Avtec Ventilation System Service Manual

OPERATOR MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

This manual provides information for:

VENTILATION

SYSTEMS

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the consignee to inspect the container upon receipt of

same and to determine the possibility of any damage, including concealed damage. Unified Brands suggests that if you are suspicious of damage to make a

notation on the delivery receipt. It will be the responsibility of the consignee to file

a claim with the carrier. We recommend that you do so at once.

Manufacture Service/Questions 888-994-7636.

Information contained in this document is known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated product information and specifications.

PART NUMBER OMANUAL_VMR-0507 Rev. A (0507)

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

avtecind.com

TABLE OF CONTENTS

4

4

4

5

5

5/6

6

6

7

7

7

9

9

9/10/11

13

13

13

13

13

13

13

13

13

14

15

15

15

15

15/16

16/17

16/17

17

17

17

17

17

17

17

17

17

17

17/18

17/18

18

18

18

18

19

19

19

19

20

20

20

20

22

A. Baffle Filter . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Modular Grease Extractors [Energy Aire] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Auto Wash [Energy Aire] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. Airflow Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .

E. Fire Extinguishing Systems .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. Ec oArch C anopi es . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Ec oArch C anopi es With Ceiling Mounted Make-Up Air Plenum . . . . . . . . . . . . . .

A. Wall Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. VCW Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. PAWS Control Panel . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Damper and Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. Ventilator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. Hot Water Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Cold Water Mist [optional] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. Field Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. Detergent Pump and Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. Interconnecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G. Detergent Flow Chart . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. VCW Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Adjustment . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Sequence Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Trouble-Shooting . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. PAWS Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

a. Fan Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

b. Fan Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c. Wash Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

d. Wash Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Trouble Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

a. Low Detergent Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

b. Supervised Valve [optional] . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Hood Plenum Fire Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

a. Automatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

b. Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Programming Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

a . Setting The Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

b. Setting The PAWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Single Wash Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Multi-Wash Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c. Setting The Fire Delay . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

d. Reviewing The Daily Event Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

e. Changing The Daily Event Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

f. Repeating The Daily Event Schedule . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .

g. Holiday Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

h. Fan On During Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i. Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

j. Last Command Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

k. Diagnostic Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l. Detergent Pump and Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 OM-VMR

A. Baffle Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Modular Grease Extractors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Auto Wash Grease Extractors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. Air Adjustment Baffle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. Fire Dampers . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. .. . . . . . . .. .. .

F. Air Make-Up [Supply] Plenums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .. .

G. Auto Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H. Cold Water Mist [Optional] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. Baffle Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Modular Grease Extractors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Grease Trough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. Grease Collection Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. Hood Canopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. Detergent System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G. Fusible Link Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. PAWS Panel - Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. VCW Panel - Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. PAWS/VCW Panel - Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. EVAC Detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. Electro-Mechanical Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. Fusible Link Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G. Hood Canopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SGNIWARDDNAATADREHTO.X

A. EVAC Cleaner Cut Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Air Movement Recordings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Calculating and Recording Air Movement Readings . . . . . . . . . . . . . . . . . . . . . .

D. Calculating and Recording Air Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22

22

22

23

23

24

24

25

25

25

25

25

25

25

26

26

26

26

27

27

27

27

28

28

29

29

30

30

31

32

33

34

OM-VMR 3

1

I. TYPES OF SYSTEMS

This manual covers three [3] of the basic types of

systems offered by AVTEC - Baffle Filter [AF],

Modular Grease Extractor [AX] and Auto W ash

Down [AW].

