AW-Lake MX Operating Manual

COMPANY

MX 9000 Process Monitor

Installation, Operating &

Maintenance Manual

©2016 AW-Lake Company. All rights reserved. Doc ID:MXM AN082416

1

Table of Contents

Unpacking ..............................................................................................3

Quick Guide ...........................................................................................3

Connect to Sensor .................................................................................3

Connect to Power ..................................................................................3

Basic Key Denitions .............................................................................3

Technical Specications ........................................................................4

Power Requirement ...............................................................................4

Analog Output 4-20mA..........................................................................4

Frequency Inputs ...................................................................................4

Integrated Linearization ........................................................................4

Programming and Data Entry ..............................................................4

Product Description ............................................................................5

Principle of Operation ...........................................................................5

Features ..................................................................................................5

Relay Contact Ratings ............................................................................7

Sensor / Pulse Inputs .............................................................................8

Analog Output(s) ....................................................................................9

Frequency Output (option boards 1 and 2) ........................................9

Relay Outputs .........................................................................................10

Analog Input (option board 1) ..............................................................11

120/240 VAC Input (option board 2) ....................................................11

Batch Controller Inputs (option board 3) ............................................12

Run Mode Screens ...............................................................................12

Rate Screens ...........................................................................................14

Total / Grand Total Screens ..................................................................14

LOGO Screen ..........................................................................................14

STATUS Screen .......................................................................................15

RATIO A/B (B/A) Screens ........................................................................16

RA, TA (RB, TB) Screens .........................................................................16

ANALOG OUT Screen .............................................................................17

L1/L2 Screen ...........................................................................................17

RA/RB Screen ..........................................................................................18

TA/TB Screen ..........................................................................................18

RATE A + B Screen ..................................................................................19

RATE A - B Screen ...................................................................................19

TOTAL (Grand Total) A - B Screen ........................................................19

BATCH TOTAL Screen ............................................................................20

Control Functions ................................................................................20

Programming ........................................................................................21

Entering programming mode ...............................................................21

Changing Values and Making Selections .............................................21

RATE, TOTAL and GRAND TOTAL Scaling ............................................22

K-factor (scaling factor) .........................................................................22

RATE unit .................................................................................................22

RATE time base .......................................................................................23

TOTAL units ............................................................................................23

Fixed output source ...............................................................................25

2

Min Flow Rate .........................................................................................26

Min Flow mA ...........................................................................................26

Max Flow Rate ........................................................................................26

Max Flow mA ..........................................................................................26

Zero Flow mA ..........................................................................................26

TOTAL Source .........................................................................................26

Zero Total mA .........................................................................................27

Max Total Value ......................................................................................27

Max Total mA ..........................................................................................27

GRAND TOTAL source ...........................................................................27

Zero Grand Total mA .............................................................................27

Max Grand Total Value ..........................................................................27

Max Total mA ..........................................................................................28

LIMIT/ Pulse Output programming ......................................................28

Limit 1 & Limit 2 .....................................................................................28

Rate Value ...............................................................................................30

Limit Margin ............................................................................................30

TOTAL / GRAND TOTAL Value ...............................................................30

Frequency Output Programming .........................................................31

Gate Time Filter ......................................................................................31

Linearizer Programming .......................................................................32

Quadrature Signal Programming .........................................................33

System Settings Programming ............................................................34

Calibrating Analog Output ................................................................34

I/O Manual Adjustment......................................................................36

installation. ...........................................................................................36

Analog Output Adjustment ...................................................................36

Fine mA adjustment ..............................................................................37

Coarse mA adjustment ..........................................................................37

Frequency Adjustment ..........................................................................37

Fine Limit Output Adjustment ..............................................................38

Coarse Limit Output Adjustment .........................................................38

ON/OFF Output Adjustment .................................................................39

Monitor External Reset Input ...............................................................39

Ratio A/B (B/A) Programming ...............................................................39

ALARM /AB ALARM B/A ........................................................................40

TARGET NBR ...........................................................................................40

BATCH TOTAL Programming ................................................................41

Batch Controller Programming ........................................................41

Basic programming setup .....................................................................42

BATCH Programming ............................................................................42

DELAY ......................................................................................................43

BATCH LIMITS .........................................................................................43

ANALOG OUTPUT ...................................................................................43

OPERATION .............................................................................................44

Restoring Factory Defaults ...................................................................44

Appendix A - Physical Dimensions ..................................................45

Appendix B – Default Variable Values .............................................47

Limited Warranty ................................................................................48

3

Unpacking

Separate the MX 9000 Flow Monitor from packaging materials and check for any

visual signs of damage. If you determine there are damages caused by shipping,

file a claim with the shipping company. If the flow monitor appears to have been

improperly assembled or does not operate properly, return it for replacement or

repair (see Limited Warranty information at the end of this manual).

CAUTION: Before connecting, programming, or operating the MX 9000 Flow

Monitor, read this manual.

Quick Guide

CAUTION: As with any precision-engineered device, always operate the MX

9000 in accordance with the manufacturer’s instructions.

Connect to Sensor

You will connect three wires from the sensor(s) to the back of the MX 9000:

An electrical power wire a signal wire, and a ground wire.

