AW Gear Meters RT-Ex15-Ex User Manual

1

FLOW

TRANSMITTERS

RT-Ex15-Ex

Flow Monitor

Usseerr

U

Maannuuaall

M

ELECTRONICS FOR

INSTRUMENTATION

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

8809 Industrial Drive, Franksville, WI 53126-9337

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

E-Mail: awinfo@aw-lake.com

RT-Ex15-Ex manual rev 6.13.11.docx Revision 3.3.10

Tel: 262-884-9800 Fax: 262-884-9810

Web: http://www.awgearmeters.com

2

RT-Ex15-Ex FLOW MONITOR

Introduction / Features…..………..……………………... page 3

Model Number/Sensor Options.……………………..….. page 3

Specifications…..………..…………………………..….. page 3

Dimensional Drawing.….………………………………. page 3

Hazardous Area Installation Instructions………………. page 4

Wiring Connections……….................…………………. page 5

DC Power Connection...........…………………... page 4

Reset Input……….................…………………... page 5

Limits/Pulse Output...............…………………... page 5

Analog Output……................…………………... page 6

Frequency Input (Calibration) Test Point.………. page 6

Display/Programming Buttons and Magnetic Switches… page 7

Disable External Programming....………………. page 7

Programming……………....…………….....…..……….. page 8

Startup Message…………...........………………. page 8

Display Modes………………….....…..………………… page 9

LOGO Mode – Turning On/Off Displays……..... page 9

RATE Display Modes..............………………….. page 10

RATE A

RATE A PL .……................……………… page 10

RATE Mode Programming.............…………….. page 11

KFR A VALUE.................……………… page 11

GATE A B……..………….……………. page 12

SAMPLE A……………………………… page 12

ENG UNITS A……………………...…... page 12

TOTAL Display Modes.....…………………..…. page 13

TOTAL A Display…….……….….……. page 13

GR TOTAL A Display…….……...……. page 13

TOTAL Reset / Rollover…….…….……. page 13

TOTAL Mode Programming........................…… page 14

KFT A VALUE.…........…………….….. page 14

ENG UNITS A...….…..………………… page 15

STATUS ONE Display Mode.….……………... page 15

ANALOG OUT Display Mode.….……………... page 15

ANALOG OUT Programming.………………… page 15

MA OFFSET.…........………………..…. page 16

ANALOG POINT....…..………………... Page 15

VALUE AT 20 MA……………………… Page 16

LIMITS Display Mode...........…….……….……. page 17

LIMITS Programming…………………………… Page 17

RATE/TOTAL limits……...…………….. Page 17

CYCLE OUT (Totalizer Pulse Output)…. Page 17

RATE & TOTAL Display Mode ....…………….. page 18

BATCH TOTAL Display Mode ....…………….. page 19

BATCH TOTAL Programming.......…………….. page 19

QUICK-GUIDE to Variables & Displays……………….. page 20

GT

.……................……………… page 10

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

RT-Ex15-Ex manual rev 6.13.11.docx Revision 3.3.10

Introduction / Features

The RT-Ex15-Ex is a meter-mounted digital flow monitor that is certified for use in Class I

Div. 1 locations when mounted on an approved AW meter. A large, back-lighted LCD

graphic display provides easy to read indication of flow rate or total in user programmable

engineering units. Programming, display mode selection or reset of the totalizer is

accomplished using an attached magnet without opening the enclosure or using the

pushbuttons on the faceplate with cover off. An isolated input also allows for remote reset of

the totalizer. Programmable opto-isolated NPN open-collector outputs provide flowrate limit

indication or a pulsed total output for remote monitoring and recording of totals. A 4-20 mA

rate output with user programmable filtering and scaling is also provided for remote

indication. A variety of sensor noses are available to provide compatibility with all AW Gear

Meters.

RT-Ex15-Ex options:

Swivel union available

HART protocol available

Specifications

Power Requirement: (Customer supplied)

Class 2, 24 VDC, 200mA min

Sensor/Monitor Frequency Range:

0-4000 Hz.

Analog Output 4-20 mA:

16-bit Isolated Loop Powered 2-Wire Output.

