Page 1

EMO-500

TWO-COMPONENT RATIO MONITOR

OperaƟon & InstallaƟon Manual

Rev. 6

Page 2

EMO-500

Operation and Programming Manual

Table of Contents

Safety Definitions and Information ............................................................................................................... 4

Unpacking ..................................................................................................................................................... 4

Quick Start Guide .......................................................................................................................................... 5

Connect to Flow Transmitters ................................................................................................................... 5

Connect Unit to Power .............................................................................................................................. 7

Overview of Display Screens ..................................................................................................................... 8

Product Description ...................................................................................................................................... 9

Features .................................................................................................................................................... 9

Principle of Operation ............................................................................................................................... 9

Technical Data ........................................................................................................................................... 9

Key Programming Features ....................................................................................................................... 9

Technical Information ............................................................................................................................... 9

Display Information................................................................................................................................. 10

Special Features ...................................................................................................................................... 10

Helpful Information For Using the EMO-500 .......................................................................................... 10

Sample Size ......................................................................................................................................... 10

Gate Time ............................................................................................................................................ 10

Serial Port Programming ..................................................................................................................... 10

Hardware Connections ............................................................................................................................... 11

Grounding Considerations ...................................................................................................................... 11

Signal and Shielding ................................................................................................................................ 11

External Resets and Controls (Hardware) ............................................................................................... 12

External Resets and Controls (Definitions) ............................................................................................. 13

Reset All .............................................................................................................................................. 13

Scroll Display ....................................................................................................................................... 13

Reset Job B - resets OFF-RATIO WARNING/ALARM (LIMIT 1 and 2) ................................................... 13

Reset Job A - resets OFF-RATIO WARNING/ALARM (LIMIT 1 and 2) .................................................. 13

1

Page 3

EMO-500

Operation and Programming Manual

Enable Full Programming .................................................................................................................... 13

Quick Programming .................................................................................................................................... 14

Activation ................................................................................................................................................ 14

Keys and Values ...................................................................................................................................... 16

F1 Ratio (Default Value = 1.00) ........................................................................................................... 16

F2 Gate Time (Default Value = 1.85) ................................................................................................... 16

F3 Warning (Default Value = 5%) ........................................................................................................ 16

F4 Alarm (Default Value = 10%) .......................................................................................................... 16

F5 DP (Decimal Point) ......................................................................................................................... 16

F6 Enter ............................................................................................................................................... 16

#0 Sample Size (Default = 200) ........................................................................................................... 16

#1 SG (Specific Gravity [Default = 1.0]) ............................................................................................... 16

Full Programming ........................................................................................................................................ 17

Enable ..................................................................................................................................................... 17

F1 ............................................................................................................................................................. 18

F2 ............................................................................................................................................................. 18

F3 ............................................................................................................................................................. 18

F4 ............................................................................................................................................................. 19

Off-Ration Warning and Alarm Settings ............................................................................................. 19

Adjust Limits 3 and 4 ........................................................................................................................... 20

F5 ............................................................................................................................................................. 22

F6 ............................................................................................................................................................. 24

Explanation of Global Variables .............................................................................................................. 24

1. KFR for A (Default 100.0) ............................................................................................................ 24

2. FT for A (Default 10000) .............................................................................................................. 25

3. KFR for B ...................................................................................................................................... 26

4. KFT for B ...................................................................................................................................... 26

5. Units for Rate. ............................................................................................................................. 26

6. Units for Total. ............................................................................................................................ 27

7. Sample Size (Default 200) ........................................................................................................... 27

2

Page 4

EMO-500

Operation and Programming Manual

8. Gate Time (Default 1.85 sec.) ..................................................................................................... 27

9. Analog Offset (Default 0000) ...................................................................................................... 28

10. Analog Gain (Default 10200) ................................................................................................... 28

11. Analog Rule (Default 06) ......................................................................................................... 29

12. Unit Number (Default 001) ..................................................................................................... 30

Default Values Throughout the EMO-500 .................................................................................................. 30

Ratio Programming ................................................................................................................................. 30

Limit Programming.................................................................................................................................. 30

Meters/Units Programming .................................................................................................................... 30

Global Variables ...................................................................................................................................... 30

Ratio Feedback Mode ................................................................................................................................. 31

Serial Port Operations ................................................................................................................................. 31

Protocol Format ...................................................................................................................................... 32

Checksum Calculation ............................................................................................................................. 33

Important Points for Serial Communication ........................................................................................... 34

Address Information ............................................................................................................................... 35

Appendixes .................................................................................................................................................. 39

Limited Warranty ........................................................................................................................................ 46

3

Page 5

EMO-500

Warning!

Caution

Notice

Caution

Operation and Programming Manual

Safety Definitions and Information

Do not attempt to install or use your AW Gear Meters product until you have read the safety

instructions in this section. Save this manual and keep it in an easily accessible place.

Warning means that failure to follow this safety statement may result in extensive product damage,

serious personal injury, or death.

Caution means that failure to follow this safety statement may result in minor or moderate personal

injury, property or equipment damage.

Notice is a statement that informs about installation, operation, maintenance, performance issues, or

general tips that are important but do not create a hazard or safety concern.

Unpacking

Separate the EMO-500 from packaging materials and check for any visual signs of damage. If you

determine there has been damage caused by shipping, file a claim with the shipping company. If the

flow monitor appears to have been improperly assembled or does not operate properly, return it for

replacement or repair (see Limited Warranty information at the end of this manual).

Before connecting, programming, or operating the EMO-500, read this manual.

4

Page 6

EMO-500

Caution

Notice

Notice

Operation and Programming Manual

Quick Start Guide

As with any precision-engineered device, always operate the EMO-500 in accordance with the

manufacturer’s instructions.

Connect to Flow Transmitters

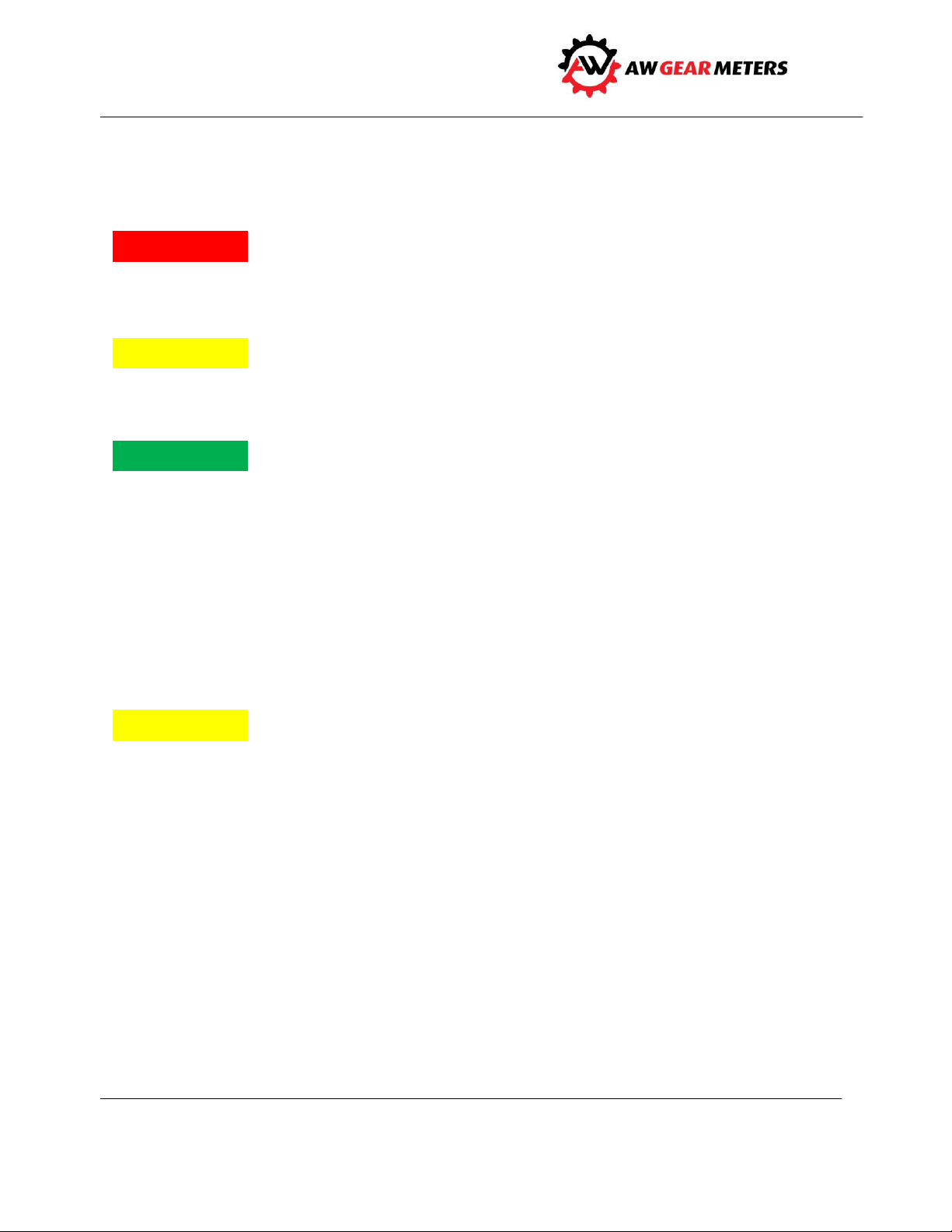

You will connect three wires from each of the two sensors to the back of the EMO-500 (see samples next

page):

Insert the two red wires (electrical power) to the two +18 volt terminals

Insert the two white (signal) wires to the input terminals

Insert the two black (ground) wires to the ground terminals

Use a screwdriver to secure.

