COMPANY

Positive Displacement Gear Meters

Installation, Operating &

Maintenance Manual

©2016 AW-Lake Company. All rights reserved. Doc ID:POSDISMAN082416

Table of Contents

Safety Denitions and Information ................................................................ 3

Unpacking .............................................................................................................. 3

Quick Start ............................................................................................................ 3

Install Pickup Sensor ............................................................................................. 3

Flush Piping ............................................................................................................ 3

Filtration .................................................................................................................. 3

Location ................................................................................................................... 4

Orientation ............................................................................................................. 4

Flow Direction......................................................................................................... 5

Product Description and Principle of Operation .......................................... 5

Filtration .................................................................................................................. 5

Installation ............................................................................................................ 5

Preferred Flow Direction ....................................................................................... 5

Preferred Orientation ............................................................................................ 6

Location ................................................................................................................... 6

Installing a Bypass ................................................................................................. 6

Pickup Sensor ......................................................................................................... 6

Location ................................................................................................................... 7

Installation .............................................................................................................. 7

Operation .............................................................................................................. 8

Overview ................................................................................................................. 8

Running the Flow meter ........................................................................................ 8

Ramp Up ................................................................................................................. 8

Regular Cleaning .................................................................................................... 8

End of Shift and Overnight Preparations ............................................................ 9

Breakdown .............................................................................................................. 9

Plugging ................................................................................................................... 9

Filtration .................................................................................................................. 10

Maintenance ......................................................................................................... 10

Use the Maintenance Guides ............................................................................... 10

Flow Testing ............................................................................................................ 10

Plugging and Filtration .......................................................................................... 10

Calibration .............................................................................................................. 11

Storage .................................................................................................................... 11

Flow Meter Do’s and Don’ts ............................................................................... 11

Calibrations ........................................................................................................... 12

If ow readings are too high ................................................................................. 12

If ow readings are too low .................................................................................. 13

If it is necessary to adjust the existing k-factor .................................................. 13

If it is necessary to re-calculate a new k-factor .................................................. 13

Trouble-Shooting Guide ..................................................................................... 14

2

Safety Denitions and Information

Do not attempt to install or use your AW Gear Meters product until you have read

the safety instructions in this section. Save this manual and keep it in an easily

accessible place.

Unpacking

Separate the flow meter from packaging materials and check for any visual

signs of damage. If you determine there has been damage caused by shipping,

file a claim with the shipping company. If the flow meter appears to have

been improperly assembled or does not operate properly, return the product

for replacement or repair (see Limited Warranty information at the end of this

manual).

Quick Start

To set up, install and operate your flow meter quickly, follow these step-by-step

instructions. Detailed installation, operational, and maintenance instructions begin

on page 5 in this manual. More information is also available in the Maintenance

Guide appropriate for your flow meter.

Install Pickup Sensor

Before attaching the sensor to the flow meter, check for any potential clearance

issues. It may be easier to install the sensor after you have installed the flow

meter in the line.

CAUTION: Whether the sensor requires tool or hand installation, tighten with

hand-tighten torque only.

NOTICE: Some ow meters are shipped with the sensor already installed.

Flush Piping

If feasible, flush piping to remove dirt and debris before installing flow meter.

Filtration

Filtration is recommended to prevent contaminants from entering the flow meter.

