AW-Lake TA-3 Operating Manual

COMPANY

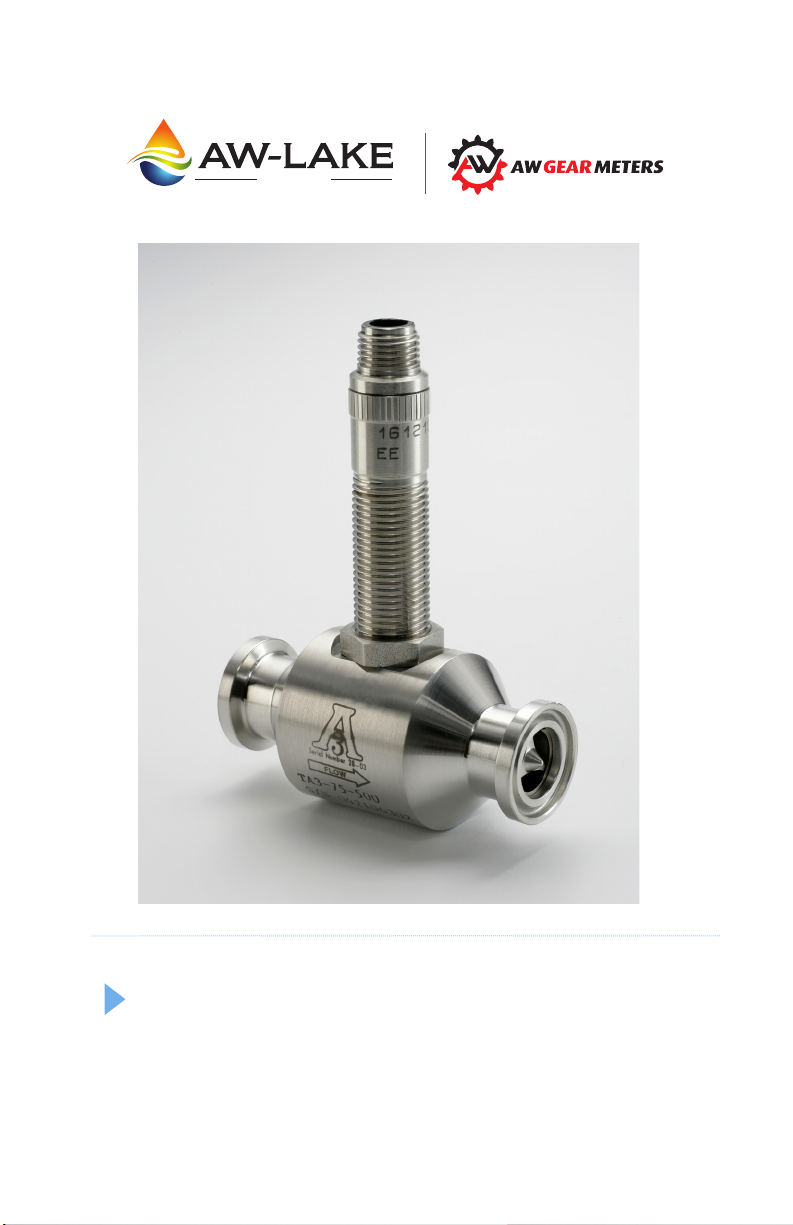

Sanitary Turbine Flow Meter - TA3

Installation, Operating &

Maintenance Manual

©2016 AW-Lake Company. All rights reserved. Doc ID:SANITARYMAN16

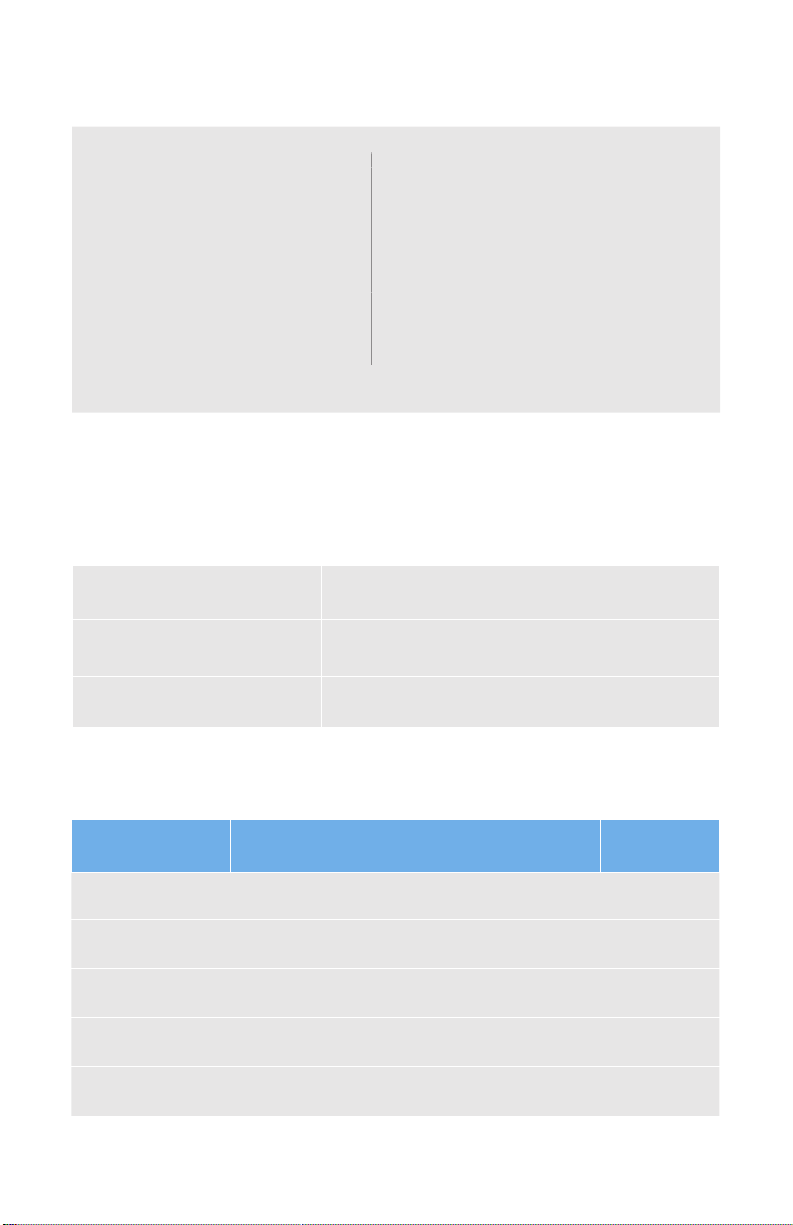

Mechanical Specications

Measuring Accuracy

± 1.0% of reading or better

Repeatability

± 0.1%

Flow Measuring Range

0.6 to 400 GPM (gal/min)

Turn Down Ratio

10:1

*Sensor & seal dependent. ** Depends on connecon size & clamp. Note: .COP (Clean-Out-of-Place)

Maximum Operating Pressure

Working pressure up to 1,000 psi

Temperature Range

Fluid temperature up to 300°F

*

Electrical Connection

NEMA 6 Connector

Port Connection

Tri-clamp

**

Materials of Construction

Body & Rotor Support 316L Stainless Steel

Rotor Nickel Plated Stainless Steel

Bearings Nickel Bindery Tungsten Carbide

Electronics

Model Sensor Type

RT-10R Baery-Powered Monitor 0 to 140

RT-30SD 15-24 VDC Powered Monitor 0 to 140

MAG-INVA Amplied Pulse Output 0 to 140

MG-300 Non-Amplied (external amplifer needed) 0 to 300

MG-450 Non-Amplied (external amplifer needed) 0 to 450

*Contact factory for addional sensor opons.

2

Temp (°F)

