Page 1

MQ

US

C

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

LIMITED WARRANTY

Products manufactured by GRUNDFOS PUMPS CORPORATION (Grundfos) are

warranted to the original user only to be free of defects in material and workmanship

for a period of 24 months from date of installation, but not more than 30 months from

date of manufacture. Grundfos' liability under this warranty shall be limited to repairing or replacing at Grundfos' option, without charge, F.O.B. Grundfos' factory or

authorized service station, any product of Grundfos' manufacture. Grundfos will not

be liable for any costs of removal, installation, transportation, or any other charges

which may arise in connection with a warranty claim. Products which are sold but

not manufactured by Grundfos are subject to the warranty provided by the manufacturer of said products and not by Grundfos' warranty. Grundfos will not be liable

for damage or wear to products caused by abnormal operating conditions, accident,

abuse, misuse, unauthorized alteration or repair, or if the product was not installed

in accordance with Grundfos' printed installation and operating instructions.

To obtain service under this warranty, the defective product must be returned to the

distributor or dealer of Grundfos' products from which it was purchased togeth er

with proof of purchase and installation date, failure date, and supporting installation

data. Unless otherwise provided, the distributor or dealer will contact Grundfos or

an authorized service station for instructions. Any defective product to be returned

to Grundfos or a service station must be sent freight prepaid; documentation supporting the warranty claim and/or a Return Material Authorization must be included

if so instructed.

GRUNDFOS WILL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOSSES, OR EXPENSES ARISING FROM INSTALLATION,

USE, OR ANY OTHER CAUSES. THERE ARE NO EXPRESS OR IMPLIED WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, WHICH EXTEND BEYOND THOSE WARRANTIES DESCRIBED OR

REFERRED TO ABOVE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages and some jurisdictions do not allow limit actio ns on how long

implied warranties may last. Therefore, the above limitations or exclusions may not

apply to you. This warranty gives you specific legal rights and you may also have

other rights which vary from jurisdiction to jurisdiction.

2

Page 3

MQ

English (US)

Installation and operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Español (MX)

Instrucciones de instalación y funcionamiento. . . . . . . . . . . . . . . . . . . . . . . . . .23

Français (CA)

Notice d'installation et de fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Contents

3

Page 4

English (US)

English (US) Installation and operating instructions

CONTENTS

1. Introduction

2. Items supplied

3. Symbols used in this document

4. Applications

4.1 Pumped liquids

5. Identification

5.1 Type key

6. Operating conditions

6.1 Suction lift

7. Mechanical installation

7.1 Location

7.2 Foundation

7.3 Space requirement

7.4 Pipework

7.5 Protective cover

8. Electrical connection

8.1 Generator or inverter

8.2 Wiring diagram

8.3 Winding resistance measurement

8.4 Winding resistance measurement

8.5 Start-up

9. Functions

9.1 Control panel

9.2 Pump stop

10. Maintenance

10.1 Service kits

10.2 Start-up after a long period of inactivity

11. Service

12. Technical data

12.1 Dimensions

12.2 Electrical data

12.3 Approvals

13. Accessories

14. Fault finding chart

15. MQ frequently asked questions

16. Disposal

Page

10

11

11

12

12

13

14

15

15

16

17

17

17

17

18

18

18

18

18

19

21

22

WARNING

4

4

5

5

5

6

1. Introduction

6

7

The MQ is a low-noise water supply system

7

consisting of pump, motor, pressure tank and

controller combined into one compact unit.

8

The system is suitable for both indoor and out-

8

door use.

8

8

The self-priming pump starts automatically

8

when water is consumed in the installation and

stops when consumption ceases. The internal,

built-in non-return valve prevents backflow

during priming and operation.

The MQ pump incorporates overtemperature

and dry-running protection as well as a userfriendly control panel.

The built-in pressure tank reduces the number

of starts and stops in case of leakage in the

installation.

Prior to installation, read these

installation and operating instructions. Installation and operation

must comply with local regulations and accepted codes of good

practice.

2. Items supplied

The MQ packaging contains these items:

• MQ water supply system with built-in nonreturn valve

• non-return inlet valve in plastic bag

• installation and operating instructions.

4

Page 5

3. Symbols used in this document

Caution

Note

WARNING

If these safety instructions are not

observed, it may result in personal

injury!

If these safety instructions are not

observed, it may re sul t in ma lfun ction or damage to the equipment!

Notes or instructions that make

the job easier and ensure safe

operation.

4. Applications

The MQ water supply system is designed for

these typical applications:

• water pressure boosting

(maximum inlet pressure: 40 psi)

• water supply from wells (maximum suction

lift: 25 ft), for example

– in private homes

– on farms

– in market gardens and other large gar-

dens.

The pump is suitable for rain water.

English (US)

4.1 Pumped liquids

Thin, clean, non-aggressive liquids, not containing solid particles or fibres.

5

Page 6

English (US)

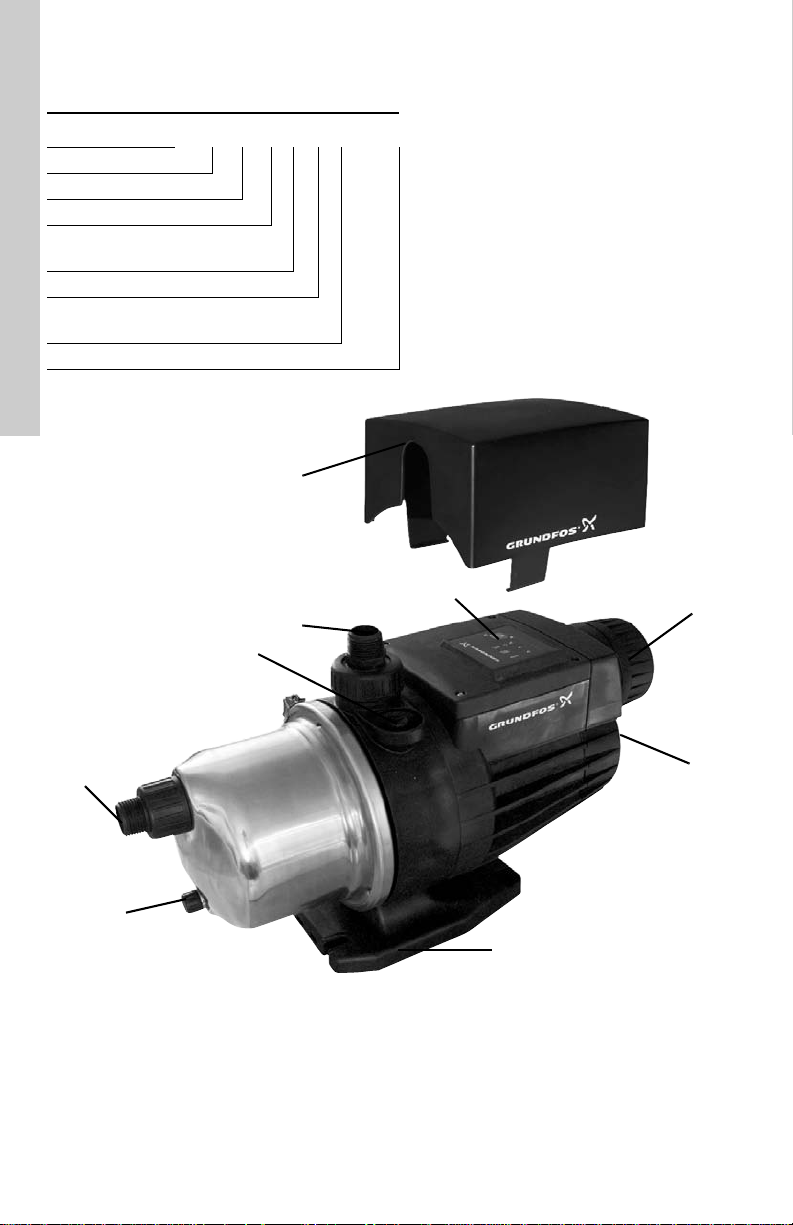

Base plate

Drain plug

Suction

port

Priming plug

Discharge port

Control panel

Pressure

tank cover

End-cover

plug

Protective cover

(accessory)

5. Identification

5.1 Type key

Example MQ 3 -35 A -O -A BVBP

Pump type

Nominal flow rate [m³/h]

Head [m]

Code for pump version

A: Standard

Code for pipework connection

Code for materials

A: Standard

Code for shaft seal

Fig. 1 MQ water supply system. Protective cover is required for outdoor use.

6

TM04 3648 4908

Page 7

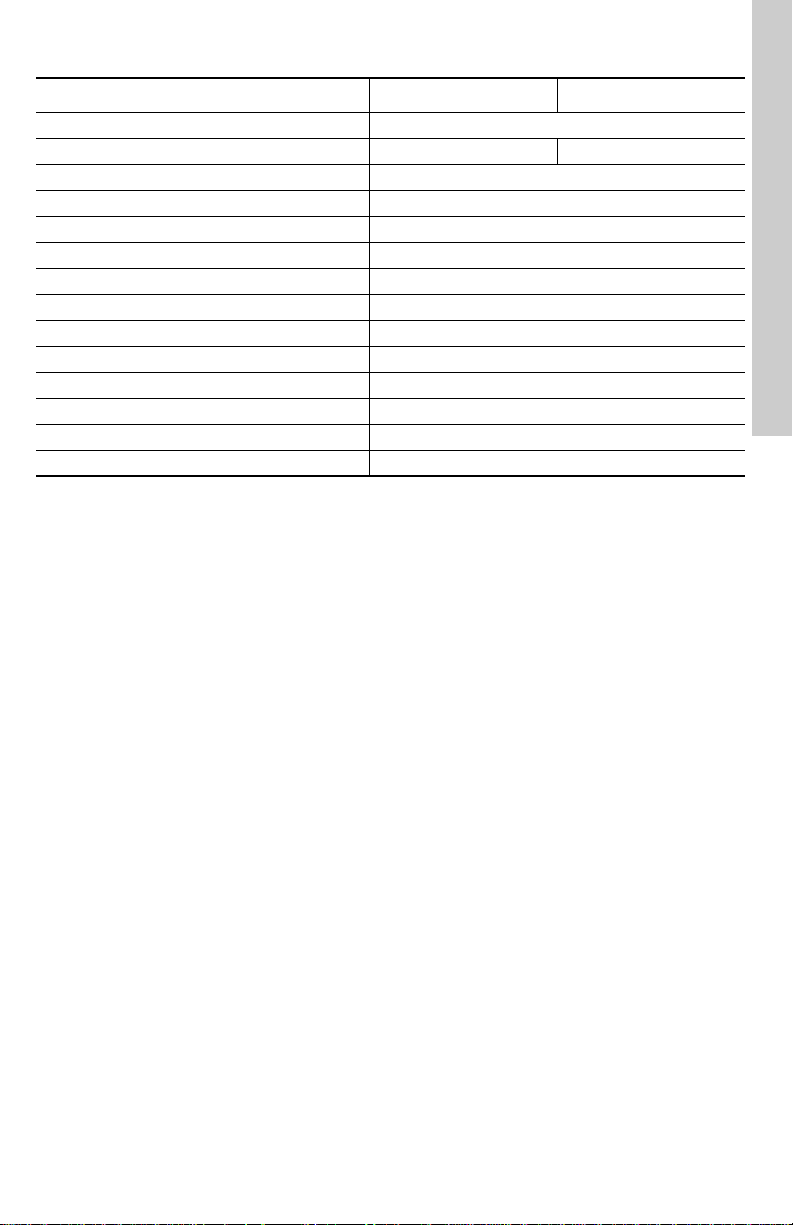

6. Operating conditions

MQ 3-35 MQ 3-45

Maximum flow rate [gpm] 22

Maximum pressure [psi] 51 65

Maximum system pressure [psi] 108

Maximum suction lift [ft]; see page 62 25

Minimum ambient temperature [°F]/[°C] 32/0

Maximum ambient temperature [°F]/[°C] 113/45

Minimum liquid temperature [°F]/[°C] 32/0

Maximum liquid temperature [°F]/[°C] 95/35

Net weight [lbs] 29

Sound pressure level [dB(A)] < 70

Tank volume [oz] 13.5

Air pressure in tank [psi] 22 to 25

Connections 1" NPT

Priming and drain plugs 3/8" GAS

6.1 Suction lift

The maximum suction lift of the pump can be

determined from the diagram, page 62.

Example:

If the suction lift is 10 ft, the length of the suction pipe must not exceed 72 ft.

English (US)

7

Page 8

English (US)

Note

Note

Max. ± 18 °

Note

Note

60"

7. Mechanical installation

7.1 Location

The pump is suitable for indoor and outdoor

installation. It is resistant to sunlight.

For outdoor installation, the pump

must be fitted with a protective

cover (accessory). See section

7.5 Protective cover and

13. Accessories.

Should the unlikely event of an

internal leakage occur, pumped

liquid will be drained out from the

base and/or end cover instead of

damaging the pump. Install the

pump in such a way that no undesirable collateral damage can

arise.