3

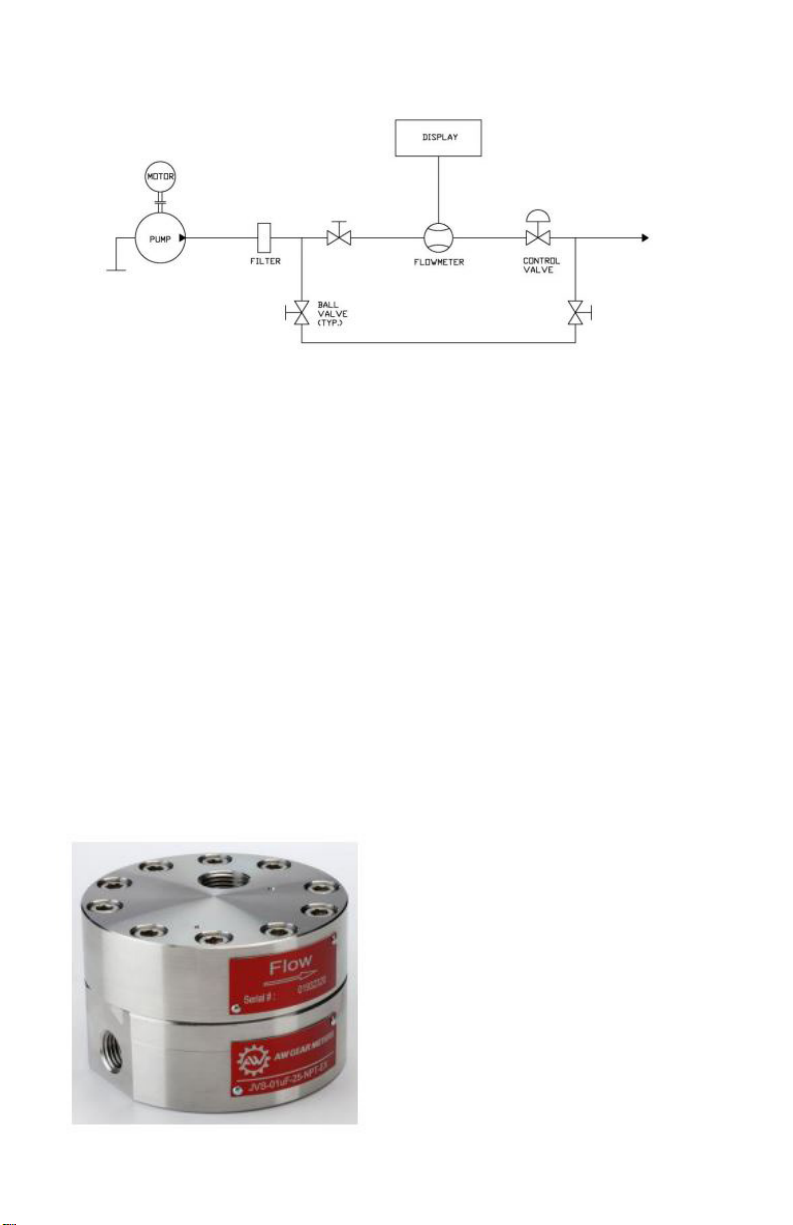

Figure 1: Typical flow meter installation with bypass

See flow meter Data Sheet for specific filter, including mesh weight and size.

Location

It’s best to install the flow meter upstream from control valves and fluid

regulators, if possible. See Figure 1.

Orientation

Positive displacement gear flow meters can be installed either a horizontal or

vertical (flow up) orientation. 2-3 psi of backpressure is required to assure

the meter is always full of fluid. No straight run pipe is required upstream or

downstream of the meter.

Figure 2: Flow meter with direction of low marked with arrow

4

Flow Direction

Flow direction is marked with an arrow on the flow meter. See Figure 2.

Product Description and Principle of

Operation

AW Gear Meters positive displacement gear flow meters are similar in design to

the gear pump. However, the principle of operation is reversed: instead of the

gears driving the medium, the medium drives the gears. A non-intrusive sensor

detects the movement of the gear. As each tooth passes the sensor, the sensor

produces a square-wave pulse and measures a discrete volume of liquid. The

resulting pulse train is proportional to the actual flow rate, providing a highly

accurate representation of the fluid flow. All flow meters are designed with

highly wear-resistant moving parts to provide exceptionally long service life. The

materials of construction are:

• stainless steel or high-strength aluminum housing

• stainless steel gears

• either tungsten carbide sleeve bushings or stainless steel ball bearings

(depending on model)

The fluids you are metering should be compatible with these materials.

Filtration

Filtration depends on the model. Make sure to follow proper filtration requirements

for your specific model. Because the internal assembly has very small

clearances, small filter sizes are required, especially for ball-bearing flowmeter

versions.

NOTE: Filters are meant to lter out impuries in the uid stream. If you are measuring uids with

llers, even if the llers are smaller than the maximum recommended lter size, please consult the

factory for correct meter selecon.

Installation

Preferred Flow Direction

The preferred flow direction is marked with an arrow on the meter showing the

flow direction in which the flow meter was calibrated (see figure 2). However,

5

the flow meters have bi-directional flow capabilities and are often used for bidirectional flow applications. Since the meters indicate flow in both directions,

if reverse flow detection is not desired, install a check valve up-stream of the

flowmeter.

