COMPANY

RT-30EX Flow Transmitter

Installation, Operating &

Maintenance Manual

©2016 AW-Lake Company. All rights reserved. Doc ID:RT30E XMAN082416

Table of Contents

Safety Denitions and Information ....................................................... 3

Unpacking ..................................................................................................... 3

Product Description ................................................................................... 3

Screen selection and programming changes ............................................ 3

Hazardous Area Installation Instructions ............................................ 4

Technical Specications ............................................................................ 5

Connections ................................................................................................... 6

Main board layout Maximum wire gauge: 12 AWG .................................. 8

Analog output ................................................................................................ 9

Limit & frequency output ............................................................................. 9

Reset input ..................................................................................................... 9

Run Mode Screens.......................................................................................11

Control Functions........................................................................................15

Programming ............................................................................................... 17

Entering programming mode ...................................................................... 17

Changing values and making selections .................................................... 17

K-factor (scaling factor) ................................................................................ 18

RATE unit ........................................................................................................ 18

RATE time base .............................................................................................. 18

TOTAL unit ..................................................................................................... 19

Analog output scaling ................................................................................... 19

Frequency output programming ................................................................ 26

Gate Time lter .............................................................................................. 26

Calibrating Analog Output ....................................................................... 28

I/O Manual Adjustment............................................................................. 29

Analog output adjustment ........................................................................... 30

Fine mA adjustments .................................................................................... 30

Limit & frequency adjustment ..................................................................... 31

Fine limit output adjustments ..................................................................... 31

Coarse limit output adjustment .................................................................. 31

ON/OFF Limit output adjustment ............................................................... 32

Monitor external reset input ....................................................................... 32

Appendix A - Physical Dimensions .......................................................... 33

Appendix B - Physical Dimensions .......................................................... 35

Limited Warranty ....................................................................................... 36

2

Safety Denitions and Information

Do not attempt to install or use your AW Gear Meters product until you have read

the safety instructions in this section. Save this manual and keep it in an easily

accessible place.

WARNING means that failure to follow this safety statement may result in

extensive product damage, serious personal injury, or death.

CAUTION means that failure to follow this safety statement may result in minor or

moderate personal injury, property or equipment damage.

NOTICE is a statement that informs about installation, operation, maintenance,

performance issues, or general tips that are important but do not create a hazard

or safety concern.

Unpacking

Separate the RT-30EX Flow Transmitter from packaging materials and check

for any visual signs of damage. If you determine there are damages caused by

shipping, file a claim with the shipping company. If the flow transmitter appears

to have been improperly assembled or does not operate properly, return it

for replacement or repair (see Limited Warranty information at the end of this

manual).

CAUTION: Before connecting, programming, or operating the RT-30EX Flow

Transmitter, read this manual.

Product Description

The RT-30EX is a digital flow transmitter housed in an epoxy painted aluminum

instrument enclosure. The RT-30EX is certified for use in Class I, Div 1

hazardous areas in both Canada and the US, and Ex d IIB and Ex tb IIIC in the

EU. The unit’s graphical, backlighted LCD display makes it easy to monitor flow

rate and total in user selectable engineering units. The sensor used with the unit

will mount on many meter models modified for use with the 3/8” NPT sensor

mounting thread. Meter model available are the JVM, JVS, JVHS and ZHM gear

meters and HM high pressure turbines.

Screen selection and programming changes

You can make program or mode changes, or reset the totalizer in two ways;

1. With the housing cover removed, enter information using the 4 pushbuttons.

2. With the housing cover closed, hold the attached magnet wand against the

3

side of the cover to activate hall switches located on the internal circuit

board.

You can also reset the totalizer and monitor flow rate limits and total output

remotely via a computer or PLC.

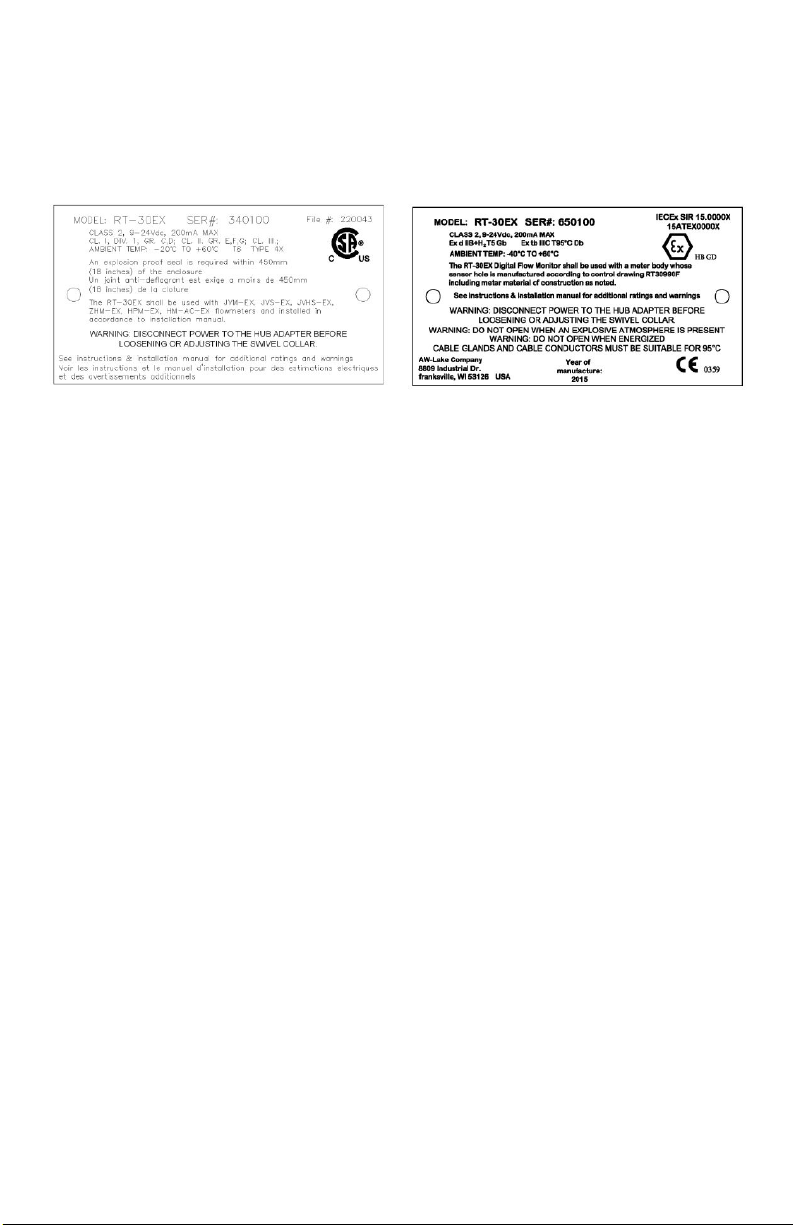

Figure 1: Hazardous area certification tag CSA (left) and ATEX / IECEx (right)

Hazardous Area Installation Instructions

The RT-30EX unit is an explosion-proof flow transmitter with local display suitable for

use in Class I, Div 1 North American locations or Ex d IIB and Ex tb IIIC European

locations, depending on the model labeling.

Above are two samples of the name plate that should be clearly attached to each

unit. Please make sure the appropriate name plate is on the unit and that the

information matches what is shown above to your desired certification, prior to

installation. If either the name plate is not on the unit or the unit name plate does

not match what is shown above, please notify AW- Lake Company to determine

appropriate course of action.

WARNING: Because the RT-30EX uses an explosion-proof enclosure for its area

protection, power must be removed from the unit before the covers are removed

while in a hazardous area. Also, disconnect power before loosening or adjusting

the swivel collar on the hub adapter.