24 Vdc Loop Supply

Max. Load Impedance 500 Ohm.@ 24V

Max. Load Impedance 250 Ohm.@ 12V

Two Opto-Isolated Open-Collector Outputs:

5-24 VDC Rating, 50 mA Max. (Minimum Load

Impedance Required, 480 Ohm @ 24 VDC)

Opto-Isolated Reset Input:

5-24 VDC Input, 3.3Kohm Impedance

Temperature Ratings:

Unit: -40 to 60ºC (-40 to 140ºF) Ambient : T6

60ºC (140ºF) Max. Fluid Temperature

RT-Ex15-Ex Certifications:

CSA:

Class I, Division 1, Groups A, B, C, D

Class II, Groups E, F, G; Class III

Connection:

Screw terminal strips

¾” NPT Conduit Entrance

Input and output signals to be supplied by a Class 2

power supply

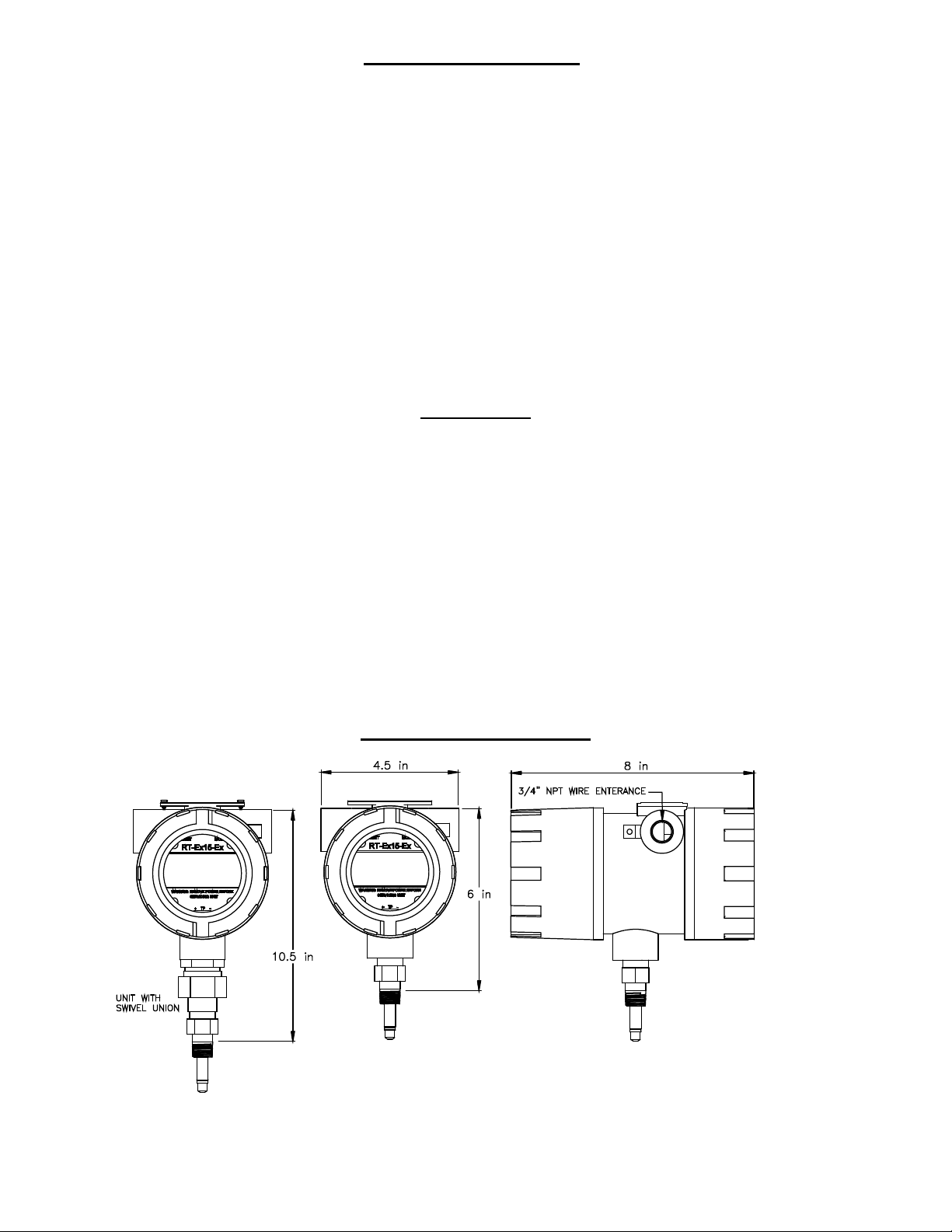

RT-Ex15-Ex Dimensions

3

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

RT-Ex15-Ex manual rev 6.13.11.docx Revision 3.3.10

4

