Page 1

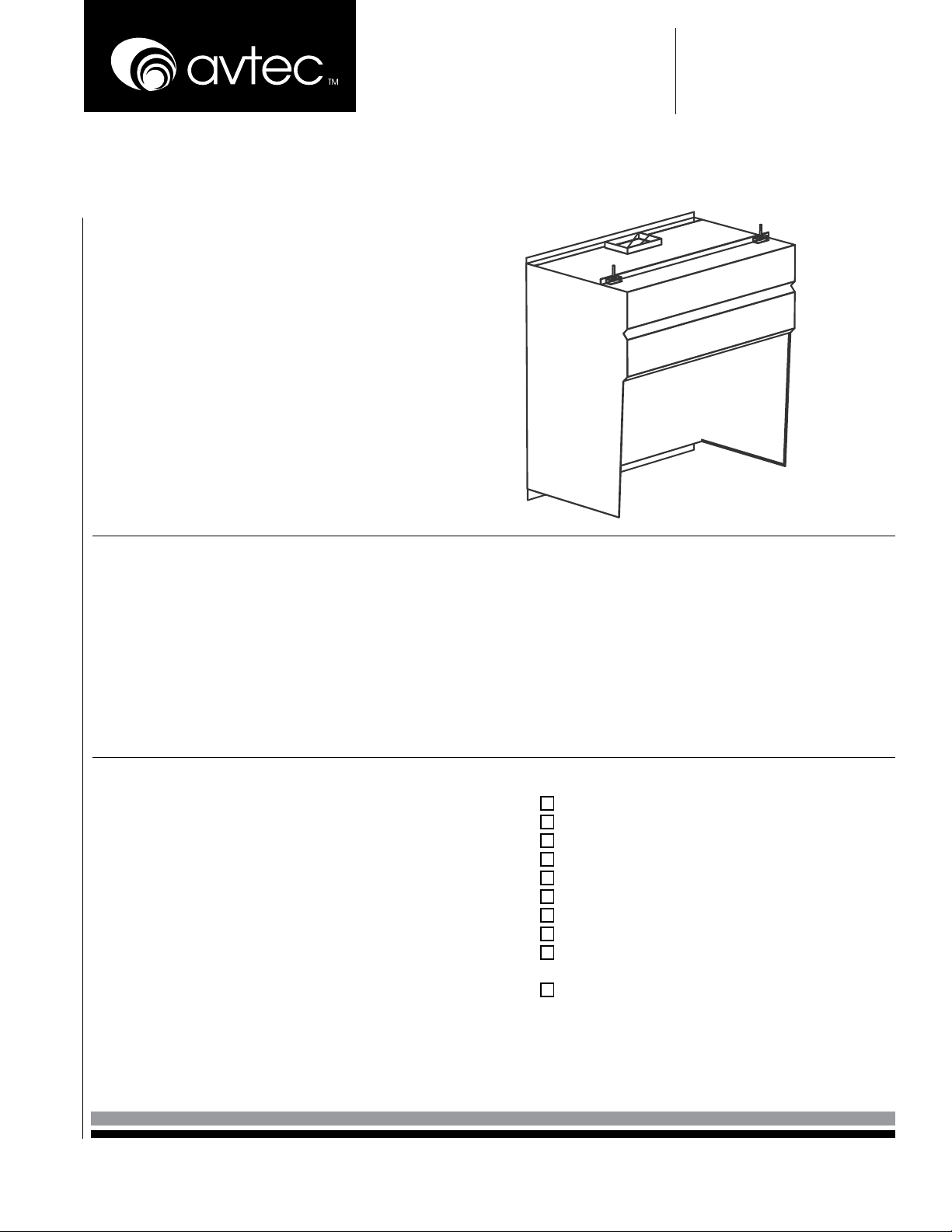

Exhaust Only Canopy

for All Types of

Cooking Equipment

CHINOOK Value Ventilation

Description:

The Avtec Model VDD is an exhaust only wall mount

canopy. The VDD is UL 710 Listed for lower air volumes

than required by national codes.

The VDD model is UL 710 Listed for use over 400, 600

and 700°F commercial cooking appliances. Suitable

for wall or island mount installations.

Specifications:

This is a Commercial Kitchen Ventilation canopy of Type I construction. A single shell, exhaust only wall mount canopy constructed

of stainless steel on all exposed surfaces and aluminized steel on all non-exposed surfaces. Canopy shall be constructed using

the standing seam method for optimum strength and shall have all welded exterior joints and seams. Canopy construction shall

conform to NFPA-96 standards. All exposed welds are to be ground smooth and polished to match finish requirements. Canopy

is to meet NSF standards for construction and UL 710 standards for operation. Grease trough(s) to be easily removable and

sloped to removable grease cup(s). UL Listed baffle type aluminum grease filters running the full length of canopy. UL Listed

globe type incandescent light fixtures mounted on 36” center lines.