For proper installation, it is also necessary that the conduit entries are properly

sealed. To maintain the unit’s explosion-proof certification, anything threaded into

the NPT conduit openings must engage by a minimum of 5 full threads. If original

units received from AW-Lake Company are versions which have the sensor

installed, this sensor will be properly installed with a minimum of 5 full threads of

engagement from the factory.

When an RT-30EX is installed into the flow meter with which it is to be used, it is

also necessary to make sure there is a minimum of 5 full threads of engagement

4

between the meter and RT-30EX unit.

When wiring the unit, please make sure to observe any local codes that

may be required. A common requirement is to have a conduit seal within 18

inches of the unit. Also, the unit may be used in a Class I, Div. II area, but

must still be installed according to Class I, Div I standards. Make sure units

are powered by a Class 2 power supply for proper regulation.

Please note that the RT-30EX must be installed properly into a flow meter

before power is applied.

Technical Specications

Power Requirement:

9-24 VDC / 200mA (customer

supplied) Class 2

Analog Output 4-20mA

3- or 2-wire plus separate supply

Max load impedance 500 ohm

Frequency Output

Three Opto-Isolated OpenCollector Outputs

• Frequency or limit outputs

• 5-30 VDC rating

• 40 mA max (min. load

impedance required 600 Ohm

@ 30 VDC)

Built in 30 point Linearizer

Temperature Rating

-20 to 60°C (-4 to 140°F)

Sensor/Monitor Frequency

Range

0-4,500 Hz

Connection

3/4” female NPT conduit provisions

One Opto-Isolated Input

9-24 VDC remote reset

cCSAus Certification

• Class I, Div. I, Groups C, D

• Class II, Div. I, Groups E, F, G

• Class III

ATEX Certification

II 2 G, Ex d IIB+H2 T5 Gb,

Ta = -40°C to +60°C

IECEx Certification

Ex d IIB+H2 T5 Gb

Ta = -40°C to +60°C

5

Connections

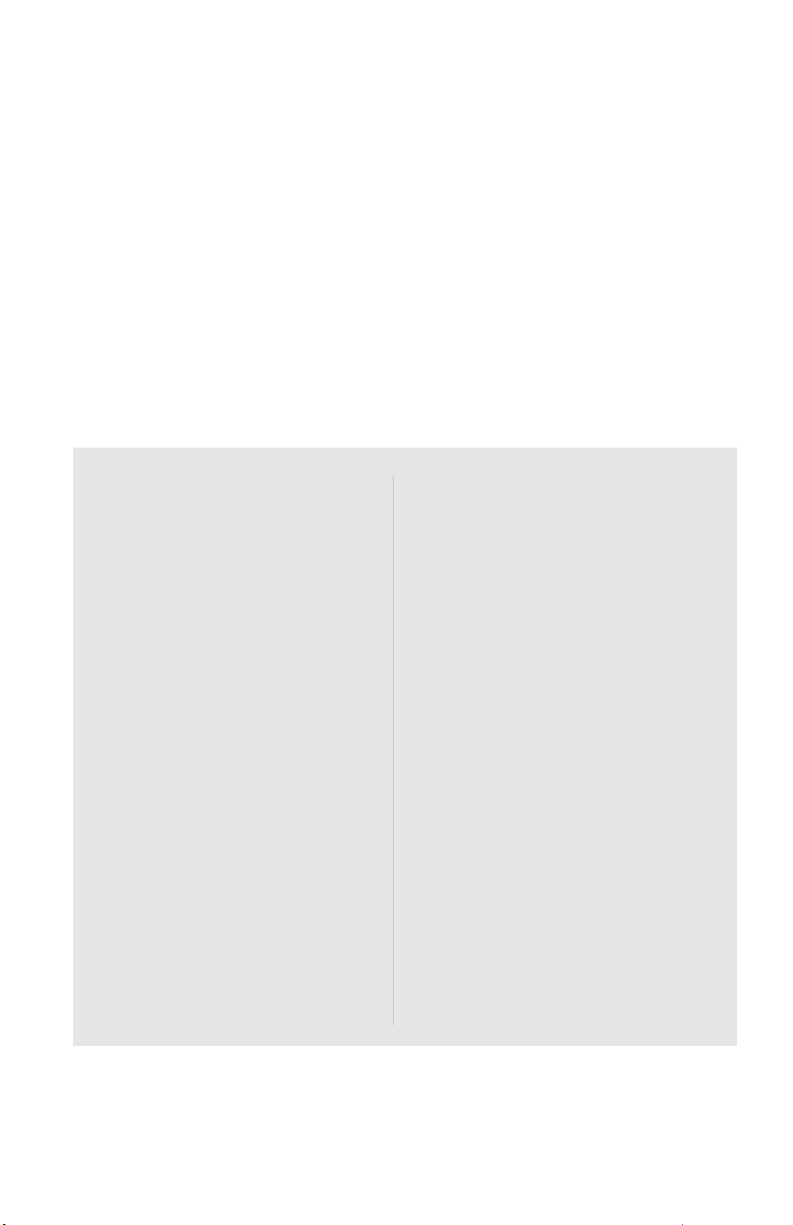

On dual access enclosure versions, the hook-up board can be accessed by

removing the blind cover.

To get access to the hook-up board on the single access enclosure models, first

remove the cover and loosen the 4 stainless steel screws visible through the face

plate as shown in Figure 18. Note that the screws are captured on the back side

of the main display board and will not fall out. Carefully remove the main display

board. The hook-up board is located at the bottom of the enclosure as shown in

Figure 2 below.

