Page 1

E-M

http://www.aw

FLOW

TRANSMITTERS

Digital Servo Pressure Control Valve

I/P Converter

IInnssttaallllaattiioonn && OOppeerraattiioonn MMaannuuaall

Rev 1.6

ELECTRONICS

FOR

8809 Industrial Drive, Franksville, WI 53126-9337

8809 Industrial Drive, Franksville, WI 53126-9337

Tel: 262-884-9800 Fax: 262-884-9810

E-Mail: awinfo@aw-lake.com Web: http://www.awgearmeters.com

ail: aw@awcompany.com Web:

Tel: 262-884-9800 Fax: 262-884-9810

company.com

Page 2

Installation….…………………………………………… page 3

Dimensions……….................………………….. page 3

Electrical Connections……….................………………. page 3

Connection for Voltage Control Input…...……... page 3

DSV-100 Start-Up……...……………….....…..……….. page 4

Setpoint……………..................………………… page 4

DSV-100 Input/Output Options…………………..…….. page 4

Response Test………………....................……… page 5

Manual Mode Operation………..………….……………. page 6

Digital Servo Pressure Control Valve

Model DSV-100

Installation and Operation Manual

Introduction / Features…..………..…………………….. page 2

Specifications…..………..………………….………….. page 2

Connection for Current Control Input ……..…... page 3

DSV-100 Display Modes.……………….....…..……….. page 4

Actual Pressure…………………............………. page 4

Difference………………………............………. page 4

Input Range Options …………...........…………. page 4

Output Range Options …………...........……….. page 4

Programming/Diagnostic Mode.…………….………….. page 5

View/Edit Input Option …………...........………. page 5

View/Edit Output Option …………...........…….. page 5

Leak Test……………………....................……… page 6

Limited Warranty Statement.............…………………… page 7

1

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 1.6 03/10 DSV-100 Manual.DOC