7.2 Foundation

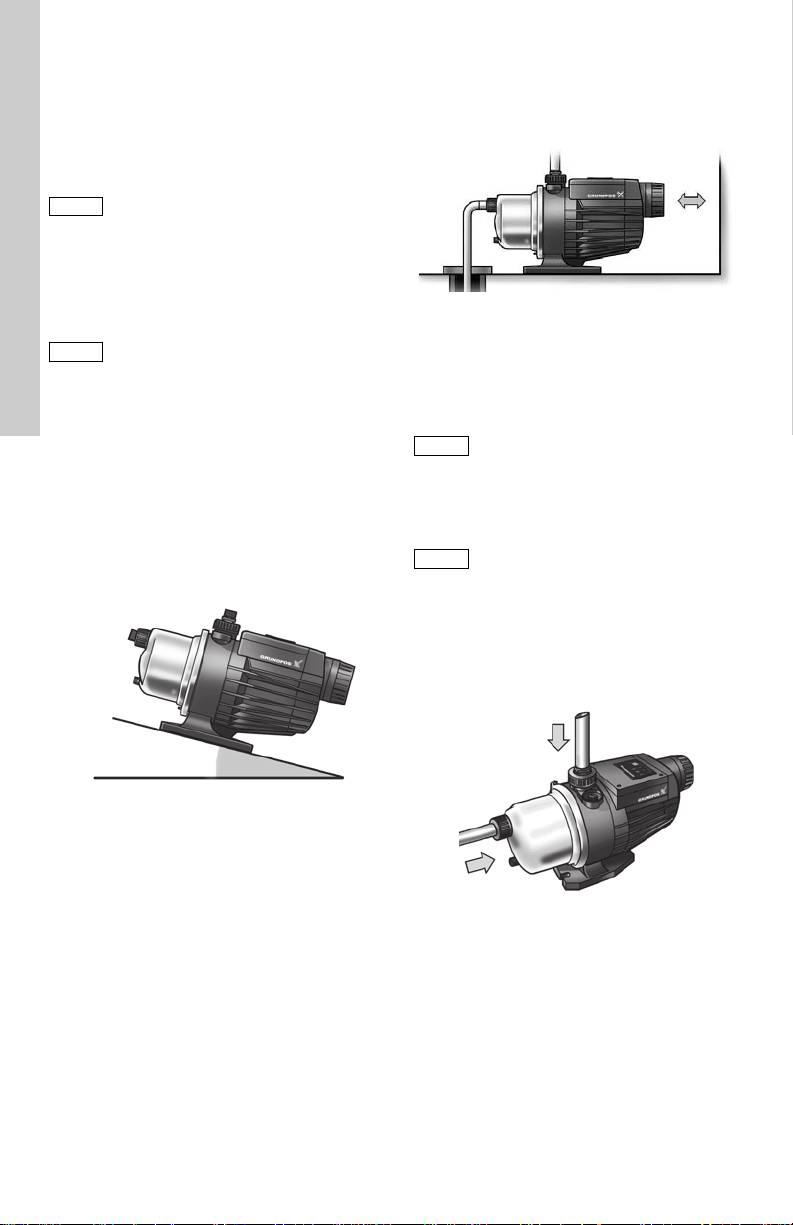

Mount the pump on the base plate with horizontal suction port and vertical discharge port.

The pump must be installed horizontally.

The maximum permissible inclination angle is

± 18 °. See fig. 2.

7.3 Space requirement

For inspection and service, allow a minimum

clearance of 60" behind the pump.

TM04 3746 5008

Fig. 3 Minimum clearance behind the

pump

Being self-cooling, the pump requires no

space or ventilation at the sides.

Ensure that the maximum ambient

temperatures do not exceed the

values stated in section

6. Operating conditions.

7.4 Pipework

Never use unnecessary force

when connecting the pipes.

The pump is supplied with 1" NPT screwed

connections. Fit the connections in the suction

and discharge ports. See fig. 4. The pump discharge port is flexible, ± 5 °, to facilitate the fitting.

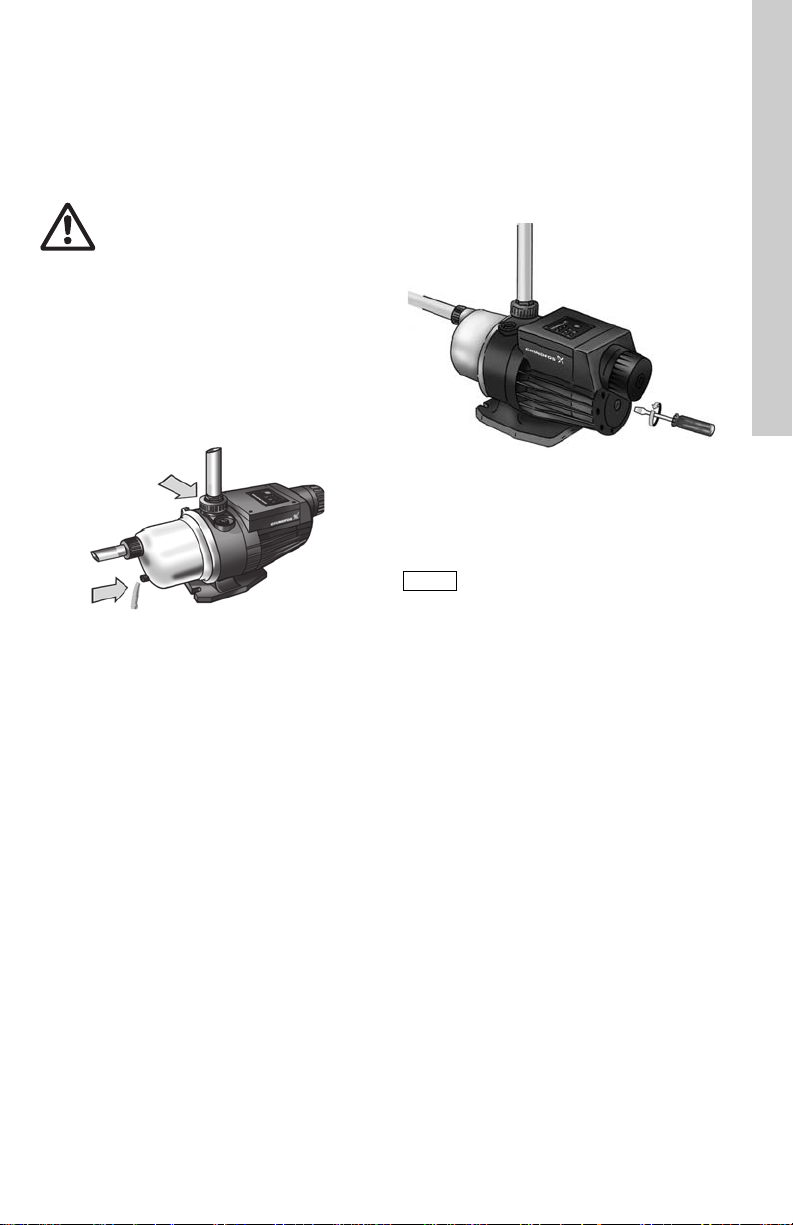

Fig. 2 Horizontal installation of the MQ

To prevent movement and vibrations, the

pump and base plate can be secured to a solid

foundation by means of the bolt holes in the

base plate. For pipework connection, see section 7.4 Pipework.

8

TM01 9691 2600

TM01 9698 2600

Fig. 4 Fitting of screwed connections in

suction and discharge ports

Page 9

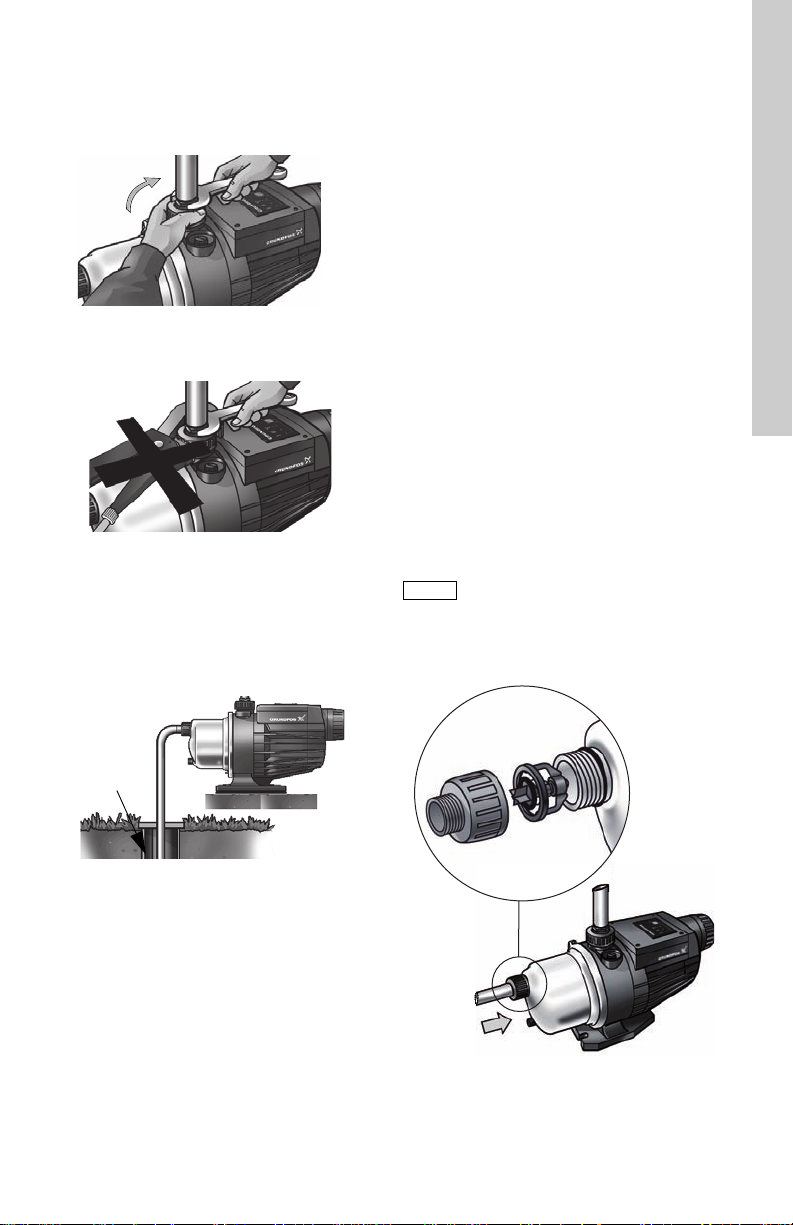

Carefully screw the discharge connection into

Foot valve

Note

the discharge port, using a spanner or similar

tool. Hold the discharge connection, and

tighten the pump discharge union nut with your

hand. See fig. 5.

Fig. 5 Correct: Tighten the discharge

union nut with your hand

Fig. 6 Wrong: Do not use a tool to tighten

the discharge union nut

7.4.1 Suction pipes connected to a well

If the pump draws water from a well, we recommend to fit a foot valve to the end of the

suction pipe. See fig. 7.

7.4.3 Long suction pipes

A separate non-return inlet valve is supplied

with the pump. In case of long suction pipes,

we recommend to fit the non-return inlet valve

in the pump suction port. See section

7.4.4 Fitting of the non-return inlet valve

The pipes must be adequately supported on

either side of the pump to avoid straining the

pump connections.

7.4.4 Fitting of the non-return inlet valve

The non-return inlet valve reduces the risk of

losing pump priming in negative suction appli-

TM04 4271 1009TM 044272 1009TM01 9693 2600

cations and improves the auto-aspiration

capability, for example in water supply from a

cistern.

Install the non-return inlet valve as follows,

see fig. 8:

1. Remove the suction connection of the

pump.

2. Fit the non-return inlet valve into the suction port in the direction shown in fig. 8.

3. Refit the pump connection.

Applications with positive inlet

pressure do not require installation of the non-return inlet valve,

due to the fact that the MQ pump

incorporates an internal nonreturn valve at the disc harg e side .

English (US)

Fig. 7 Suction pipes connected to a well

7.4.2 Suction hose instead of pipe

If a suction hose is used instead of a pipe, the

hose should not exceed the lengths stated in

the graph, page 62. The suction hose must be

minimum Ø1". The hose must be of the noncollapsible type.

TM 04 4121 0809

Fig. 8 Fitting of non-return inlet valve

9

Page 10

English (US)

Note

7.5 Protective cover

Failure to use the protective cover

in outdoor installations will invalidate the warranty.

The protective cover protects the control p anel

against the weather. It is available as an

accessory. See section 13. Accessories.

To fit the protective cover, click the cover onto

the top of the control panel so that it engages

with the top cooling ribs.

To remove the cover, pull the two clips outwards, free of the cooling ribs, and pull the

cover upwards.