Figure 2: Single access enclosure model, hook-up board location

To get access to the sensor wiring terminal which is located on the back of the

main display board, the same procedure must be followed for both the single and

dual access enclosure models. 10

RT-30EX User Manual, Rev. 1.9 07/17/2015

6

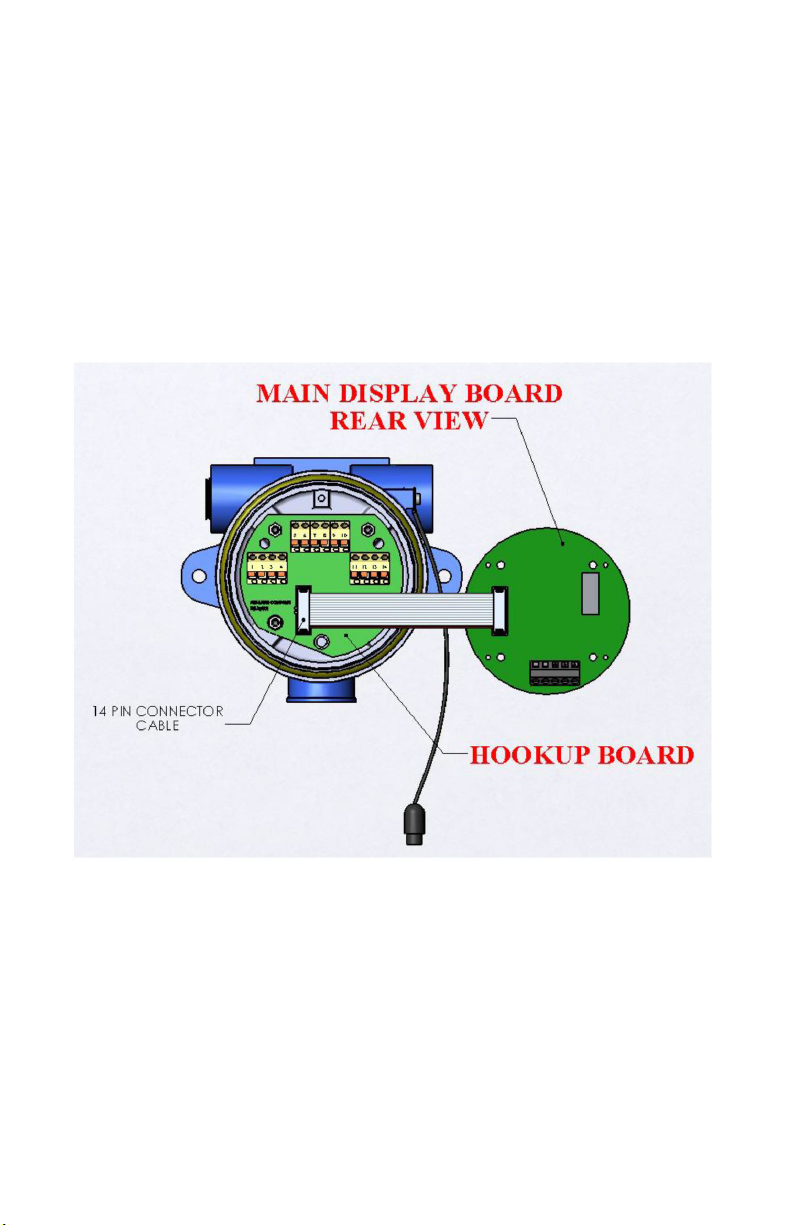

Hook-up board layout

Figure 3: Hookup board connection diagram

Maximum wire gauge: 16 AWG

Pin 1: (+) Reset

Pin 2: (-) Reset

Pin 3: (+) Frequency Out

Pin 4: (-) Frequency Out

Pin 5: (+) Supply Voltage

Pin 6: (-) Supply Voltage / Ground (Supply may be floating or jumpered

to housing ground, if needed, for noise reduction.)

Pin 7: Housing Ground

Pin 8: +Vcc

Pin 9: mA Loop Connection See Figure 5 & Figure 6 on page 12 for mA

signal polarity

Pin 10: mA Loop Connection

Pin 11: (+) Limit 1

Pin 12: (-) Limit 1

7

Pin 13: (+) Limit 2

Pin 14: (-) Limit 2

NOTE: See electrical specicaons page.

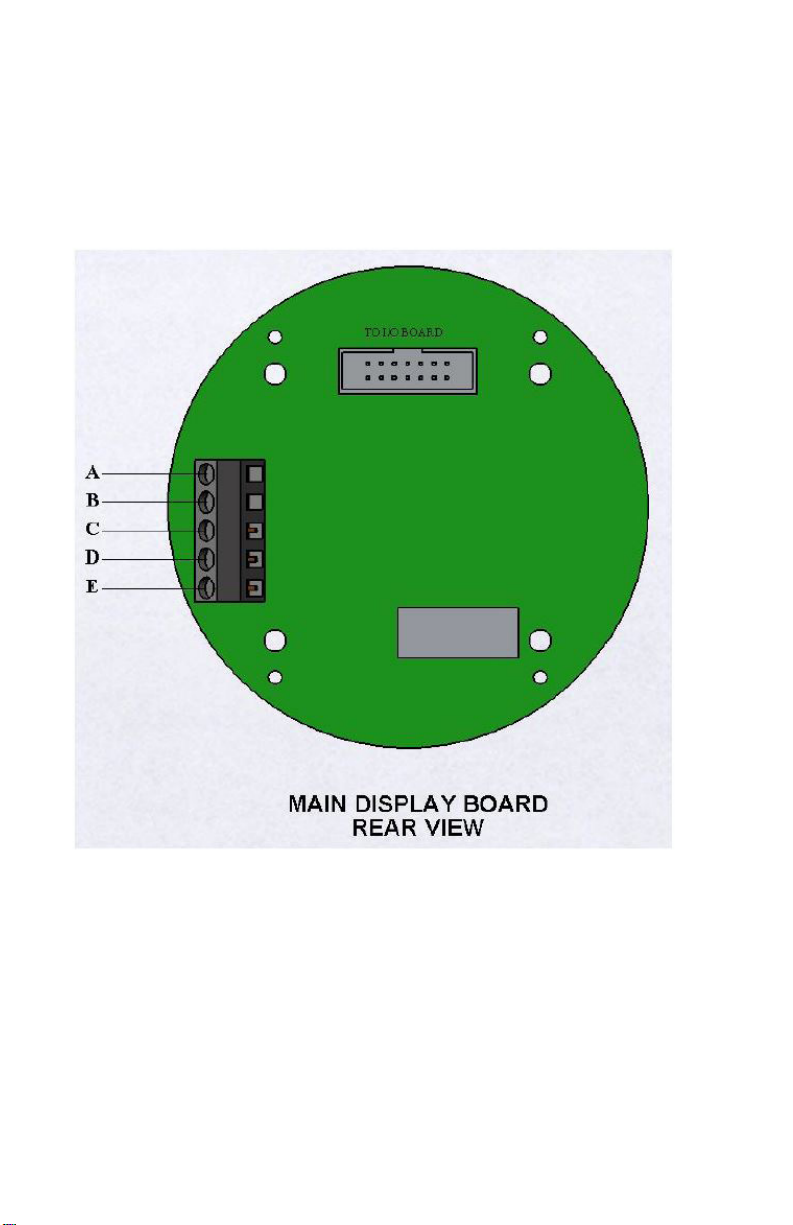

Main board layout Maximum wire gauge: 12 AWG

Figure 4: Main board input signal connection

Pin A: Magnetic Coil input

Pin B: Magnetic Coil input

Pin C: Ground

Pin D: High level pulse Input

Pin E: (+) 12Vdc Output for sensor supply

NOTE: See electrical specicaons page.