Preferred Orientation

The preferred orientation for mounting gear meters, especially in low flow and

or low viscosity applications, is so that the internal shaft/gear assembly is in a

horizontal orientation (housing bolts facing sideways, not up/down). This allows

for the least amount of internal drag due to mass of gears.

Location

It is important to make sure that the flowmeter is always full of fluid and never

partially filled. Do this by making sure there is always a small amount of

backpressure on the meter, usually 2 to 5 psi minimum.

Create backpressure by making sure there is some flow restriction downstream

from the flowmeter such as a check valve, regulator, or piping rising above

location of flowmeter. See Figure 1.

Backpressure from control valving is beneficial for stable running. In similar

fashion, if a flowmeter is installed with fluid flow in a downward direction, the fluid

cannot exit the flowmeter directly into a container with no restriction due to the

fact the meter will not be full of fluid, causing inaccurate measurement.

CAUTION: Eliminate all dirt, debris and metal shavings from the piping, as

the liquid must be free from any particles larger than what the manufacturer’s

specifications allow. Install any recommended filtration before operation, as

potential plugging most often occurs at startup.

Installing a Bypass

If possible, install a bypass around the flow meter, and flush existing piping with

the appropriate liquid before first use. See Figure 1.

Pickup Sensor

Review the pickup instructional guide prior to installation.

6

Location

Locate the pickup and wiring away from A/C motors, actuators, heaters, relays,

etc. Use only shielded cable and if possible, a dedicated power supply for the

electronics. If sharing power with other devices in the system, be aware that

power-draw spikes from other equipment could cause a surge into the sensor,

which in turn can cause sensor to give erroneous pulses. Ensure clean power

supplies that utilize a true earth ground. Install Intrinsic Safety Barriers if the

circuit is intended to be intrinsically safe.

Installation

Before attaching the sensor to the flow meter, check for any potential clearance

issues. It may be easier to install the sensor after the flow meter has been

installed in the line.

CAUTION: Do not use a wrench or Channellock®* to aid in hand installing the

pickup sensor.

CAUTION: Whether the sensor requires a tool to install or is hand installed,

tighten to hand-tighten torque only. Over tightening may cause damage to the

sensor and as a result it may not function properly.

Figure 3: Flow meter with pickup sensor installed

*Channellock® is a registered trademark of Channellock, Inc.

7

Operation

CAUTION: Before installing, operating or attempting maintenance on a flow

meter, read the appropriate Maintenance Guide. As with any precisionengineered device, always operate and maintain the equipment in

accordance with the manufacturer’s instructions.

Overview

Flow meters are designed to measure the flow of liquids, which assist in

cooling and lubrication. Always close meters to air except when air is part of

an automated purge cycle, such as certain paint systems. In this case, the air

segments are typically under 1 or 2 seconds and are interspersed with lubrication

liquid for a scrubbing effect; in addition, the air segments are short enough that

the flow meter does not dry out.

CAUTION: Do not dry lines using only pressurized air, as this will lead to

premature wear.

Running the Flow meter

Never run the flow meter dry or spin with air only. Gear flow meters are

precision-engineered flow devices. Always maintain them in a clean, lubricated

condition with the internal parts wet at all times. Do not allow air or water to

contact the internal parts except in short (1-2 second) cycles as part of an

automated flush. If you flush meter with water, make sure to run non-corroding

fluid through the meter afterwards. Even stainless steel meters will stain or

corrode from the minerals in most water.

Ramp Up

Do not increase flow to a full flow condition instantaneously. Gear flow meters are

rugged yet precise instruments that respond almost instantaneously to changes in

fluid flow. To avoid damage to the system, increase flow to maximum over a few

seconds rather than instantaneously and do not inject high flow speeds into an

empty flow meter.

Regular Cleaning

Designing and maintaining a flush procedure that keeps the flow meter internals

clean and wet is critical to optimum performance and minimum maintenance.

Cleaning cycles vary due to the differences in coatings, equipment, and cleaning

fluids, and some testing may be prudent to determine the most efficient method.

8

More corrosive fluids may also require more frequency flush cycles, or if meter

sits idle for longer periods of time, such as between shifts, flushing may also

be required more often. Consult with the fluid manufacturer for recommended

cleaning fluids.

NOTE: During line shutdowns such as overnight and over weekends, ush and leave meters lled

with proper cleaning uid under pressure to allow any residue that may have built up to soak and

dissolve.

