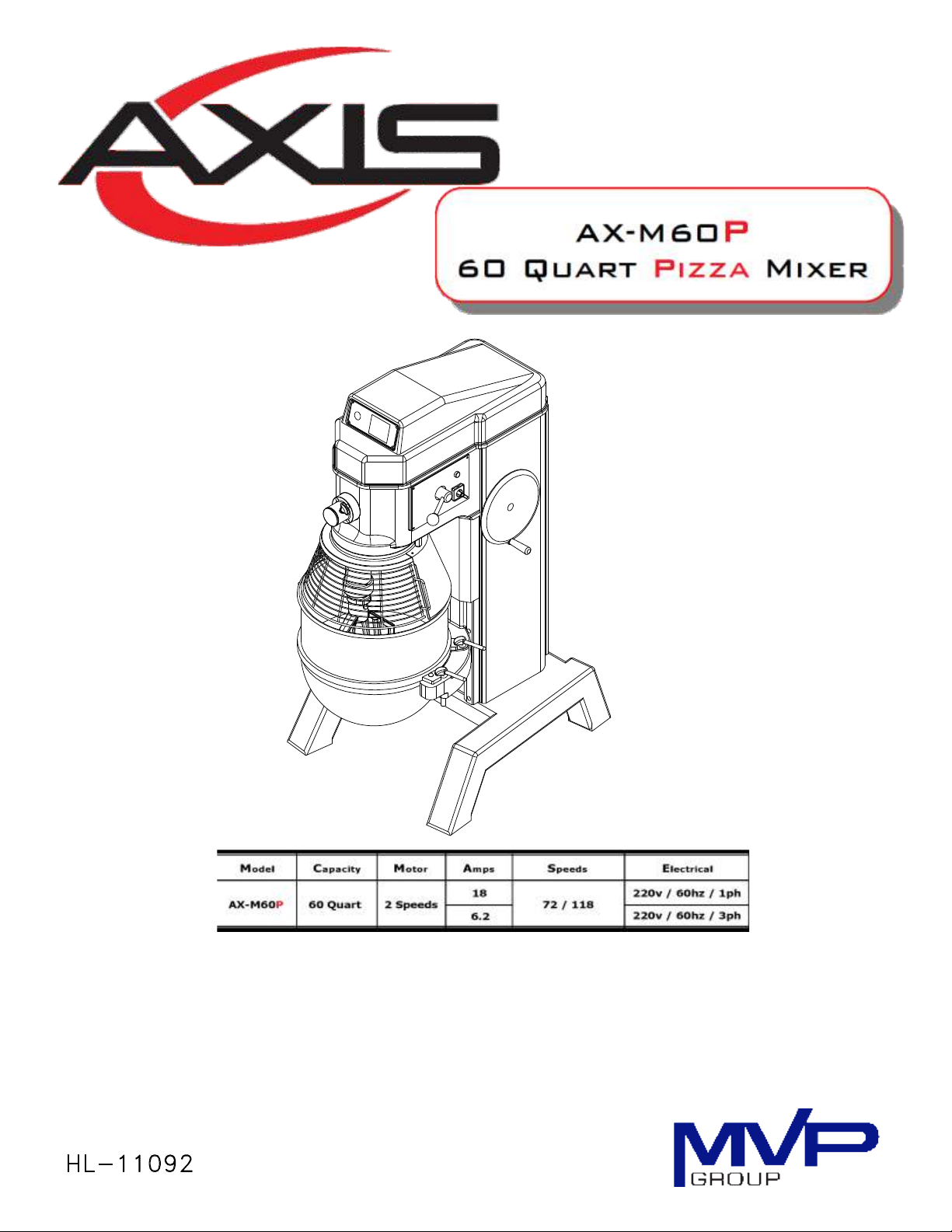

Page 1

REV:201509.01

1

TECHNICAL MANUAL

Page 2

INSTALLATION, OPERATION AND CARE

OF MODEL AX-M60P

GENERAL

The AX-M60 planetary mixer is an advance design, highly reliable professional food processing tool,

and is ideal for mixing all types of dough as well as eggs, cream, mayonnaise, etc.

There are 2 speeds and various style attachments which can be selected. They are made of alloy

aluminum to meet with hygiene standard.

This model mixers is equipped with powerful 3 HP motors and strong gear drive design. The gears are

made of heat-treated alloy steel and a harnessed steel worm wheel.

If your operation and maintenance are correct, then it will give you years of service, and obtain the best

using result.

INSTALLATION

UNPACKING

Immediately before unpacking mixer, check it for possible shipping damage. If you find the packaging

material or the machine is damaged before unpacking, contact the carrier within 3 days of delivery.

Prior to installation, test the electrical service to assure it agrees with the specifications on the machine

data place located on the backside of the pedestal.