8

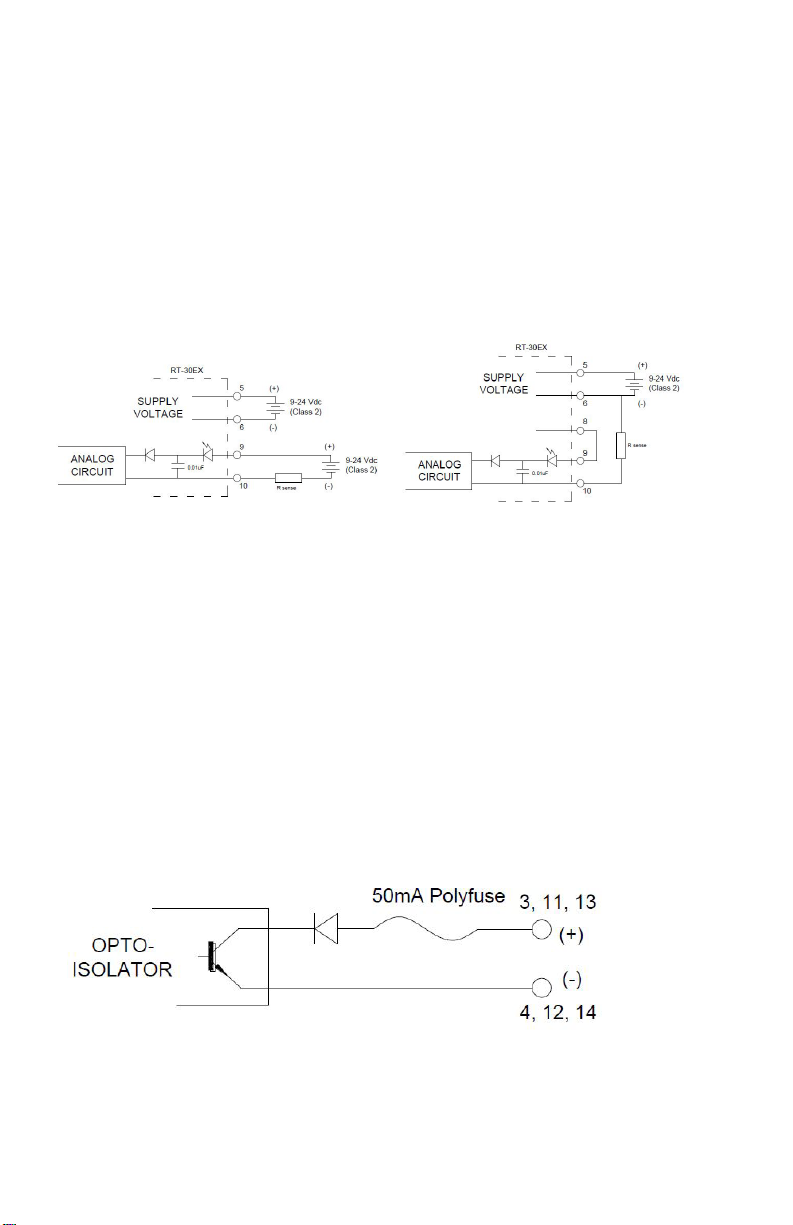

Analog output

The isolated 16-bit 4-20mA output can be wired for use with Loop powered

inputs or for ground referenced inputs. The analog signal has an LED in

series which varies in intensity as the mA signal varies. This can be used for

troubleshooting purposes.

When using the analog signal with inputs used with loop powered signals, it is

important to note that the RT-30EX still requires a separate power supply to

power the unit as shown Figure 5 below.

Figure 5: Loop powered analog output Figure 6: Ground referenced analog output

When using the analog signal with ground referenced inputs, jumper pins 8 and

9 together as shown in Figure 6 above. Analog signal is taken from pin 10 and

returns to pin 6 (supply ground).

Limit & frequency output

Three opto-isolated NPN open-collector outputs can sink or source depending

on connection. Attention must be paid to polarity of connections. See page 8

for electrical specification and page 10 for Limit 1, Limit 2 & Frequency pin-out

pairing.

Figure 7: Limit 1, Limit 2 & Frequency outputs

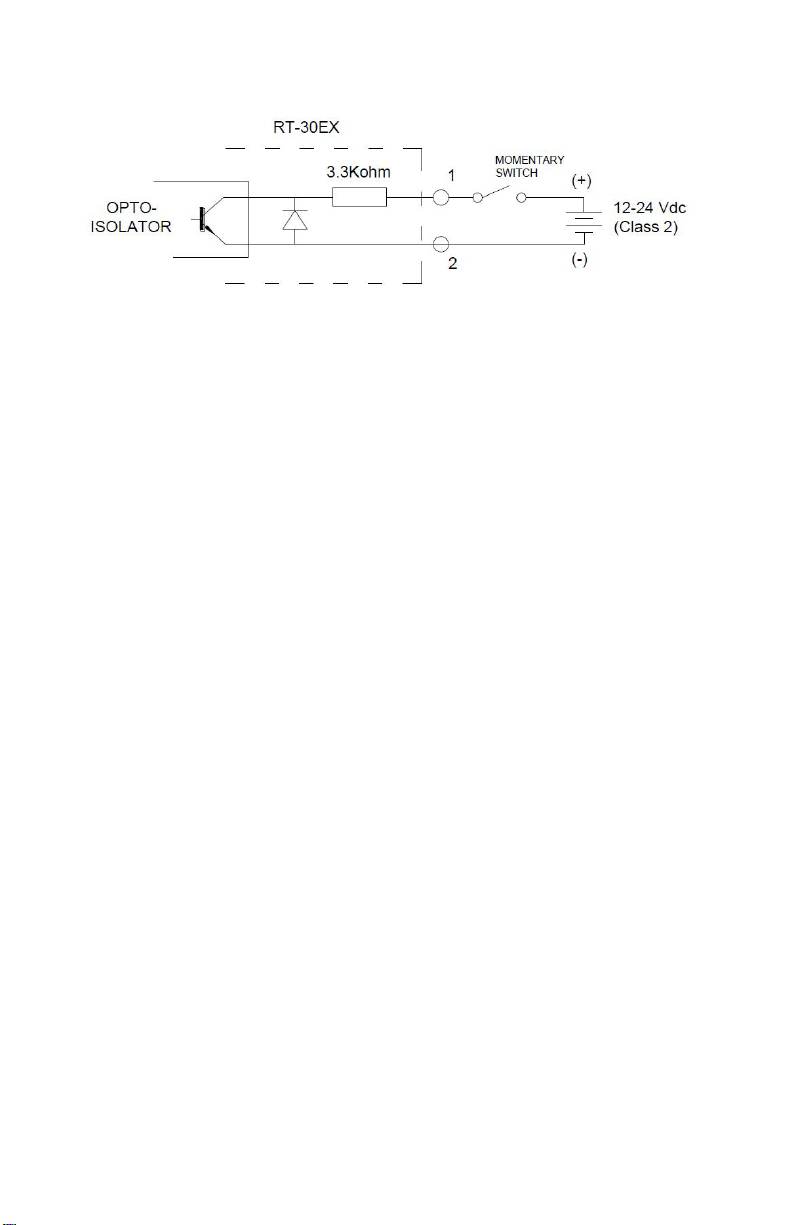

Reset input

Opto-isolated external reset input will trigger the RT-30EX to reset the totalizer

when the input sees a momentary transition from low (ground) to high (near

supply).