Color of wires may vary.

Connect the higher flow side to flow meter A as the Ratio calculation is A/B.

5

Page 7

EMO-500

Operation and Programming Manual

Figure 1: Sample pickup connections

6

Page 8

EMO-500

Warning!

Operation and Programming Manual

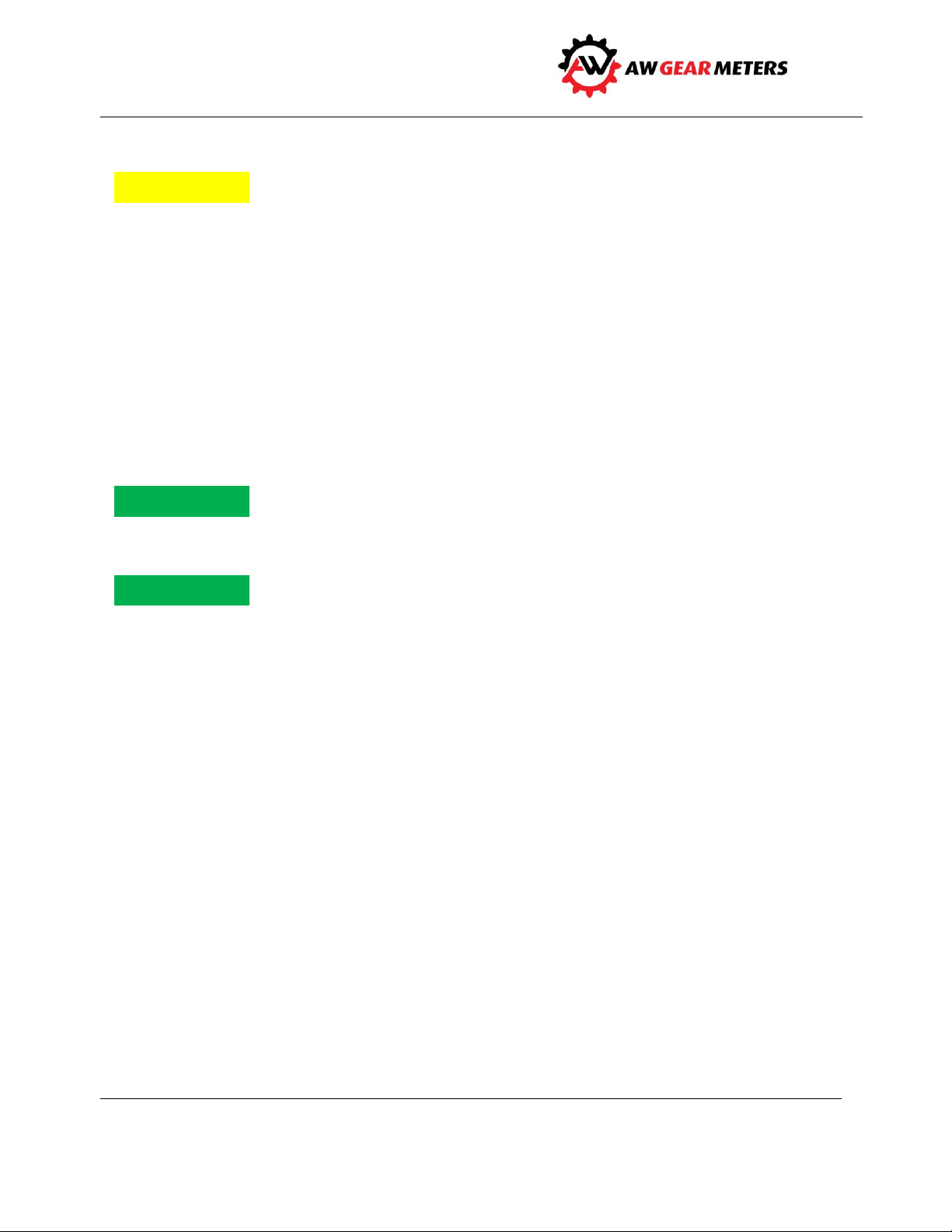

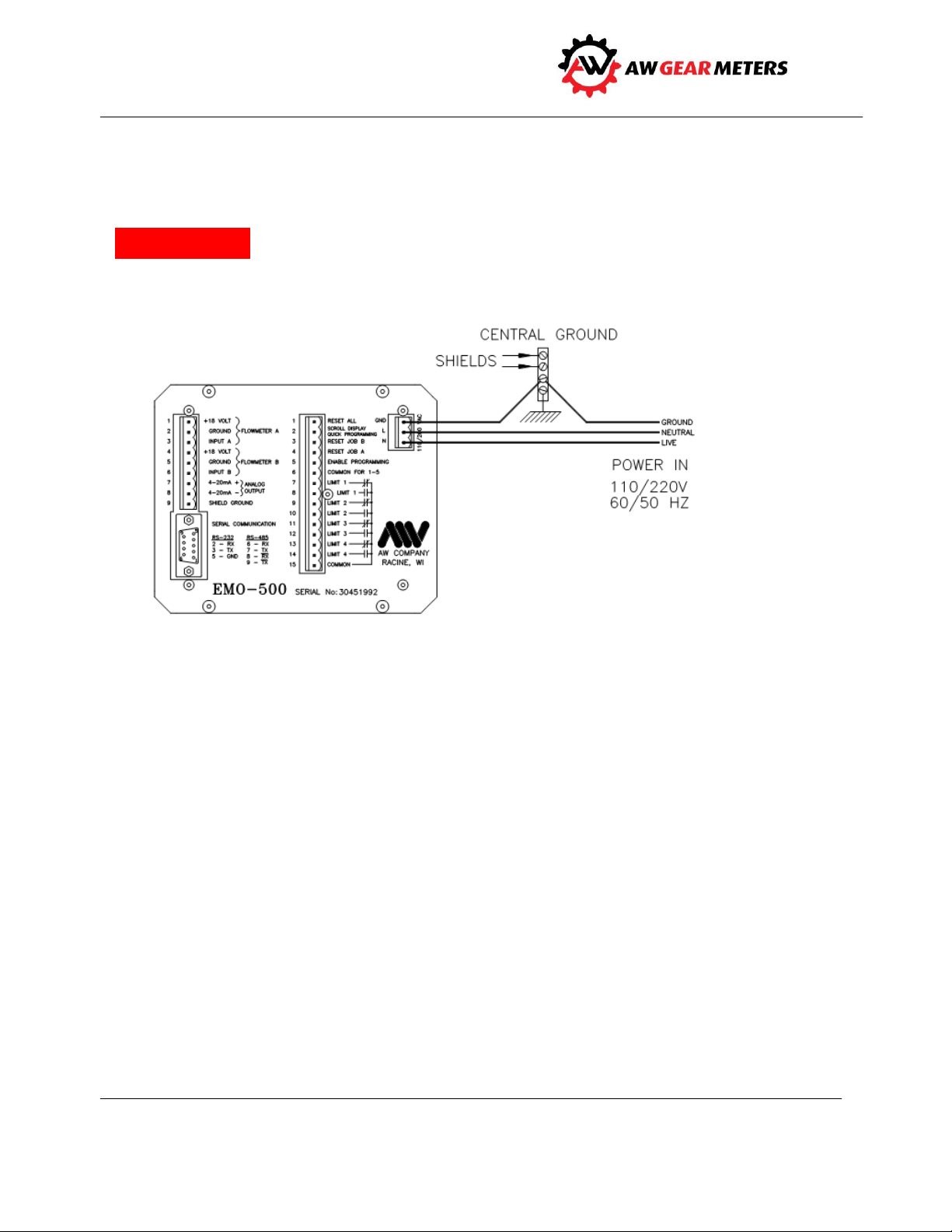

Connect Unit to Power

Before connecting to power source, connect ground, neutral and live wires to terminals on back of the

EMO-500 (see diagram below). See shielding information on page 11.

Connect wires to back of unit before applying power and wire the unit only as described on label on back

of unit.

Figure 2: Connections to power

7

Page 9

EMO-500

0-KEY = = =>

RATIOA/B = 1.19

W=Y A=N I = 1.00

= = => Current Ratio A/B

= = => Warning, Alarm, Ideal Ratio

1-KEY = = =>

FLW A=139.3 CCM

FLW B=136.3 CCM

= = = > Flow A

= = = > Flow B

2-KEY = = =>

JOB A=10779. CC

JOB B=11703. CC

= = = > Job Total A

= = = > Job Total B

3-KEY = = =>

GR A=300912. CC

GR B=313391. CC

= = = > Grand Total A

= = = > Grand Total B

4-KEY = = =>

J A+B 614303. CC

G A+B 623476. CC

= = = > Job Total (A+B)

= = = > Grand Total (A+B)

5-KEY = = =>

CURRENT RATIO LI

WAR=005% ALA=010%

= = = > Ratio Warning/Alarm Settings *

6-KEY = = =>

SD1: AO=0000

IN=11111OUT=0000

= = = > Analog Out, 0-4095 = 0-20mA

= = = > Inputs pins 1-5, Limits Out

7-KEY = = =>

SD2:FA=139FB=136

TA=10779TB=11793

= = = > Frequency A, B .....(Hz)

= = = > Total Impulses A, B

8-KEY = = =>

RATIO A/B=1.19

FL A+B 275.6 CCM

= = = > Current Ratio A/B

= = = > Flow Rate (A+B)

9-KEY = = =>

L1 L2 L3 L4

OFF OFF ON ON

= = = > Limit Status

F1-KEY ===>

T A-B= 24321. CC

F A-B= 15.4CCM

= = = > Total Differences

= = = > Flow Differences

*

Operation and Programming Manual

Overview of Display Screens

The 0 through 9, and F1 keys display these screens except when programming.