End of Shift and Overnight Preparations

At the end of a shift or overnight, leave cleaning fluid in the flow meter under

pressure, to soak. This helps keep unflushed residual fluids from drying, and

facilitates subsequent startups. Opening a flow meter after a flush cycle helps

determine if the purge is thoroughly cleaning the flow meter.

Breakdown

NOTE: Full breakdown instrucons are included in the Maintenance Guide.

NOTE: If you remove a ow meter from the line during maintenance, do not allow uids to dry

inside. Clean the internals immediately, lubricate them, and cap the uid ports.

NOTE: Clean the carbide surfaces at the point where the gear rotates on the sha. Buildup here

may occur as a thin smear and may be dicult to see, but causes fricon and accelerate addional

buildup later when the gears are reinstalled. Spin the gears by hand to verify that they rotate freely

on the sha and apply a suitable lubricaon uid before closing the ow meter. Aer ghtening the

bolts, a short squirt of shop air will briey spin the gears, which should be easily audible.

CAUTION: Do not overspin gears if using shop air to verify free rotation of

gears prior to installation

.

CAUTION: Do not use wrenches or a Channellock to aid in re-installing the

pickup sensor by hand. Whether you are installing the sensor with a tool or by

hand, tighten to hand-tighten torque only.

Plugging

In the event of plugging, the flow meter passes a reduced volume of fluid with an

increased backpressure and no frequency output. Careful installation is important

because this is the time when contaminants such as tape or metal shavings can

enter the flow meter. Filters should be in line to prevent oversized particles from

entering the flow meter.

In the event the flow meter needs to be returned to the factory for further

evaluation, flush the flow meter in place and cap the ports. Pack carefully (with

9

original packing materials, if possible) prior to shipping to prevent damage.

Filtration

Filtration is recommended to prevent contaminants from entering the flow meter.

If the flow meter is plugged, a reduced flow can still be observed from the nozzle

or outlet, as fluid pressure squeezes fluid through the flow meter. Should this

occur, review the cleaning and maintenance procedures in the following sections.

Maintenance

Follow these general guidelines for operating and maintaining your positive

displacement flow meter.

Use the Maintenance Guides

Always review the Maintenance Guides provided with the flow meter

(download additional copies at www.awgearmeters.com ) prior to attempting

any maintenance work. The majority of down time and repairs is the result

of breakages due to improper maintenance actions, lack of training or rough

handling.

Flow Testing

Do not use water for flow testing. The viscosity of water is too low to produce

accurate results unless the flow rate is elevated, and the internals would then

have to be dried and lubricated to avoid corrosion or scaling. If system calibration

is necessary, the preferred calibration fluid is the actual fluid to be metered.

Alternatively, using a fluid with a viscosity of approximately 30 cSt° such as

mineral oil or thinned glycerin is recommended.

Plugging and Filtration

Filtration is recommended to prevent contaminants from entering the flow meter.

Should the flow meter become plugged, a reduced flow may still be observed

from the outlet as fluid pressure will squeeze fluid through the flow meter –

visual flow does not necessarily mean that the flow meter’s gears are turning.

If contaminants are causing the plugging, install filtering. If particle buildup

repeatedly causes plugging, review the cleaning and maintenance procedures in

the Regular Cleaning section on page 8. Because of the considerable differences

in fluid types and in-plant procedures, some trial and error may be required to

determine the ideal flushing or cleaning regimen.

*cSt is a unit of kinemac viscosity that equals one hundredth of a stoke.

10

Calibration

A calibration factor (k-factor) is established at the factory on a preferred

calibrating fluid. This number, which is provided with the flow meter either on a

Calibration Data Sheet or on a tag attached to the flow meter, is usually accurate

for a wide variety of fluids and should not usually be changed. Should the data

sheet become lost, contact the factory for a duplicate copy. See the Calibrations

section on page 12 for a calibration verification procedure.

Storage

When the flow meter is idle or stored for any extended period, perform the

following:

1. Clean the internals thoroughly with the appropriate fluid

2. Lubricate with a light oil or other non-corrosive fluid

3. Cap or plug the ports to prevent drying

Flow Meter Do’s and Don’ts

DO: Leave flushing fluid in the lines overnight or during extended off-times. This

keeps internals wet, prevents residual fluids from drying, and facilitates startups.

