AW-Lake RT-Ex15 Operating Manual

FLOW

ELECTRONICS FOR

TRANSMITTERS

R

R

FFLLO

T--

T

O

W

W

Users Manual

E

E

M

M

O

O

x

x

1

1

NIITT

N

5

5

O

R

O

R

INSTRUMENTATION

8809 Industrial Drive, Franksville, WI 53126-9337

Tel: 262-884-9800 Fax: 262-884-9810

E-Mail: aw@awcompany.com Web: http://www.awcompany.com

RT-Ex15 FLOW MONITOR

Introduction / Features…..………..……………………... page 2

Model Number/Sensor Options.……………………..….. page 2

Specifications…..………..…………………………..….. page 2

Dimensional Drawing.….………………………………. page 2

Wiring Connections……….................…………………. page 3

DC Power Connection...........…………………... page 3

Reset Input……….................…………………... page 3

Limits/Pulse Output...............…………………... page 3

Analog Output……................…………………... page 4

Frequency Input (Calibration) Test Point.………. page 4

Display/Programming Buttons and Magnetic Switches… page 5

Disable External Programming....………………. page 5

Programming the RT-Ex15..…………….....…..……….. page 6

Startup Message…………...........………………. page 6

RT-Ex15 Display Modes………………….....…..……….. page 6

LOGO Mode – Turning On/Off Displays……..... page 7

RATE Display Modes..............………………….. page 8

RATE A

RATE A PL .……................……………… page 8

RATE Mode Programming.............…………….. page 9

KFR A VALUE.................……………… page 9

GATE A B……..………….……………. page 10

SAMPLE A……………………………… page 10

ENG UNITS A……………………...…... page 10

TOTAL Display Modes.....…………………..…. page 11

TOTAL A Display…….……….….……. page 11

GR TOTAL A Display…….……...……. page 11

TOTAL Reset / Rollover…….…….……. page 11

TOTAL Mode Programming........................…… page 12

KFT A VALUE.…........…………….….. page 12

ENG UNITS A...….…..………………… page 13

STATUS ONE Display Mode.….……………... page 13

ANALOG OUT Display Mode.….……………... page 13

ANALOG OUT Programming.………………… page 13

MA OFFSET.…........………………..…. page 14

ANALOG POINT....…..………………... Page 14

VALUE AT 20 MA……………………… Page 14

LIMITS Display Mode...........…….……….……. page 15

LIMITS Programming…………………………… Page 15

RATE/TOTAL limits……...…………….. Page 15

CYCLE OUT (Totalizer Pulse Output)…. Page 15

RATE & TOTAL Display Mode ....…………….. page 16

BATCH TOTAL Display Mode ....…………….. page 17

BATCH TOTAL Programming.......…………….. page 17

QUICK-GUIDE to the RT-Ex15 Variables & Displays... page 18

Limited Warranty Statement.............…………………… page 19

GT

.……................……………… page 8

1

AW Company 8809 Industrial Drive, Franksville, WI 53126 à web: www.awcompany.com

Tel: 262-884-9800 Fax: 262-884-9810 | Email: aw@awcompany.com

RT-Ex15 manual.doc Revision 031507

2

Introduction / Features

The RT-Ex15 is a meter-mounted digital flow monitor housed in a Class I Div. 1 Rated

Enclosure. A large, back-lighted LCD graphic display provides easy to read indication of

flow rate or total in user programmable engineering units. Programming, display mode

selection or reset of the totalizer are accomplished using an attached magnet without opening

the enclosure or using the pushbuttons on the faceplate with cover off. An isolated input also

allows for remote reset of the totalizer. Programmable opto-isolated NPN open-collector

outputs provide flowrate limit indication or a pulsed total output for remote monitoring and

recording of totals. A 4-20 mA rate output with user programmable filtering and scaling is

also provided for remote indication. A variety of sensor noses are available to provide

compatibility with all AW Company flowmeters.

RT-Ex15 Model/Sensor options:

RT-Ex15A MAG-PB sensor (standard) for JV-CG/KG, HPM & TRG series flowmeters.

RT-Ex15B IR-PB sensor for JVK series flowmeters.

RT-Ex15C

CP-30 high temp sensor (to 350ºF) for JVM-CG/KG, JVS-CG/KG HPM series meters.