Fig. 9 Protective cover

TM04 3745 5008

10

Page 11

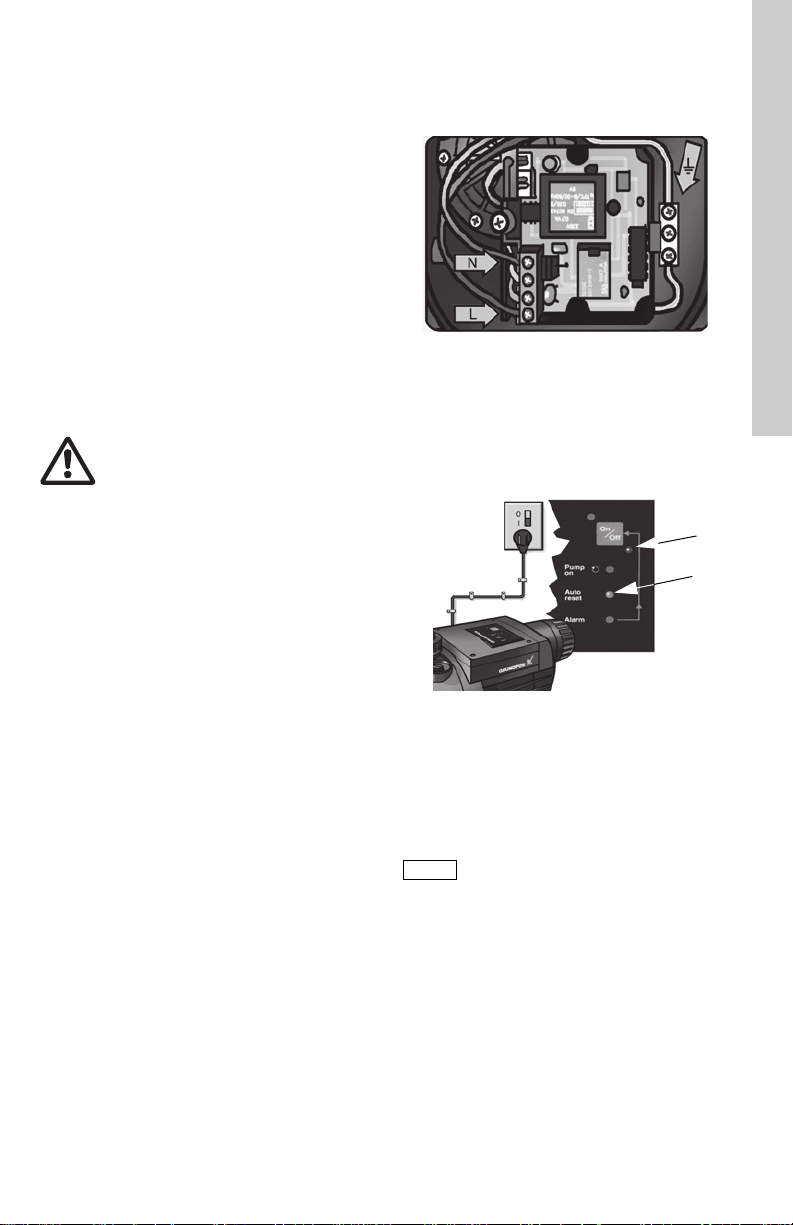

8. Electrical connection

Note

The electrical connections and additional protection should be carried out by qualified persons in accordance with local regulations.

The pump must be connected to the mains via

a sheathed cable with a protective ground

lead. It is possible to replace the mains supply

cable. See fig. 10.

WARNING

Non-submersible pump.

If the power cord is damaged, it

must be replaced by the manufacturer, an authorized service center

or by a qualified person in order to

avoid risks.

Never make any connections in

the pump terminal box unless the

electricity supply has been

switched off for at least 5 minutes.

Risk of electric shock:

This pump is supplied with a

grounding conductor and grounding type attachment plug.

To reduce the risk of electric

shock, install only on circuit protected by a Ground-Fault-CircuitInterrupter (GFCI).

This pump is not intended, nor has

it been investigated for use in

swimming pool or marine areas.

This pump has been evaluated for

use with water only.

Do not start the pump until it has

been filled with water (primed, see

fig. 12).

Acceptable for indoor and outdoor

use.

Enclosure type 3.

The operating voltage and frequency are

marked on the nameplate. Make sure that the

motor is suitable for the electricity supply on

which it will be used.

English (US)

TM01 9694 2600TM01 9695 2600

Fig. 10 Electrical connection

Connect the mains supply cable of the pump

to the electricity supply. When the cable is

connected, a red and a green indicator light on

the control panel will be on. See fig. 11.

Fig. 11 Connection of mains supply cable

8.1 Generator or inverter

The MQ can be powered by a generator or an inverter. However, the

pump will only operate satisfactorily if the generator or inverter

generates a true sinusoidal wave

with the necessary power and voltage input. The generator must be

sized 10 % above the P1

(input power) of the pump. For P1,

see section 12.1 Dimensions.

11

Page 12

English (US)

Black (phase)

Red

Black

Orange

> Flow sensor

> Pressure switch

Capacitor

Yellow

Yellow

Electric motor

Yellow/green (ground)

Red (main)

Black

White (neutral)

> Cable

B

A

Yellow

White

C

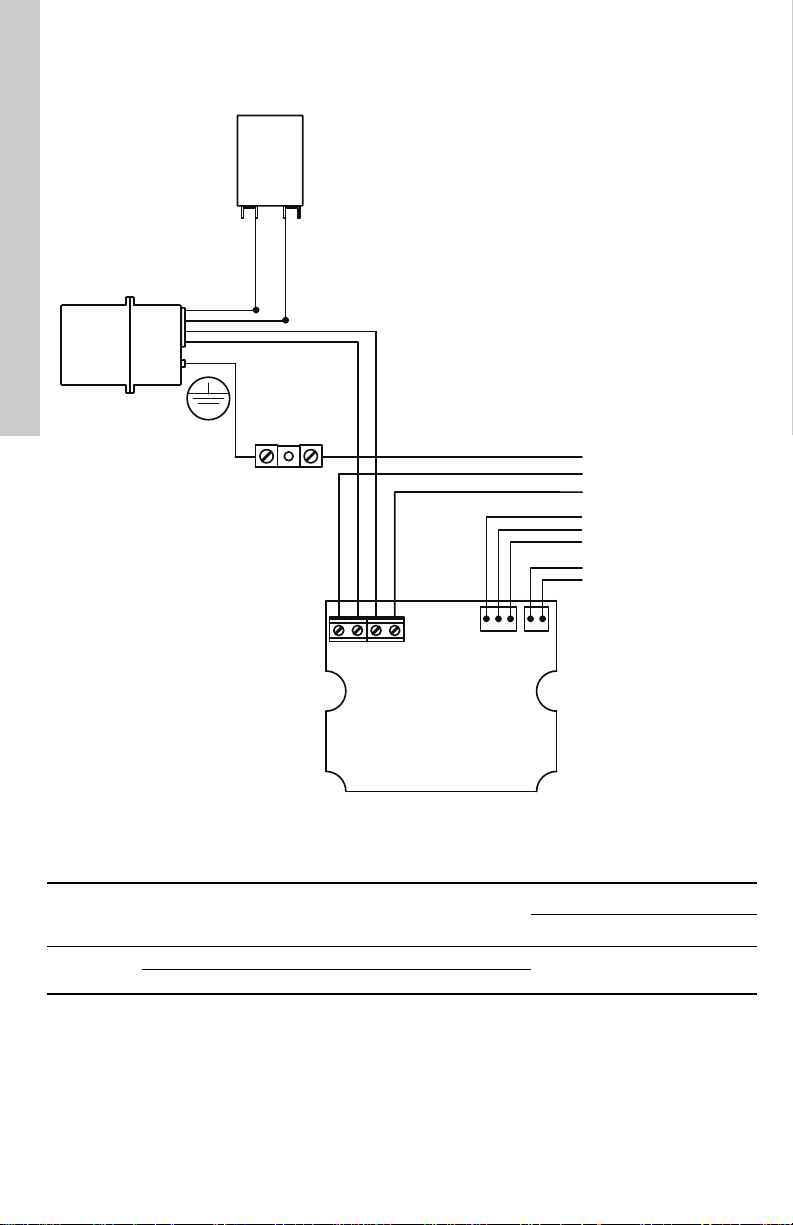

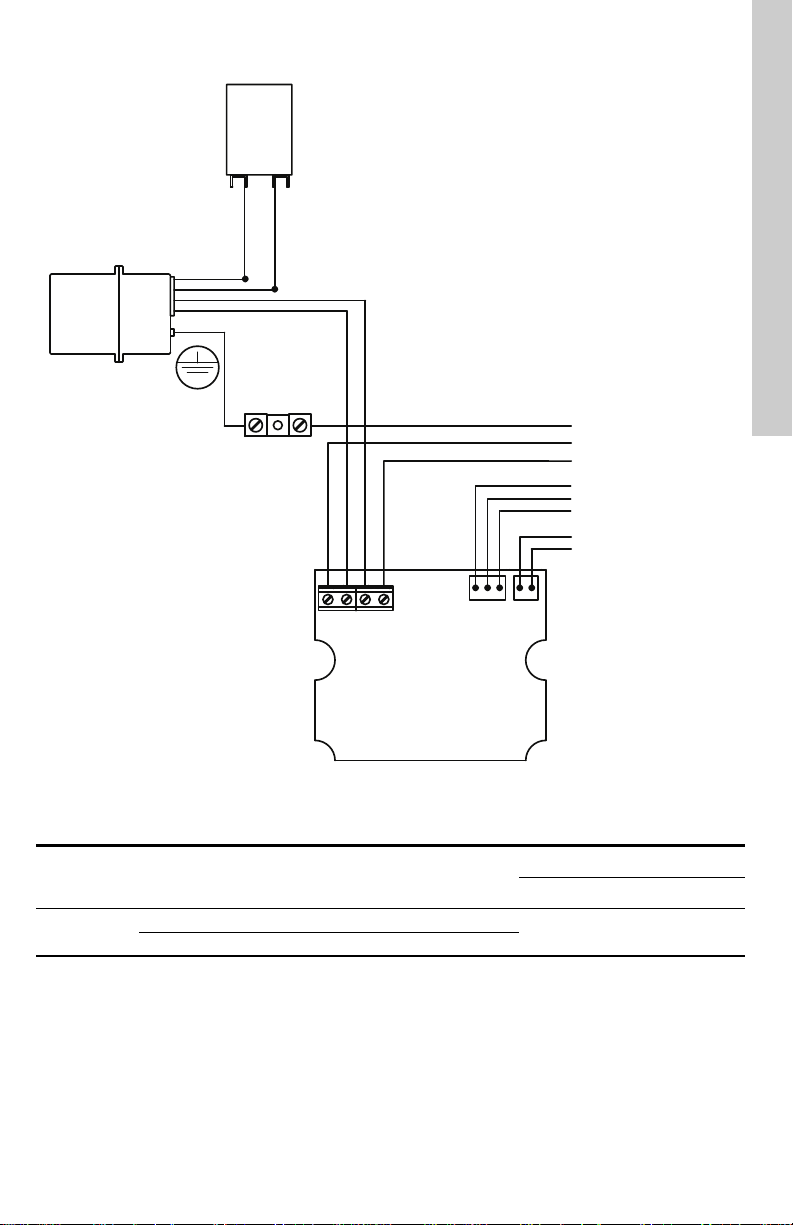

8.2 Wiring diagram

8.2.1 115 V

Fig. 12 Wiring diagram - 115 V

8.3 Winding resistance measurement

Motor

[V/Hz]

115/60

The measurement can be done with or without cables connected to the PCB and the capacitor.

12

Measuring point Winding

A-B (black - red) Main 1.4

A-C (black - white) Aux 5.5

Resistance

[± 10 %]

Ambient temperature

[°F] [°C]

70 21

TM02 2424 4708

Page 13

8.3.1 230 V

Black (phase)

Red

Black

Orange

> Flow sensor

> Pressure switch

Capacitor

Yellow

Yellow

Electric motor

Yellow/green (ground)

Blue

White (neutral)

> Cable

B

A

Yellow

White

English (US)

Fig. 13 Wiring diagram - 230 V

8.4 Winding resistance measurement

Motor

[V/Hz]

230/60

Measuring point Winding

A-B (blue - red) Main 5.4

A-C (blue - white) Aux 5.4

The measurement can be done with or without cables connected to the PCB and the capacitor.

