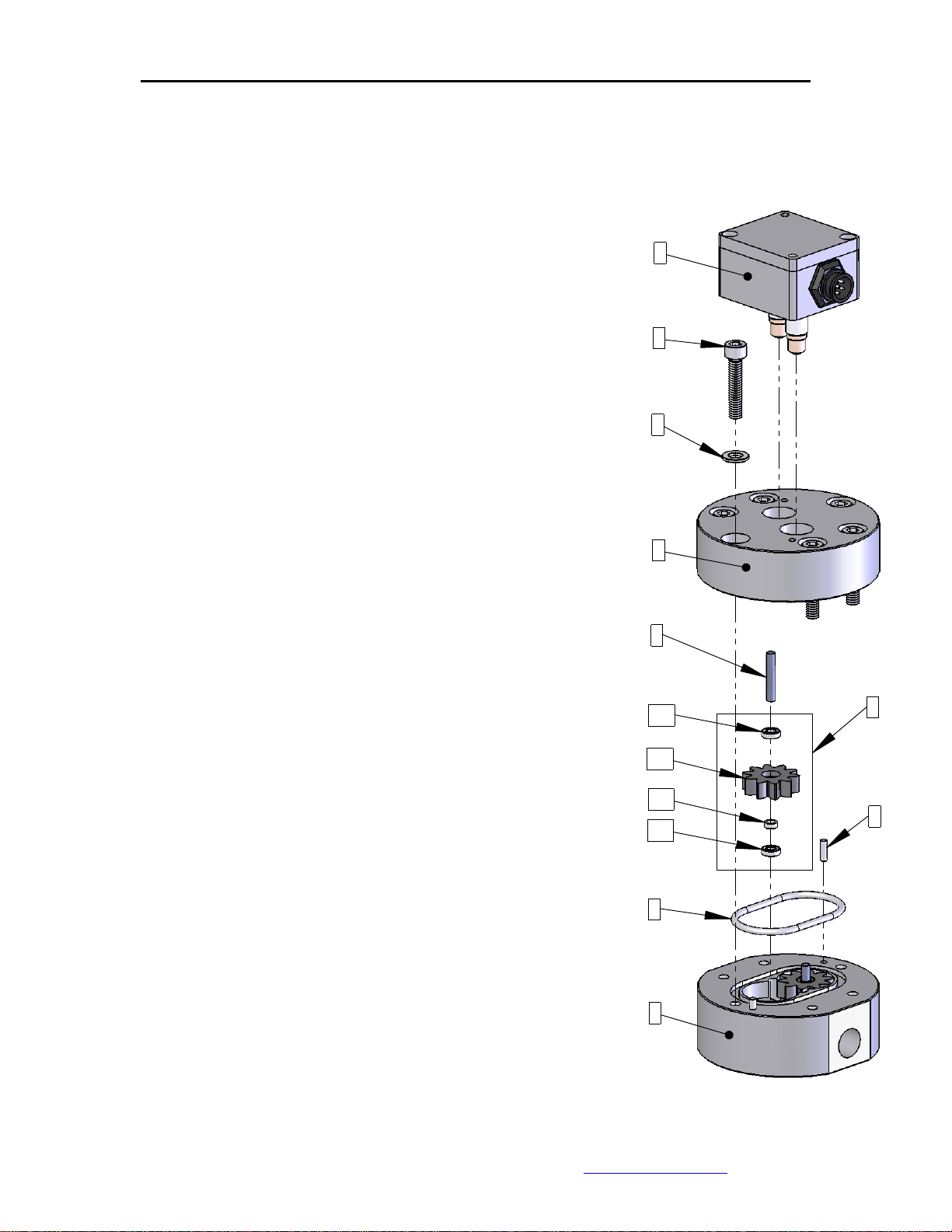

Page 1

1

2

3

4

5

6a

6a

6c

7

8

9

6b

6

MAINTENANCE GUIDE FOR THE JV-XXKG SERIES FLOW METER

Cleaning, inspecting or repairing a JV-KG Series gear flow meter is easily accomplished by following the

procedures below.

