RT-30EX

EXPLOSION-PROOF FLOW RATE TRANSMITTER

OperaƟon & InstallaƟon Manual

Rev. 1.7

RT-30EX Flow Transmitter

Operation and Programming Manual

Table of Contents

Safety Definitions and Information ............................................................................................................... 4

Unpacking ..................................................................................................................................................... 4

Product Description ...................................................................................................................................... 5

Screen selection and programming changes ............................................................................................ 5

Hazardous Area Installation Instructions ...................................................................................................... 6

Specifications ................................................................................................................................................ 7

Connections .................................................................................................................................................. 8

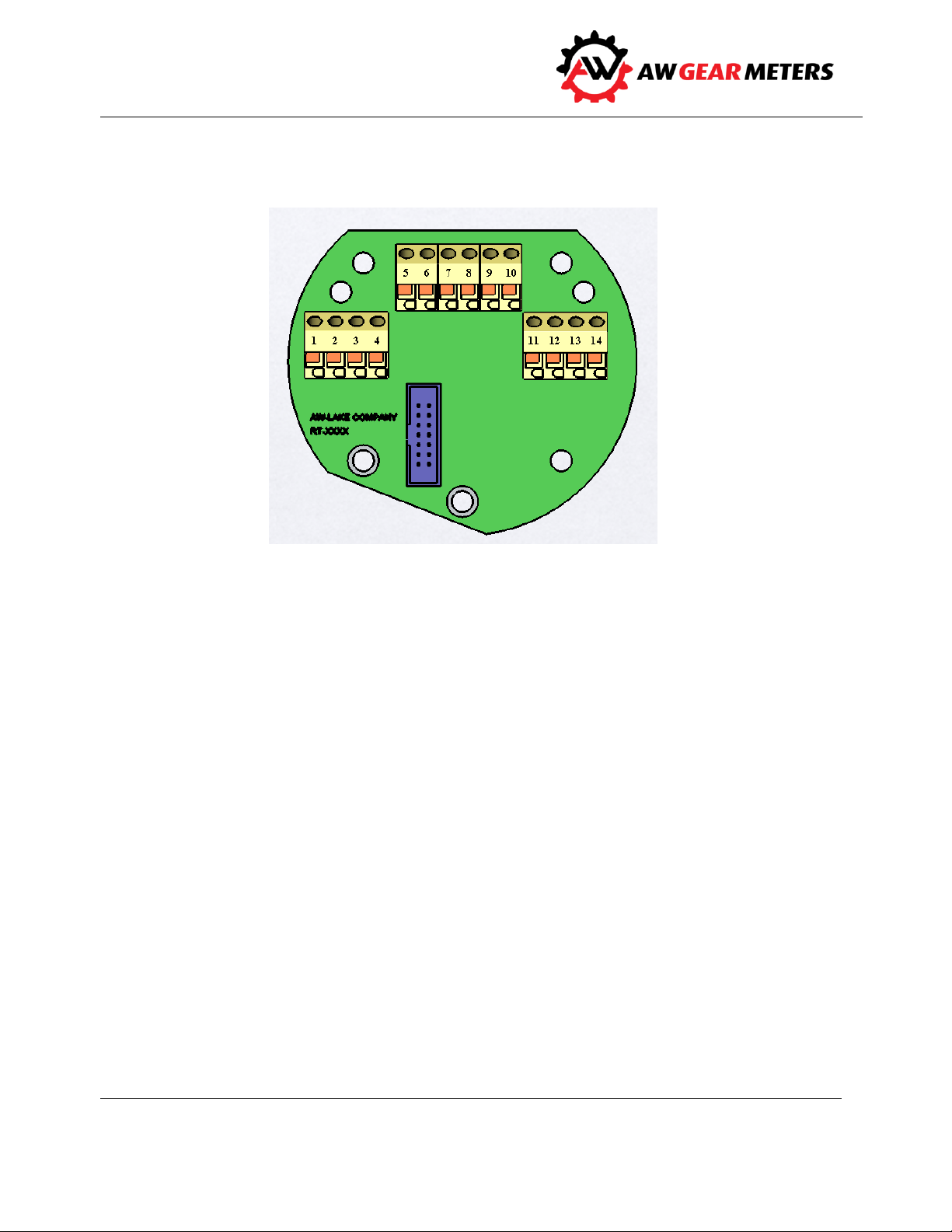

Hook-up board layout ............................................................................................................................... 9