RT-Ex15D MG-300 sensor for TR series turbine flowmeters.

Specifications

Power Requirement:

15-24 VDC/200mA. (customer supplied)

Sensor/Monitor Frequency Range:

0-4000 Hz.

Analog Output 4-20 mA:

16-bit Isolated Loop Powered 2-Wire Output.

12-27 Vdc Loop Supply

Max. Load Impedance 500 Ohm.@ 27V

Max. Load Impedance 250 Ohm.@ 12V

Two Opto-Isolated Open-Collector Outputs:

5-30 VDC Rating, 50 mA Max. (Minimum Load

Impedance Required, 600 Ohm @ 30 VDC)

Opto-Isolated Reset Input:

5-30 VDC Input, 3.3Kohm Impedance

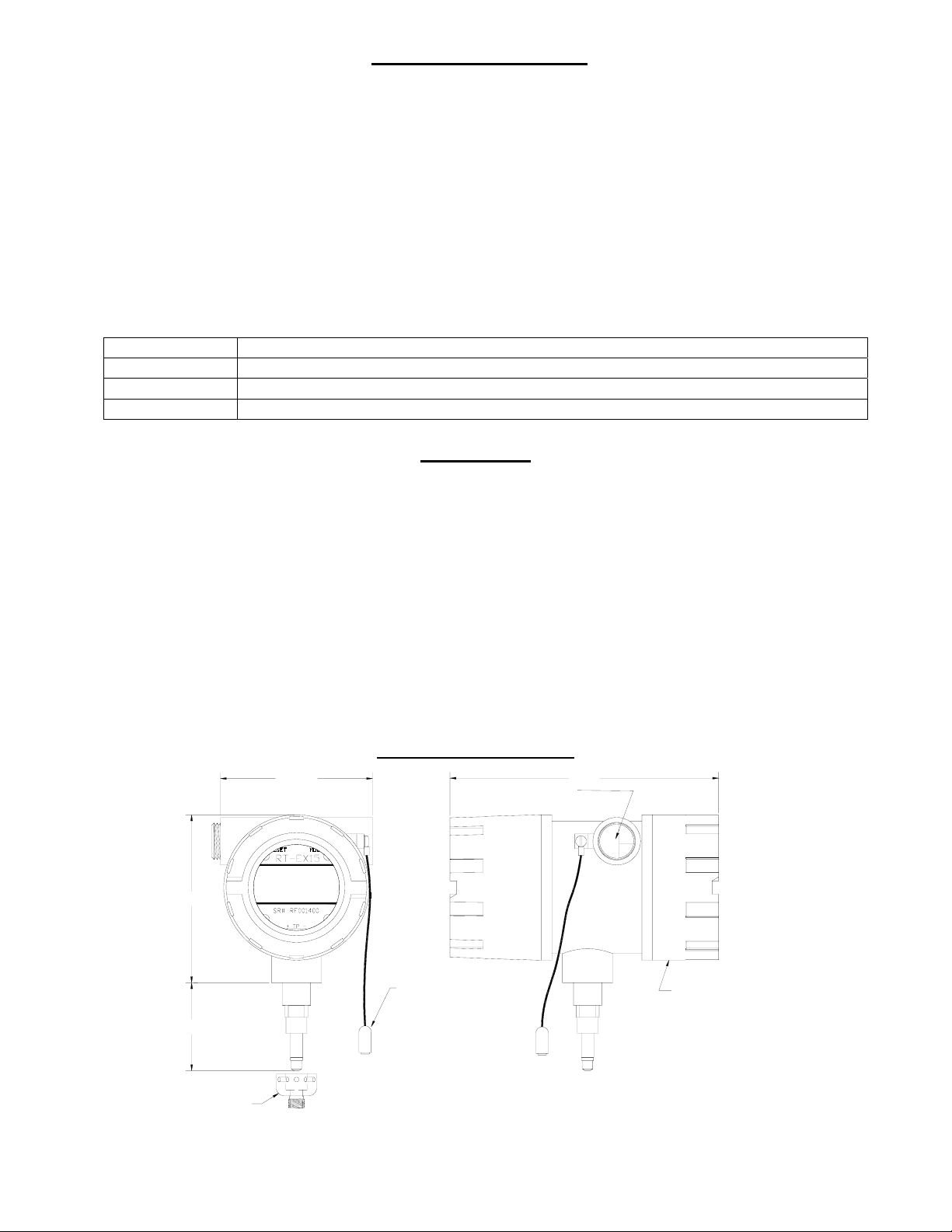

RT-Ex15 Dimensions

4.5 in.