Page 3

2

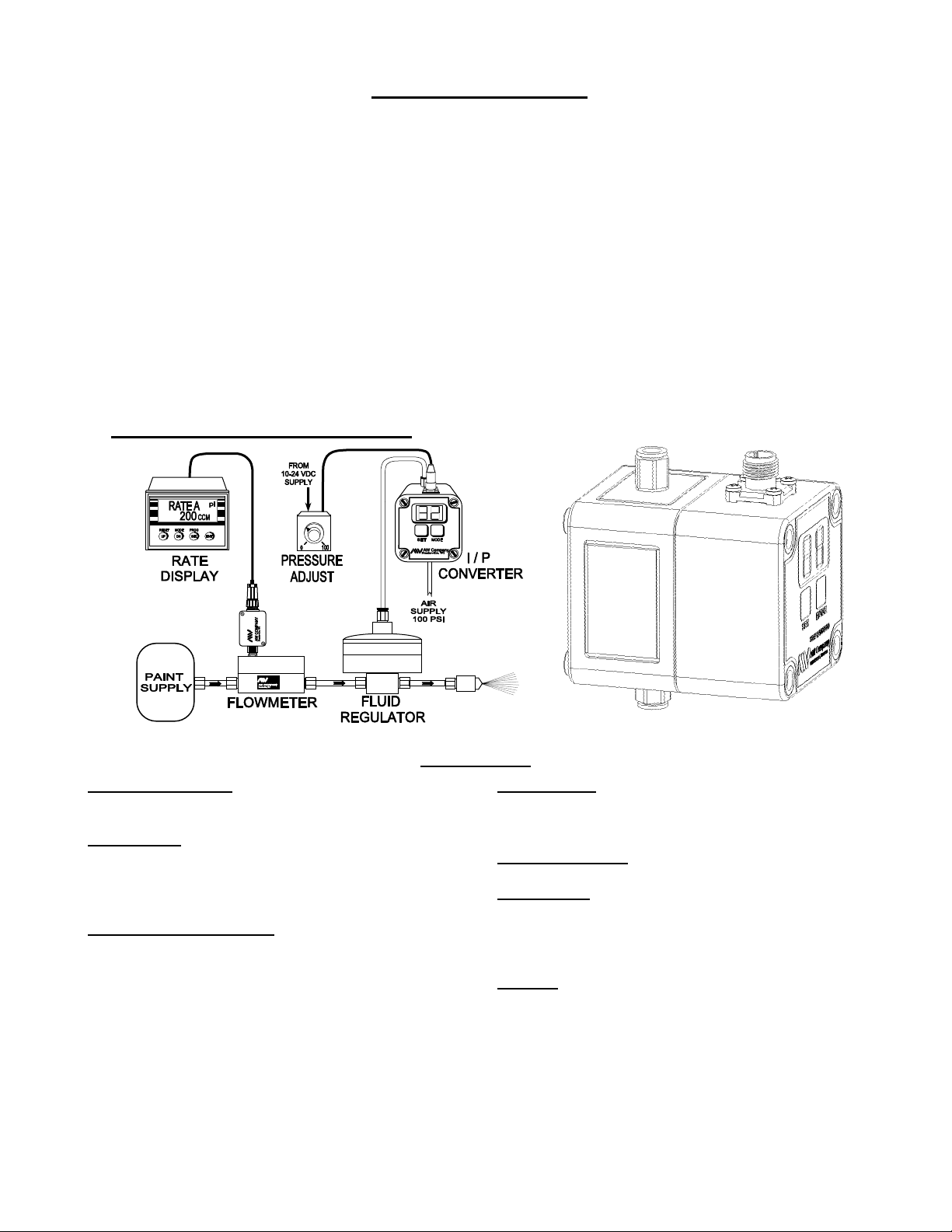

Introduction / Features

The DSV-100 I/P Converter from AW Gear Meters is a compact high performance digital servo pressure

control valve. Accepting either current, voltage or touch-key input, the I/P Converter precisely regulates

air pressure for directing process control valves and air or fluid regulators. This microprocessor-based

converter delivers high accuracy pressure regulation with extremely low dynamic response times for

improved process control and higher product quality. A highly visible integral LED display eliminates the

need for additional display components providing a display of actual pressure, set point pressure or the

actual pressure deviation from set point. Additional diagnostic test modes measure the system response

time or check for line leaks providing actual real-time data invaluable in commissioning, monitoring or

troubleshooting an installation. An analog output representing output pressure is provided. User set-up of

output pressure range and input voltage or current span is accomplished quickly and easily via the two

touch-keys and display. The lightweight and compact DIN rail mount package maximizes panel

component density while the push-in type ¼” pneumatic hose connectors and threaded electrical

connection minimize installation time and cost.

A Typical Spray Painting Application

Specifications

Power Requirements:

Supply Voltage 10 - 24 Vdc

Supply Current 85 mA. @ 15 Vdc

Signal Inputs:

Voltage Input (programmable) 0-5, 1-5, 0-10 Vdc

Voltage Input Impedance 10 KΩ

Current Input (programmable) 0-20 mA, 4-20 mA

Current Input Impedance 250Ω

Performance Specifications:

Max. Input Pressure 130 psig*

Output Psig (programmable) 3 to 15, 0 to 15,30,50, 100

Flow Rate, 100 psig @ Inlet .6 SCFM max

Recommended Filtration 20 Micron

Min. Closed End Volume 2.13 cu. in. (35 ml)

Linearity (typical) ± 0.1% F.S.

Hysterisis (typical) ± 0.1% F.S.

Repeatability (typical) ± 0.2% F.S.

Accuracy (typical) ± 0.3% F.S.

* Supply pressure should be 10% higher than max. required

output pressure, not to exceed 130 psig.

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 1.6 03/10 DSV-100 Manual.DOC

Signal Output:

Pressure Signal 0-5 Vdc

(Actual pressure, 0 to 100%

of programmed output range)

Dynamic Response:

10 - 90% F.S. Rated Output 180 ms.

Wetted Parts:

Elastomers RTV, Glass

Manifold Aluminum

Valves Nickel Plated Brass

Press. Transducer RTV, Aluminum, Plastic

Physical:

Operating Temp. Range 32-158°F (0-70°C)

Page 4

3

Installation

The DSV-100 has DIN rail mounting provisions on the back of the unit. Units can be mounted directly

beside each other for maximum panel component density. It is recommended to install the unit oriented

horizontally as shown below or vertically on it’s back. Air fittings are push-in type ¼” O.D. pneumatic

hose connectors.

