FLOW

TRANSMITTERS

ELECTRONICS FOR

INSTRUMENTATION

LLC - BA

Batch Unit

Manual Rev. 4

Software Versions 1.15 to 1.19

8809 Industrial Drive, Franksville, WI 53126-9337

Tel: 262-884-9800 Fax: 262-884-9810

E-Mail: awinfo@aw-lake.com Web: www.aw-lake.com

LLC-BA Batch Unit Manual

Rev. 4.0 for LLC-BA Software Version 1.15-1.19

Table of Contents

Introduction.................................................... page 3

Features.......................................................... page 3

Technical Data............................................... page 3

Relay Contact Ratings...................... page 4

Dimensional Drawings..................... page 4

Input & Output Connections.......................... page 5, 6

Typical Connection Diagram............ page 7

LLC Initial Messages..................................... page 8

Display Modes............................................... page 8

RATE Display Mode......................... page 8

TO1 Display Mode............................ page 8

TO2 Display Mode............................ page 9

BATCH Status Display Mode........... page 9

TO1- Reverse Display Mode............. page 9

Operation/Reset of Totalizers........................ page 9

Totalizer 1......................................... page 9

Totalizer 2......................................... page 9

Operating Modes........................................... page 10

RUN Mode..................................................... page 10

Batch Operation................................ page 10

Automatic Overrun Compensation... page 10

Batch Selection/Activation............... page 11

Batch Input & Output Functions....... page 11

Batch Function Timing Diagram...... page 12

Programming the LLC................................... page 13

Programming Label Diagram........................ page 13

Program Mode............................................... page 13

Entering/Editing the Variables..................... page 13

Delay.................................................. page 13

Precut................................................. page 14

Gate Time.......................................... page 14

0-set mA’s......................................... page 14

KFR-Factor........................................ page 15

Decimal Point for KFR..................... page 15

Engineering Units KFR..................... page 16

KFT-Factor........................................ page 16

Decimal Point for KFT...................... page 17

Engineering Units KFT..................... page 17

Batch Programming....................................... page 18

Limited Warranty Statement.......................... page 19

3

Introduction

The LLC-BA Batch Unit provides accurate and repeatable batch control, stores up to nine

different programmable batch quantities, and is a rate, total or batch indicator. The LLC-BA

provides relay outputs to initiate and stop the flow. The relay outputs can be used to control two

solenoids with different flow rates to allow for a slow stop/start of the flow.

In batching operations, the LLC-BA activates the low flow solenoid on the START input and

after a programmed variable DELAY, the high flow solenoid is activated producing a

combined high flow rate. The high flow solenoid is deactivated before the batch amount has

been reached by means of the PRECUT variable reducing the flow for a slow stop. The low

flow solenoid is de-activated when the programmed batch amount is reached.

The LLC-BA compensates for a valve or fluid delay in the batch system with the Automatic

Over-run Compensation feature. Any over-run is detected by the A.O.C. feature and the LLCBA anticipates and corrects for the delay on the next batch. This feature is always active and

adapting continuously to correct for long term changes in valves and fluid characteristics.

Features

* 87C51FB Microprocessor based design

* Dust-proof LEXAN front panel, resistant to chemicals compatible with LEXAN.

* 16 character alpha numeric LCD display, .35 inch character height

* All wiring via two rear mounted removable 10 pin screw terminals

* EEPROM variable storage with 5 year minimum life

Technical Data

Enclosure: DIN #43700, panel mount, plastic

Height 67mm/2.6in Height w/ flange 69mm/2.8in

Width 92mm/3.6in Width w/ flange 97mm/3.8in

Depth 132mm/5.2in Depth w/ flange 139mm/5.5in

Weight: 12 0z. (approx. 360 grams) without power supply.

Environment: Storage -40 to 85 deg. C

Operating 0 to 50 deg. C (standard)

Humidity 10-90% non-condensing

Power Supply: Supplied:

110VAC wall plug unit -16VAC/1000mA.. output w/6ft. cable to

standard 2.1mm I.D. x 5.5mm O.D. female plug.

Allowable supply range:

12-16VAC/300mA. or 17-22VDC/300mA.

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.aw-lake.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 4 01/11 LLC-BA Manual.DOC

Frequency Input: Voltage triggered, 2.00 Volt min. input level, 0 - 4KHz, 10KOhm imp.

