Axiom Industries NC-1W Installation Manual

Reversible

Clearance: 70mm [3.75”]

NC-1W WALL HUNG CONDENSATE NEUTRALIZATION KIT

INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS

Installation Instructions

NOTE - Check with your local water authority for regulations regarding discharge of treated condensate to the drain or

sewer system.

WARNING

- “Risk of damage to appliance”. The neutralization kit inlet and discharge must be at a lower elevation than the

condensate drain from appliance.

- Do not allow exhaust flue gases to vent through the neutralization kit. All condensate drains must have a trap to

prevent flue gas leakage. Flue gas leakage can cause injury or death from carbon monoxide.

- Connection to the appliance and neutralization kit must be installed to ensure that no condensate backflow into

the appliance can occur.

- This product can expose you to Silica, crystalline (airborne particles of respirable size) which is known in the

state of California to cause cancer. For more information go to www.P65Warnings.ca.gov

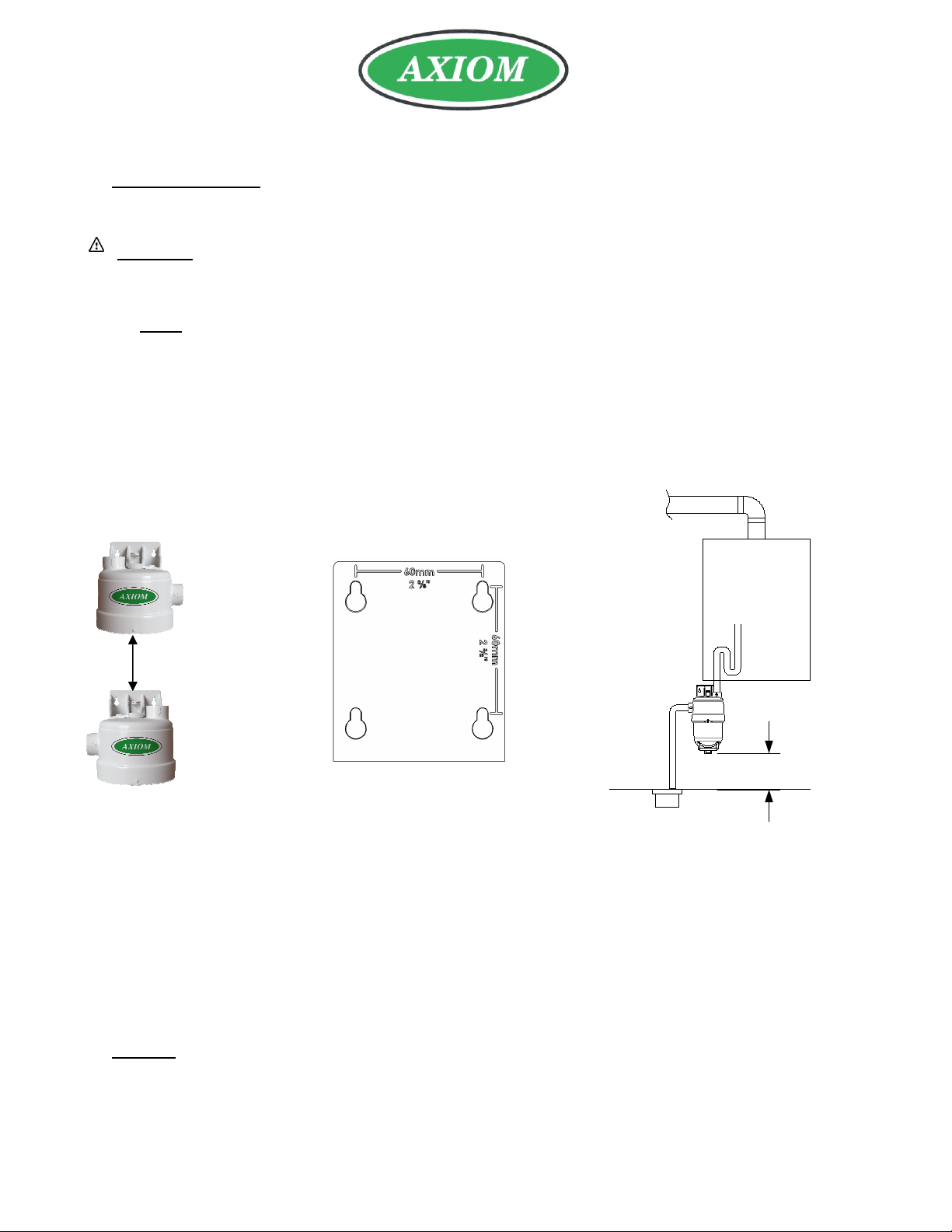

Open the capsule and ensure media is level inside. If necessary, the orientation of the NC-1W can be reversed by removing

the wall bracket and moving it to the other side of the lid. (see figure 1 below). Mount the neutralization capsule on the wall

securing it with the provided wall bracket (see figure 2 and 3 below).

Wall bracket

Figure 1 Figure 2 Figure 3

Connections to the appliance and neutralization kit must be installed to ensure that no condensate backflow can occur.

Connect corrosion resistant piping and secure it to the wall to prevent movement. Do not route the condensate line through

any area that is exposed to freezing temperatures or sunlight. If traffic poses a risk, install some protection to prevent

movement and/or damage. Mount as per installation diagram. The NC-1W should be installed after the trap. Ensure that the

condensate will flow freely from the appliance drain into the capsule then to the drain. Access to the discharge is necessary for

proper maintenance in order to check the effectiveness of the neutralizing media, using pH test strips.

Wall Hung

Condensing

Boiler or

Furnace

If there is no gravity drain available, install a condensate removal pump designed for use on condensing boilers and furnaces.