Main board layout ................................................................................................................................... 10

Analog output ......................................................................................................................................... 11

Limit & frequency output ........................................................................................................................ 11

Reset input .............................................................................................................................................. 12

Run Mode Screens ...................................................................................................................................... 13

LOGO screen ........................................................................................................................................... 14

RATE screen ............................................................................................................................................ 14

TOTAL screen .......................................................................................................................................... 14

RATE / TOTAL screen ............................................................................................................................... 15

GRAND TOTAL screen ............................................................................................................................. 15

STATUS screen ........................................................................................................................................ 15

ANALOG OUT screen ............................................................................................................................... 16

LIMIT screen ............................................................................................................................................ 16

Control Functions ........................................................................................................................................ 17

Programming .............................................................................................................................................. 19

Entering programming mode .................................................................................................................. 19

Changing values and making selections .................................................................................................. 19

RATE, TOTAL and GRAND TOTAL scaling ................................................................................................ 20

K-factor (scaling factor) ....................................................................................................................... 20

RATE unit ............................................................................................................................................. 20

RATE time base ................................................................................................................................... 20

RT-30EX User Manual, Rev. 1.7 02/07/2012

2

RT-30EX Flow Transmitter

Operation and Programming Manual

TOTAL unit ........................................................................................................................................... 21

Analog output scaling ............................................................................................................................. 21

Fixed output source ............................................................................................................................ 21

RATE source ........................................................................................................................................ 22

TOTAL source ...................................................................................................................................... 23

GRAND TOTAL source ......................................................................................................................... 23

LIMIT / Pulse output programming ......................................................................................................... 24

Limit 1 & Limit 2 .................................................................................................................................. 25

Frequency output programming ......................................................................................................... 27

Gate Time filter ....................................................................................................................................... 27

Linearizer programming .......................................................................................................................... 28

Calibrating Analog Output .......................................................................................................................... 30

I/O Manual Adjustment .............................................................................................................................. 31

Analog output adjustment ...................................................................................................................... 31

Fine mA adjustment ............................................................................................................................ 32

Coarse mA adjustment ........................................................................................................................ 32

Limit & frequency adjustment ................................................................................................................ 32

Fine limit output adjustment .............................................................................................................. 33

Coarse limit output adjustment .......................................................................................................... 33

ON/OFF Limit output adjustment ....................................................................................................... 33

Monitor external reset input .................................................................................................................. 34

Appendix A – Physical Dimensions ............................................................................................................. 35

Appendix B – Default Variable Values ........................................................................................................ 37

Appendix C – Revision History .................................................................................................................... 38

Limited Warranty ........................................................................................................................................ 39

3

RT-30EX User Manual, Rev. 1.7 02/07/2012

RT-30EX Flow Transmitter

Warning!

Caution

Notice

Caution

Operation and Programming Manual

Safety Definitions and Information

Do not attempt to install or use your AW Gear Meters product until you have read the safety

instructions in this section. Save this manual and keep it in an easily accessible place.

Warning means that failure to follow this safety statement may result in extensive product damage,

serious personal injury, or death.

Caution means that failure to follow this safety statement may result in minor or moderate personal

injury, property or equipment damage.

Notice is a statement that informs about installation, operation, maintenance, performance issues, or

general tips that are important but do not create a hazard or safety concern.

Unpacking

Separate the RT-30EX Flow Transmitter from packaging materials and check for any visual signs of

damage. If you determine there are damages caused by shipping, file a claim with the shipping

company. If the flow transmitter appears to have been improperly assembled or does not operate

properly, return it for replacement or repair (see Limited Warranty information at the end of this

manual).

