Page 1

SRZ-40 Helical Flow Meter Maintenance Guide

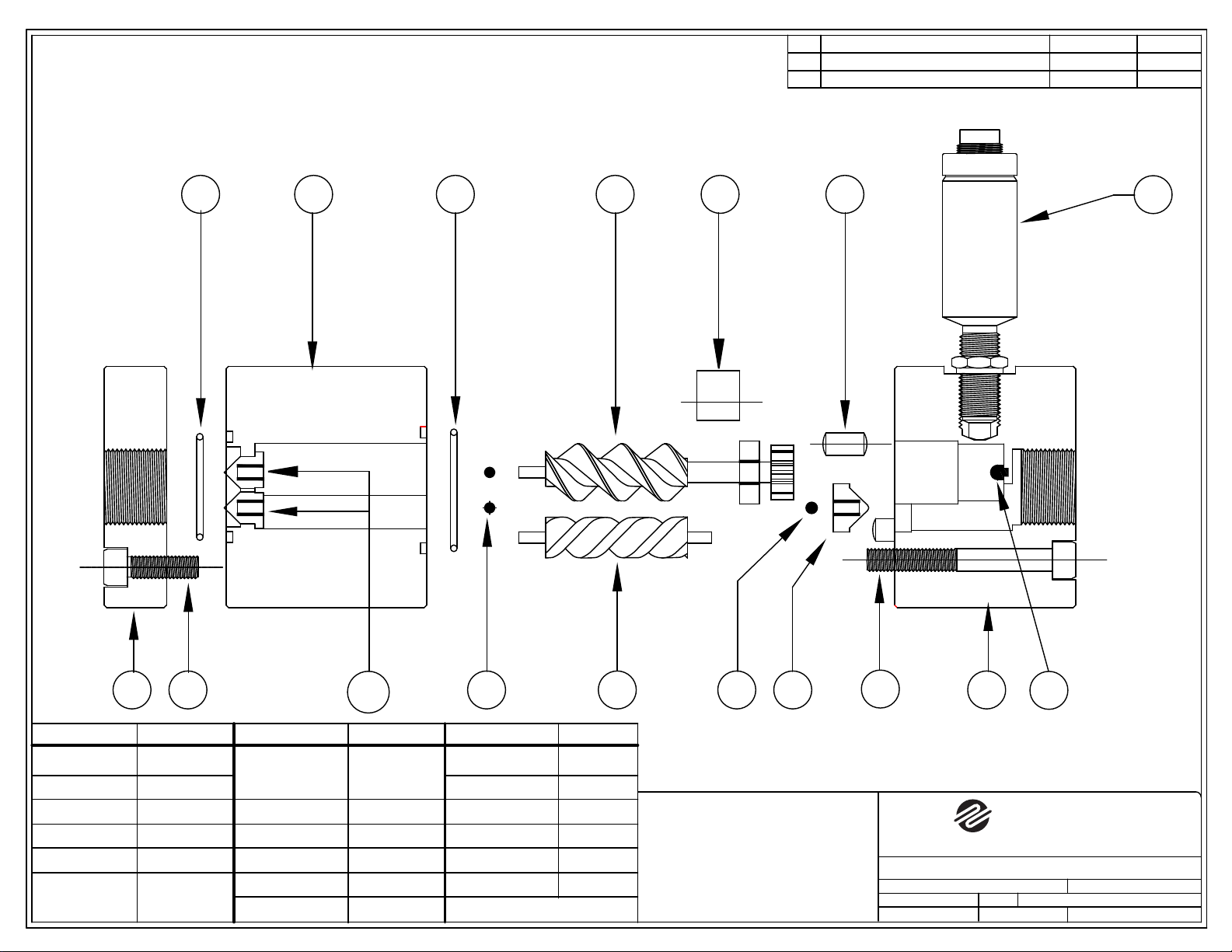

Disassembly Procedure - Refer to the attached drawing.

Never pry any housing components apart with a chisel or screwdriver. There are delicate

carbide shafts inside this unit - to avoid damaging these parts lay the unit horizontally on a

flat table or bench and follow the procedures below.

First remove the sensor (13) by releasing the locknut and removing the sensor from the flowmeter

housing. Next relax the six hex head bolts (2) at the sensor end (6) with a 6mm Allen hex key.