Supply Output: (to sensor) Approx. 20mA.. at approx. 15VDC

Relay Outputs: 2 Form C relay outputs. See Table 1 for contact r ating inf o rmation

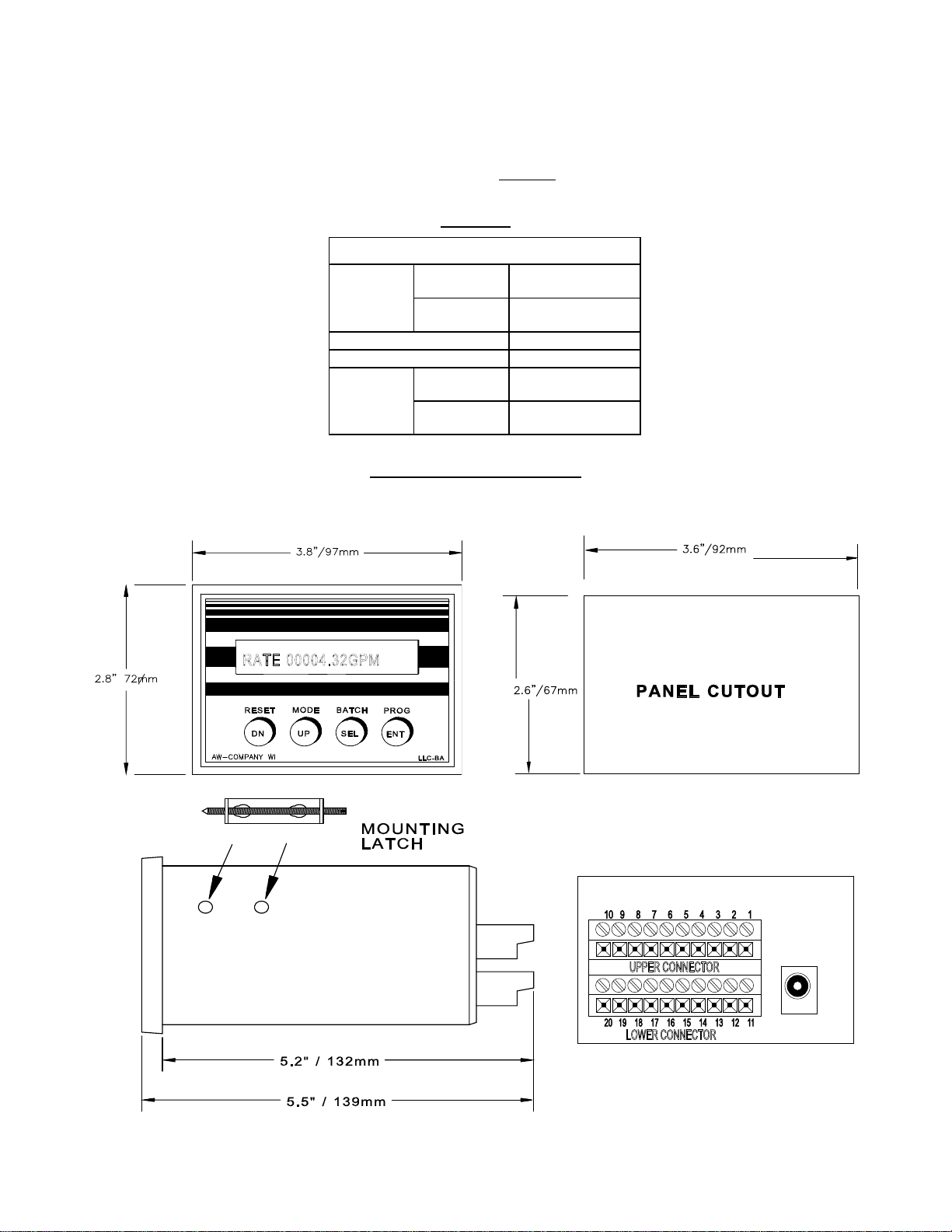

Table 1

Rela y C o n ta c t R a tin g s

Maximum

Switched

Power

Maximum Switch Voltage

Maximum Switch Current

Rate d

Load

Resistive Load

Inductive Load

Resistive Load

Inductive Load

DC : 60 W AC:

125VA

DC : 30 W AC:

60VA

220 V D C , 2 5 0 V AC

2A

DC : 30 V , 2 A AC :

110V, 0.5A

DC : 30 V , 1 A AC :

110V, 0.3A

Dimensional Drawings

4

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.aw-lake.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 4 01/11 LLC-BA Manual.DOC