Before connecting, programming, or operating the RT-30EX Flow Transmitter, read this manual.

4

RT-30EX User Manual, Rev. 1.7 02/07/2012

RT-30EX Flow Transmitter

Operation and Programming Manual

Product Description

The RT-30EX is a digital flow transmitter housed in an epoxy painted aluminum instrument enclosure.

The RT-30EX is certified for use in Class 1, Div 1 hazardous areas in both Canada and the US. The

unit’s graphical, backlighted LCD display makes it easy to monitor flow rate and total in user

selectable engineering units. The sensor used with the unit will mount on many meter models

modified for use with the 3/8” NPT sensor mounting thread. Meter model available are the JVM, JVS,

JVHS and ZHM gear meters and HM high pressure turbines.

Screen selection and programming changes

You can make program or mode changes, or reset the totalizer in two ways;

1. With the housing cover removed, enter information using the 4 pushbuttons

2. With the housing cover closed, hold the attached magnet wand against the side of the cover

to activate hall switches located on the internal circuit board.

You can also reset the totalizer and monitor flow rate limits and total output remotely via a computer

or PLC.

5

RT-30EX User Manual, Rev. 1.7 02/07/2012

RT-30EX Flow Transmitter

Warning!

Warning!

Warning!

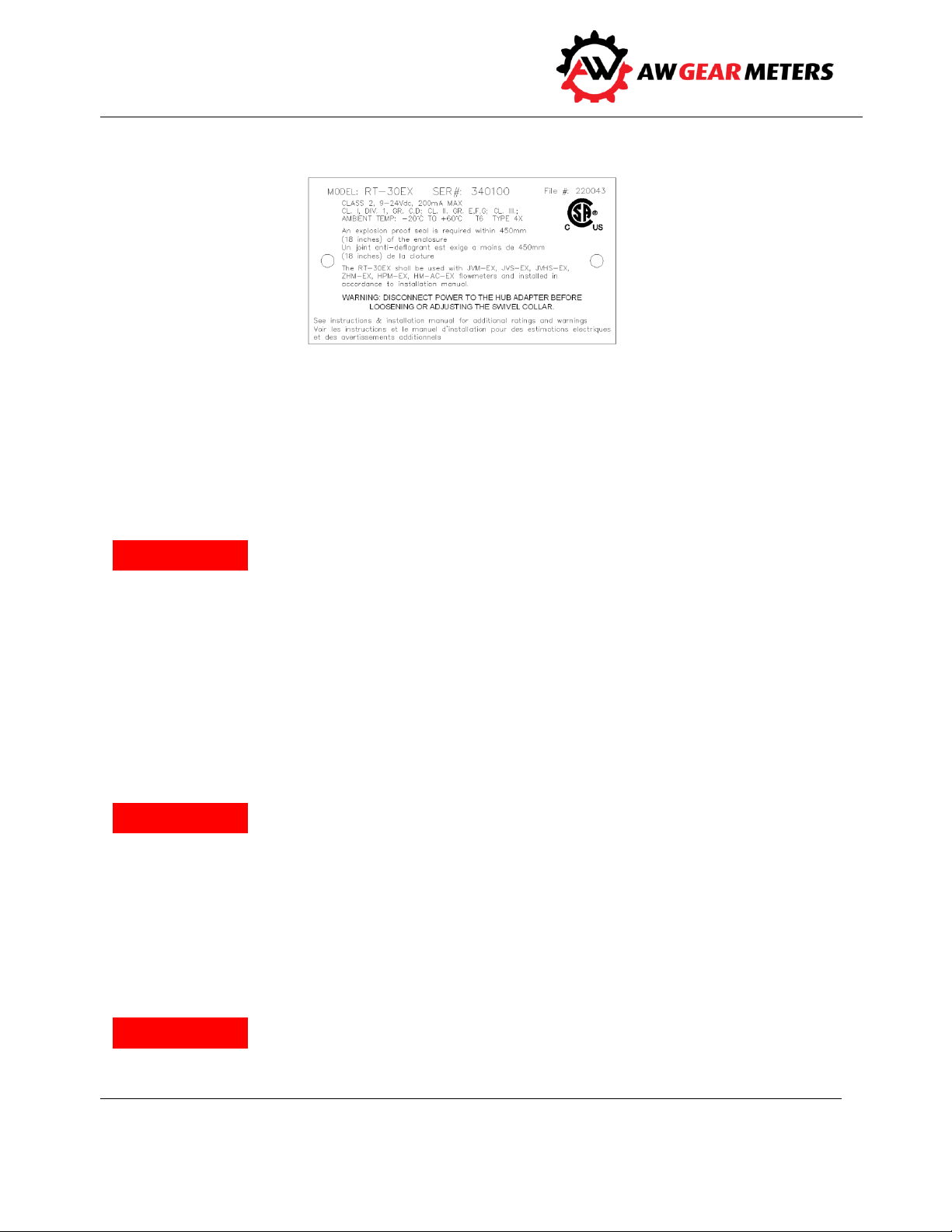

Figure 1: Hazardous area certification tag

Operation and Programming Manual

Hazardous Area Installation Instructions

The RT-30EX unit is an explosion-proof flow transmitter with local display which may be used in Class 1,

Div 1 locations. Above is a sample of the name plate that should be clearly attached to each unit.

Please make sure this name plate is on the unit and that the information matches what is shown above,

prior to installation. If either the name plate is not on the unit or the unit name plate does not match

what is shown above, please notify AW-Lake Company to determine appropriate course of action.

Because the RT-30EX uses an explosion-proof enclosure for its area protection, power must be removed

from the unit before the covers are removed while in a hazardous area. Also, disconnect power before