Resistance

[± 10 %]

Ambient temperature

[°F] [°C]

70 21

TM02 2424 2409

13

Page 14

English (US)

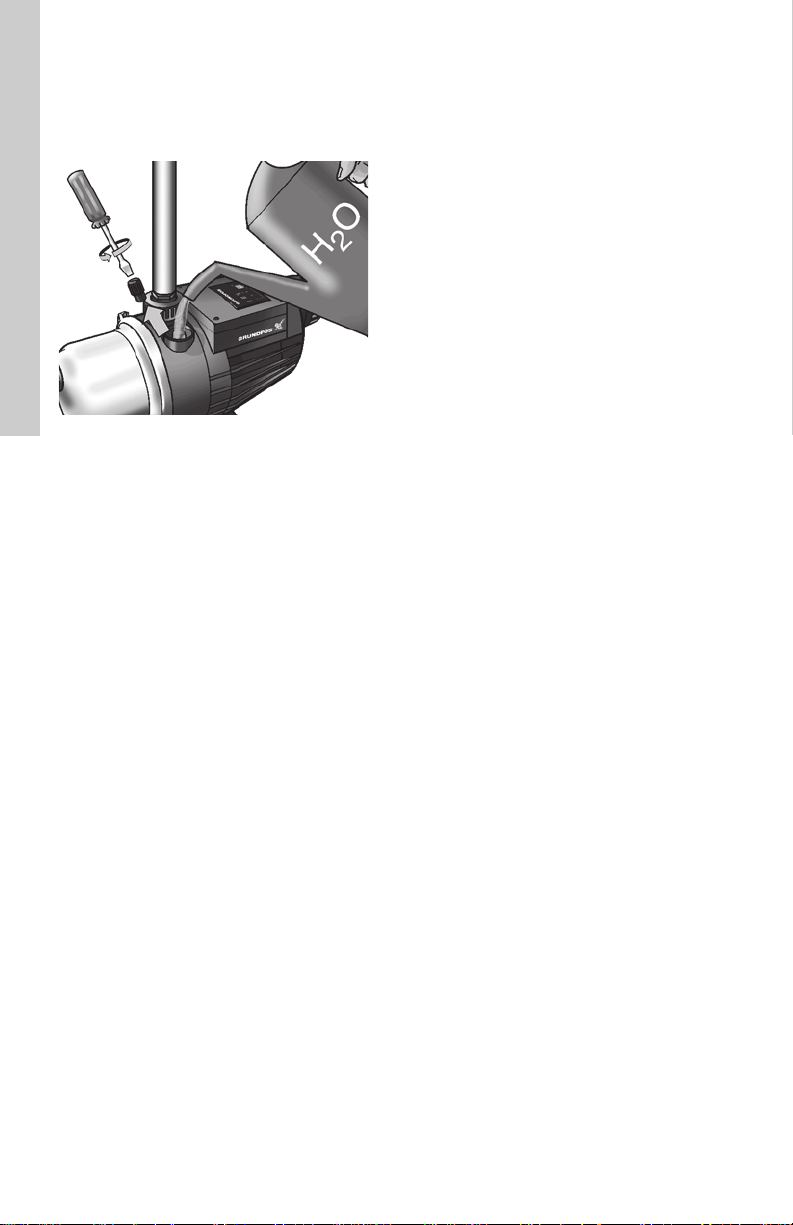

8.5 Start-up

Before start-up, the pump must be filled with

1.2 to 1.5 gallons of water to enable it to selfprime, see fig. 14. The pump is self-priming

with a maximum suction lift of 25 ft.

Fig. 14 Priming the pump

When started, the pump begins to self-prime.

When it has been primed, the pump will automatically change over to normal operation.

If the priming has not been completed within

5 minutes, the pump will stop automatically

and attempt to restart after 30 minutes. It is

possible to reset the pump manually, see point

2 in the table of section 9.1 Control panel.

TM01 9696 2600

14

Page 15

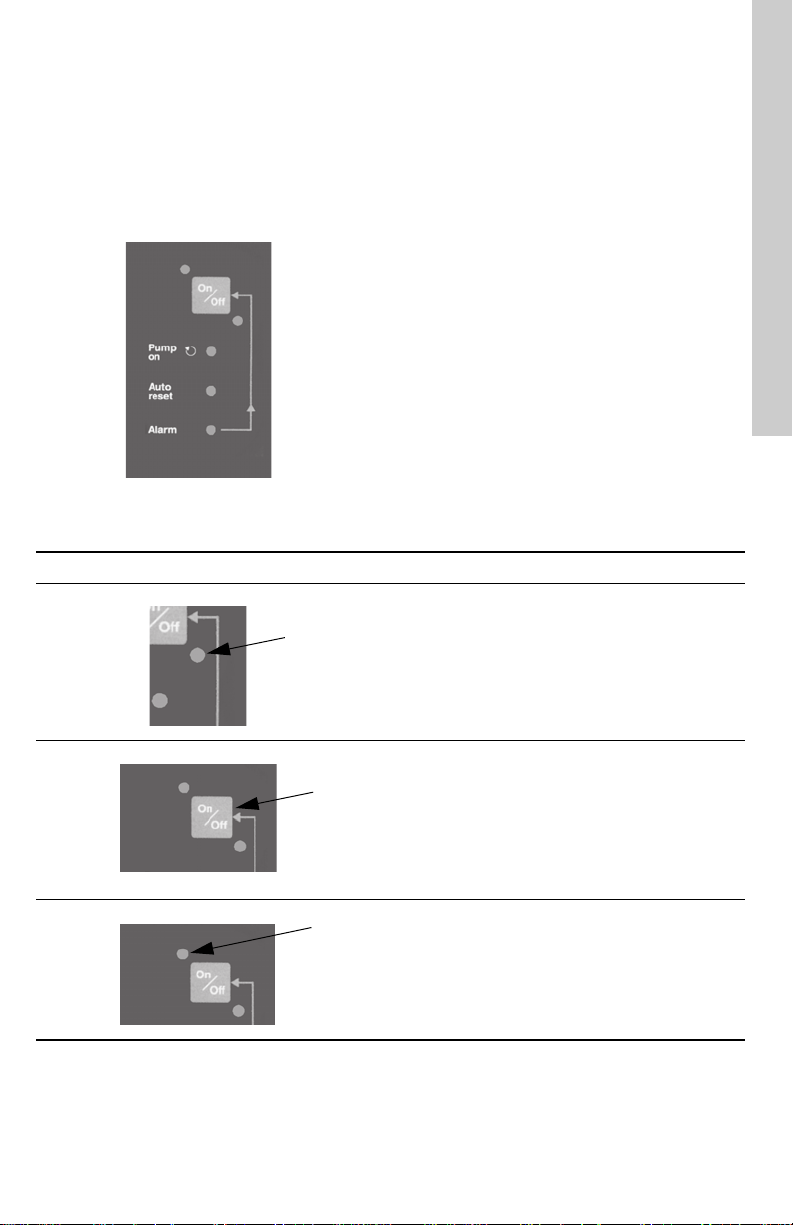

9. Functions

9.1 Control panel

The MQ pump is operated entirely by means

of the control panel. See fig. 1. The control

panel offers the possibility of starting/stopping

the pump. The pump settings and operating

condition are indicated by indicator lights.

See fig. 15.

TM01 9684 2600

Fig. 15 Control panel

The functions of the control panel are described in the table below:

Illustration Description

1 Indicator light (red)

When the indicator light is on, the pump is on standby.

English (US)

2 On/Off button

The pump is started/stopped by means of the on/off

button.

The on/off button can also be used for manual resetting in case of an alarm condition:

• press once for resetting and

• press once more for starting.

3 Indicator light (green)

Indicates that the pump is ready for operation.

When the indicator light is on, the pump will start auto-

matically when water is consumed. The pump will stop

a few seconds after the water consumption has

ceased.

15

Page 16

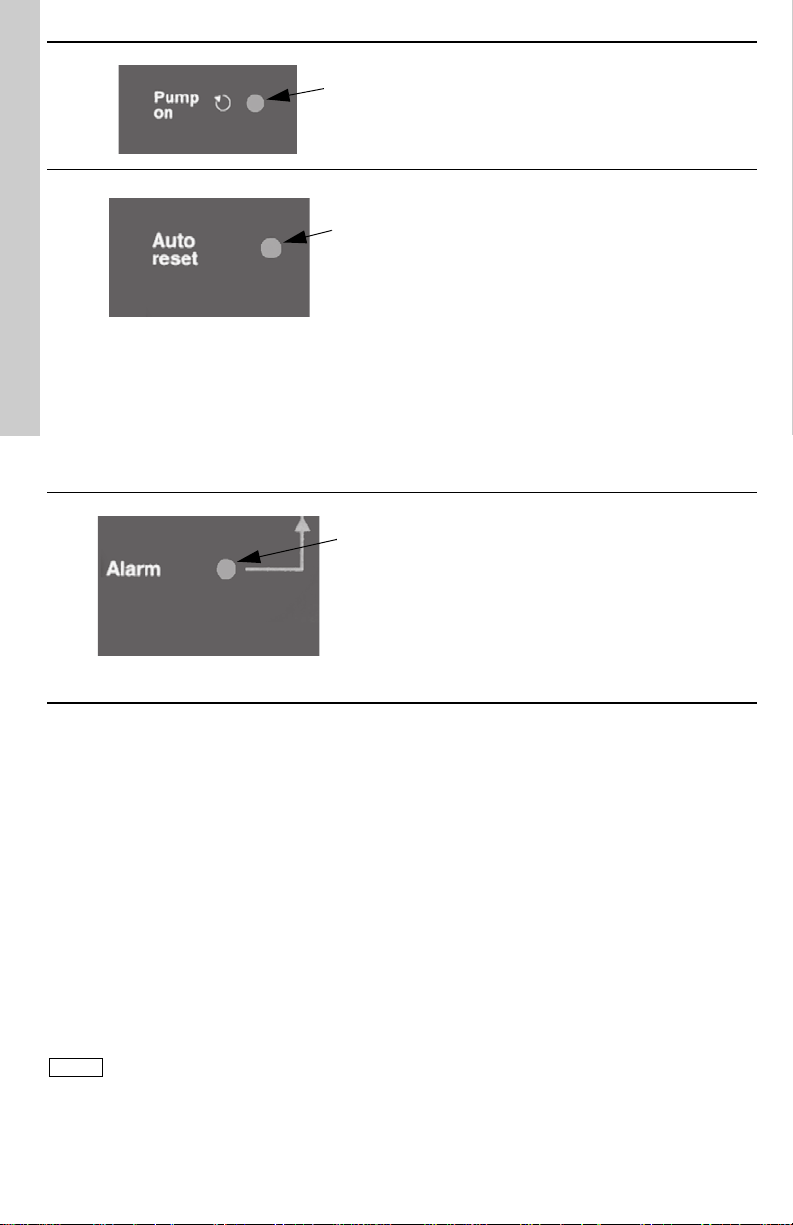

English (US)

Note

4 Pump on (green)

The indicator light is on when the pump is running.

5 Auto reset (green)

As standard, this function is activated on delivery.

• When the indicator light is on, the auto-reset function is activated. The pump will automatically

attempt to restart every 30 minutes after an alarm/

fault over a period of 24 hours. After this period,

the pump will remain in the alarm condition.

• When the indicator light is off, the auto-reset function is deactivated. The pump will not restart after

an alarm/fault.

The auto-reset function can be activated/deactivated

by pressing the on/off button for 5 seconds.

Note: When water is consumed, the pump will start

and stop automatically, whether the auto-reset light is

on or off.

6 Alarm (red)

The indicator light is on when the pump is in alarm

condition.

The alarm condition may have been caused by:

• dry running

• overtemperature

• overloaded motor

• seized-up motor/pump.

See section 9.2 Pump stop.

9.2 Pump stop

The pump incorporates an electronic protective function that will stop the pump in case of

• dry running

• overtemperature

• overloaded motor

• seized-up motor/pump.

The pump will restart automatically after

30 minutes (for 24 hours) in case of any type

of fault if the auto-reset function is activated

(the green indicator light on the control panel

is on, see point 5 in the table of section

9.1 Control panel).

The pump settings are stored.

After supply failure, the pump will

automatically revert to its previous

operating condition when the electricity supply is reconnected.

16

Page 17

10. Maintenance

Note

Under normal operating conditions, the pump

is maintenance-free. However, it is recommended to keep the pump clean.

WARNING

Do not remove the pressure tank

from the pump unless it has been

vented through the air escape

valve.

Never touch the electronics unless

the pump has been switched off

for at least 5 minutes.

If there is any risk of frost damage, drain the

pump through the drain hole and slacken the

union nut on the discharge pipe, see fig. 16.

The pump must be filled with liquid before it is

started up again. See fig. 14.

Fig. 16 Draining the pump

10.1 Service kits

Service kits are available for the MQ pump.

The service kits consist of the following

replaceable parts:

• shaft seal

• motor

• electronic units

• hydraulic components.

10.2 Start-up after a long period of

inactivity

The end cover incorporates a plug which can

be removed by means of a suitable tool.

See fig. 17. It is then possible to free the pu mp

rotor if it has seized up as a result of inactivity.

If it has been drained, the pump must be filled

with liquid before start-up. See fig. 14.

Fig. 17 Removing the end-cover plug

11. Se rvi ce

If a pump has been used for a liquid that is injurious to health or

TM01 9697 4403

If Grundfos is requested to service the pump,

Grundfos must be contacted with details about

the pumped liquid, etc. before the pump is

returned for service. Otherwise Grundfos can

refuse to accept the pump for service.

Possible costs of returning the pump are paid

by the customer.

However, any application for service (no matter to whom it may be made) must include

details about the pumped liquid if the pump

has been used for liquids which are injurious

to health or toxic.

toxic, the pump will be classified

as contaminated.

