AWEA SP2016, SP3016, SP4016 OPERATOR'S MANUAL

AWEA SP/LP SERIES PROGRAMMER'S AND OPERATOR'S MANUAL (FANUC 18iMB) NO. SPEMFI13 DATE:2006/09/06

CNC DOUBLE COLUMN VER TICAL MACHINING CENTER

MODEL : SP2016/SP3016/SP4016

LP3021/LP4021/LP5021

LP4025/LP5025/LP6025

PROGRAMMER'S AND

OPERATOR'S MANUAL

VER. No.: SPEMFI13

AWEA MECHANTRONIC CO., LTD.

AWEA

DOUBLE COLUMN

VERTICAL MACHINING CENTER

PROGRAMMER'S AND OPERATOR'S

AWEA

MANUAL

VERSION : NO. SPEMFI13

EDITOR : Eric, Wei-Shinn LOO

MACHINE MODEL : SP/LP SERIES

CONTROLLER TYPE : F ANUC 18 iMB

NAME OF CUSTOMER :

MACHINE SERIAL NUMBER :

DATE OF MANUFACTURED :

At the time of writing, the book was completely up-to-date. However, due to continual

improvements in design, it is possible that descriptions contained herein may vary to a slight extent

from the machine delivered to you. This merely implies that the machine has been improved to

better fulfill your requirements. If there are any questions, you are encouraged to contact the nearest

AWEA representative for clarification.

Patents Notice:

The machines and attachments and parts thereof illustrated and described in this book are

manufactured under and protected by issued and pending local and foreign Patents and copyright is

reserved in any original design features thereof and in the contents of this manual and every part

thereof.

AWEA

AWEA SP/LP series, Manual-Content

CONTENTS

1. SAFETY RECOMMENDATIONS: ............................................................................1-1

1.1 SAFETY INSTRUCTIONS:................................................................................. 1-2

1.2 SAFETY LABELS EXPLANATION .....................................................................1-5

2. INSTRUCTION.........................................................................................................2-1

2.1 DESCRIPTION OF MACHINE DESIGN AND CONSTRUCTION ...........................................2-1

2.1.1 Machine bed................................................................................................2-2

2.1.2 The bridge................................................................................................... 2-2

2.1.3 The table ..................................................................................................... 2-2

2.1.4 The spindle head.........................................................................................2-2

2.1.5 The feed system.......................................................................................... 2-3

2.1.6 The ATC and Magazine...............................................................................2-3

2.2 C

2.3 S

2.4 OPERATOR’S CONTROL PANEL .............................................................................2-13

3. POWER UP AND POWER DOWN ..........................................................................3-1

3.1 INSPECTION BEFORE OPERATION ...........................................................................3-1

3.2 POWER DOWN...................................................................................................... 3-3

3.3 P

3.4 P

4. OPERATION INSTRUCTION................................................................................... 4-1

4.1 MODE SELECT OPERATION ....................................................................................4-1

4.2 M

4.3 MDI OPERATION .................................................................................................4-13

4.4 AUTOMATIC OPERATION ......................................................................................4-18

OORDINATION..................................................................................................... 2-4

PECIFICATIONS ...................................................................................................2-6

2.3.1 Technical Data............................................................................................. 2-6

2.3.2 Control function (Standard) .......................................................................2-10

2.4.1 LCD/MDI panel.......................................................................................... 2-13

2.4.2 Machine control panel ............................................................................... 2-18

3.1.1 Checking before Power Up .........................................................................3-1

3.1.2 Power Up ....................................................................................................3-2

3.1.3 Checking After Power Up ............................................................................ 3-2

3.2.1 Emergency Stop..........................................................................................3-4

3.2.2 Other Stops ................................................................................................. 3-4

3.2.3 Power Down................................................................................................3-7

OWER ON PROCEDURE LIST ................................................................................3-7

OWER DOWN PROCEDURE LIST............................................................................ 3-7

ANUAL OPERATION .............................................................................................4-3

4.2.1 Reference Point Return............................................................................... 4-3

4.2.2 JOG Feedrate Operation

4.2.3 HANDLE Wheel Operation..........................................................................4-6

4.2.4 Manual operation of the Spindle.................................................................. 4-7

4.2.5 Spindle Tool Loading and Unloading ........................................................... 4-8

4.2.6 Tool magazine operation instruction and trouble shooting ........................ 4-10

4.3.1 MDI Instruction .......................................................................................... 4-13

4.3.2 Tool Number Initial and Command ............................................................ 4-15

4.3.3 Magazine Tool Loading and Unloading .....................................................4-17

4.4.1 Executing Automatic Operation ................................................................. 4-18

4.4.2 Block Skip .................................................................................................4-19

4.4.3 Manual Absolute........................................................................................ 4-20

4.4.4 Program Restart........................................................................................ 4-25

.............................................................................4-4

I

AWEA

4.4.5 3D work coordinate rotating command format (Optional function on multi-head) 4-28

4.4.6 Rigid tapping operation for the multi-head.................................................4-28

4.4.7 Manual tool movement in axial and radial dire

4.4.8 Spindle multi-head operation instruction ................................................... 4-30

4.4.9 Three axes MPG operation ....................................................................... 4-34

4.4.10 Memory card operation .............................................................................4-36

4.4.11 Manual Guide i Editing operation ..............................................................4-38

4.5 PROGRAM CHECK AND TEST ................................................................................4-40

4.5.1 Machine Lock ............................................................................................4-40

4.5.2 Z Axis Cancel ............................................................................................4-40

4.5.3 MST Function Lock ...................................................................................4-40

4.5.4 Dry Run..................................................................................................... 4-41

4.5.5 Cutting Feedrate Override......................................................................... 4-41

4.5.6 Rapid Feedrate Override........................................................................... 4-41

4.5.7 Spindle Speed Override ............................................................................4-42

4.6 A

4.7 A

5. TROUBLE SHOOTING ............................................................................................5-1

5.1 TROUBLE SHOOTING GUIDE................................................................................... 5-1

5.2 OPERATION MESSAGE......................................................................................... 5-18

5.3 RESET OF OVER TRAVEL......................................................................................5-22

5.4 REMEDY METHOD IN AUTO TOOL CHANGING TROUBLE...........................................5-23

5.5 DOOR INTERLOCK SAFETY REGULATION (CE VERSION) OPTION............................... 5-25

6. MAINTENANCE .......................................................................................................6-1

6.1 P

6.2 G

6.3 ADJUSTMENT FOR SLIP CLUTCHES (TORQUE LIMITING OVERLOAD) ON EACH AXIS........6-5

6.4 LUBRICATION ........................................................................................................6-6

6.5 COOLANT FACILITIES ............................................................................................. 6-7

6.6 PNEUMATIC SYSTEM ..............................................................................................6-9

6.7 SPINDLE TEMPERATURE CONTROL SYSTEM (OPTION)........................................... 6-11

6.8 HYDRAULIC POWER UNIT ..................................................................................... 6-14

UTOMATIC TOOL CHANGE (ATC) ......................................................................... 4-43

UTOMATIC TOOL LENGTH MEASUREMENT (ATLM) (G37 OR M137) (OPTION) ........ 4-48

5.1.1 Alarm message ...........................................................................................5-2

5.1.2 Remedial Measures ....................................................................................5-4

5.3.1 Soft Limit Over travel................................................................................. 5-22

5.3.2 Hard Limit Over travel ...............................................................................5-22

5.5.1 Operator door safety door interlock instruction:.........................................5-25

5.5.2 Magazine door interlock instruction:.......................................................... 5-25

5.5.3 Safety regulation rule: ...............................................................................5-25

REVENTIVE MAINTENANCE. ..................................................................................6-1

6.1.1 Daily inspection ...........................................................................................6-1

6.1.2 Weekly

6.1.3 Monthly maintenance (480 hours)

6.1.4 Maintenance every six months....................................................................6-2

6.1.5 Maintenance Chart...................................................................................... 6-2

IB ADJUSTMENT. .................................................................................................6-4

6.7.1 General ..................................................................................................... 6-11

6.7.2 Lubrication ................................................................................................ 6-11

6.7.3 Setting temperature................................................................................... 6-12

6.7.4 Maintenance and inspection .....................................................................6-12

6.7.5 Failure and countermeasure .....................................................................6-13

6.8.1 Description ................................................................................................6-14

6.8.2 Hydraulic unit specification........................................................................ 6-15

maintenance (120 hours)................................................................ 6-2

AWEA SP/LP series, Manual-Content

ction................................... 4-29

...............................................................6-2

II

AWEA

6.9 CHIPS CONVEYOR AND CHIPS COLLECTOR ............................................................. 6-16

6.10 C

6.11 CLAMPING AND UNCLAMPING DEVICE (OPTIONAL FOR THRU SPINDLE COOLANT) ....... 6-16

7. INSTALLATION ........................................................................................................7-1

7.1 GENERAL .............................................................................................................7-1

7.2 THERMAL EXPANSION ............................................................................................7-1

7.3 HEAT RADIATION ...................................................................................................7-1

7.4 MACHINE SERIAL NUMBER......................................................................................7-2

7.5 CNC CONTROL SERIAL NUMBER .............................................................................7-2

7.6 CHOOSING THE FINAL LOCATION ............................................................................. 7-2

7.7 F

7.8 P

7.9 AIR CONNECTION ..................................................................................................7-9

7.10 POWER CONNECTION............................................................................................ 7-9

7.11 EARTH GROUND..................................................................................................7-10

7.12 S

7.13 P

7.14 CLEANING MACHINE ............................................................................................ 7-13

7.15 COOLANT THROUGH SPINDLE CONNECTION (OPTION)............................................ 7-13

8. ASSEMBLY DRAWING (SPARE PART)...................................................................8-1

8.1 STANDARD PARTS LIST: ..........................................................................................8-1

8.A-1 SPINDLE ASSEMBLY WITH 2 STEP GEAR, 30/35 HP MOTOR .................................... 8-2

8.A-2 SPINDLE ASSEMBLY WITH TRANSMISSION SHAFT(GEAR BOX) ...........................8-8

8.A-3 SPINDLE PAWL DRAW BAR ASSEMBLY ...............................................................8-12

8.A-4 TOOL HOLD CONFIGURATION DIAGRAM .............................................................8-18

8.A-5 SPINDLE HEAD WITH HEAD CHANGEABLE INTERFACE (OPT)................................ 8-22

8.A-6 HYDRAULIC COUNTER BALANCE CYLINDER ON SPINDLE HEAD .............................. 8-28

8.B-1 OVERLOAD CLUTCH FOR FEED SYSTEM.............................................................8-30

8.B-2 X AXIAL FEED SYSTEM ASSEMBLY ..................................................................... 8-32

8.B-3 FEED SYSTEM - TAIL SUPPORT BLOCK ON Y AXIS................................................. 8-36

8.B-4 Z

8.C-1 ATC

8.C-2 ATC

8.D-1 T

9. APPENDIX............................................................................................................... 9-1