loosening or adjusting the swivel collar on the hub adapter.

For proper installation, it is also necessary that the conduit entries are properly sealed. To maintain the

unit’s explosion-proof certification, anything threaded into the NPT conduit openings must engage by a

minimum of 5 full threads. If original units received from AW-Lake Company are versions which have

the sensor installed, this sensor will be properly installed with a minimum of 5 full threads of

engagement from the factory.

When an RT-30EX is installed into the flow meter with which it is to be used, it is also necessary to make

sure there is a minimum of 5 full threads of engagement between the meter and RT-30EX unit.

When wiring the unit, please make sure to observe any local codes that may be required. A common

requirement is to have a conduit seal within 18 inches of the unit. Also, the unit may be used in a Class

I, Div. II area, but must still be installed according to Class I, Div I standards. Make sure units are

powered by a Class 2 power supply for proper regulation.

Please note that the RT-30EX must be installed properly into a flow meter before power is applied.

6

RT-30EX User Manual, Rev. 1.7 02/07/2012

RT-30EX Flow Transmitter

Operation and Programming Manual

Specifications

Power Requirements: 9-24 VDC/200mA, Class 2 (customer supplied)

Sensor/Monitor Input Ratings:

o Frequency Input Range: 0.3-4,500 Hz

o Sensor Supply Voltage: 12 VDC @ 50mA Max.

o Magnetic Sensor Input: 15mV

o High Level Pulse Input: 2V

P-P

Min., 24V

PEAK

Min., 24V

PEAK

Max.

PEAK

Max.

Analog Output 4-20 mA: 16-bit isolated loop powered 2-wire output; 9-24 VDC, Class 2 loop

supply; max. load impedance = 500 Ohm @ 24V; max. load impedance = 250 Ohm @ 12V

Three Opto-Isolated Open-Collector Outputs: 5-30 VDC, Class 2 rating, 40 mA Max.

(minimum load impedance required = 600 Ohm @ 24 VDC)

Opto-Isolated Reset Input: 12-24 VDC Input, Class 2, 3.3Kohm Impedance

Temperature Ratings: -4 to 140°F (-20 to 60°C) ambient; 185°F (85°C) max. fluid

temperature (standard); 350°F (175°C) max. fluid temperature with optional high

temperature pickup version.