NOTICE: Dual input models use two sensors (terminals for sensor 2). Insert the stripped end of the

red wire into lower terminal #3 (6) and use a screwdriver to secure. Insert the stripped end of the

white wire into lower terminal #4 (7) and the stripped end of the black wire into lower terminal #5

(8). Use a screwdriver (push / release) to secure these wires with the spring terminals.

Connect to Power

Insert the leads from the 120VAC adaptor into terminals 1 & 2 of the lower block.

Plug the adaptor into a wall receptacle. If you are supplying power from a DC

source, insert the positive lead into terminal #1 and the negative lead to terminal

#2. DC input should be from 18 to 24 volts.

Basic Key Denitions

The MX 9000 has four keys for data input and programming:

• DOWN / NO

• UP / YES

• SELECT / RESET

• ENTER / EXIT

4

Use the SELECT key to move the cursor to the digit you would like to change or

reset the total values, use the UP and DOWN keys to change between screens

or increase or decrease the value as desired, and use the ENTER key to enter

the information.

Programming and Data Entry

Upon power up, move to the screen that you wish to adjust. Hold the ENTER

key in for 3 seconds and screen will change to programming mode. Follow

screen prompts.

When in programming mode, numerical values are underlined or you are

prompted to answer YES or NO. Use the SELECT key to move between

characters then the DOWN / UP keys to change. Press ENTER to store the

value. Use YES / NO to enter other setup functions and EXIT when completed.

See Programming the MX 9000 beginning on page 21 for complete details.

Technical Specications

Power Requirement

14 to 16 VAC/250mA, or 18-24

VDC/200mA (customer supplied), or

120/240 VAC (optional).

*All units are shipped wit 120VAC/1000mA

wall transformer.

Analog Output 4-20mA

External-powered loop output into a

maximum 500 ohm load impedance

with 24 VDC supply. 2nd loop output

optional.

Frequency Inputs

0-4 KHz, sine, square or saw-tooth;

4 volts minimum amplitude; 3.3 Kohm

maximum impedance.

Integrated Linearization

Maximum 30-point linearization table

for improved accuracy over range.

Flow Sensor Power Supplies

(2) @ 15 VDC / up to 50 mA each

5

Product Description

The MX 9000 Flow Monitor is a versatile, multi-functional device that helps you

track rate, flow, limit, ratio, and other variables. The unit’s multicolor back-lighted

LCD display is easy-to-read with up to 22 different display modes available,

depending on model. The standard unit is one channel, but the optional twochannel version allows you to monitor dual flows and display them in a number

of ways: separately, as a sum (for example in total material use), as a difference

(as in fuel consumption), or as a ratio of product A/product B. You can also

use the MX 9000 to detect bi-directional flow when A and B channel signals

are available from a single flow meter. Other capabilities include the capacity to

monitor data and program the unit remotely. Four model variations give the MX

9000 the capability of performing limit, warning and alarm duties and batching.

Principle of Operation

After first making connections to the power source and to flow transmitter input

and output, you can choose up to 22 display modes. These include rates,

totals, ratios, limits and others, based on the model purchased. Then input kfactor values, the required engineering units, gate times, limits, etc. A 20 point

linearizer is built-in for added display accuracy. You may also program other

values such as warning/alarm limits and ratios, depending on model.

Features

Rate, total, limit, batch and ratio options

• Single or dual channel

• Two programmable Form C relay outputs (optional)

• One or two assignable 4-20 mA output (optional)