English (US)

TM04 3633 4608

17

Page 18

English (US)

12. Technical data

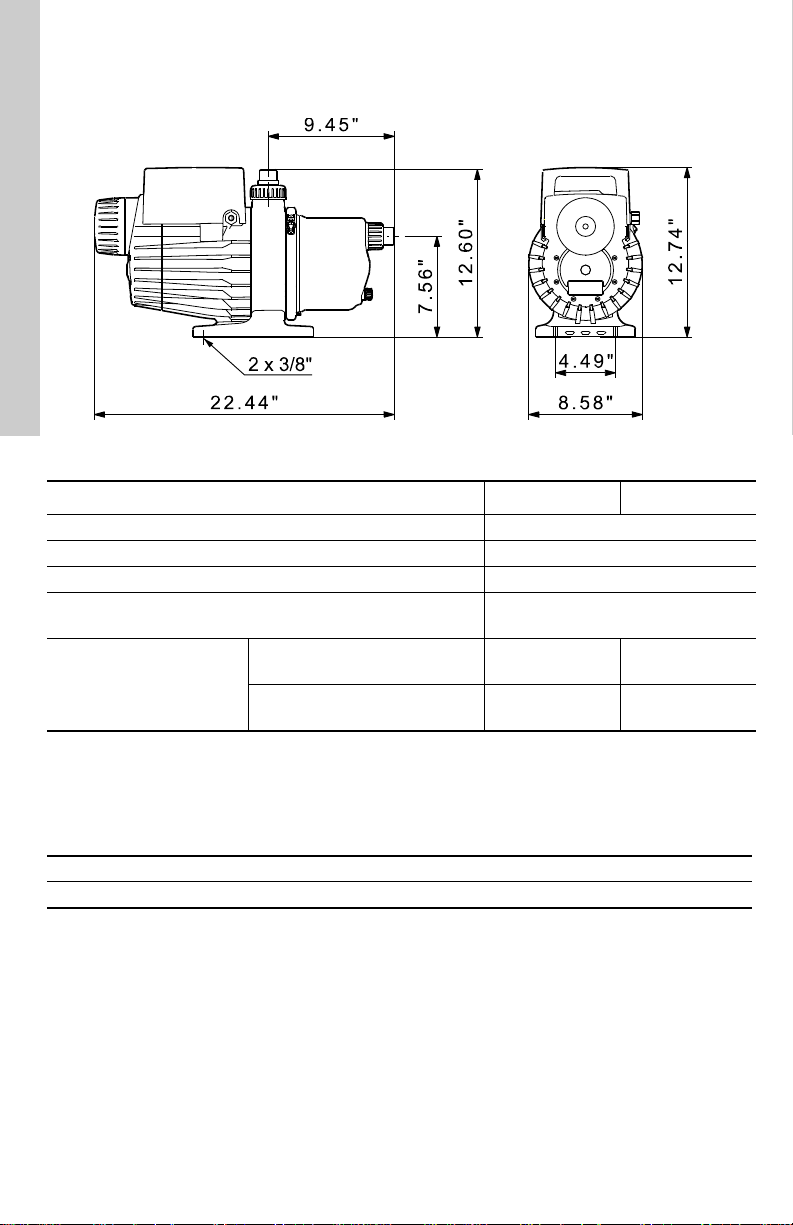

12.1 Dimensions

12.2 Electrical data

MQ 3-35 MQ 3-45

Enclosure type 3

Enclosure class IP 54

Insulation class B

Supply cable

Voltage,

power consumption,

[W]

P

1

1 x 115-120 V – 10/+ 6 %,

60 Hz

1 x 220-240 V – 10/+ 6 %,

60 Hz

6.56 ft SJTW 18 awg

900 W/8.0 A 1100 W/10.0 A

850/4.0 A 1050/4.8 A

TM01 9799 508

with/without plug

12.3 Approvals

UL-listed and CSA-approved.

13. Accessories

Model Designation Product number

MQ 3-35 / MQ 3-45 Protective cover 96590745

18

Page 19

14. Fault finding chart

Fault Cause Remedy

1. The pump does

not start.

2. The pump does

not stop.

3. The pump cuts

out during

operation.

4. The pump

starts and

stops too frequently.

5. The pump

gives electric

shocks.

a) Insufficient water. Check the water supply/suction

pipe.

b) Overheating due to excessive

liquid temperature

(above +95 °F/+35 °C).

c) Overheating due to seized-up/

choked-up pump.

d) Too low or too high supply volt-

age.

e) No electricity supply. Connect the electricity supply.

f) No water consumption. Open a tap. Check that the height

g) Shaft is blocked. Rotate the shaft as described in 10.2

h) Pump is in alarm condition. Reset the pump by means of the on/

a) Existing pipework is leaking or

defective.

b) Non-return valve is blocked or

missing.

a) Dry running. Check the water supply/

b) Overheating due to excessive

liquid temperature

(above +95 °F/+35 °C).

c) Overheating caused by:

– high ambient temperature

(> 113 °F/45 °C)

– overloaded motor

– seized-up motor/pump.

d) Too low supply voltage. Check the supply voltage and cor-

a) Leakage in suction pipe or air

in water.

b) Too low or too high pressure in

pressure tank.

a) Defective ground connection. Connect the ground connection to

Supply cold liquid to the pump.

Contact your pump supplier.

Check the supply voltage and correct the fault, if possible.

between the top point of the discharge pipe and the pump does not

exceed 50 ft.

off button. See point 2 in the t able o f

section 9.1 Control panel.

Repair the pipework.

Clean the valve or fit a new nonreturn valve.

suction pipe.

Supply cold liquid to the pump.

Contact your pump supplier.

rect the fault, if possible.

Check the water and the supply/suc-

tion pipe.

Check the pressure in the pressure

tank. See section 6. Operating con-

ditions.

the pump in accordance with local

regulations.

English (US)

19

Page 20

English (US)

Fault Cause Remedy

6. The pump

starts when no

water is consumed.

If the pump does not start when the fault has been corrected, contact your pump supplier or

Grundfos for further information.

a) Internal non-return valve is

defective, or the existing pipework is leaking or defective.

Clean the valve or fit a new one.

20

Page 21

15. MQ frequently asked questions

1. What causes the MQ to start?

Answer: The MQ is equipped with both an

internal flow switch and pressure switch.

Each of these can turn the MQ on, depending on water consumption. The pump will

start when:

The flow rate is greater than 0.3 gpm

OR

the pressure is below 29 psi.

2. What causes the MQ to stop?

Answer: Other than the manual on/off button, only the flow switch is authorized to

automatically stop the MQ during normal

operation when flow drops below 0.3 gpm.

The pump will shut off in 12-15 seconds

after flow stops.

Additionally , the MQ will be turned of f in the

event of a dry-run or overtemperature

alarm.

3. What is the maximum height of a tap

above the MQ?

Answer: If a tap or faucet is installed at

heights greater than 50 ft above the MQ,

there is the potential risk that the MQ will

never start. In cases where the MQ starts

due to low pressure (low flow rates), the

pressure has to fall below the pressure

switch activation point (28- 30 psi facto ry

setting). To allow for the pressure of 50 f t of

water, tolerances and a safety margin, we

recommend a maximum height of 50 ft

between the MQ and any tap.

4. What is the purpose of the built-in pres-

sure tank?

5. How is the dry-run condition deter-

mined?

Answer: The dry-run alarm is declared

when the motor is running AND the flow

rate is less than 1.6 gpm AND when pressure is less than the pressure switch setting. When this condition lasts for 12 seconds, the alarm will be declared after

1 minute, and the motor is stopped.

The MQ attempts to automatically restart

every 30 minutes for a maximum of

24 hours. If more than 24 hours pass without water, the pump must b e restarted manually.

6. What is the maximum inlet pressure

allowed in the MQ?

Answer: For both MQ 3-35 and MQ 3-45,

the maximum internal pressure allowed is

109 psi. The maximum inlet pressure when

added to the MQ pressure must not exceed

109 psi.

Remember that inlet pressure adds to the

MQ pressure, so with a 40 psi inlet pressure supplied to the MQ 3-45, internal pressures can reach approximately 105 psi

(65 + 40 psi).

Additionally, if inlet pressures exceed the

built-in pressure switch activation point

(28-30 psi factory setting), the pressure

switch will be unable to activate, and the

ability to turn the MQ on at low flow rates

will be lost. In this situation, only the flow

switch will be able to turn the MQ on at flow

rates above its activation point of 0.3 gpm

7. What is the priming capacity of the MQ?

Answer: Approx. 1.2 gallons.

English (US)

Answer: The built-in pressure tank comes

from the factory, pressurized at approximately 23 psi (with the pump pressure at

zero) and holds a volume of 14 ounces of

water. It is designed to minimize motor

startup due to small leaks.

21

Page 22

English (US)

Subject to alterations.

8. How is overload temperature/overtem-

perature of the MQ detected?

Answer: The motor has a thermal switch

incorporated in the motor windings.

The switch will cut out the motor and start

again. See the table below.

Thermal protection

[V] [°F] [°C]

Cut-out

Cut-in Both 151 65-67

9. Where can a pressure gauge be easily

installed to measure the discharge pressure?

Answer: In the discharge piping or in 3/8"

GAS straight thread opening used to add

priming water to the pump.

115 302 150

230 275 135

16. Disposal

This product or parts of it must be disposed of

in an environmentally sound way:

1. Use the public or private waste collection

service.

2. If this is not possible, contact the nearest

Grundfos company or service workshop.

22

Page 23

Español (MX) Instrucciones de instalación y funcionamiento

ÍNDICE

1. Introducción

2. Artículos suministrados

3. Símbolos utilizados en este

documento

4. Aplicaciones

4.1 Líquidos bombeados

5. Identificación

5.1 Nomenclatura

6. Condiciones de fun cionam ien to

6.1 Altura de succión

7. Instalación mecánica

7.1 Ubicación

7.2 Cimentación

7.3 Requisitos de espacio

7.4 Tuberías

7.5 Cubierta protectora

8. Conexión eléctrica

8.1 Generador o inversor

8.2 Diagrama de cableado

8.3 Medida de la resistencia de bobinado

8.4 Medida de la resistencia de bobinado

8.5 Puesta en marcha

9. Funciones

9.1 Panel de control

9.2 Paro de la bomba

10. Mantenimiento

10.1 Kits de mantenimiento

10.2 Puesta en marcha tras un periodo

prolongado de inactividad

11. Mantenimiento

12. Datos técnicos

12.1 Dimensiones

12.2 Datos eléctricos

12.3 Homologaciones

13. Accesorios

14. Tabla de búsqueda de averías

15. Preguntas frecuentes acerca de la

bomba MQ

16. Eliminación

Página

23

23

24

24

24

25

25

26

26

27

27

27

27

27

29

30

30

31

31

32

33

34

34

36

37

37

37

37

38

38

38

38

38

39

41

42

ADVERTENCIA

Antes de llevar a cabo la instalación, lea estas instrucciones de

instalación y funcionamiento.

La instalación y el funcionamiento de la bomba deben satisfacer los requisitos de la normativa

local vigente y los códigos aceptados de buenas prácticas.

1. Introducción

La bomba MQ es un sistema de suministro de

agua con bajo nivel de emisión de ruidos compuesto por un motor, un recipiente a presión y

un regulador, todo ello combinado en una unidad de tamaño compacto. El sistema es apto

para el uso interior y exterior.

La bomba autocebante se pone automáticamente en marcha cuando se consume agua

en la instalación, y se detiene cuando cesa el

consumo. La válvula de retención, interna e

integrada, evita el reflujo durante el cebado y

el funcionamiento de la bomba.

La bomba MQ está dotada de protección contra exceso de temperatura y funcionamiento

en seco, así como de un sencillo panel de

control.

El recipiente a presión integrado reduce el

número de arranques y paros en caso de que

exista una fuga en la instalación.

2. Artículos suministrados

El paquete de la bomba MQ contiene los

siguientes artículos:

• sistema de suministro de agua MQ con válvula de retención integrada

• válvula de retención de entrada en bolsa

de plástico

• instrucciones de instalación y funcionamiento.

Español (MX)

23

Page 24

Español (MX)

Precaución

Nota

3. Símbolos utilizados en este

documento

ADVERTENCIA

Si no se respetan estas instrucciones de seguridad podrían producirse lesiones personales.

Si no se respetan estas instrucciones de seguridad podrían producirse problemas o daños en el

equipo.

Notas o instrucciones que facilitan

el trabajo y garantizan un funcionamiento seguro.

4. Aplicaciones

El sistema de suministro de agua MQ ha sido

diseñado para cumplir los requisitos de las

siguientes aplicaciones típicas.

• aumento de la presión de agua

(presión máxima de entrada: 40 psi)

• suministro de agua desde pozos (altura

máxima de succión: 25 ft), por ejemplo

– en hogares privados

– en granjas

– en huertas y jardines grandes de otros

tipos.

La bomba es apta para bombear aguas pluviales.

4.1 Líquidos bombeados

líquidos de baja densidad, no agresivos, que

no contengan partículas o fibras sólidas.

24

Page 25

5. Identificación

Plataforma de base

Tapón de

drenaje

Puerto de

succión

Tapón de cebado

Puerto de descarga

Panel de control

Cubierta del

depósito a presión

Tapón de

la cubierta

posterior

Cubierta protectora

(accesorio)

5.1 Nomenclatura

Ejemplo MQ 3 -35 A -O -A BVBP

Tipo de bomba

Caudal nominal [m³/h]

Altura [m]

Código de versión de la bomba

A: Estándar

Código de conexión a tubería

Código de materiales

A: Estándar

Código del sello de flecha

Español (MX)

Fig. 1 Sistema de suministro de agua MQ. Se requiere una cubierta protectora para el uso

en exteriores

TM04 3648 4908

25

Page 26

Español (MX)

6. Condiciones de funcionamiento

MQ 3-35 MQ 3-45

Caudal máximo [gpm] 22

Presión máxima [psi] 51 65

Presión máxima del sistema [psi] 108

Altura máxima de succión [ft];

consulte la página 49

Temperatura ambiente mínima [°F]/[°C] 32/0

Temperatura ambiente máxima [°F]/[°C] 113/45

Temperatura mínima del líquido [°F]/[°C] 32/0

Temperatura máxima del líquido [°F]/[°C] 95/35

Peso neto [lbs] 29

Nivel de presión sonora [dB(A)] < 70

Volumen del depósito [oz] 13,5

Presión de aire en el depósito [psi] 22 a 25

Conexiones 1" NPT

Tapones de cebado y drenaje GAS de 3/8"

25

6.1 Altura de succión

La altura máxima de succión de la bomba se

puede determinar haciendo uso del gráfico

que se encuentra en la página 49.

