AW-Lake TRG, HM Operating Manual

COMPANY

Turbine Flow Meters

Installation, Operating &

Maintenance Manual

©2016 AW-Lake Company. All rights reserved. Doc ID:TURBINEMAN16

Description of Operation

Turbine flow meters are designed with wear resistant internal components to

provide trouble-free operation and a long service life. Fluid entering the flow

meter is first conditioned by the inlet flow straightener which reduces turbulence in

the fluid. The moving fluid causes the rotor to spin at a speed that is proportional

to its flow rate. As the blades on the rotor pass through the magnetic field of the

pickup, an electronic pulse is generated. This pulse train signal can then be used

to monitor the fluids actual flow rate or the total amount of fluid that has passed

through the flow meter.

The number of electronic pulses generated by the meter, per unit volume, is

known as its K-Factor. Each flow meter is calibrated to find its unique K-Factor,

which is supplied with the flow meter when purchased.

Turbine Specications

Operation Limitations

Corrosion

The internal parts are constructed from stainless steels and tungsten carbide

with a nickel binder. Ensure that your fluid is compatible with these materials.

Incompatible fluids could deteriorate the internal parts, causing inaccurate

readings. Consult the manufacturer of the fluid regarding its chemical compatibility

with these materials.

Pulsation

Severe fluid pulsation will have a negative effect on the flow meters accuracy and

may shorten the life of the flow meter.

Vibration

Severe vibration may decrease the life of the flow meter.

