AW Gear Meters CAPM-2 User Manual

CAPM-2 Carrier Frequency Pickup Module

Installation & Technical Guide

Installation:

• Ensure that the flow meter sensor cavity is free of debris prior to installation.

• Screw the CAPM-2 into the flow meter by hand until the sensor nose contacts the bottom of the cavity.

• Do not screw in harder than hand tight, as a thin metal section is under the sensor nose.

Please heed the following warning:

CAUTION: DO NOT EXCEED 7 NEWTON-METERS FORCE TO SEAT THE SENSOR, THIS IS

EQUIVALENT TO HAND TIGHT. EXCESS FORCE MAY CRUSH THE SENSOR NOSE OR

DAMAGE THE FLOW METER BY FORCING THE METAL SECTION UNDER THE SENSOR INTO

THE MEASURING CHAMBER.

Wiring should be installed by a qualified instrumentation technician.

Some basic installation guidelines are reviewed overleaf.

Description:

The CAPM-2 is a Carrier Frequency sensor, which means there is no permanent magnet in the

pickup, and any magnetic drag on the flow meter is avoided. The CAPM-2 requires a supply voltage

between 10 VDC and 30 VDC. A diode in the supply input prevents damage to the module in case

the polarity of the supply voltage is wrong. The output signal is a square wave, voltage pulse of

approximate amplitude (supply – 1.5 V). The frequency is proportional to the flow rate.

The output is a sourcing open collector transistor (PNP Type).

An NPN sinking type is available and is designated as CAPM-2N.