9

Figure 8: External reset input

10

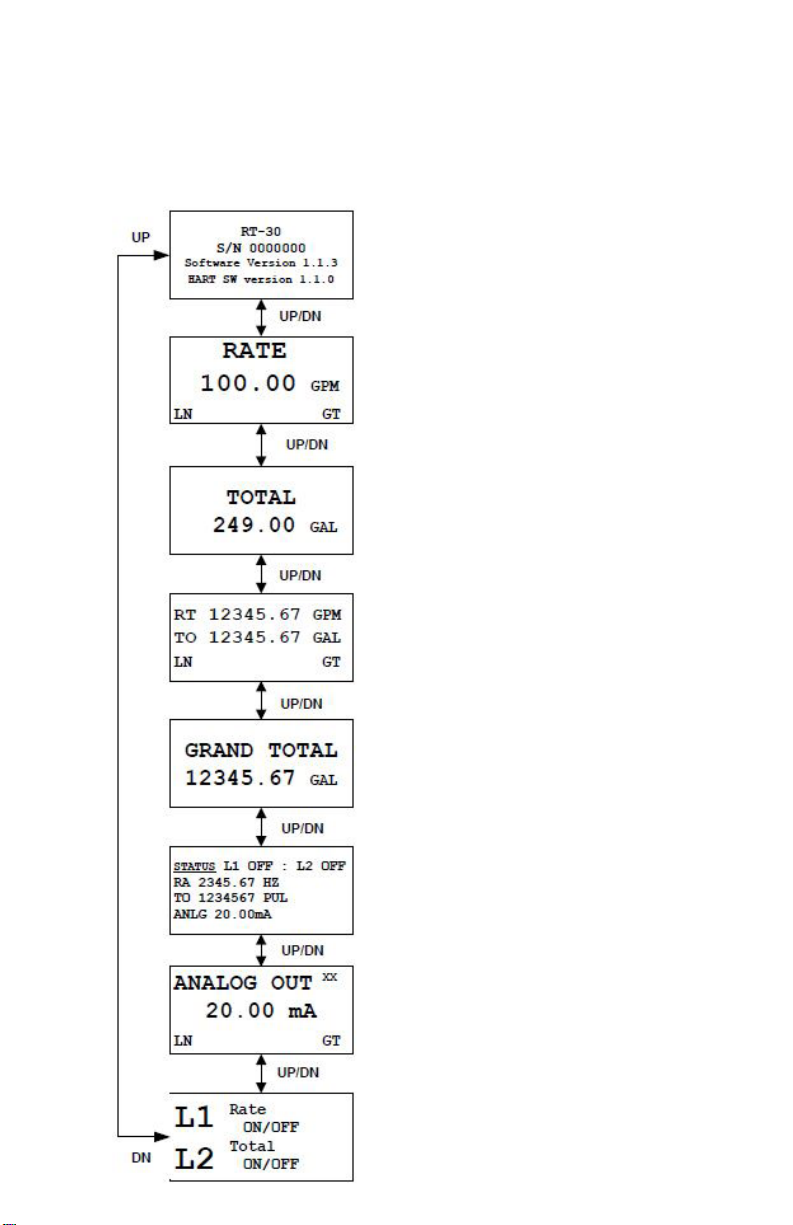

Run Mode Screens

Figure 9: Run Mode Screens - overview

The run mode screens, as shown below, can be accessed by using the UP and

DN buttons or using theattached magnet wand to activate internal hall switches.

Logo screen shows critical information on

RT-30EX firmware version.

RATE screen shows active flow rate

information in programmed engineering

units.

TOTAL screen shows totalized volume in

programmed engineering units.

RT/TO screen shows both the flow

rate and total values in programmed

engineering units.

GRAND TOTAL screen shows totalized

volume in programmed engineering units

and is not affected if TOTAL is reset.

STATUS screen shows data summary.

Flow and total are in un-scaled units of

Hertz for flow and Pulses for total.

ANALOG OUT screen shows the mA value

the RT-30EX is outputting.

L1/L2 screen shows information for Limit

outputs.

11

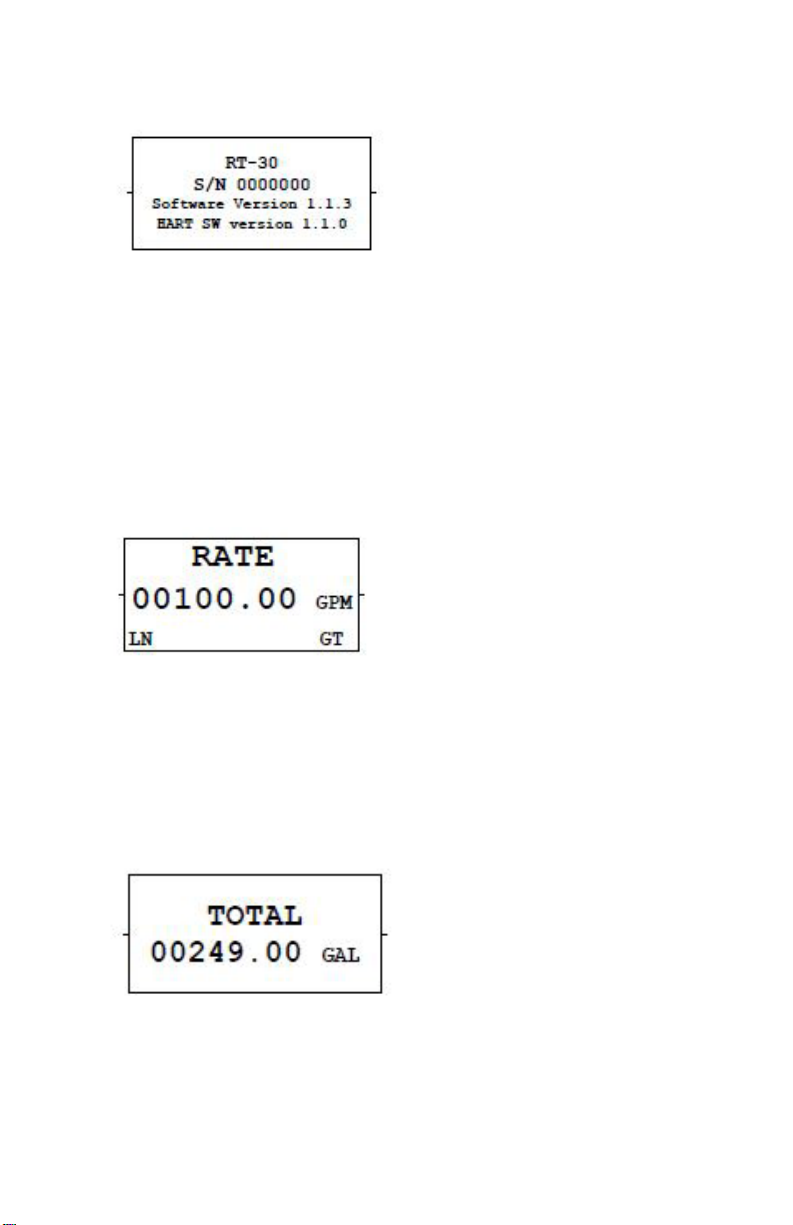

Figure 10. LOGO screen

The LOGO screen shows 3 or 4 lines of important data for the display unit which

is needed if contacting the factory for support issues.

1. Line 1 shows the basic model name.

2. Line 2 shows the unique serial number of the unit.

3. Line 3 shows the firmware version of the unit.

Figure 11. RATE screen

The RATE screen displays the flow rate in the programmed engineering units. If

the linearizer is active, ‘LN’ shows in lower left corner. If the Gate Time filter is

active, ‘GT’ shows in lower right corner.

Figure 12. TOTAL screen

The TOTAL screen displays the flow total in programmed engineering units.

Pressing the RESET button resets the value back to zero (0). The Total can also

be reset remotely by connecting a momentary voltage to the external RESET pin.

12

The RT/TO screen shows both the flow rate and total values in programmed

engineering units. If the linearizer is active, ‘LN’ shows in lower left corner. If the

Gate Time filter is active, ‘GT’ shows in lower right corner. Pressing the RESET

button resets the total value back to zero (0). The Total can also be reset

remotely by connecting a momentary voltage to the external RESET pin.

Figure 13. RATE/TOTAL screen

The RT/TO screen shows both the flow rate and total values in programmed

engineering units. If the linearizer is active, ‘LN’ shows in lower left corner. If the

Gate Time filter is active, ‘GT’ shows in lower right corner. Pressing the RESET

button resets the total value back to zero (0). The Total can also be reset

remotely by connecting a momentary voltage to the external RESET pin.

Figure 14. GRAND TOTAL screen

The GRAND TOTAL screen displays the flow total in programmed engineering

units. The GRAND TOTAL value does not reset when the TOTAL value is

reset and is therefore often used to collect a day total in batch applications. To

reset the GRAND TOTAL a password is required. The password is 53126. This

password cannot be changed.

Figure 15. STATUS screen

The STATUS screen shows multiple values and is used more as a summary

screen, especially if trouble shooting a system. The following values are shown:

1. The output state of Limit 1 and Limit 2

2. The flow rate in un-scaled units of Hertz (frequency).

NOTE: The Gate Time lter and linearizer, if acve, do not aect the ow rate value in the STATUS

screen. This is the raw incoming frequency.

13

3. The total value in un-scaled units of Pulses.

4. The analog output in milliamps (mA).

NOTE: Because the mA value is an actual signal output, it is aected by the Gate Time and linearizer,

if acvated.

Figure 16. Analog Out Screen

The ANALOG OUT screen shows the mA value the RT-30EX is outputting. The

2 letters in the upper right corner indicate what variable the mA output has been

assigned to represent.