A no Ratio Mode when Limit 2 Rule is not on Ratio

8

Page 10

EMO-500

Operation and Programming Manual

Product Description

For use in steady or pulsing streams, the EMO-500’s primary purpose is to monitor the flow rates of two

flow meters, measuring flow rates, comparing totals, and verifying the ratio of flow A to flow B. You can

also wire an alarm to the EMO-500 so it can alert you to fluctuations from normal.

The unit comes from the factory with default values already programmed. However, if programming

parameters require change, you can input data from the front keypad; you can also do this from a

computer.

You can “Quick Program” the EMO-500, or take advantage of the Full Programming option. Program

keys are in red on the unit’s keyboard (some keys have a dual function). You can also program the EMO-

500 through the unit’s serial port. As a security measure, you can block access to programming when in

the Full and Serial Port programming modes.

Features

Seven different totalizers for record keeping and reports

Nine programmable units of measure

Net consumption display

“Ready-to-Hardwire” function controls allow for remote resets, operation of displays, and

Quick/Full Programming

Four programmable relay switched limits for warnings, alarms, or automatic shut-down control

RS-232 and RS-485 serial ports

Analog outputs (4 - 20mA) and (0 - 5V)

Principle of Operation

After you connect two flow meters to the unit and power it up, the EMO-500 can begin monitoring flow,

totals, and ratios. Monitor data on-screen; fine tune and adjust programming parameters as needed.

Technical Data

Key Programming Features

Ideal Ratio: user-defined, compared to actual ratio

Gate Time: time-before-the-flow rate display updates

Sample Size: number of pulses counted before ratio updates

Limits: Ratio, Flow Rate and Total

Units of Measure: liter, cc, gal, oz, gr, kg, lb, rpm, Hz

Technical Information

Power Supply: input = 110 or 220 VAC; consumption = 4 watts

Communication: type = RS-232 and RS-485; protocol type similar to OPTO 323

9

Page 11

EMO-500

Operation and Programming Manual

Environmental: storage = -40°C to 85°C; operating = 0°C to 50°C; humidity = 10 to 90%, non-

condensing

Limits: 10 amp, 110 V dry contact relays

Display Information

Ratio (ideal): Flow Rate A, Job Total A, Grand total A

Ratio (actual): Flow Rate B, Job Total B, Grand Total B

Limit Settings: Flow Rate A+B, Job Total A+B, Grand Total A+B

Limit Status: Flow Rate A-B, Job Total A-B

Special Features

The EMO-500 is geared toward applications where the main interest is the ratio of components

dispensed over a period of time, for example in a batch, rather than monitoring on an instantaneous

basis. The unit is especially suited for use in dispensing systems with irregular flow patterns. The EMO500 features a programmable sampling size, which governs how often the ratio display updates and

provides maximum control over the sampling period. The EMO-500 is easy to adjust to suit system

parameters.

Helpful Information For Using the EMO-500

Sample Size

This is the number of impulses collected for the ratio calculation. To determine the ratio, the EMO-500

separately counts the total number of pulses from both flowmeters until the fastest one reaches the

SAMPLE SIZE. The EMO-500 divides the number of pulses flowmeter A produces by flowmeter B’s

pulses, and the result is the ratio. The accuracy and response time of the ratio calculation is therefore

dependent upon the SAMPLE SIZE. The flowmeter with the lowest pulse rate should produce 100 pulses

before the ratio calculation updates to achieve a 1% accuracy. Default value is 200. The display screen

#7 is a useful guide for this purpose.

Gate Time

This is the time period over which the EMO-500 makes Rate Calculations. The gate time (in seconds) is

the time period during which the microprocessor collects pulses to perform rate calculations. Default

value is 1.85.

Serial Port Programming

You can program the EMO-500 through the serial port using RS-232- or RS-485-type communication.

Refer to the Serial Port Operations on page 31 for complete information.

10

Page 12

EMO-500

Warning!

Operation and Programming Manual

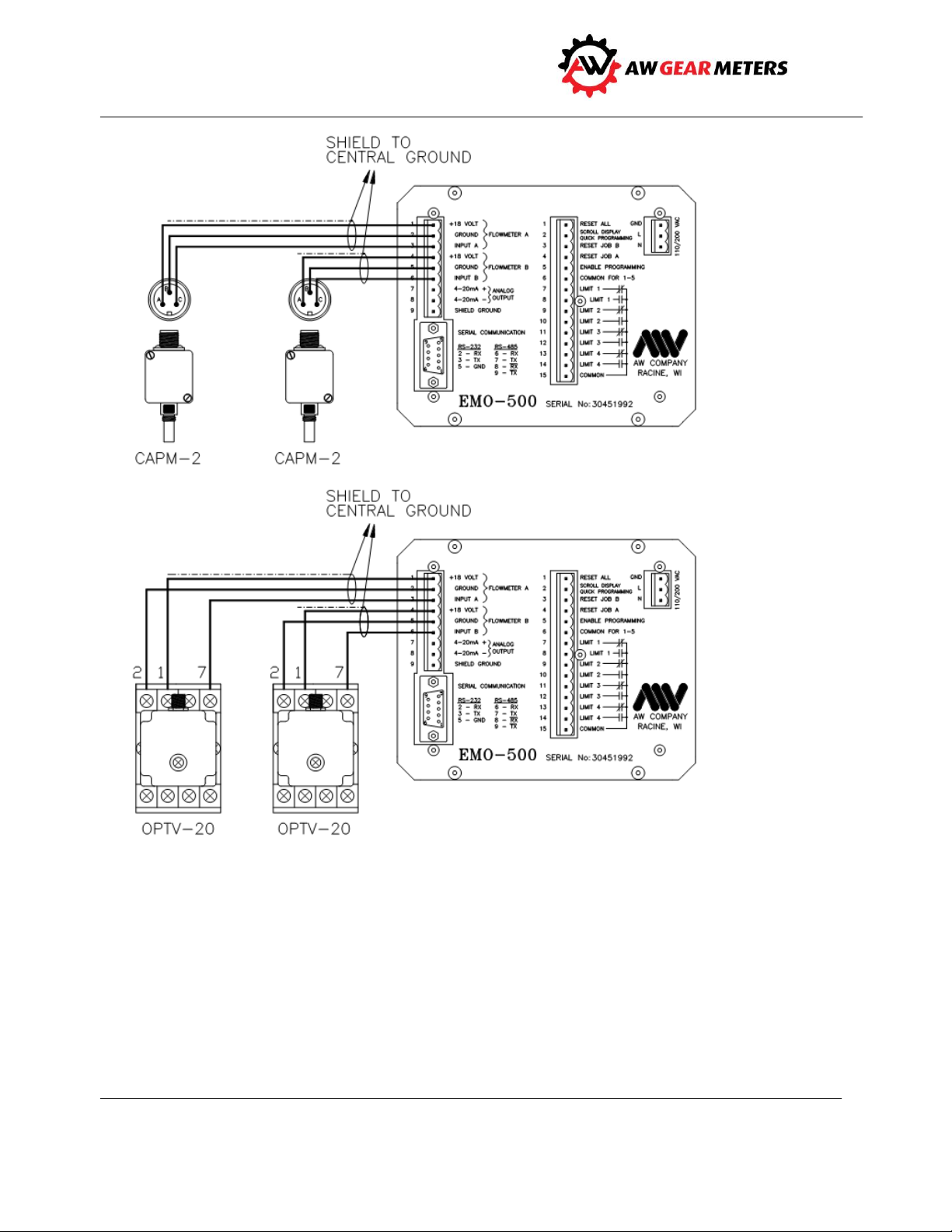

Hardware Connections

Before connecting to power source, connect ground, neutral and live wires to terminals on back of the

EMO-500: PIN 1= ground, PIN 2 = line 110 or 220 V, and PIN 3 = line neutral (see Figure 3).

Wire the AC power only as labeled on the three pin connector.

Figure 3: Connections to power

Grounding Considerations

The grounding is a most important consideration in an installation where microprocessor technology is

applied. The EMO-500 is a panel-mounted unit where the casing connects to a sub-panel. If the

sub-panel is metal, it should be grounded. If the sub-panel is made of non-conductive material, PIN 1 of

the three-pin connector on the EMO-500 back panel must be grounded. To insure a proper ground, the

factory recommends connecting PIN 1 of the three-pin connector to the panel's central ground point.

Signal and Shielding

The two flow meter pickups should be supplied with their respective 18-volt supply voltages and

referenced to their respective grounds. This insures the input signals from the flow meters are

referenced to the ground connections on pins 2 and 5. Most applications require some signal shielding;

a solid-aluminum wrap shielding works well. Connect the shield to pins 2 and 5 on the flow meter

connector. DO NOT connect the shielding at the flow transmitter.