Temperature Ratings:

-20 to 60ºC (-4 to 140ºF) Ambient

85ºC (185ºF) Max. Fluid Temperature (standard)

175ºC (350ºF) Max. Fluid Temperature (RT-Ex15C)

Enclosure Certifications:

Class I, Groups B, C, D

Class II, Groups E, F, G

Class III

Atex: EEx d IIC, IP68

NEMA 4X, 7BCD, 9EFG

Connection:

Screw terminal strips

¾" NPT Conduit Entrance

3/4" NPT WIRE

EN TRANCE

8 in.

5 in.

RA 002.50

TA 003.23

GPD

GAL

GT

MAGNET

WAND FOR

2.6 in.*

SW IVEL

FITTING

* WITH MAG-PB

SENSOR.

PROG RA M MIN G /

RESET/

DISPLAY

SELECTION

WIRING

TERM INAL

COVER

AW Company 8809 Industrial Drive, Franksville, WI 53126 à web: www.awcompany.com

Tel: 262-884-9800 Fax: 262-884-9810 | Email: aw@awcompany.com

RT-Ex15 manual.doc Revision 031507

3

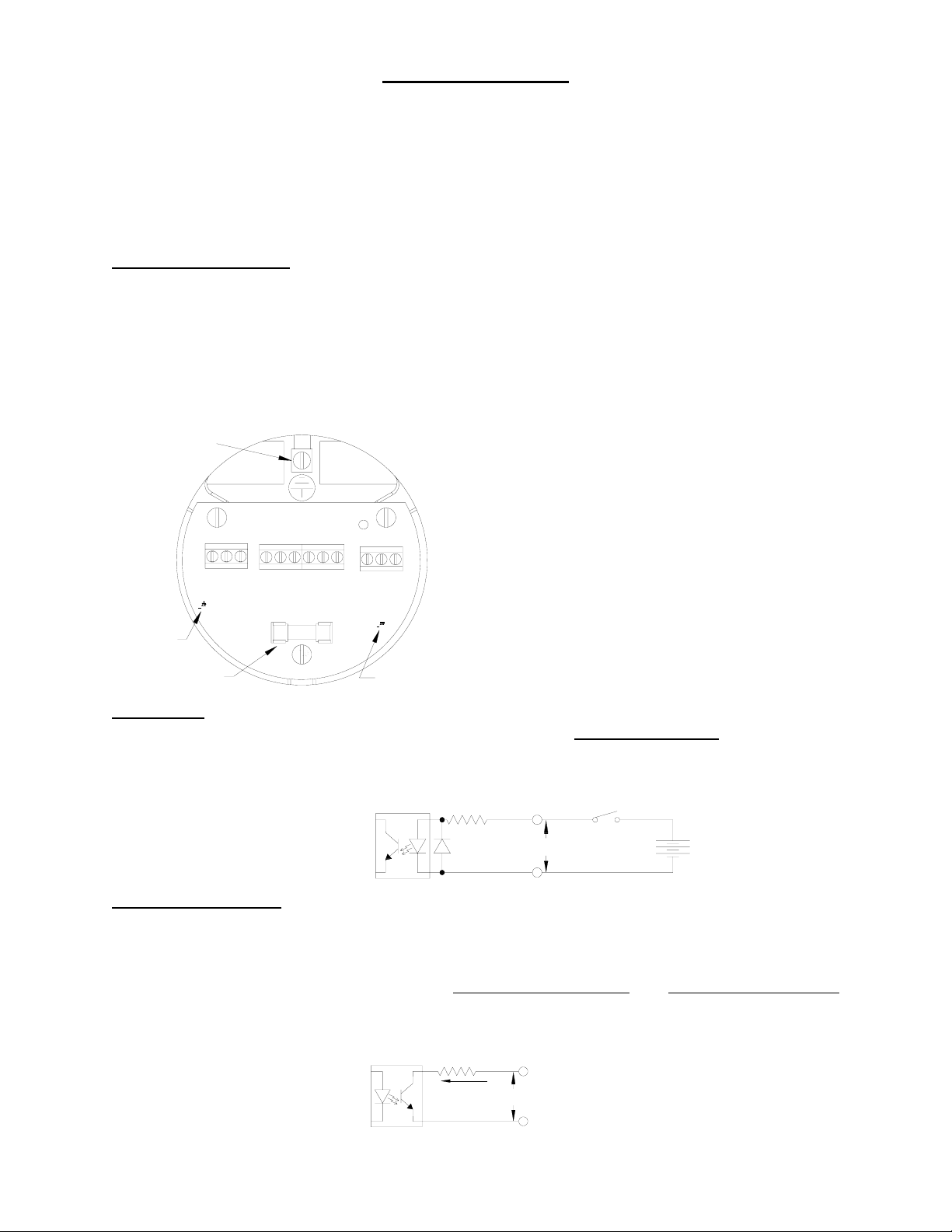

Wiring Connections

Wiring connections are to terminal strips inside the rear cover. A ¾” NPT wire exit for conduit

connection is provided. Connection to conduit is required to maintain the enclosures explosionproof rating and must be made in accordance with all local and national electrical codes. TO

PREVENT IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT CIRCUITS

BEFORE REMOVING COVER. KEEP COVER TIGHTLY CLOSED WHILE

CIRCUITS ARE ALIVE.

DC Power Connection

The RT-Ex15 requires a 15-24 VDC/200mA supply for operation. NOTE: A power supply is

still required to operate the RT-Ex15 even if the analog output is used in a loop-powered

configuration. The RT-Ex15 is internally isolated from the DC supply by a DC/DC converter. A

power-on LED is provided on the connection board and a 2 Amp mini-fuse protects the circuitry