Ejemplo:

Si la altura de succión es de 10 ft, la longitud

del tubo de succión no deberá superar los

72 ft.

26

Page 27

7. Instalación mecánica

Nota

Nota

Máx. ± 18 °

Nota

Nota

60"

7.1 Ubicación

La bomba es apta para su instalación en

entornos interiores y exteriores. Resiste la luz

solar directa.

Si desea instalar la bomba en un

entorno exterior, deberá equiparla

con una cubierta protectora (accesorio). Consulte las secciones

7.5 Cubierta pr otect ora y

13. Accesorios.

En el caso improbable de que se

produzca una fuga interna, el

líquido bombeado se drenará de la

base y/o la cubierta posterior para

evitar que la bomba resulte

dañada. Instale la bomba de tal

modo que no puedan surgir daños

colaterales no deseados.

7.2 Cimentación

Monte la bomba sobre la plataforma de base

con el puerto de succión en posición horizontal y el puerto de descarga en posición vertical.

La bomba debe instalarse en posición horizontal.

El ángulo máximo de inclinación admisible es

de ± 18 °.

Consulte la fig. 2.

7.3 Requisitos de espacio

A fin de permitir la realización de operaciones

de inspección y mantenimiento, debe mantenerse un espacio mínimo de 60" tras la

bomba.

Español (MX)

TM04 3746 5008

Fig. 3 Espacio mínimo tras la bomba

Al disponer de un sistema de autorrefrigeración, la bomba no requiere espacio ni ventilación en los laterales.

Asegúrese de que las temperaturas ambiente máximas no superan

los valores indicados en la sección 6. Condiciones de funcionamiento.

7.4 Tuberías

No aplique demasiada fuerza

durante la conexión a las tuberías.

La bomba cuenta con conexiones roscadas de

1" NPT. Realice las conexiones en los puertos

de succión y descarga. Consulte la fig. 4.

El puerto de descarga de la bomba es flexible

(± 5 °), lo cual facilita la conexión.

Fig. 2 Instalación horizontal de la bomba

MQ

A fin de evitar movimientos y vibraciones, la

bomba y la plataforma de base pueden fijarse

a un cimiento sólido por medio de los orificios

de sujeción de la base. Si desea obtener más

información acerca de la conexión de la

bomba al sistema de tuberías, consulte la sección 7.4 Tuberías.

TM01 9691 2600

TM01 9698 2600

Fig. 4 Instalación de las conexiones ros-

cadas en los puertos de succión y

descarga

27

Page 28

Español (MX)

Válvula

de pie

Enrosque con cuidado la conexión de descarga en el puerto de descarga utilizando una

llave fija o herramienta similar. Sostenga la

conexión de descarga y apriete la tuerca de

unión de descarga de la bomba con la mano.

Consulte la fig. 5.

Fig. 5 Correcto: Apriete la tuerca de unión

de descarga con la mano

Fig. 6 Incorrecto: No utilice una herra-

mienta para apretar la tuerca de

unión de descarga

7.4.2 Uso de una manguera de succión en

lugar de un tubo

Si se utiliza una manguera de succión en

lugar de un tubo, la manguera no deberá

superar las longitudes indicadas en el gráfico

de la página 49. La manguera de succión

debe tener un diámetro mínimo de Ø1".

La manguera debe ser de tipo no plegable.

7.4.3 Tubos de succión largos

La bomba incluye una válvula de retención de

entrada independiente. Si se utilizan tubos de

succión de gran longitud, se recomienda instalar la válvula de retención de entrada en el

TM04 4271 1009TM 044272 1009TM01 9693 2600

puerto de succión de la bomba. Consulte la

sección 7.4.4 Instalación de la válvula de

retención de entrada

Los tubos deben apoyarse debidamente a

cualquier lado de la bomba para evitar forzar

sus conexiones.

7.4.1 Tubos de succión conectados a un

pozo

Si la bomba extrae agua de un pozo, se recomienda instalar una válvula de pie en el

extremo del tubo de succión.

Consulte la fig. 7.

Fig. 7 Tubos de succión conectados a un

pozo

28

Page 29

7.4.4 Instalación de la válvula de retención

Nota

Nota

de entrada

La válvula de retención de entrada reduce el

riesgo de pérdidas de cebado de la bomba en

aplicaciones de succión negativa y mejora la

capacidad de autosucción, por ejemplo al

suministrar agua desde una cisterna.

Instale la válvula de retención de entrada de la

siguiente manera, consulte la fig. 8:

1. Retire la conexión de succión de la bomba.

2. Instale la válvula de retención de entrada

en el puerto de succión, en la dirección que

se indica en la fig. 8.

3. Vuelva a instalar la conexión de la bomba.

Las aplicaciones con presión de

entrada positiva no requieren la

instalación de una válvula retención de entrada debido al hecho

de que la bomba MQ incorpora

una válvula de retención interna

en el lado de descarga.

7.5 Cubierta protectora

La garantía quedará invalidada si

no se usa la cubierta protectora en

una instalación exterior.

La cubierta protectora protege el panel de

control contra las inclemencias climatológicas.

Se encuentra disponible como accesorio.

Consulte la sección 13. Accesorios.

Para instalar la cubierta protectora, encájela

en la parte superior del panel de control de

modo que quede sujeta por los bordes disipadores.

Para quitar la cubierta, tire de las dos sujeciones hacia fuera, sepárela de los bordes disipadores y tire de ella hacia arriba.

Fig. 9 Cubierta protectora

Español (MX)

TM04 3745 5008

Fig. 8 Instalación de una válvula de

retención de entrada

TM 04 4121 0809

29

Page 30

Español (MX)

Nota

8. Conexión eléctrica

Las conexiones eléctricas y la instalación de

protecciones adicionales deben ser llevadas a

cabo por personas debidamente cualificadas

de acuerdo con las normas locales.

ADVERTENCIA

Esta bomba no es sumergible.

Si el cordón de alimentación es

dañado, éste debe sustituirse por

el fabricante, por su agente de servicio autorizado o por personal

calificado con el fin de evitar un

peligro.

No realice ninguna conexión en el

cuadro de terminales a menos que

se haya mantenido desconectada

la fuente de alimentación eléctrica

durante al menos 5 minutos.

Riesgo de descarga eléctrica:

Esta bomba está equipada con un

conductor de masa y un enchufe

con conexión a masa. A fin de

reducir el riesgo de descarga eléctrica, realice la instalación únicamente en circuitos protegidos por

un interruptor de circuito de fallos

de conexión a tierra (GFCI).

Esta bomba no está destinada al

uso en piscinas o áreas marítimas

ni ha sido desarrollada para ello.

Esta bomba ha sido evaluada para

su uso exclusivo con agua.

No ponga la bomba en marcha

hasta que se haya llenado de agua

(cebado, consulte la fig. 12).

Apta para uso interior y exterior.

Categoría de aislamiento 3.

El voltaje y la frecuencia de funcionamiento se

encuentran marcados en la placa de características. Asegúrese de que el motor sea apto

para la fuente de alimentación eléctrica a la

que va a conectarse.

La bomba debe conectarse a la red eléctrica

por medio de un cable apantallado con conductor protector de masa. Es posible sustituir

el cable de alimentación. Consulte la fig. 10.

TM01 9694 2600TM01 9695 2600

Fig. 10 Conexión eléctrica

Conecte el cable de alimentación de la bomba

a la fuente de alimentación eléctrica. Al conectar el cable se iluminarán dos indicadores en

el panel de control, uno en color rojo y otro en

color verde.

Consulte la fig. 11.

Fig. 11 Conexión del cable de alimentación

eléctrica

8.1 Generador o inversor

La bomba MQ se puede alimentar

utilizando un generador o un

inversor. No obstante, la bomba

sólo funcionará satisfactoriamente si el generador o inversor

genera una onda perfectamente

sinusoidal con la entrada necesaria de potencia y voltaje. El generador debe dimensionarse superando en un 10 % el valor P1

(entrada de potencia) de la bomba.

Si desea conocer el valor de P1,

consulte la sección

12.1 Dimensiones.

30

Page 31

8.2 Diagrama de cableado

Negro (fase)

Rojo

Negro

Naranja

> Sensor de flujo

> Presostato

Conden-

sador

Amarillo

Amarillo

Motor eléctrico

Amarillo / verde (masa)

Rojo (vivo)

Negro

Blanco (neutro)

> Cable

B

A

Amarillo

Blanco

C

8.2.1 115 V

Español (MX)

Fig. 12 Diagrama de cableado - 115 V

8.3 Medida de la resistencia de bobinado

Motor

[V/Hz]

115/60

La medida puede realizarse con o sin los cables conectados a la placa PCB y el condensador.

Punto de medida Bobinado

A-B (negro - rojo) Principal 1,4

A-C (negro - blanco) Auxiliar 5,5

Resistencia

[ ± 10 %]

Temperatura ambiente

[°F] [°C]

70 21

TM02 2424 4708

31

Page 32

Español (MX)

Negro (fase)

Rojo

Negro

Naranja

> Sensor de flujo

> Presostato

Conden-

sador

Amarillo

Amarillo

Motor eléctrico

Amarillo / verde (masa)

Rojo (vivo)

Azul

Blanco (neutro)

> Cable

B

A

Amarillo

Blanco

8.3.1 230 V

Fig. 13 Diagrama de cableado - 230 V

8.4 Medida de la resistencia de bobinado

Motor

[V/Hz]

230/60

Punto de medida Bobinado

A-B (azul - rojo) Principal 5,4

A-C (azul - blanco) Auxiliar 5,4

La medida puede realizarse con o sin los cables conectados a la placa PCB y el condensador.

32

Resistencia

[ ± 10 %]

Temperatura ambiente

[°F] [°C]

70 21

TM02 2424 2409

Page 33

8.5 Puesta en marcha

Antes de su puesta en marcha, la bomba debe

llenarse con entre 1,2 y 1,5 galones de agua

para permitir que se cebe. Consulte la fig. 14.

La bomba cuenta con una función de autocebado con una altura de succión máxima de

25 ft.

Fig. 14 Cebar la bomba

Una vez puesta en marcha, la bomba comenzará a autocebarse. Tras la fase de cebado, la

bomba pasará automáticamente al modo de

funcionamiento normal. Si la fase de cebado

no finaliza antes de 5 minutos, la bomba se

detendrá automáticamente e intentará volver a

ponerse en marcha después de 30 minutes.

Es posible restablecer la bomba manualmente. Para ello, siga los pasos descritos en

el punto 2 de la tabla de la sección 9.1 Panel

de control.

Español (MX)

TM01 9696 2600

33

Page 34

Español (MX)

9. Funciones

9.1 Panel de control

La bomba MQ se controla íntegramente a través del panel de control. Consulte la fig. 1.

El panel de control ofrece la posibilidad de

poner en marcha / detener la bomba. La configuración de la bomba y sus condiciones de

mantenimiento pueden conocerse por medio

de los indicadores luminosos. Consulte la

fig. 15.

TM01 9684 2600

Fig. 15 Panel de control

Las funciones del panel de control se describen en la tabla siguiente:

Ilustración Descripción

1 Indicador luminoso (rojo)

Si el indicador luminoso se encuentra encendido,

indica que la bomba está en estado de reposo.

2 Botón de encendido / apagado

La bomba se pone en marcha / detiene por medio del

botón de encendido / apagado.

El botón de encendido / apagado también se puede

usar para restablecer manualmente la bomba en caso

de que se genere una situación de alarma:

• púlselo una vez para restablecer la bomba,

y púlselo de nuevo para ponerla en marcha.

3 Indicador luminoso (verde)

Indica que la bomba se encuentra preparada para funcionar.

Si el indicador luminoso se encuentra encendido,

indica que la bomba se pondrá automáticamente en

marcha si se consume agua. La bomba se detendrá

unos segundos después de que cese el consumo de

agua.

34

Page 35

4 Bomba encendida (verde)

El indicador luminoso se activa cuando la bomba se

encuentra en funcionamiento.

5 Restablecimiento automático (verde)

De forma predeterminada, esta función se encuentra

activada.

• Si el indicador luminoso se encuentra encendido,

indica que la función de restablecimiento automático está activada. La bomba intentará volver a

ponerse en marcha automáticamente cada

30 minutos después de una alarma / avería

durante un periodo de 24 horas. Una vez

transcurrido dicho periodo, la bomba permanecerá

en estado de alarma.

• Si el indicador luminoso se encuentra apagado,

indica que la función de restablecimiento automático está desactivada. La bomba no volverá a

ponerse en marcha después de una alarma /

avería.

La función de restablecimiento automático puede activarse / desactivarse manteniendo el botón de encendido / apagado durante 5 segundos.

Nota: Durante el consumo de agua, la bomba se pone

en marcha y se detiene automáticamente, independientemente de si el indicador luminoso de restablecimiento automático se encuentra encendido o apagado.

6 Alarma (rojo)

El indicador luminoso se enciende si la bomba se

encuentra en estado de alarma.

El estado de alarma podría haber sido provocado por:

• funcionamiento en seco

• exceso de temperatura

• motor sobrecargado

• motor / bomba agarrotados.

Consulte la sección 9.2 Paro de la bomba.