Enclosure Certification: Type 4X

Connection: spring terminal strips; ¾" NPT conduit entrance

Display update rate: 250 milliseconds (4 times per second)

Analog output update rate: 20 milliseconds (if Gate Time filter off)

7

RT-30EX User Manual, Rev. 1.7 02/07/2012

RT-30EX Flow Transmitter

Operation and Programming Manual

Connections

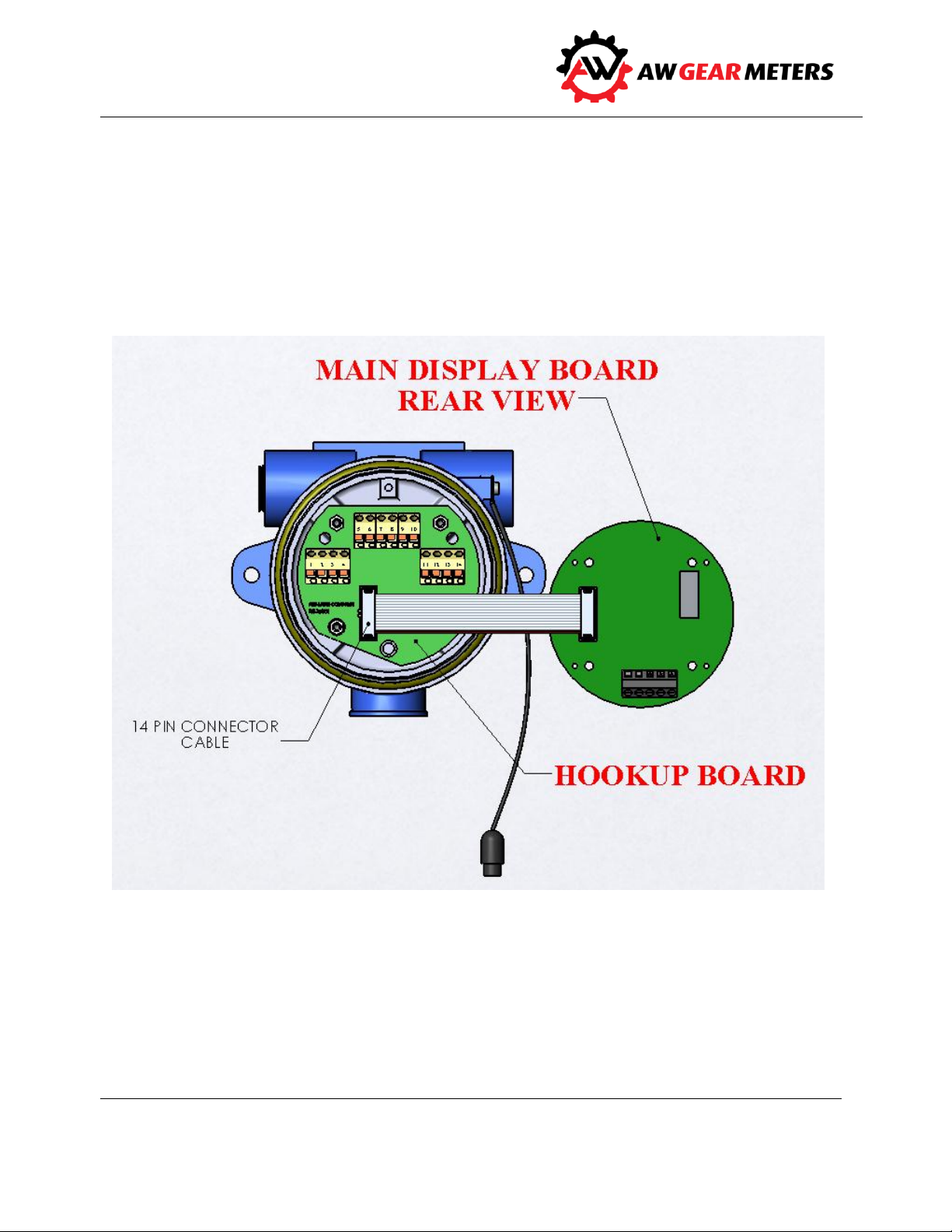

On dual access enclosure versions, the hook-up board can be accessed by removing the blind cover.