9.A-1 G

9.A-2 M

9.A-3 MACHINE DIMENSION:........................................................................................ 9-5

9.A-4 RECOMMENDED FOUNDATION DRAWING:............................................................. 9-9

9.A-5 TABLE DIMENSION : .........................................................................................9-19

9.A-6 TOOL SHANK AND STUD DIMENSIONS:................................................................ 9-22

9.A-7 SLIDES TRAVEL LIMIT: ......................................................................................9-23

9.A-8 HYDRAULIC CIRCUIT DIAGRAM AND PARTS LIST:................................................. 9-30

9.A-9 PNEUMATIC CIRCUIT DIAGRAM AND PARTS LIST:................................................. 9-32

9.A-10 HEAVY-MEDIUM WAY OIL P-67....................................................................... 9-33

9.A-11 SPINDLE POWER CHART: .................................................................................9-38

9.A-12 T

OOLANT PUMP ..................................................................................................6-16

OUNDATION FOR MACHINE....................................................................................7-3

RE-INSTALLATION ................................................................................................ 7-4

YSTEM GROUNDING........................................................................................... 7-11

OWER REQUIREMENT ........................................................................................ 7-12

AXIAL FEED SYSTEM......................................................................................8-38

SYSTEM - ARM ROTATION UNIT...................................................................8-40

SYSTEM - TOOL MAGAZINE ASSEMBLY ........................................................8-46

HROUGH THE SPINDLE COOLANT SYSTEM (OPTION).......................................... 8-48

CODE LIST FOR SP SERIES:............................................................................ 9-1

ISCELLANEOUS FUNCTION LIST ( M CODE ) : .....................................................9-3

9.A-8.1 For the machine equipped with gear head: ...........................................9-30

9.A-8.2 For the machine without gear head(opt) : ........................................9-31

9.A-11.1 For the machine equipped with gear head ............................................9-38

9.A-11

.2 For the machine without gear head(OPT) :......................................9-38

HRU SPINDLE COOLANT SYSTEM (AS OPTION) :................................................ 9-39

III

AWEA SP/LP series, Manual-Content

AWEA

9.A-13 PNEUMATIC CIRCUIT DIAGRAM AND PARTS LIST: .................................................. 9-40

9.A-14 90

9.A-15 35 DEGREE MILLING HEAD (OPT): ................................................................... 9-43

9.A-16 EXTENSION MILLING HEAD (OPT): ....................................................................9-45

9.B-1. SAFETY CHECKING LIST: ...........................................................................9-47

9.B-1.1. Reference point return........................................................................... 9-47

9.B-1.2. SAFELY PROTECTING TEST: .............................................................. 9-49

9.B-1.3. Overtravel protection : ...........................................................................9-51

9.B-1.4. Manual operation test : .......................................................................... 9-53

9.B-1.5. Spindle rotation and stop .......................................................................9-56

9.B-1.6. Automatic tool change : ( the MACHINE LOCK button is released)

9.B-1.7. Safe interlock during all axes movement ...............................................9-62

9.B-2. W

9.B-3. TEST PROGRAM ( ALL TEST DIMENSION ARE IN METRIC SYSTEM) .....................9-66

9.B-3.1. MAIN PROGRAM FOR FUNCTION TEST ............................................ 9-66

9.B-3.2. AXES'S STROKE TEST ........................................................................ 9-66

9.B-3.3. TOOL

9.B-3.4. CANNED

9.B-3.5. DRILLING AND RIGID TAPPING ..........................................................9-68

9.B-3.6. AUTOMATIC TOOL CHANGE ............................................................... 9-69

9.B-3.7. Face Milling ...........................................................................................9-70

9.B-3.8. Automatic tool length measurement ......................................................9-72

9.C-1 UPDATE INFORMATION .....................................................................................9-73

DEGREE ANGULAR HEAD (OPT):................................................................. 9-41

ARM UP PROGRAMMING .............................................................................. 9-64

COMPENSATION TEST .............................................................9-67

CYCLE TEST PROGRAM ..................................................... 9-67

AWEA SP/LP series, Manual-Content

...... 9-60

IV

AWEA

AWEA SP/LP series, Manual-Content

FIGURE CONTENTS

Figure 1-1 ......................................................................................................................... 1-5

Figure 1-2 ......................................................................................................................... 1-5

Figure 1-3 ......................................................................................................................... 1-5

Figure 1-4 ......................................................................................................................... 1-6

Figure 1-5 ......................................................................................................................... 1-6

Figure 1-6 ......................................................................................................................... 1-6

Figure 1-7 Safety Instruction Plate ...................................................................................1-7

Figure 2-1Over V

Figure 2-2 Machine

Figure 2-3 Maximum Travel Limit .....................................................................................2-5

Figure 2-4 LCD/MDI panel..............................................................................................2-13

Figure 2-5 Software Operator's Panel ............................................................................2-15

Figure 2-6 Machine Control Panel .................................................................................. 2-18

Figure 2-7 M.P.G. control panel ...................................................................................... 2-27

Figure 3-1 Location of E-Stop button................................................................................ 3-4

Figure 4-1 Operation panel at magazine side................................................................. 4-10

Figure 6-1 Feed system on each axes .............................................................................6-5

Figure 6-2 Detail drawing on Overload slip clutch ............................................................6-5

Figure 6-3Lubricating circuit layout................................................................................... 6-6

Figure 6-4 Coolant piping .................................................................................................6-8

Figure 6-5 Coolant supply.................................................................................................6-8

Figure 6-6 Pneumatic circuit diagram ............................................................................... 6-9

Figure 6-7Pneumatic combination units............................................................................6-9

Figure 6-8 Location of pneumatic control valve ..............................................................6-10

Figure 6-9 Control range of the spindle temperature control .......................................... 6-11

Figure 6-10 Hydraulic circuit diagram ............................................................................. 6-14

Figure 7-1 Machine name plate ........................................................................................... 7-2

Figure 7-2 Recommended lifting method on SP series.....................................................7-4

Figure 7-3 Lift

Figure 7-4 Lift

Figure 7-5 Lifting method on the conveyor .......................................................................7-5

iew of SP type Machine layout ..............................................................2-1

Axis Orientation................................................................................. 2-4

ing method on the magazine ......................................................................7-4

ing method on Coolant tank........................................................................7-5

I

AWEA

AWEA SP/LP Series Manual - Chapter 1. SAFETY RECOMMENDATIONS:1-1

1. SAFETY RECOMMENDATIONS:

THESE SAFETY RECOMMENDATIONS FOR THIS AWEA MACHINE HAVE

BEEN PREPARED TO ASSIST THE OPERATOR AND MAINTENANCE

PERSONNEL IN PRACTICING GOOD SHOP SAFETY PROCEDURE.

OPERATOR AND MAIN-TENANCE PERSONNEL MUST READ AND

UNDERSTAND THESE PRE-CAUTIONS COMPLETELY BEFORE OPERATING,

SETTING UP, RUNNING OR PERFORMING MAINTENANCE ON THE MACHINE.

THERE ARE THREE WARNING LABELS ATTACHED TO THE MACHINE. NEVER

REMOVE OR DISFIGURE ANY LABELS OR INSTRUCTION PLATES FROM THE

MACHINE.

INDICATES FAILURE TO DO SO WILL RESULT IN SERIOUS

DANGER

WARNING

CAUTION

‧Indicates points to be followed.

DANGER

INJURY OR DEATH.

INDICATES FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY OR DEATH.

INDICATES FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY OR DEATH.

Shows to follow safety instructions.

‧(same as above)

‧

‧

1.(Indicates: refer to the points below)

2.________________________________________

3.________________________________________

(Indicates manuals, chapters or sections to

be searched for)

1-1

AWEA

1.1 SAFETY INSTRUCTIONS:

READ COMPLETE INSTRUCTIONS CAREFULLY BEFORE OPERATING MACHINE

When this instruction manual was printed, the information given was current.

However, since we are constantly improving the design of our machine tools, it is

possible that the illustrations and descriptions may vary from the machine you

received. This means that the machine you received is the latest improved model to

better fulfill your requirements.

Your AWEA machine is designed and built for maximum ease and safety of

operation. However, some previously accepted shop practices may not reflect

current safety regulations , environment protection and procedures, and should be

re-examined to insure compliance with the current safety, environment protection,

resources recycling and health standards.

We recommend that all shop supervisors, maintenance personnel, machine and

tool operators be advised of the importance of safety maintenance, environment

protection, setup and operation of AWEA built equipment. Our recommendations

are described below.

PLEASE READ THESE SAFETY RECOMMENDATIONS BEFORE

PROCEEDING ANY FURTHER. (“*” indicated: safety item, “+” indicated

environment protection items)

* ALLOW ONLY AUTHORIZED PERSONNEL to have access to enclosures

containing electrical equipment.

* READ APPROPRIATE MANUAL OR INSTRUCTIONS before attempting

operation or maintenance of machine. Make sure you understand all

instruction.

* CONSULT YOUR SUPERVISOR when in doubt as to the correct way to do a

job.

* DO NOT OPERATE EQUIPMENT unless proper maintenance has been

regularly performed and the equipment is known to be in good wor

* DO NOT OPERATE EQUIPMENT in the possible environment of air explosive.

+ DO NOT CUT THE FLAMMABLE MATERIAL (like Magnesium base) by

operating of the machine to avoid any possibility of fire.

* BEFORE OPERATING THE MACHINE check that all protective components

and interlocks work properly. If not immediately contact your local distributor.

* DO NOT REMOVE ANY WARNING or INSTRUCTION TAGS from machine.

* DO NOT OPERATE MACHINE if unusual or excessive noise or vibration

occurs. Report any excessive or unusual vibration, sounds, smoke, or heat as

well as any damaged parts.

* MAKE SURE MACHINE IS PROPERLY GROUNDED. CONSULT NATIONAL

ELECTRIC CODE and all local code.

* KEEP AREA AROUND MACHINE well light and dry.

* KNOW WHERE ALL stop push buttons are located in case of an emergency.

* DO NOT REACH into any control or power cases area unless electrical power

is OFF.

* DO NOT TOUCH ELECTRICAL EQUIPMENT when hands are wet or when

standing on a wet surface.

AWEA SP/LP Series Manual - Chapter 1. SAFETY RECOMMENDATIONS:1-2

king order.

1-2

AWEA

+ DO NOT USE a toxic or flammable substance as a solvent cleaner or coolant.

* DO NOT ALTER THE MACHINE to bypass any interlock, overload,

dis-connect or other safety device.

* KEEP CHEMICAL AND FLAMMABLE MATERIAL away from electrical or

operating equipment.

* DO NOT OPEN GUARD DOORS while any machine component is in motion.

* MAKE SURE PROPER GUARDING is in place and all doors are closed and

secured.

* MAKE SURE fixture plates and all other spindle-mounted tool holding devices

are properly mounted and secured before starting machine.