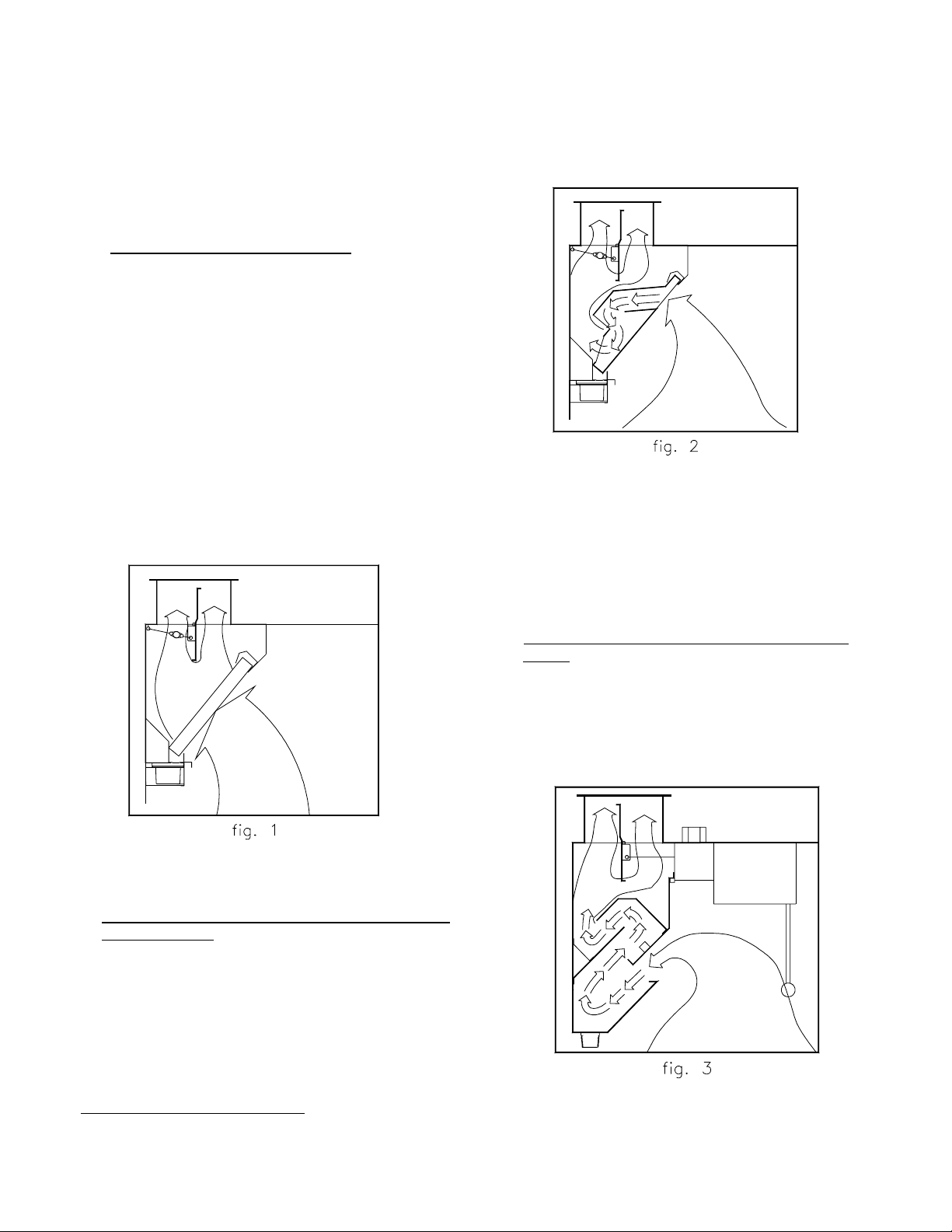

A.Baffle Filter [AF Series] [See fig. #1

]

Model AF ventilators are listed by Underwriters

Laboratories Inc. [UL] and are built in accordance

with the National Fire Protection Association

[NFPA] Standard No. 96 for use with UL Listed

fire extinguishing systems for duct hood

protection. They are available with or without an

automatic exhaust fire damper. They utilize UL

Classified removable baffle filters to extract

grease and provide a limited fire barrier. The

canopy contains an integral grease trough and

removable grease receptacle(s). Surface,

plenum and duct collar fire extinguishing systems

may be factory supplied.

Vent Control Panels may be supplied with these

systems. See additional wiring diagrams for

options.

Installation shall be in accordance with NFPA 96.

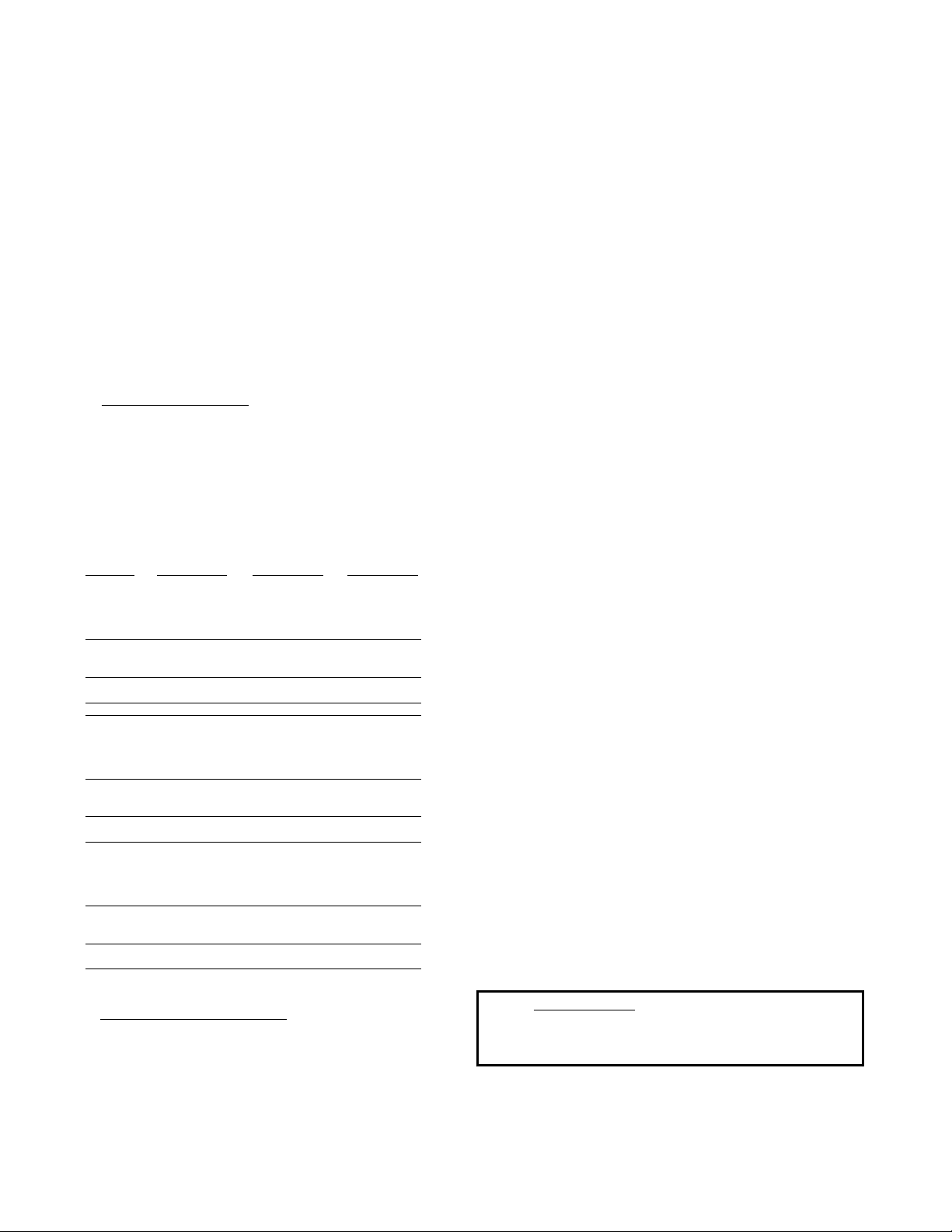

B.Modular Grease Extractors [AX Series] Energy

Aire [see fig. #2]

Model AX ventilators are listed by UL and built in

accordance with NFPA Standard No. 96 for use

with UL Listed fire extinguishing systems for duct

and hood protection. They are available with or

without an automatic exhaust fire damper.

These models utilize high velocity removable

grease extractors. This exclusive design extracts

up to 95%* of airborne grease contaminants. The

1

*Data from independent tests not a part of UL test

procedure.

canopy contains an integral grease trough and

grease collection receptacle(s). Surface, plenum

and duct collar fire extinguishing systems are

required and may be factory supplied.

Vent control panels may be supplied with these

systems. See additional wiring diagrams for

options.