5

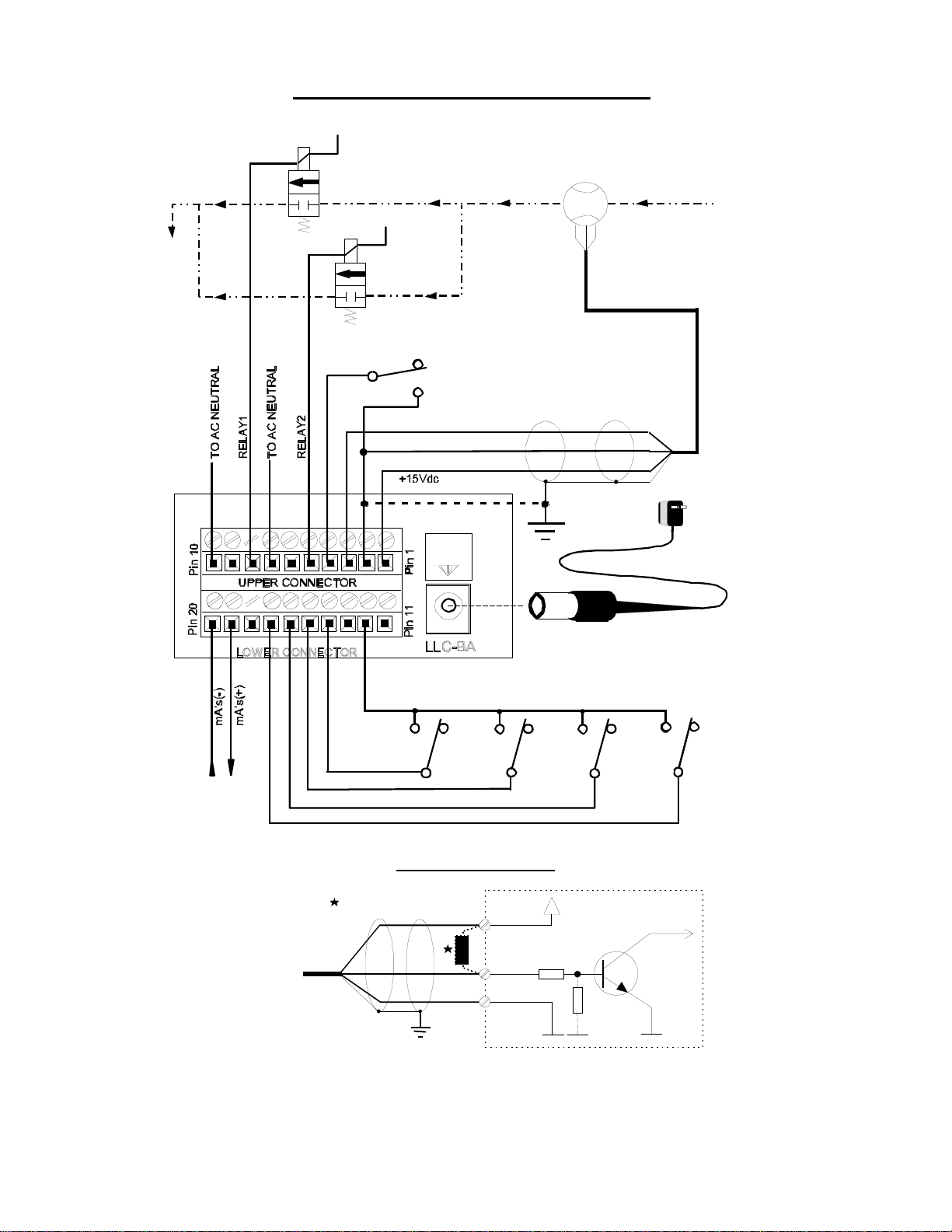

Input & Output Wiring Connections

All customer connections are made in the back of the unit. Power is delivered to the LLC-BA

unit through a plug-in connector from the wall plug type power supply normally supplied with

the unit. If necessary, any standard AC wall plug unit providing 12-16VAC/300 mA. or 1722VDC/300mA. to a standard female plug (2.1mm I.D. x 5.5mm O.D.) may be used.

All other connections are accomplished through the two 10 pin screw terminals that are

removable for ease of wiring. These are referred to as the upper and lower connectors.

Connection information is labeled on the connectors. See the LLC-BA Connection Diagram on

page 7 for connector detail and typical batch application connections.

The connections on the upper connector are as follows:

TERM 1 +15VDC Power supply for the transmitter. Approx. 15VDC (power supply

dependant), approx. 20mA.. max. Source for pull-up resistor if required.

TERM 2 GROUND (floating), power supply negative for the transmitter.

TERM 3 SIGNAL frequency input from the transmitter. 0-4KHz , 2 volts minimum,

10KOhm input impedance. A pull-up resistor is required for pickups with a

sinking output. Size resistor not to exceed rated output current of pickup.

Typical pull-up values range from 2.2Kohm to 5.1Kohm

TERM 4 RUN/PROG Input. Enables RUN-Mode and EXTERNAL functions when

connected to GROUND (TERM 2). When open, LLC-BA is in the

PROGRAM Mode. This input must be activated with a dry contact!