• Easy-to-read LCD display with color backlight that changes color for warning

or alarm

• Batch controller - stores up to 20 batch recipes

6

Model Number Key

MX9 - -

4

X

Main board options

Single channel flow/total

S

Dual channel flow/total

D

Ratio monitor

R

Batch controller

B

X

Communication protocol

No additional options

Options boards

4-20mA output 2, Frequency out, Analog in, 2 relay out

1

120/240VAC supply, 4-20mA out, Frequency out, 2 relay out

2

Only for batch controller

3

No option board

4

Output options

4-20mA output 1

No outputs

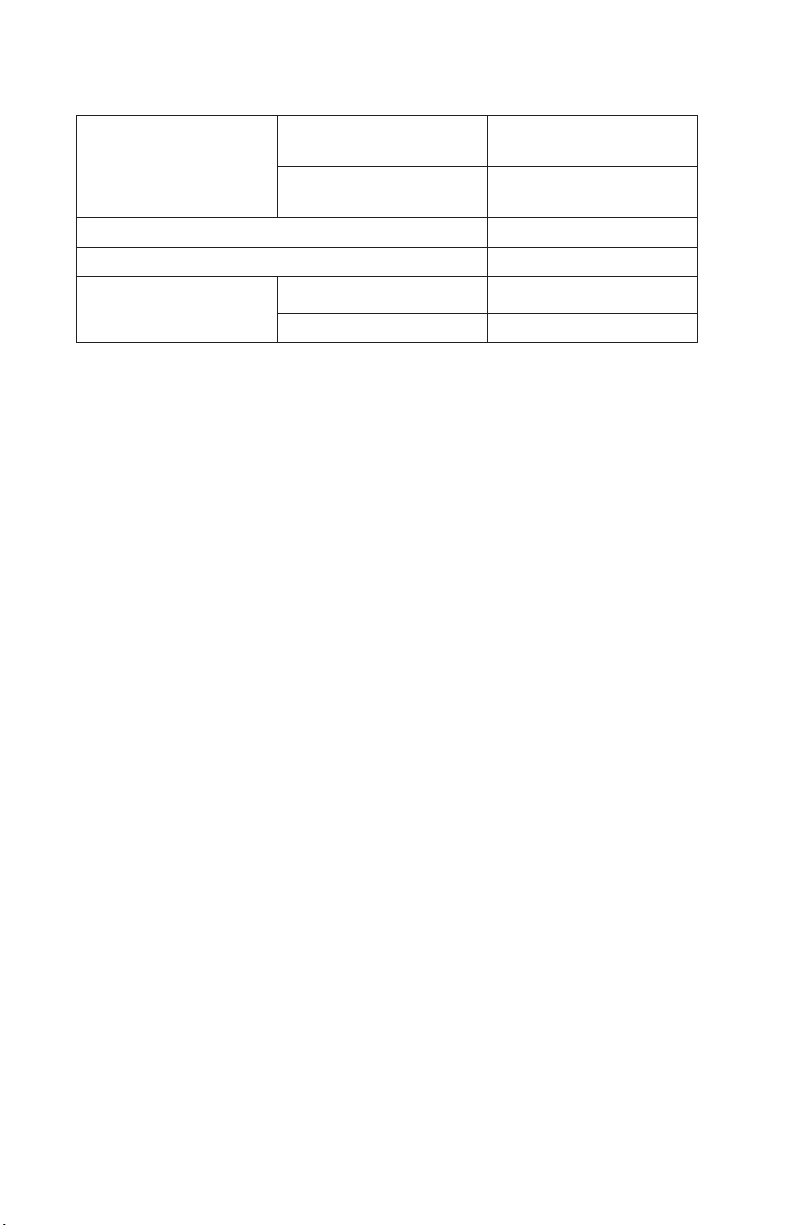

Technical Data

Minimum Power Supply Requirements

• 16 VAC/250mA with supplied 110 VAC transformer, or

• 18-24 VDC/250mA. (customer supplied direct current)

• 120/240 VAC with option board 2

Flow Sensor Power Output

• (2) @ 15 VDC/50 mA. each

Frequency Inputs

• 0-4.5 KHz, sine, square or saw-tooth; 5 volts minimum amplitude;

3.3K Ohm impedance

Analog Output(s)

• 4-20 mA external-powered loop output into a maximum 500 Ohm load

impedance with 24 volt supply

7

Relay Contact Ratings

Maximum Switched

Power

Maximum Switched Voltage 100 VDC, 250VAC

Maximum Switched Current 2A/DC, 1A/AC

Rated Load Resisve Load DC: 30V, 2A

NOTE: Maximum wire gauge 16 AWG

Resisve Load DC: 60W

AC: 125VA

Inducve Load DC: 30W

AC: 60VA

Inducve Load AC: 125V, 0.3A

LOWER TERMINAL BLOCK CONNECTIONS:

Pin 1: (+) 18-24 VDC Supply Voltage / 16 VAC Input

Pin 2: (-) 18-24 VDC Supply Voltage Ground / 16 VAC Input

Pin 3: (+) Sensor 1 Supply Voltage 15 VDC 25 mA MAX

Pin 4: Sensor 1 Signal Input

Pin 5: (-) Sensor 1 Supply / Signal Common

Pin 6: (+) Sensor 2 Supply Voltage 15 VDC 25 mA MAX

Pin 7: Sensor 2 Signal Input Housing Ground

Pin 8: (-) Sensor 2 Supply / Signal Common

Pin 9: (+) External Reset Input

Pin 10: (-) External Reset Input

Pin 11: (+) mA Loop 1 Output

Pin 12: (-) mA Loop 1 Output

UPPER TERMINAL BLOCK CONNECTIONS (Option Board 1):

Pin 1: Limit 2 Relay NC

Pin 2: Limit 2 Relay NO

Pin 3: Limit 2 Relay COM

Pin 4: Limit 1 Relay NC

Pin 5: Limit 1 Relay NO

Pin 6: Limit 1 Relay COM

Pin 7: (+) Analog Input

Pin 8: (-) Analog Input

Pin 9: (+) Frequency Out

Pin 10: (-) Frequency Out

Pin 11: (+) mA Loop 2 Output

Pin 12: (-) mA Loop 2 Output

8

UPPER TERMINAL BLOCK CONNECTIONS (Option Board 2):

Pin 1: Limit 2 Relay NC

Pin 2: Limit 2 Relay NO

Pin 3: Limit 2 Relay COM

Pin 4: Limit 1 Relay NC

Pin 5: Limit 1 Relay NO

Pin 6: Limit 1 Relay COM

Pin 7: (+) mA Loop 2 Output

Pin 8: (-) mA Loop 2 Output

Pin 9: (+) Frequency Out

Pin 10: (-) Frequency Out

Pin 11: 120/240 VAC Input Common

Pin 12: 120/240 VAC Input Line

UPPER TERMINAL BLOCK CONNECTIONS (Option Board 3):