1. FX – Fixed mA output

2. RA – mA output is scaled to represent the RATE value

3. TO – mA output is scaled to represent the TOTAL value

4. GR – mA output is scaled to represent the GRAND TOTAL value

If the linearizer is active, ‘LN’ shows in lower left corner. If the Gate Time filter is

active, ‘GT’ shows in lower right corner.

Figure 17. LIMIT screen

The L1/L2 screen shows what the Limits are programmed to represent and the

state of the output.

The first line of each limit represents what the Limit is programmed for:

1. OFF – Limit output has been turned off.

2. Frequency – The Limit outputs the incoming frequency

3. Rate – The Limit output will change state when the flow rate reaches the

programmed value

4. Total – The Limit output will change when the TOTAL reaches the

14

programmed value

5. Grand Total - The Limit output will change when the GRAND TOTAL reaches

the programmed value

The second line of each limit represents the actual state of the output pin(s)

Control Functions

There are two methods that can be used to scroll through screens or make

changes within programming modes. If in a safe area with the front cover

removed, the 4 push buttons showing through the front face plate can be used

with the button function as shown on the face plate.

Figure 18. Front View

WARNING: If programming or screen changes are to be made while the RT30EX is in the hazardous area, do not remove cover to use the push buttons.

Keep cover on and use the magnetic wand. Only use push buttons in a nonhazardous area.

15

Alternately, with the cover closed it is possible to make changes using the

magnetic wand attached to the outside of the unit. The push button functions are

duplicated with internal Hall switches which activate when the magnetic wand is

held in the 3, 6, 9 or 12 o’clock positions as shown in Figure 19 and Figure 20.

The face plate is marked at each position with the corresponding function.

Figure 19. Dual access magnetic switch locations

Figure 20: Single access magnetic switch locations

16

Programming

Entering programming mode

The RT-30EX programming menu can be accessed from 4 of the run mode

screens; [RATE], [TOTAL], [ANALOG OUT] and limit [L1/L2] screens. To enter

the programming menu from these screens, press and hold the ENT button

for 3 seconds until one of the programming screens appears (see Figure 21).

The programming menu will show the screen relevant to the run mode screen

from which the programming menu was entered. Use the buttons as shown in

Figure 21 below to navigate through the screens. When exiting the programming

menu, the RT-30EX will always return to the run mode screen from which the

programming menu was entered.

Figure 21: Main programming menu

Changing values and making selections

When in a programming screen which requires a value to be changed, the active

character is indicated by an underscore. To increment the value use the UP

button and to decrease the value use the DN button. The character value will

wrap around when reaching either 9 or 0.

Once a character has been changed press the SEL button to move to the next

character to the right. If at the right most character, pressing SEL will bring the

cursor back to the left most character.

If a value has a decimal point whose position can be changed, press the SEL

button until the underscore is under the decimal point. Press the DN button to

move the decimal point to the left and press the UP button to move the decimal

point to the right.

NOTE: Not all programming screens allow the decimal point locaon to be changed such as any

milliamp value.

17

Once a variable has been changed to the desired value, press the ENT button

to accept the value and move to the next screen or programming value. If an

incorrect value is programmed, a warning screen will appear. Press any button to

exit a warning screen.

Figure 22: RATE, TOTAL and GRAND TOTAL scaling

K-factor (scaling factor)

The RT-30EX uses only one K-factor for scaling all displays. This value is

always entered in units of Pulses per Gallon. Once the rate and total units are

selected, the RT-30EX uses internal calculations to automatically correct the

displayed values to match the user selected units. When the correct K-factor

value has been programmed, press ENT to continue.

RATE unit

Use the UP and DN buttons to scroll through the available units to scale the

RATE screen.

The available units are:

GAL (US gallons)

LIT (Liters)

CC (Cubic centimeters)

BBL (Barrels)

ML (Milliliters)

M3 (Cubic meters)

OZ (Liquid ounces)

PUL (Pulses)

Once the desired unit is showing, press ENT to continue.

RATE time base

Use the UP or DN buttons to select the time base to use in conjunction with the

previously selected RATE units to define the flow rate unit.

The available time units are:

Seconds

Minutes

Hours

18

Days

When the correct time base is showing, press ENT to continue.

NOTE: If the rate unit & me base are selected as PUL & Seconds, the RATE screen will show the unit

as Hz, NOT PUL/SEC.

TOTAL unit

Use the UP and DN buttons to scroll through the available units to scale the

TOTAL and GRAND TOTAL screens.

The available units are:

GAL (US gallons)

LIT (Liters)

CC (Cubic centimeters)

BBL (Barrels)

ML (Milliliters)

M3 (Cubic meters)

OZ (Liquid ounces)

PUL (Pulses)

The Rate and Total units do not have to be the same. Once the desired unit is

showing, pressing ENT completes the scaling programming and returns display to

the main programming menu.

Analog output scaling

When entering the Analog programming menu, the first screen asks to select

the Analog Source, or what the analog output value is to represent. There are 4

choices as shown in Figure 23.

Figure 23: Analog source selection screen

Using the UP and DN buttons scrolls through the 4 choices that the mA output

can represent: a fixed mA output value, the input flow rate, the totalizer value or

the grand totalizer value. Press ENT when correct choice is showing.

19

Figure 24. Fixed mA output programming

This option allows the user to select a constant mA value the RT-30EX will

output regardless of any changing values. A constant mA signal could be used

as an external indicator showing if the RT-30EX is on. Allowable values are from

2mA to 20mA.

This option allows the user to select a constant mA value the RT-30EX will

output regardless of any changing values. A constant mA signal could be used

as an external indicator showing if the RT-30EX is on. Allowable values are from

2mA to 20mA.

Figure 25. Analog Output, RATE Source programming Screens

RATE source allows the user to configure the mA output to represent the flowrate

value. The analog output span can be scaled for either zero to max flow or a

non-zero flow to max flow. If the flow rate goes above the programmed maximum

flow rate, the analog output will continue to increase, up to a maximum of 22mA.

This is useful for system fault detection.

Min Flow Rate

Enter the minimum user flow rate. This can be a non-zero value, such as the

lowest application flow rate if the equipment monitoring the mA signal can be

programmed as such. It can also be entered as zero, but in this case it will affect

the accuracy of the mA reading vs flow accuracy. If a non-zero value is entered,

the user will also be asked to enter a mA value to represent zero flow.

Min Flow mA

Enter the mA to represent the above entered minimum flow rate. Value must be

20

equal to or greater than 2mA.

Max Flow Rate

Enter the maximum flow rate to monitor.

Max Flow mA

Enter the mA value to represent the above entered maximum flow rate value.

20mA is the maximum allowable value.

Zero Flow mA

This screen only shows if the Min Flow Rate was programmed as a non-zero

value. Enter the mA value to represent zero flow. Lowest value allowable is 2mA

and it cannot be greater than the Min Flow mA value.

Figure 26. Analog Output, TOTAL source programming screens

TOTAL source allows the user to configure the mA output to represent the

Totalizer value. If the totalizer value goes above the programmed maximum total

value, the analog output will continue to increase, up to a maximum of 22mA.

This is useful for system fault detection.

Zero Total mA

Enter the mA value to represent a zero totalizer value. Minimum allowable value

is 2mA.

Max Total Value

Enter the maximum totalizer value to monitor.

Max Total mA

Enter the mA to represent the above entered maximum totalizer value. 20mA is

the maximum allowable value.

21

Figure 27. Analog Output, GRAND TOTAL source programming screens

GRAND TOTAL source allows the user to configure the mA output to represent

the Grand Total value. If the Grand Total value goes above the programmed

maximum Grand Total value, the analog output will continue to increase, up to a

maximum of 22mA. This is useful for system fault detection.

Zero Grand Total mA

Enter the mA value to represent a zero Grand Total value. Minimum allowable

value is 2mA.