* REMOVE ANY LOOSE PARTS OR TOOLS left on machine or in the work area

before operating machine. Always check machine and work area for loose

tools and parts especially after work had been done by maintenance personal.

* CHECK LUBE LEVEL and status of indicator lights before operating machine.

* MAKE CERTAIN that all guards are in good condition and are functioning

properly before operating machine.

* DISCONNECT MAIN ELECTRICAL POWER before attempting repair or

maintenance.

* REPLACE BLOWN FUSES with fuses of the same size and type as originally

furnished.

* ASCERTAIN AND CORRECT cause of a shutdown caused by overload

heaters before starting machine.

* WEAR SAFETY GLASSES AND PROPER FOOT PROTECTION at all times.

When necessary, (example: remove the workpieces from the table, tools from

the spindle, clean the table, replacing the liquid or maintain the equipment)

wear respirator, helmet, gloves and ear muffs or plugs.

* DO NOT WEAR GLOVES if you are operating the control panel or the chip

conveyor

* HAVE CORRECT TYPE OF FIRE EXTINGUISHER handy when machining

combustible material and keep chips clear of working area.

* BEFORE PRESSING CYCLE START PUSH-BUTTON, make

proper functions are programmed and that all controls are set in desired

modes.

* CHECK SETUP, TOOLING AND SECURITY OF WORKPIECE if machine has

been off for any length of time.

* DRY CYCLE a new setup to check for programming errors.

* DO NOT REMOVE CHIPS with hands. Use a hook or similar device and make

certain that all machine movements have ceased.

* BE CAREF

* DO NOT REMOVE OR LOAD workpieces while any part of the machine is in

motion.

* DO NOT CHECK finishes or dimensions of workpiece near running spindle or

moving slides.

* DO NOT ATTEMPT to brake or slow the machine with hands or any makeshift

device.

* USE CAUTION around exposed mechanisms and tooling especially when

setting up. Be careful of sharp edges on tools.

* DO NOT USE worn or defective hand tools. Use proper size and type for job

being performed.

* USE ONLY a soft-faced hammer on tools and fixtures.

* DO NOT USE worn or broken tooling on machine.

AWEA SP/LP Series Manual - Chapter 1. SAFETY RECOMMENDATIONS:1-3

certain that

UL of sharp edges when handling newly machined workpieces.

1-3

AWEA

* MAKE CERTAIN that all tool mount surfaces are clean before mounting tools.

* INSPECT ALL CLAMPING DEVICES daily to make sure they are in good

operating condition. Replace defective clamper before starting machine.

* USE LIGHTER THAN NORMAL feedrate and depth of cut when machining a

workpiece size that is larger than the WORKING CAPACITY.

* DO NOT EXCEED rated capacity of machine.

* DO NOT LEAVE machine unattended while it is operating.

* DO NOT CLEAN machine with an air hose.

* RECYCLING all replaced parts and chips to save the resources.

* MAKE SURE that the waste are well disposed to conform to the environmental

protection regulations. (like wasted oil, coolant etc.)

* DO NOT LEAVE the leaking oil unattended, recycling the leaking oil by

wooden chip.

AWEA SP/LP Series Manual - Chapter 1. SAFETY RECOMMENDATIONS:1-4

1-4

AWEA

1.2 SAFETY LABELS EXPLANATION

The following warning labels and an instruction plate are attached to the machine.

Read and make sure you understand the warnings before operation. If any label is

damaged or becomes illegible, contact your local distributor. A new one will be

supplied immediately.

NEVER REMOVE OR DISFIGURE ANY WARNING LABEL OR INSTRUCTION PLATE.

AWEA SP/LP Series Manual - Chapter 1. SAFETY RECOMMENDATIONS:1-5

DANGER

ONLY qualified personnel are authorized to service electric cabinet. Failure to do so will result in serious injury or death.

Figure 1-1

WARNING

NEVER open the door during AUTO operation.

Figure 1-2

WARNING

ALWAYS keep away from spindle or tool in motion. Shut power OFF before access to spindle for servicing.

Figure 1-3

1-5

AWEA

AWEA SP/LP Series Manual - Chapter 1. SAFETY RECOMMENDATIONS:1-6

WARNING

KEEP AWAY from movable

area during operation.

Shut machine OFF for

servicing.

Figure 1-4

WARNING

WEAR HELMET and proper

foot protection to setup and

service.

Shut machine OFF when

step in/on machine.

Figure 1-5

WARNING

NEVER open the cover, only qualified person is authorized to service. Shut the machine OFF before servicing.

Figure 1-6

1-6

AWEA

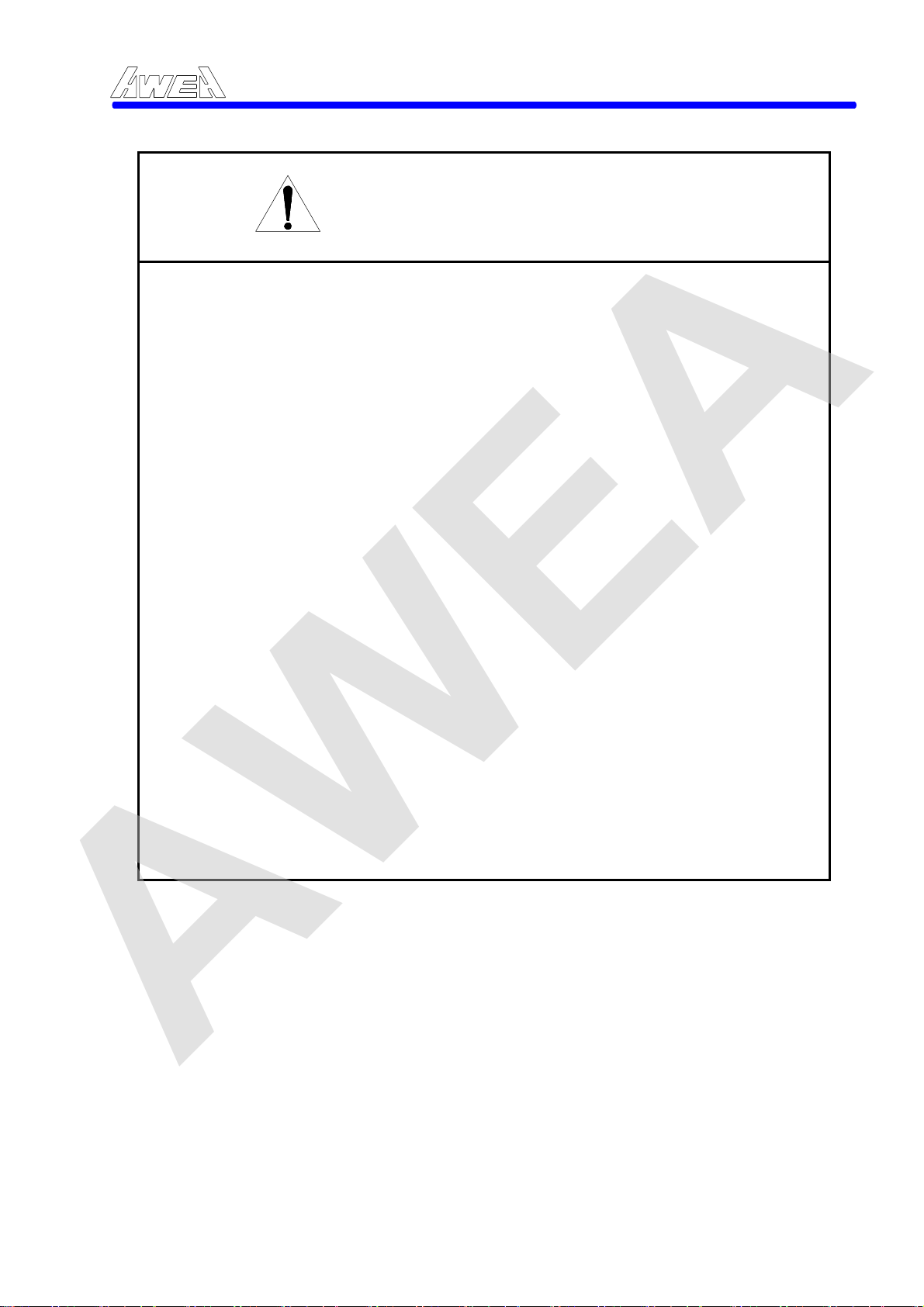

Follow instructions written on labels, Removal and / or damage to labels

is prohibited.

1. BEFORE operation of machine, READ operator's manual and safety

instructions.

2. ONLY trained and qualified personnel are to operate this machine.

3. ALL GUARDS MUST remain in place during machine operation.

4. MANDATORY wearing of hard hat for set-up and service. Clothing

suitable for operation of machine a MUST. (safety shoes, goggles,

protection cap, etc.)

5. Proper use, knowledge and location of EMERGENCY STOP BUTTON is

imperative.

AWEA SP/LP Series Manual - Chapter 1. SAFETY RECOMMENDATIONS:1-7

SAFETY INSTRUCTIONS

6. SHUT OFF POWER before servicing.

7. ONLY TRAINED AND QUALIFIED personnel may service this machine.

8. STAND CLEAR of machine while in operation. KEEP hands free of

movable areas.

9. SECURE ALL tools and workpiece safely. Check that nothing will

interfere with machine motions.

10. ONLY USE WATER-BASE coolant to prevent fire during unmanned

operation.

Failure to follow the above instructions may result in serious personal

y or death. If any questions or doubt exist regarding the instruction or

injur

operation procedures, contact your local distributor.

