AW Gear Meters LLC-BA User Manual

LLC-BA

BATCH CONTROLLER

OperaƟon & InstallaƟon Manual

Rev. 2

LLC-BA Batch Unit

Operation and Installation Manual

Table of Contents

Safety Definitions and Information ............................................................................................................... 4

Unpacking ..................................................................................................................................................... 4

Quick Start Guide .......................................................................................................................................... 5

Connect to Flow Transmitter .................................................................................................................... 5

Relays-to-Solenoid Connections ............................................................................................................... 5

Other Connections .................................................................................................................................... 5

Connect Unit to Power .............................................................................................................................. 5

Basic Key Definitions and Key Strokes ...................................................................................................... 5

Product Description ...................................................................................................................................... 6

Features .................................................................................................................................................... 6

Principle of Operation ............................................................................................................................... 6

Technical Data ............................................................................................................................................... 6

Enclosure ................................................................................................................................................... 6

Weight ....................................................................................................................................................... 7

Environment ............................................................................................................................................. 7

Power Supply ............................................................................................................................................ 7

Relay Contact Ratings ............................................................................................................................... 7

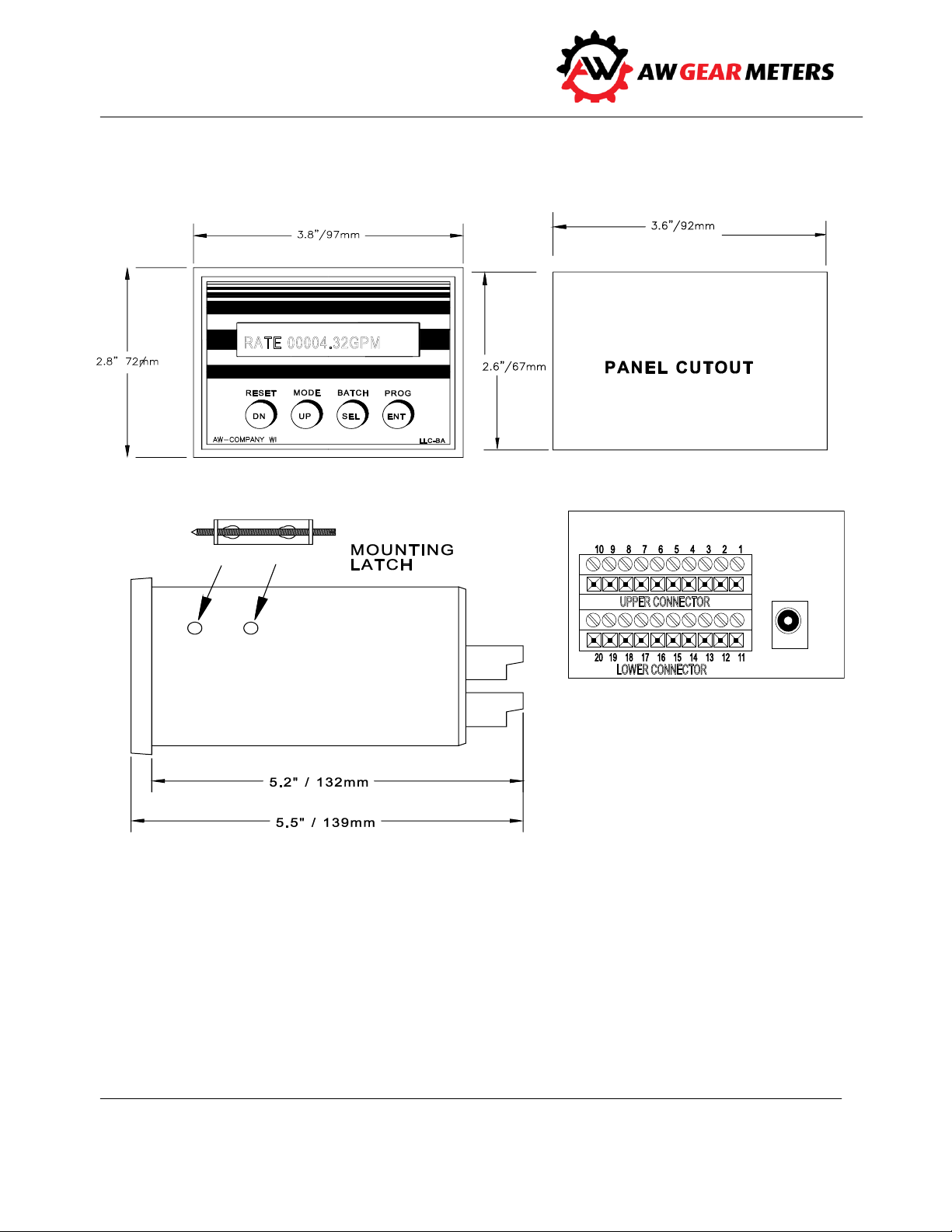

Dimensional Drawings .............................................................................................................................. 8