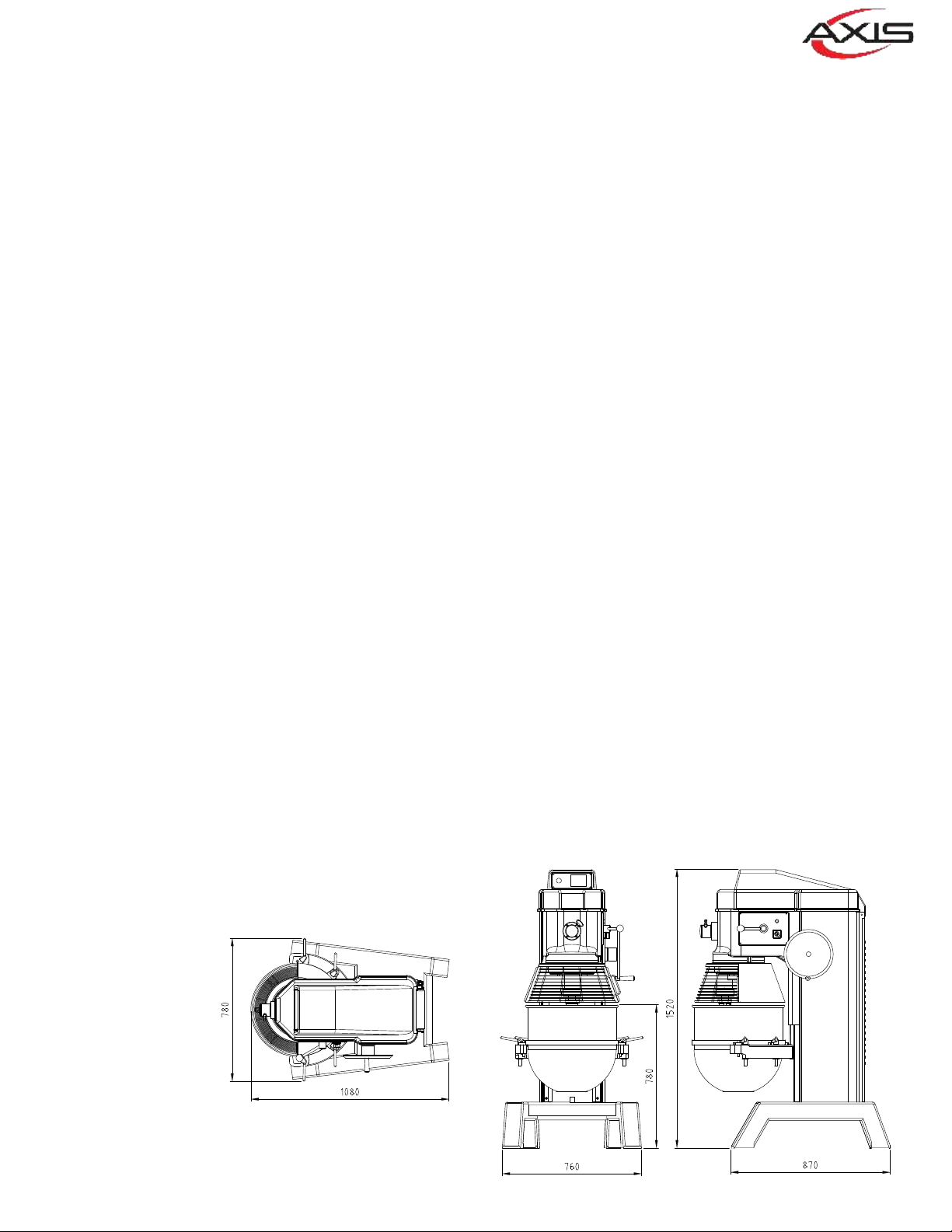

LOCATION

Place the Mixer in a convenient location, and allow working space on the hand-wheel or power bowl lift

switch side. All maintenance can be handled from this side, the top and the front. Set the mixer level

and use shims if the floor is uneven, the machined edge on the top of the transmission case makes an

excellent surface for leveling.