Español (MX)

35

Page 36

Español (MX)

Nota

9.2 Paro de la bomba

La bomba está equipada con una función de

protección que provoca que la bomba se

detenga en caso de

• funcionamiento en seco

• exceso de temperatura

• motor sobrecargado

• motor / bomba agarrotados.

La bomba volverá a ponerse en marcha auto-

máticamente después de 30 minutos (durante

24 horas) si se produce cualquier tipo de avería y la función de restablecimiento automático

está activada (el indicador luminoso de color

verde del panel de control debe encontrarse

activado, consulte el punto 5 de la tabla de la

sección 9.1 Panel de control).

La configuración de la bomba se

almacena. Tras una falla en el

suministro eléctrico, la bomba

recupera automáticamente su

anterior estado de funcionamiento al restaurarlo.

36

Page 37

10. Mantenimiento

Nota

En condiciones de funcionamiento normales,

la bomba no precisa mantenimiento. No obstante, se recomienda mantener la bomba limpia.

ADVERTENCIA

No retire el depósito a presión de

la bomba a menos que se haya

ventilado a través de la válvula de

escape de aire.

No toque los componentes electrónicos a menos que la bomba se

haya mantenido desconectada

durante, al menos, 5 minutos.

Si existe riesgo de daños por congelación,

drene la bomba a través del orificio de drenaje

y afloje la tuerca de unión del tubo de descarga. Consulte la fig. 16. La bomba debe llenarse de líquido antes de arrancarla de nuevo.

Consulte la fig. 14.

Fig. 16 Drenaje de la bomba

10.1 Kits de mantenimiento

Existen kits de mantenimiento disponibles

para la bomba MQ. Los kits de servicio se

componen de los siguientes componentes

sustituibles:

• sello de flecha

• motor

• unidades electrónicas

• componentes hidráulicos.

10.2 Puesta en marcha tra s un pe riodo

prolongado de inactividad

La cubierta posterior incorpora un tapón que

se puede retirar utilizando la herramienta adecuada. Consulte la fig. 17. Ello permite liberar

el rotor de la bomba si se encuentra agarrotado como resultado de un periodo de inactividad. Si ha sido drenada, la bomba deberá llenarse de líquido antes de ponerla en marcha.

Consulte la fig. 14.

Fig. 17 Retirar el tapón de la cubierta

posterior

11. Mantenimiento

Si una bomba se utiliza para bombear líquidos perjudiciales para la

TM01 9697 4403

Si se solicita a Grundfos la inspección de la

bomba, deberán enviarse los detalles relacionados con el líquido bombeado, etc. antes de

enviar la bomba para su inspección. De lo

contrario, Grundfos podría rechazar la inspección de la bomba.

Los posibles gastos de devolución de la

bomba correrán por cuenta del cliente.

No obstante, todas las solicitudes de reparación (independientemente de a quién vayan

dirigidas) deberán incluir los detalles acerca

del líquido bombeado si la bomba se ha utilizado con líquidos perjudiciales para la salud o

tóxicos.

salud o tóxicos, se clasificará

como contaminada.

Español (MX)

TM04 3633 4608

37

Page 38

Español (MX)

12. Datos técnicos

12.1 Dimensiones

12.2 Datos eléctricos

MQ 3-35 MQ 3-45

Tipo de protección 3

Categoría de protección IP 54

Categoría de aislamiento B

Cable de suministro eléctrico

Voltaje, consumo de

potencia, P

1

[W]

1 x 115-120 V – 10/+ 6 %, 60 Hz 900 W / 8,0 A 1100 W / 10,0 A

1 x 220-240 V – 10/+ 6 %, 60 Hz 850 / 4,0 A 1050 / 4,8 A

6.56 ft SJTW 18 awg con/

TM01 9799 508

sin enchufe

12.3 Homologaciones

Homologaciones UL y CSA.

13. Accesorios

Modelo Designación

MQ 3-35 / MQ 3-45 Cubierta protectora 96590745

38

Número de

producto

Page 39

14. Tabla de búsqueda de averías

Avería Causa Solución

1. No se puede

poner en marcha la bomba.

2. La bomba no

se detiene.

3. La bomba se

detiene durante

el funcionamiento.

a) No hay agua suficiente. Compruebe el suministro de agua /

tubo de succión.

b) Se ha producido un sobrecalen-

tamiento debido a que la temperatura del líquido es excesiva

(superior a +95 °F / +35 °C).

c) Se ha producido un sobrecalen-

tamiento debido a un agarrotamiento / estrangulamiento de la

bomba.

d) El voltaje de suministro es

demasiado alto o demasiado

bajo.

e) La bomba no recibe suministro

eléctrico.

f) No se consume agua. Abra un grifo. Compruebe que la

g) El eje está bloqueado. Gire el eje según lo descrito en la

h) La bomba se encuentra en

estado de alarma.

a) Existe una fuga en el sistema

de tuberías o éste no está bien

instalado.

b) La válvula de retención está

bloqueada o no se encuentra

instalada.

a) La bomba está funcionando en

seco.

b) Se ha producido un sobrecalen-

tamiento debido a que la temperatura del líquido es excesiva

(superior a +95 °F / +35 °C).

c) Se ha producido un sobrecalen-

tamiento provocado por:

– una alta temperatura ambien-

tal (> 113 °F/45 °C)

– una sobrecarga del motor

– un agarrotamiento del motor /

bomba.

d) El voltaje de suministro es

demasiado bajo.

Suministre líquido frío a la bomba.

Póngase en contacto con el proveedor de la bomba.

Compruebe el voltaje de suministro

y corrija la avería, si es posible.

Conecte el suministro eléctrico.

separación entre el punto superior

del tubo de descarga y la bomba no

sea superior a 50 ft.

sección 10.2

Restablezca la bomba utilizando el

botón de encendido / apagado.

Consulte el punto 2 de la tabla de la

sección 9.1 Panel de control.

Repare el sistema de tuberías.

Limpie la válvula o instale una válvula de retención nueva.

Compruebe el suministro de agua /

tubo de succión.

Suministre líquido frío a la bomba.

Póngase en contacto con el proveedor de la bomba.

Compruebe el voltaje de suministro

y corrija la avería, si es posible.

Español (MX)

39

Page 40

Español (MX)

Avería Causa Solución

4. La bomba se

pone en marcha y se

detiene con

demasiada frecuencia.

5. La bomba

transmite descargas eléctricas.

6. La bomba se

pone en marcha aunque no

se consuma

agua.

Si la bomba no se pone en marcha una vez corregida la avería, póngase en contacto con el proveedor de la bomba o con Grundfos para obtener más información.

a) Existe una fuga en el tubo de

succión o aire en el agua.

b) La presión del depósito a pre-

sión es demasiado alta o demasiado baja.

a) La conexión a tierra se ha reali-

zado de forma incorrecta.

a) La válvula de retención inte rna

está defectuosa o el sistema de

tuberías presenta fugas o está

defectuoso.

Compruebe el agua y el tubo de

suministro / succión.

Compruebe la presión del depósito

a presión. Consulte la sección

6. Condiciones de funcionamiento.

Conecte la conexión a tierra de la

bomba de acuerdo con los reglamentos locales.

Limpie la válvula o instale una

nueva.

40

Page 41

15. Preguntas frecuentes acerca de la bomba MQ

1. ¿Qué provoca que la bomba MQ se

ponga en marcha?

4. ¿Cual es la finalidad del depósito a

presión integrado?

Respuesta: La bomba MQ está equipada

con un interruptor de caudal interno y un

presostato. Ambos pueden poner en marcha la bomba MQ dependiendo del consumo de agua. La bomba se pondrá en

marcha si:

El caudal es superior a 0,3 gpm

O

la presión es inferior a 29 psi.

2. ¿Qué provoca que la bomba MQ se

detenga?

Respuesta: Además del uso del botón de

encendido / apagado manual, únicamente

el interruptor de caudal está autorizado a

detener automáticamente la bomba MQ

durante su funcionamiento normal si el

caudal cae por debajo de 0,3 gpm. La

bomba se detiene entre 12 y 15 segundos

después de que el caudal se detenga.

Por otra parte, la bomba MQ se detiene

también en caso de funcionamiento en

seco o si se activa una alarma de exceso

de temperatura.

3. ¿Cuál es la altura máxima de un grifo

situado por encima de la bomba MQ?

Respuesta: El depósito a presión inte-

grado viene presurizado de fábrica a,

aproximadamente, 23 psi (con la presión

de la bomba a cero) y contiene un volumen

de 14 onzas de agua. Ha sido diseñado

para minimizar la puesta en marcha del

motor provocada por pequeñas fugas.

5. ¿Cómo se determina el estado de

funcionamiento en seco?

Respuesta: La alarma de funcionamiento

en seco se activa cuando el motor se

encuentra en funcionamiento, el caudal es

inferior a 1,6 gpm Y la presión es inferior a

aquella configurada en el presostato.

Si dicha condición perdura durante

12 segundos, la alarma se activa una vez

transcurrido 1 minuto y el motor se detiene.

La bomba MQ intentará volver a ponerse

en marcha automáticamente cada 30 minutos durante un periodo de 24 horas.

Si transcurren más de 24 horas sin que

penetre agua en la bomba, la bomba

deberá volver a ponerse en marcha

manualmente.

Español (MX)

Respuesta: Si se instala un grifo o espit a a

una altura superior a 50 ft por encima de la

bomba MQ, existirá el posible riesgo de

que la bomba MQ no se ponga nunca en

marcha. Si la bomba MQ se pone en marcha debido a un nivel bajo de presión (caudales reducidos), la presión deberá caer

por debajo del punto de activación del presostato (entre 28 y 30 psi de forma predeterminada). A fin de poder utilizar la bomba

con una presión de agua de 50 ft manteniendo las tolerancias y un cierto margen

de seguridad, se recomienda aplicar un

límite máximo de altura de 50 ft entre la

bomba MQ y cualquier grifo.

41

Page 42

Español (MX)

Sujeto a modificaciones .

6. ¿Cuál es la presión máxima de entrada

admisible en la bomba MQ?

Respuesta: Tanto en el caso de la bomba

MQ 3-35 como en el de la bomba MQ 3-45,

la presión interna máxima admisible es de

109 psi. La presión máxima de entrada

sumada a la presión de la bomba MQ no

debe superar los 109 psi.

Recuerde que la presión de entrada debe

sumarse a la presión de la bomba MQ, por

lo que si se aplica una presión de entrada

de 40 psi a la bomba MQ 3-45, podrían

alcanzarse presiones internas de aproximadamente 105 psi (65 + 40 psi).

Por otra parte, si las presiones de entrada

superan la presión del punto de activación

del presostato integrad o (ent re 28 y 3 0 psi

de forma predeterminada), el presostato no

se podrá activar y se perderá la capacidad

de poner en marcha la bomba MQ con

niveles reducidos de caudal. En tal situación, sólo el interruptor de caudal podrá

poner en marcha la bomba MQ con niveles

reducidos de caudal por encima de su

punto de activación, de 0,3 gpm.

7. ¿Cuál es la capacidad de cebado de la

bomba MQ?

9. ¿Dónde es más sencillo instalar un

manómetro para medir la presión de

descarga?

Respuesta: En la tubería de descarga o en

el orificio de rosca recta GAS de 3/8" que

se utiliza para agregar agua de cebado a la

bomba.

16. Eliminación

La eliminación de este producto o las piezas

que lo componen debe realizarse de forma

respetuosa con el medio ambiente:

1. Solicite ayuda a un servicio de recogida de

residuos público o privado.

2. Si esto no fuera posible, póngase en con-

tacto con la delegación u oficina de asistencia de Grundfos más cercana.

Respuesta: Aprox. 1,2 galones.

8. ¿Cómo se detecta la temperatura de

sobre carga / exceso de temperatura en

la bomba MQ?

Respuesta: El motor cuenta con un inte-

rruptor térmico incorporado en el bobinado.

El interruptor detiene el motor y lo pone en

marcha de nuevo. Consulte la tabla

siguiente.

Protección térmica

[V] [°F] [°C]

Des-

activación

Activación Ambos 151 65-67

42

115 302 150

230 275 135

Page 43

Français (CA) Notice d'installation et de fonctionnement

SOMMAIRE

1. Introduction

2. Composants fournis

3. Symboles utilisés dans ce document

4. Applications

4.1 Liquides pompés

5. Identification

5.1 Désignation

6. Conditions de fonctionnement

6.1 Hauteur d'aspiration

7. Installation mécanique

7.1 Lieu d'installation

7.2 Base

7.3 Dégagement requis

7.4 Tuyauterie

7.5 Couvercle de protection

8. Branchement électrique

8.1 Générateur ou inverseur

8.2 Schéma de câblage

8.3 Mesure résistance d'enroulement

8.4 Mesure de la résistance d'enroulement

8.5 Démarrage

9. Fonctions

9.1 Panneau de commande

9.2 Arrêt de la pompe

10. Maintenance

10.1 Kits de service

10.2 Démarrage après une longue période

d'inactivité

11. Service

12. Caractéristiques techniques

12.1 Dimensions

12.2 Caractéristiques électriques

12.3 Approbations

13. Accessoires

14. Tableau de recherche de défauts

15. Questions fréquemment posées

concernant la pompe MQ

16. Mise au rebut

Page

43

43

44

44

44

45

45

46

46

47

47

47

47

47

49

50

50

51

51

52

53

54

54

55

56

56

56

56

57

57

57

57

57

58

60

61

1. Introduction

Le groupe MQ est un système d'alimentation

d'eau à faible sonorité composé d'une pompe,

d'un moteur, d'un réservoir sous pression et

d'un système de commande combinés dans

une unité compacte. La pompe est conçue

pour une utilisation en intérieur et en extérieur.