in case of a supply fault. (See drawing below).

EN CL O S U R E

GROUND

TERM INAL

POWER

LED

2A MINI-FUSE

Reset Input

Opto-isolated input to reset the TOTAL A (Job Total). See TOTAL A RESET on page 11 for

information regarding reset of the job totalizer.

Limits/Pulse Outputs

Two opto-isolated NPN open-collector outputs can sink or source depending on connection.

Attention must be paid to polarity of connections, collector (+), emitter (-). See diagram below.

Output ratings are listed on page 2. Either output can be assigned to a rate limit, total limit for

batching or as a totalizer pulsed output. See LIMITS Display Mode

on page 15 for information regarding the display and programming of the limit and pulse output.

WIRING TERMINALS

(UNDER REAR C O VER)

C U STO MER C O NN ECTIO N S

(LEFT TO R IGH T)

15- 2 4/DC SUPPLY +Vdc Su p p ly

SUPPLY NEGATIVE -Vdc Su p p ly

EARTH G RO U N D (No t U s e d , u s e En cl. Gn d Te rm .)

RES ET + O ptically is olat ed input (+ )

RES ET - O ptically is olat ed input (- )

LIM IT1 + Optically isolated output (+)

LE1

15-24V/DC SUPPLY

RESET+

RESET-

LIMIT1 +

LIMIT1 -

LIMIT2 +

EARTH GROUND

SUPPLY NEGATIVE

F2

LIMIT2 -

Z00257 ver 1.2

JUL 2005 aw

LOOP -

LOOP +

+Vcc

LE2

mA OUT

LED

RESET IN PUT

LIM IT1 - Op tically isolated output (- )

LIM IT2 + Optically isolated output (+)

LIM IT2 - Op tically isolated output (- )

+ Vcc Supply Output (same as DC Supply)

LOOP + Isolated mA Loop (+ )

LOOP - Isola te d mA Loop (-)

(Isolated)

3.3 Kohm

RESET +

5-30VDC

Momentary

+

RESET -

and LIMITS Programming

LIM IT OUTPUTS

(Isolated)

100 Ohm

50 m A M ax.

