AW-Lake MX Specifications

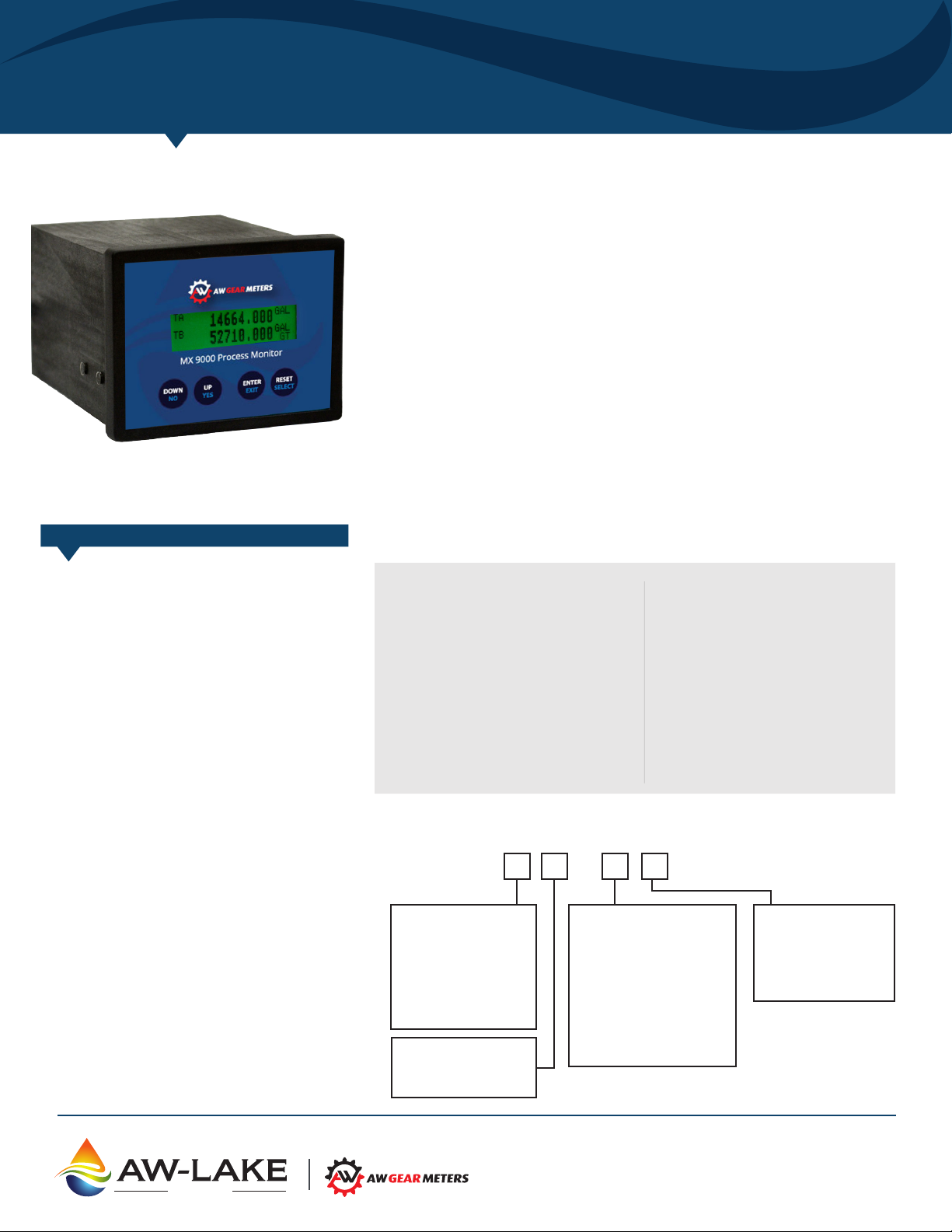

MX 9000 PROCESS MONITOR

Ideal for monitoring various uids in applications in industrial ow measurement where a simple, compact &

easy-to-use remote panel meter is required.

