MODEL MF200 ‘PRESSURE PAL’ MINI SYSTEM FEEDER

The ‘PRESSURE PAL’ is ideal for feeding and

pressurizing closed hydronic systems that do not

require cold static fill pressures higher than 170 kPa

(25 psig). It is compatible with both water and

glycol/water solutions. Perfect for small boiler/chiller

systems, snow/ice melt circuits, outside air

heating/cooling glycol coils, solar heating systems.

FEATURES and BENEFITS

25 liter (6.6 US gallon) tank for storage and mixing

UL listed Power supply plugs into any standard 115 VAC outlet

Diaphragm pump can run dry without damage

No direct connection to potable water supply eliminates need for backflow prevention

Make-up fluid stored in the feeder tank can be pre-treated

Diverter valve allows easy purging of air on initial start-up, and manual agitation of solution

Prevents major floods - in the event of system rupture, only the contents of the tank will be

pumped into the system

Provides leak detection - dropping fluid level provides immediate notice that the system has

developed a leak

Fluid drained for service can easily be put back into the system

Fluid level switch shuts the pump off if the storage tank level gets too low

Represented By:

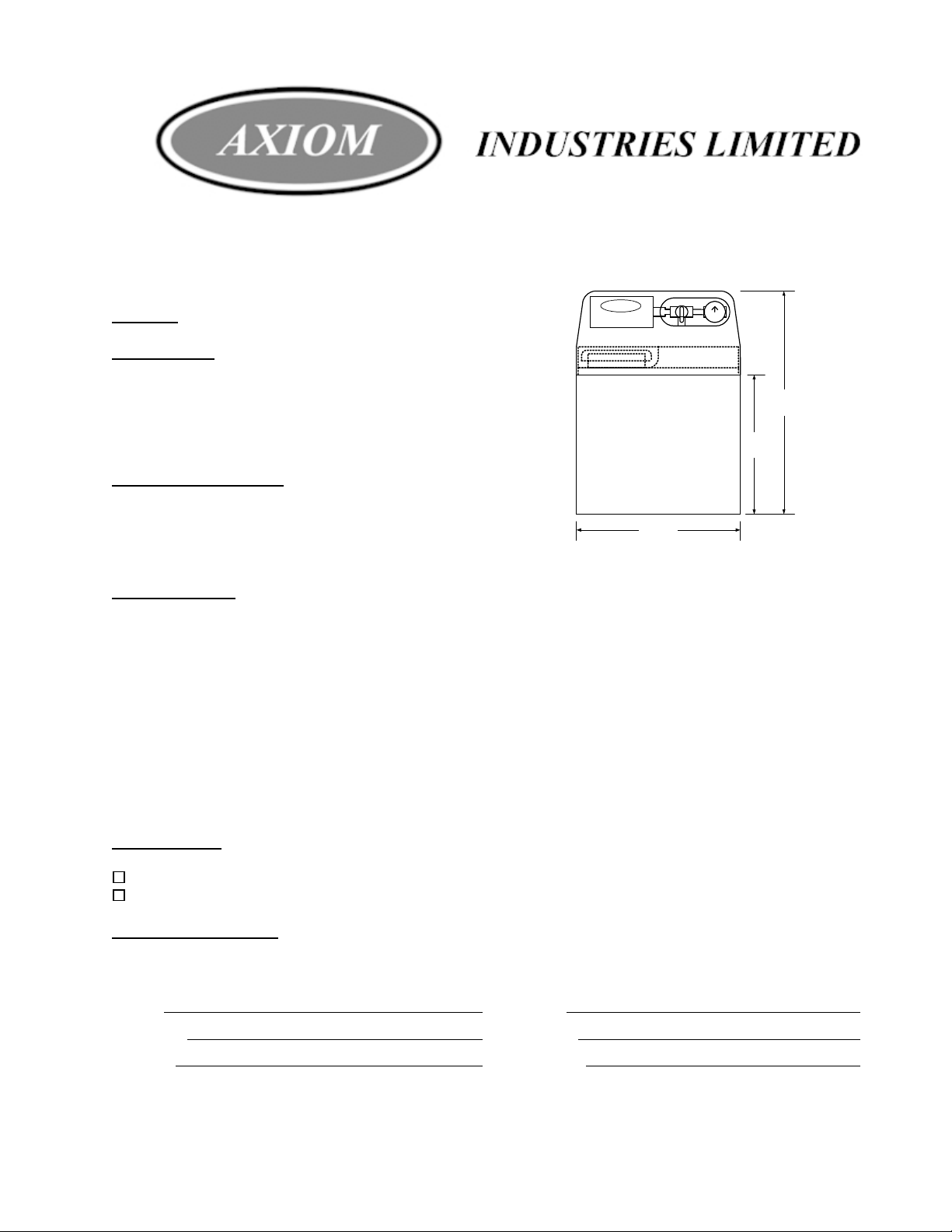

MF200 HYDRONIC SYSTEM FEEDER TECHNICAL INFORMATION

WEIGHT - 3.2 kg, 7 lbs.

Axiom

Mini - Feed

ELECTRICAL

Fused Power supply adapter (UL listed)

115/60/1 to 24 VDC

Rated 50 watts AC

LED Power Light

PUMP PERFORMANCE

0.04 l/s (0.7 gpm) @ free flow

Self-priming up to 1.2 m (4 feet)

SPECIFICATION

Depth - 11 . 75 in 300 mm

Clearances – Right Side and Top - 12 in 305 mm

Weight When Full 60 lbs / 27 kg .

Discharge 1 / 2 " FPT

Hydronic system feeder shall be AXIOM INDUSTRIES LTD. Model MF200. System shall include 25 litre

(6.6 U.S. gallon) storage/mixing tank with molded-in level gauge, 125 mm (5”) fill/access opening and

cover; pump suction hose with inlet strainer and check valve; pressure pump with fuse protection; low

fluid level pump cut-out float switch; manual diverter valve for purging air and agitating contents of

storage tank; pressure switch with snubber, each individually adjustable from 70 kPa (10 psig) to 170 kPa

(25 psig) cut-out pressure; factory cut-out pressure set to 115 kPa (17psig); and liquid filled pressure

gauge. Unit to be c/w UL listed and fused power supply adapter with LED power indicator light, 115/60/1

to 24 VDC 50 watts AC, supplied loose for field installation.

Feeder shall be compatible with glycol solutions of up to 50% concentration. Pump shall be capable of running dry

without damage. Unit shall be completely assembled.

ACCESSORIES

MF200-1430 – Tank Mounting Shelf

RIA10-1-SAA – Low level Alarm Panel c/w Remote Monitoring Dry Contacts and Selectable Audible Alarm

LIMITED WARRANTY

11 . 75 in

300 mm

The MF200 is warranted against defects in materials and workmanship for one year.

Project Location

0 30

15

16 in

400 mm

10 in

250 mm

Consultant Contractor

Unit Tag Sales Agent

Loading...

Loading...