Input and Output Wiring Connections ...................................................................................................... 9

Upper Connector Terminal Designations .............................................................................................. 9

Lower Connector Terminal Designations ................................................................................................ 10

LLC-BA Initial Messages............................................................................................................................... 13

Display Modes ............................................................................................................................................. 13

RATE ........................................................................................................................................................ 13

TOTALIZER 1 (TO1) .................................................................................................................................. 14

TOTALIZER 2 (TO2) .................................................................................................................................. 14

BATCH Status .......................................................................................................................................... 14

1

LLC-BA Batch Unit

Operation and Programming Manual

TO1 (REVERSE TOTAL 1) .......................................................................................................................... 14

Operations/Reset of Totalizers ............................................................................................................... 14

Totalizer 1 ............................................................................................................................................... 15

Totalizer 2 ............................................................................................................................................... 15

Operating Modes ........................................................................................................................................ 15

RUN Mode ............................................................................................................................................... 16

Batch Operation .................................................................................................................................. 16

Automatic Overrun Compensation ..................................................................................................... 16

Batch Selection/Activation ...................................................................................................................... 16

Batch Input and Output Functions .......................................................................................................... 17

INPUT1 ................................................................................................................................................ 17

INPUT2 ................................................................................................................................................ 17

INPUT3 ................................................................................................................................................ 17

INPUT4 ................................................................................................................................................ 17

RELAY1 ................................................................................................................................................ 17

RELAY2 ................................................................................................................................................ 17

mA’s (+/-) OUTPUT .............................................................................................................................. 17

Batch Progress Signal .......................................................................................................................... 18

Batch Number Signal ........................................................................................................................... 18

Programming the LLC-BA ............................................................................................................................ 20

Program Mode ........................................................................................................................................ 20

Entering/Editing Variables ...................................................................................................................... 20

DELAY .................................................................................................................................................. 21

PRECUT ................................................................................................................................................ 21

Gate Time ............................................................................................................................................ 21

0-set mAs ............................................................................................................................................ 22

KFR-Factor ........................................................................................................................................... 22

Decimal Point for KFR ......................................................................................................................... 23

Engineering Units KFR ......................................................................................................................... 23

KFT-Factor ........................................................................................................................................... 24

2

LLC-BA Batch Unit

Operation and Programming Manual

Decimal Point for KFT .......................................................................................................................... 25

Engineering Units KFT ......................................................................................................................... 25

Batch Programming .................................................................................................................................... 25

Limited Warranty ........................................................................................................................................ 27

3

LLC-BA Batch Unit

Warning!

Caution

Notice

Caution

Operation and Programming Manual

Safety Definitions and Information

Do not attempt to install or use your AW Gear Meters product until you have read the safety

instructions in this section. Save this manual and keep it in an easily accessible place.

Warning means that failure to follow this safety statement may result in extensive product damage,

serious personal injury, or death.

Caution means that failure to follow this safety statement may result in minor or moderate personal

injury, property or equipment damage.

Notice is a statement that informs about installation, operation, maintenance, performance issues, or

general tips that are important but do not create a hazard or safety concern.

Unpacking

Separate the flow monitor from packaging materials and check for any visual signs of damage. If you

determine there has been damage caused by shipping, file a claim with the shipping company. If the

flow monitor appears to have been improperly assembled or does not operate properly, return it for

replacement or repair (see Limited Warranty information at the end of this manual).

Before connecting, programming, or operating the LLC-BA Batch Unit, read this manual.

4

LLC-BA Batch Unit

Caution

Notice

Operation and Programming Manual

Quick Start Guide

As with any precision-engineered device, always operate the LLC-BA Batch Unit in accordance with the

manufacturer’s instructions.