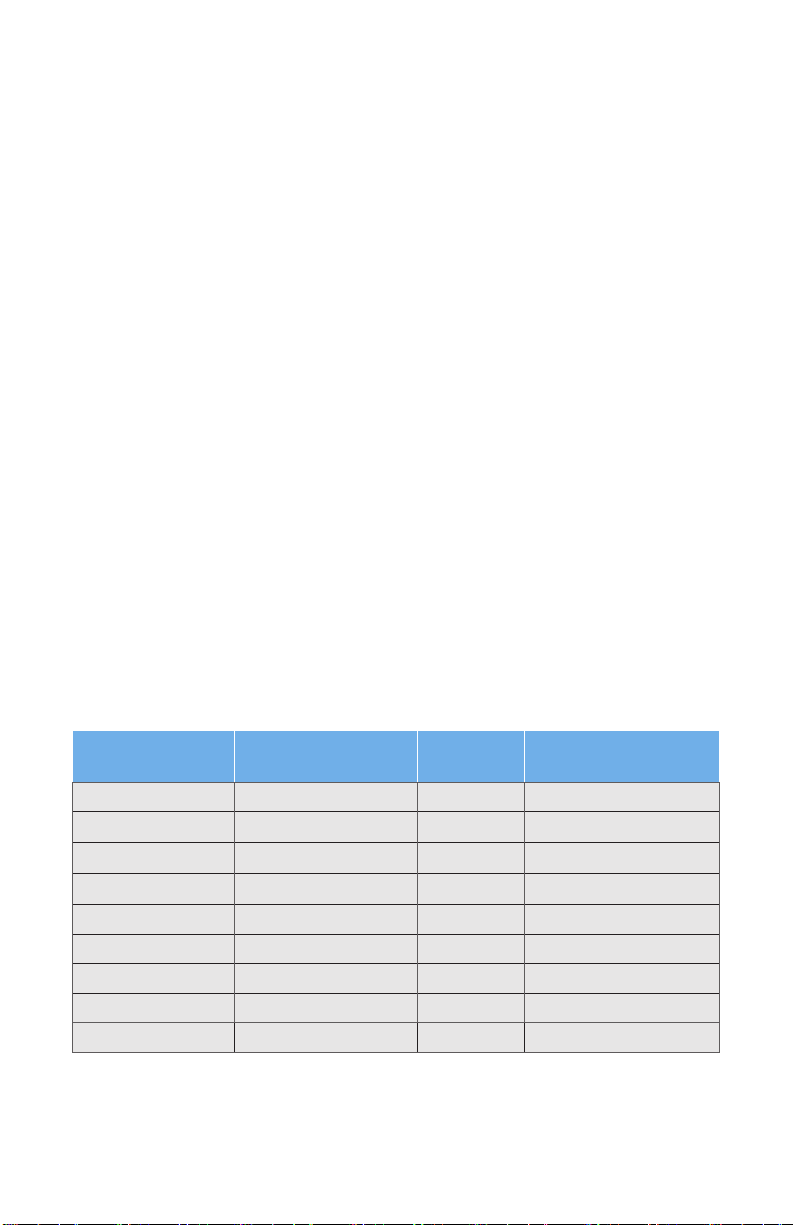

Meter Specications

Part

Number

Range

(gal/min)

K-Factor *

(Pulses/ gal)

Meter

Size

Clamp Size Weight

TA3-75-375 0.6 to 3 20,000 3/8” 3/4” 1

TA3-75-500 0.75 to 7.5 13,000 1/2” 3/4” 1

TA3-75-750 2 to 15 2,750 1/2” 3/4” 1

TA3-150-500 0.75 to 7.5 13,000 1/2” 1-1/2” 3

TA3-150-750 2 to 15 2,750 1/2” 1-1/2” 3

TA3-150-875 3 to 30 2,600 7/8” 1-1/2” 3

TA3-150-100 5 to 50 870 1” 1-1/2” 3

TA3-150-150 15 to 180 330 1-1/2” 1-1/2” 5.5

TA3-250-200 40 to 400 50 2” 2-1/2” 8.5

* K-Factors given are averaged. A calibraon sheet accompanies every meter sold.

(lbs)

3

Introduction

The TA-3 Sanitary turbine flow meter is designed with wear resistant moving

parts to provide trouble-free operation and long service life. The durable 316L

stainless steel construction provides a cost efficient flow measurement system

that offers excellent accuracy and repeatability. The TA-3 Sanitary turbine meter

repair kit is designed for easy field service of a damaged flow meter, rather than

replacing the entire flow meter. See Repair Kits on page 8 for information.