Installation shall be in accordance with NFPA 96.

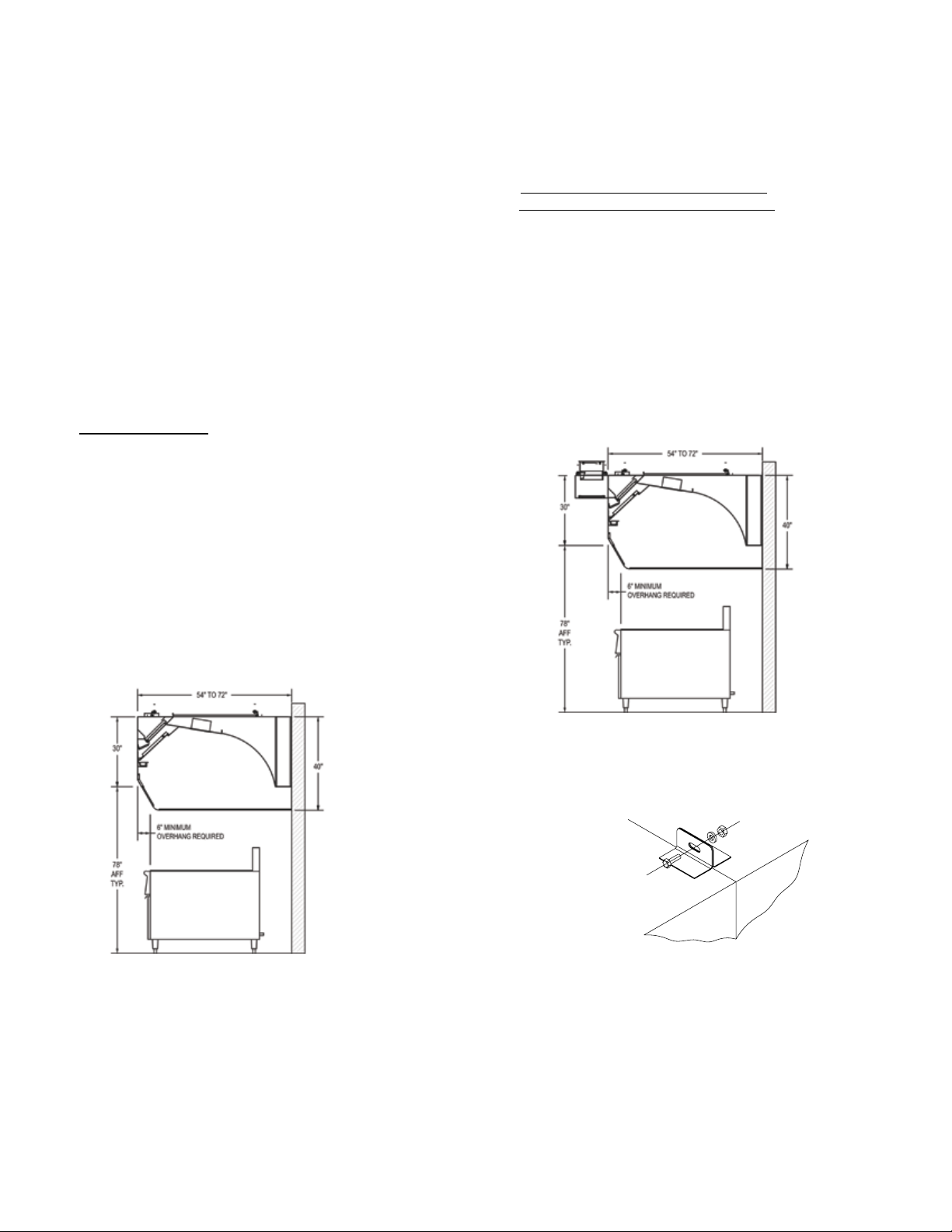

C.Auto Wash Down [AW Series] Energy Aire [see

fig. #3]

Model AW ventilators are listed by UL and built in

accordance with NFPA Standard No. 96 for use

with UL Listed fire extinguishing systems for duct

and hood protection. They are available with or

without an automatic exhaust fire damper.

These systems utilize a high velocity grease

extractor. This exclusive design extracts up to

95%* of airborne grease contaminants. An

4 OM-VMR

integral water wash system cleans the inside of

the grease extraction chamber either by manual

activation of the Wash Start button or by a

programmable timer. The duration of the wash is

electrically controlled. The wash system is also

activated by an electrical thermostat or a manual

switch in the event of a fire condition. A surface

fire extinguishing system is required and may be

factory supplied.

Auto Wash control panels are provided with these

systems. Wiring diagrams are provided with this

manual.

Installation shall be in accordance with NFPA 96.

D.Airflow Requirements

Minimum exhaust airflow requirements and

maximum make-up airflow requirements [where

air is introduced directly inside the canopy] are

shown on the chart below. These flow rates were

established under laboratory conditions. Greater

exhaust airflows and/or reduced make-up airflows

may be required for complete capture.

CFM REQUIREMENTS

400°F Cooking 600°F Cooking 700°F Cooking

Model No. Surface Equip. Surface Equip. Surface Equip.

AFWO,AFBO 200 300 525

AFDO,AFWP

AFBP,AFDP

AFWE,AFDE

AFBE

AFWI,AFBI 250[175] N/R N/R

AFDI,AFWD

AFBD,AFDD

AFIO,AFIP 250 400 600

AFIE

AFII,AFID 300[150] N/R N/R

AXWO,AXBO 200 275 525

AXDO,AXWP

AXBP,AXDP

AXWE,AXDE

AXBE

AXWI,AXBI 250[175] N/R N/R

AXDI,AXWD

AXBD,AXDD

AXIO,AXIP 250 400 600

AXII 300[150] N/R N/R

AWWO,AWWP 194 270 *525

AWWE,AWDO

AWDP,AW DE

AWBO,AW BP

AWBE

AWWI,AWBI 250[190] 270[146] N/R

AWDI,AWWD

AWBD,AW DD

AWTE,AW TP 400 420 N/R

AWTO

N/R = Not Recommended

*=Manufacturer's test results not yet submitted to U.L. for capture tests.