Pin 1: Limit 2 Relay NC

Pin 2: Limit 2 Relay NO

Pin 3: Limit 2 Relay COM

Pin 4: Limit 1 Relay NC

Pin 5: Limit 1 Relay NO

Pin 6: Limit 1 Relay COM

Pin 7: +15 VDC (for remote switch select)

Pin 8: Mode Change Input

Pin 9: Batch Select Input

Pin 10: Batch Reset Input

Pin 11: Start / Stop Input

Pin 12: Program / Run Input

9

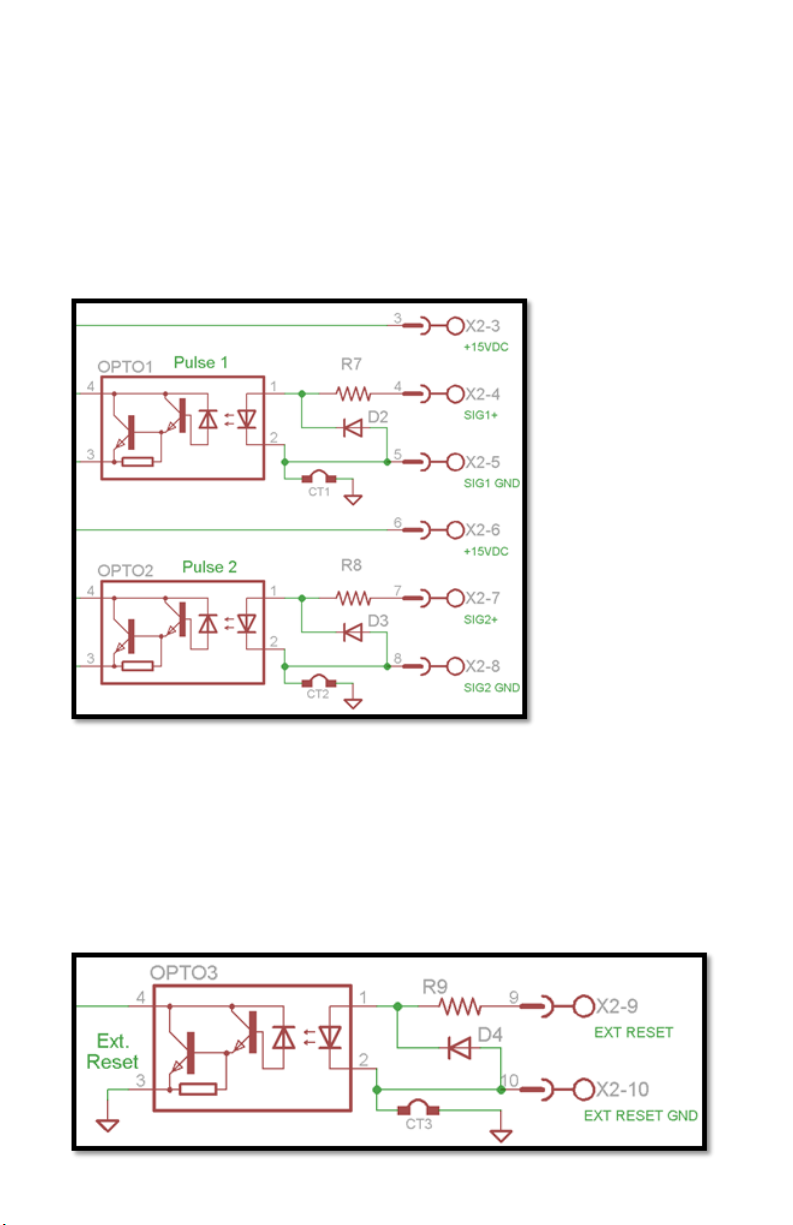

Sensor / Pulse Inputs

Pulse inputs are opto isolated and come referenced to signal ground. Regulated

+15 VDC at 50mA max is available for powering each sensor. Inputs can also be

isolated from the control power by cutting CT1 or CT2 with a sharp knife but then

the internal +15 VDC supply is not available. Minimum input voltage is 5 VDC

peak for pulses.

Figure 2: Sensor/Pulse Inputs

Reset Input

Opto-isolated external reset input will trigger the MX 9000 to reset the

totalizer(s) when the input sees a momentary transition from low (ground) to high

(near supply). Reset input can be isolated from internal ground by cutting CT3

with a sharp knife.