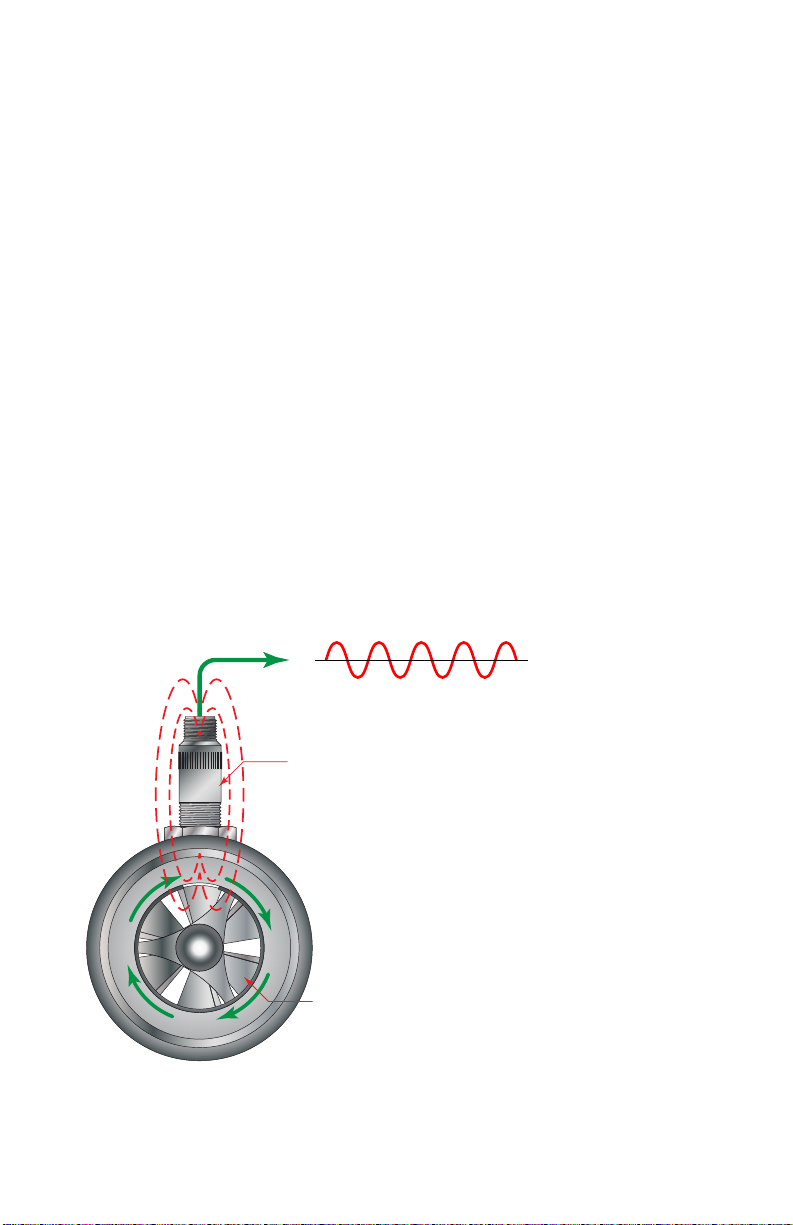

Theory of Operation

Fluid entering the meter passes through the inlet flow straightener which reduces

its turbulent flow pattern and improves the fluid’s velocity profile. Fluid then

passes through the turbine, causing the rotor to rotate at a speed proportional

to the fluid velocity. As each turbine blade passes through the magnetic field,

the blade generates an AC voltage pulse in the pickup coil at the base of the

magnetic pickup (see Figure 1). These pulses produce an output frequency

proportional to the volumetric flow through the meter. The output frequency

represents flow rate and/or totalization of fluid passing through the turbine flow

meter.

Figure 1. Theory of Operation

4

Output Signal

Magnetic

Pickup

Rotor

Installation

WARNING: The meter should not be subjected to temperatures above 300°

F (149° C), below -150° F (-101°C) or the freezing point of the metered

liquid. High temperatures will damage the magnetic pickup, while lower

temperatures will limit the rotation of the rotor.

WARNING: Incompatible fluids could deteriorte internal parts and cause the

meter to read inaccurately.

Plumbing

Install the flow meter with the flow arrow, which is etched on the exterior of the

meter body, pointing in the direction of fluid flow. Install the meter horizontally

with the magnetic pickup facing upward.

The liquid being measured must be free of any large particles that may obstruct

spinning of the rotor. If particles are present, install a mesh strainer.

If small particles are present in the fluid, install a strainer upstream of the meter.