E.Fire Extinguishing Systems

There are two basic types of ventilator fire

extinguishing systems in use today:

Wet Chemical and Water Mist. Wet Chemical

Systems may be all or partially factory installed

[by the Fire System Manufacturer]; final hook up

and certification at job site is done by the Fire

System Manufacturer's local representative.

These systems must be periodially inspected,

and critical parts replaced. It is suggested that a

service contract be purchased from the local

representative. For further details refer to the

manufacturer's technical manual.

AVTEC manufactures and installs a water mist

fire extinguishing system, "MIST-A-FIRE", that

connects to the building fire sprinkler system

[must be "wet" type system]. Final connect of this

system must be done in the field by the sprinkler

contractor or authorized plumber. A

certification/inspection report is done by an

authorized AVTEC representative. Periodic

inspection is generally required, but replacement

of parts and periodic maintenance is virtually

eliminated. For further details, refer to the

AVTEC MIST-A-FIRE Installation and Operating

Technical Manual.

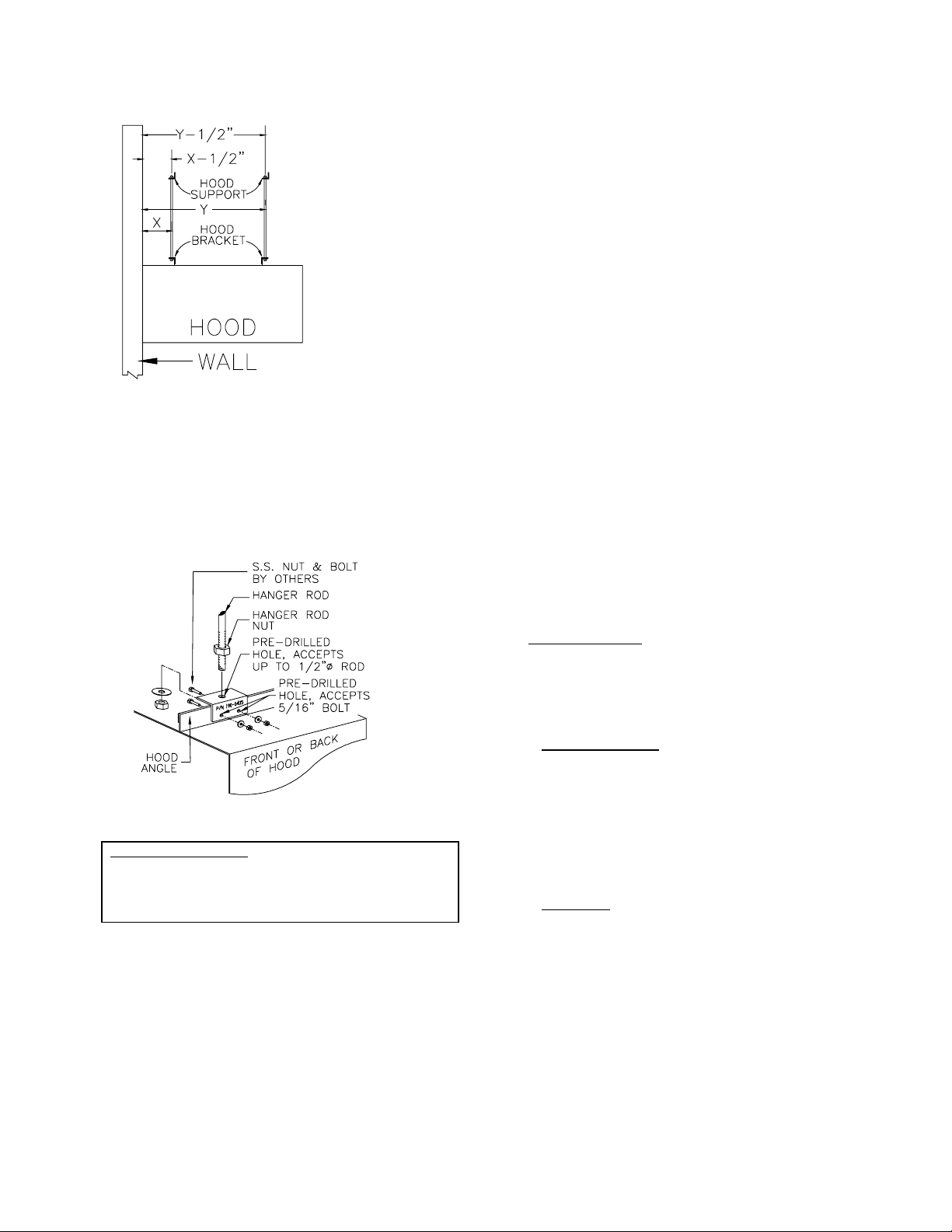

II. INSTALLING THE VENTILATOR

The ventilator is supplied with brackets to facilitate

the attachment of hanger rods to the vent. Hanger

rods should be attached to all brackets to ensure

proper support.

A.Ascertain that the ceiling/roof structure is strong

enough to support the weight of the hood and

support system. The approximate weight of the

hood is shown below:

45 lbs/linear ft. for hoods w/o AMU plenums.

55 lbs/linear ft. for hoods w/AMU plenums.

125 lbs for fire control cabinet.

B.Carefully uncrate the hood so as not to dent or

scratch the outer surface.

C.Position the hood on the floor in approximately

its final installed location.

D.Use 1/2" threaded rods to hang the hood. The

hanger rods should be approximately 1/2" closer

to the wall at the structural attachment location

than at the top of the hood. [see fig. #4] This

ensures that the hood is held tightly against the

wall.

Note! Do not remove

Support Brace until Ventilator

installation is complete. Upon completion of

installation, dispose of Support Brace and replace the

Acorn Nuts to their original locations.

OM-VMR 5

Fig 4

E.The hood should be hung so that the bottom of the

hood is 6'-6" above the finished floor unless otherwise

specified. Carefully lift the hood into position being

certain to avoid scratching the finished surfaces.

Install 1/2" threaded rod from each bracket and the

structural support. Secure rods with heavy duty nuts.

[see fig. #5] Be sure that the hood is level.