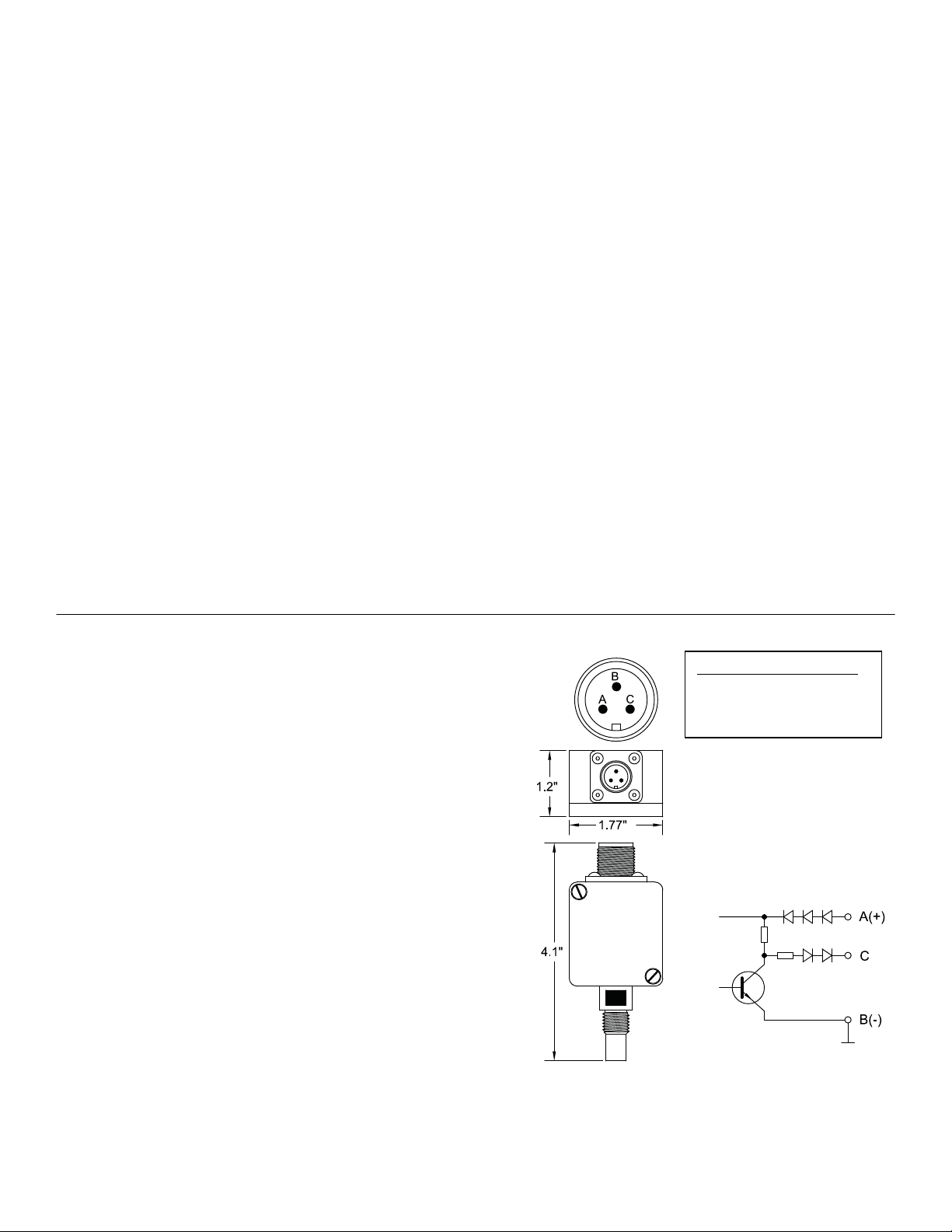

Technical Data

Supply Voltage: 10 to 30 VDC

Supply Current: 9 mA @ 15 Volt, Max 18 mA

Minimum Signal: 0.5 Hz

≈ V

Signal Output: Square wave, V

V

Duty Cycle: 50%

Frequency Output: Flow dependent, up to 2000 Hz

Load: >500Ω

Driving Capacity: 10 mA Max

Temperature Range: -60°F to 185°F (-50°C to 85°C)

Connections:

A = +10 to 30 VDC supply voltage

B = Ground for supply and signals

C = Frequency signal output

Note: If signal does not go to ground, connect

external resistor, 5 K-10 Kohm, between input and

ground of monitoring equipment.

High

Low

CC

≈ 0V

- 1.5V

AW Wiring Color Code:

Supply Voltage: Red

Ground: Black

Signal: White

Figure 1

AW Gear Meters 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 10/11 CAPM-2.DOC

Electrical Installation Tips for Sensors and Flow Meters

Wiring should be installed by a qualified electrician or instrumentation technician. When dealing with low

voltage/power signals from pickups and transmitters, it is important to use a shielded cable between the

transmitter and the signal processing unit. A shielded cable will keep most of the electromagnetic interference

(EMI) from entering the signal cable and disrupting the signal before it can be processed. A 20-22 gauge 3 or 4

conductor cable with shield is acceptable. Recommended cable: Belden #88723 2 pair stranded, 22 awg

Teflon coated cable. This cable is available from AW Gear Meters.

When hooking up to instrumentation, connect the shield together with the wire for the signal ground, to the

Instrument Ground terminal.

NEVER CONNECT THE SHIELD TO GROUND AT BOTH ENDS.

When hooking up to AW Gear Meters instrumentation, refer to the following drawing:

PICKUP PINS

CAPM-2 or -3

CAPM-2o or -3o

CF-1 and HEF-1

A

C

B

+ SUPPLY

SIGNAL

GROUND

SHIELD

FEM-03

1

3

2

Figure 2

INSTRUMENT CONNECTIONS

EMO-500 EMO-1005JFC-01

1 or 4

3 or 6

2 or 5

3

5

4

EMO-3000

1

4

2

1. To prevent extraneous signal noise, ensure that a clean, central ground is established for both the flow

meter and sensor.

2. Where possible, keep the signal cable at least 1 foot from any cable handling 110 Volt AC. If several

signal cables are used, consider using metal conduit tubing for the signal cables for extra protection

and shield from external noise and EMI. If possible, ground the conduit at one end. Ground to a water

pipe or another good ground connection.

3. Place the pickup well away from motors, starters and relays. If used in a location where there are

starters and other controls using relays, be sure there are diodes mounted across the coils for DC

relays, and an R-C network for AC relays. This will dampen EMI from the relays when they operate.

4. Supply clean, regulated DC power with a ripple under 3% of supply.

If the sensor appears faulty, review the following steps:

1. Detach the wiring connector from the sensor. Using a short wire, repeatedly touch pin A to C inside the

wiring connector. These simulated pulses should register at the instrument. If this does not occur, verify

that the wiring connections are set up as shown in Figure 2 above and check the instrument. If using a

non-AW instrument, check the specifications for signal compatibility.

2. If the pulses do register, re-attach the wiring connector and rapidly move a screwdriver back and forth

1/16” in front of the sensor nose. If pulses register, the sensor is okay. If not, contact the factory for a

return tracking number.

Note: If the sensor transmits a frequency irrespective of flow or by touch, the cable shielding and/or

grounding is faulty and the equipment is behaving as an antenna.

AW Gear Meters 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800Fax: 262-884-9810 Email: awinfo@aw-lake.com

REV. 10/11 CAPM-2.DOC

Loading...

Loading...