11

Page 13

EMO-500

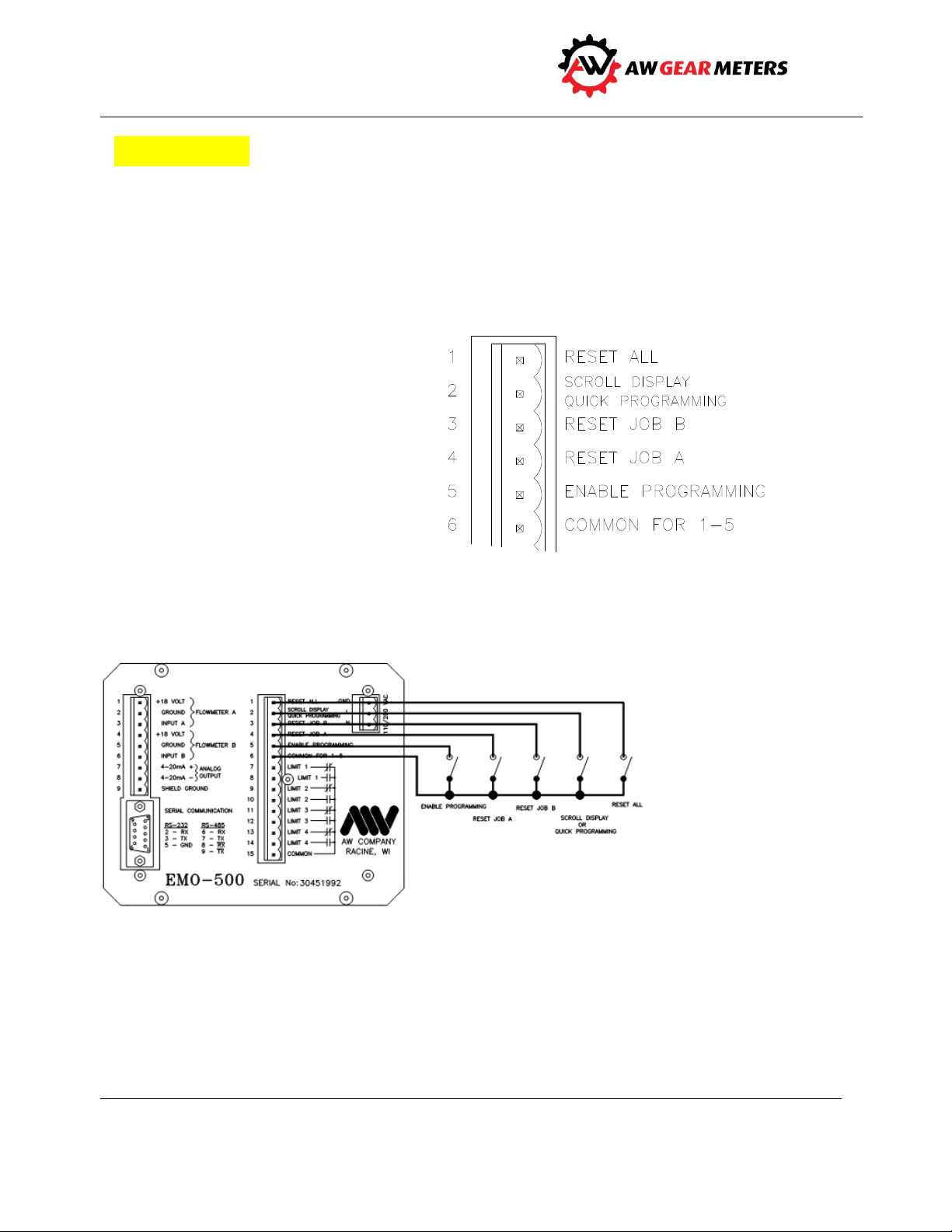

Figure 4: Connecting five inputs to common

Caution

Figure 5: Pin 1-4 and Pin 5 connections

Operation and Programming Manual

Never connect the shield to ground at both ends. Doing so can produce unwanted oscillations in the

signal wires.

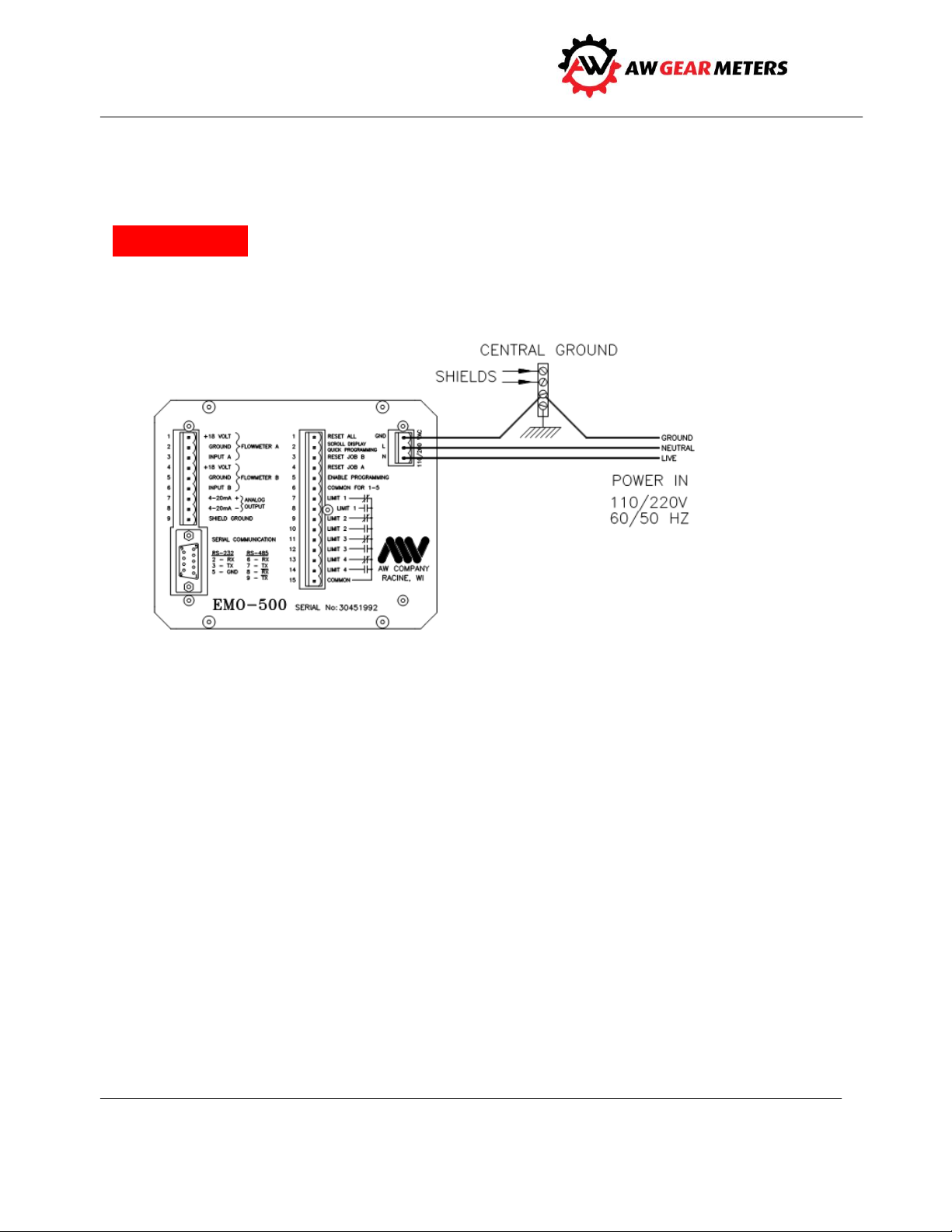

External Resets and Controls (Hardware)

Five inputs to the 15-pin connector help provide extra control without having to go through the

keyboard. To activate the external resets and controls, connect the respective pin to the “Common for 1

– 5” pin. See Figure 4.

Pins 1 - 4 are edge-triggered; use

momentary contact switches to activate

them. Pin 5 (enable programming) is an

on/off function; use a single-pole toggle

switch for it. See Figure 5.

12

Page 14

EMO-500

Notice

Notice

Operation and Programming Manual

External Resets and Controls (Definitions)

Reset All

This reset is the most powerful on the EMO-500. It resets:

Ratio A/B

Job Vol A, Job Vol B and Job Vol A+B

Warning and Alarm Limits

Limits 3 and 4

Grand Totals

Analog Outputs to start point

Scroll Display

This input scrolls through all of the 11 screens available. It also allows access to the Quick Programming

functions, which are highlighted in red on the upper keypad line. (See page 14 for more details on Quick

Programming).

Reset Job B - resets OFF-RATIO WARNING/ALARM (LIMIT 1 and 2)

This input resets the Job B totalizer. It also resets the A/B RATIO to the IDEAL setting, which

simultaneously resets the WARNING and ALARM LIMITS.

Reset Job A - resets OFF-RATIO WARNING/ALARM (LIMIT 1 and 2)

This resets the Job A total. It also resets the A/B RATIO to the IDEAL setting, which simultaneously resets

the WARNING and ALARM LIMITS.