Connect to Flow Transmitter

You will connect three wires from the sensor to the back of the LLC-BA:

a red wire (electrical power)

a white wire (signal), and

a black wire (ground)

Color of wires may vary.

Insert the end of the red wire into upper connection #1 and use a screwdriver to secure. Insert the end

of the black into upper connection #2 and the end of the white wire into upper connection #3. Use a

screwdriver to secure.

Relays-to-Solenoid Connections

In a two-valve system, connect the 110VAC power wire from the optional high flow valve to upper

connection #5, neutral to #7; and connect power wire from low flow valve to upper connection #8 and

neutral to upper connection #10.

Other Connections

Other connections may be required, depending on your system. These include connections for remote

input/output devices, PLCs, and computers. See Input and Output Wiring Connections on page 9.

Connect Unit to Power

Insert the female end of the 110VAC adaptor into the AC 16V input at the back of the LLC-BA. Plug the

adaptor into a wall receptacle.

Basic Key Definitions and Key Strokes

The LLC-BA has four keys for data input and programming:

DN (down)

UP (up)

SEL (select)

ENT (enter)

5

LLC-BA Batch Unit

Operation and Programming Manual

Use the SEL key to isolate the data you would like to enter. Use the UP and DN keys to move the cursor

as desired and to enter information. Use the ENT key to confirm data and to enter information into the

LLC-BA. Find complete programming information in the Programming the LLC-BA section on page 20.

Enter KFR and KFT Factors

The Calibration Sheet packed with the flow meter(s) includes the KFR and KFT factors. To program these

variables and the appropriate enginnering units, see the section on Programming the LLC-BA beginning

on page 20.

Product Description

The LLC-BA allows accurate control a small- to medium-sized fluid batch system. The microprocessorcontrolled design allows you to select from nine different batches and provides START, STOP, or RESET

functions. While the batch is going through its cycle, the LLC-BA monitors the operation and informs you

if the batch is RUNNING, PAUSED, or DONE. The device also can monitor two different flow rates to

allow for a slow stop/start of the flow and can show a combined flow rate.

The LLC-BA’s Automatic Over-Run Compensation function corrects any overrun on the next batch. This

feature is always active and adapting continuously to correct for long-term changes in valves and fluid

characteristics.

Features

Easy-to-read LCD display

Batch/totalizer data retained up to five years

Dust and chemical resistant Lexan® front panel

Panel mount enclosure

Two valve-control outputs

Customizable industrial enclosures available

Principle of Operation

After the user enters the batch amount into the controller, the unit monitors the batch either up from

zero or down to the batch amount depending on user choice. The user can program nine different

batches into the LLC-BA and have access to all of them.

Technical Data

Enclosure

DIN #43700, panel mount, plastic

Height = 67mm/2.6 inches; height w/ flange 69mm/2.8 inches

Width = 92mm/3.6 inches; width w/ flange = 97mm/3.8 inches

6

LLC-BA Batch Unit

Maximum

Switched

Power

Resistive Load

DC: 60W

AC: 125VA

Inductive Load

DC: 30W

AC: 60VA

Maximum Switched Voltage

220V DC, 250V AC

Maximum Switched Current

2A

Rated

Load

Resistive Load

DC: 30V, 2A

AC: 110V, 0.5A

Inductive Load

DC: 30V, 1A

AC: 110V, 0.3A

Operation and Programming Manual

Depth = 132mm/5.2 inches; depth w/ flange = 139mm/5.5 inches

Lexan® is a registered trademark of SABIC Innovative Plastics.

Weight

12 0z. (approx. 360 grams) without power supply

Environment

Storage: -40 to 85 deg. C

Operating: 0 to 50 deg. C (standard)

Humidity: 10-90% non-condensing

Power Supply

Supplied: 110VAC wall plug unit -16VAC/1000mA output w/6ft. cable to standard 2.1mm I.D. x

5.5mm O.D. female plug

Allowable supply range: 12-16VAC/300mA or 15-24VDC/300mA

Frequency Input: voltage triggered, 2.00 volt min. input level, 0 - 4KHz, 10KOhm imp.

Supply Output: (to sensor) approx. 20mA at approx. 15VDC

Relay Outputs: 2 Form C relay outputs (see table below for contact rating information)

Relay Contact Ratings

7

LLC-BA Batch Unit

Operation and Programming Manual

Dimensional Drawings

8

Loading...

Loading...