4

V 4011

V 6279

T 1022

M 7132

-120V/60Hz-1

S 9315

V 6065

n.2

n.4

n.2

V 634015

V 8048

n.2

R 6508X n.2

n.2

I 3647

S 9134

S 9113

C 6583

R 6504

V 6278

B 6155

S 3262

120V/60Hz

I 3646

T 1001

P 7925

V 6066

V 634015 n.2

V 6279

V 6279

P 2009

n.6

R 6927 n.6

P 4787

n.2

P 2008

V 6206

R 6003

M 8054

C 3265

S 101875

V 6278

n.2

D 5715 n.2

V 6293

n.2

C 5809 -120V/60Hz

I 1683

V 6291

n.3

R 6508

n.3

V 6285

P 2001

n.4

C 6577

R 4002

120V/60Hz n.2

M 8050

C 3633

D 0135

V 6403

M 8052

Page 8

A 5403

D 0153X

S 7527

R 6804

V 7020

P 3423

V 6064

S 9089

V 7915

P 6805A

C 4601

C 4602

n.20

n.13

P 1034

n.2

I 1901A

V 6083

MOD.

dal/from Ser.Nr.

fino al/to Ser.Nr.

B 6052 n.2

30 - 01 - 07 3

GL MATIC 300

P 6905A

C 4640

T 1690

O 4040

B 1270

P 1134

I 1942

P 103401

M 7030 n.2

D 5762

n.2

D 0165

D 5863

B 6057

B 1360

S 7542

B 1086

F 1610

n.2

C 187361

V 7917

D 0163

B 1861

C 6246

n.2

V 6066

D 0165

D 0135X

F 3019

P 1001

D 5873

P 7431

V 8036

V 7053X

S 8804A

C 8067

P 3583

I 1936

P 4411A

V 602115 n.2

P 4511A

B 1330A

R 6810

D 0165X

D 0155X

R 6520

T 1003

P 1012

n.2

n.2

I 203576

Page 9

27 - 11 - 02 4

T 8521

P 4621

V 6462X

I 1926

V 3029

B 6104B

G 5027

B 6144

R 6806

D 0135X

T 5002

T 5032

V 6067

L 0612

V 7014X

C 5001

R 6905

R 6870

MOD.

dal/from Ser.Nr.

fino al/to Ser.Nr.

GLMATIC 300

P 1533

I 1990A

T 1606

T 1603

M 7071

V 6212

R 6840

T 1617A

F 6090

I 1970A

D 0102

M 7052

R 6840

B 6057

E 1420

B 6211

V 7934

D 0163

S 3802

V 6066

R 6030

D 0163

V 6331

P 4661

V 6496

V 7917

M 7032

Page 10

A 5475

C 8022

A 5910

MOD.

03 - 05 - 06

GLMATIC 300

5

B 6192

P 3391

A 5446

C 8007

A 5475

E 1457

V 6253

P 8053

M 8345 M 8356 M 8495 M 8258 -

A 5905

V 6278

C 4813

V 8020

120V/60Hz-1

220-240V/50Hz-1

220V/60Hz-1

110V/50Hz-1

dal/from Ser.Nr.

fino al/to Ser.Nr.

R 6505

T 8044

D 0102

C 5812 C 5806A C 5807

120V/60Hz

220-240V/50-60Hz

n.2 - 110V/50HZ

T 5024

A 5472

C 6452

C 8015

C 8007

P 2013

R 8054

S 8511 S 8510 S 8445 S 8567 -

C 6444

120V/60Hz-1

220-240V/50Hz-1

220V/60Hz-1

110V/50Hz-1

Page 11

03 - 04 - 04

1

C 1601

R 6903

A 5403

C 6803

R 6508

V 6484

M 7017

P 3222

I 1953

V 6215

M 7017

P 3221

M 6622

R 6854

D 0133

S 3005

MOD.

dal/from Ser.Nr.

fino al/to Ser.Nr.

A 1001

AFFILATOIO A1019

A 1019

V 7901

P 8601

M 6601

R 6854

D 0133

Loading...

Loading...