AW Company 8809 Industrial Drive, Franksville, WI 53126 à web: www.awcompany.com

Tel: 262-884-9800 Fax: 262-884-9810 | Email: aw@awcompany.com

RT-Ex15 manual.doc Revision 031507

LIMIT (+ )

(Collect or )

5-30VDC

LIMIT (- )

(Em itter)

4

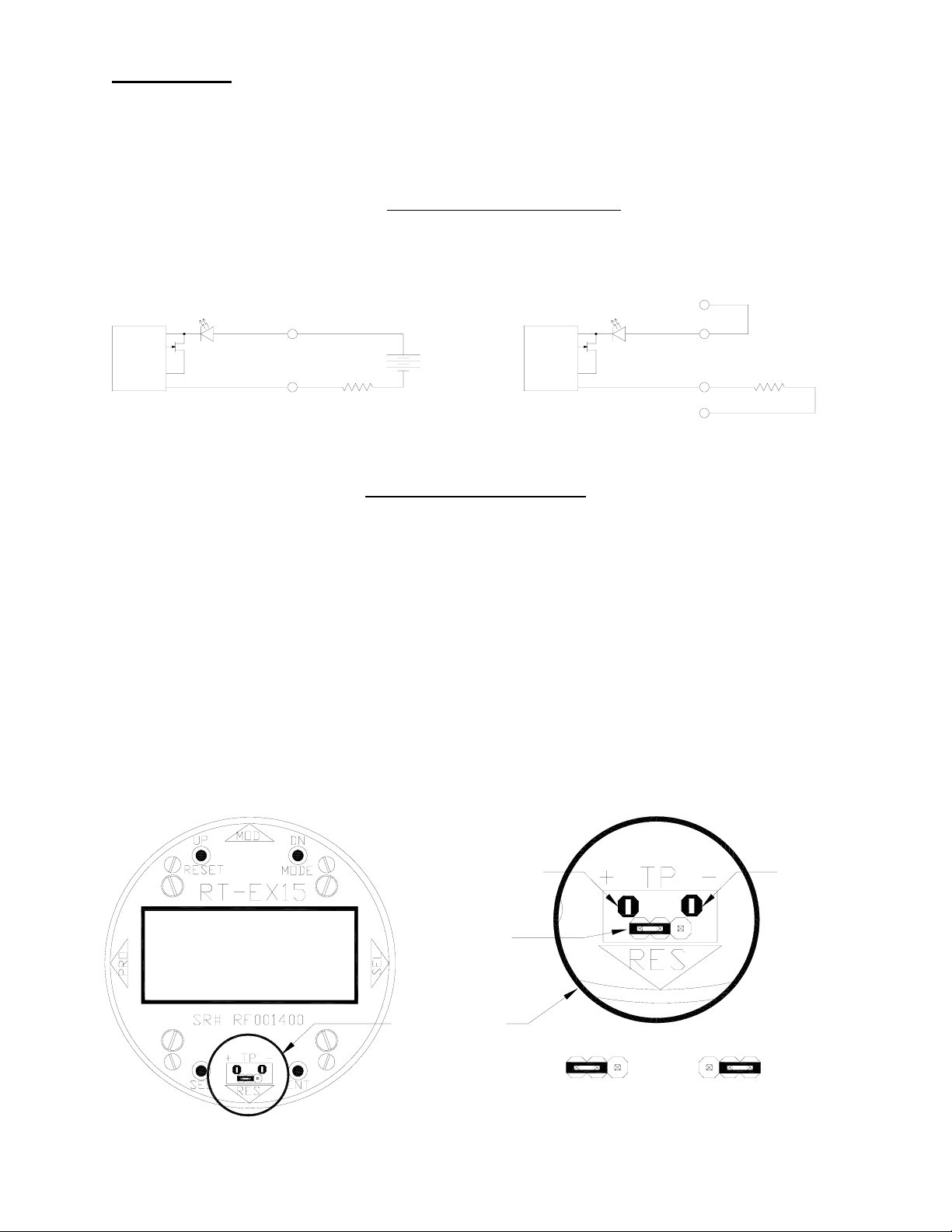

Analog Output

The isolated 16-bit 4-20mA output can be wired in a 2-wire loop-powered arrangement or loop

power can be supplied via the DC supply as shown in the wiring examples below. NOTE: A

separate power supply is required to operate the RT-Ex15 even if the analog output is used

in a loop-powered configuration. The mA LED will light with varying intensity in proportion

to the mA output for troubleshooting purposes. The assignment, offset, and scaling values for the

mA output are programmable. See ANALOG OUT Programming

on page 13 for information

regarding set-up of the analog output.

mA LOOP OUTPUT (2-WIRE, Isolated)

N O TE : S e pe rate s upp ly v o lt ag e s t ill r equir ed

for RT- Ex15 operation.