Simultaneously pressing and holding RESET JOB A and RESET JOB B on the keyboard, or through the

back-panel connections, actuates HOLD TOTAL.

Enable Full Programming

Enables the F2 through F6 keys to perform the programming functions shown in red on the banner strip

above the keypad.

F3, F4, and F5 serve as Job Resets in the Job Totals screen when the Enable Programming switch is OFF.

13

Page 15

EMO-500

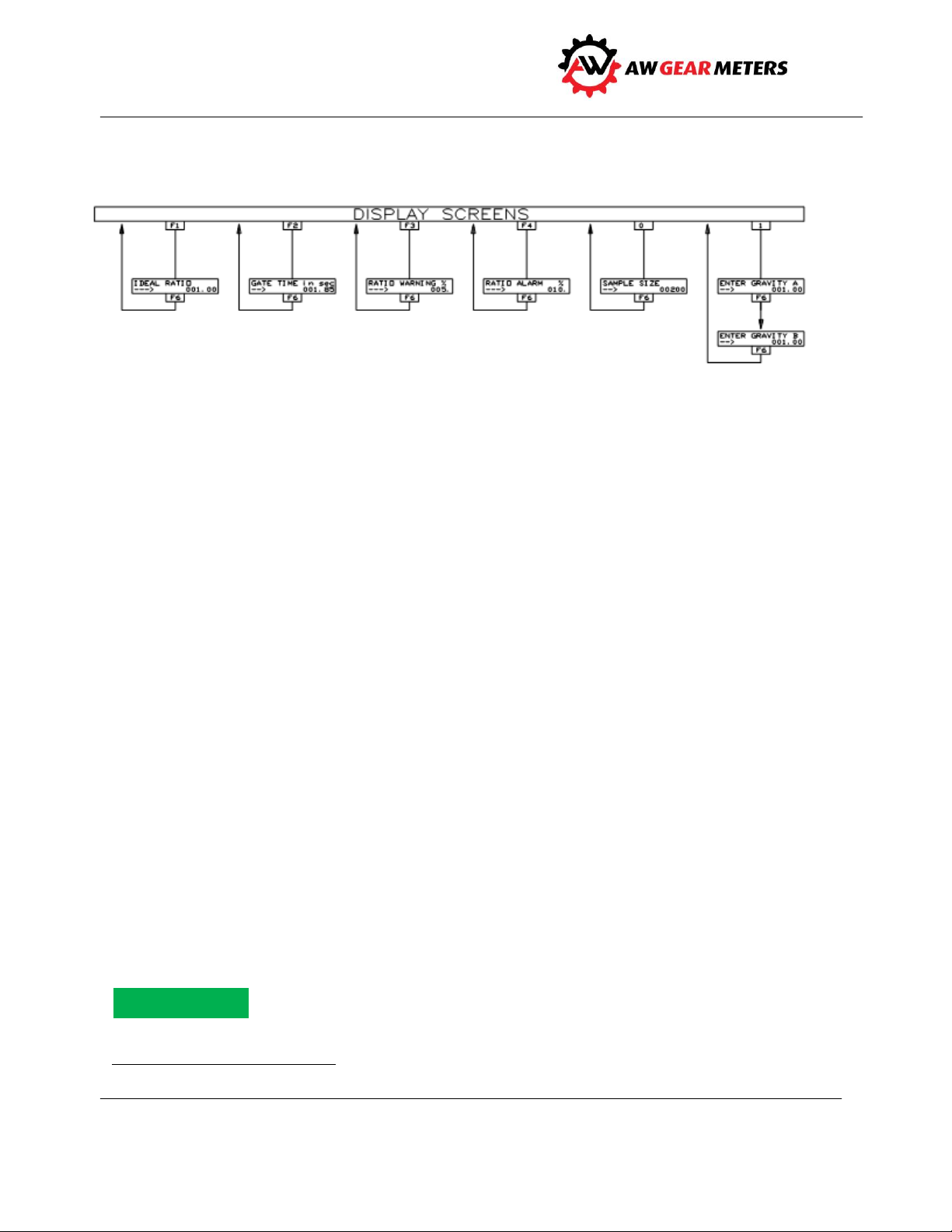

Figure 6: Quick Programming Display Screens

†

Notice

Operation and Programming Manual

Quick Programming

Many programming variables such as KFR† or meter selection only require a "one time" setting; other

variables require some experimentation to find maximum efficiency settings. It is also desirable to allow

field personnel the limited ability to make some quick adjustments.

To accommodate these circumstances the EMO-500’s "Quick Programming" option allows you to jump

directly into some limited programming functions. These functions are noted in red on the keypad on

the top line of function keys F1 through F6, and the 0 and 1 keys (also see Figure 6). The keys and their

functions are:

F1 = Ideal Ratio

F2= Gate Time

F3 = Ratio Warning %

F4 = Ratio Alarm %

F5 = Decimal Point

F6 = Enter

0 = Sample Size

1 = Specific Gravity

Activation

To activate Quick Programming, connect the Scroll Line Input (Pin 2) and the “Common 1 – 5” (Pin 6) of

the 15-Pin connector on the back panel of the EMO-500 with a momentary contact switch. With this

connection established, push any one of the above keys.

This does not work if full programming is enabled.

A rate scaling factor.

14

Page 16

EMO-500

Operation and Programming Manual

Figure 7: Sample Connections, Inputs and Outputs

15

Page 17

EMO-500

Operation and Programming Manual

Keys and Values

F1 Ratio (Default Value = 1.00)

This function is the address of the IDEAL RATIO, which represents the desired ratio of FLOW A/FLOW B.

The default is 1.00, which represents a 1 to 1 ratio.

F2 Gate Time (Default Value = 1.85)

The GATE TIME is the period of time, in seconds, during which the EMO-500 calculates the flow rate. The

accuracy and response time of the flow rate display is therefore dependent upon this value. To achieve a

1% accuracy, the slowest pulse rate should deliver at least 100 pulses.

F3 Warning (Default Value = 5%)

The WARNING variable is set as a percent deviation from the Ideal Ratio. The first meter to deliver the

number of pulses programmed as the SAMPLE AMOUNT triggers the ratio calculation. The calculation

compares the measured ratio to the Ideal Ratio; if the difference in percent exceeds the programmed

value, the warning activates.

F4 Alarm (Default Value = 10%)

Similar to the above Warning variable.

F5 DP (Decimal Point)

Use this key to locate the decimal point when programming the EMO-500.

F6 Enter

Use this key to lock in programmed values.

#0 Sample Size (Default = 200)

To determine the ratio, the EMO-500 separately counts the total number of pulses from both

flowmeters until the fastest one reaches the SAMPLE SIZE. The EMO-500 divides the number of pulses

flowmeter A produces by flowmeter B’s pulses, and the result is the ratio. The accuracy and response

time of the ratio calculation is therefore dependent upon the SAMPLE SIZE. The flowmeter with the

lowest pulse rate should produce 100 pulses before the ratio calculation updates to achieve a 1%

accuracy. The display screen #7 is an useful guide for this purpose.

#1 SG (Specific Gravity [Default = 1.0])

If needed, enter specific gravity values for each metered flow.

16

Page 18

EMO-500

ESCAPE

ACCESS

RATIO

LIMITS

METERS

GLOBALS

PROGRAMMING

Notice

Notice

Operation and Programming Manual

Full Programming

The three methods of programming the unit are:

Quick Programming

Full Programming, and

Serial Programming

You can change all of the default program variables to alternative values through the keypad or by a

host computer with an RS-232 serial port.

For information about Quick Programming, go to page 14. For information about Serial Programming, go

to page 31. See below for Full Programming instructions.

Full and Serial Programming have lockout features to prevent unauthorized access.

Enable

Quick Programming functions allocated to certain keys are in red on the keypad. Keys F1 through F6

have multiple functions and are also used for Full Programming. A banner on the keypad immediately

above specific keys indicates the alternative function each key has in the Full Programming Mode.

When full programming is not enabled, F3/F4/F5 serve as Job Resets, and you can use keys 0 through 9

to select from the 11 operating displays shown on page 8. IMPORTANT: The higher flow side should be

connected to flow meter A as the Ratio calculation is A/B.

To access the Full Programming menu, place a jumper between pin 5 (enable programming) and pin 6

(common). Use the F2 key to page through the menu of programming options, which are indicated in

red lettering on a banner above the upper function keys (representation below).

As a security measure, access is denied to F3, F4, and F5 until you press F2 first.

Reminder: Quick Programming activates the functions indicated in red on the F1 - F6 and 0 - 1 keys. See

page 14.

After jumpering pin 5 to pin 6, the access sequence is:

17

Page 19

EMO-500

MAIN MENU

F2

OPTIONS

Enable Prog --> F2

-->

-->

-->

-->

F3

F4

F5

F6

(Access to Ratio Prog)

(Access to Limit Prog)

(Access to Meter/Units)

(Access to Global Prog)

Operation and Programming Manual

F3 F4 F5 F6

RATIO PRG. LIMIT PRG. METER/UNIT PRG. GLOBALS PRG.

F1

Serves as an ESCAPE key to leave the programming functions and return to the last screen displayed.

F2

Pages you through the programming options above AND IS REQUIRED TO ALLOW FURTHER ACCESS.