La pompe auto-amorçante démarre automatiquement quand l'eau est consommée dans

l'installation et s'arrête dès que la consommation cesse. Le clapet anti-retour interne intégré

empêche le refoulement pendant l'auto-amorçage et le fonctionnement.

La pompe MQ est équipée d'une protection

contre la surchauffe et la marche à sec ainsi

que d'un panneau de commande facile à utiliser.

Le réservoir sous pression intégré réduit le

nombre de démarrages et d'arrêts, en cas de

fuites dans l'installation.

2. Composants fournis

Le colis du MQ contient :

• un système d'alimentation d'eau MQ avec

clapet anti-retour intégré

• un clapet d'entrée anti-retour en sachet

plastique

• une notice d'installation et de fonctionnement.

Français (CA)

AVERTISSEMENT

Avant de procéder à l'installation,

veuillez lire cette notice d'installation et de fonctionnement. L'installation et le fonctionnement

doivent être conformes à la réglementation locale et aux règles de

bonne pratique en vigueur.

43

Page 44

Français (CA)

Précaution

Nota

3. Symboles utilisés dans ce

document

AVERTISSEMENT

Le non respect de ces consignes

de sécurité peut entraîner des

accidents corporels.

Le non respect de ces consignes

de sécurité peut entraîner des dysfonctionnements ou des dommages à l'équipement.

Remarques ou instructions facilitant le travail et assurant un fonctionnement sécurisé.

4. Applications

Le groupe d'alimentation d'eau MQ est conçu

pour les applications types suivantes :

• surpression d’eau

(pression d'entrée maximale : 40 psi).

• alimentation en eau en provenance de

puits

(hauteur d'aspiration maximale : 7,62 m,

25 pieds), par exemple

– dans les résidences privées

– dans les exploitations agricoles

– dans les jardins maraîchers et autres

grands espaces verts.

La pompe est adaptée à l'eau de pluie.

4.1 Liquides pompés

Liquides fluides, clairs, non agressifs ne

contenant pas de particules solides ni de

fibres.

44

Page 45

5. Identification

Socle

Bouchon de

vidange

Orifice

d'aspiration

Bouchon d'amorçage

Orifice de refoulement

Panneau de commande

Couvercle

réservoir

sous pression

Bouchon du

couvercle

d'extrémité

Couvercle de protection

(accessoire)

5.1 Désignation

Exemple MQ 3 -35 A -O -A BVBP

Type de pompe

Débit nominal [m³/h]

Hauteur [m]

Code du modèle de pompe

A: Norme

Code du raccordement tuyauterie

Code des matériaux

A: Norme

Code joint d'arbre

Français (CA)

Fig. 1 Système d'alimentation d'eau MQ. Le couvercle de protection est requis pour une uti-

lisation en extérieur

TM04 3648 4908

45

Page 46

Français (CA)

6. Conditions de fonctionnement

MQ 3-35 MQ 3-45

Débit maximal [gpm] 22

Pression maximale [psi] 51 65

Pression de service maximale [psi] 108

Hauteur maximale d'aspiration [pieds],

voir page 49

Température ambiante minimale [°F]/[°C] 32/0

Température ambiante maximale [°F]/[°C] 113/45

Température minimale du liquide [°F]/[°C] 32/0

Température maximale du liquide [°F]/[°C] 95/35

Poids net [lbs] 29

Niveau de pression sonore [dB(A)] < 70

Capacité du réservoir [oz] 13,5

Pression d'air dans le réservoir [psi] 22 à 25

Branchements 1" NPT

Bouchons de vidange et d'amorçage 3/8" GAS

25

6.1 Hauteur d'aspiration

La hauteur maximale d'aspiration de la pompe

peut être déterminée d'après le schéma de la

page 49.

Exemple

Si la hauteur d'aspiration est de 3 m

(10 pieds), la longueur du conduit d'aspiration

ne doit pas dépasser 22 m (72 pieds).

46

Page 47

7. Installation mécanique

Nota

Nota

Max. ± 18 °

Nota

Nota

60"

7.1 Lieu d'installation

La pompe est conçue pour une installation en

intérieur et en extérieur. Elle résiste à la

lumière du soleil.

Si la pompe est installée en extérieur, elle doit être équipée d'un

couvercle de protection (accessoire). Voir paragr. 7.5 Couvercle

de protection et 13. Accessoires.

En cas de fuite interne accidentelle, le liquide pompé sera

vidangé du socle et/ou du couvercle d'extrémité pour éviter

d'endommager la pompe. Installer

la pompe de manière à éviter tout

dommage collatéral indésirable.

7.2 Base

Installer la pompe sur le socle, avec l'orifice

d’aspiration à l'horizontale et l'orifice de refoulement à la verticale.

La pompe doit être installée horizontalement.

Angle d'inclinaison maximal admissible :

± 18 °. Voir fig. 2.

7.3 Dégagement requis

Pour l'inspection et l'entretien, prévoir un

dégagement d'au moins 150 cm (60") derrière

la pompe.

Français (CA)

TM04 3746 5008

Fig. 3 Dégagement minimal derrière la

pompe

La pompe étant auto-refroidie, elle ne nécessite ni dégagement ni ventilation sur les côtés.

S'assurer que les températures

ambiantes maximales ne

dépassent pas les valeurs indiquées au paragr. 6. Conditions de

fonctionnement.

7.4 Tuyauterie

Ne jamais forcer lors du raccordement de conduits.

La pompe est fournie avec des raccords filetés

NPT 1". Fixer les raccords dans les orifices

d'aspiration et de refoulement. Voir fig. 4.

Pour faciliter la fixation, l'orifice de refoulement de la pompe est orientable, ± 5 °.

Fig. 2 Installation horizontale d e la po mpe

MQ

Pour éviter mouvements et vibrations, la

pompe et le socle peuvent être sécurisés à

une base solide, par les orifices de boulons

dans le socle. Pour raccordement tuyauterie,

voir paragr. 7.4 Tuyauterie.

TM01 9691 2600

TM01 9698 2600

Fig. 4 Fixation des raccords filetés dans

les orifices d'aspirat ion et de ref oulement

47

Page 48

Français (CA)

Clapet de

pied

Visser avec précaution le raccord de refoulement dans l'orifice de refoulement avec une

clé ou un outil similaire. Maintenir le raccord

de refoulement et serrer manuellement

l'écrou-union de refoulement de la pompe.

Voir fig. 5.

Fig. 5 Correct : serrer manuellement

l'écrou-union de refoulement

Fig. 6 Incorrect : ne pas utiliser d'outil

pour serrer l'écrou-union de refoulement

7.4.2 Flexible d'aspiration au lieu de

conduit

Si un flexible d'aspiration est utilisé au lieu

d'un conduit, il ne doit pas excéder les longueurs indiquées dans le graphique, page 49.

Le flexible d'aspiration doit être d'au moins

Ø1". Le flexible doit être de type semi-rigide.

7.4.3 Conduits d'aspiration longs

Un clapet d'entrée anti-retour séparé est fourni

avec la pompe. Avec les conduits d'aspiration

longs, il est recommandé de fixer un clapet

d'entrée anti-retour dans l'orifice d'aspiration

de la pompe. Voir paragr. 7.4.4 Installation du

TM04 4271 1009TM 044272 1009TM01 9693 2600

clapet anti-retour en entrée

Les conduits doivent être soutenus de manière

adéquate, de chaque côté de la pompe, pour

éviter des contraintes sur les raccords de la

pompe.

7.4.1 Conduits d'aspiration branchés à un

puits

Si la pompe est utilisée pour le pompage d'un

puits, il est recommandé d'installer un clapet

de pied à l'extrémité du conduit d'aspiration.

Voir fig. 7.

Fig. 7 Conduits d'aspiration branchés à

un puits

48

Page 49

7.4.4 Installation du clapet anti-retour en

Nota

Nota

entrée

Le clapet d'entrée anti-retour réduit le risque

d'infiltration d'amorçage de la pompe, dans les

applications d'aspiration négative. Il augmente

aussi la capacité d'auto-aspiration, par

exemple avec de l'eau provenant d'une

citerne.

Installer le clapet d'entrée anti-retour de la

manière suivante, voir fig. 8.

1. Retirer le branchement d'aspiration de la

pompe.

2. Fixer le clapet d'entrée anti-retour dans

l'orifice d'aspiration, dans la direction indiquée en fig. 8.

3. Rebrancher le raccord de pompe.

Les applications avec pression

d'entrée positive ne nécessitent

pas l'installation d'un clapet

d'entrée anti-retour. La pompe MQ

est en effet équipée d'un clapet

anti-retour interne côté refoulement.

7.5 Couvercle de protection

L'absence d'utilisation du couvercle de protection sur les installations en extérieur rend la garantie caduque.

Le couvercle de protection protège le panneau

de commande des intempéries. Il est disponible en option. Voir paragr. 13. Accessoires.

Pour fixer le couvercle de protection, le cliquer

sur le haut du panneau de commande pour

qu'il s'emboîte dans les nervures supérieures

de refroidissement.

Pour retirer le couvercle, tirer les deux clips

vers l'extérieur, le libérer des nervures de

refroidissement et le ti rer vers le haut.

Fig. 9 Couvercle de protection

Français (CA)

TM04 3745 5008

Fig. 8 Installation du clapet d'entrée anti-

retour

TM 04 4121 0809

49

Page 50

Français (CA)

Nota

8. Branchement électrique

Les branchements électriques et protections

complémentaires doivent être effect ués par un

électricien agréé, conformément aux réglementations locales.

AVERTISSEMENT

Pompe non submersible.

Si le câble d'alimentation est

endommagé, il doit être remplacé

par le fabricant, un réparateur

agréé Grundfos ou des personnes

qualifiées et autorisées pour éviter

des risques.

Ne jamais effectuer de branchements dans la boîte à bornes de la

pompe, sauf si l’alimentation électrique a été mise hors tension pendant au moins 5 min.

Risque de choc électrique.

Cette pompe est fournie avec un fil

de mise à terre et une fiche de

mise à terre. Pour réduire le risque

de choc électrique, brancher uniquement sur un circuit protégé par

un disjoncteur différentiel de type

GFCI.

Cette pompe n'est ni conçue ni

testée pour une utilisation en piscines ou dans les zones marines.

Cette pompe a été évaluée uniquement pour une utilisation avec de

l’eau.

Ne pas démarrer la pompe avant

de l'avoir remplie d'eau (amorcée,

voir fig. 12).

Convient pour une utilisation en

intérieur et en extérieur.

Type de protection 3.

La fréquence et la tension de fonctionnement

sont indiquées sur la plaque signalétique.

S’assurer que le moteur est conçu pour l’alimentation électrique qui sera utilisée.

La pompe doit être branchée au réseau d'alimentation par un câble gainé avec protection

à la terre. Il est possible de remplacer le câble

d'alimentation électrique. Voir fig. 10.

TM01 9694 2600TM01 9695 2600

Fig. 10 Branch emen t élec tri que

Brancher le câble d'alimentation de la pompe

au réseau électrique. Une fois le câble branché, un voyant vert et un voyant rouge situés

sur la panneau de commande s'allument.

Voir fig . 11.

Fig. 11 Branchement du câble d'alimenta-

tion secteur

8.1 Générateur ou inverseur

Le groupe MQ peut être alimenté

par un générateur ou par un inverseur. Cependant, la pompe ne

fonctionnera de manière satisfaisante que si le générateur ou

l'inverseur fournissent une véritable onde sinusoidale avec la

puissance et la tension d'entrée

nécessaires. Le générateur doit

être dimensionné 10 % au-dessus

du P1 (puissance d'entrée) de la

pompe. Pour P1, voir paragr.

12.1 Dimensions.

50

Page 51

8.2 Schéma de câblage

Noir (phase)

Rouge

Noir

Orange

> Capteur débit

> Pressostat

Conden-

sateur

Jaune

Jaune

Moteur électrique

Jaune/vert (terre)

Rouge (principal)

Noir

Blanc (neutre)

> Câble

B

A

Jaune

Blanc

C

8.2.1 115 V

Français (CA)

Fig. 12 Schéma de câblage - 115 V

8.3 Mesure résistance d'enroulement

Moteur

[V/Hz]

115/60

Point de mesure Enroulement

A-B (noir - rouge) Principal 1,4

A-C (noir- blanc) Aux. 5,5

Résistance

[ ± 10 %]

Température ambiante

[°F] [°C]

70 21

La mesure peut être effectuée avec ou sans câbles raccordés au PCB et au condensateur.

TM02 2424 4708

51

Page 52

Français (CA)

Noir (phase)

Rouge

Noir

Orange

> Capteur débit

> Pressostat

Conden-

sateur

Jaune

Jaune

Moteur électrique

Jaune/vert (terre)

Rouge (principal)

Bleu

Blanc (neutre)

> Câble

B

A

Jaune

Blanc

8.3.1 230 V

Fig. 13 Schéma de câblage - 230 V

8.4 Mesure de la résistance d'enroulement

Moteur