Remove four of the six bolts but keep two opposing bolts engaged by a few threads. With the

flowmeter laying on its side on a table, hold the upper housing at the sensor end (6) and gently tap

on the two bolts alternately with a hammer until the housing parts (6) & (7) separate. Remove the

last two bolts and ease the two flowmeter sections fully apart. NOTE: Carefully slide the upper

housing (6) straight off until it is completely clear of the gears (8) so as not to break the gear

shafts. With the housing separated, remove the helical gears (8), the sleeve bearing (11), and the

sleeve (10) by lifting the gears straight out of the housing. Check that the ball bearings (9) do not

fall out. Unscrew the remaining housing bolts (1) and remove the inlet housing (5).

Reassembly Procedure - Refer to the drawing

Check the condition of the 2 o-rings (3), replace them if any deterioration is noticed. Set housing part

(7) down with the inlet side pointing up. Check that the o-ring is seated snugly and screw the inlet

housing (5) on hand tight - make sure the index marks on the housing parts line up. Check that the

other o-ring (3) is also fitted snugly in its groove. Next set housing part (6) down on a table with the

locating pins (4) pointing up. Insert the larger helical gear, including the donut bearing (8a), into the

opening with the tooth gear end going first - press the donut bearing into the hole as well. Raise the

gear (8a) until the spacer sleeve (10) can be placed into the same hole above the donut bearing.

Press down the sleeve (10) until it sits flush in the housing (6) - make sure the sleeve is turned so

that it does not close off the opening inside the housing. Place the sleeve bearing (11) into the other

opening and set it flush with the housing. If necessary, lift the larger gear (8a) slightly to get sleeve

bearing (11) into its opening. Insert the smaller helical gear (8b) into the sleeve bearing (11) making

sure the two helical gears mesh with each other. Turning the gears will help. Next, lay the housings

(6 & 7) sideways on a table, match the holes in housing (7) with the gears and carefully slide the

housing (7) over the helical gears. Make sure to slide the housing on straight without any

twisting to avoid stress on the shafts. Insert two opposing bolts (2) and alternately tighten each

down until the two housing parts (6 & 7) are together. Insert and tighten down the remaining four

bolts with the 6 mm allen hex key. If the parts are reassembled correctly, a snug hand tight torque

will provide a sufficient seal. Reassembly should not require use of a vise.

FOOTNOTE: The use of thread seal tape or pipe dope on the fluid fittings should be avoided as pieces may

enter the meter. It is not recommended that the meter be operated or flushed with water. Should this occur,

residual water should be removed with alcohol and the internals oiled. If the device is to remain inoperative for

any extended period it is recommended that the internals be oiled.

AW Gear Meters 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 05/24/12 SRZ-40.DOC

Page 2

SRZ-40 HELICAL FLOWMETER

DESCRIPTIONREV

CHANGED SENSOR TO/P VERSIONF 11-20-01 S.W.

CHANGED PART# 5 & 6

G

DATE

11-25-09

APPR.BY

C.H.

3

7 3

8a

10 4

13

REF #PART #

M825

M865

COV-40

COT-40

LP-40 4

CE-401

CE-402

1

12

11 698b95

2

14

REF #PART # REF # PART #

1

2

3

3

SE-401

SE-402

MB-40

GR-40M

6

7

8a

GR-40F 8b

5

BB-40

BS-40

9

10

BFO-40

11

MFO-40 12

VTER/P

13

BN-40 14

PART 5 & 6: xx1 = NPT PORT. xx2 = BSPP PORT

AW-LAKE COMPANY USE ONLY

AW-LAKE COMPANY

THIS PRINT, INCLUDING THE INFORMATION CONTAINED IN IT,

IS THE PROPERTY OF AW-LAKE COMPANY. IT IS CONSIDERED

PROPRIETARY IN NATURE AND MAY NOT BE USED OR

DISCLOSED OUTSIDE OF AW-LAKE COMPANY, EXCEPT UNDER PRIOR

WRITTEN AGREEMENT. ANY MODIFICATIONS MADE TO OR

COMMENTS WRITTEN ON THIS DRAWING BY UNAUTHORIZED

PERSONNEL WILL VOID THIS DRAWING.

ARE SUBJECT TO CHANGE WITHOUT NOTICE.

ALL DIMENSIONS SHOWN

TITLE:

DRAWING NUMBER:

DATE: DRAWN BY:

CHECKED BY:

A TASI GROUP COMPANY

SRZ-40 HELICAL FLOW METER

SRZ4907G

11-25-09

S.W.

REV:

G

PAGE OF

1

1

8809 INDUSTRIAL DRIVE

FRANKSVILLE, WI 53126

TEL. # (262) 884-9800

FAX. # (262) 884-9810

PART NUMBER:

CHRIS HUSSON

SCALE:

BD00040

NONE