Figure 1-7 Safety Instruction Plate

1-7

AWEA

2. INSTRUCTION

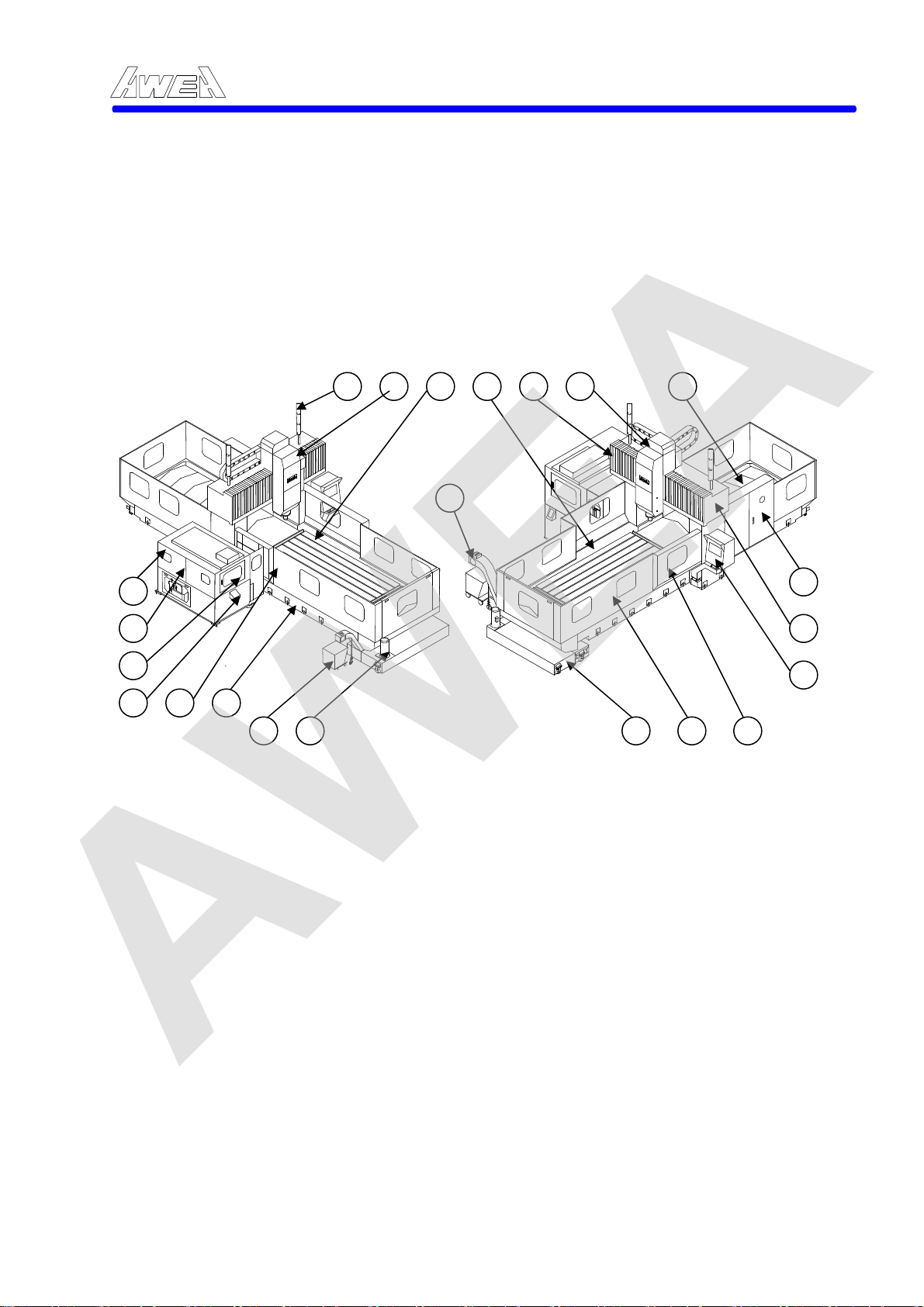

2.1 Description of machine design and construction

The basic machine consists of the Machine bed, Table, The bridge, Saddle, Spindle

Carrier, Dual hydraulic counter balance system and Auto tool changing system.

(Refer to Figure 2-1). All of which are designed to give high precision for long term

and heavy duty cutting performance over many years of machining operation. All of

which are described as below:

9 10 11 12 13 14 15

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-1

22

1

2

3

4 5 6

7 8

Figure 2-1Over View of SP type Machine layout

The main components of the machine are as below:

1. Tool magazine 12. Chip and coolant through

2. Magazine sheet metal 13. Y axial way cover

3. Magazine operator door 14. Carriage

4. ATC operation panel 15. X axial way telescopic cover

5. ATC automatic door 16. Main electric cabinet

6. Machine bed 17. The Bridge

7. Chip bucket 18. Operator panel

8. Coolant pump 19. Main operator door

9. Finish, alarm & operation lamp 20. Splash guard

10. Spindle head 21. Coolant tank

11. Table

19 20 21

16

17

18

2-1

AWEA

2.1.1 Machine bed

The machine bed is the foundation of the machining center structure. In addition to providing rigidity and support for the sliding members, machine alignment is maintained through the precision leveling of this structure.

2.1.2 The bridge

The bridge is made of one piece, which means columns and beam in one piece.

The thick walls and reinforcement ribs give the machining unsurpassed rigidity and

prevent any bending or twisting that may affect machining accuracy. The bridge is

bolted to the side of the machine bed. The upper linear way bearing is located 75

mm (2.9") behind the lower linear bearing. This step design greatly reduces

headstock overhang for added stability and helps maintain machining accuracy

during heavy cutting operations. The column is bolted to the side of the table base

to ensure the best accuracy alignment and squareness and to allow for maximum

rigidity. The double column construction supports the cutting load symmetrically;

thus bending movement and thermal deflection is minimized.

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-2

2.1.3 The table

The largest table size not only allows for the machining of large parts but also

increases the productivity of small to medium sized parts as they can be set up and

processed at one time. The wide distance between the columns all allows for extra

clearance for larger work pieces.

2.1.4 The spindle head

The large front bearing to assure efficient power transmission to the spindle nose

and to enable heavy duty machining supports the spindle. For rigidity, a

square-shaped cross section headstock was designed. In addition, with only 90 mm

from the spindle centerline to Z axis, so rigidity is unsurpassed. A floating hydraulic

cylinder keeps the spindle bearing from being pushed during tool change cycle.

This assured long term machine accuracy and spindle life. The counter-balance

system for the headstock consists of two hydraulic cylinders, which are arranged to

perfectly balance the distribution of the weight of the headstock. The twin hydraulic

cylinders are symmetrically placed to ensure equal lading to the way area and to

maintain sensitivity and accuracy to the cutting area.

The spindle temperature is kept constant by use of oil recirculating heat exchanger,

which reduces heat generation. Harmonized temperature between spindle head

and machine body assures minimum spindle expansion at high speeds rotation in

long time continuous use.

2-2

AWEA

2.1.5 The feed system

A custom designed safety device is used on all feed systems to protect the machine

from damage caused by accidental, incorrect programming or accidental operator

error. If tool head interference occurs, a unique torque limiter clutch protects the

machine from major damage. Operations are then restored quickly and easily with

a simple manual realignment of the clutch. Use of low friction linear bearing (X and

Y axes) and Turcite B (Z axis) which has outstanding vibration dampening

characteristics, This allows for high efficiency, high stability, high accuracy for long

term machining and machine life.

The guide ways and ball screw are automatically lubricated. The lubricant is

collected in a reservoir. So that the area keep clean and also extends the life of the

coolant. The entire guide way is fully covered by telescopic covers and coolant

recovery is ensured. Build-in spiral chip conveyor and flood coolant flushing

minimized cleaning time.

2.1.6 The ATC and Magazine

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-3

Unique ATC assures safe and easy tool storage and construction assures

interference free work setting and trouble-free operation. A standard magazine can

store 32 tools (60 option) of maximum size Φ125 mm X 350 mm ( Φ50" X 13.8")

and weight 20 kg (44 LB) ATC time, tool to tool : 8 seconds. Tools are always

protected from coolant, chips and dust by the automatic tool magazine door. The

door is automatically opened and closed by program command when changing

tools.

Especially design lock pin mechanisms are used to prevent the gripper failure while the arm is rotating. A unique hydra-pneumatic cylinder is used to limit the transfer force, which prevents damage if any malfunction occurs.

Microcomputer controlled random pot coding assures tool selection from magazine

in the shortest bi-direction tool path. The control p

the front side of the cabinet along with the foot release switch. The operator can

manually exchange tools with ease.

anel for the tool magazine is at

2-3

AWEA

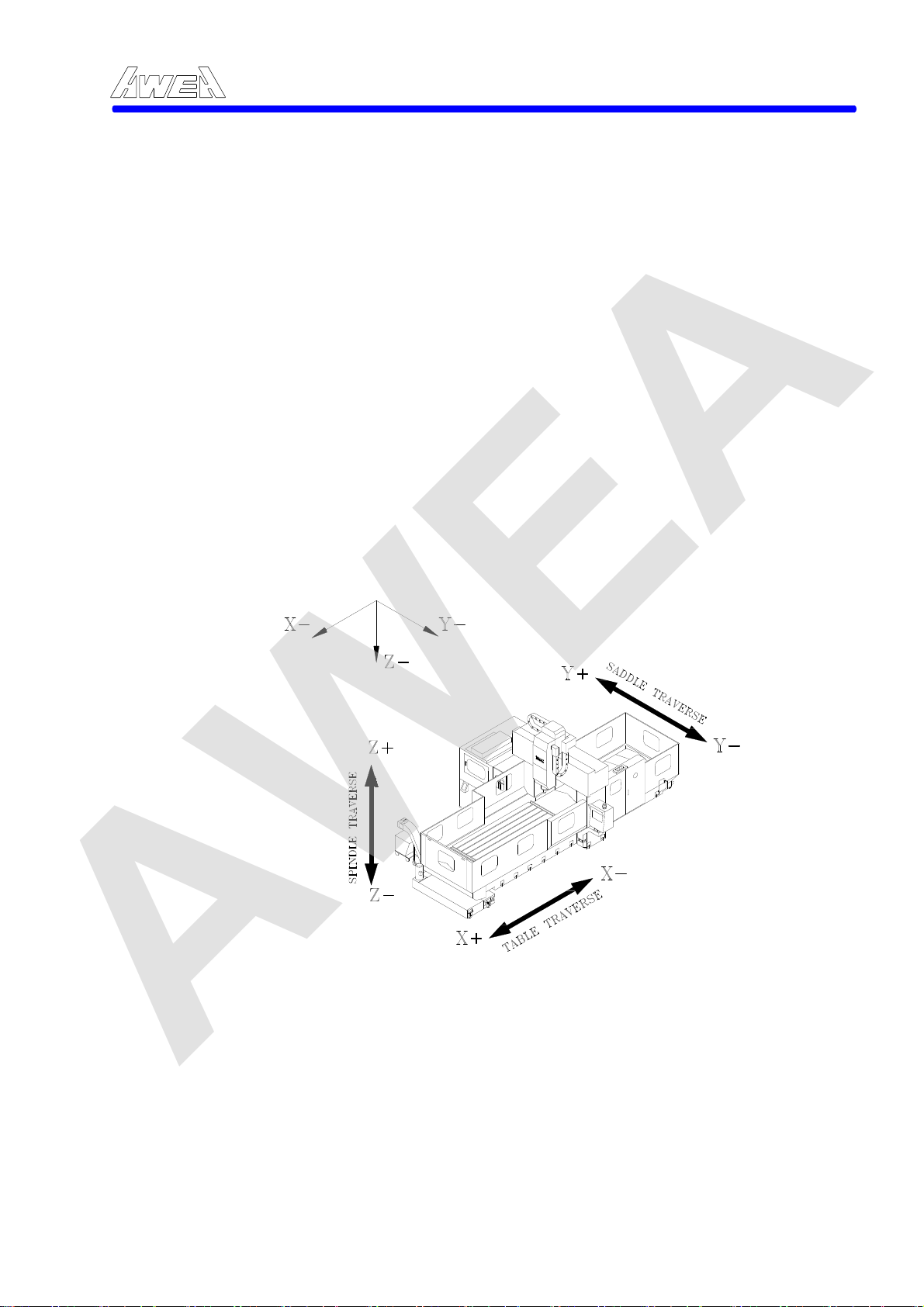

2.2 Coordination

Machining centers use the right-hand co-ordinate system to describe the

relationship of the axes. This relationship is in accordance with E.I.A. RS-267-A and

I.S.O. R841 Axis and Motion Nomenclature. The right-hand co-ordinate system

also establishes the direction of cutter motion with respect to the workpiece. The

programming exercise depends on the programmer visualizing the workpiece to be

fixed, and that the cutter does all the moving, (theoretical cutter motion). It is also

essential that the programmer view the workpiece from the normal operator

position, looking through the tool from the machine spindle. A theoretical cutter

motions to the back of current position in the Y axis origin which is created by a

similar movement of the table to the front of current position.

