8809 Industrial Drive, Franksville, WI 53126 Phone: (262) 884-9800 Fax: (262) 884-9810

Email: awinfo@aw-lake.com www.awflowmeters.com

Technical Specifications:

· 1, 2, 3 or 4 Channels available · Parameter storage in EEPROM

· Each channel is independent · Analog inputs for set point

· Wall mountable NEMA 12 enclosure · Includes I/P Converters

· Serial Interface for software · 110 Volts AC

What is a EMO 3000 PID Multi Channel Flow Computer?

Precise, reliable control of fluid flow in industrial applications can result in significant material savings

and a superior end product. But a sophisticated fluid control system can also be extremely complex

and difficult to implement. The sales and engineering staff at AW Company has provided easy-to-use,

cost-effective systems to the closed-loop fluid control industry for over 20 years. The EMO-3000/PID

Controller provides an out-of-the-box flow control solution that allows you to control as many as 4 lines

without the need for a PLC or other complicated system integration. The EMO-3000/PID features a

micro-processor based controller, rheostat knobs for flow control, I/P converters for control of air pressure and a software package that allows you to control every parameter in the PID loop. The system is

able to update the closed-loop control as often as 5 times per second. The EMO-3000/PID comes in a

wall-mountable NEMA-12 industrial enclosure that features soft touch interface keys on the controller,

setpoint knobs for the flow and switches for flush cycles.