DO: Follow the Maintenance Guide instructions when opening and cleaning a flow

meter. During cleaning, separate the gears from the shafts. On carbide bearings,

clean inside the center of the gear bearing and on the outer surface of the shafts

at the point where the gear rotates on the shaft. Apply a suitable lubricating fluid

before closing the flow meter. After tightening the bolts, a short squirt of shop

air will briefly spin the gears, which should be easily audible.

DO: Install and maintain filters. Install the recommended filter to eliminate

potential plugging. Should plugging occur, the flow meter will still pass fluid but

with no signal output.

DO: Check electrical compatibility between the flow meter’s output signal and the

input of the PLC. If signals are not being detected at startup, first check wiring

and electrical compatibility.

DO: Verify reliable grounding of electrical parts, as per installation guidelines. A

dedicated power supply is recommended. Voltage spikes on shared power lines,

negligent grounding and sloppy wiring will likely produce erratic readings and

chronic maintenance.

11

DO: Install the flow meter immediately upstream of the regulator or control valve.

The control valve provides backpressure, which stabilizes the flow.

DON’T: Allow air into the flow meter. Always keep the flow meter internally wet.

DON’T: Dry lines using pressurized air. Flow meters are designed to flow liquids.

Close meters to air except when air is part of an automated purge cycle. Do not

dry lines after purging.

DON’T: Allow materials to dry inside the flow meter. When a flow meter is

removed from the line during maintenance, clean the internals immediately,

lubricate the gears, and cap the fluid ports.

DON’T: Over tighten the pick-up sensor beyond hand tight. When installing the

pickup sensor, turn it in lightly to a hand-tight torque. Do not use a wrench on

the pickup as over tightening may cause a dimple of metal under the sensor nose

to protrude into the gear cavity and interfere with the gear’s rotation.

DON’T: Use water or solvent for calibration or test purposes. Water or solvent

may not turn the gears at low flow and may leave the impression that the flow

meter is not functioning. A calibration factor (kfactor) is issued with the flow

meter, which is valid for most fluids except water or equivalent viscosities.

Calibrations

Each flow meter is calibrated and given a “k-factor” using a standard calibrating

fluid at the factory. This number is accurate for all fluids with most viscosities,

except the most water-like. There should be no need to change this except for

fluid viscosities below 30cSt.

If ow readings are too high

If the display shows significantly more than the volume actually dispensed or

shows flow when there is definitely no flow, this most likely indicates an electrical

noise problem. In such cases, turn off nearby motors, heaters or relays, check

cable shielding, and establish a clean ground independent of other electrical

devices before repeating accuracy tests. If the problem continues, it may be

necessary to relocate the offending device or reroute cabling away from noise

sources.

12

If ow readings are too low

If the display shows significantly less than the volume actually dispensed, most

likely the flow meter has a high slippage factor, and the fluid is bypassing the

gears and the k-factor may require adjustment. Dirt or dried material can also

keep gears from rotating freely.

If it is necessary to adjust the existing k-factor

Trigger at least 500ml of your sample fluid in a steady stream at approximately

the desired flow rate into a graduated beaker. Compare the volume in the beaker

to the volume on the display. Do not time the operation; merely measure the

volume dispensed. Repeat the sample 3 times and take an average. If the

result is outside an acceptable margin, adjust the k-factor by the percentage

of difference between the average beaker sample and the average displayed

total. If the error is not rectified, clean the flow meter thoroughly and repeat the

procedure. Do not use water for this test. For most accuracy results,

calibrate using fluid to be measured with flowmeter.

If it is necessary to re-calculate a new k-factor

You will first need a data-collecting instrument to count pulses produced by the

flow meter. An AW display may be used in totalizer mode provided the KFT is

set to count each pulse (KFT = 10000). Trigger at least 500ml of your sample

fluid in a steady stream at approximately the desired flow rate into a graduated

beaker.Divide the number of pulses by the volume dispensed and the result is

your new kfactor in the units of your sample. In the example above, the k-factor

units would be impulses/ml.

13

Trouble-Shooting Guide

14

15

COMPANY

414.574.4300 | www.aw-lake.com

2440 W. Corporate Preserve Dr. #600 Oak Creek, WI 53154

©2016 AW-Lake Company. All rights reserved. Doc ID:POSDISMAN082416

Loading...

Loading...