To get access to the hook-up board on the single access enclosure models, first remove the cover and

loosen the 4 stainless steel screws visible through the face plate as shown in Figure 18. Note that the

screws are captured on the back side of the main display board and will not fall out. Carefully remove

the main display board. The hook-up board is located at the bottom of the enclosure as shown in Figure

2 below.

Figure 2: Single access enclosure model, hook-up board location

To get access to the sensor wiring terminal which is located on the back of the main display board, the

same procedure must be followed for both the single and dual access enclosure models.

RT-30EX User Manual, Rev. 1.7 02/07/2012

8

RT-30EX Flow Transmitter

Figure 3: Hookup board connection diagram

Operation and Programming Manual

Hook-up board layout

Maximum wire gauge: 16 AWG

Pin 1: (+) Reset

Pin 2: (-) Reset

Pin 3: (+) Frequency Out

Pin 4: (-) Frequency Out

Pin 5: (+) Supply Voltage

Pin 6: (-) Supply Voltage / Ground

Pin 7: Housing Ground

Pin 8: +Vcc

Pin 9: mA Loop Output See Figure 5 & Figure 6 on page 11 for mA signal polarity

Pin 10: mA Loop Output

Pin 11: (+) Limit 1

Pin 12: (-) Limit 1

Pin 13: (+) Limit 2

Pin 14: (-) Limit 2

NOTE: See page 7 for electrical specifications

9

RT-30EX User Manual, Rev. 1.7 02/07/2012

RT-30EX Flow Transmitter

Figure 4: Main board input signal connection

Operation and Programming Manual

Main board layout

Maximum wire gauge: 12 AWG

Pin A: Magnetic Coil input

Pin B: Magnetic Coil input

Pin C: Ground

Pin D: High level pulse Input

Pin E: (+) 12Vdc Output for sensor supply

NOTE: See page 7 for electrical specifications

10

RT-30EX User Manual, Rev. 1.7 02/07/2012

RT-30EX Flow Transmitter

OPTO-

ISOLATOR

50mA Polyfuse

3, 11, 13

4, 12, 14

(+)

(-)

R sense

ANALOG

CIRCUIT

0.01uF

9

10

5

6

SUPPLY

VOLTAGE

9-24 Vdc

(Class 2)

(+)

(-)

9-24 Vdc

(Class 2)

(+)

(-)