1. Remove the Sensor (1) from the flow meter body Upper Housing (4). Using a

3mm hex key, loosen the 2 mounting screws inside the sensor.

2. For the JV-30 size and smaller use M6 Bolts (2), loosen them using a 5mm hex

key. The JV-60 uses M10 Bolts (2), loosen them using an 8mm hex key. Keep

the 2 opposing bolts near the Locating Pins (7) engaged by a few threads to

avoid stress on the shafts and the locating pins during housing separation.

Please note the orientation of the Upper and Lower housings with respect

to each other so that the meter is reassembled the same way.

3. Holding the Upper Housing (4), gently tap on the top of the 2 opposing bolt

heads to separate the Upper Housing (4) from the Lower Housing (9). Do NOT

use chisels or screwdrivers to split and pry apart the housings. This can

cause damage to the meter bodies and meter internal parts.

4. After separation, remove, clean and inspect the gear assemblies (6) and shafts

(5). Clean out the o-ring groove, shaft holes and meter cavity.

IMPORTANT: The gear assembly consists of two bearings (6a), the Gear

(6b), and a Bearing Spacer (6c. These parts are loosely fitted and can fall

out. These parts are matched together and careful attention MUST be

made to their orientation and location as they MUST be replaced the exact

way they were.

5. After cleaning all parts completely, the Gear Assemblies (6), Shafts (5) and

Locating Pins (7) can be reinserted. Check for free and easy rotation of the

gears.

6. Replace the O-Ring (8). PTFE o-rings should always be replaced. FKM o-rings

can be reused if they are not damaged.

Note: JVx-60KG flow meters use 2 o-rings per meter.

7. During reassembly keep the meter housings as parallel as possible. Make sure

the housings are orientated the same way they were prior to disassembly.

8. Replace the Washers (3) and the Bolts (2). Torque the bolts to 15Nm for

the12, 20 and 30 size meters and 30Nm for the 60 size meters. Do not force

the meter housings together. Do NOT use a hammer or other such device.

Over tightening will not cause damage to the meter, but may fatigue the bolts

and/or restrict the operation if internal surfaces are not completely clean.

9. After reassembly, gently blow air through the meter so the gears spin. This

should be clearly audible given a moderate background noise level.

10. Clean any debris from the pickup holes before remounting the sensor (1) to the

Upper Housing (4). Use a 3mm hex key to tighten the mounting screws in the

sensor to mount the sensor on the housing. Note that there is a correct and

incorrect orientation for the sensor to be mounted on the flow meter.

Please see the AW Gear Meters website for documentation if you do not have

it. The orientation is noted by the sensor’s connector with respect to the outlet

port of the flow meter.

JV-20KG w/ DH-B Shown

AW Gear Meters 8809 Industrial Drive, Franksville, WI web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 05/24/12 JVXX-KG W-DH.DOC