Fig 5

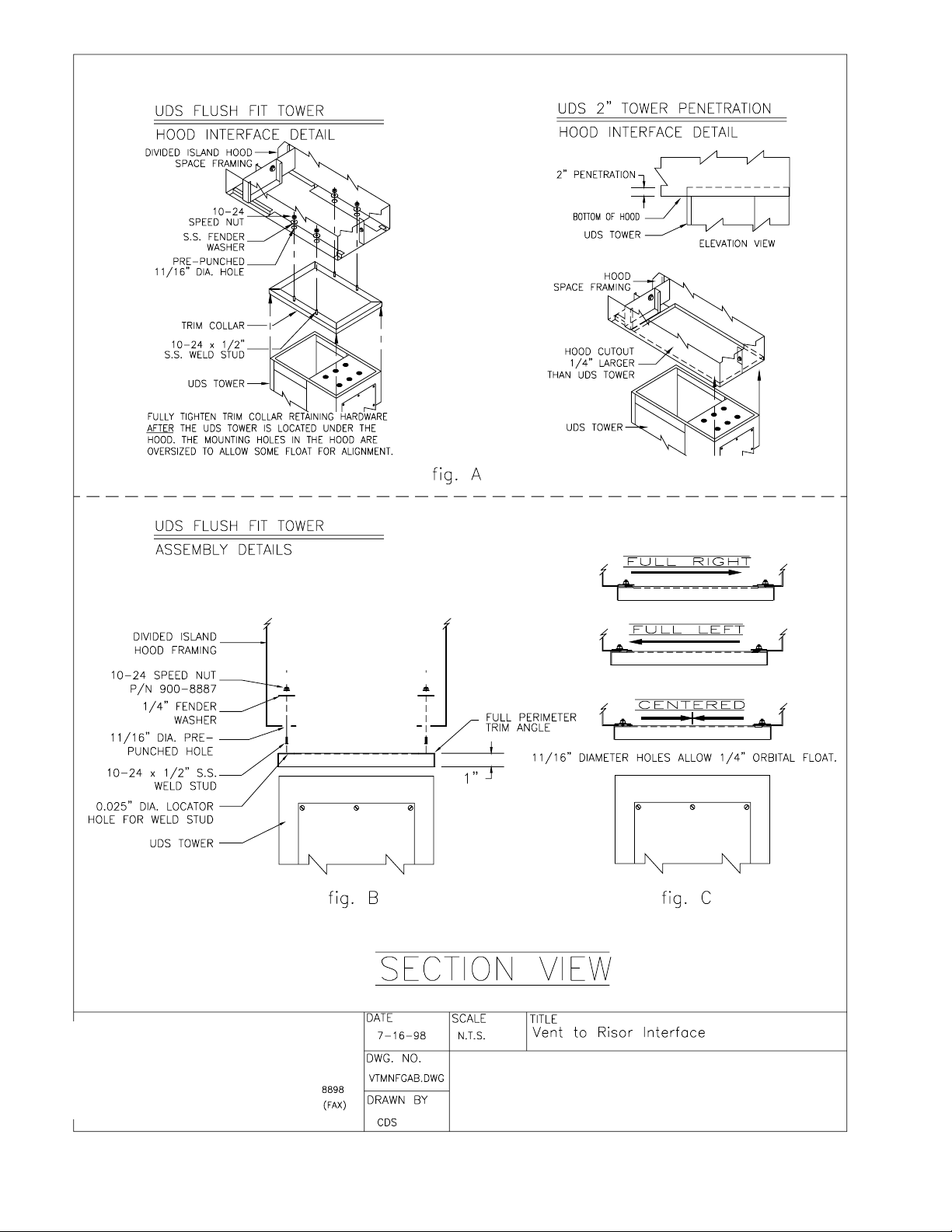

Tower Interface Detail

Place trim collar on tower. Position tower under hood.

Fully tighten trim collar retainer hardware after tower

and hood are aligned properly. See fig. A, B, and C

(next page).

F.The entire exhaust duct system must be con-

tinuously welded. This includes the connection

to the duct collar and the roof curb. All welds

must be liquid tight.

NOTE: Welds must not impede operation of

damper.

G.Connect the lights to the circuit breaker panel

through the light switch. All connections should

be in compliance with NFPA 70, National Electric

Code [NEC].

H. Install bulbs in the light fixture[s].

I.Install the grease filters [AF] or modules [AX].

J.Install the grease receptacles [AF or AX]

NOTE: A minimum of a three inch [3"] insulated

fire barrier and air space must be maintained

between the capture area skin of the ventilator

and any combustible surface, including wall and

ceiling. AVTEC ventilators normally have a 3" air

space; insulation is added when specified.

III.CONTROL PANEL [if provided]

Control panels are provided with all auto wash type

ventilators [Models AW- ] and are optional with the

baffle filter type [AF- ] and modular grease

extractor type [AX- ]. Control panels with Models

AF- and AX- do not have the auto wash plumbing

assembly compartments. Any control panel may

be provided with a integral MIST-A- FIRE

Extinguishing System alarm panel and sprinkler

assembly piping; refer to the MIST-A-FIRE

technical manual.

A.Wall Attachment

Control panel dimensions and connection detail

are shown on the enclosed shop drawing.

Panels may be surface mounted, partially

recessed or fully recessed as shown on fig. 6.

1.Surface Mounted

Drill four [4] holes in ventilator plumbing

compartment as required. Be careful not to

damage any components. Avoid drilling into

electrical compartments. Bolt to wall with

anchor bolts or other acceptable means.

Weight of control panel varies from 90 lbs. to

200 lbs.

2.Recessed

Cut hole in wall 1/2" greater than O/A

dimensions of control box [shown on shop

drawing]. Spacers or support angles may be

necessary to provide proper support. It is

recommended that panel be bolted to wall

similar to method used for surface mounted

above.

6 OM-VMR

ECOARCH HOOD MODELS

The Avtec EcoArch is the latest addition in premium ventilation

systems that continues Avtec’s reputation as an innovative,

technology leader focused on providing solutions for our

customers needs. The combination of the patent pending

arch top and the front mounted high velocity exhaust slot

reduces the amount of exhausted CFM by 45% compared to

traditional CFM rates. This translates into an annual electric

and gas savings of up to 40%.