2

Page 3

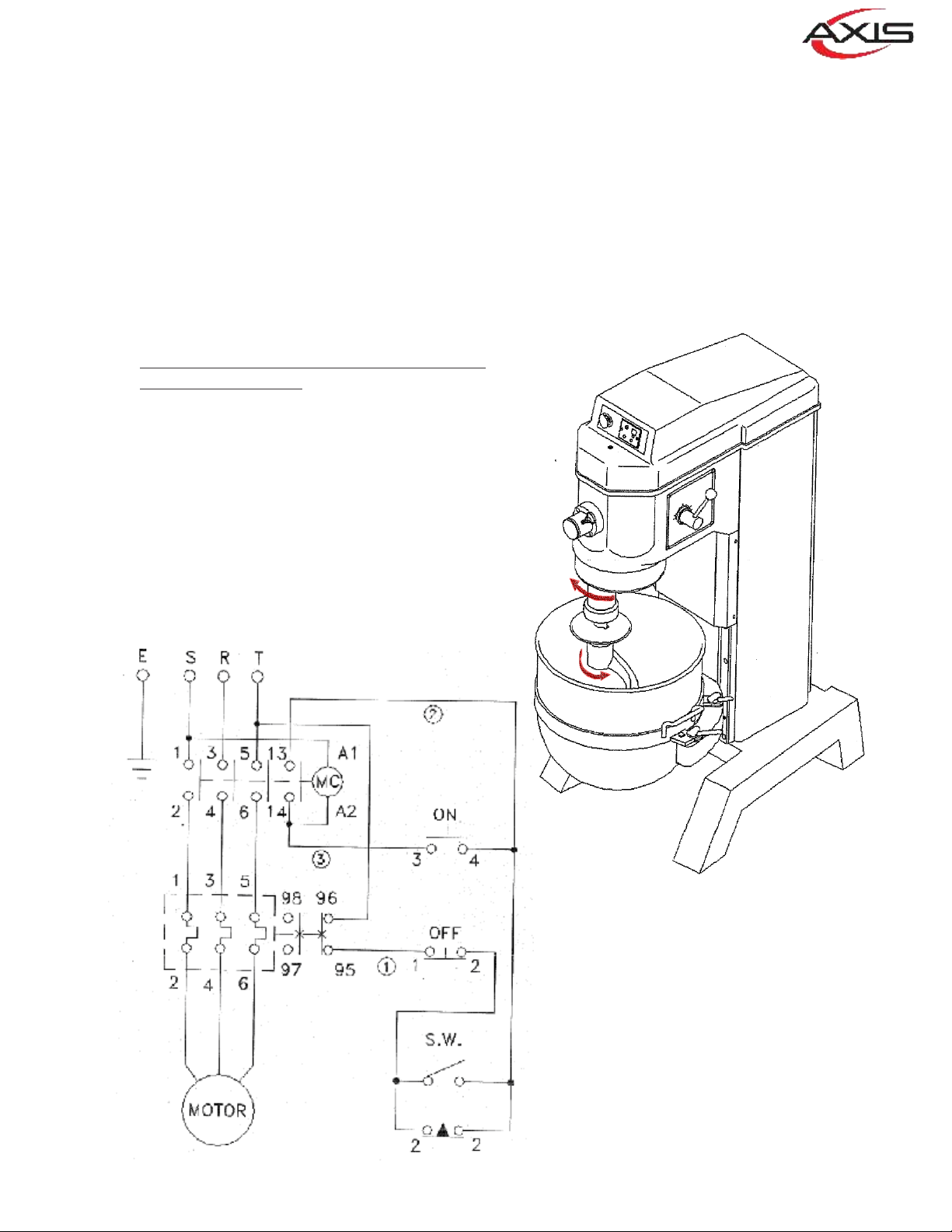

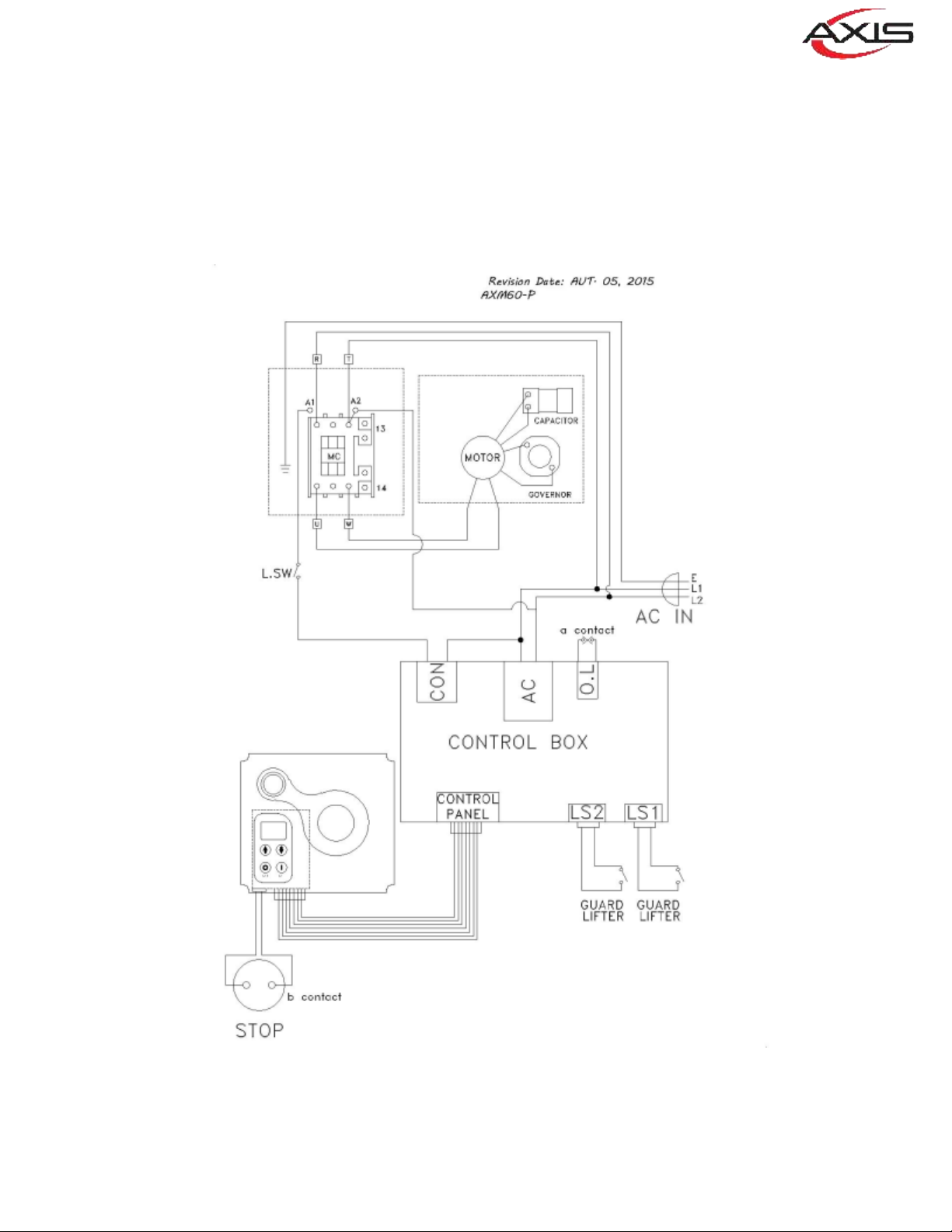

Electrical Connections (Cord Connected Mixers)

· Before making the electrical connections, read the specifications on the nameplate to

make sure that they agree with those of your electric service.

· Electrical connections should be made by qualified technician or electrician, who will

observe all applicable Safety Codes and the

National Electrical Code.

· Be sure the planetary runs in the direction

shown by the arrow in the planetary head.

Reverse direction is forbidden.

· To start motor, push ON button. The speed

selector handle must be at one of the

numbers indicating a speed, not at an

intermediate position.

On a 3 Phase Mixer, the installer must check the

mixing rotation of the planetary when the

electrical is connected.

3

Page 4

4

Page 5

OPERATION

WARNING: MOVING PARTS,

BEATER OR HOOK IN BOWL; KEEP

HANDS, CLOTHING, AND UTENSILS

OUT WHILE IN OPERATION.

All models are furnished with two

buon-switches, which control

power to the mixer.

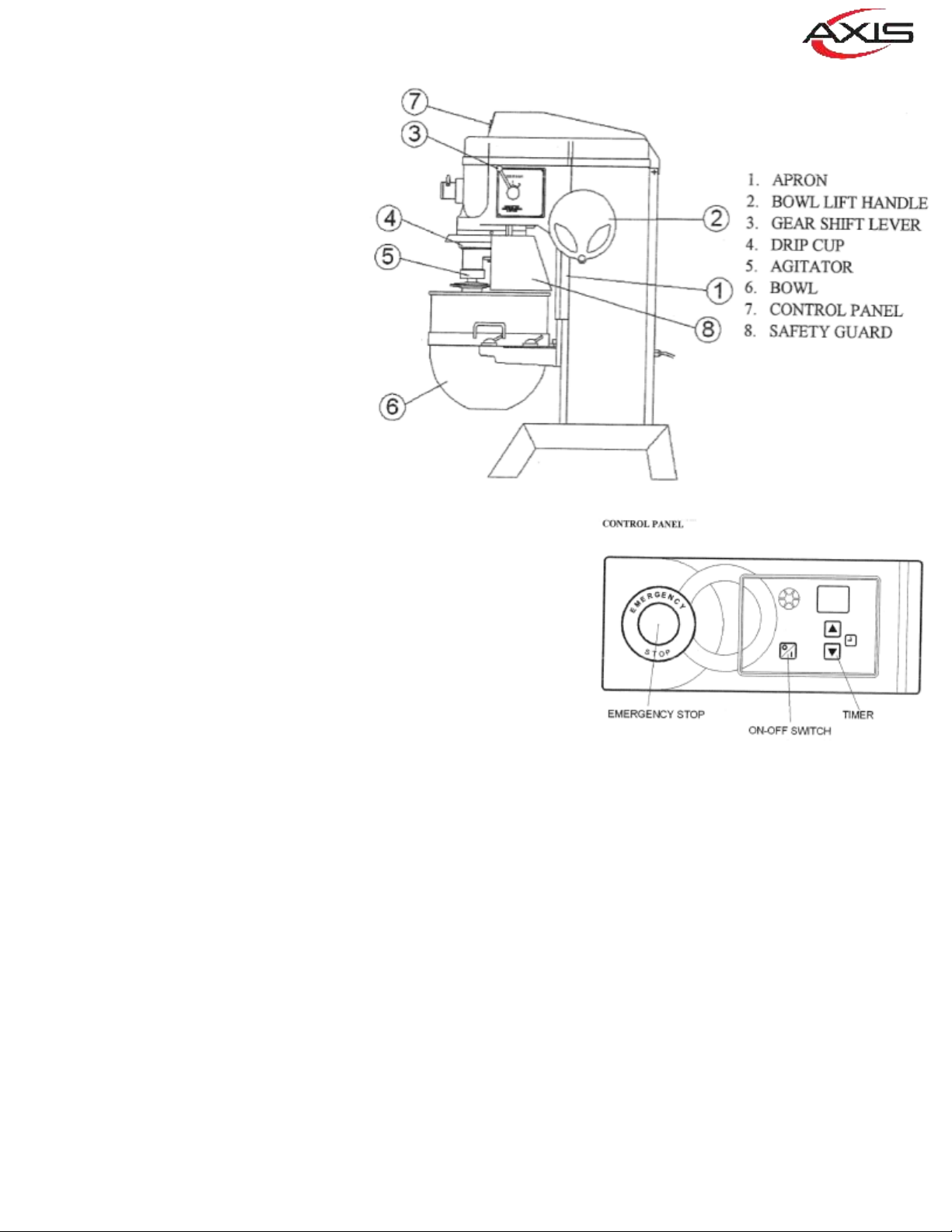

The GEAR SHIFT LEVER (No.3) is

used to change speed. Always stop

the mixer before changing speeds.