Figure 3: Reset Input

10

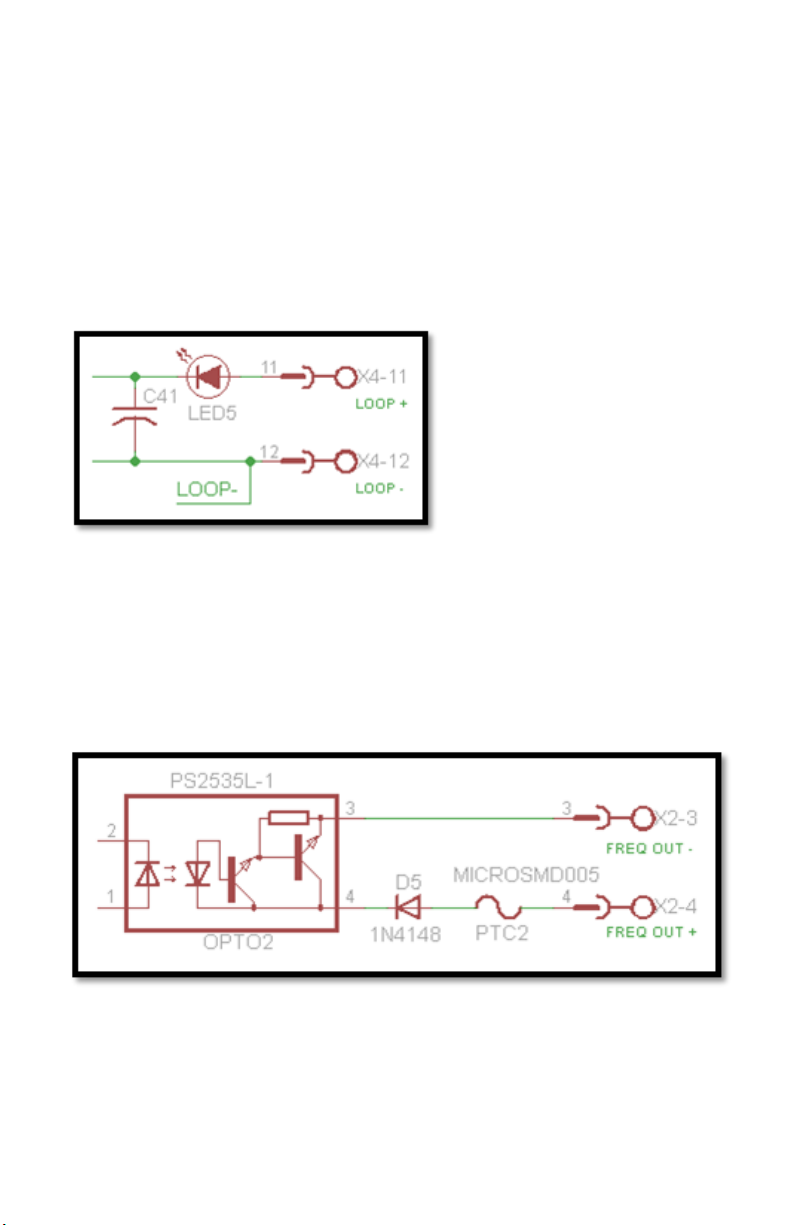

Analog Output(s)

The isolated 16-bit 4-20mA output(s) can be wired for use with Loop powered

inputs or for ground referenced inputs. The analog signal has an internal LED

in series which varies in intensity as the mA signal varies. This can be used

for troubleshooting purposes. When using the analog signal with inputs used

with loop powered signals, it is important to note that the MX 9000 requires an

external power supply to power the loop as shown below.

Figure 4: Analog Outputs

Frequency Output (option boards 1 and 2)

An opto-isolated NPN open-collector output can sink or source depending on

connection. Attention must be paid to polarity of connections. Limit circuit

current to 50 mA and 30 VDC for this circuit.