INSTALLATION INSTRUCTIONS

All EcoArch hoods by Avtec are provided with hanging brackets

designed to receive ½” threaded rod with a ½” bolt and washer.

Supporting rods (provided by others) must be connected to all

factory installed brackets. Recommended hanging height is

between 6’-6” and 7’-0” above the nished oor.

ALL AVTEC VENTILATION SYSTEMS MUST BE INSTALLED

IN ACCORDANCE WITH NFPA-96 REMOVAL OF SMOKE

AND GREASE-LADEN VAPORS FROM COMMERCIAL

COOKIGN EQUIPMENT.

A. EcoArch Canopies

1. Check all local codes prior to installation. Special

requirements may be necessary depending upon

building construction.

8. For make-up air hoods, the supply collar with built-in

UL listed re damper and air volume damper must be

installed per instructions on collar.

9. Provide a removable service door in supply duct near

re damper.

B. EcoArch Canopies equipped with a

Ceiling Mounted Make up Air Plenum

If your EcoArch hood comes equipped with a ceiling

mounted make up air plenum please refer to the following steps.

Follow steps 1-3 as outlined at left.

4. Suspend hood from adequate roof supports using ½”

threaded rods with nuts and washers.

5. Level hood left to right and front to back.

6. The make up air plenum is designed to mount against

the front face of the hood.

2. Move crated hood to location of installation and very

carefully uncrate hood.

3. Front Mounted Exhaust Plenum: The EcoArch is

different from almost all other kitchen exhaust hoods on

the market today. The exhaust plenum is in the front of

the hood versus the traditional rear location to minimize

exhausted kitchen air and for easier and safer access

to the lter medium for cleaning and/or replacement.

Refer to drawing before proceding to step 4.

4. Suspend hood from adequate roof supports using 1/2”

threaded rods with nuts and washers.

5. Level hood left to right and front to back.

6.

Brackets are provided for hoods which are to be installed

end to end or back to back. Bolt brackets together using

3/8” bolt through holes provided. (See Fig. 6 at right)

7. Install C channel where the ends of the hood meet and

install T moldings on front face of hoods where they

join. High temperature silicone can be used to install C

channel and T moldings.

7. Brackets are provided at the top front of the hood and

the top of the make-up air plenum box. Bolt brackets

together using 3/8” bolt through holes provided. (See

Fig. 6)

Fig 6

8. Install C channel where the ends of the hood meet

and install T moldings on front face of hoods where

they join. High temperature silicone can be used to

install C channel and T moldings.

9. For make-up air hoods, the supply collar with built-in

UL listed re damper and air volume damper must be

installed per instructions on collar.

10. Provide a removable service door in supply duct near

re damper.

OM-VMR 7

8 OM-VMR

IV. ELECTRICAL CONNECTIONS

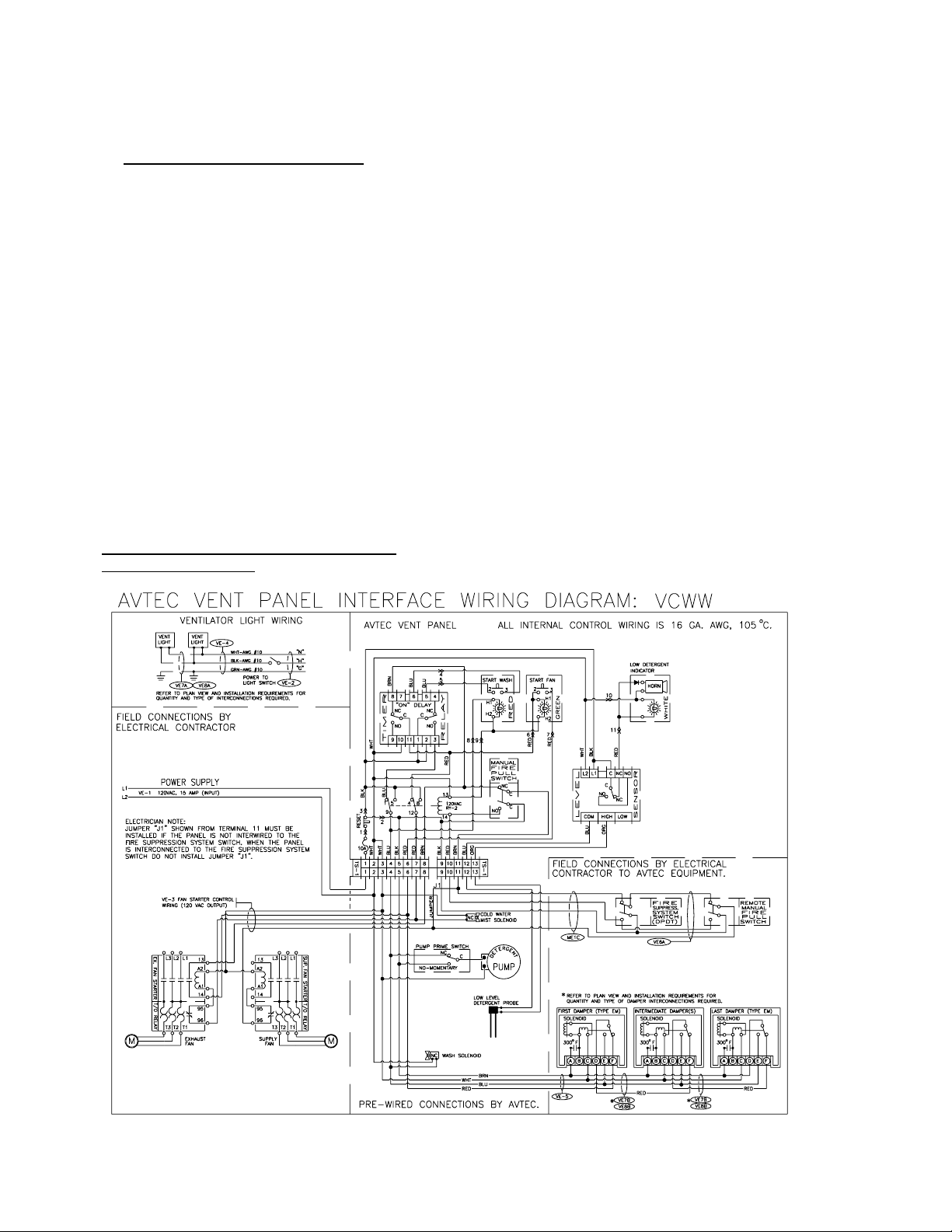

A.VCW Control Panel [Refer to fig. 7]

1.Typical field connection terminals for VCW

Control Panel are shown in fig. 7. For custom

features such as sequential wash, time delay,

etc. refer to AVTEC shop drawing in back of

this manual.