The condensate pump must be equipped with an over flow switch to prevent the appliance from running should a failure

occur.

Operation

The appliance condensate will flow through the neutralizing media, raising the pH of the condensate to a level that

will help prevent corrosion of the domestic drain and the public sewer system.

3603 Burron Avenue, Saskatoon, SK S7P 0 Ph: (306) 651-1815 email: sales@axiomind.com

website: www.axiomind.com Provisionally Patented © 2019 Axiom Industries Ltd.

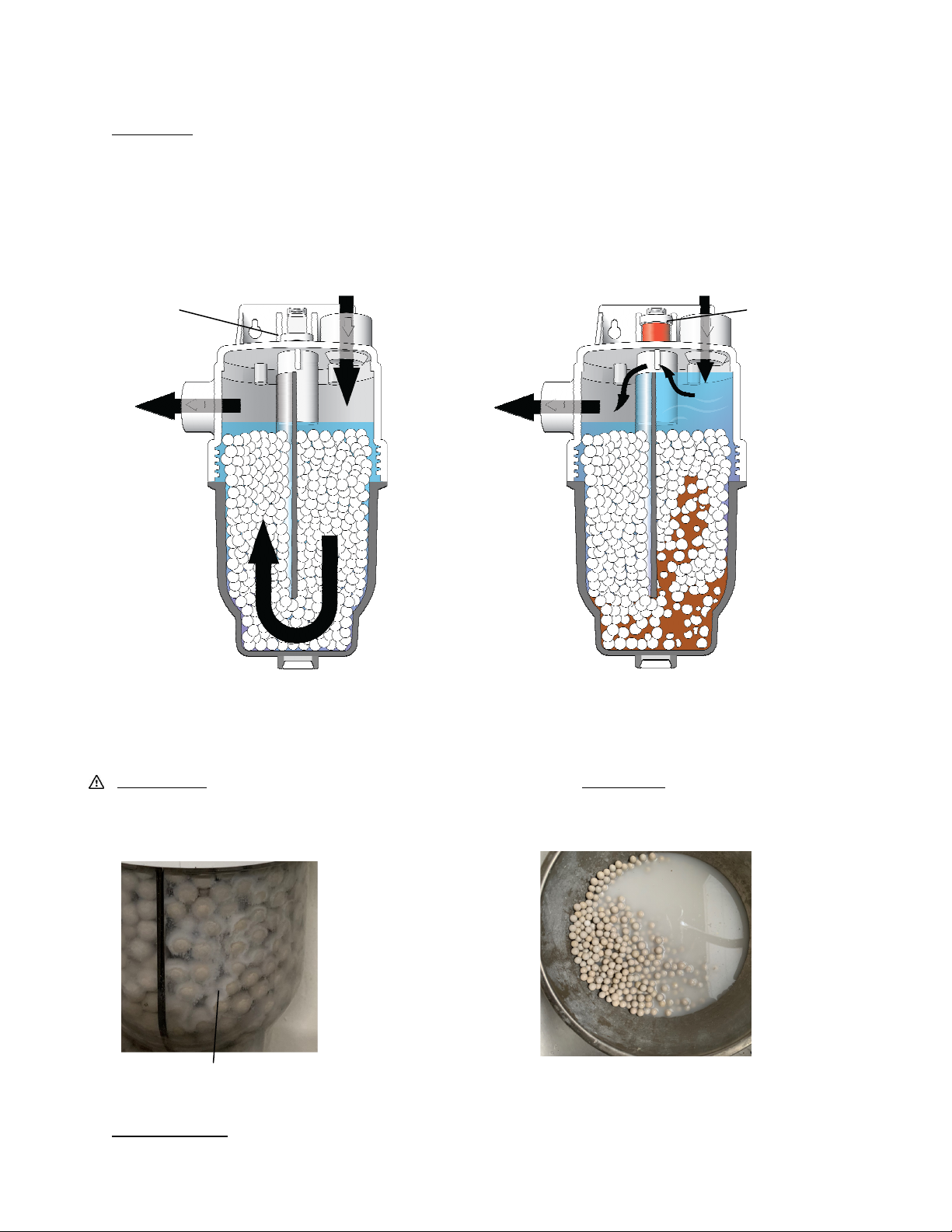

Maintenance

Monitor the cleanliness, level of the neutralization media, and pH level in the capsule monthly. Remove any precipitate

coating or debris found to prevent blockages. Check the pH level at the outlet of the neutralizing kit using a suitable pH test

strip paper or an electronic pH meter for precise measurement. The neutralizing media should be replaced when the pH level

drops below the minimum level of the local water authority, when the float rises (see figure 4 below), or after one year,

whichever comes first. For replacement LipHter+ media contact your local Axiom distributor.

Float is

down

Normal Operation

Restricted Flow

Float is up, and

locked in position,

indicating the

neutralizer requires

cleaning or

replacement media.

Patent Pending

Figure 4

The float should be down during normal operation. If flow in the NC-1W becomes restricted, the float will rise and lock in

position, indicating that the media should be cleaned or replaced (see figure 4 above). After replacing the media, reset the float

by pushing it back down.

ATTENTION: ADDITIONAL MAINTENANCE FOR BOILERS WITH ALUMINUM HEAT EXCHANGERS

- Boilers with Aluminum heat exchangers deposite white salt on the neutralization media that restricts flow

through the neutralizer. To clean the media, remove the clear jar, rinse the media with water, and twist the jar

back onto the lid.

Figure 5: Salt precipitate deposited on neutralization

media from Aluminum heat exchangers

Figure 6: Neutralization media that has been

Limited Warranty

The unit is warranted against defects in materials and workmanship for one year.

Loading...

Loading...