AW-Lake ProScan Operating Manual

COMPANY

ProScan In-Line Process Sensor

Installation, Operating &

Maintenance Manual

©2016 AW-Lake Company. All rights reserved. Doc ID:PROSMAN082416

Table of Contents

Product Description.......................................................3

Principle of Operation......................................................3

Features.............................................................................3

Technical Specications...................................................4

Preliminaries...................................................................4

Standard Shipments.........................................................4

Unpack and Check Contents...........................................4

Electrical Connections......................................................5

Operation..........................................................................6

Applying Power.................................................................6

Installation......................................................................7

Deadleg..............................................................................7

Installation Site.................................................................7

Vertical...............................................................................8

Horizontal..........................................................................8

Straight Sections...............................................................8

Installations Not Recommended....................................8

Clamp Connection Gasket...............................................8

Connect..............................................................................8

Calibration Verication.................................................8

Calibration Procedure.................................................10

Sensor Oset and Span Calibration.........................11

Disclaimer......................................................................19

2

Product Description

ProScan is an in-line optical sensor that mounts directly to the process line,

providing real-time information about the process.

ProScan can accurately detect the point of transition from water to product, which

is the primary application. Depending on the degree of solids difference between

two materials, it can also detect a product–to-product transition. And for products

such as skim, 1 percent, 2 percent and whole milk, ProScan can act as a monitor

of milkfat percentage and an indicator of product quality.

The most common calibration entered into ProScan includes points for water,

skim milk, 1 percent milk, 2 percent milk, whole milk and a maximum response

standard equal to 20 mA.

The 3A Certified ProScan also has uses in the brewing, pharmaceutical, and

juice processing industries. The device accurately monitors turbidity and product

concentration and can help processors recover as much product as possible

before a cleaning cycle begins. It can also help to ensure equipment adds costly

chemicals at the appropriate time.

The ProScan sensor assists in determining if fluid should be added to recovery

tanks or sent to the drain, and is an excellent monitor of BOD loading on waste

lines. Solid construction means the ProScan Sensor stands up to the high

temperatures and temperature fluctuations.

Principle of Operation

Utilizing advanced optical technology, ProScan sends a beam of light into

the process and measures the backscatter, which is proportional to solids

concentration. The device’s internal microprocessor then converts the scatter to a

linearized 4-20 mA output, which easily links to a PLC, DCS or data logger.

Features

• 3A Certification

• Real-time process control

• Detects phase transitions

• Stainless steel construction

• Sapphire lens

3

• Sanitary clamp connections

• NEMA 6 /IP67 enclosure

• Easy to install, set up and maintain

Technical Specications

Output

4-20 mA

Power Consumption

0.45 Watts

Supply Voltage

15-24 VDC

Standard

3-A Sanitary Standard, 46-03

Optical Lens

Sapphire

Lens Seal

FDA approved silicone rubber

Process Connections

1-1/2”, 2”, 2-1/2”, 3” Sanitary Clamp

Temperature Rating

32-212°F (0-100°C) - constant

32-300°F (0-149°C) - intermittent

Housing

NEMA 6 / IP67 enclosure

Body & Connector

316L stainless steel

Preliminaries

Standard Shipments

Unless specified otherwise, ProScan sensors are shipped with a standard

calibration covering a span of 4 to 20 mA and representing clean water at 4 mA

and a maximum white standard at 20 mA. A calibration document is included in

the shipment to inform you of the calibration date and details.

Unpack and Check Contents

Upon receipt of the shipment, carefully remove all items from the shipping

package and compare the contents to the shipping documents.

4

Also check:

• The ProScan sensor and other components for any damage that may have

occurred during shipping.

• To make sure the sapphire lens is clean and undamaged. (If the lens needs to

be cleaned, clean it gently with a mild soap solution and a soft, clean cloth.)

• The sensor’s electrical connector; it should easily mate with the connector pins

on the sensor body.

• To make sure the threaded collar allows a snug, secure fit when fully engaged.