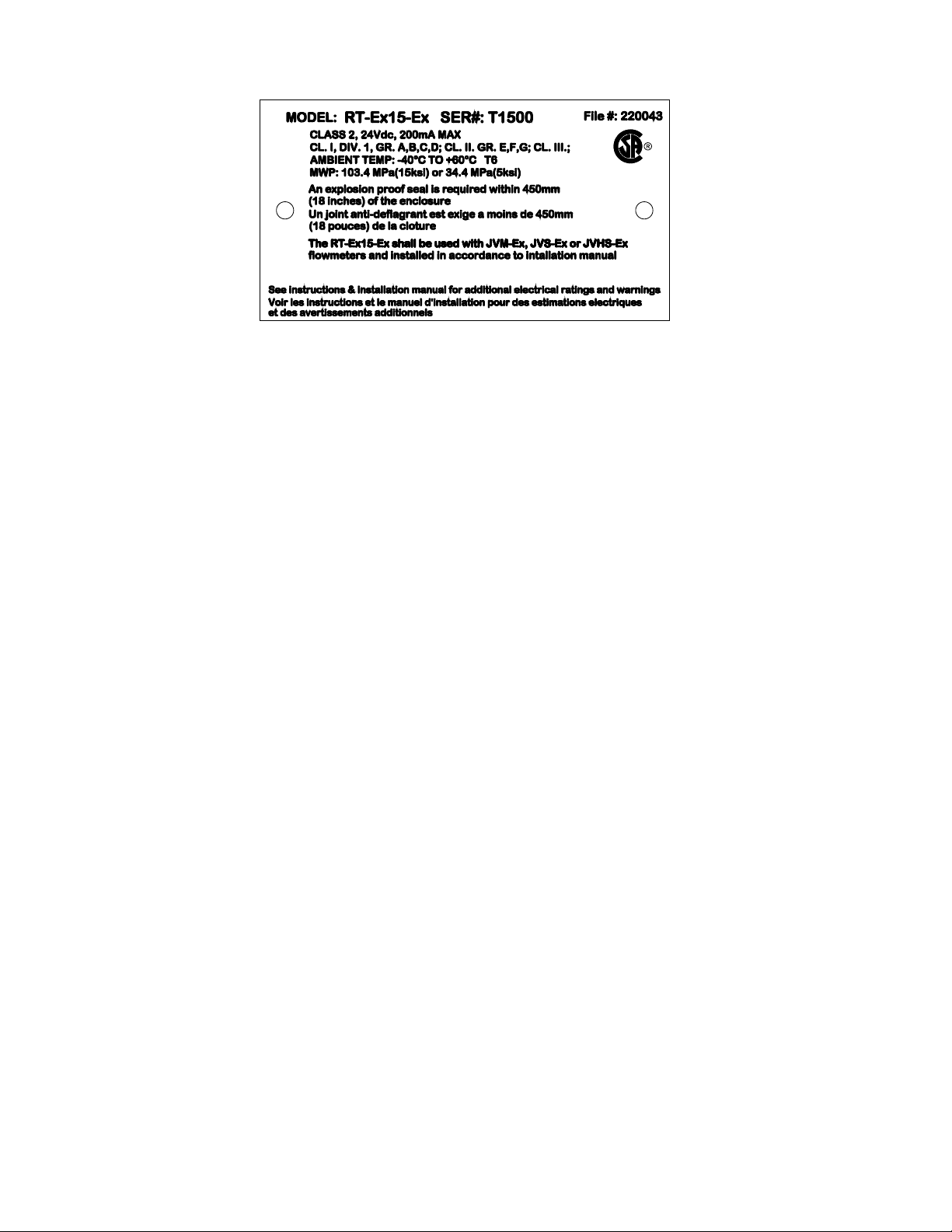

Special installation instruction for use in hazardous area environments

Figure 1. RT-Ex15-Ex name plate

The RT-Ex15-Ex unit is an explosion proof local display which may be used in Class I, Division 1 locations. Above

is a sample of the name plate that should be clearly attached to each unit. Please make sure this name plate is on the

unit and that the information matches what is shown above, prior to installation. Depending on whether the unit is

equipped with a swivel union and/or installed with either a 303ss or 316ss flowmeter, the tag may not include the

Type 4X rating. If either the name plate is not on the unit or the unit name plate does not match what is shown

above, please notify AW-Lake Company and determine what needs to be done.