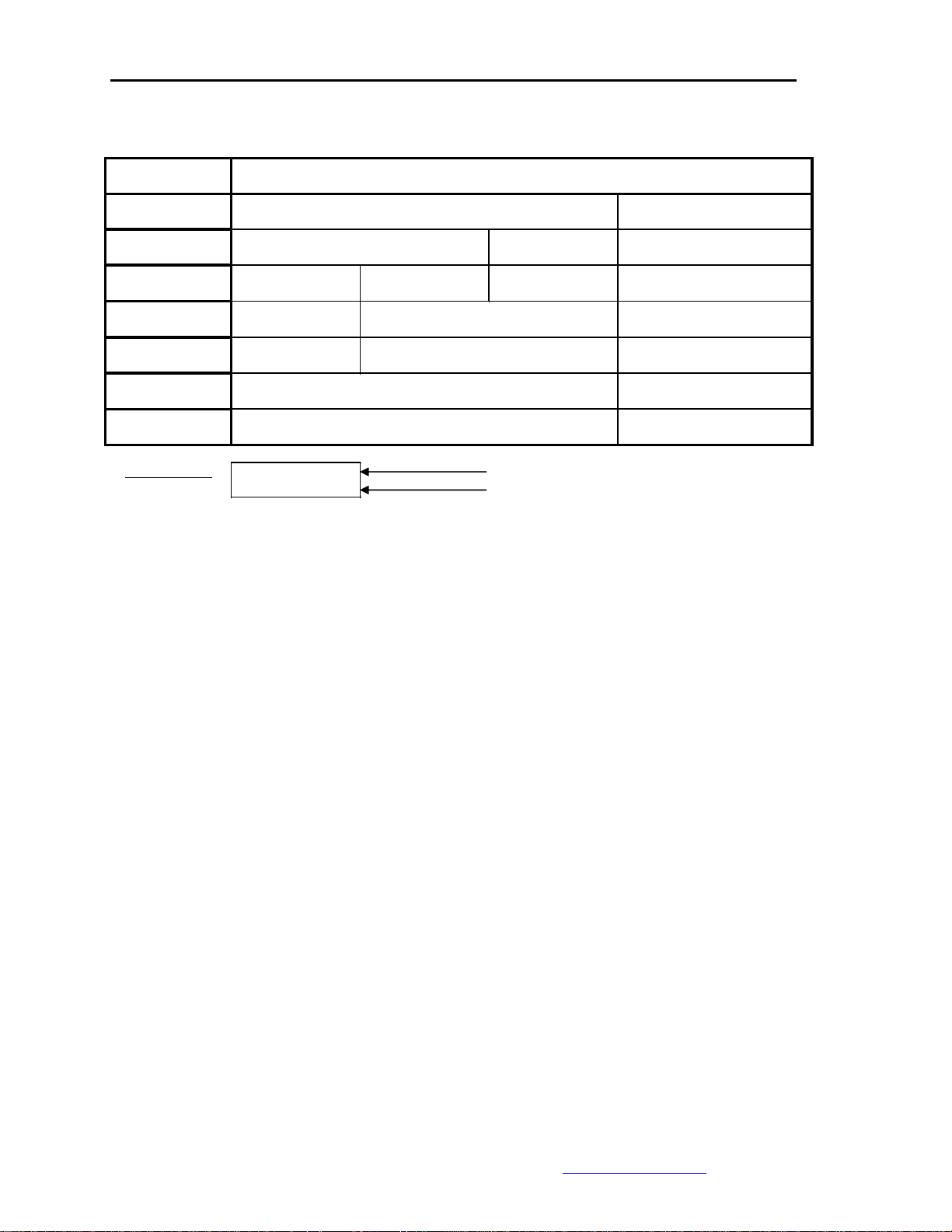

Page 2

AG60030

LP-60CG Locating Pin

AG30055 AG60075

ST-30KG Shaft ST-60KG Shaft

AG12010 AG20040 AG30050 AG60070

GR-12KG GR-20KG GR-30KG GR-60KG

AG12020 AG60080 - 2 pcs

COT-12KG COT-60KG

AG12025 AG60085 - 2 pcs

COV-12KG COV-60KG

AG60050 - 12 pcs

M10x70mm

AG60055 - 12 pcs

Washer - M10 Hardened Washer

Table Format: AG15030 AW Part #

LP-CG Locating Pin AW Part Description

AG12015

ST-12KG Shaft

AG15040

COT-15CG

AG15060 - 6 pcs

SC-M6x1-30mm - 6 pcs

AG15065 - 6 pcs

Washer - M6 Hardened Washer

JV-60KG

Part - Qty. per meter

[Drawing Ref. #]

JV-12KG

JV-20KG

JV-30KG

FKM O-Ring - 1

[8]

AG15030

LP-CG Locating Pin

AG15045

COV-15CG

Bolts - 6

[2]

Washers - 6

[3]

Locating Pin - 2

[7]

Shaft - 2

[5]

Gear Assembly - 2

[6]

PTFE O-Ring - 1

[8]

CROSS REFERENCE GUIDE FOR JV-XXKG SERIES SPARE PARTS

AW Gear Meters 8809 Industrial Drive, Franksville, WI web: www.awflowmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email:awinfo@aw-lake.com

REV. 05/24/12 JVXX-KG W-DHB.DOC

Loading...

Loading...