Page 1

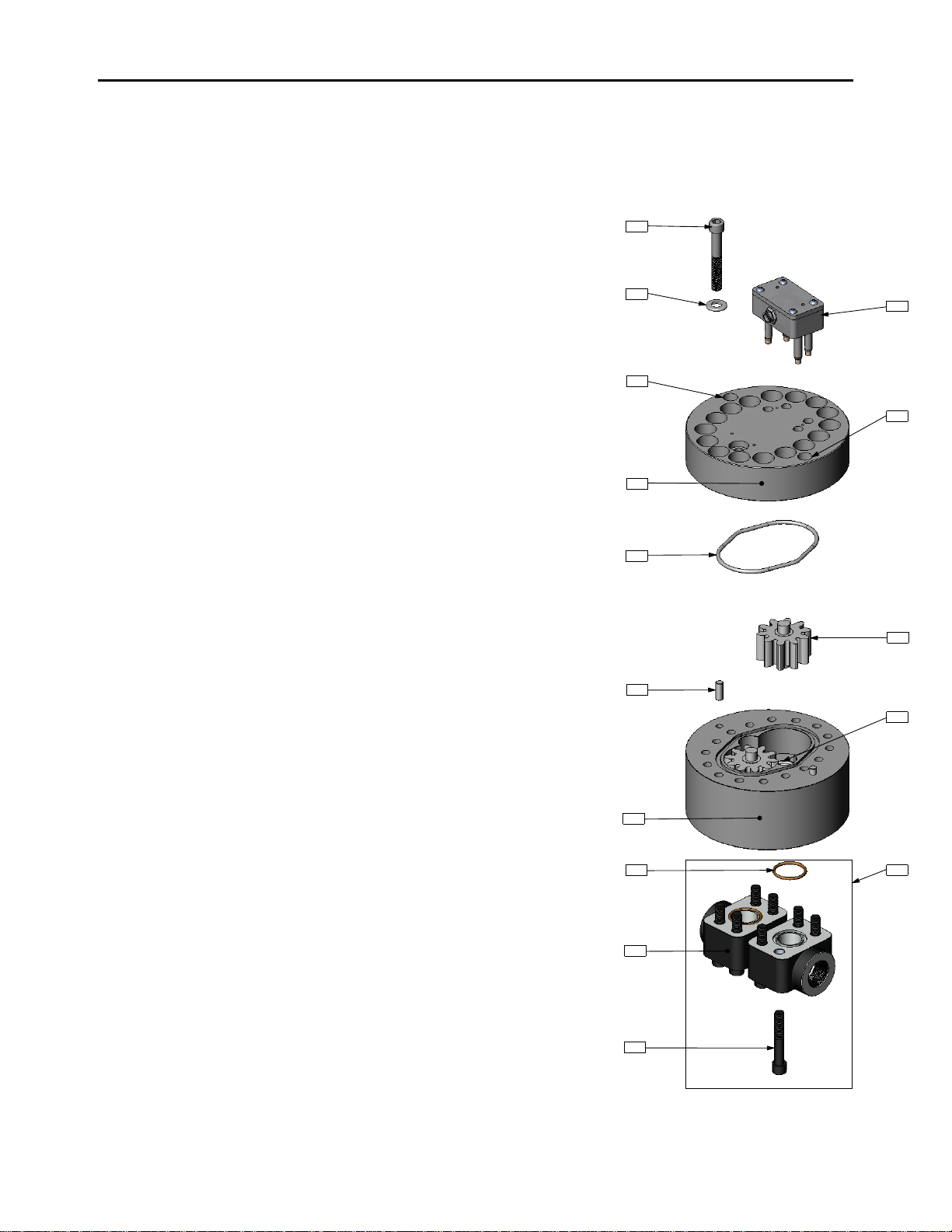

1

2

3

4

4

5

6

7

8

9

10

1111a

11b

11c

MAINTENANCE GUIDE FOR THE JVx-80KL & 90KL SERIES FLOW METER

Cleaning, inspecting or repairing a JVx-80KL & 90KL Series gear flow meter is easily

accomplished by following the procedures below.

1. Remove the Sensor (3) from the flow meter body Upper

Housing (5). Using a 9/64 hex key, loosen the 2 mounting

screws inside the sensor.

2. Remove the hex bolts (1) with a 3/8 hex key.

3. Turn 2 of the hex bolts into the extraction bolt holes (4) until

they make contact with the lower housing (10). Using these

bolts for separating the housings helps to reduce any stress

on the locating pins and gear shafts.

4. With the extraction bolts turned down to the lower housing,

give each bolt a half-turn, alternating them, until the

housings have separated enough to where you can lift the

upper housing (5) straight off the locating pins. CAUTION:

When lifting the top housing off, make sure the gears

stay in the lower housing. If they come out with the

upper housing, they may fall off and damage the lower

housing or the gears themselves.

5. After separation, inspect the gears (7) and bearings (9).

Carefully remove the gears and thoroughly clean them with

solvent. Special care must be observed when cleaning or

flushing either the upper (5) or lower housing (10) as the

bearing could dislodge from the housing. NOTE: Do not

remove the bearings. For bearing repairs the meter

should be returned to the factory.

6. After cleaning, add lubrication if possible. The gears can be

reinserted into their previous positions. Check for free and

easy rotation of the gears.

7. Replace the O-ring (6) if it is damaged or deformed.

8. Keep the meter housings parallel during reassembly and

align the index marks on the housings so they are on the

same side. NOTE: Do not force the housings together

using a hammer or other similar device. Make sure to

turn out the bolts from the extraction holes.