To change speeds, turn the switch

OFF, move the gearshi lever to

the desired speed, and turn the

switch back ON.

· Speed 1 (low) – This speed

is for heavy mixtures such

as bread dough, heavy

baers, and potatoes.

· Speed 2 (medium) – This speed is for light dough which

must rise quickly, heavy baers, and some whipping

operaons.

DOUGH HOOK:

To install the dough hook (No 5), the bowl must be installed and

fully lowered. Place the hook in the bowl, push it up on agitator

sha, and turn it clockwise to seat the sha pin in the slot of the

agitator shank.

It is frequently used for heavy bread dough, and preferable to be

use at low speed.

The moisture content of heavy dough is a crical when selecng

proper mixing speed. You should never use 2 speed when

mixing heavy dough with an Absorpon Rao (AR) of 50% or

less.

BOWL – CAPACITY: 60 QUART

New mixers bowls and dough hook should be removed and thoroughly washed with hot water and mild soap

soluon, rinsed with either a mild soda or vinegar soluon, and thoroughly rinsed with clean water BEFORE

being put into service. This cleaning procedure should also be done daily or aer each use.

The bowl must be installed before the agitator. To install the bowl, fully lower the bowl support. Posion the

bowl so the alignment bracket on the back of the bowl is in the bowl retainer and the alignment pins on the

front of the bowl support fit in the holes on the sides of the bowl.

nd

ATTACHMENTS

To install an aachment, loosen the thumbscrew on the aachment hub and remove the plug. Insert the

aachment into the aachment hub making certain that the square shank of the aachment is in the square

driver of the mixer. Secure the aachment by ghtening the thumbscrew.

Move the gearshi lever to the desired speed and star the mixer to operate the aachment.

The meat and food chopper aachment should be operated in second or third speed. If material in the cylinder

stalls the mixer, stop the mixer at once. DO NOT aempt to restart the mixer in a lower speed – remove the

adjusng ring, knife, plate, and worm and clear the obstrucon.

5

Page 6

MAINTENANCE

CAPACITY (QTS. LIQUID) 60 qt.

Egg Whites Wire Whip 2 qt.

Mashed Potatoes Flat Beater 40 lbs.

Mayonnaise (Qts. Oil) Flat Beater 18 qt.

Meringue (Qts. Water) Wire Whip 1.5 qt.

Waffle/Pancake Batter Flat Beater 24 qts.

Whipped Cream Wire Whip 12 qts.

Sheet Cake Batter Flat Beater 45 lbs.

Cup Cake Flat Beater 50 dz.

Layer Cake Flat Beater 70 lbs.

Pound Cake Flat Beater 55 lbs.

Sugar Cookie Flat Beater 100 dz.

Bread or Roll Dough (Light/Medium,

60% AR, =) Dough Hook 80 bs.**

Bread or Roll Dough (Heavy, 55% AR, =) Dough Hook 60 lbs.**

Pie Dough Flat Beater 50 lbs.

Thin Pizza Dough (40% AR, = , 5

min.max. mix time) Dough Hook 40 lbs.**

Medium Pizza Dough (50% AR, =) Dough Hook 70 lbs.*

Thick Pizza Dough (60% AR, =) Dough Hook 70 lbs.**

Raised Donut Dough (65% AR) Dough Hook 30 lbs.*

Whole Wheat Bread Dough (70% AR) Dough Hook 70 lbs.**

Egg & Sugar for Sponge Cake Flat Beater 24 lbs.*

* 1st speed ** 2nd Speed

* = If high gluten flour is used, reduce above dough batch size by

NOTE: All maintenance work should be done only aer unit has been disconnected from electrical power

and grounding.

CLEANING

Never use a metal or sff brush to clean mixer. Never clean the mixer with a water hose

or any fluid under pressure.

The mixer should be thoroughly cleaned daily.

Bowl and agitators should be removed from the mixer and cleaned in a sink.

The transmission case and planetary mechanism should be inspected weekly for leaks,

damage, etc. should it become necessary to repack the ball bearings; an authorized

service technician or the manufacturer should be contacted. Use of unapproved grease of

lubricants may lead to damage and void the unit's warranty.

The bowl li track should be lubricated semi-annually, or more oen under heavy usage. Disconnect the unit

from power supply before removing the top housing or apron. The drip cup (Fig. 1)? should be inspected

periodically for moisture or lubricant dripping. Remove the cup and wipe it with a so cloth.

DO NOT use a hose to clean the mixer – it should be washed with a clean damp cloth.

MIXING HEAVY DOUGH

The moisture content of heavy dough is a crical factor when selecng proper mixing speed. You should never

nd

use 2 speed when mixing heavy dough with an Absorpon Rao (AR) of 50% or less.

To determine the Absorpon Rao (AR) of a product, divide the water weight by the flour weight.

Example: Calculate the Absorpon Rao of a mixture containing 10 lbs. of flour and 5 lbs. of water.