Figure 5: Frequency Output

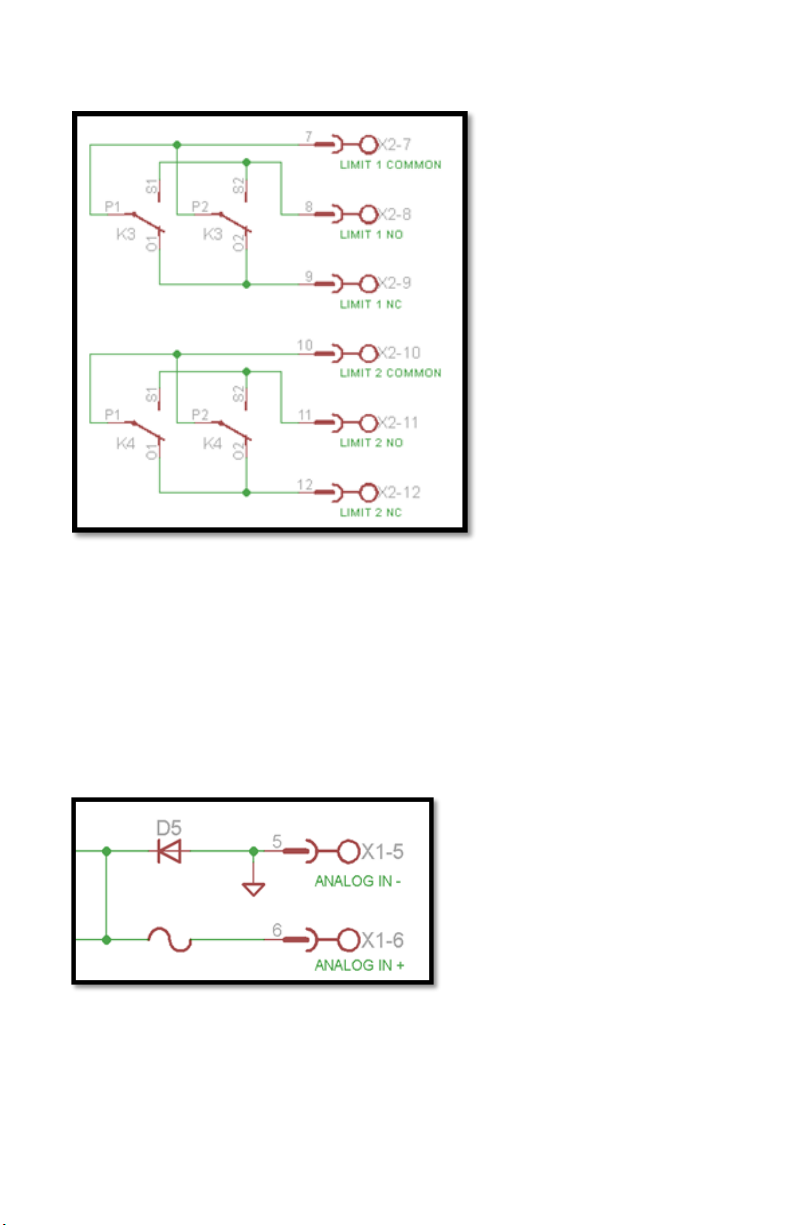

Relay Outputs

Two form C relay outputs are available on option boards 1 and 2. They are

programmed by the limit screens as to the function of each. See Relay Contact

Ratings on page 10 for limits.

11

Figure 6: Relay Outputs

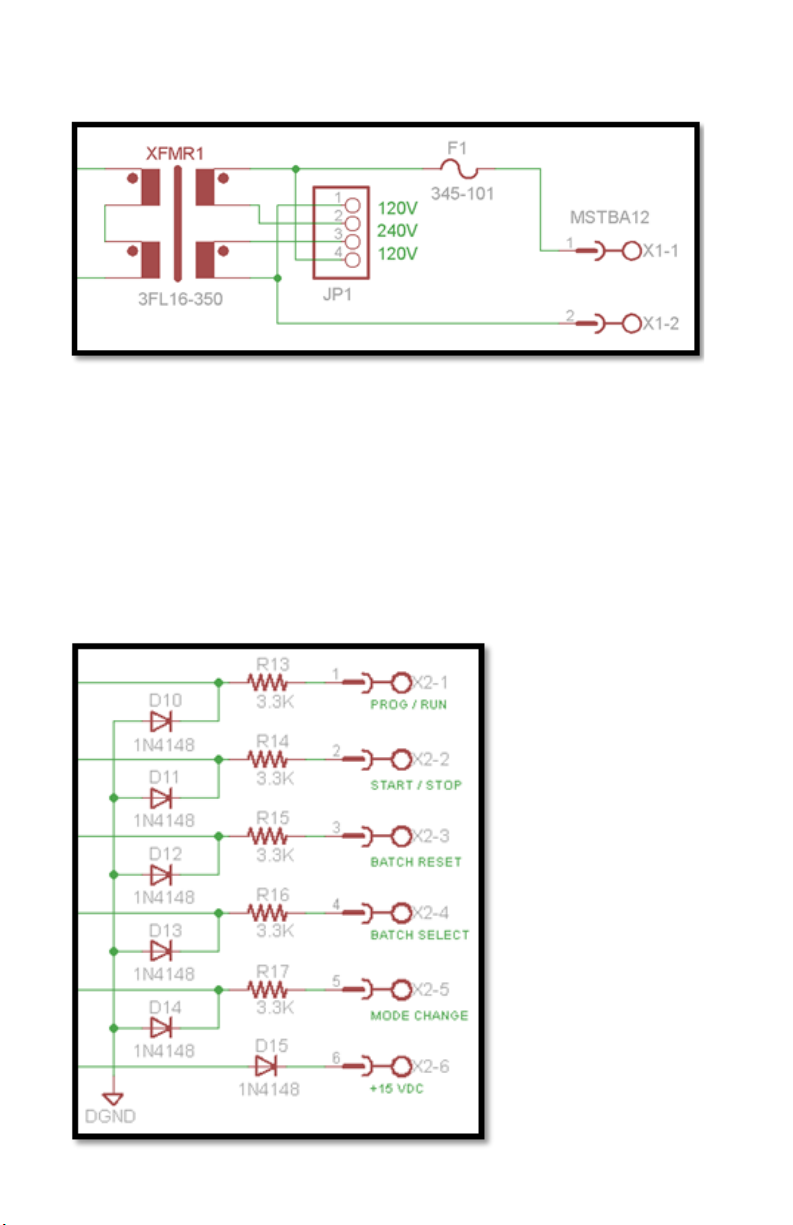

Analog Input (option board 1)

The analog input is available on option board 1. It can be configured for either

a 4-20 mA input or a 0-5 or 0-10 VDC input. The input is referenced to the

system common. Programming of the input is done using JP1. For 4-20 mA,

use jumper pins 1&3 and 2&4. For 0-5 VDC, use jumper pins 3&5 and 4&6.

For 0-10 VDC, use jumper pins 3&5 only. Pins are identified on the printed

circuit board. Remove back cover to access.