Dimensions

Electrical Connections

Power and signal connections to the DSV-100 are through a 5-pin threaded circular connector (4-pin

connector on versions preceding 1.6). The use of shielded cable is recommended and the shield should be

connected to earth ground at the source. The DSV-100 requires a 10-24 VDC @ 35-136 mA supply for

operation. See specifications for complete voltage and current requirements. The DSV-100 will respond

to either voltage or current control determined by electrical connection and input option selection. See

Input/Output Options and Input/Output Options Programming on page 4 for input options. Voltage or

current control is referenced to Supply Common or the DSV-100 will accept a fully isolated mA input

when isolated mA input mode is selected in set-up. (On versions prior to 1.6 the –mA input must be

connected to supply common for proper operation when a current control input is used).

Connection for Voltage Input

* -mA Control Signal must be connected to the Supply Common for proper operation on DSV-100 versions

previous to 1.6. For version 1.6 and up isolated mA input operation is permitted when selected in set-up.

** Analog output available on version 1.6 and up only.

Electrical

10-24 VDC Supply

Supply/Signal Common

+ Volts Control Signal

No Connection

Analog Pressure Output**

Connection for Current Input

Electrical

10-24 VDC Supply

Supply Common*

+ mA Control Signal

- mA Control Signal*

Analog Pressure Output**

Connector

1

2

3

4

5**

Connector

1

2*

3

4*

5**

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 1.6 03/10 DSV-100 Manual.DOC

Page 5

4

DSV-100 Start-Up

The DSV-100 has several options for control input as well as several output range options that require setup before operation. To view and/or edit the input/output options see DSV-100 Input/Output Options on

this page and Programming/Diagnostic Mode on page 5.

DSV-100 Display Modes

After briefly indicating the operating software version, the DSV will always display the AP (actual

pressure) at power-up or after programming/diagnostics. The DSV-100 has three display modes:

AC - Actual Pressure – Displays the actual pressure in psi at the outlet port.

SE - Setpoint Pressure – Displays the set-point pressure in psi based on the analog input or manual set point.

di - Difference – Displays the difference in psi between the Actual Pressure and the Setpoint Pressure.

The MODE-key is used to change the display to another mode. When the MODE-key is touched the

display will briefly flash AC for actual pressure, SE for setpoint, or di for difference to indicate which

mode will be displayed. The DSV-100 will remain in the last selected display mode until the MODE-key

is used or the power is removed.

DSV-100 Input/Output Options

Input Range Options - The DSV-100 has six possible input options supporting 0-5, 1-5, or 0-10 volt

input, isolated or common grounded 0-20 or 4-20 mA input, or manual control of setpoint from the

keypad. The input options are assigned a number for programming as follows:

(01) 0-20 mA/0-5 volt (02) 4-20 mA/1-5 volt (03) Manual (keypad) Operation*

(04) 0-10 volt (05) 4-20 mA isolated input** (06) 0-20 mA isolated input**

** Options (05) and (06) for isolated mA input are only available on DSV-100 version 1.6 or higher.

For proper operation with DSV-100 versions previous to 1.6 the -mA Control Signal must be connected to

the Supply Common. Version number is displayed at power-up or in set-up mode.

Output Range Options - Five output range options are offered. The output range options are assigned a

number for programming as follows:

(01) 0-100 psi* (02) 0-50 psi (03) 0-30 psi

(04) 0-15 psi (05) 3-15 psi

*Manual operation will produce a 0-100 psi output range controlled directly from the front keypad. See

Manual Operating Mode on page 6 for more information.

The selected output range will always linearly represent the selected voltage or current input range and

pressure output is limited to maximum value of the selected range. The DSV-100 will respond to either

voltage or current control as determined by electrical connection (see Electrical Connections on page 3)

and input option setting. The DSV-100 default settings configure the unit for 0-20 mA/0-5 volt analog

input range (option 01) with 0-100 PSI output (option 01).

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 1.6 03/10 DSV-100 Manual.DOC

Page 6

5

Programming/Diagnostic Mode

To view or edit programmed input and output ranges and/or perform system diagnostic tests the

programming/diagnostic mode is used. Programmed input and output options are retained by the DSV100 indefinitely until edited. In the programming/diagnostic mode the input and output range options are

first presented for viewing or editing after which the DSV-100 performs a system response and leak test.