LOOP +

V loop

AD421

LOOP -

R sense = 250 Ohm max. @ 12-15 Vdc

R sense = 500 Ohm max. @ 15-27 Vdc

R sens e

+

12-27 Vdc

(Loop Power from RT- Ex15 DC Supply)

AD421

SUPPL Y NEG A TIVE

R sense = 250 Ohm m ax. @ 15 Vdc

R sense = 500 Ohm m ax. @ 24 Vdc

mA OUTPUT (3-WIRE)

+Vcc

LOOP +

mA LEDmA LED

LOOP -

+-

R sens e

Frequency Input Test Point

The RT-Ex15 has a frequency input test point allowing the user to directly input a frequency

signal. This is especially useful for purposes of setting up and testing pulse output or analog

output signals during commissioning when flow is not present or where it is not feasible to allow

continuous flow for set-up and calibration purposes. The position of a programmable jumper

must be changed to allow use of the test point input. The test points and jumper positions are

detailed in the diagram below. Be certain to change the jumper back to the correct position

before beginning normal operation using the sensor nose.

Test Point input specifications:

Waveform: DC signal - pulse, square-wave, triangle, or sawtooth.

Minimum signal amplitude: 2 Volts peak.

Maximum signal amplitude: 10 Volts peak.

Frequency: 0-4000Hz

RA 002.50

TA 003.23

GT

GPD

GAL

Te s t Po int (+ )

(Sig n al In put )

Pro gr a m

Jumpe r

Te s t Po int (- )

(Isolated

Supply

Com m on)