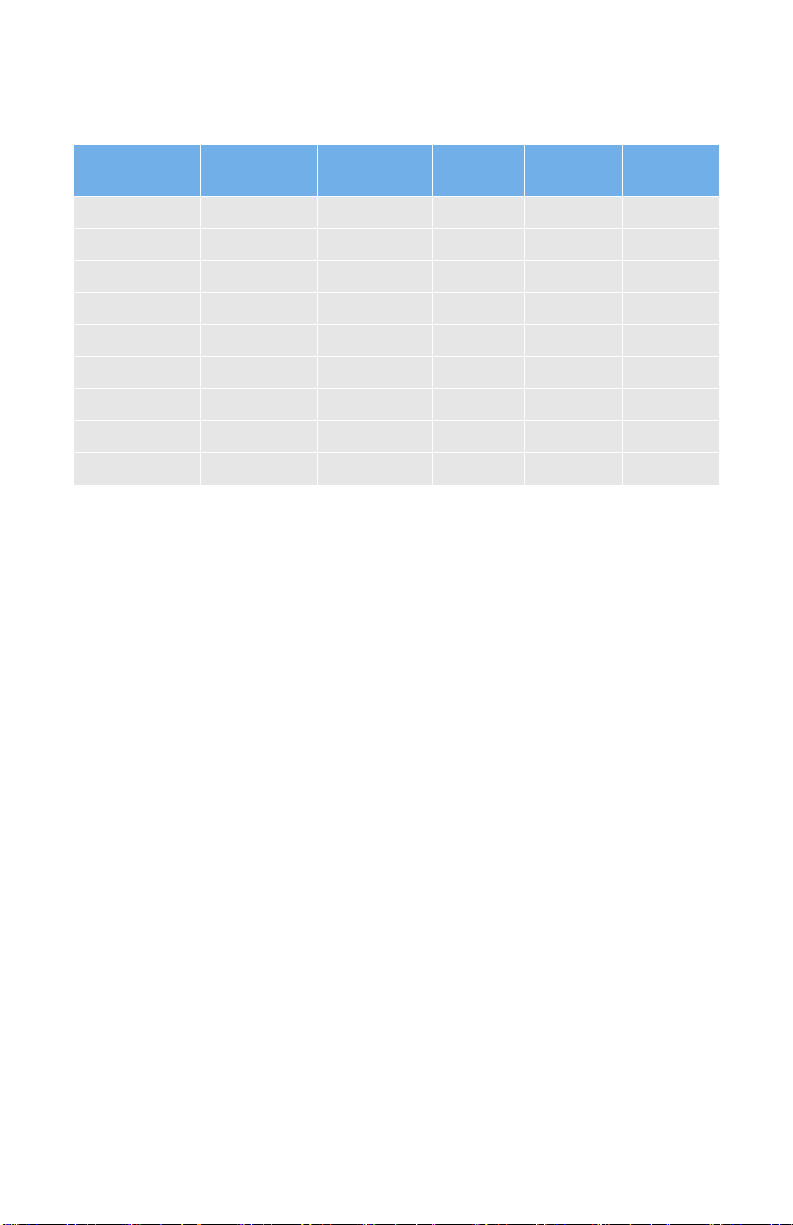

See Table 1 for filtration recommendations.

Table 1

Bore Size Ferrule Size

3/8 in. (9.53 mm) 0.984 in. (24.99 mm) 60 × 60 0.0092 in. (0.23 mm)

1/2 in. (12.7 mm) 0.984 in. (24.99 mm) 60 × 60 0.0092 in. (0.23 mm)

3/4 in. (19.05 mm) 0.984 in. (24.99 mm) 60 × 60 0.0092 in. (0.23 mm)

1/2 in. (12.7 mm) 1.984 in. (50.39 mm) 60 × 60 0.0092 in. (0.23 mm)

3/4 in. (19.05 mm) 1.984 in. (50.39 mm) 60 × 60 0.0092 in. (0.23 mm)

7⁄8 in. (22.23 mm) 1.984 in. (50.39 mm) 60 × 60 0.0092 in. (0.23 mm)

1 in. (25.4 mm) 1.984 in. (50.39 mm) 60 × 60 0.0092 in. (0.23 mm)

1-1/2 in. (38.1 mm) 1.984 in. (50.39 mm) 20 × 20 0.034 in. (0.86 mm)

2 in. (50.8 mm) 3.047 in. (77.39 mm) 10 × 10 0.065 in. (16.51 mm)

Strainer

Size

Clearance

5

Loading...

Loading...