Figure 7: Analog Input

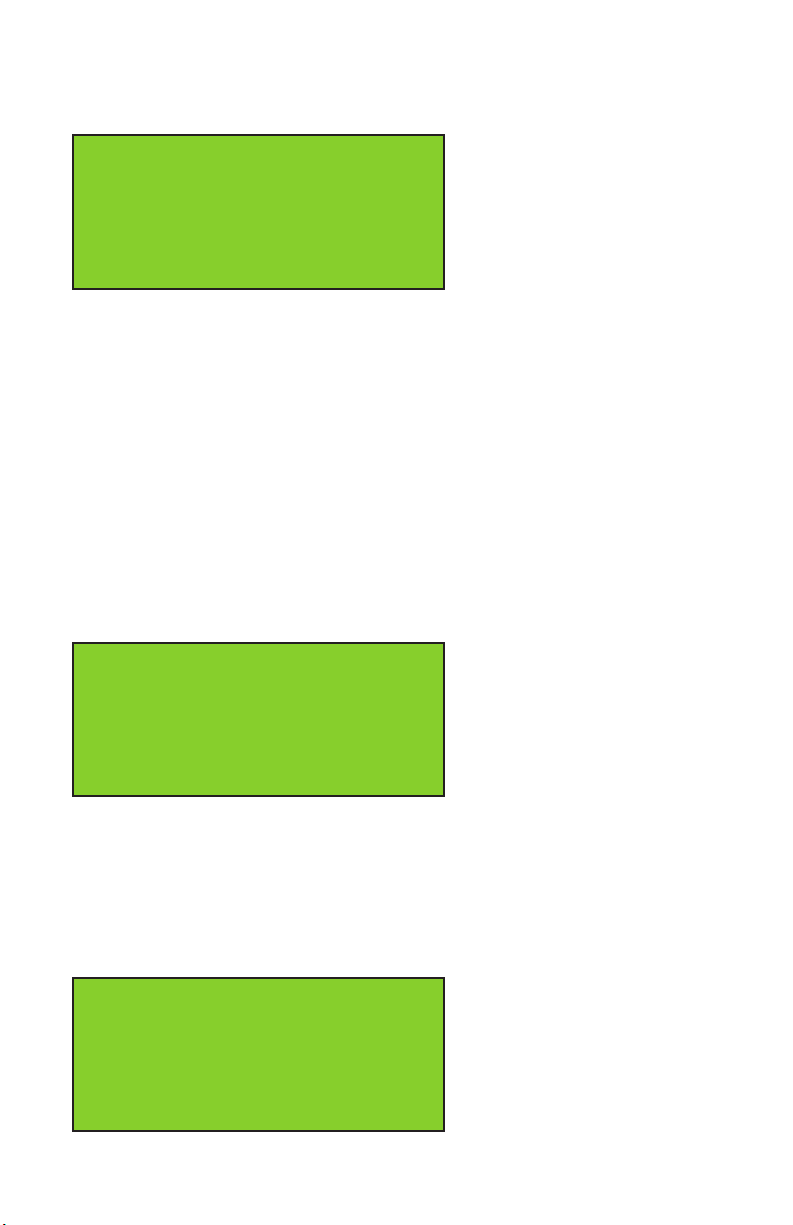

120/240 VAC Input (option board 2)

The line voltage input is available on option board 2. It can be configured for

120 or 240 volt input using jumper pins 1. For 120 volt input jumper both sets

of outside pins (see decal on board). For 240 volt input jumper only the center

two pins (see decal). NOTE – board is factory set for 120 volt input.