10 ÷ 5 = 0.50 = 50% = AR

6

Page 7

7

1

Page 8

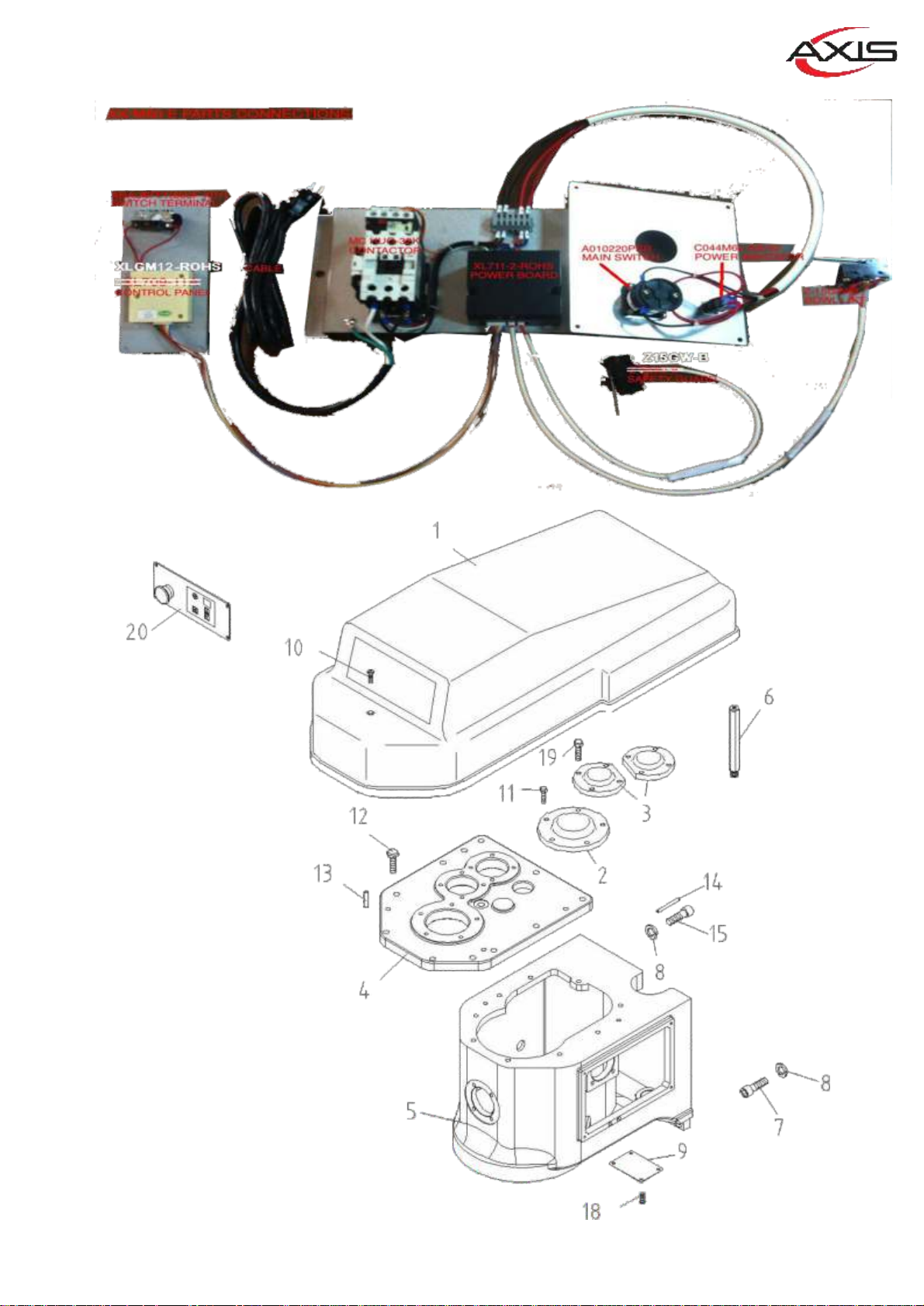

Description or Name Parts No. Qty

TOP COVER

1

RETAINER- MAIN SHAFT

2

RETAINER- TRANSMISSION SHAFT

3

GEAR HOUSE COVER

4

TRANSMISSION CASE

5

SUPPORT TO TOP COVER

6

SCREW

7

SPRING WASHER 1/2"

8

COVER PLATE

9

SCREW

10

BOLT 5/16*3/4

11

BOLT 3/8*1- 1/4

12

SPRING PIN 6*28

13

11091-01-001A 1

1109S-01-002 1

1109S-01-003 2

1109S-01-004 1

11100B-01-005 1

1109S-01-006 1

S-C-1/2*1-1/4 2

SW-1/2 6

BM10-01-006 1

S+BR-1/4*3/8 1

S-5/16*3/4 5

S-3/8*1-1/4 8

SPP-6*28 4

SPRING PIN 10*50

14

SCREW

15

MACH SCREW 3/16*3/8

16

OIL COCK

17

MACH SCREW 3/16*3/8

18

BOLT 5/16*1/2

19

CONTROL PANEL

20

SPP-10*50 2

S-C-1/2*2-1/4 4

S+R3/16*3/8 4

712-050 1

S+R3/16*3/8 4

S-5/16*1/2 8

11091-01-011B 1

8

Page 9

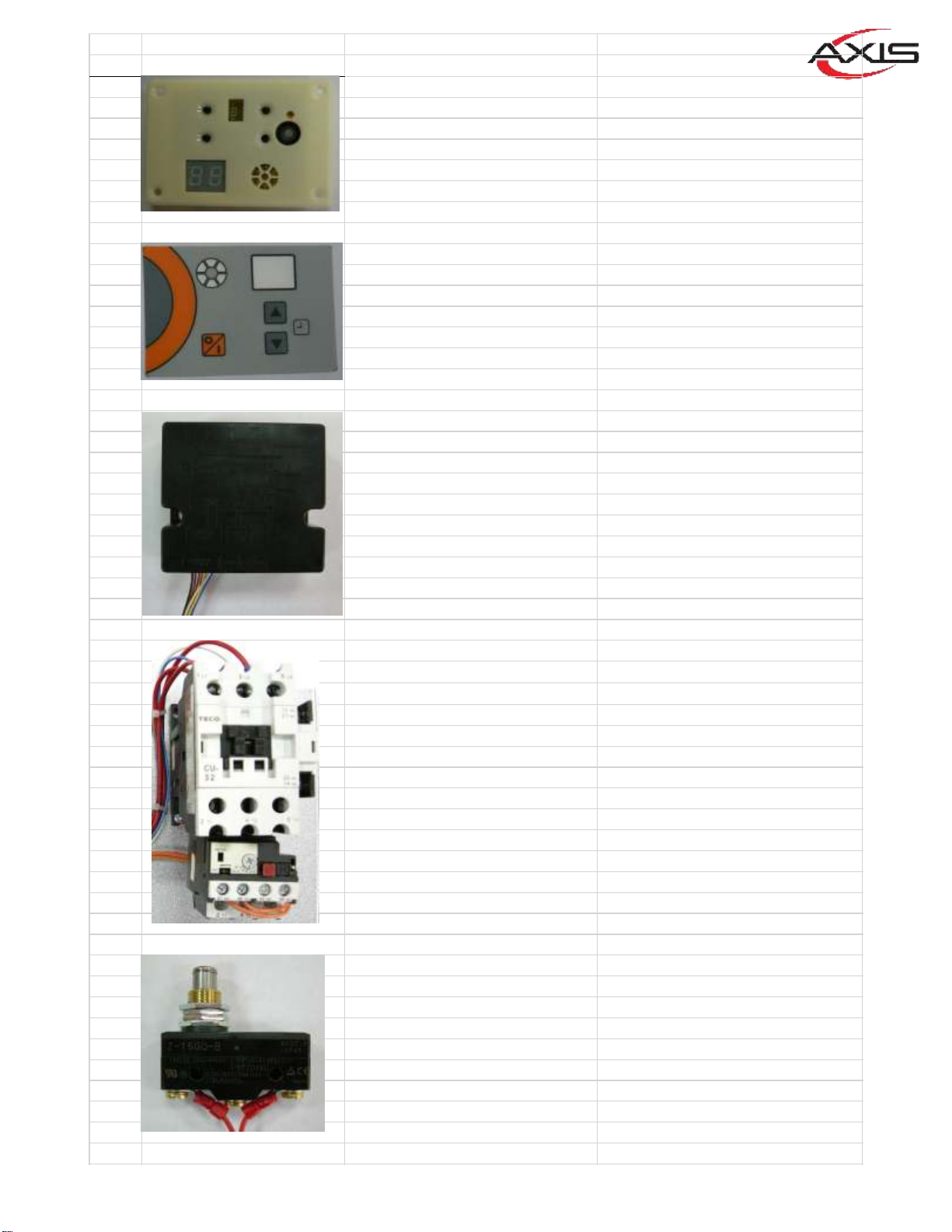

NO. PI CTURE PARTS NUMBER PARTS NAME

1 XL709-11A CONTROL PANEL W/BOX

2 D11001R STICKER OF PANEL

3 XL711-2-ROHS Power Board W/ BOX

4

MC HUO-11AK/2HP CONTACTOR-220V-3 PHASE

5 Z-15GQ-B LIMIT SWITCH FOR GUARD

9

Page 10

6 Z-15GW-B LIMIT SWITCH FOR BOWL LIFT

10

7

8

9

CABLE-12-3C-NEMA6-15P-UL POWER CABLE W/PLUG

EMERGENCY STOP (RED

ABESMT44

ABMS800M

ABAU8F01

(800F-X01)