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-4

X axis:

Y axis:

Z axis:

Table travel left in "+" direction and travel right in "-" direction.

Spindle head travel out in "+" direction (approach to the Magazine) and travel in in "-" direction (leave from the Magazine).

Spindle carrier travel up in "+" direction and travel down in "-" direction.

Figure 2-2 Machine Axis Orientation

2-4

AWEA

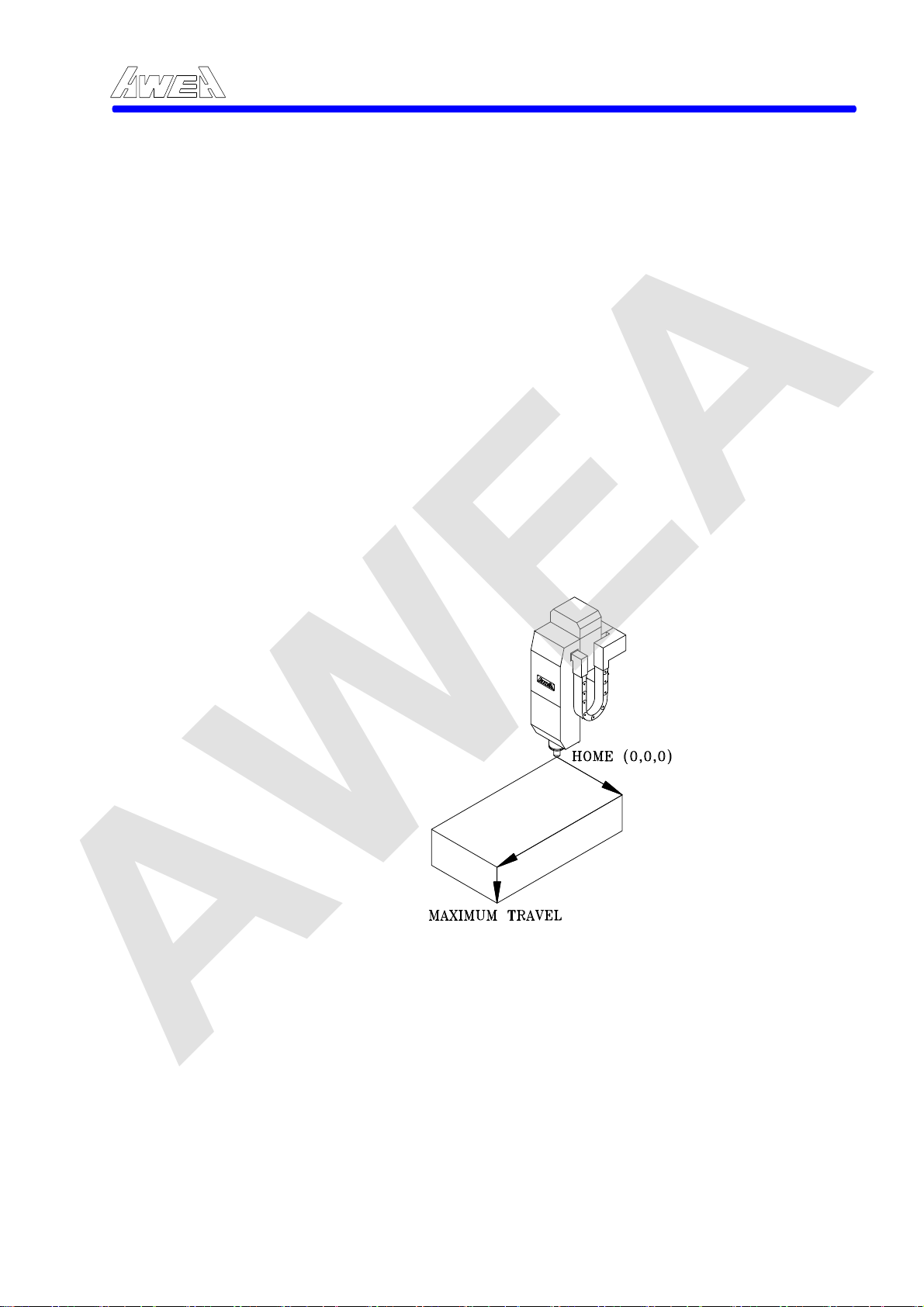

When the origin Point of this co-ordinate system agree with the mechanical 0-0-0

reference point of the machine, all coordinate dimensions will be as mentioned

above drawing, (from center of spindle) The maximum of all axial stroke shown as

mentioned below:

Axis and Machine model SP2016 SP3016 SP4016

X axis 2100(82.7") 3000(120.5") 4000(157.5") Y axis 1600(63") 1600(63") 1600(63") Z axis 760(30") 760(30") 760(30")

Axis and Machine model LP3021 LP4021 LP5021

X axis 3000(118.1") 4000(157.5") 5000(196.8") Y axis 2100(82.6") 2100(82.6") 2100(82.6") Z axis 760(30") 760(30") 760(30")

Axis and Machine model LP3025 LP4025 LP5025 LP6025

X axis 3000(118.1") 4000(157.5") 5000(196.8") 6000(236.2) Y axis 2500(98.4") 2500(98.4") 2500(98.4") 2500(98.4") Z axis 760(30") 760(30") 760(30") 760(30")