2.Terminals No. 1 and No. 2 are for the

120vac Power Supply. Terminal No. 1 is Hot

and Terminal No. 2 is Neutral.

3.Terminals No. 3 and No. 4 are 120vac

power for the Water Solenoid and Detergent

Pump. These terminals are "hot" whenever

the Water Wash Solenoid and the Detergent

Pump is scheduled to be "ON" or when there

is a fire condition. Terminal No. 5 provides

power for a pump/prime switch with a

momentary closed/normally open contact.

This switch is helpful in checking the

performance of the pump as well as in

priming the pump.

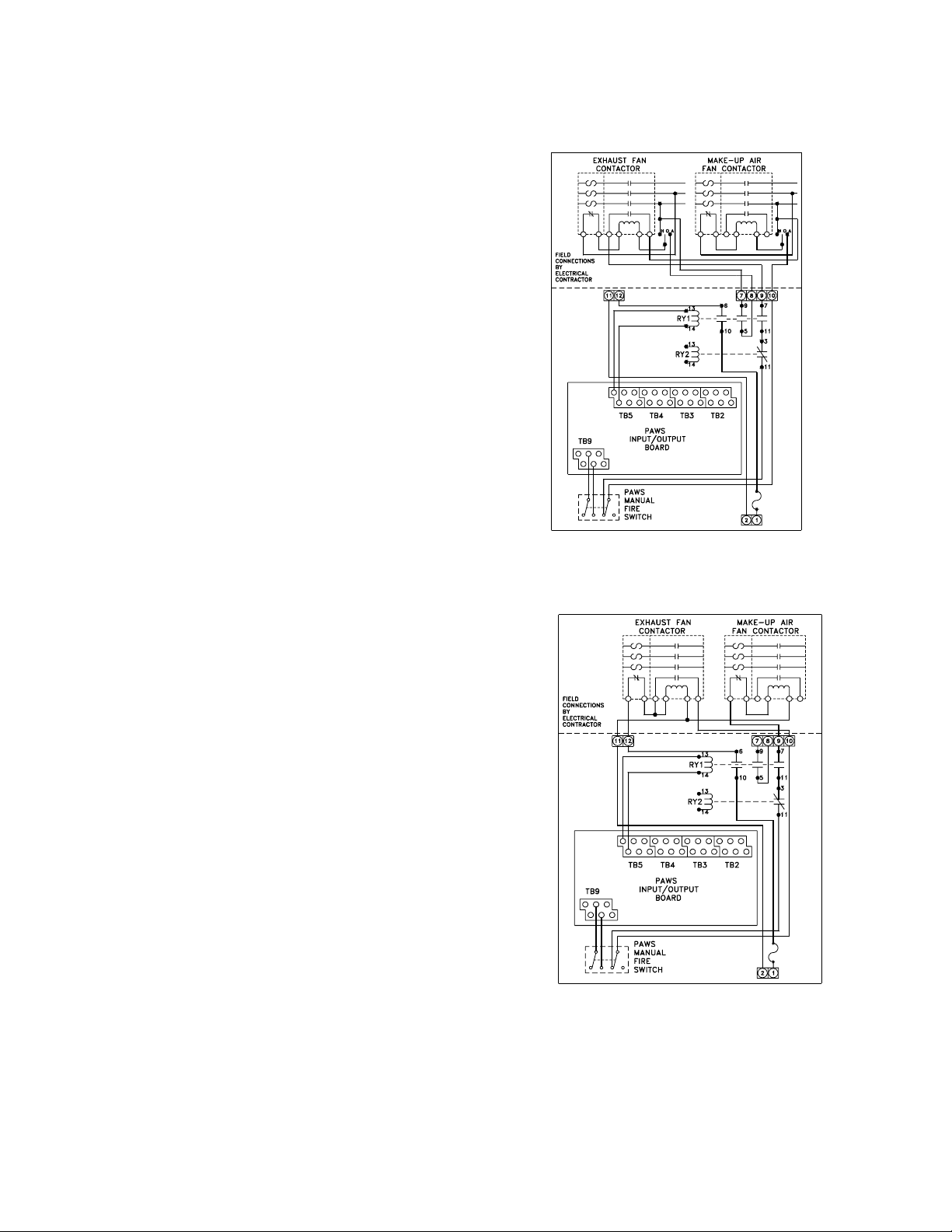

B.Programmable Automatic Wash Sequence

[PAWS] Control Panel

1.Typical Field Connections for the PAWS

Control Panel are shown on [figs. 10, 11, and

12]. Note that all options and connections may

not be included on your system.

2.Terminal Block #1 [TB-1] has three [3]

terminals and is located on the right-hand side of

the Input/Output [I/O] Board. Terminal #1

[uppermost] is for the Hot lead of the power

supply and is protected by a fuse located within

the panel. Terminal #2 [center] is for the Neutral

lead of the power supply. Terminal #3

[lowermost] is used to ground the Input/Output

Board to the Control Panel Housing.

Terminal No. 4 is Hot and Terminals No. 2 & 3

are Neutral.

3.Terminals No. 3 and No. 6 carry 120vac

whenever the fans are scheduled to be ON.

They are used to activate the fan contactor[s]. In

the event of a fire situation, power is removed

from Terminal 5 which provides power for

Terminal No. 6. Terminal No. 6 is the Hot lead

and Terminal No. 3 is Neutral.