Because the RT-Ex15-Ex uses an explosion proof enclosure for its area protection, power must be removed from the

unit before the covers are removed while in a hazardous area.

For proper installation, it is also necessary that the conduit entries are properly sealed. To maintain the units

explosion proof certification, anything threaded into the NPT conduit openings must engage by a minimum of 5 full

threads. Original units received from AW-Lake Company will have a sensor installed. This item is properly

installed with a minimum of 5 full threads of engagement and should not be tampered with. The unit also comes

with a blind plug. It is the customer’s responsibility to make sure that any blind plugs used are properly installed

with a minimum of 5 full threads of engagement. NOTE: It is strongly suggested to use anti-seize grease on threads

prior to installation to avoid galling.

When installing the RT-Ex15-Ex into an AW spur gear meter, in order to maintain the unit’s explosion proof rating,

make sure the 3/8” NPT male portion of the sensor is engaged by a minimum of 5 threads into the flowmeter.

NOTE: It is strongly suggested to use anti-seize grease on threads prior to installation to avoid galling.

When wiring the unit, please make sure to observe any national or local codes that may be required. An explosionproof seal is required within 18 inches (450mm) of the enclosure. If installed in a Class I, Division 2 area, an

explosion-proof seal is still required within 18 inches (450mm) of the enclosure according to Class I, Division 1

installation requirements. Make sure units are powered by a Class 2 power supply for proper regulation.

Removal of the external housing ground terminal is not permitted for safety reasons. Please make sure to follow

local electrical code practices when installing equipment in hazardous areas.