F3

Ratio programming (see below):

18

Page 20

EMO-500

Notice

Operation and Programming Manual

Enter the Ideal Ratio. This number

represents the desired Ratio of Flow

Amount A to Flow Amount B. The

default is 1.00, meaning a 1 to 1 ratio.

Enter the Ratio Warning. This number

represents the percentage of error

between the actual measured ratio

and the desired ideal ratio. The default

is 5%; therefore, if the actual and

measured ratio differ by more than

5%, the Limit 1 relay closes.

Enter the Ratio Alarm. This number

works the same as Ratio Warning

except that after the warning, the

EMO-500 waits for one more sample

amount before closing the Limit 2

Relay if the ratio error is greater than

the programmed percentage. Default

is 10%.

F4

Limit programming.

Off-Ration Warning and Alarm Settings

Since the EMO-500 is primarily a Ratio Monitor, Limits 1 and 2 are factory-set, which an “off” condition

triggers.

Default values are:

Limit 1 = Warning 5%

Limit 2 = Alarm 10%

For example, if you program the RATIO WARNING at +/- 10%, the LIMIT 1 contact closes when this event

occurs. The programmed value similarly activates LIMIT 2 in the RATIO ALARM.

Press key #5 to review the current ratio alarm settings and key #9 to review the limit status. Press either

F3 (Reset A) or F4 (Reset B) to reset off-ratio alarms.

19

Page 21

EMO-500

Operation and Programming Manual

As mentioned previously, Limits 1 and 2 are preset for ratio alarms, which you can easily adjust for

different ratio settings via Quick Programming.

Adjust Limits 3 and 4

Limits 3 and 4 are used to warn of other monitored parameters such as flow rates or totalized fluid

volumes. Adjust these settings as follows:

Three parts make up the Limit Programming section; do each part in order:

1. Limit 3 Rule and value

2. Limit 4 Rule and value

3. Limit 2 Rule and/or value

20

Page 22

EMO-500

Notice

Notice

Operation and Programming Manual

This procedure is also shown pictorially on the previous page.

1. Enter the “Limit 3 Rule.” This means you must select the function to trigger the Limit 3 relay.

Options are:

Job Total for A

Job Total for B

Job Total for A+B

Flow A

Flow B

Flow A+B

Press F4 to page through the options; press F6 to enter your selection.

The display flashes “DP Location Will Match KFT/KFR.” This means the number you entered for the Limit

trip point automatically takes the same decimal point location as the Total Scaling Factor (KFT) for Total

Limits, or Rate Scaling Factor (KFR) for Flow Rate Limits.

2. Type in the Limit 3 value; press F6 to enter (you must enter the Limit 3 number to proceed to

Limit 4).

3. Enter the Limit 4 Rule and number exactly as above (you must enter the Limit 4 number to

proceed to Limit 2).

4. Enter the Limit 2 Rule.

If you select Ratio A/B, the Limits 1 and 2 operate on the ratio percentage of error under F3 Ratio

Programming. Therefore, if you select Ratio A/B, limit programming is complete.

In another scenario, you can program Limit 1 and 2 for Warning and Alarm settings on Flow A, while you

can allocate Limit 3 and 4 to Warning and Alarm for Flow B or Flow A+B and Total B, respectively. In this

case, you can select Limits 3 and 4 independently but you cannot separate 1 and 2.

Other options are as follows (page using F4; enter, F6):

Ratio A/B

Job Total for A

Job Total for B

Job Total for A+B

Flow A

21

Page 23

EMO-500

Flow Meter

Approximate K-factor

ZHM01

160000 PPG

ZHM03

6600 PPG

HPM-15

32000 PPG

ZHM02

1.32000 PPG

ZHM04

1800 PPG

HPM-20

16000 PPG

ZHM02

16000 PPG

ZHM05

500 PPG

HPM-30

6600 PPG

Notice

Operation and Programming Manual

Flow B

Flow A+B

If you select any function other than Ratio A/B for the Limit 2 Rule, the EMO-500 still monitors the ratio

of flow A/B, but no Warning or Alarm trips when flow is out of the error percentages. Display 5 indicates

“NO RATIO MODE FOR LIMITS 1 & 2.”

F5

In the Meters/Units programming section, you select from nine Flow Meters and three Engineering

Units. Scroll through the Meters until the selection desired appears on the display and enter your

selection with the F6 key. The EMO-500 automatically enters the Rate Scaling Factors (KFR) and Total

Scaling Factors (KFT) for each of the selections below.

The unit then asks you to select the Engineering Units in the same manner. Choose from:

CC & CCPM

GAL & GPM

OZ & OZM

The EMO-500 flashes “Direct Selection, Meter A or B” and the display reads “F2=A, F3=B, F4=A&B.” This

is where you choose the Flow Meter and set the Engineering Unit. The display reads “More Selections?,

F2=Yes, F3=No.” If both Flow Meters are programmed, select F3; if not, press F2 to start the

Meters/Units Program section again.

22

Page 24

EMO-500

Notice

Notice

Operation and Programming Manual

The Engineering Units for A and B should be the same.

The KFR and KFT values in Meters/Units Programming are only approximations because the K-factors of

the above flow meters are only approximations. Calculate the (KFR) and (KFT) using the calibrated

K-factor whenever possible. See the Global Programming section on page 24.

23

Page 25

EMO-500

Global Default Values

1.

KFR for A

-----------

100.0

2.

KFT for A

-----------

10000

3.

KFR for B

-----------

100.0

4.

KFT for B

-----------

10000

5.

Units for Rate

-----------

12 Hz

6.

Units for Total

-----------

08 impulses

7.

Sample Size

-----------

200 impulses

8.

Gate Time

-----------

1.85 seconds

9.

Analog Offset

-----------

0000

10.

Analog Gain

-----------

10200

11.

Analog Rule

-----------

06 Ratio

12.

Unit Number

-----------

01

Operation and Programming Manual

F6

The F6 key calls up Global Programming.

Explanation of Global Variables

1. KFR for A (Default 100.0)

In order to display the correct rate in an engineering unit such

as GPM, the EMO-500 must calculate a scaling factor. This Rate

Scaling Factor is called the KFR. The EMO-500 uses the K-factor

of the flow transmitter being monitored to calculate the KFR.

The K-factor is the number of impulses per engineering unit

established by a calibration test.

For example, a flow meter could have a K-factor of 6304

imp/Gal. To calculate the KFR multiplier for the EMO-500, apply

the following formula:

24

Page 26

EMO-500

Notice

Notice

KFT =

KFR =

100 is the constant for seconds

6000 is the constant for minutes

360000 is the constant for hours

= 2.921 GPM

KFR =

Operation and Programming Manual

6000

K -factor

Enter this KFR number in the Global Programming section. The K-factor is the number the manufacturer

provides as the average K-factor for the transmitter.

For example, a flow meter has the K-factor 2053.7 imp/GAL and the display should show

Gallons/minute.

6000

2053.7

Enter 2921 as the KFR; use the DP (decimal point) key to move the DP to the number 2.921.

Calculator mathematics produce insignificant decimal numbers for our purposes. These produce a

misleading level of precision in the display. The factory recommends using a maximum of four digits

regardless of the decimal point position.

Example:

for 60.675, enter 60.67

for 2.3456, enter 2.346

The largest number you can enter as a KFR is 65000, ignoring the decimal point position. A message

alerts you if the number you enter is too large.

2. FT for A (Default 10000)

In order to make the EMO-500 display the correct Totalized Value in Engineering Units, again the most

important thing to know is the K-factor of the flow meter. The K-factor is the relationship between the

amount of the impulses and the engineering units.

To calculate the KFT, apply the following formula:

K-factor

10000

25

Page 27

EMO-500

KFT =

= .9376 Gal

Notice

Notice

Operation and Programming Manual

Enter the KFT in the Global Programming section. The K-factor is the number manufacturer provides as

the average K-factor for the transmitter. If this is in imp/Gal, set the totalizer in, say cc’s , by converting

the K-factor to imp/cc. 10000 is a constant.

For example, a flow meter has a K-factor of 106666.0 imp/Gal and the display should show

gallons/minute:

10000

10666.0

Enter 9376 as the KFT and move the DP to 0.937. (See note below).

Calculator mathematics produce insignificant decimal numbers for our purposes. These produce a

misleading level of precision in the display. The factory recommends using a maximum of four digits

regardless of the decimal point position. For example, for 60.675, enter 60.6; for 2.34543, enter 2.345

The largest number you can enter as a KFT is 65000. Refer to KFR note above.

3. KFR for B

The same as KFR for A.

4. KFT for B

The same as KFT for A.

5. Units for Rate.

This variable displays the Engineering Units required for the flow rate display. It is strictly a display and

does not perform the actual conversion of raw counted impulses; the KFR handles those calculations.

Enter the two-digit number for the desired Units for Rate:

00 - cc/min 06 - gram/sec

01 - liter/min 07 - lb/min

02 - gallon/min 08 - Kg/min

03 - ounce/min 09 - Kg/sec

04 - RPM 10 - lb/sec

05 - gram/min 11 - lb/Hr

12 - Hz (impulses/sec)

26

Page 28

EMO-500

Notice

Operation and Programming Manual

6. Units for Total.

This variable determines the Engineering Units for Total displayed after the totalizer value. It too is a

“display only” function and does not perform the actual conversion of total impulses to the correct

value. The KFT handles those calculations.