12

Figure 8: 120/240 VAC Input

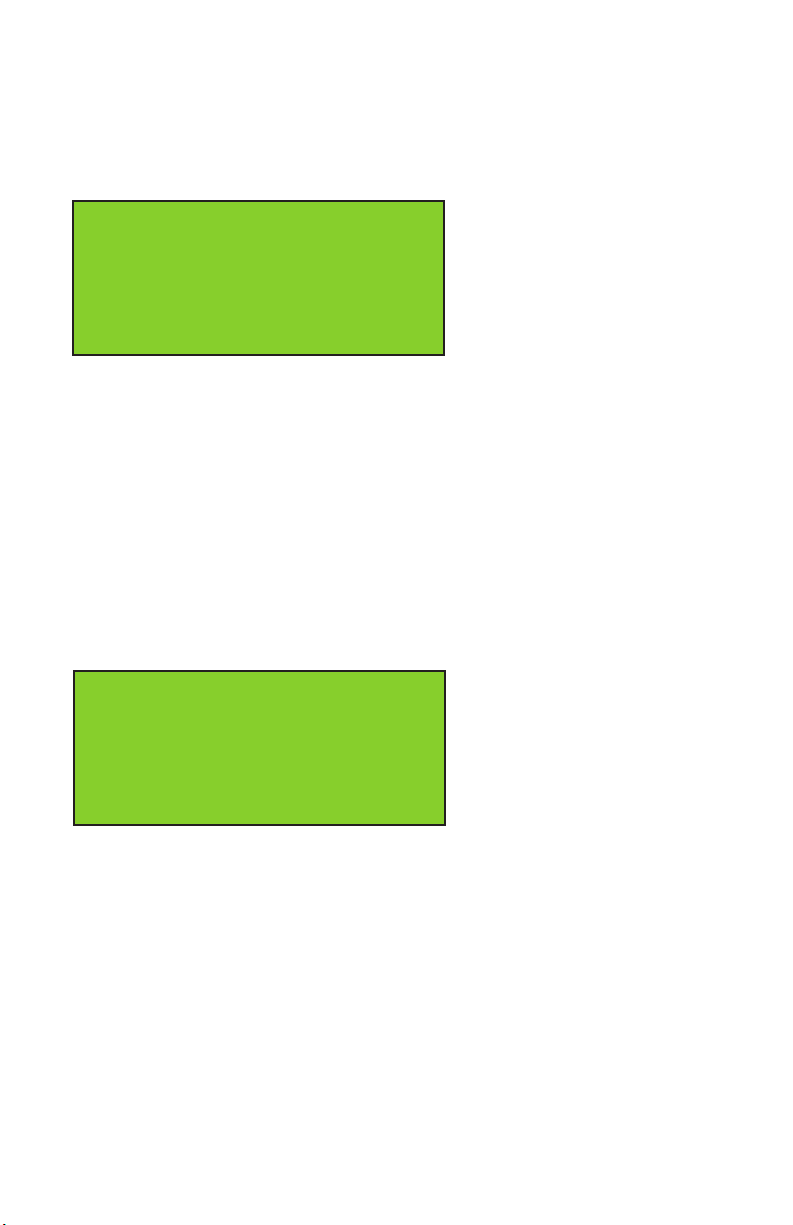

Batch Controller Inputs (option board 3)

Five inputs are available for remote control of the batch process. You must have

ordered the batch model to access these inputs (MX9-B). A 15 VDC output is

provided as a supply for the inputs. Program / Run uses a maintained contact

(switch), and the other inputs require momentary signals.

Figure 9: Batch Controller Inputs

13

Run Mode Screens

The run mode screens, as shown below, can be accessed by using the UP and

DN buttons. Info screen shows critical information on MX 9000 model number,

serial number and firmware version

NOTICE: Please have this informaon available when calling for technical support.

RATE screen A shows active flow rate information in programmed engineering units

RATE screen B shows active flow rate information in programmed engineering units

TOTAL screen A shows totalized volume in programmed engineering units

TOTAL screen B shows totalized volume in programmed engineering units

STATUS screen shows data summary. Flow and total are in un-scaled units of

Hertz for flow and Pulses for total.

RATIO A/B screen displays rate ratio in % between A&B flows

RATIO B/A screen displays rate ratio in % between B&A flows

RT/TO screen A shows both the flow rate and total values in programmed

engineering units

RT/TO screen B shows both the flow rate and total values in programmed

engineering units

ANALOG OUT screen shows the mA value the MX 9000 is outputting

Limits screen shows status of current relay outputs

Rate A&B screen shows both rates on one screen

Total A&B screen shows both running totals on one screen

Rate A plus B screen shows mathematical total of both rates

Rate A minus B screen shows differential between rate A and rate B

Total / Grand Total A minus B screen shows differential between total A and B

Batch total screen shows current total and relay status

Direction screen shows flow direction when programmed for a dual sensor

(quadrature) input

14

LOGO Screen

MX 9000

S/N 0000000

Software Version 1.0.0

HART SW Version 1.0.0

The LOGO screen shows 3 or 4 lines of important data for the display unit which

is needed if contacting the factory for support issues.

1. Line 1 shows the basic model name

2. Line 2 shows the unique serial number of the unit.

3. Line 3 shows the firmware version of the unit

Pushing the SELECT button on the LOGO screen will show the actual model

number of the MX 9000. As the features vary with the model, please make a

note of this while reading through this manual.

Rate Screens

RATE A (B)

600.00 GPM

The RATE screen displays the flow rate of A or B in the programmed engineering

units. If the linearizer is active, ‘LN’ shows in lower left corner. If the Gate Time

filter is active, ‘GT’ shows in lower right corner.

Total / Grand Total Screens

TOTAL A (B)

6000 GAL

15

The TOTAL screen displays the flow total of A or B in programmed engineering

units. Pressing the RESET button resets the value back to zero (0). The Total

can also be reset remotely by connecting a momentary voltage to the external

RESET input.

GRAND TOTAL A (B)

6000 GAL

The GRAND TOTAL screen can be accessed using the ENTER button from the

TOTAL screen. To reset this total pressing the RESET button will request the

user to enter a password at this point. Use the UP – DOWN – SELECT buttons

to enter the password code of “53126”. Then press the RESET button which will

reset the grand total value back to zero (0).

Note that both grand totals must be reset independent of one another.

The STATUS screen is a raw data display of the current major properties of

STATUS Screen

STATUS L1 OFF L2 OFF

RTA 100.14 TOA 15400

RTB 150.32 TOB 03561

ANLG 04.00 mA

the monitor. The rates are shown as Hz, total in pulses, limits as on or off and

current loop output (main loop only) in programmed mA DC.

NOTE: The Gate Time lter and linearizer, if acve, do not aect the ow rate value in the STATUS

screen.

This is the raw incoming frequency. The mA shown is not a direct reading of the

loop current if there are other problems outside of the controller such as a broken

wire or defective loop power source.

NOTE: Because the mA value is an actual signal output, it is aected by the Gate Time and linearizer,

if acvated.

16

Loading...

Loading...