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

RT-Ex15-Ex manual rev 6.13.11.docx Revision 3.3.10

5

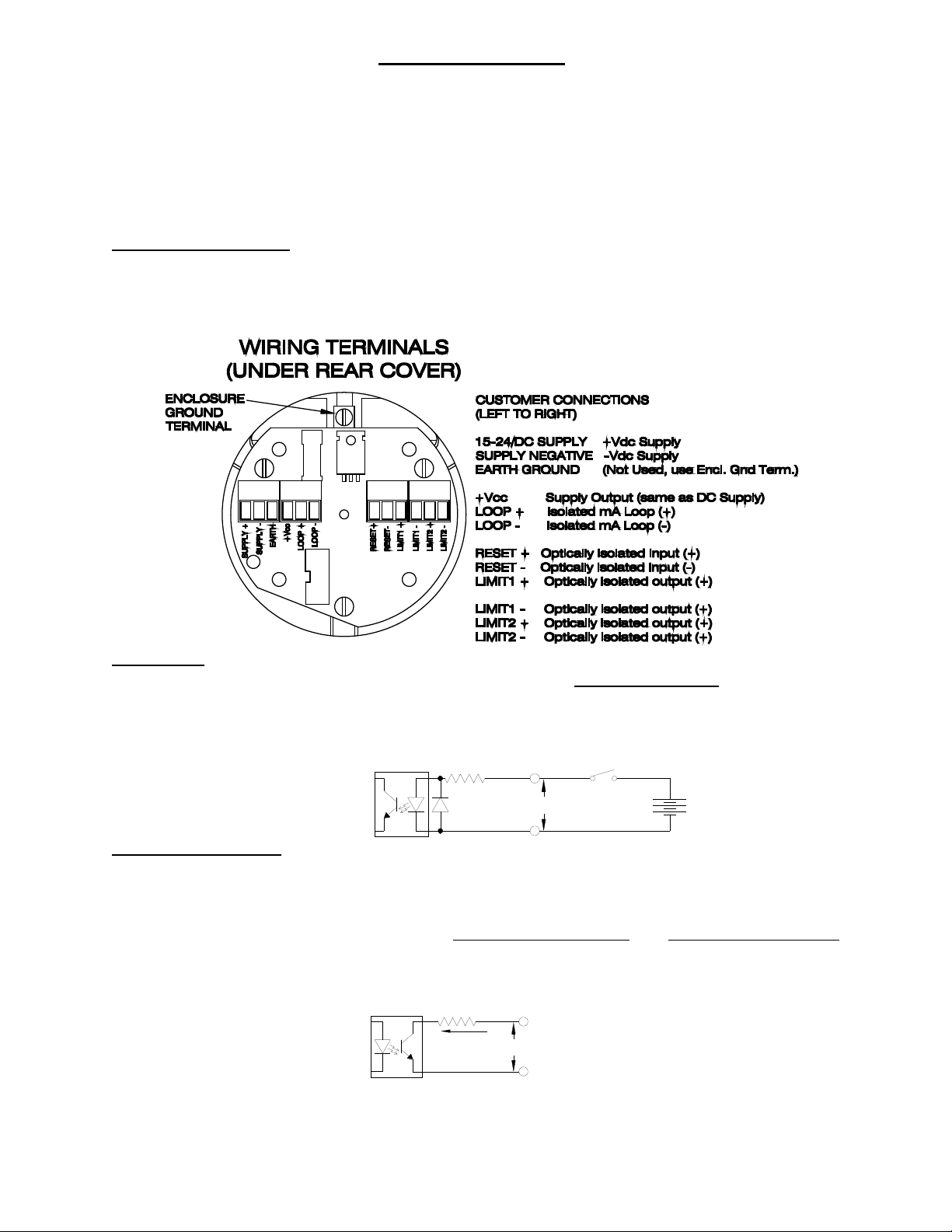

Wiring Connections

Wiring connections are to terminal strips inside the rear cover. A ¾” NPT wire exit for conduit

connection is provided. Connection to conduit is required to maintain the enclosures explosionproof rating and must be made in accordance with all local and national electrical codes. TO

PREVENT IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT CIRCUITS

BEFORE REMOVING COVER. KEEP COVER TIGHTLY CLOSED WHILE

CIRCUITS ARE ALIVE.

DC Power Connection

The RT-Ex15-Ex requires a Class 2, 24 VDC, 200mA min supply for operation. A power-on

LED is provided on the connection board and a 250mA mini-fuse protects the circuitry in case of

a supply fault. (See drawing below)

Reset Input

Opto-isolated input to reset the TOTAL A (Job Total). See TOTAL A RESET on page 11 for

information regarding reset of the job totalizer.

RESET INPUT

(Iso la te d )

2.35 Kohm

RESET +

5-24VDC

Momentary

+

Limits/Pulse Outputs

RESET -

Two opto-isolated NPN open-collector outputs can sink or source depending on connection.

Attention must be paid to polarity of connections, collector (+), emitter (-). See diagram below.

Output ratings are listed on page 2. Either output can be assigned to a rate limit, total limit for

batching or as a totalizer pulsed output. See LIMITS Display Mode and LIMITS Programming

on page 15 for information regarding the display and programming of the limit and pulse output.

LIM IT OUTPUTS

(Iso la te d )

100 Ohm

50 m A Max.

5-24VDC

LIM IT (+ )

(Co lle c tor)

LIM IT (-)

(Em itter)

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

RT-Ex15-Ex manual rev 6.13.11.docx Revision 3.3.10

6

Analog Output

The isolated 16-bit 4-20mA output can be wired in a 2-wire loop-powered arrangement or loop

power can be supplied via the DC supply as shown in the wiring examples below. The mA LED

will light with varying intensity in proportion to the mA output for troubleshooting purposes.

The assignment, offset, and scaling values for the mA output are programmable. See ANALOG

OUT Programming on page 13 for information regarding set-up of the analog output.

m A LOOP OUTPUT (2-W IRE)

NO TE: SEPERATE + 24VDC STILL REQUIRED TO POW ER UN IT

AD421

(Iso la t ed )

LOOP +

+

V loop

LOOP -

R sense = 250 Ohm m ax. @ 12-15 Vdc

R sense = 500 Ohm m ax. @ 15-24 Vdc

R sense

12-24 Vdc

(Loop Power from RT-Ex15-Ex DC Supply)

AD421

SUPPLY NEGATIVE

mA OUTPUT (3-WIRE)