9. Replace the hex bolts and torque all the bolts to 50 ft/lbs,

once one bolt is torqued, move to the bolt that is opposite it

and repeat until all bolts have been torqued. Over tightening

will not cause damage, but may restrict operation if surfaces

are not completely clean.

10. After reassembly, gently blow air into the meter so the gears

spin. This should be clearly audible given a moderate

background noise level.

11. The bearings should be lubricated prior to storage.

Never allow contact with water without immediately

drying and lubricating after use.

AW Gear Meters 8809 Industrial Drive, Franksville, WI 53126 web: www.awflowmeters.com

REV. 05/24/12 JVX-80KL & 90KL W-QUAD-4.DOC

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

JVx-80KL w/ QUAD-4 Shown

Page 2

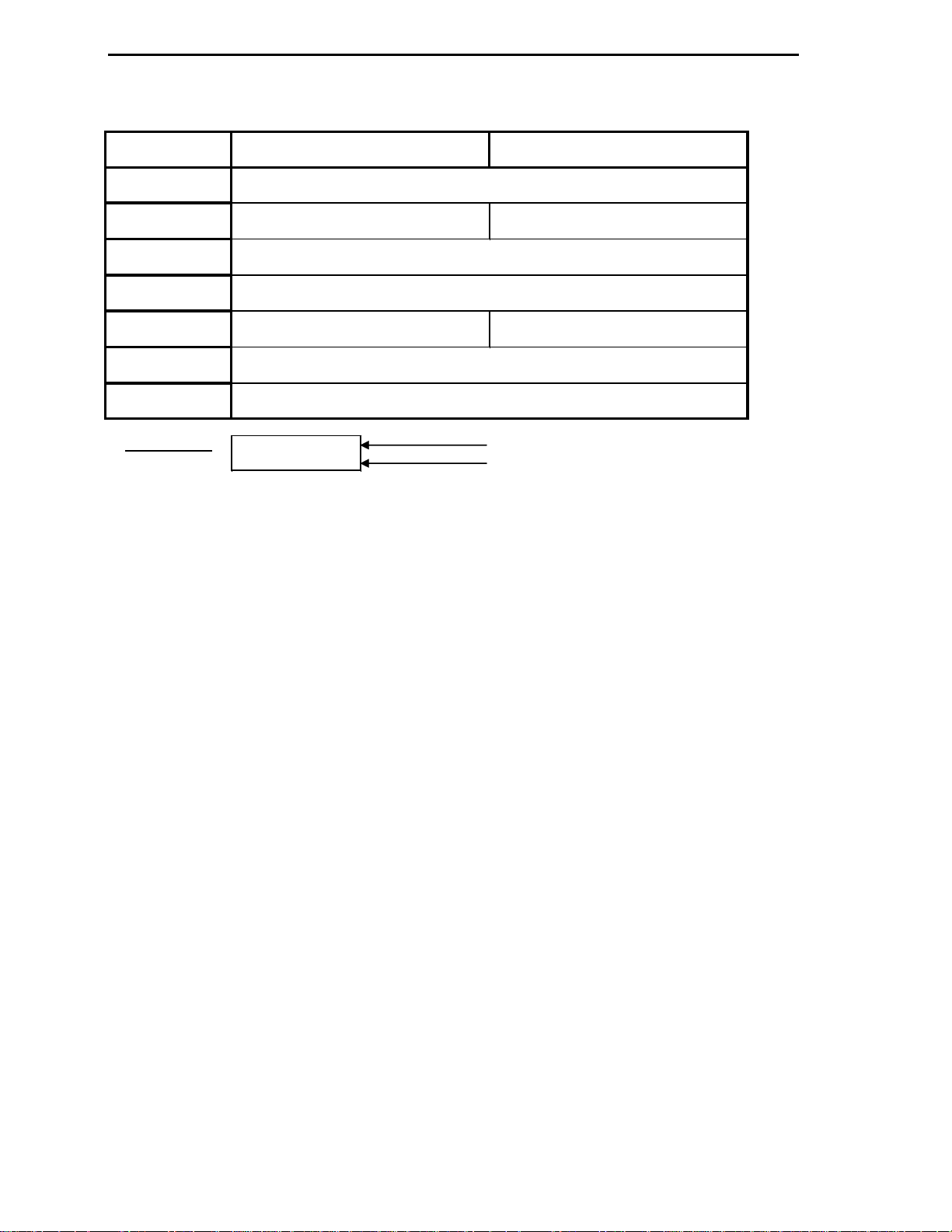

CROSS REFERENCE GUIDE FOR JVx-80KL SERIES SPARE PARTS

Table Format: AG15030 AW Part #

LP-CG Locating Pin AW Part Description

BZ20000

Washer - 1/2 SAE Grade 8

BG23090

JGR-90KL

Flange Assembly - 2

[11]

Bolts - 16

[1]

Washers - 16

[2]

Locating Pin - 2

[8]

Gear Assembly - 2

[7]

PTFE O-Ring - 1

[6]

BO10185

COT-80KL

B010180

COV-80KL

BZ05700

JSC-80KL 1/2-20 x 2.5

BZ05500

JSC-90KL 1/2-20 x 3.5

BC80165

90DEG - NPT - JVM - 90 - 303 SS

Part - Qty. per meter

[Drawing Ref. #]

JVx-80KL

JVx-90KL

FKM O-Ring - 1

[6]

BZ25280

LP-JVA-80KL

BG23080

JGR-80KL

AW Gear Meters 8809 Industrial Drive, Franksville, WI 53126 web: www.awflowmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 05/24/12 JVX-80KL & 90KL W-QUAD-4.DOC

Loading...

Loading...