BUTTON)

LOCK NUT

SWITCH TERMINAL

10

11

C044M6L-AS-02 POWER INDICATOR

12

A010220PSR MAIN SWITCH

Page 11

11

Description or Name Part No. Qty

AGITATING SHAFT

1

GEAR(50T)

2

Resistance oil casing

3

Bevel gear

4

WASHER

4

LOCK WASHER

5

LOCK NUT

6

BALL BEARING 6207Z

7

BALL BEARING 6010Z

8

KEY

9

KEY

10

11100B-02-001B 1

11100B-02-003 1

11100B-02-004 1

11193-02-006 1

11193-02-006A 1

M55 1

MN55 1

BR-6207 1

BR-6010 2

KR-1/4*1/4*100 1

KR-09*14*52 1

Page 12

Description or Name Part No. Qty

GEAR SHAFT

1

GEAR(16T)

2

WASHER

3

CLUTCH COPPER BUSHING

4

GEAR(19T)

5

SHIFTING CLUTCH

6

CLUTCH COPPER BUSHING

7

GEAR(32T)

8

KEY

9

C- TYPE SNAP RING S25

10

WASHER

11

WASHER

12

BALL BEARING 6205

13

BOLT 3/8*1/2

14

11100B-03-001 1

11100B-03-002 1

11100B-03-003 1

11100B-03-004 1

11100B-03-005 1

11091-03-002 1

11100B-03-007 1

11100B-03-008 1

KRR-08*08*43 1

STW-S25 1

1100B-03-011 1

11100B-03-012 1

BR-6205 1

S-3/8*1/2 1

12

SPRING WASHER

15

SW3/8 1

Page 13

13

Description or Name Part No. Qty

PULLEY

1

GEAR SHAFT

2

GEAR(22T)

3

BALL BEARING 6206

4

C- TYPE SNAP RING S25

5

KEY 1/4*1/4*50

6

KEY

7

BALL BEARING 6205

8

LOCK WASHER

9

LOCK NUT

10

SPRING WASHER

11

NUT

12

11092-03-001 1

11100B-04-001 1

11100B-04-004 1

BR-6206 1

STW-S25 1

KR-1/4*1/4*50 1

KRR-10*08*28 1

BR-6205 1

M40*1.5P 1

MN40 1

SW-1/2 1

W1*12NF 1

Page 14

Description or Name Part No. Qty

1 Motor Fixed Seat 11092-05-006 1

MOTOR PULLEY

2

MOTOR

3

BELT

4

KEY 7*7*40

5

SET SCREW 1/4*5/8

6

BOLT 3/8*3/4

7

WASHER 3/8"

8

BOLT 1/2*4

9

NUT

10

BOLT 3/8*3/4

11

11092-05-003 1

11092-05-005 1

M7*1320 8

KR-7*7*40 1

S-S1/4*5/16 1

S-3/8*3/4 4

W-3/8 4

S-1/2*4 1

NUT-W1/2"*12NC 1

S-3/8*3/4 2

14

Page 15

Description or Name Part No. Qty

GEAR (14T)

1

CAP SCREW 5/16*1- 1/4

2

HUB ATTACHMENT

3

ATTACHMENT HOLE PLUG

4

THUMB SCREW

5

BALL BEARING 2907

6

7 O SNAP RING P35 OR-P35 2

11093-06-001 1

S-C-5/16*1-1/4 4

11093-06-002 1

11091-06-004 1

11031-06-005 1

BR-2907 1

15

Page 16

Description or Name Part No. Qty

CONTROL PANEL

1

HUB & CAM ASSY.

2

ECCENTRIC SHIFT SHAFT

3

SHAFT FORK

4

SHIFTER FIXED SHAFT

5

BRACKET GEAR SHIFT

6

HANDLE SEAT

7

NUT 1/2*12NC

8

COMPRESSION SPRING

10

STEEL BALL 6

11

SCREW

12

SPRING PIN 5*28

13

OIL SEAL TC38*50*07

14

MACH SCREW 3/16*3/8

15

1109S-01-006D 1

1109S-07-013B 1

1109S-07-003B 1

11091S-07-004B 1

11091S-07-005B 1

11091-07-006 1

11092-07-007 1

NUT-1/2*12NC 1

11091-07-018 2

SB-6 2

S-C5/16*5/8 4

SPP-5*28 1

OS-TC38*50*07 1

S+R3/16*3/8 4

16

SHIFT HANDLE KNOB

16

SHIFT HANDLE

17

SHIFTING CAM

18

PLUNGER

19

COMPRESSION SPRING

20

SET SCREW

21

11091-07-012 1

11091-07-001 1

11091S-07-008B 1

11091S-07-009B 1

11091-07-010 2

11091-07-011 2

Page 17

Description or Name Part No. Qty

1 INTERNAL DRIVE GEAR(59T) 11091-08-001 1

CAP SCREW 3/8*1- 1/4

2

3 INTERNAL PINION (18T) 11091-08-003 1

RETAINER

4

PLANETARY HEAD

5

HEAD RING

6

KEY 6*6*35

7

AGITATING SHAFT

8

TAPERED PIN

9

OIL SEAL TC43*58*08

10

OIL SEAL TC40*72*10

11

BALL BEARING 6306Z

12

BALL BEARING 6207Z

13

CAP SCREW 3/8*1

14

WASHER 3/8"

15

S-C-3/8*1-1/4 4

11091-08-004 1

11091-08-005 1

11091-08-006 1

KR-6*6*35 1

11091-08-008 1

11091-08-009 1

OS-TC43*58*08 1

OS-TC40*72*10 1

BR-6306Z 1

BR-6207Z 1

S-C-3/8*1 1

WB-3/8 1

17

MACH SCREW 1/4*5/8

16

BOLT 1/2*3/4

18

S+R1/4*5/8 2

S-1/2*3/4 1

Page 18

18

Description or Name Part No. Qty

HINGE SCREW

1

COLUMN

2

SLIDEWAY

3

BASE

4

COLUMN COVER

5

NUT 5/16*18NC

6

BOLT 1/4*3/8

7

SPRING PIN 8*50

8

CAP SCREW 3/8*1- 1/2

9

BOLT 5/8*3

10

SPRING WASHER 5/8"