EMO-3000 PID Series

Multi Channel Flow Computer

Rev. 02/06

8809 Industrial Drive, Franksville, WI 53126 Phone: (262) 884-9800 Fax: (262) 884-9810

Email: awinfo@aw-lake.com www.awflowmeters.com

PID Technical Dat

a

EMO-3000 PID Series

Multi Channel Flow Computer

Rev. 02/06

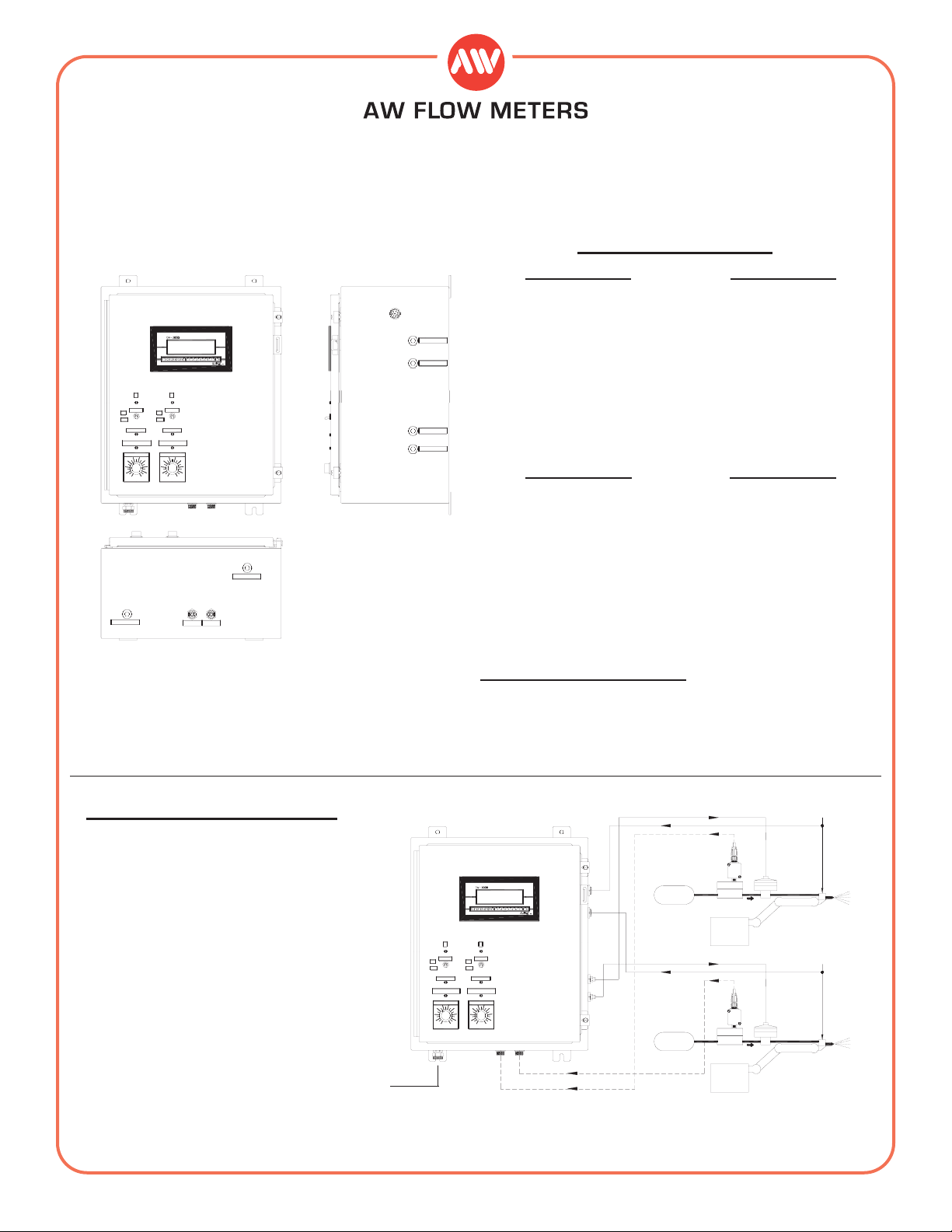

EMO 3000/2/PID

2 Channel Closed Loop

Controller in an enclosure with

trigger pressure switches,

lights, manual set point knob,

manual flush switches, 2 I/P

Converters, Heavy Duty Power

Supply, 2 Intrinsically Safe

Barrier Cards and 2 AMP

Fused Power Inlet

Products may be subject to change without notice – Contact factory for current information

EMO 3000/1/PID

1 Channel Closed Loop

Controller in an enclosure with

trigger pressure switch, lights,

manual set point knob, manual

flush switch, 1 I/P Converter,

Heavy Duty Power Supply,

Intrinsically Safe Barrier Card

and a 2 AMP Fused Power

Inlet

EMO 3000/3/PID

3 Channel Closed Loop

Controller in an enclosure with

trigger pressure switches,

lights, manual set point knob,

manual flush switches, 3 I/P

Converters, Heavy Duty Power

Supply, 3 Intrinsically Safe

Barrier Cards and a 2 AMP

Fused Power Inlet

EMO 3000/4/PID

4 Channel Closed Loop

Controller in an enclosure with

trigger pressure switches,

lights, manual set point knob,

manual flush switches, 4 I/P

Converters, Heavy Duty Power

Supply, 4 Intrinsically Safe

Barrier Cards and 2 AMP

Fused Power Inlet

FLUSH

ON

OFF

1

SET REACHED

TRIGGER

0

%

100%

SET POINT SET POINT

100%

0

%

TRIGGER

SET REACHED

2

OFF

ON

FLUSH

FREQUENCY FEEDBACK FRO M FLOW METER

PNEUM ATIC CONTROL SIGNAL

FLOW METER

FLUID

TRIGGER SIGNAL

REGULATOR

SUPPLY

PAINT

ROBOT

PNEUM ATIC TRIGGER SIGNAL

PNEUM ATIC TR IGGER SIGNAL

ROBOT

PAINT

SUPPLY

REGULATOR

TRIGGER SIGNAL

FLUID

FLOW METER

PNEUM ATIC CONTROL SIGNAL

FREQUENCY FEEDBACK FRO M FLOW METER

115 VAC IN

METER 1

100 PSI AIR IN

FLUSH

ON

OFF

1

SET REACHED

TRIGGER

0

%

100%

SET POINT

I/P OUTPUT 1

TRIG INPUT 1

TRIG INPUT 2

I/P OUTPUT 2

METER 2

SET POINT

100%

0

%

TRIGGER

SET REACHED

2

OFF

ON

FLUSH

Typical EMO 3000 PID Application

Optional Software Package:

The GR-3000 Flow Control Software will allow the user to

upload and download PID parameters directly to the

EMO-3000, format color tables and graph flow rates and

trigger times.

The diagram at right shows a typical

2 channel closed loop control scheme

with the EMO-3000/2/PID. Each flow

loop includes a paint supply line, flow

meter, fluid regulator and spray gun.

The EMO-3000/2/PID receives a

signal from each flow meter and, with

its self-contained I/P converter, controls the fluid regulator to precisely

and accurately deliver paint, air or

other fluid.

110 VAC

Loading...

Loading...