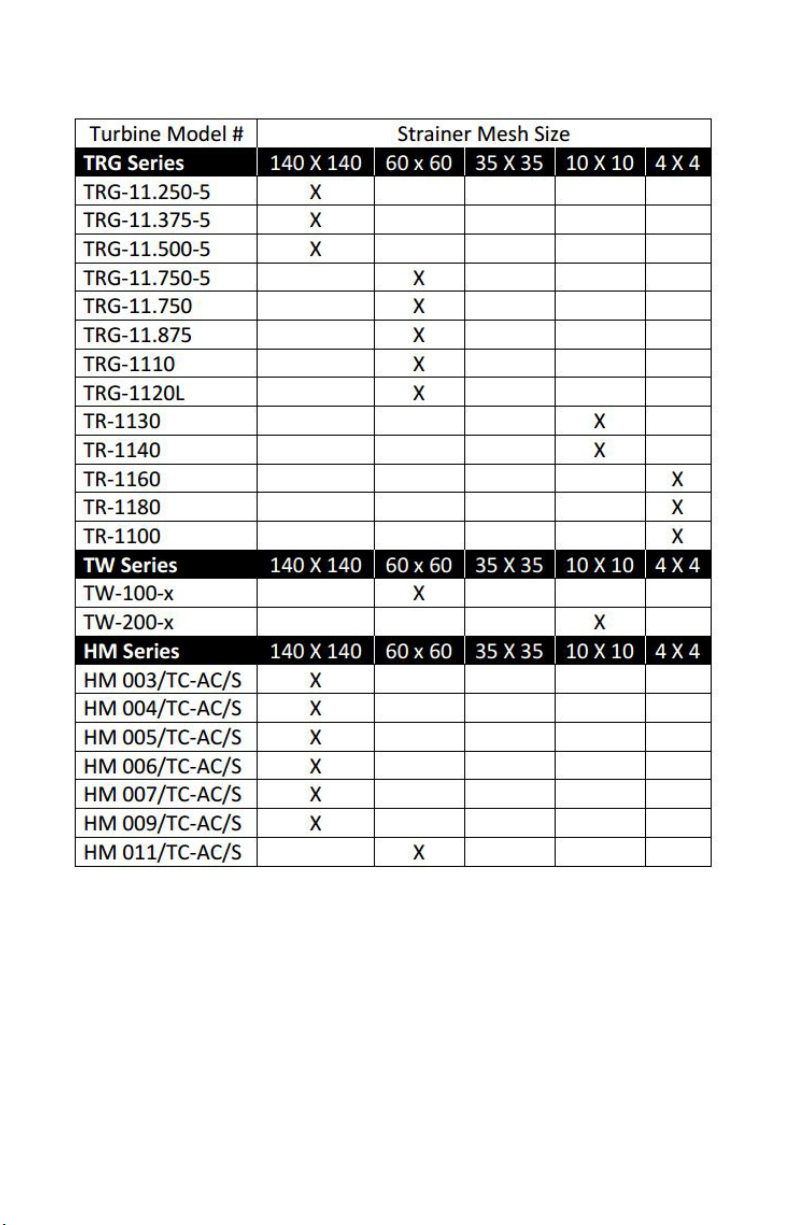

Filter/Strainer

A filter or strainer is recommended to be installed upstream of the flow meter

(see Table 1 for recommended filtration). Particles entering the flow meter may

cause pitting of the internal components, reducing its service life. Build up of

particles on rotating parts can adversely affect the performance of the flow meter.

2

Table 1

3

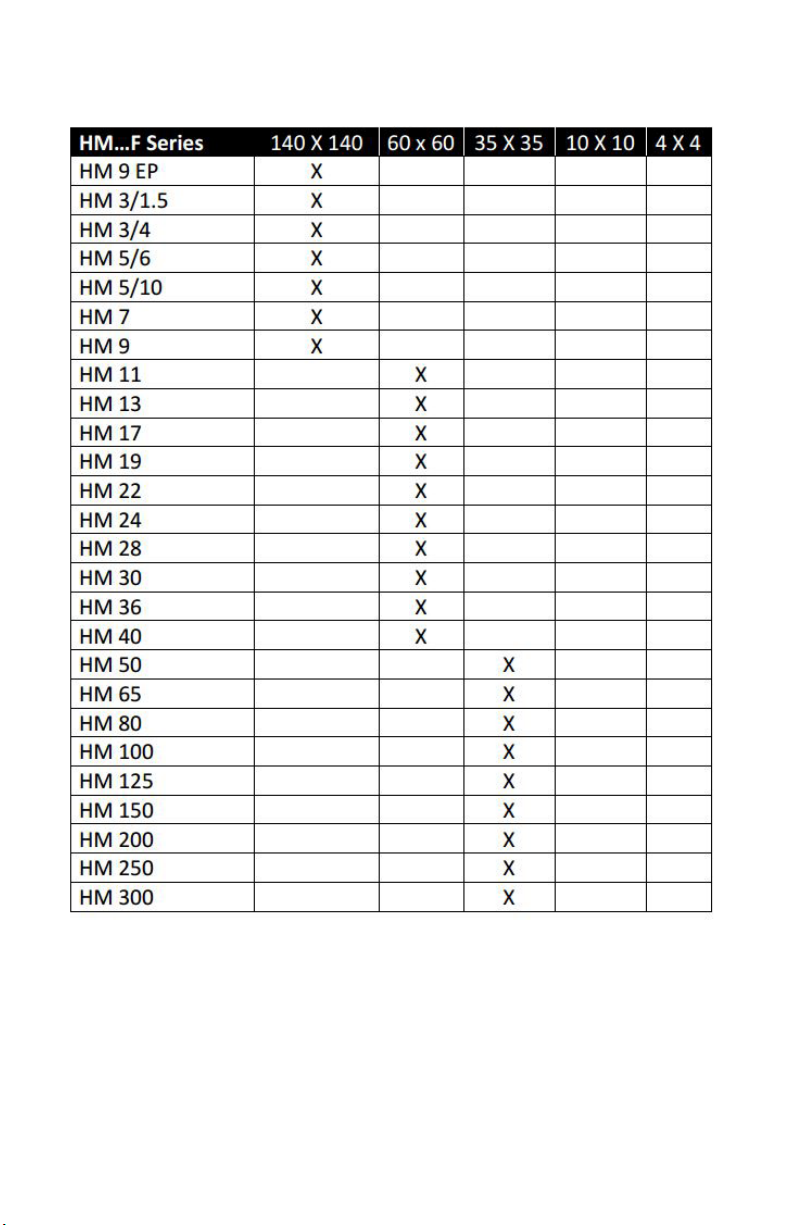

Table 1 (Continued)

4

Loading...

Loading...