Page 1

Internal Make-up Air Canopy for

Light And Medium

Duty Cooking Equipment

CHINOOK Value Ventilation

Description:

This internal make-up air canopy is designed to

reduce exhausting large quantities of air from the

conditioned space. Non-tempered make-up air is

introduced under the hood reducing the amount of

conditioned air removed from the building.

The VID model is UL 710 Listed for use over 400

and 600°F commercial cooking appliances. This

model is recommended for all projects where energy

consumption is a factor or when adequate makeup air is not available from the heating and cooling

system.

Specifications:

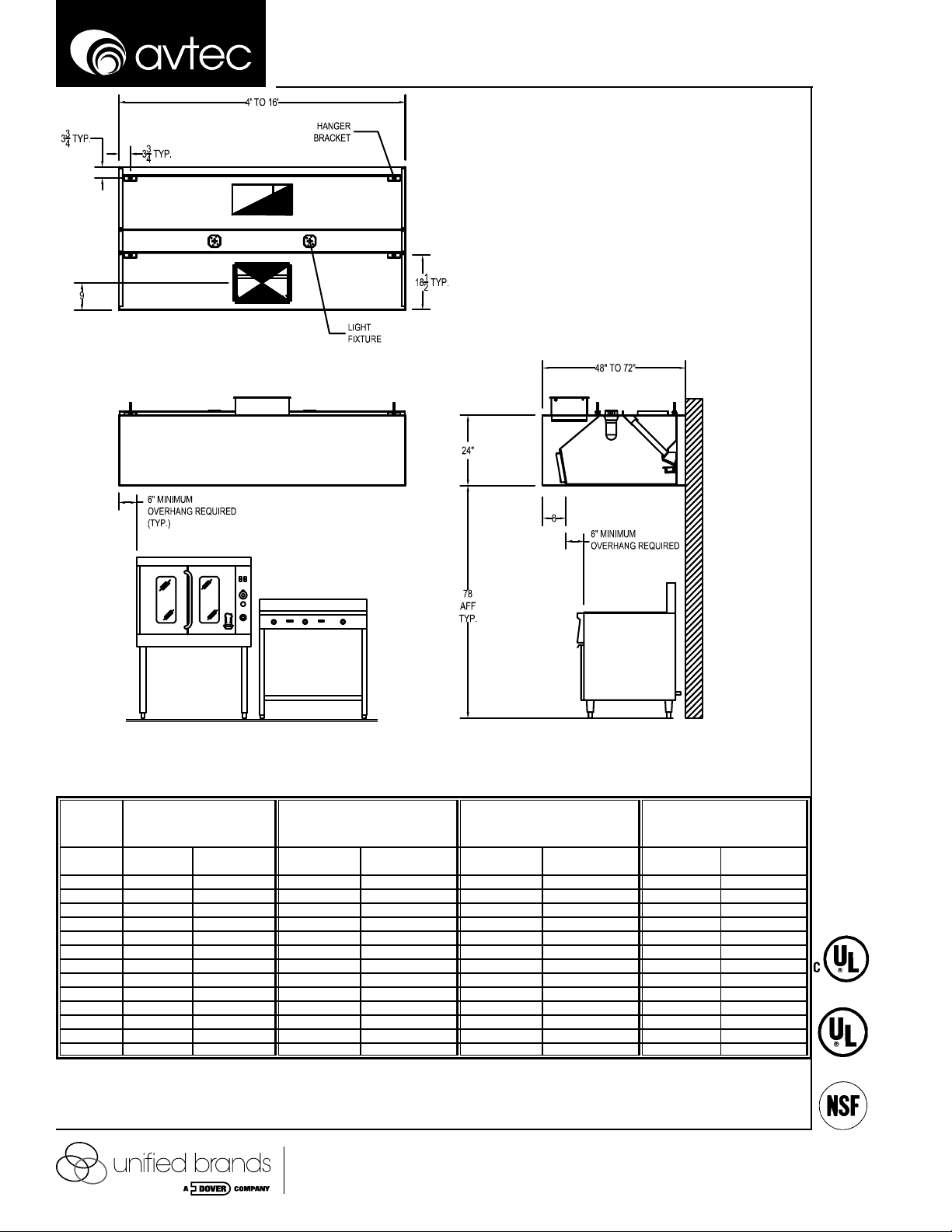

A double shell, internal make-up air canopy constructed of stainless steel on all exposed surfaces and aluminized steel on all

non-exposed surfaces. Canopy shall have all welded exterior joints and seams. Canopy construction shall conform to NFPA 96

standards. All exposed welds are to be ground and polished to match nish requirements. Canopy is to meet NSF standards for

construction and UL standards for operation. Grease trough(s) to be easily removable and sloped to removable grease cup(s).