CALIBRATION

TEST PO INTS

& JUMPER

JUM PER S ETTING S

123 123

Norm al

Operation

Jum p 1 & 2

Te s t Point

Operation

Jum p 2 & 3

AW Company 8809 Industrial Drive, Franksville, WI 53126 à web: www.awcompany.com

Tel: 262-884-9800 Fax: 262-884-9810 | Email: aw@awcompany.com

RT-Ex15 manual.doc Revision 031507

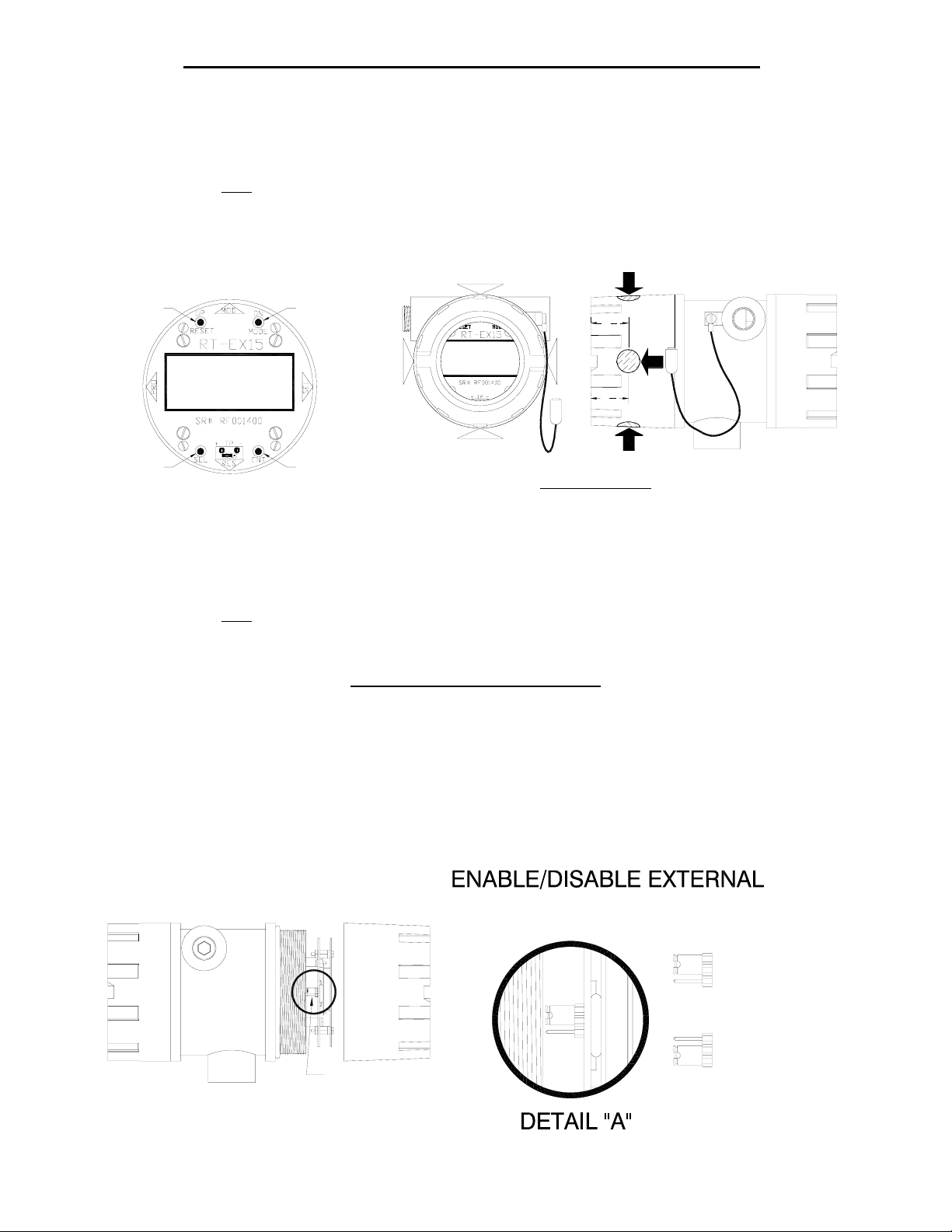

Display/Programming Buttons and Magnetic Switches

Display mode changes, reset of total and programming functions are accomplished using the

buttons located on the face plate when the cover is off or external to the cover using the magnetic

switches. The magnetic switches are located at the 3, 6, 9 and 12 o’clock positions on the side of

the housing. The function of each position is indicated on the faceplate of the RT-Ex15.

Touching the side of the magnet wand to the appropriate location will activate the magnetic

switches.

DISPLAY/PROGRAM MING

B U TTO N LOCA TIONS

RESET/UP

BU TTON

MAGNETIC

SWITCH (MOD E/DN)

MODE/DN

BU TTON

MAGNETIC

SWITCH

(ENT)

RA 002.50

TA 003.23

GPD

GAL

GT

MAGNETIC

SWITCH

(SEL)

EN T

SEL

BU TTON

MAGNETIC

SW ITC H (RESET/UP)

ENT

BU TTON

Display mode changes, reset of total and programming functions are accomplished using the

buttons located on the face plate when the cover is off or external to the cover using the magnetic

switches. The magnetic switches are located at the 3, 6, 9 and 12 o’clock positions on the side of

the housing. The function of each position is indicated on the faceplate of the RT-Ex15.

Touching the side of the magnet wand to the appropriate location will activate the magnetic

switches.

Disable External Programming

All programming is initiated by using the ENT button located on the face plate when the cover is

off or external to the cover using the ENT magnetic switch when the cover is installed. The ENT

external magnetic switch can be disabled to prevent programming when the cover is on. A

jumper is located on the back of the main circuit board on the edge at the 9 o’clock position. If

the jumper is set to disable the ENT magnetic switch, the MODE and RESET external magnetic

switches are still active to allow mode changes and total reset but program changes can not be

made without removing the cover and using the ENT button on the faceplate. The default is

switch enabled.

MAG NET IC SW ITCH L OC ATIO NS

DN/

MODE

1

1

4

RA 002.50

TA 003.23

RESET

GT

GPD

GAL

UP/

TOUCH SIDE OF MAGN ET TO SWITCH LOCATION

SEL

1

1

4

5

PROGRAMMING

"ENT" MAGNETIC

1

SWITCH ENABLED

2

3

JUMP 1 & 2

"ENT" MAGNETIC

1

2

SWITCH DISABLED

3

ENABLE/DISABLE EXTERNAL

PROGRAMMING JUMPER ON BACK

OF MAIN CIRCUIT BOARD AT THE

EDGE IN 9 O'CLOCK POSITION

(SEE DETAIL "A")

AW Company 8809 Industrial Drive, Franksville, WI 53126 à web: www.awcompany.com

Tel: 262-884-9800 Fax: 262-884-9810 | Email: aw@awcompany.com

RT-Ex15 manual.doc Revision 031507

JUMP 2 & 3

Loading...

Loading...