TERM 5 REL2COM is the common contact of Relay 2 (Form C). Relay 2 is used in

batching applications for control of the high flow solenoid valve in a two

valve system with slow start/stop function. See Connection Diagram page 7

for solenoid connection details. See Table 1 on page 4 for relay

contact ratings.

TERM 6 REL2NC is the normally closed contact for Relay 2.

TERM 7 REL2NO is the normally open contact for Relay 2.

TERM 8 REL1COM is the common contact of Relay 1 (Form C). Relay 1 is used in

batching applications for control of the low flow solenoid valve in a two

valve system with slow start/stop function. See Connection Diagram page 7

for solenoid connection details. See Table 1

contact ratings.

TERM 9 REL1NC is the normally closed contact for Relay 1.

TERM 10 REL1NO is the normally open contact for Relay 1.

on page 4 for relay

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.aw-lake.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 4 01/11 LLC-BA Manual.DOC

6

The connections on the lower connector are as follows:

TERM 11 VOLTAGE SUPPLY OUTPUT - 15 VDC, 25 mA

TERM 12 GROUND for Batch External Function Inputs (Inputs 1-4)

TERM 13 ANALOG OUTPUT SELECT – Connect to TERM 11 to change the function of

the analog output from a Batch Progress Signal to a Batch Number Signal.

(Software revision 1.18 and above only)

TERM 14 INPUT1, START/STOP Input (momentary) for batching applications.

Start/Stop is accomplished by momentarily connecting INPUT1

(TERM14) to GROUND (TERM 12). Batch start will occur on rising edge of

signal as the connection is opened. If input is closed again before the batch

total has been reached, stop will occur on falling edge of the signal as the

connection is closed. Batch function will resume on the rising edge of the next

momentary closure of the STOP/START input. START/STOP function

is active in RUN mode.

TERM 15 INPUT2, BATCH RESET Input (momentary) for batching applications. Batch

Reset is accomplished by momentarily connecting INPUT2 (TERM15)

to GROUND (TERM 12). When connected, the batch operation

will be terminated and the batch totalizing value is reset to zero on the

falling edge of the signal as the connection is closed. Reset function is active

in RUN mode.

TERM 16 INPUT3, BATCH SELECT Input (momentary) for batching applications. Used

for selection of pre-programmed batch quantities (Batch 1- 9) while in

the RUN mode. Batch number is incremented and display indicates batch

selected and programmed batch quantity while the input is closed.

TERM 17 INPUT4, MODE CHANGE Input (momentary) for batching applications. Used

to select the display mode while operating in the RUN mode. Display

mode is incremented on each closure of the input.

TERM 18 NO CONNECTION

TERM 19 mA’s (+), Positive of mA’s output – this analog output is a batch progress signal

or with software revision 1.18 or higher can alternately indicate the currently

selected batch number. A Batch Progress Signal directly corresponds with the

progress of the batch where 4mA equals zero progress and 20mA is equal to the

full batch amount. A Batch Number Signal (Software revision 1.18 and above

only) indicates the currently selected batch number in 1 mA increments with 5 –

13mA representing batch numbers 1-9. To assign the output to the Batch

Number Signal function it is necessary to wire a jumper to the back of the LLC-

BA controller between lower connector terminal 11 and terminal 13.

TERM 20 mA’s (- ), Negative of mA’s output - see mA’s (+) above...

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.aw-lake.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 4 01/11 LLC-BA Manual.DOC

7

LLC-BA Typical Connection Diagram

110VAC

TO

DISPENSE

HEAD

LOW

FLOW

VALVE

FLOW TRANSMITTER

FLUID FLOW

110VAC

OPTIONAL

HIGH FLOW

VALVE

SIGNAL

GROUND

PROGRAM

MODE

RUN MODE

10

7

Opti on al Hard Gro u nd

385421

12-16VAC

300m A.

Hot Center

20

17

19

141516

12

BATCH EXTERNAL FUNCTIONS

ACTIVE IN RU N M ODE ONL Y

BATCH

PROGRESS

OUTPUT

START/

STOP

(mom.)

BATCH

RESET

(mom.)

Input Circuit Detail

BATCH

SELECT

(mom.)

MODE

CHANGE

(mom.)

Pull-up resistor required for

pickups with sinkin g outpu ts

From

Pickup

+1 5 Vdc

1

Freq. In put

3

Gnd(-)

2

LLC Input

Circuit

To signal

processing

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.aw-lake.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 4 01/11 LLC-BA Manual.DOC

Loading...

Loading...