RT-30EX

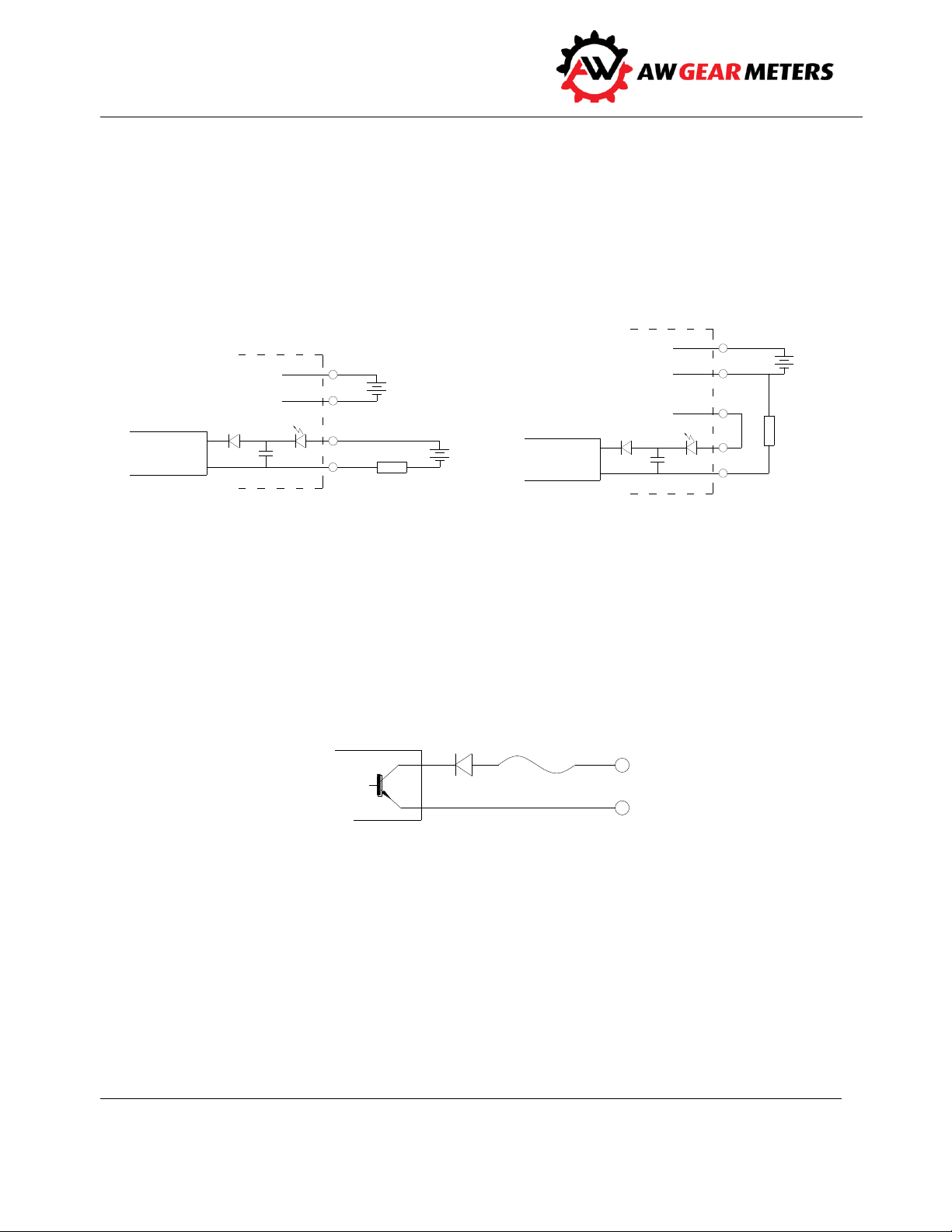

Figure 5: Loop powered analog output

Figure 6: Ground referenced analog output

Figure 7: Limit1, Limit 2 & Frequency outputs

R sense

ANALOG

CIRCUIT

0.01uF

9

10

5

6

SUPPLY

VOLTAGE

9-24 Vdc

(Class 2)

(+)

(-)

RT-30EX

8

Operation and Programming Manual

Analog output

The isolated 16-bit 4-20mA output can be wired for use with Loop powered inputs or for ground

referenced inputs. The analog signal has an LED in series which varies in intensity as the mA signal

varies. This can be used for troubleshooting purposes.

When using the analog signal with inputs used with loop powered signals, it is important to note that

the RT-30EX still requires a separate power supply to power the unit as shown Figure 5 below.

When using the analog signal with ground referenced inputs, jumper pins 8 and 9 together as shown in

Figure 6 above. Analog signal is taken from pin 10 and returns to pin 2 (supply ground).

Limit & frequency output

Three opto-isolated NPN open-collector outputs can sink or source depending on connection. Attention

must be paid to polarity of connections. See page 7 for electrical specification and page 9 for Limit 1,

Limit 2 & Frequency pin-out pairing.