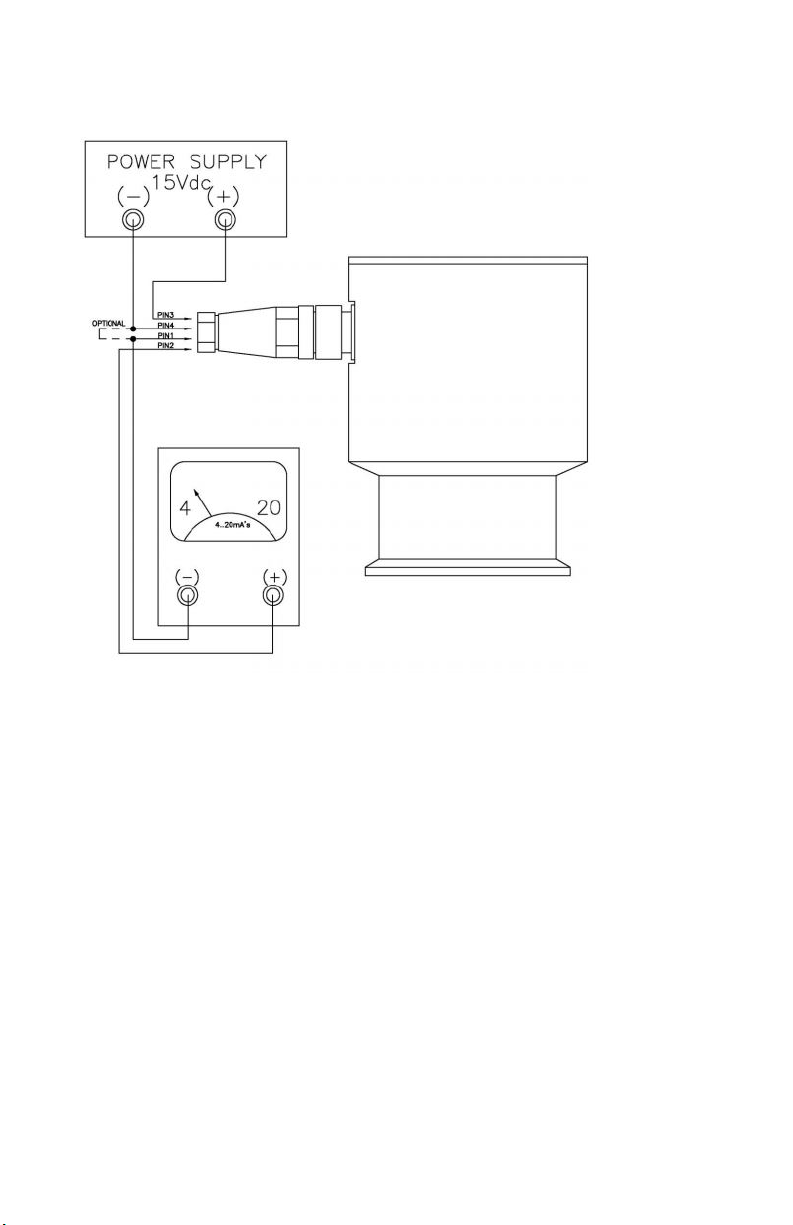

Electrical Connections

ProScan has a 5-pin electrical connector. The electrical connection scheme is

shown in Figure 9, page 20.

If you purchased the molded, NEMA-6 electrical connector and cable from AW

Gear Meters, simply connect the cable as provided.

If you are using the Hirschmann connector (Part Number 932 878-100 ELST 512

PG9 (www.hirschmannusa.com) and need to make a cable connection, please

read the following steps.

The most common wiring scheme for ProScan is a 3-wire connection:

• Pin 2 is the mA output

• Pin 3 is the 12 to 24 VDC power supply

• Pin 4 is the ground (negative side of the supply).

A 4-wire connection can also be used to connect ProScan. In this wiring

scheme, connect

• Pin 1 (the negative side of the mA output)

• Pin 2 (positive side of the mA output)

• Pin 3 (12 to 24 VDC power supply)

• Pin 4 (ground).

Pin 1 is the negative side of the mA output and is connected internally to Pin

4. This makes it more convenient if you want to make a 4-wire connection as

shown in Figure 1, page 8.

NOTICE: Pin 5, located in the center of the connector, is not used.

Once you make the connections inside the electrical connector, tighten the

threaded cord grip on the connector. This helps keep moisture from entering.

5

Figure 1: Electrical Connections

Operation

Once ProScan is calibrated and you make the proper electrical connections, the

sensor is ready for operation. Before attaching the sensor to the process line,

however, it is advisable to perform a quick check of the unit’s operation.

You must connect the sensor output to a digital display, multimeter or some other

electronics that allows you to monitor the ProScan’s mA output.

Applying Power

To view the unit’s internal electronics board, remove the screw cap on the sensor

(see Figure 3, page 15). When you apply power to the ProScan sensor, the

green LED on the unit’s internal electronics board blinks.

6

Loading...

Loading...