11

APRON

12

11091-09-001 1

BM60-09-002 1

11091-09-003 2

11091S-09-004C 1

11091-09-005 1

NUT-5/16*18NC 2

S-1/4*3/8 8

SPP-8*50 4

S-C-3/8*1-1/2 12

S-5/8*3 4

SW-5/8 4

AXM60-09-016 1

Page 19

19

Description or Name Part No. Qty

BOWL CLAMP(LEFT)

1

BOWL CLAMP(RIGHT)

1

NUT 5/8*11NC

2

BOWL SUPPORT

3

BOWL RETAINER

4

BOWL LOCATING PIN

5

APRON

6

MACH SCREW 3/16*1/4

7

CAP SCREW 1/4*3/4

8

NUT 1/2*12NC

9

SPRING WASHER 1/2"

10

11091-10-001A 2

11091-10-001B 2

NUT-5/8*11NC 4

11091-10-003 1

11091-10-004 1

11091-10-005 2

11091-10-006 1

S+R3/16*1/4 4

S-C-1/4*3/4 2

NUT-1/2*12NC 2

SW-1/2 2

Page 20

20

Page 21

Description or Name Part No. Qty

WHEEL HANDLE

1

LIFTING WHEEL

2

CLAMPING ARM

3

WHEEL HANDLE

4

WHEEL BRACKET

5

6 LIFTING GEAR (41T) 11091-11-006 1

LIFTING SCREW

7

LIFTING NUT

8

RETAINER

9

10 GEAR (31T) 11091-11-010 1

11 BEVEL GEAR (23T) LIFTING 11091-11-011 1

SHAFT

12

13 BEVEL GEAR (23T) WHEEL 11091-11-013 1

11091-11-001 1

11091-11-002 1

11091-11-003 1

11091-11-004 1

11091-11-005 1

BM60-11-007 1

11091-11-008 1

11091-11-009 1

11091-11-012 1

CAP SCREW 5/16*1- 1/2

14

TAPERED PIN 4*32

15

C- TYPE SNAP RING S19

16

KEY 5*5*15

17

OIL CUP ( 五) OIL-BELL-1/8*3/4

18

NUT 1/2*12NC

19

KEY 5*5*10

20

FLAT WASHER

21

KEY 5*5*13

22

BALL BEARING 2903

23

BALL BEARING 6203

24

LOCK WASHER 17

25

LOCK NUT

26

SPRING WASHER 3/8"

27

BOLT 3/8*1

28

S-C-5/16*1-1/2 4

TP-4*32 2

STW-S19 1

KR-5*5*15 1

NUT-1/2*12NC 1

KRR-5*5*10 1

WB-3/4 1

KRR-5*5*13 1

BR-2903 1

BR-6203 1

M17 1

MN17 1

SW-3/8 2

S-3/8*1 2

1

21

Page 22

22

Description or Name Part No. Qty

BEATER

1

SS WHIP

2

HOOK

3

TROLLEY BASE

4

WHEEL 2.5"

5

NUT 1/2*12NC

6

BOWL

7

11091-12-001 1

11091-12-002 1

11091-12-003 1

11091-12-011 1

WHEEL-001 3

NUT-1/2*12NC 3

11091-12-008 1

Page 23

Description or Name Part No. Qty

23

BACK COVER

1

FRONT COVER (WIRE)

2

FIXED RING

3

FIXED SHEET

4

BOLT 3/16*1/2

5

SET SCREW 5/16*3/8

6

SCREW

7

SCREW

8

CONTROL SHAFT

9

COMPRESSING SPRING

10

CONTROL SHAFT SEAT

11

GM60-13-001A

GM60-13-002B

11091-13-003A

11091-13-004

S-3/16*1/2

S-S5/16*3/8

S+BR-3/16*1/4

1109P-13-008

11091-13-007

11091-13-012

1109P-13-006

1 只

1 只

1 只

1 只

6 支

3 只

4 支

1 只

1 只

1 只

1 只

Page 24

GREASE AND OIL

for AX-M60(AXIS M-60 s/n: 07040051 the machine is made before May 30, 2008).

And the AXIS M-60 s/n: 07040051 is use grease in the transmission & planetary head.

But since May 30, 2008, the AXIS M-60 is all use oil.

SHELL DARINA Ep0 (GADUS) should be applied to the gear-box of mixers ranging from 7QT to

40QT, while SHELL SPIRAX S2 A is for either gear-box or planetary head for only 60QT and 80QT.

GREASE

OIL

SHELL SPIRAX® HD

Heavy-duty gear oil for automotive differentials and

manual transmissions

Product Description

Shell Spirax®

HD oils are high performance multigrade extreme-pressure, multipurpose gear lubricants.

They are suitable for heavy-duty truck and automotive differentials, manual transmissions and oil

lubricated wheel bearings. drive-train gears of heavy-duty automotive, trucking and off-road

equipment operated under high-speed/shock load, high-speed/low torque and low-speed/high

torque conditions. They meet the

requirements of API GL-5 and MIL-PRF-2105E and are available in two SAE viscosity grades: 80W90 and 85W-140.

Grease in Gear-box Grease in planetary head

Grease type Grease type

7 QT. 0.25 lit. 8.45 us fl oz 0.055 lit. 1.86 us fl oz

12 QT 0.5 lit. 16.90 us fl oz 0.06 lit. 2.03 us fl oz

20 QT. 1 lit. 33.81 us fl oz 0.065 lit. 2.20 us fl oz

30 QT. 1.2 lit. 40.57 us fl oz 0.08 lit. 2.70 us fl oz

40 QT. 2.4 lit. 81.15 us fl oz 0.1 lit. 3.38 us fl oz

60 QT. 4 lit. 135.25 us fl oz 0.3 lit. 10.14 us fl oz

80 QT. 4 lit.

135.25 us fl oz

S2 V220 0 JX-3-5G

S2 V220 0 JX-3-5G

S2 V220 0 JX-3-5G

S2 V220 0 JX-3-5G

S2 V220 0 JX-3-5G

HD85W/140 HD85W/140

HD85W/140 HD85W/140

0.3 lit.

10.14 us fl oz

24

Page 25

Scheduled maintenance

NOTE: All maintenance work should be done only after unit has been disconnected from

electrical power and grounding.

Never use a metal or stiff brush to clean the mixer. Never clean the mixer with water hose

or any fluid under pressure.

Do not run the mixer for any extended period of time.

Daily:

The mixer should be cleaned daily. Bowl and agitators should be removed from the mixer

and cleaned in a sink with soapy warm water.

Weekly:

The transmission case and planetary mechanism should be inspected weekly for leak

and damages. Should it become necessary to repack the ball bearings, an authorized

service technician or the manufacturer should be contacted. Use of unproven grease or

oil (lubricant) may lead to damage and void the warranty.

Monthly:

Verify bowl lift track and

mechanism. The bowl lift

track should be lubricated

semiannually, or more

often under heavy usage.

Disconnect the unit from

power supply before

removing the top housing

or apron. The drip cup

should be inspected

periodically for moisture or

lubricant dripping. Remove

the cup and wipe it with a

soft cloth.

Verify oil level inside the

gear box.