7.giF

OM-VMR 9

4.Terminal Block #2 [TB-2] has three [3] pairs of

terminals and is located at the upper right corner

of the Input/Output Board. The first pair of

terminals are for the number one wash valve

solenoid. This will be the only wash output

active in a P-10-__ or P-15-__ Control Panel.

The second pair of terminals are for the number

two wash valve solenoid. The third pair of

terminals are for the number three wash valve

solenoid.

5.Terminal Block #3 [TB-3] has three [3] pairs of

terminals. It will not be present on P-10-__ or P15-__ Control Panels. The first pair of terminals

are for wash valve solenoid number four. The

second pair of terminals are for the number five

wash valve solenoid. The third pair of terminals

are for the number six wash valve solenoid.

6.Terminal Block #4 [TB-4] has three [3] pairs of

terminals. It will not be present on P-10-__ or P15-__ Control Panels. The first pair of terminals

are for the number seven wash valve solenoid.

The second pair of terminals are for the number

eight wash valve solenoid.

7.Terminal Block #5 [TB-5] has three [3] pairs of

terminals. The first pair provides power for the

detergent pump. The second pair provides

power for the PAWS Alarm/Trouble horn. [The

third pair provides power for the vent fan

contactors. [see figs. #8a & 8b]

Note that the maximum output is one-and-onehalf [1-1/2] amperes. If the total inrush current

for all contactors will exceed this limit, an

intermediate relay must be used.

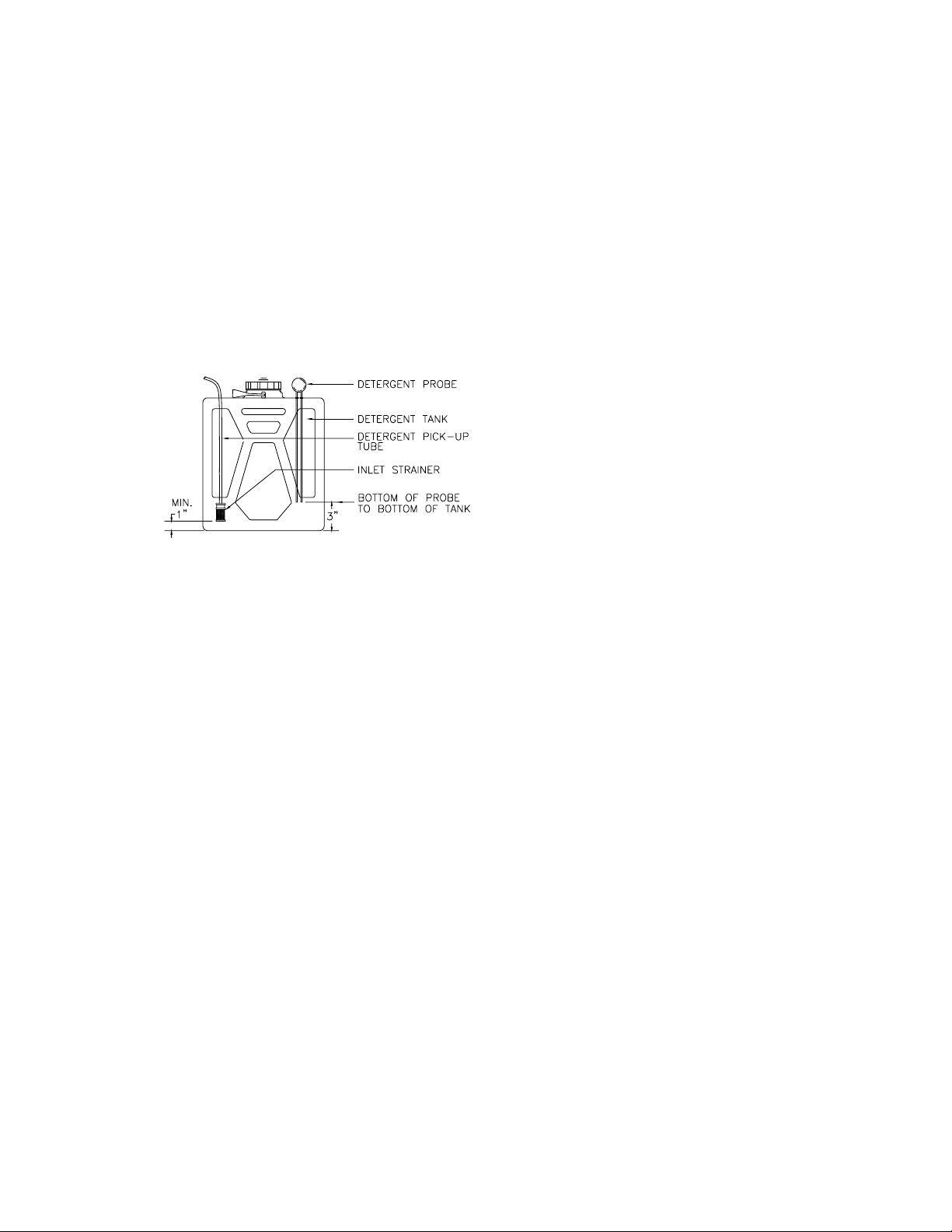

8.Terminal Block #9 [TB-9] has three [3] pairs of

terminals and is located at the lower left corner of

the Input/Output Board. The first pair of

terminals are for connection to the optional

supervised shut-off valve. If the panel is not

equipped with this option, a jumper wire must be

installed. The second pair of terminals are for

connection to the Manual Fire Switch. The third

pair of terminals are for connection to the

automatic fire switch contacts terminals are for

connection to the automatic fire switch contacts.

Fig 8a

Fig 8b

10 OM-VMR

9.Terminal Block #11 [TB-11] has three [3] pairs of

terminals. The first pair of terminals are low voltage

connections for the detergent low level probe. The

probe should be installed in the detergent container

so that it does not protrude above the top of the

detergent pump inlet strainer. [fig. #9] This is

intended to prevent cavitation of the pump and will

advise when the tank needs to be refilled. The probe

rods may be cut to facilitate a neat and effective

installation.

Fig 9

10.Terminal Block #12 [TB-12] has three [3] pairs

of terminals. The first pair of terminals are for

connection to the optional battery.

OM-VMR 11

Loading...

Loading...