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-5

Figure 2-3 Maximum Travel Limit

2-5

AWEA

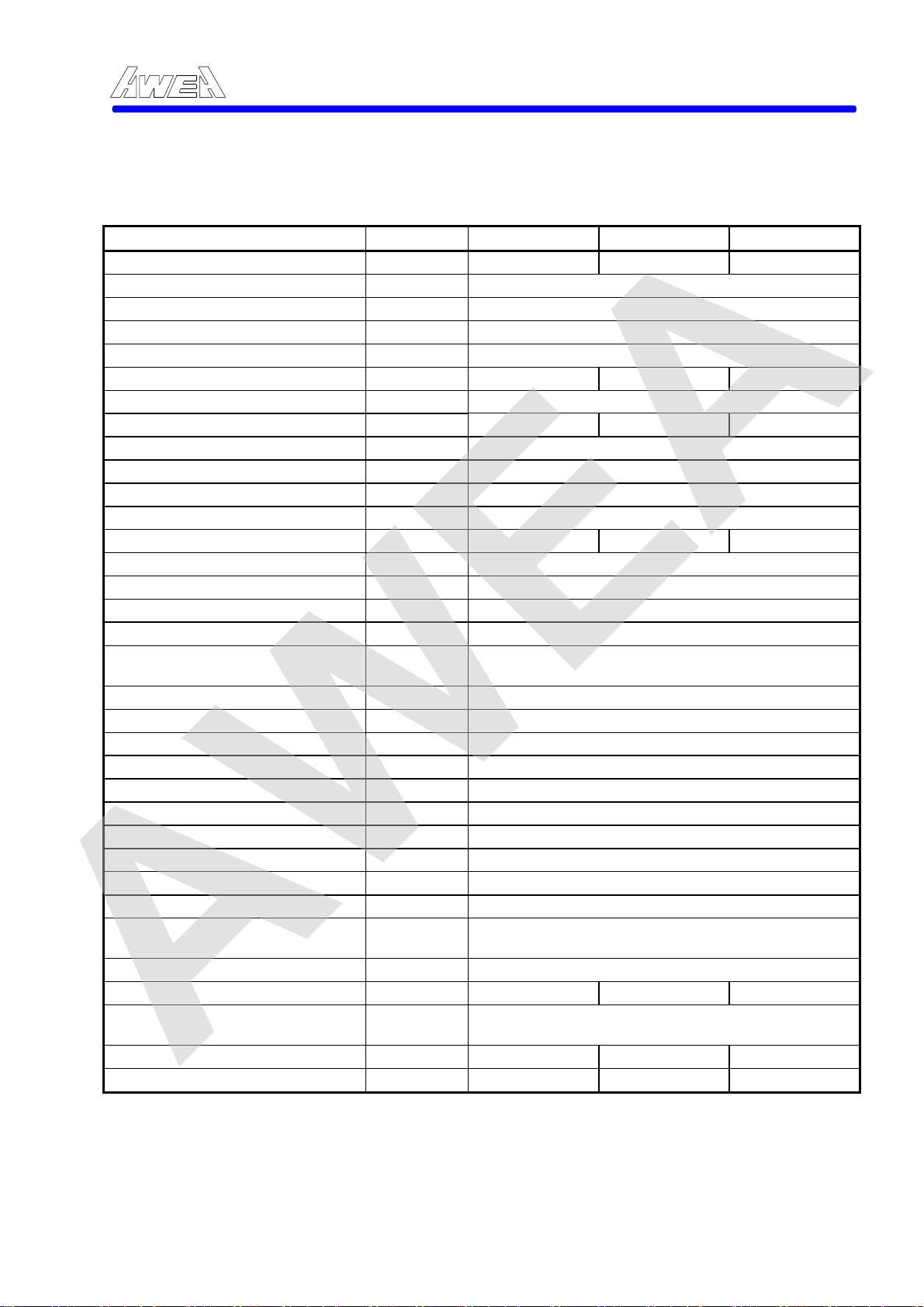

2.3 Specifications

2.3.1 Technical Data

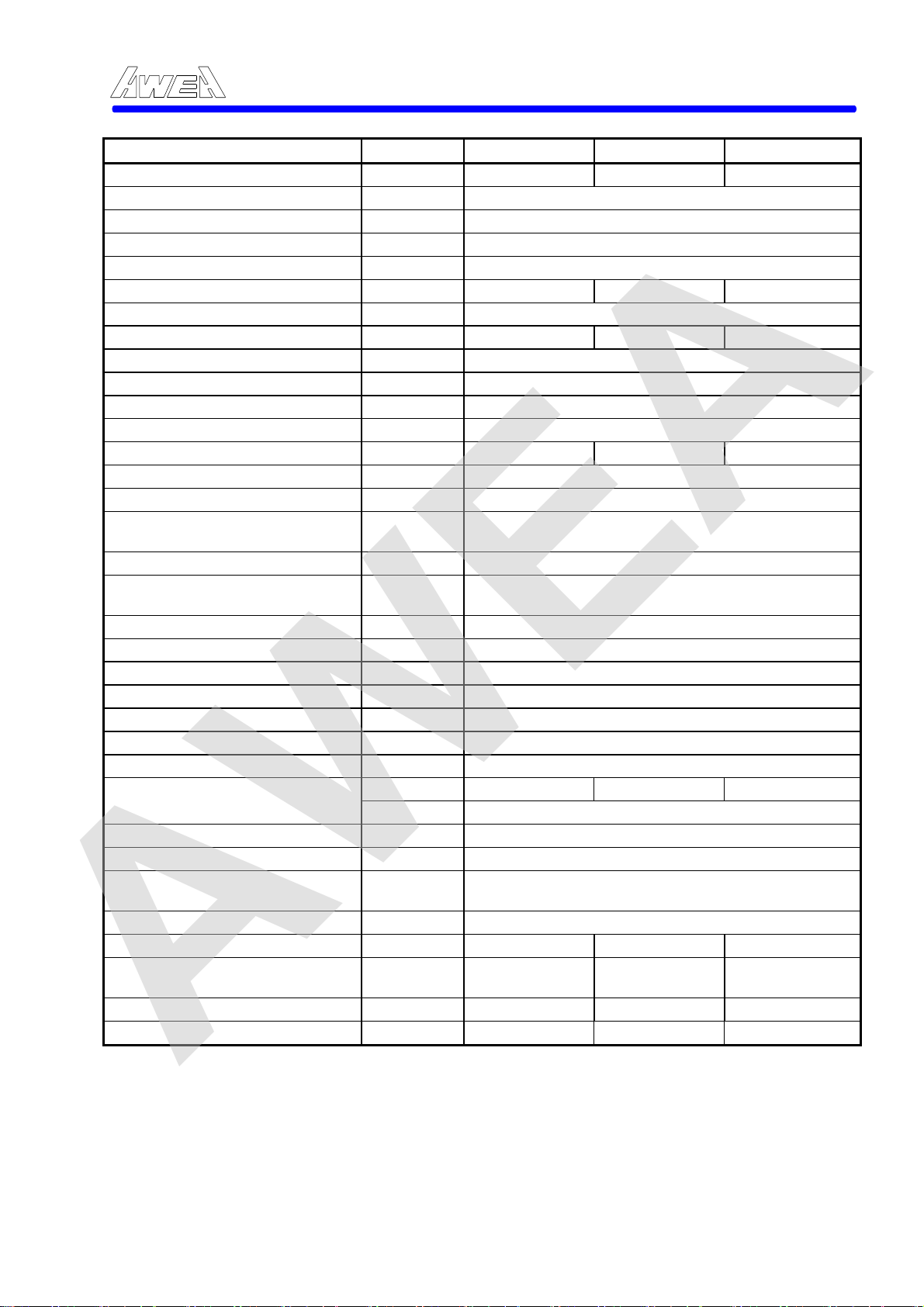

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-6

Item unit

X axis travel mm (inch) 2100 (82.7) 3060 (120.5) 4000 (157.5) Y axis travel mm (inch) 1600 (63.0) Z axis travel mm (inch) 760 (30.0) Distance from spindle to table mm (inch) 240-1000 (9.4-39.4) Distance between columns mm (inch) 1700 (66.9) Table size in X direction mm (inch) 2310 (90.9) 3260 (128.3) 4200 (165.4) Table size in Y direction mm (inch) 1500 (59.0) Table load capacity kg (lb.) 8000 (17600) 10000 (22000) 12000 (26400) Spindle motor (cont./30 min) kW (HP) 22/26 (30/35) Spindle speed rpm Two steps geared spindle 10-6000 Spindle taper BT#50 (ISO50) Pull-stud MAS403P50T-1 (45Deg.) / DIN69782 Rapid traverse rate X axes mm(in)/min. 20,000 (787.4) 20,000 (787.4) 15,000 (590.6) Rapid traverse rate Y axes mm(in)/min. 20,000 (787.4) Rapid traverse rate Z axis mm(in)/min. 10,000 (393.7) Cutting feed rate (max.) mm(in)/min. 1 – 1,0000 (0.04 – 393.7) Tool magazine capacity Max. tool diameter/ adjacent

pocket empty Max. tool length mm (in) 350 (13.8) Max. tool weight kg (lb.) 20 (44.1) Tool change time (T to T) sec 8 Position accuracy (JIS B6338) mm (in) ±0.01 (0.004) / full travel Position accuracy (VDI 3441) mm (in) P=0.030 (0.0012) Repeatability (JIS B6338) mm (in) ±0.003 (0.0001) Repeatability (VDI 3441) mm (in) Ps=0.024(0.001) Total required power 60 KVA / AC220V ±10%, 3 Phase, 60 Hz/50Hz Air resource Hydraulic tank capacity liter (gallon) 120 with 10HP (31.8)

Lubrication oil tank capacity

Coolant tank capacity liter (gallon) 420 (110) at 1.5HP Floor space requirement, L mm (in) 6,690 (263.3) 8,680 (341.7) 10,680 (420.5)

Floor space requirement, WxH mm (in)

Machine weight kg (lb.) 23,000(50700) 27,000(59500) 30,000 (66100) CNC controller FANUC 18 iMB FANUC 18 iMB FANUC 18 iMB

mm (in)

kg/c㎡

Liter

(gallon)

SP2016 SP3016 SP4016

32 (60,120 Option)

127/215 (5.0/8.5)

5

6 (1.6)

4700 x 3980

(185 x 156.7)0

2-6

AWEA

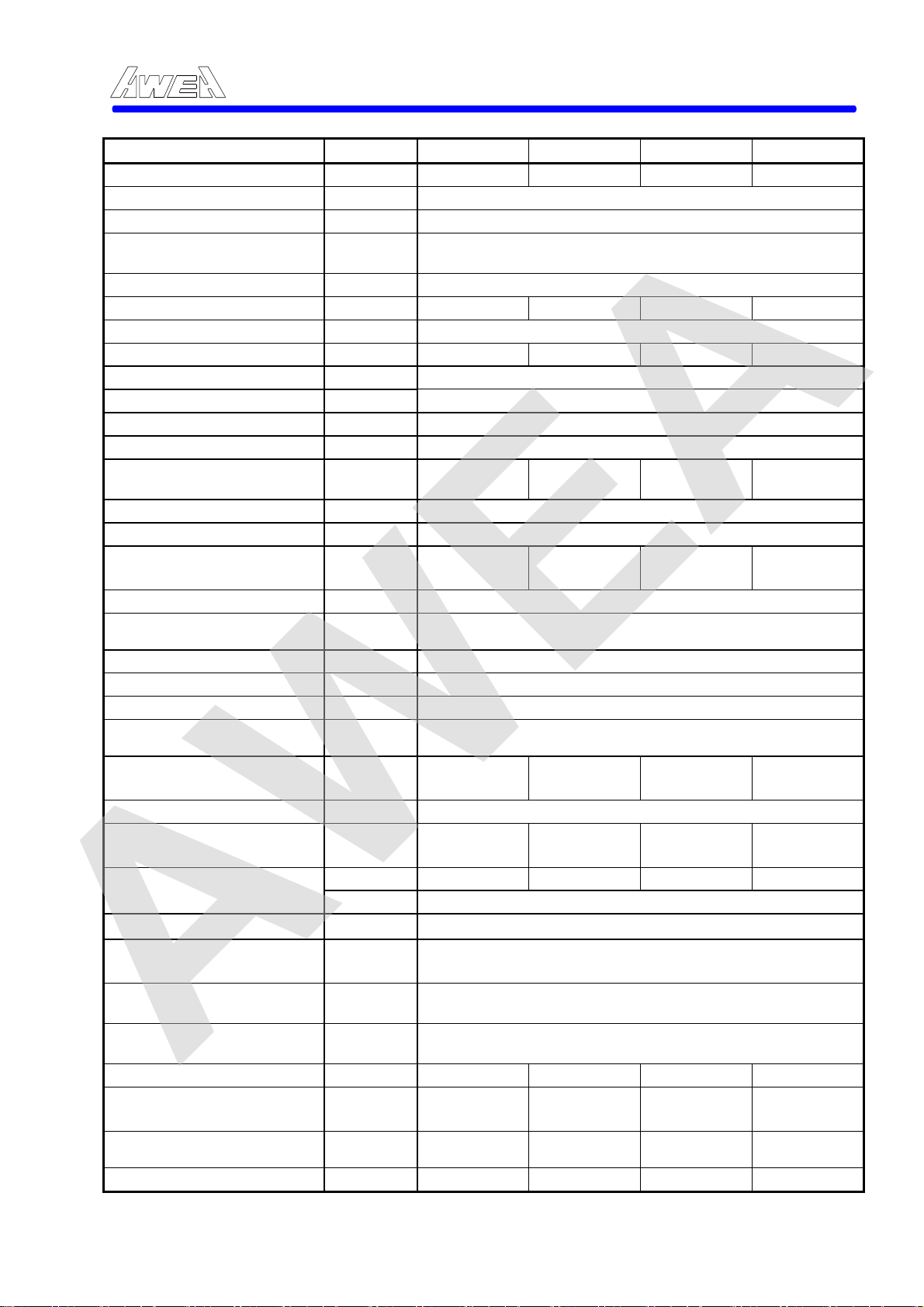

Item

X axis travel mm (inch) 3000 (118.1) 4000 (157.5) 5000 (196.8) Y axis travel mm (inch) 2100 (82.6) Z axis travel mm (inch) 760 (30.0) Distance from spindle to table mm (inch) 240-1000 (9.4-39.4) Distance between columns mm (inch) 2300 (90.5) Table size in X direction mm (inch) 3020 (118.9) 4020 (158.3) 5020 (197.6) Table size in Y direction mm (inch) 2010 (79.1) Table load capacity kg (lb.) 10000 (22000) 12000 (26450) 15000 (33000) Spindle motor (cont./30 min) kW (HP) 22/26 (30/35) Spindle speed rpm Two steps geared spindle 10-6000 Spindle nose configuration BT#50 (ISO50) DIN69871A Pull-stud MAS403P50T-1 (45Deg.) / DIN69782 Rapid traverse rate X axes mm(in)/min. 15,000 (590.0) 15,000 (590.0) 10,000 (393.7) Rapid traverse rate Y axes mm(in)/min. 15,000 (590.0) Rapid traverse rate Z axis mm(in)/min. 10,000 (394)

Cutting feedrate (max.) mm(in)/min.