FEATURES

Rate, total, limit, batch and ratio options

• Single or dual channel

• Two programmable Form C relay outputs (optional)

• One or two assignable 4-20 mA output (optional)

• Data logging capabilities

• Easy-to-read LCD display with color backlight that changes color for warning or alarm

• Batch controller - stores up to 20 batch recipes

APPLICATIONS

The MX 9000 Process Monitor is a versatile, multi-functional device that helps you track

rate, total, limit, ratio, and more. Standard unit is one channel. Optional two channels allow

you to monitor dual flows, and display them in a number of ways: separately, as a sum

(for example in total material use), as a difference (as in fuel consumption), or as a ratio

of product A/product B. Also use the MX 9000 to detect bi-directional flow when A and B

channel signals are available from a single flow meter.

The MX 9000 has a number of related functions that add to its capabilities. Four model

variations (see reverse side) give the MX 9000 the capability of performing limit, warning

and alarm duties.

BENEFITS

Monitoring Versatility

The MX 9000 is available with one or two

channels, to monitor:

• Flow rate from one or two meters

• Flow volume (sum or difference of two flows)

• Ratio (product A/product B)

Intuitive Setup PC Software

The MX 9000 can be setup from the convenience

of your PC with a simple download of the MX

9000 Toolkit software, found on the AW-Lake

website (www.aw-lake.com/software/). You can

change all settings from the PC Toolkit, including:

• K-factor

• Limits

• Analog outputs

• Flow measurement units

Customizable Housing Options

The MX 9000 is available in custom enclosures to

meet your application requirements.

Easy Remote Programming

This unit can be easily programmed to display what

you need in a variety of engineering units.

Up and Running in Minutes

Easy plug-in installation. A quick setup procedure

allows you to have the flow monitor working with

just a few simple programming steps.

TECHNICAL SPECIFICATIONS

Power Requirement

14 to 16 VAC/250mA, or 18-24

VDC/200mA (customer supplied), or

120/240 VAC (optional).

*All units are shipped wit 120VAC/1000mA wall transformer.

Analog Output 4-20mA

External-powered loop output into a

maximum 500 ohm load impedance

with 24 VDC supply. 2nd loop output

optional.

PART NUMBER GUIDE

MX 9 – –

Main Board

S = Single channel

flow/total

D = Dual channel

flow/total

R = Ratio monitor

B = Batch controller

Output

4 = 4-20mA output

X = No output

Frequency Inputs

0-4 KHz, sine, square or saw-tooth;

4 volts minimum amplitude; 3.3 Kohm

maximum impedance.

Integrated Linearization

Maximum 30-point linearization table

for improved accuracy over range.

Flow Sensor Power Supplies

(2) @ 15 VDC / up to 50 mA each

Option Boards

1 = 4-20mA out, 2 relay

out

2 = 120/240VAC supply,

4-20mA out, 2 relay

out

3 = only for batch

controller

X = No option board

Options

E = Industrial

Enclosure

assembly

X = No addl options

COMPANY

2440 W. Corporate Preserve Dr. #600, Oak Creek, WI 53154 | www.aw-lake.comawinfor

©2016 AW-Lake Company. All rights reserved. Doc ID:M X9000DS110816

MX 9000 PANEL MONITOR

MX 9000 Process Monitor

2.8” / 72mm

3.8” / 97mm

Ideal for monitoring various uids in applications in industrial ow measurement where a simple, compact &

easy-to-use remote panel meter is required.