Enter the two-digit number for the desired Units for Total:

00 - cc 04 - revolution

01 - liter 05 - gram

02 - gallon 06 - lb

03 - ounce 07 - kg

08 - impulses

7. Sample Size (Default 200)

To determine the ratio, the EMO-500 separately counts the total number of pulses from both flow

meters until one of them reaches the programmed Sample Size. The number of pulses from flow meter

A is then divided by the number of pulses received from flow meter B. The accuracy and response time

of the ratio calculation are therefore dependent on the Sample Size.

To determine a reasonable number to program for Sample Size, the main factor is the flow meter with

the lowest pulse rate, but with at least 100 pulses before the Ratio calculation. If 100 pulses are counted

on the slowest moving totalizer then the accuracy of the ratio calculation should be about 1%.

The pulses counted are straight from the flow meter, not scaled engineering unit values.

The display screen #7 (Status Display 2) is a useful guide in this selection. The lower line shows the

incoming raw pulse count. For example, if the Sample Amount is 1000, the ratio display updates each

time the fastest total increments by 1000. Also by this method, the slower pulse count can be observed.

Default value is 200.

8. Gate Time (Default 1.85 sec.)

The gate time (in seconds) is the amount of time pulses are accepted before the EMO-500 performs flow

rate calculations. The accuracy and response time of the flow rate display are dependent on the gate

time. To achieve a 1% flow rate accuracy, the lowest pulse rate should produce 100 pulses before the

device performs the rate calculation. In display #7 (Status Display 2), the lower line indicates incoming

flow meter impulses, an estimate of the time elapsed for 100 pulses, to be accumulated by the slowest

meter, which gives a good approximation of the minimum recommended gate time.

27

Page 29

EMO-500

Analog Ouput =

GAIN =

GAIN =

Operation and Programming Manual

Another method is to change the default Gate Time value by trial and error until achieving the best

results.

9. Analog Offset (Default 0000)

The Analog Output Offset is a number from 0000-4095 that becomes the bottom end of the 0 - 5 volt

and 4 - 20 mAmp analog outputs.

For example:

0000 for 0 to 20mAmps and 0 to 5v.

819 for 4 to 20mAmps and 1 to 5v.

1638 for 8 to 20mAmps and 2 to 5v.

2457 for 12 to 20mAmps and 3 to 5v.

10. Analog Gain (Default 10200)

The analog gain factor integrates the controller output range and speed with the rest of the system

capabilities. If the gain factor is correct, the full range of the analog output signal can be used to cover

the operating range of the equipment in which it is installed.

Use this formula to determine the analog output:

(Variable Value) X Gain

512

The Analog Output arrived at above should be a number from 0000-4095, which drives a D/A converter

for a 4 - 20 mAmp and a 0 - 5 volt output on Pins 7 and 8 of the 9 Pin connector. Therefore the gain

factor can be estimated by re-arranging the analog output equation as follows:

(512) (Analog Out)

Variable Value

If the desired maximum output of the system is achieved at 5V or 20 mAmp, this is equivalent to an

Analog Out value of 4095 and the above equation would read:

(512) (4095)

Variable Value

The “Variable Value” is the true flow rate or volume capability of the system measured at the analog

value discussed above and therefore depends upon the ANALOG RULE selected. The Analog Rule is

discussed further below.

28

Page 30

EMO-500

Notice

Notice

Operation and Programming Manual

The value you enter ignores the decimal point position.

For Example:

In Ratio Mode (06)

If Ideal Ratio = 5.00, variable value = 500

If Ideal Ratio = 10.00, variable value = 1000

In Flow Mode (00-02)

If Flow Rate = 80.0 cc/m, variable value = 800

If Flow Rate = 200.0 cc/m, variable value = 2000

If Flow Rate = 5.25 GPM, variable value = 525

In Flow Mode (03-05)

If Total Flow = 10.00 Gal, variable value = 1000

11. Analog Rule (Default 06)

The analog rule allows you to set the analog output to follow any of the variables listed below. Enter a

number as the Analog Rule.

00 - Flow A 06 - Ratio

01 - Flow B 07 - Ratio Feedback Mode

02 - Flow A+B 08 - Ratio w/Reset

03 - Total A 09 - Ratio Feedback w/Reset

04 - Total B 10 - A - B Job Total

05 - Total A+B 11 - A - B Flow Rate

These variables are used in the computations as numbers in Engineering Units (ccpm, gals, ozs., etc.).

This means that any Decimal Points are dropped. For example, 113.7ccpm is 1137 for computation

purposes.

29

Page 31

EMO-500

Operation and Programming Manual

12. Unit Number (Default 001)

This variable is used for Serial Communication with a host computer. It identifies each EMO-500 unit if

there is more than one on the communication line. Unit #1 is 01, unit #2 is 02, etc.

Default Values Throughout the EMO-500

Ratio Programming

Ideal Ratio = 1.00

Ratio Warning = 5%

Ratio Alarm = 10%

Limit Programming

Limit Rule 3 = Job Total A, value = 3000

Limit Rule 4 = Job Total A, value = 4000

Meters/Units Programming

Meter = Hz

Units = IMPULSES

Global Variables

KFR for A = 100.0

KFT for A = 10000

KFR for B = 100.0

KFT for B = 10000

Units Rate = 12

Units Total = 08

Sample Size = 200

Gate Time = 1.85

Analog Offset = 0000

Analog Gain = 10200

Analog Rule = 06

Unit Number = 01

30

Page 32

EMO-500

Notice

Warning!

Operation and Programming Manual

Ratio Feedback Mode

The Ratio Feedback Mode compares the Ideal Ratio and the Actual Measured Ratio. The EMO-500

generates a 4-20 mA signal to control one of the Flow Rates. This maintains the Ideal Ratio over a wide

range of flow rates. The formula used to determine the correct analog output is:

Analog Output = Half Range + (Ideal Ratio-Actual Ratio) X Gain

Half Range refers to the middle point of the Analog Output. If the output varies from 0 to 20mAmp., the

half point is 10mAmp. If the Analog Offset is set to give an output of 4 to 20mAmp., the Half Point is

12mAmp.

To use the Ratio Feedback Mode, enter 07 as the Analog Rule (see page 29).

The Ratio Feedback Mode w/Reset works in exactly the same manner except that the analog output goes

to the start point (mid-point) on Reset All.

Serial Port Operations

The EMO-500 has standard RS-232 and RS-485 serial port connections on the 9-pin back panel. You can

connect this port to a host computer and then Read or Write to any memory location in the EMO-500.

The RS-232 pins on the 9-pin connector are:

pin 3 (TX transmit)

pin 2 (RX receive)

pin 5 (Ground)

The RS-485 connections are:

pin 6 (RX)

pin 7 (TX)

pin 8 (RX)

pin 9 (TX)

The communications port does not discriminate addresses. This means that any address can be written

to as well as read from. Writing to certain addresses changes the operation of the EMO-500 drastically.

Caution is a must when programming through a host computer. Double check addresses and variables

before writing to the EMO-500.

31

Page 33

EMO-500

Notice

Notice

Operation and Programming Manual

Communication through the serial port does not work if the EMO-500 is in programming mode.

Protocol Format

The EMO-500 uses a protocol format that follows OPTO 22 Company’s OPTOMUX.

^ means “add one letter or digit”; ^^ means add two letters or digits, ^^^ means add three letters or

digits, etc.; “cr” means “carriage return.”

The format for reading from the EMO-500 is as follows:

>01K0F3404XXcr

^................start of string must use the > sign

^^.............unit number (under global variables)

^.............read command K (use J to write)

^^^^......address to read from

^^......number of bytes to read

^^....checksum for the string 01K0F3404

......carriage return (ASCII 13) ends the string

The answer received back from the EMO-500 looks like this:

A03E36712XXcr

^...............all answers start with A

^^............low byte (at address 0F34)

^^..........next byte(at address 0F35)

^^........next byte(at address 0F36)

^^......high byte(at address 0F37)

^^....checksum

......carriage return ends the string

The protocol format for writing to the EMO-500 is as follows:

32

Page 34

EMO-500

Operation and Programming Manual

>01J03340F3587XXcr

^.....................start of string must use the > sign

^^..................unit number

^..................write command J (use K to read)

^^^^...........address to write into

^^...........byte written to 0334

^^.........byte written to 0335

^^.......byte written to 0336

^^.....checksum

.....carriage return

If the operation was successful, the EMO-500 answers with: Acr.

The following error messages have been implemented in the EMO-500 protocol:

NO1cr - Undefined command (something other than K/J)

NO2cr - Checksum error

NO3cr - Non printable ASCII character

OPTO 22 has published a booklet on the protocol format.

Checksum Calculation

The calculation for the string variables in the read command would be as follows:

>01K0F3404XXcr

^^^^^^^^^.......these characters are used in the calculation.

Add the values for the ASCII Decimal variables.

HEX 0 + 1 + K + 0 + F + 3 + 4 + 0 + 4

ASCII 48 + 49 + 75 + 48 + 70 + 51 + 52 + 48 + 52 = 493

To calculate the final checksum, convert the decimal number 493 into HEX (493=1EDh) and take the last

two characters (ED) for the checksum. The final string would look like this:

>01K0F3404Edcr

33

Page 35

EMO-500

Operation and Programming Manual

Important Points for Serial Communication

1. Serial communication is disabled if the EMO-500 is in programming mode.

2. All characters in the communication string should be in CAPITALS.

Example: the EMO-500 recognizes K is ASCII 75, but it does not recognize k is ASCII 107.