Tool magazine capacity 32 (60 , 120 Option) Max. tool diameter/ adjacent

pocket empty Max. tool length mm (in) 350 (13.8) Max. tool weight kg (lb.) 20 (44.1) Tool change time (T to T) sec 8 Position accuracy (JIS B6338) mm (in) ±0.015 (0.006) / full travel Position accuracy (VDI 3441) mm (in) P=0.035 (0.0014) Repeatability (JIS B6338) mm (in) ±0.003 (0.0001) Repeatability (VDI 3441) mm (in) Ps=0.028(0.001) Total required power KVA 60 70 70 220 ±10% Vac, 3 Phase, 60 / 50Hz Air resource Hydraulic tank capacity liter (gallon) 120 with 10HP (31.8)

Lubrication oil tank capacity

Coolant tank capacity liter (gallon) 650 (170) at 1.5HP Floor space requirement, L mm (in) 8580 (337.8) 10580 (416.5) 12680 (499.2)

Floor space requirement, WxH mm (in)

Machine weight kg (lb.) 33000 (72750) 38000 (83700) 45000 (99200) CNC controller FANUC 18 iMB FANUC 18 iMB FANUC 18 iMB

mm (in)

kg/c㎡

Liter

(gallon)

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-7

unit LP3021 LP4021 LP5021

1 - 10000

(0.04-393.7)

127/215 (5.0/8.5)

5

6 (1.6)

5240 x 4000

(206.3 x 157.5)

5240 x 4000

(206.3 x 157.5)

5240 x 4000

(206.3 x 157.5)

2-7

AWEA

Item unit LP3025 LP4025 LP5025 LP6025 X axis travel Y axis travel Z axis travel

Distance from spindle to table

Distance between columns

Table size in X direction

Table size in Y direction

Table load capacity

Spindle motor (cont./30 min)

Spindle speed

Spindle nose configuration

Pull-stud MAS403P50T-1 (45Deg.) / DIN69782

Rapid traverse rate X axes

Rapid traverse rate Y axes

Rapid traverse rate Z axis

Cutting feed rate (max.)

Tool magazine capacity

Max. tool diameter/ adjacent pocket empty

Max. tool length

Max. tool weight

Tool change time (T to T)

Position accuracy (JIS B6338)

Position accuracy (VDI

3441)

Repeatability (JIS B6338)

Repeatability (VDI 3441)

Total required power KVA 60 70 70 80 220 ±10% Vac, 3 Phase, 60 Hz / 50Hz Air resource

Hydraulic tank capacity

Lubrication oil tank capacity

Coolant tank capacity

Floor space requirement, L

Floor space requirement, WxH

Machine weight

CNC controller

mm (inch) 3000 (118.1) 4000 (157.5) 5000 (196.8) 6000 (236.2)

mm (inch) 2500 (98.4)

mm (inch) 760 (30.0)

mm (inch) 240-1000 (9.4-39.4)

mm (inch) 2700 (106.3)

mm (inch)

mm (inch) 2400 (94.5)

kg (lb.) 12000 (26400) 15000 (33000) 18000 (39680) 20000 (44000)

kW (HP) 22/26 (30/35)

rpm Two steps geared spindle 10-6000

mm(in)/min.

mm(in)/min.

mm(in)/min.

mm(in)/

min.

mm (in)

mm (in) 350 (13.8)

kg (lb.) 20 (44.1)

sec 8

mm (in) ±0.015 (0.006) / full travel

mm (in)

mm (in) ±0.003 (0.0001)

mm (in)

kg/c㎡

Liter

(gallon)

Liter

(gallon)

liter

(gallon)

mm (in) 8600 (338.5) 10600 (417.3) 12600 (496) 14600 (574.8)

mm (in)

kg (lb.)

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-8

3020 (118.9) 4020 (158.3) 5020 (197.6)

BT#50 (ISO50) DIN69871A

15,000 (590.0)

1-10000

(0.04-393.7)

P=0.035

(0.0014)

Ps=0.028

(0.0011)

5630 x 4000

(221.7 x 157.5)

36000 (79400) 40000 (88100) 44000 (97000)

FANUC 18 iMB FANUC 18 iMB FANUC 18 iMB FANUC 18 iMB

2-8

10,000 (393.7)

15,000 (590.0) 10,000 (393.7)

1-10000

(0.04-393.7)

32 (60 , 120 Option)

127/215(5.0 / 8.5)

P=0.035

(0.0014)

Ps=0.028

(0.0011)

120 with 10HP (31.8)

6 (1.6)

750 (198) at 1.5HP

5630 x 4000

(221.7 x 157.5)

10,000 (393.7)

1-10000

(0.04-393.7)

P=0.045

(0.0018)

Ps=0.028

(0.0011)

5

5630 x 4000

(221.7 x 157.5)

6020 (237)

7500 (295.3)

1-5000

(0.04-196.9)

P=0.055

(0.002)

Ps=0.045

(0.0018)

5630 x 4000

(221.7 x 157.5)

48000

(105800)

AWEA

A. Standard Accessories :

1. Spindle temperature control system

2. Spindle lubricating monitoring system

3. Two step gear head

4. Adjustable torque-limiting overload clutch (3 axes).

5. External pulse coder installed on end of ball screw, 3axes

6. Centralized automatic lubricating system

7. Flood coolant system

8. Recycling lubricating oil collector for all axes

9. Full splash guard - 1700 mm (66.9")

10. Foot switch for tool clamping (operator and magazine sides).

11. Remote hand wheel control.

12. Work light.

13. Operation cycle finish and alarm lights.

14. RS-232 interface.

15. Foundation bolt kit.

16. Tool box

17. Operation and maintenance manual

B. Optional accessories.

1. Rigid tapping

2. 8000 rpm spindle (30/35 HP, direct driven)

3. Linear scale feedback system for X, Y axes.

4. 60 tools magazine.

5. Angular head indexing in 4 position (Max. speed up to 1500 rpm)

6. Dual screw type chip conveyor

7. Caterpillar type chip conveyor and chip bucket

8. Automatic tool length measurement

9. Automatic workpieces measuring system (Renishaw MP10)

10. 10. Scanning system for mold and die.

11. CNC rotary table

12. Coolant thru the tool adaptor

13. Coolant thru the spindle with filtering system (Form 1 or 2).

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-9

2-9

AWEA

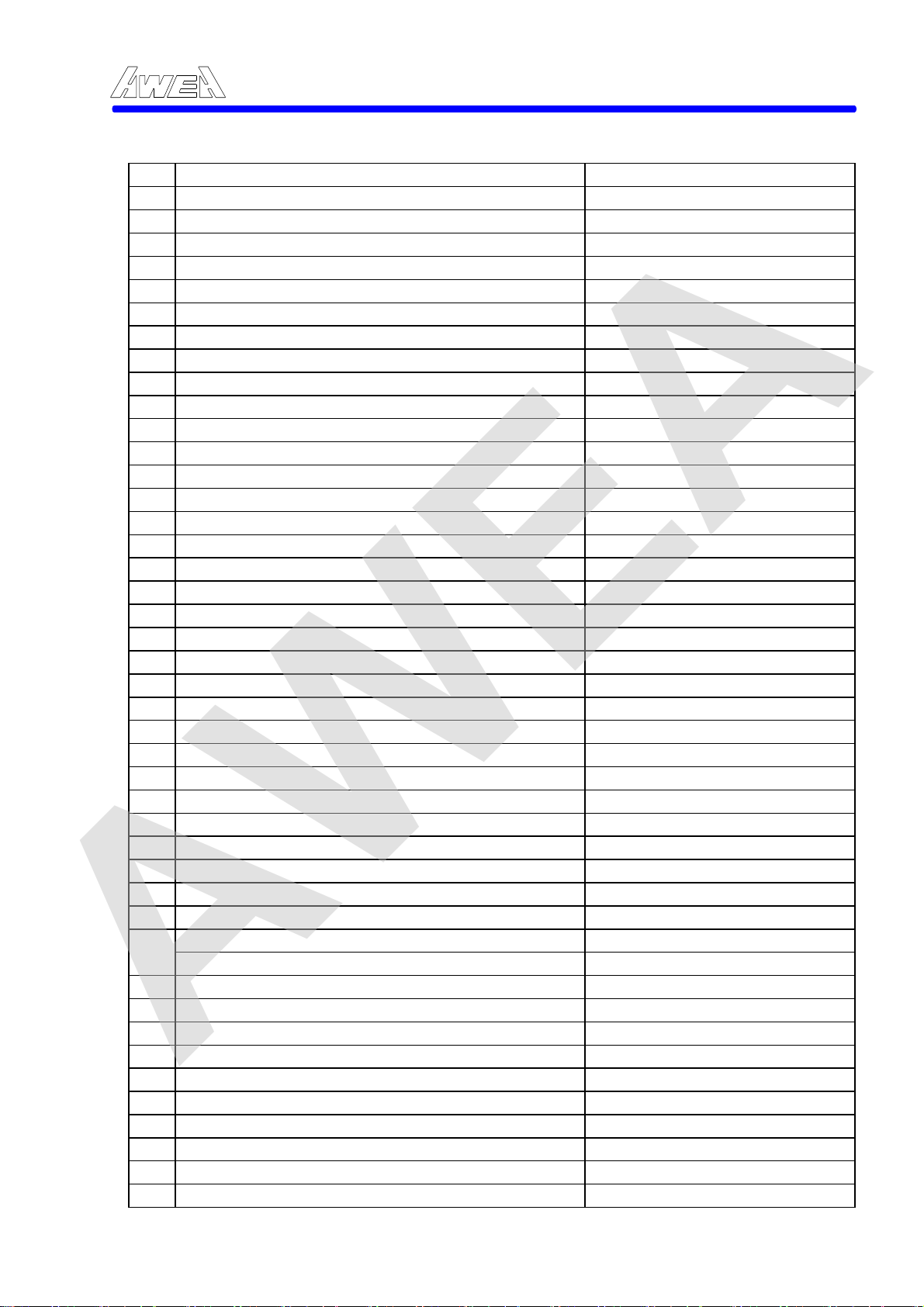

2.3.2 Control function (Standard)

01. Controlled axes 3 Axes 3 Axes

02. Simultaneous controllable axes 3 Axes 3 Axes

03. Least input increment

04. G20 Inch/ G21 metric conversion

05. Interlock

06. Machine lock

07. Emergency stop

08. Stored stroke check

09. Backlash compensation

10. Stored pitch error compensation

11. Automatic operation (memory)

12. DNC operation

13. MDI operation

14. Program number search

15. Sequence number search

16. Dry run

17. Single block

18. JOG feed

19. Manual reference position return

20. Manual handle feed

21. Incremental feed

22. G00 Positioning (G01 type positioning is possible)

23. G61 Exact stop mode

24. G09 Exact stop

25. G01 Linear interpolation

26. G02, G03 Circular interpolation

27. Dwell

28. G31 Skip function

29. G28 Reference position return

30. G27 Reference position return check

31. 2nd reference position return

32. Rapid traverse rate

33. Rapid traverse override Fo,25,50,100%

34. Automatic acceleration/deceleration (Rapid traverse:linear, Cutting feed:exponential)

35. Feedrate override

36. Override cancel

37. EIA/ISO Automatic recognition

38. Label skip

39. Optional block skip

40. Program number O4-digit

41. Sequence number N5-digit

42. G90 Absolute/G91 incremental programming

43. Decimal point input

44. Pocket calculator type decimal point input

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-10

:

.001mm/0.00001inch

x1,x10,x100

2-10

AWEA

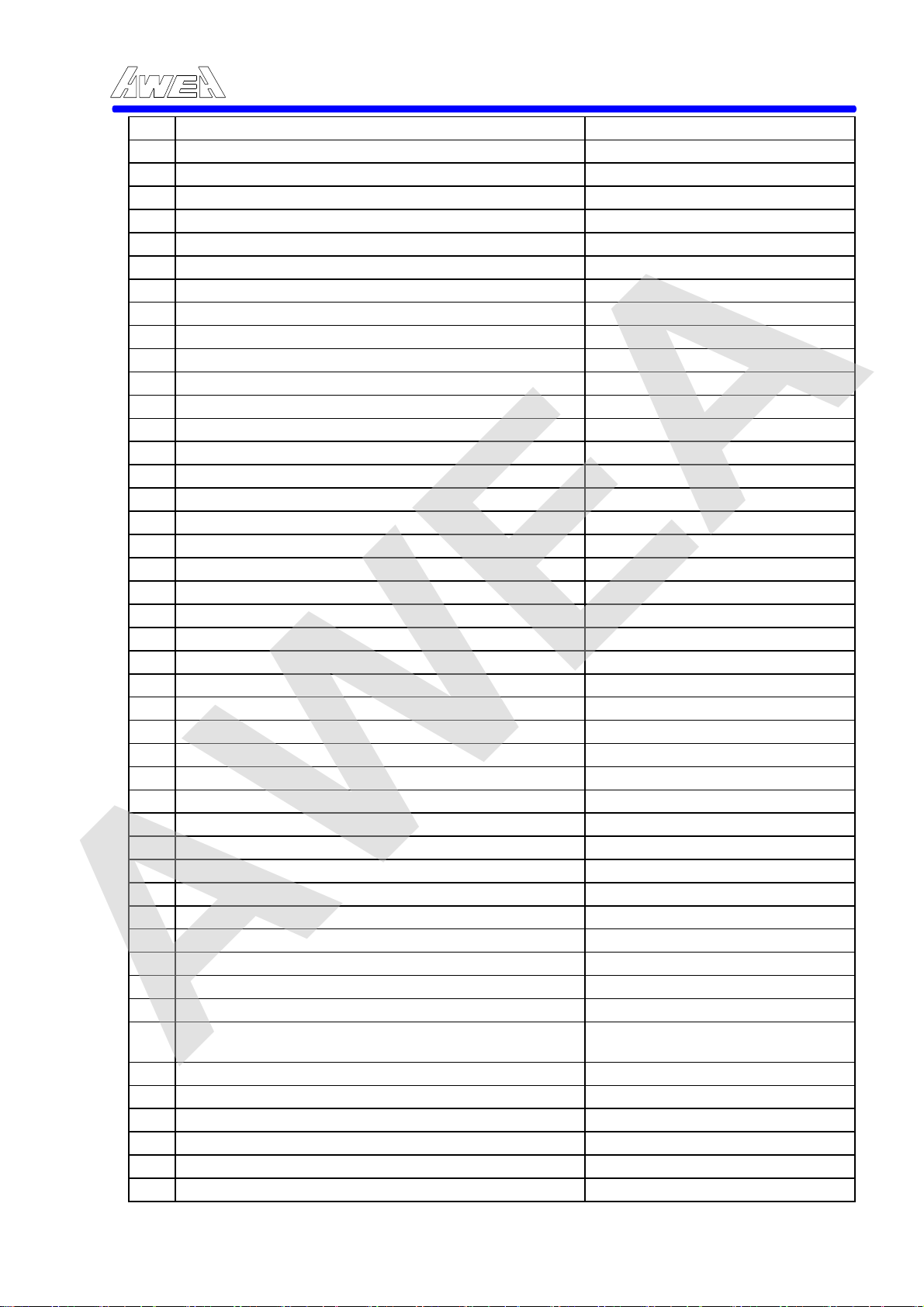

45. Plane selection G17,G18,G19

46. Coordinate system setting

47. Automatic coordinate system setting

48. Workpiece coordinate system

49. Manual absolute on/off

50. Rigid tapping

51. Sub program call: 4 folds nested

52. Custom macro B

53. Canned cycles for drilling

54. Circular interploation by R programming

55. Miscellaneous function

56. Miscellaneous function lock

57. S code

58. Spindle speed override

59. Spindle orientation

60. T code

61. Tool offset memory

62. Tool length compensation

63. Cutter cpmpensation C

64. Part program storage length

65. Registered programs

66. Part program editing

67. Program protect signal

68. Status display

69. Clock function

70. Current position display

71. Program display (Program name 31 characters)

72. Parameter setting and display

73. Self-diagnosis function

74. Alarm display

75. Alarm history display

76. Tool offset

77. Help function

78. Run hour and parts count display

79. Actual cutting feedrate display

80. Servo setting screen

81. English display

82. Data protection key 3 types

83. Erase CRT screen display

84.

85. Chinese/English display

86. RS232-C interface

87. Input power supply 220 Vac ±10%

88.

89. Mirror image

90. Program restart

Setting and display unit 10.4" color LCD/MDI

(standard size)

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-11

G52、G53、G54~G59

:

99 sets

:

160 Meter

:

63

50~60Hz±3Hz

2-11

AWEA

91. Manual handle interruption

92. Single direction positioning

93. Programmable data input

94. 2D coordinate rotation

95. Manual guide

96. Background editing

97. Playback

98. Scaling

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-12

2-12

3、So

AWEA

2.4 Operator’s Control Panel

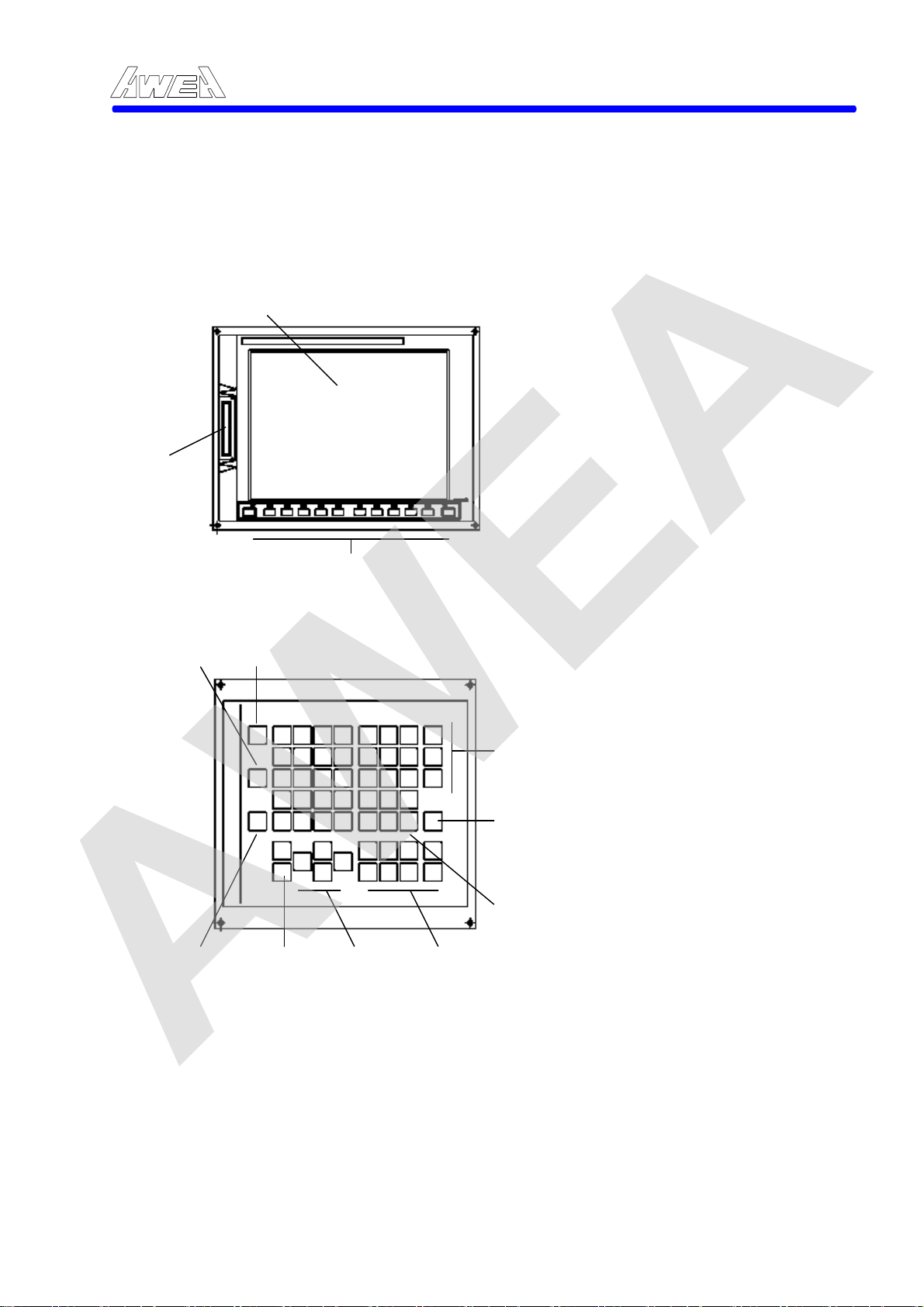

2.4.1 LCD/MDI panel

LCD/MDI consisted of LCD (10.4” color display) and keyboard, shown as Figure 2-4.

【LCD unit】

1、Liquid-crystal display

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-13

1、10.4 LCD 2、Memory card interface

2、Memory card interface

【MDI unit】

4、Help key

5、Reset key

ft key switch

6、Edit key

7、Cancel key

8、Input key

3、Soft key switch

4、Help key

5、Reset key

6、Edit key

7、Cancel key

8、Input key

9、Function keys

10、Cursor keys

11、Page-Up/Down keys

、Shift key

12

12、Shift key

11、Page-Up/Down keys

10、Cursor keys

Figure 2-4 LCD/MDI panel

9、Function keys

2-13

AWEA

A. Key function:

The position push-button indicates the current position of the slides. The information is spread over pages.

In "EDIT" mode the cursor can be moved the any desired command by

using the Cursor Forward or Reverse.

In "MDI" mode the cursor can be input data to the buffer memory.

In "AUTO" mode the cursor can be displayed current commends.

The OFFSET push-button displays either the offset chapter or work shift chapter. Repeatedly pressing "OFFSET" push-button will alternately display on chapter or the other.

The button displays setting of the System Diagnostic data and System parameter data.

The button displays Alarm messages of interest to the operator in two chapter.

The software operator's manual shown as following figure which can be determined by the following procedure:

1. Press the Offset & Setting button.

AWEA SP/LP Series Manual - Chapter 2. INSTRUCTION 2-14

Î

OPR 3. Select the OPR soft

2. Select the manual by pressing this button which located under the CRT

-key by pressing the button located under the CRT

4. Press the page button down, then the following picture will be displayed.

2-14

Loading...

Loading...