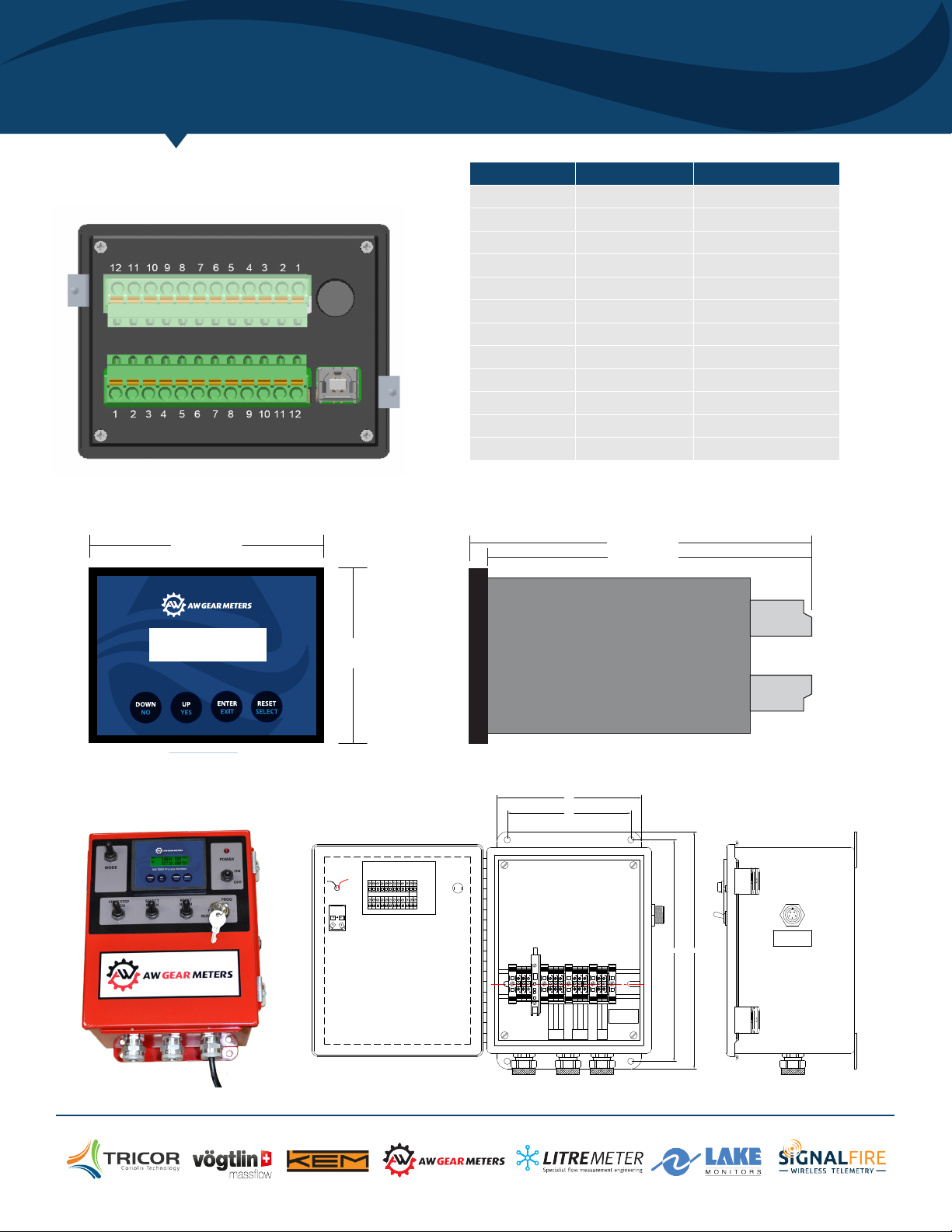

Terminal Upper Connector Lower Connector

TERMINAL ASSIGNMENTS

Opon board

MONITOR DIMENSIONS

1 +18-24VDC/16VAC

2 DC COM/16VAC

3 +15VDC Out

4 Sig. 1 In

5 Sig. 1 Common

6 +15VDC Out

7 Sig. 2 In

8 Sig. 2 Common

9 EXT Reset +

10 EXT Reset -

11 I + Out 1

OPTION BOARD DEPENDENT

12 I - Out 2

3.8” / 97mm

MX 9000 Process Monitor

OPTIONAL INDUSTRIAL ENCLOSURE

2.8” / 72mm

PIN 12

LED1

PIN 1

SW1

MX9-S4-2X

UPPER CONNECTOR

LOWER CONNECTOR

5.5” / 139mm

5.2” / 132mm

Op�on board

Main board

7.00

6.00

PIN 1

PB1

PIN 12

FLOWMETER

INPUT

TB1 TB2

11.52

TB3

TB4

10.75

Products may be subject to change without noce - Contact factory for the most up-to-date product informaon.

LOOP REQUIRES

15-24VDC

EXTERNAL

POWER

RELAY 2 N.C.

RELAY 1 N.C.

RELAY 2 N.O.

RELAY 1 N.O.

mA + LOOP IN

RELAY 2 COM

RELAY 1 COM

mA - LOOP OUT

4-20

RELAY

RELAY

mA

2

1

OUT

©2016 AW-Lake Company. All rights reserved. Doc ID:M X9000DS110816

Loading...

Loading...