Max Grand Total Value

Enter the maximum Grand Total value to monitor.

Max Total mA

Enter the mA to represent the above entered maximum totalizer value. 20mA is

the maximum allowable value.

LIMIT / Pulse output programming

Three opto-isolated NPN open-collector outputs can sink or source depending on

connection (i.e., power can flow in or out). Output ratings are listed on page 8.

NOTICE: Connecon polarity: collector (+), emier (-). See Figure 7.

Figure 28. Limit programming choices

From the first screen, the output to be programmed is selected. All three outputs

can be independently setup and if any of the outputs are not to be used, they

can be turned off. Limit 1 and Limit 2 can be configured as a frequency output

matching the incoming frequency from the flow meter, as a totalizer cycle

22

output, a flow rate set point trigger or to trigger on a set value of the Total or

Grand Total. The third Frequency Out can only be used to output the incoming

frequency from the flow meter. To exit the LIMIT programming screen, press

the UP or DN button until Select Limit option shows Exit. Then press the EXIT

button From the first screen, the output to be programmed is selected. All three

outputs can be independently setup and if any of the outputs are not to be used,

they can be turned off. Limit 1 and Limit 2 can be configured as a frequency

output matching the incoming frequency from the flow meter, as a totalizer cycle

output, a flow rate set point trigger or to trigger on a set value of the Total or

Grand Total. The third Frequency Out can only be used to output the incoming

frequency from the flow meter.

To exit the LIMIT programming screen, press the UP or DN button until Select

Limit option shows Exit. Then press the EXIT button.

Figure 29. Limit 1 & Limit 2 Output options

Turn Limits OFF

To turn either of the Limits off, choose the OFF Limit Type and press ENT. The

corresponding Limit pin will now stay low regardless of any variable changes.

Frequency Output on Limit pins

To have the incoming frequency be routed to a Limit pin, choose the Frequency

option. There is no other programming required.

Figure 30: Cycle Output volume scaling

23

The Cycle Output (pulsed output) The CYCLE OUT limit function provides an

incremental output signal for a remote totalizer, typically at a lower resolution and

frequency. Assigning a limit to the CYCLE OUT function toggles the state of the

limit output whenever the TOTAL increments by the programmed cycle amount.

The output remains ON until the cycle amount accumulates and does not turn

OFF until the cycle amount accumulates again as represented in Figure 31 on

page 27. The total accumulated between a rising and falling edge is the

cycle value. The total accumulated between any two rising edges is twice the

cycle value. You enter the cycle value in programmed engineering total units.

CAUTION: Do not program a cycle amount that produces more than 20 pulses

per second (20 Hz).

Consider the maximum flow rate to determine the resulting output frequency. The

frequency produced (in Hz) is the actual flow rate in Engineering Units per Minute

divided by 120, divided by the CYCLE AMOUNT.

Figure 31. Cycle Output definition

Figure 32. Limit Output Sources

Each Limit can be set to trigger its output based on a certain flow rate or total set

point. This is often used to indicate if a flow rate is outside its intended limits or if

a certain total value has been reached in a batch application.

24

Figure 33. Rate Limit Variables

Rate Value

The limit output will be off if the incoming flow rate is below the programed Rate

Value and the output will be on if the incoming flow rate is equal to or above the

programmed Rate Rate Value.

Limit Margin

The Limit Margin variable is programmed in engineering units and determines

whether the Rate Limit functions as an absolute limit or activates within a margin

or “window” around the programmed Rate Value. When the Limit Margin is

programmed as zero, the limit activates whenever the flow rate equals

or exceeds the programmed value. When you enter a Limit Margin value other

than zero, the limit is active whenever the selected flow rate is within the

“window” of the programmed Rate Value, plus or minus the MARGIN value. The

programmed Limit Margin must be less than the programmed Rate

Value.

TOTAL & GRAND TOTAL Limits

Figure 34. Total & Grand Total Limit Variables

TOTAL / GRAND TOTAL Value

Enter the Total or Grand Total value at which the respective Limit output should

change state. When the Total or Grand Total is reset to zero, the limit pin

changes back to initial state.

25

Frequency output programming

Figure 35. Frequency Output Programming

The third output can only be set to output the incoming frequency. From the top

Limit programming menu, choose the Frequency Output option, press ENT and

use the UP or DN button to turn the output frequency on. There are no other

variables to program. The output frequency is not affected by the Gate Time filter

and cannot be linearized. It is always the raw incoming frequency from the sensor.

Gate Time filter

Figure 36. Gate Time variable

This variable sets the sample time on the incoming frequency for the RATE

displays. Programmed in tenths of a second with an allowable range from 0.1 to

999.9 seconds, this variable affects the update of the display and analog output,

and is useful in stabilizing the display and output when dealing with fluctuating

flow rates. Setting the Gate Time to zero (0) disables the Gate Time filter and all

data is updated at an internal default rate of approximately 0.02 seconds. If the

Gate Time filter is active (any non-zero value) any run mode screen affected by

the filter will show ‘GT’ in the lower right hand corner of the screen.

Figure 37. Linearizer activation screens

The RT-30EX has a 30-point linearizer which can be used to increase the

linearity of the flow rate reading. When entering the Linearizer programming

mode, the first question asked is if the Linearizer should be activated. If the

linearizer has already been programmed, de-activating the linearizer does

not erase any previously programmed table values. It only turns off the use of the

linearizer and causes the RT-30EX to use the single programmed K-Factor value

26

under the Rate/Total programming menu for its calculations. If the Linearizer is

used, the minimum number of points required for programming is 2.

Figure 38. Linearizer variables

When programming the linearizer, each table point requires a frequency value

and K-Factor to be entered. To obtain these values it may be necessary to

have a separate calibration done on the flow meter ahead of time. Often this

information can be found on the original calibration sheet from the

manufacturer.

Freq. variable

When populating the linearizer table, it is required that Point 1 has the lowest

frequency and each subsequent table point frequency must be in continuously

increasing frequency value. The frequency value represents the signal from the

flow meter at each flow rate to be programmed into the linearizer table.

K-F variable

The K-Factor is the scaling factor in Pulses per Gallon for each frequency

programmed.

When the desired number of linearizer table points have been programmed on

the next table point leave the frequency value as zero and press ENT. This is

understood by the RT-30EX as meaning end of table programming and saves

the table values and exits the linearizer programming menu.

Clearing the linearizer table

To clear a previously programmed linearizer table, enter the linearizer table and

change Point 1 Freq. to zero (0). After pressing the ENT button, the RT-30EX

will display a warning that all table values will be cleared. If this is correct, press

the YES button. This will cause all table values to be set to zero and the

Linearizer will be turned OFF. The user has the ability to press NO button to

cancel this option and return to Point 1 programming screen.

Changing the linearizer table

To change a table Point value, enter the programming screen and press the

27

ENT button to get to the table value to change. After changing the relevant

values, continue pressing the ENT button through the remaining table values until

reaching the end of the programmed table (first table point whose Freq. is zero)

to exit the table.

Adding linearizer table point

To add more table points, it must be noted that data can only be added to

the end of a table. Therefore, if the additional point(s) to add do not have a

frequency greater than the last entered point, it will require the user to manually

“shift” the table points by entering the new points after the next smallest existing

value and then re-entering the remaining points.

If an existing table is changed and has more points than required, once the

required points have been entered and the next table value has the Freq.

changed to zero, all remaining points will automatically be reset to zero when

exiting the table.

Calibrating Analog Output

The analog output can be calibrated to correct for any variances caused by the

users input equipment. The calibration routine allows the user to adjust the 4mA

and 20mA output values.

The calibration routine is entered from the STATUS screen.