3. All numbers in the communication string are represented in hexadecimal format.

4. Do not try to read or write more than 12 bytes at a time due to limitations of the EMO-500's

serial buffers.

5. The least significant byte of a number is stored at the lower address.

6. The > in the transmit string and the A in the reply string are not used in the checksum

calculation.

The ASCII characters needed for checksum calculations are:

ASCII Decimal ASCII Decimal

0 48 A 65

1 49 B 66

2 50 C 67

3 51 D 68

4 52 E 69

5 53 F 70

6 54

7 55

8 56 J 74

9 57 K 75

34

Page 36

EMO-500

Address = 05A0H

05A1H

05A2H

05A3H

Vaule = 90H

D5H

89H

01H

Warning!

Notice

Operation and Programming Manual

The communications port does not discriminate any addresses. This means that any address can be

written to as well as read from. Writing to certain addresses changes the operation of the EMO-500

drastically. Caution is a must! Double check addresses and variables before writing to the EMO-500.

The bytes are always arranged such that the low byte (LSB) is first and the more significant bytes (MSB)

follow. In the EMO-500, the least significant byte is at the lower address. For example, if the data from

the totalizer is read as:

90D58901

the LSB is 90 and the MSB is 01.

The arrangement of these four bytes in the EMO-500 memory is:

Interpret the totalizer value as:

0189D590H = 25,810,320 (in decimal)

Address Information

When writing to the EMO-500, there are always two locations to be changed for a permanent entry into

the memory. This is because there are locations for data running currently in the RAM and for data that

is battery-backed. If the information has been written to the running locations alone, it is lost when the

EMO-500 is turned off.

Below is a QBASIC program that allows you to communicate with the EMO-500 by initiating serial port

#1 and prompting for read and write strings. The strings must use the OPTO 22 protocol format

described on page 32.

35

Page 37

EMO-500

Warning!

Operation and Programming Manual

DEFINT A-Z

'* Serial Communication Test Program for OPTOMUX Code

'* For use with AW Company's EMO-Series Flow Computers

'* Open serial port #1 to 9600 baud

OPEN "COM1:9600,N,8,1,RS,CS,DS,CD" FOR RANDOM AS #1

'* set up loop for transmitting several strings

CLS

DO

PRINT "Enter String to send. (Press ENTER alone to END)"

INPUT "Transmitting String: >", Transm$

IF LEN(Transm$) = 0 THEN END

'* Calculate Chksum

Chk = 0

FOR Char = 1 TO LEN(Transm$)

Chk = Chk + ASC(MID$(Transm$, Char, 1))

NEXT

Chk$ = HEX$(Chk)

'* Must be 2 characters, 1 byte

IF LEN(Chk$) < 2 THEN Chk$ = "0" + Chk$

'* Add the recognition character plus checksum

'* use only the last byte of checksum

Transm$ = ">" + Transm$ + RIGHT$(Chk$, 2)

'* Send it to the EMO

PRINT #1, ; Transm$; CHR$(13);

'* Read what the EMO sending back

LINE INPUT #1, Receive$

PRINT "Received: "; Receive$

PRINT

LOOP

The communications port does not discriminate any addresses. This means that any address can be

written to as well as read from. Writing to certain addresses changes the operation of the EMO-500

drastically. Caution is a must! Double check addresses and variables before writing to the EMO-500.

36

Page 38

EMO-500

Running

Address in HEX

Back-up

Address in HEX

Bytes

Description

Default Value

05F5

0402

2

KFR A

1000

061A

0404

2

KFR A Decimal Pt.

01

0637

0412

2

KFR A Eng. Units

00

05FF

040A

2

KFT A

10000

061C

040C

2

KFT A Decimal Pt.

00

0639

0414

2

KFT A Eng. Units

00

05F7

0406

2

KFR B

1000

061E

0408

2

KFR B Decimal Pt.

01

063B

0416

2

KFR B Eng. Units

00

0601

040E

2

KFT B

10000

0620

0410

2

KFT B Decimal Pt.

00

063D

0418

2

KFT B Eng. Units

00

050A

042D

2

Limit 1 Value

1000

050C

042F

2

Limit 2 Value

2000

050E

0422

2

Limit 3 Value

3000

0510

0424

2

Limit 4 Value

4000

060B

042C

2

Limit 1 & 2 Rule

06

0604

0429

2

Limit 3 Rule

00

0605

042A

2

Limit 4 Rule

00

0614 (4)*

042 2 Ideal Ratio

100

0618

0420

2

Ratio Alarm

10

0622

041E

2

Ratio Warning

05

059D

0437

2

Analog Rule

06

05AA

0433

2

Analog Gain

102000

05B9

0431

2

Analog Offset

0000

0606

041A

2

Sample Size

200

053D**

041C

2

Gate Time

1.85

0626

042C

1

Unit Number

001

0516

read only

4

Flow A

xxxx

051A

read only

4

Flow B

xxxx

051E

read only

4

Flow A & B

xxxx

05B5

read only

4

Ratio A/B

xxxx

05A0†

read only

4

Job Total A (SD2)

xxxxxxxx

05A6††

read only

4

Job Total B (SD2)

xxxxxxxx

05EF

read only

4

Job Total A + B

xxxxxxxx

052E‡

read only

4

Grand Total A

xxxxxxxx

0533‡‡

read only

4

Grand Total B

xxxxxxxx

0504

read only

4

Grand Total A & B

xxxxxxxx

05A4

read only

2

Analog Out

xxx

Operation and Programming Manual

37

Page 39

EMO-500

Operation and Programming Manual

Special variables (see previous page) function in the following manner:

*Ideal Ratio – The largest number that can be written into the Ideal Ratio without an overflow is 640.

Variable at address 0426h is 3 bytes; at 0614h, 4 bytes.

**Gate Time – This variable is a converted number because the keypad entry is made in seconds and a

constant must be applied for computations. Therefore after reading the Gate Time, the number read

must be converted to decimal, then divided by 5388 for an answer in seconds.

†Job Total A (SD2) – This variable shows twice the amount read from the Job A display. This is because

the number is actually a raw count from the frequency input. The number read matches the totals seen

in the Status Display 2 screen.

†† Job Total B (SD2) – Same as above.

‡Grand Total A – This variable is not stored into the backup memory until Job Volume A is reset.

Therefore, the location reads zero until the count is stored away with the Reset Job A.

‡‡ Grand Total B – Same as above.

38

Page 40

EMO-500

Operation and Programming Manual

Appendixes

39

Page 41

EMO-500

Operation and Programming Manual

40

Page 42

EMO-500

Operation and Programming Manual

41

Page 43

EMO-500

Operation and Programming Manual

42

Page 44

EMO-500

Operation and Programming Manual

43

Page 45

EMO-500

Operation and Programming Manual

44

Page 46

EMO-500

Operation and Programming Manual

45

Page 47

EMO-500

AW Gear Meters warrants the product to be in good working order for a period of 1 (one) year

from the date of purchase from AW Gear Meters or an Authorized AW Gear Meters distributor.

Should the product fail to be good working order at any time during this 1-year warranty period,

AW Gear Meters will, at its option, repair or replace the product at no additional charge except as

set forth below. Repair parts and replacement products will be furnished on an exchange basis and

will be reconditioned or new. All replaced parts and products become the property of AW Gear

Meters. This limited warranty does not include service to repair damage to the product resulting

from accident, disaster, abuse, or a non AW Gear Meters modification to the product.

Limited Warranty service may be obtained by delivering the product during the 1-year warranty

period to AW Gear Meters and provide proof of purchase date. If this product is delivered by mail,

you agree to insure the product or assume the risk of loss or damage in transit, to prepay shipping

charges to warranty location and use the original shipping container or equivalent.

For further information contact:

ALL EXPRESS AND IMPLIED WARRANTIES FOR THIS PRODUCT INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO A

PERIOD OF 1 (ONE) YEAR FROM DATE OF PURCHASE, AND NO WARRANTIES, WHETHER EXPRESS

OR IMPLIED, WILL APPLY AFTER THIS PERIOD. SOME STATES DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO

YOU.

IF THIS PRODUCT IS NOT IN GOOD WORKING ORDER AS WARRANTED ABOVE, YOUR SOLE

REMEDY SHALL BE REPAIR OR REPLACEMENT AS PROVIDED ABOVE. IN NO EVENT WILL AW

COMPANY BE LIABLE TO YOU FOR ANY DAMAGES, INCLUDING ANY LOST PROFITS, LOST SAVINGS

OR INCIDENTAL OR CONSEQUENTIAL DAMAGE ARISING OUT OF THE USE OR INABILITY TO USE

SUCH PRODUCT, EVEN IF AW GEAR METERS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES, OR FOR ANY CLAIM BY ANY OTHER PARTY.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS,

WHICH MAY VARY FROM STATE TO STATE.

AW Gear Meters

8809 Industrial Drive

Franksville, WI 53126

Phone: (262) 884-9800

Fax: (262) 884-9810

Operation and Programming Manual

Limited Warranty

46

Page 48

8809 Industrial Drive

Franksville, WI 53126

800-850-6110

©2012 AW-Lake Company All rights reserved. Doc ID: EMO500MAN

www.awgearmeters.com

Loading...

Loading...