WARNING!! The DSV-100 will pressurize the system and perform a response and leak test after

the input and output range options are viewed or edited. This can cause unexpected motion, flow or

other physical response. Always use caution when using the programming/diagnostic mode and be

aware of the results it can produce.

To access programming/diagnostic mode, the SET-key must be pushed before and held in while power is

applied to the DSV-100. With the SET-key held in, apply power to the panel and/or plug in the electrical

connector to activate the converter. The DSV-100 will briefly show a software revision number before

entering the programming/diagnostic mode.

View/Edit Input Option - The display will blink ir (input range) five times and then display the

currently selected input option number for 2-3 seconds. If the desired option is displayed, do nothing and

wait a few seconds for the display to blink or(output range). If the displayed number is not the desired

input option, press the MODE-key immediately. The display will again blink ir (input range) five times

and display the next input option number. If the displayed number is not the desired input option, press

the MODE-key and repeat the procedure until the desired option number appears. When the desired

option is displayed, do nothing and wait a few seconds. The DSV-100 will save the last displayed

number as the input option and the display will then blink or (output range).

View/Edit Output Option - The same procedure is used to select one of five output range options. The

display will blink or (output range) five times and then display the currently selected output option

number for 2-3 seconds. If the desired option is displayed, do nothing and wait a few seconds for the

display to blink

MODE-key immediately. The display will again blink or (output range) five times and display the next

input option number. If the displayed number is not the desired output option, press the MODE-key and

repeat the procedure until the desired option number appears. When the desired option is displayed, do

nothing and wait a few seconds. The DSV-100 will save the last displayed number as the output option

and the display will then blink

Response Test - Once the input and output options have been viewed or edited the DSV-100 performs

two diagnostic tests, a response test and a leak rate test. The first is a dynamic response test and the

display will blink rP (for response test). The DSV-100 will first vent any pressure on the outlet then

pressurize the output to the maximum pressure dictated by the programmed output range for 100

milliseconds, read the system response, and display the result. Results appear as a number from 0 to 100%

with 100% indicating the best possible response. Responses will vary with length of hose and actuator

volume. Responses above 80% can be considered very good, a response below 50% indicate a low

response system. Lower responses can be due to long hoses, high volume components, excessive Cv

requirement, or may indicate a leak or malfunction.

rP (response test). If the displayed number is not the desired output option, press the

rP (response test).

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 1.6 03/10 DSV-100 Manual.DOC

Page 7

6

Leak Test - After a brief display of the response test result, the display will blink Lr (for leak rate) while

the DSV-100 performs a leak test. The DSV-100 pressurizes the output to the maximum pressure dictated

by the programmed output range and then reads the pressure for 2-3 seconds to determine if the system is

holding pressure or at what rate it is depleted. The leak rate is displayed as a number from 0 to 100% with

0% indicating a completely open output and 100% indicating that there is no leakage. A result less than

100% indicates that pressure has diminished over time likely due to a leak in a hose, fitting, diaphragm or

actuator. The leak rate result will be displayed for a few seconds and then the DSV-100 will then revert to

the AP display (Actual Pressure) and begin operation according to the programmed options.

Manual Operating Mode

When the manual operating mode is selected the default setpoint is 4 psi and the output range is 0-100 psi.

Whenever power is applied or after programming/diagnostics are completed the display will revert to the

AC display (Actual Pressure). As with analog input modes, the MODE-key is used to view the AC

(actual pressure), SE(set-point), or di (difference) displays. The two touch-keys are used to increment

(MODE-key) or decrement (SET-key) the setpoint value. To adjust the setpoint, press the SET-key

causing the display to blink SE(set) for 1-2 seconds. The DSV-100 looks for a key to be pressed before

SE stops blinking so quickly press and hold the MODE-key to increment the setpoint, or press and hold in

the SET-key to decrement the setpoint. Once either key is released, the SET-key must be pressed again

change the setpoint. In manual mode the DSV-100 will not retain the setpoint if power is removed and the

setpoint will always revert to four psi whenever power is applied or after programming/diagnostics are

completed.

AW-Lake Company 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 1.6 03/10 DSV-100 Manual.DOC

Loading...

Loading...