The internal make-up air louver shall be an extruded aluminum diffuser with 15 degree non-adjustable vanes spaced ½” apart.

The hood supply plenum shall be lined with 1” thick foil backed insulation for prevention of condensation. The supply air shall

pass through two perforated metal bafes for even air ow out of the louvers. A UL Listed re damper and air volume damper

in the supply collar shall be supplied by the factory and may be installed in the eld if required. Canopy to be complete with UL

Listed removable bafe style aluminum grease lters. Canopy complete with UL Listed globe type incandescent light xtures

mounted on 36” centers.

Internal MUA Filter

model VID

Standard Features: Optional Accessories:

• Stainless steel construction where visible

• UL Listed aluminum grease lters

• UL Listed globe light xtures mounted on 48” centers

• 3” rear air space

• Removable grease trough & cup(s)

• Hanging brackets

• 1” thick supply air plenum insulation

• Extruded aluminum interior linear diffuser

• UL Listed re damper in supply collar

• Air volume damper in supply collar

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

UL Listed stainless steel grease lters

14” Utility cabinet

Insulated 3” air space

Electrical Control Panel

Pre-plumbed re suppression

Stainless steel top enclosures

Light and fan switch

Recessed uorescent light xtures

Stainless steel wall panel

Stainless steel side skirts

Melink Intelli-Hood® system controls

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Avtec CHINOOK Value Ventilation, Page 13

PP SPEC1037 Rev. D

Revised 05/09

Page 2

Model VID

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1100 8 x 14 1300 8 x 14 1400 10 x 12 800 12 x 12

5’-0” 1375 8 x 16 1625 8 x 18 1750 10 x 16 1000 10 x 16

6’-0” 1650 8 x 18 1950 10 x 18 2100 10 x 18 1200 12 x 18

7’-0” 1925 8 x 22 2275 10 x 20 2450 10 x 22 1400 12 x 24

8’-0” 2200 8 x 24 2600 10 x 24 2800 10 x 24 1600 12 x 24

9’-0” 2475 10 x 22 2925 12 x 22 3150 12 x 22 1800 10 x 30

10’-0” 2750 10 x 24 3250 12 x 24 3500 12 x 26 2000 10 x 40

11’-0” 3025 10 x 28 3575 12 x 26 3850 12 x 28 2200 2-10 x 20

12’-0” 3300 12 x 30 3900 12 x 30 4200 12 x 30 2400 2-10 x 20

13’-0 3575 2-10 x 16 4225 2-10 x 20 4550 2-10 x 20 2600 2-10 x 30

14’-0” 3850 2-10 x 18 4550 2-10 x 20 4900 2-10 x 22 2800 2-10 x 30

15’-0” 4125 2-10 x 18 4875 2-12 x 18 5250 2-12 x 20 3000 2-10 x 30

16’-0” 4400 2-10 x 20 5200 2- 12 x 20 5600 2-12 x 22 3200 2- 10 x 30

Note: Greater exhaust and/or lesser supply air ow rates may be required for each specic installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600FPM. Duct collars are

located on centerline of canopy, unless otherwise specied. Hoods with double collars have them located on ¼” lines hood length lines. Canopy is to

have a minimum 6” overhang on all exposed sides and front leading edge of canopy to the perimeter of the cooking equipment surface.

CFM @

.625 SP

Duct Collar

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

.75” SP

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

Exhaust CFM

CFM @

1.00”SP

Duct Collar

CFM @

.375”SP

Supply CFM

Duct Collar

NFPA-96

Loading...

Loading...