25

Page 26

Lubrication

The mixer comes with grease-packed ball bearing that do not require regular

lubrication. When it becomes necessary to repack them, contact your local service

company or MVP group Corp.

The polished drip cup protects against lubricant seeping out of the planetary into the

bowl. The drip cup should be wiped clean monthly and inspected for excessive

leakage. The drip cup may be removed by pulling it down.

The bowl lift track and mechanism requires periodic lubrication with a small quantity of

high-quality mineral oil. This lubricant can be applied with a cotton swab or by

fingertip.

CLEANING

Never use a metal or stiff brush to clean mixer. Never clean the mixer

with a water hose or any fluid under pressure.

The mixer should be thoroughly cleaned daily. It should be washed

with a clean damp cloth.

Bowl and agitators should be removed from the mixer and cleaned in a

sink.

The transmission case and planetary mechanism should be

inspected weekly for leaks, damage, etc.

26

Page 27

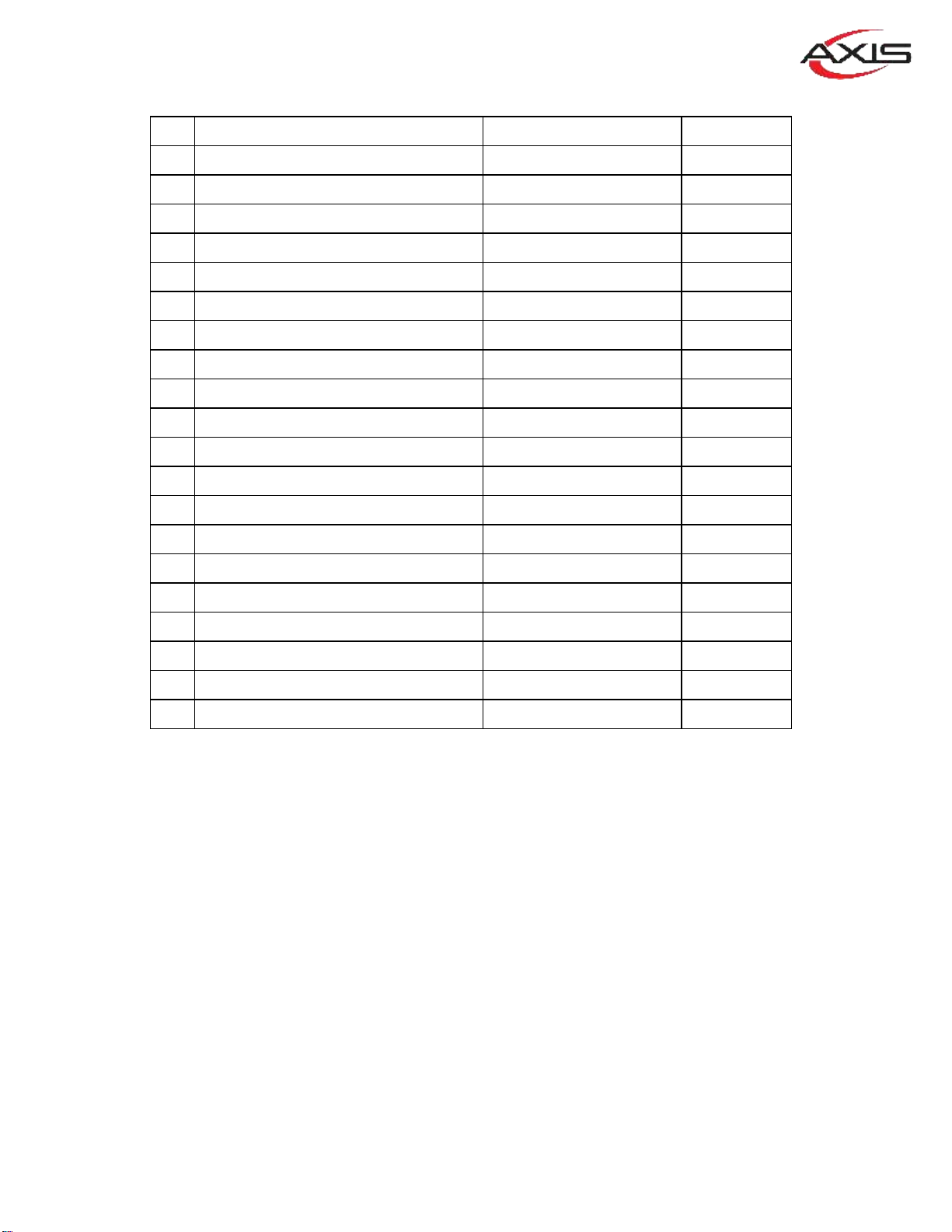

MAINTENANCE

DAILY WEEKLY MONTHLY

CLEANING

BOWL

AGITATORS

MIXER

VISUAL INSPECTION

PLANETARY

BOWL LIFT

BOWL GUARD

TOUCH PAD

GEAR BOX

LUBRICATING

BOWL LIFT TRACK

WHAT LUBRICANT TO USE

Never use vegetable oil. Vegetable oil may look like a lubricant but it does not work as a

lubricant. It will congeal, gum up and solidify, acting as a glue. If vegetable oil has been

used, the entire track system must be cleaned and grease with proper lubricant. A mineral

oil will do. There are no specific brands. It is easily found at the hardware store or

pharmacy. See below for lubricants used inside the unit.

GREASE AND OIL

For AX-M60 (AXIS M-60 s/n: 07040051, machine made before May 30, 2008) use grease

in the transmission & planetary head.

But since May 30, 2008, the AXIS M-60 all use oil.

SHELL DARINA Ep0 (GADUS) should be applied to the gear-box of mixers ranging from

7QT to

40QT, while SHELL SPIRAX S2 A is for either gear-box or planetary head for only 60QT

and 80QT.

Grease and Oil in Gear-box

7 QT. 0.25 lit. 8.45 us fl oz 0.055 lit. 1.86 us fl oz

12 QT 0.5 lit. 16.90 us fl oz 0.06 lit. 2.03 us fl oz

20 QT. 1 lit. 33.81 us fl oz 0.065 lit. 2.20 us fl oz

30 QT. 1.2 lit. 40.57 us fl oz 0.08 lit. 2.70 us fl oz

40 QT. 2.4 lit. 81.15 us fl oz 0.1 lit. 3.38 us fl oz

60 QT. 4 lit. 135.25 us fl oz 0.3 lit. 10.14 us fl oz

80 QT. 4 lit.

135.25 us fl oz

Grease and Oil in planetary

head

Grease type Grease type

S2 V220 0 JX-3-5G

S2 V220 0 JX-3-5G

S2 V220 0 JX-3-5G

S2 V220 0 JX-3-5G

S2 V220 0 JX-3-5G

HD85W/140 HD85W/140

HD85W/140 HD85W/140

0.3 lit.

10.14 us fl oz

27

Page 28

28

AXIS M60P MIXER TECHNICAL MANUAL

Loading...

Loading...