+Vcc

LOOP +

mA LEDmA LED

LOOP -

R sense = 250 Ohm m ax. @ 15 Vdc

R sense = 500 Ohm m ax. @ 24 Vdc

+-

R sense

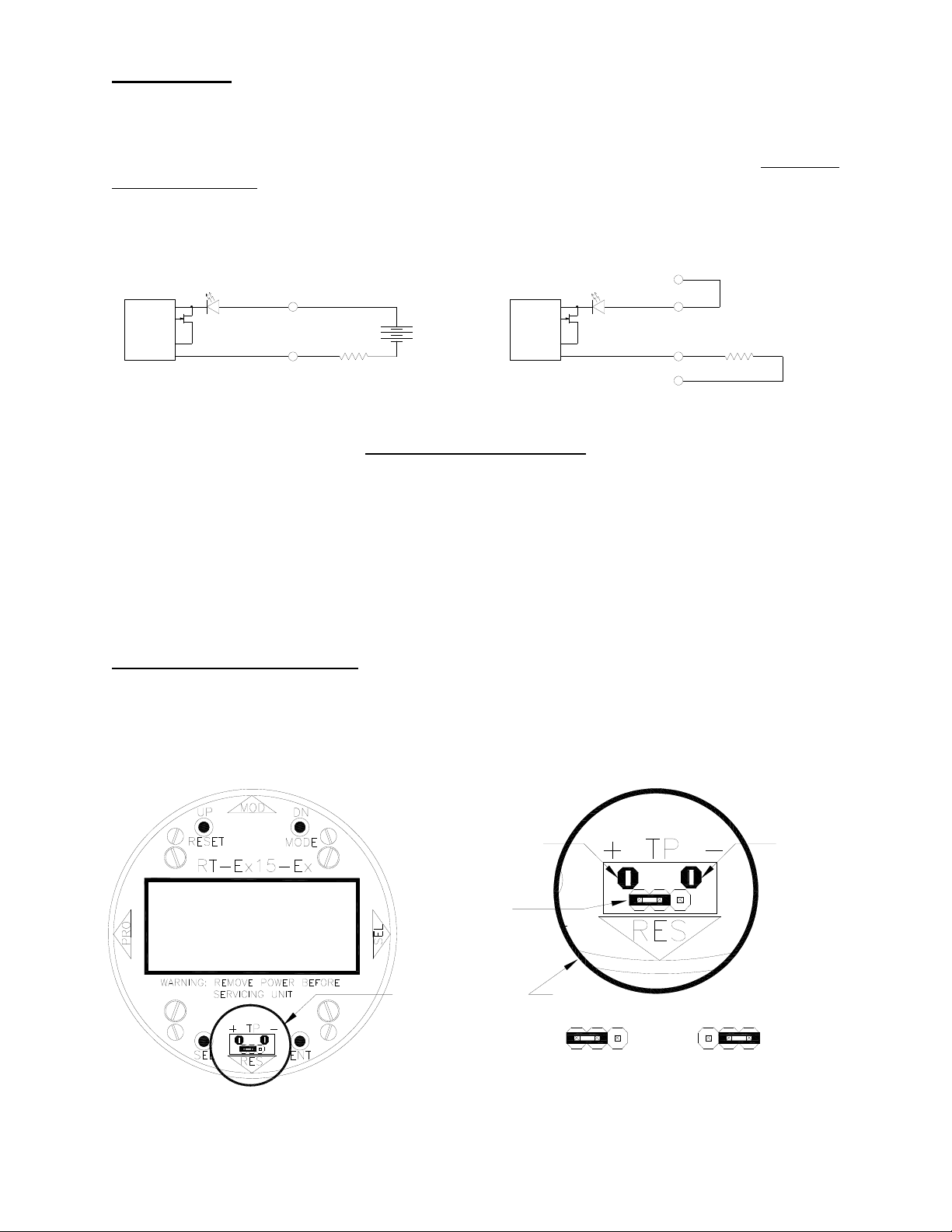

Frequency Input Test Point

The RT-Ex15-Ex has a frequency input test point allowing the user to directly input a frequency

signal. This is especially useful for purposes of setting up and testing pulse output or analog

output signals during commissioning when flow is not present or where it is not feasible to allow

continuous flow for set-up and calibration purposes. The position of a programmable jumper

must be changed to allow use of the test point input. The test points and jumper positions are

detailed in the diagram below. Be certain to change the jumper back to the correct position

before beginning normal operation using the sensor nose.

Test Point input specifications:

Waveform: DC signal - pulse, square-wave, triangle, or sawtooth.

Minimum signal amplitude: 2 Volts peak.

Maximum signal amplitude: 10 Volts peak.

Frequency: 0-4000Hz

RA 002.50

TA 003.23

GT

GPD

GAL

Tes t Point (+ )

(Signal Inp ut)

Progra m

Jum per

Test Po int (-)

(Iso la te d

Supply

Com m on)

CALIBRATION

TEST POIN TS

& JUM PER

JUM PER SETTINGS

123 123

Norm al

Operation

Jum p 1 & 2

Test Po int

Operation

Jum p 2 & 3

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

RT-Ex15-Ex manual rev 6.13.11.docx Revision 3.3.10

Loading...

Loading...