NOTE: When entering the calibraon roune, any incoming frequency to the RT-30EX is ignored.

Before starting the calibration routine, make sure the analog output is connected

to the intended readout equipment. To calibrate the RT-30EX it is necessary to

enter the analog value read from the user’s readout equipment.

28

Figure 39. Analog output calibration routine

From the run mode STATUS screen, press and hold the ENT button for 3

seconds to enter the I/O Function programming screen. Press the UP or DN

button to display the ‘Calibrate Output’ choice and then press ENT.

At the first mA adjustment screen, the RT-30EX outputs the value that should

equal 4mA output. Adjust the mA value to match the value shown on the user’s

readout equipment and press ENT when done.

At the second mA adjustment screen, the RT-30EX outputs the value that should

equal 20mA output. Adjust the mA value to match the value shown on the user’s

readout equipment and press ENT when done.

At the next screen, the RT-30EX outputs the corrected 4mA value. At the last

screen the RT-30EX outputs the corrected 20mA value. If either measured output

is still not close enough to the required value, enter the calibration routine again.

When done, press EXIT until back at STATUS screen.

I/O Manual Adjustment

Whether for troubleshooting purposes or to manually control external equipment,

the RT-30EX allows the user to enter an I/O routine in which the analog output,

Limit outputs and Frequency outputs can be controlled and the external Reset

input can be monitored. A good use of this feature is to verify communication

between the RT-30EX outputs and the users’ readout equipment in a controlled

fashion before final system installation.

29

Figure 40. I/O adjustment top menu

When entering the I/O programming mode from the STATUS screen, use the UP

or DN button to change the I/O Function to ‘Test output’ as shown in Figure 40

above and press ENT. Next choose which I/O to change.

Analog output adjustment

The user can manually control the mA output to any value between 2mA to 20mA

in one of two ways. Fine adjustment allows user to program a specific mA value to

output. Coarse adjustment allows user to increment or decrement the mA value in

1mA steps using the UP and DN buttons.

Fine mA adjustments

Figure 41. Fine mA output adjustment screens

When choosing the Fine adjustment option, the screen will appear which shows

the active mA output value. Change this number to any desired value between

2mA and 20mA and when ENT button is pressed, the RT-30EX will output this

value. This also returns the screen to the adjustment type screen. Press SEL to

see output value again and make new change.

30

Course mA Adjustments

Figure 42. Fine mA output adjustment screens

When choosing the Coarse adjustment option, the screen will appear where the

mA output value can be changed. When pressing the UP button, the screen

value (and mA output value) increments by 1mA, to a max of 20mA. When

pressing the DN button, the screen value (and mA output value) decrements by

1mA to a min of 2mA. This is the fastest way to test the mA output range if no

specific mA output value is required. Press the EXIT button to leave this mode.

Limit & frequency adjustment

The Limit and Frequency outputs can be manually controlled to change states

simultaneously using one of 3 methods. The fine adjustment allows the user

to enter a specific frequency to output between 2Hz to 4,500Hz. The coarse

adjustment allows the user to output a frequency and change the rate in 25Hz

increments using the UP and DN buttons. The ON/OFF adjustment allows the

user individually toggle the output state between on and off using the UP, DN

and SEL buttons.

Fine limit output adjustments

When choosing the Fine adjustment option, the screen will appear which shows

the active frequency output value on the Limit 1, Limit 2 and Frequency outputs.

Change this number to any desired value between 2Hz and 4,500Hz and when

ENT button is pressed, the RT-30EX will output this value on the 3 outputs at

the same time. This also returns the screen to the adjustment type screen. Press

SEL to see output value again and make new change.

Coarse limit output adjustment

31

Figure 44. Course Limit Adjustment Screens

When choosing the Coarse adjustment option, the screen will appear where

the frequency output value can be changed. When pressing the UP button,

the screen value (and Hz output value) increments by 25Hz to a max of

4,500Hz. When pressing the DN button, the screen value (and Hz output value)

decrements by 25Hz to a min of 2Hz. Press the EXIT button to leave this mode.

ON/OFF Limit output adjustment

Figure 45. ON/OFF Limit adjustment screens

When choosing the ON/OFF adjustment option, the screen will appear showing

the current state of each output pin. By pressing the UP, DN and SEL buttons,

each associated output as shown in Figure 45 above will change the state.

Monitor external reset input

When choosing the Monitor Reset input option, if the external reset input will be

used to reset the TOTAL value, this screen will show the current state of the pin

as interpreted by the RT-30EX firmware.

Figure 46. External Reset input monitor screens

32

To monitor the current state of the external Reset pin, press the YES button

from the Monitor Reset input screen. The screen that follows will show what the

current state of the pin is. Using an external control signal, toggle the voltage

level between high and low and monitor that the RT-30EX also sees the change.

Appendix A - Physical Dimensions

Figure 47. Dual access model dimensions

33

Figure 48. Single access model dimensions

34

Appendix B - Physical Dimensions

Analog output 2mA (Fixed)

Frequency output OFF

Gate Time 1.0 Seconds

GRAND TOTAL units GAL (always same as TOTAL units)

K-factor 1

Limit 1 OFF

Limit 2 OFF

Linearizer OFF

RATE unit GAL

RATE time base Minutes

TOTAL GAL

35

Limited Warranty

AW-Lake Company warrants the product to be in good working order for a

period of 1 (one) year from the date of purchase from AW-Lake Company or an

Authorized AW-Lake Company distributor. Should the product fail to be good

working order at any time during this 1-year warranty period, AW-Lake Company

will, at its option, repair or replace the product at no additional charge except as

set forth below. Repair parts and replacement products will be furnished on an

exchange basis and will be reconditioned or new. All replaced parts and products

become the property of AW-Lake Company. This limited warranty does not

include service to repair damage to the product resulting from accident, disaster,

abuse, or a non AW-Lake Company modification to the product.

Limited Warranty service may be obtained by delivering the product during the

1-year warranty period to AW-Lake Company and provide proof of purchase date.

If this product is delivered by mail, you agree to insure the product or assume the

risk of loss or damage in transit, to prepay shipping charges to warranty location

and use the original shipping container or equivalent.

For further information contact:

AW-Lake Company

2440 W. Corporate Preserve Dr. Suite #600

Oak Creek, WI 53154

ALL EXPRESS AND IMPLIED WARRANTIES FOR THIS PRODUCT

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO A PERIOD OF 1

(ONE) YEAR FROM DATE OF PURCHASE, AND NO WARRANTIES, WHETHER

EXPRESS OR IMPLIED, WILL APPLY AFTER THIS PERIOD. SOME STATES

DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

IF THIS PRODUCT IS NOT IN GOOD WORKING ORDER AS WARRANTED

ABOVE, YOUR SOLE REMEDY SHALL BE REPAIR OR REPLACEMENT AS

PROVIDED ABOVE. IN NO EVENT WILL AW-LAKE COMPANY BE LIABLE TO

YOU FOR ANY DAMAGES, INCLUDING ANY LOST PROFITS, LOST SAVINGS

OR INCIDENTAL OR CONSEQUENTIAL DAMAGE ARISING OUT OF THE USE

OR INABILITY TO USE SUCH PRODUCT, EVEN IF AW-LAKE COMPANY HAS

BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY

CLAIM BY ANY OTHER PARTY.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY

ALSO HAVE OTHER RIGHTS, WHICH MAY VARY FROM STATE TO STATE.

36

373839

COMPANY

414.574.4300 | www.aw-lake.com

2440 W. Corporate Preserve Dr. #600 Oak Creek, WI 53154

©2016 AW-Lake Company. All rights reserved. Doc ID:RT30E XMAN082416

Loading...

Loading...