RT-30EX User Manual, Rev. 1.7 02/07/2012

11

RT-30EX Flow Transmitter

1

2

3.3Kohm

12-24 Vdc

(Class 2)

(+)

(-)

RT-30EX

MOMENTARY

SWITCH

OPTO-

ISOLATOR

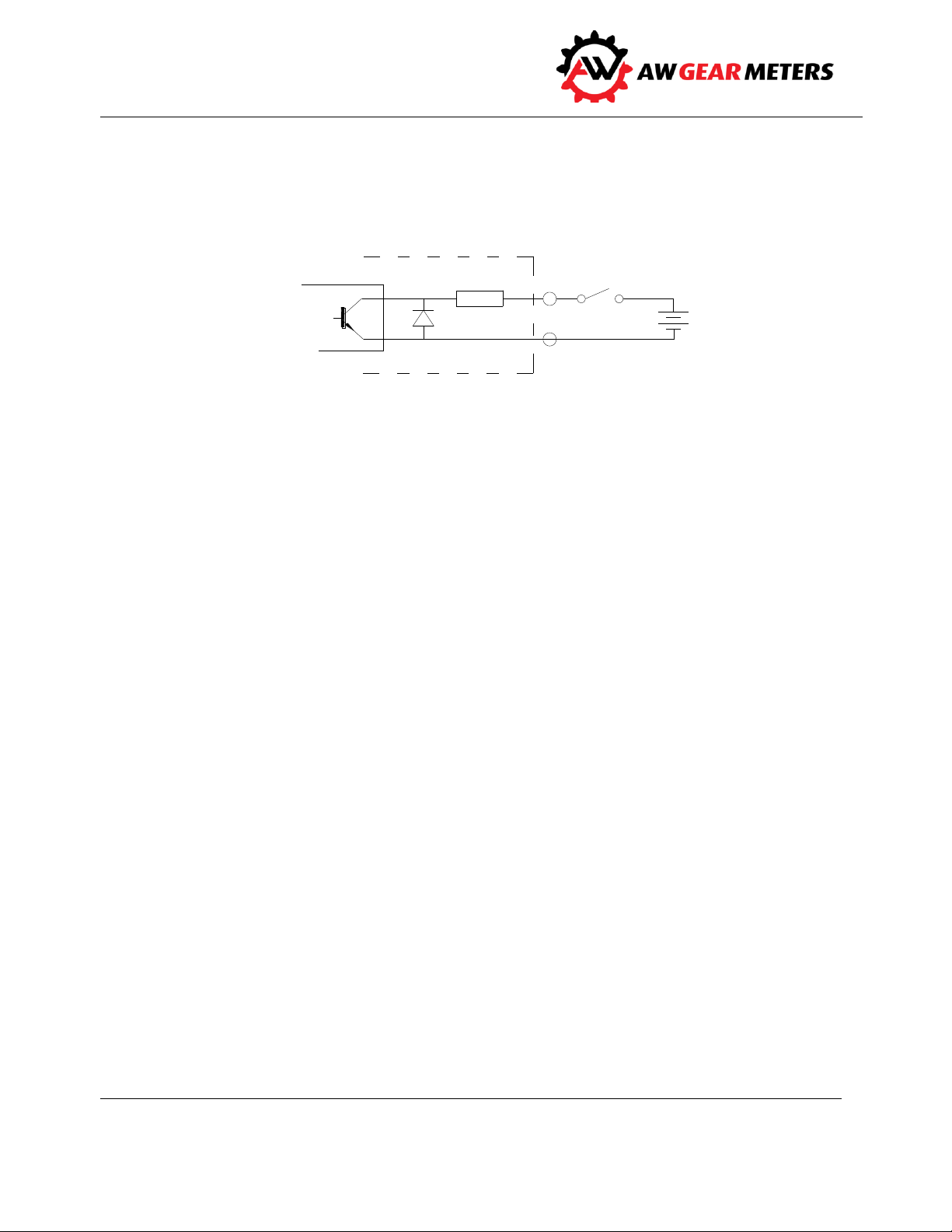

Figure 8: External reset input

Operation and Programming Manual

Reset input

Opto-isolated external reset input will trigger the RT-30EX to reset the totalizer when the input sees a

momentary transition from low (ground) to high (near supply).

RT-30EX User Manual, Rev. 1.7 02/07/2012

12

Loading...

Loading...