Exhaust Only Filter

model VDD

Standard Features: Optional Accessories:

• Stainless steel construction on all exposed surfaces

• UL Listed baffle style aluminum grease filters

• UL Listed globe light fixtures on 48” center lines

• 3 “ rear air space

• Removable grease trough & cup(s)

• Fixed location hanger brackets

• Exhaust collar installed

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

All stainless steel construction

UL Listed stainless steel grease filters

14” Utility cabinet (mounted on end of canopy)

Insulated 3” air space

Electrical control panel

Pre-plumbed fire suppression

Stainless steel top enclosures

Light and fan switch

Recessed incandescent and fluorescent light fixtures

Stainless steel wall panel

Stainless steel side skirts

Melink Intelli-Hood® control systems

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Sloped front design for low ceiling applications

Avtec CHINOOK Value Ventilation, Page 1

PP SPEC1025 Rev. C

Revised 05/09

Page 2

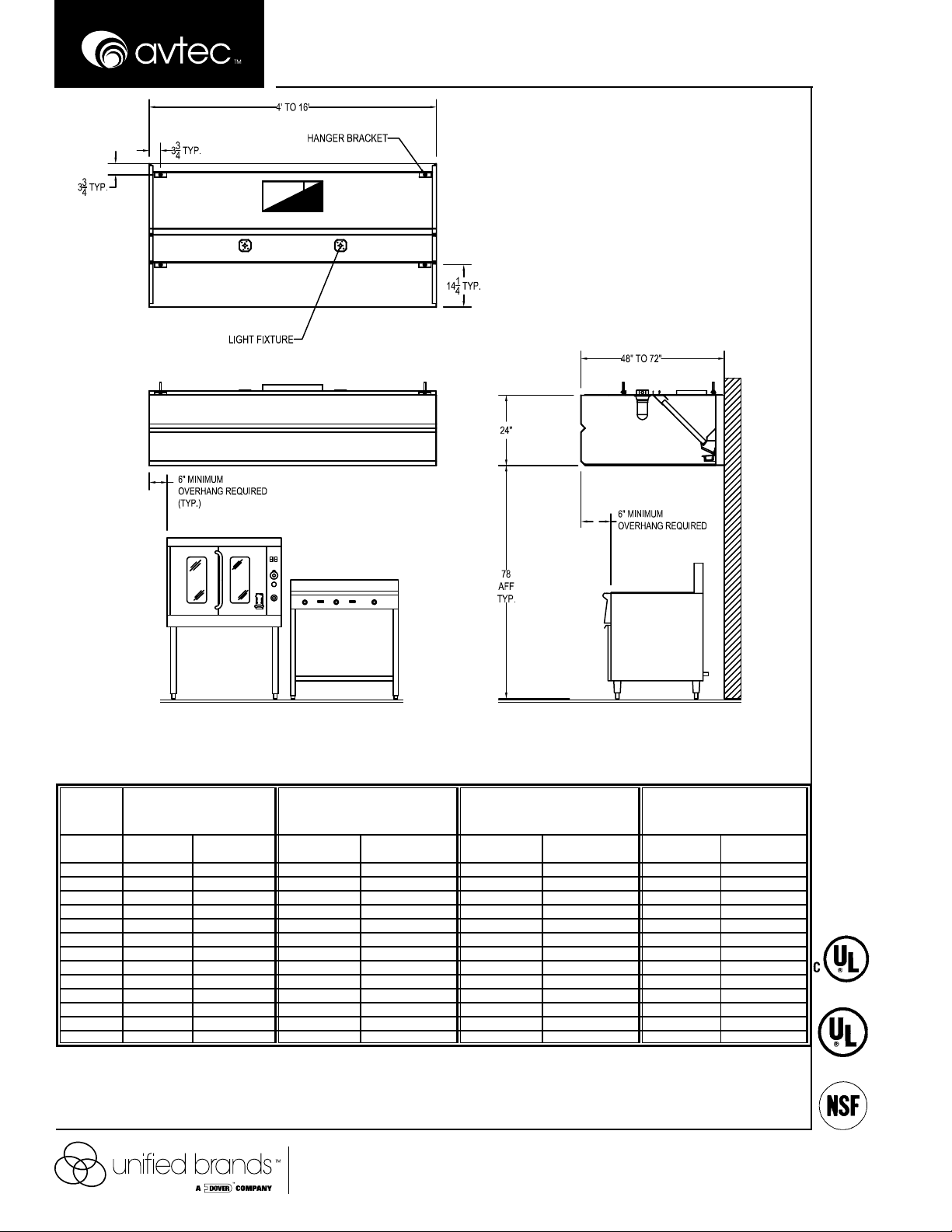

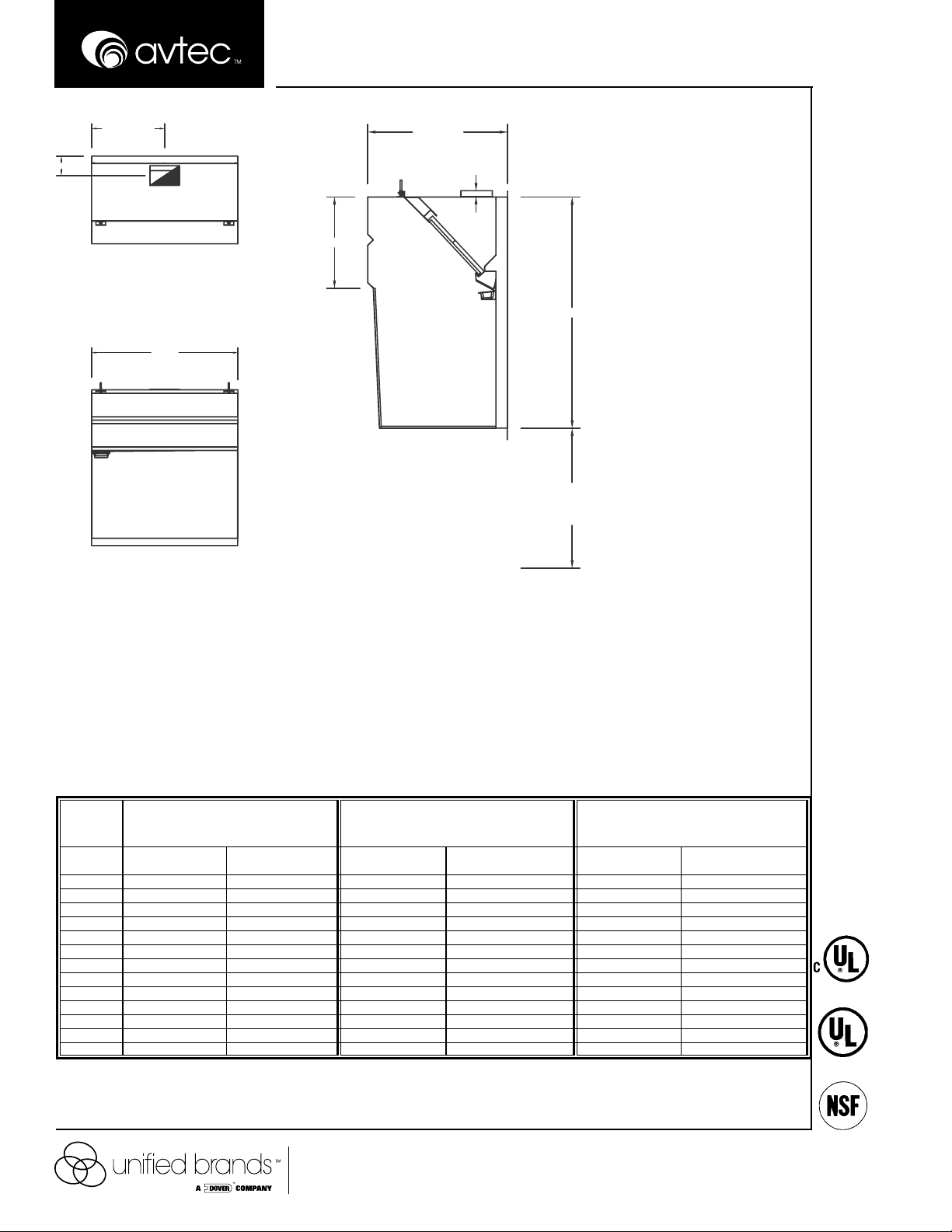

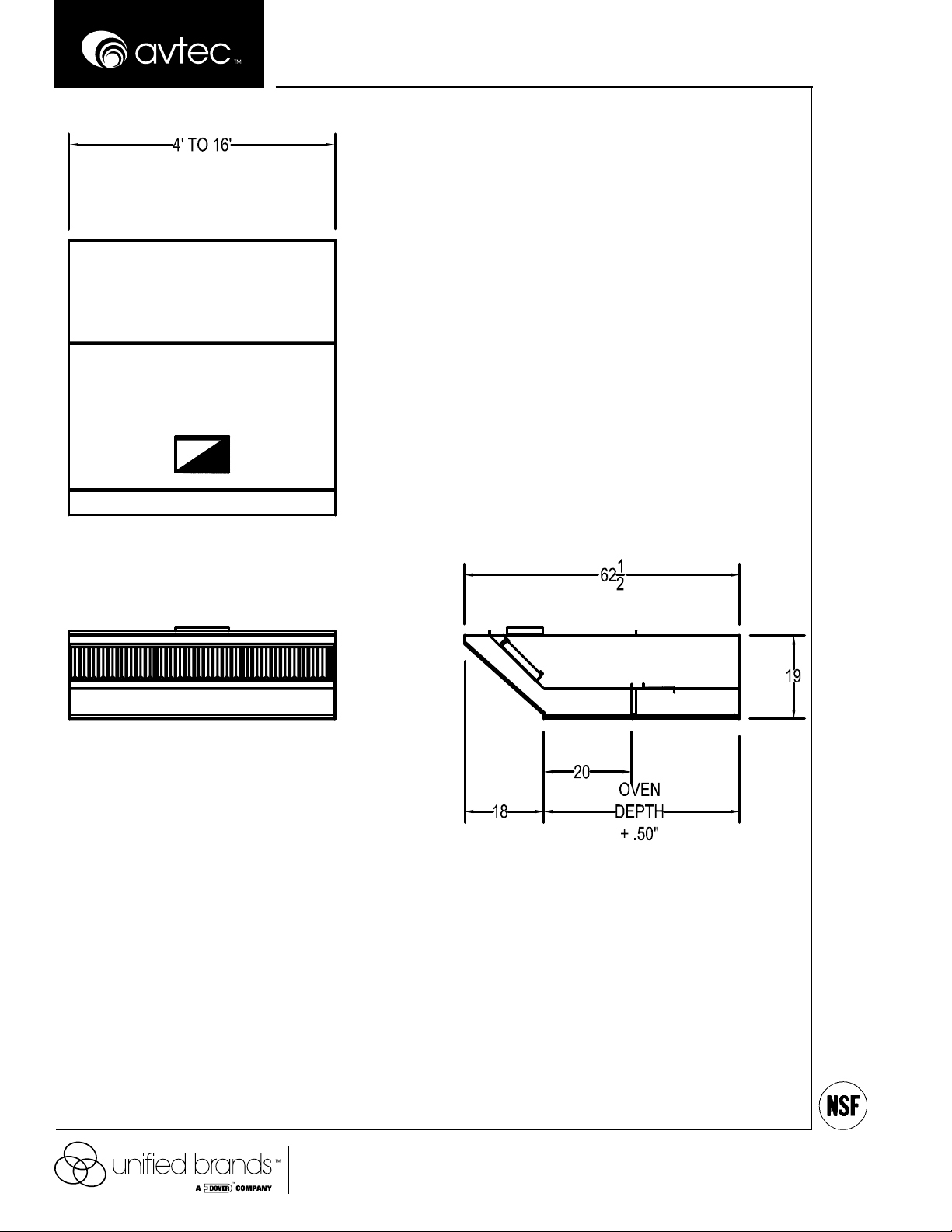

Model VDD

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

Extra-Heavy Temperature Cooking Equipment – 700°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1000 8 x 12 1200 8 x 14 1400 8 x 16 2100 8 x 24

5’-0” 1250 8 x 14 1500 8 x 16 1750 8 x 20 2625 10 x 22

6’-0” 1500 8 x 16 1800 8 x 20 2100 8 x 24 3150 10 x 28

7’-0” 1750 8 x 20 2100 8 x 24 2450 8 x 28 3675 12 x 28

8’-0” 2000 8 x 22 2400 8 x 28 2800 10 x 24 4200 12 x 32

9’-0” 2250 8 x 26 2700 10 x 24 3150 10 x 28 4725 12 x 36

10’-0” 2500 8 x 28 3000 10 x 28 3500 12 x 26 5250 12 x 40

11’-0” 2750 10 x 24 3300 12 x 24 3850 12 x 30 5775 12 x 44

12’-0” 3000 2-10 x 14 3600 2-12 x 14 4200 2-12 x 16 6300 2-12 x 24

13’-0 3250 2-10 x 16 3900 2-12 x 14 4550 2-12 x 16 6825 2- 12 x 26

14’-0” 3500 2-10 x 16 4200 2- 12 x 16 4900 2-12 x 18 7350 2- 12 x 28

15’-0” 3750 2-10 x 18 4500 2- 12 x 16 5250 2-12 x 20 7875 2- 12 x 30

16’-0” 4000 2-10 x 18 4800 2- 12 x 18 5600 2-12 x 22 8400 2- 12 x 32

Note: Greater exhaust air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with double exhaust collars have them located on ¼ hood length lines unless

otherwise specified. Canopy is to have a minimum 6” overhang on all exposed sides and the front leading edge of canopy to edge of the perimeter of the

cooking equipment surface.

CFM @

.625 SP

Duct Collar

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

Solid fuel broilers)

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

.75” SP

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

Exhaust CFM

CFM @

1.00”SP

Duct Collar

700 Degree Extra-Heavy

Duty Cooking Equipment

Exhaust CFM

CFM @

1.25”SP

Duct Collar

NFPA-96

Page 3

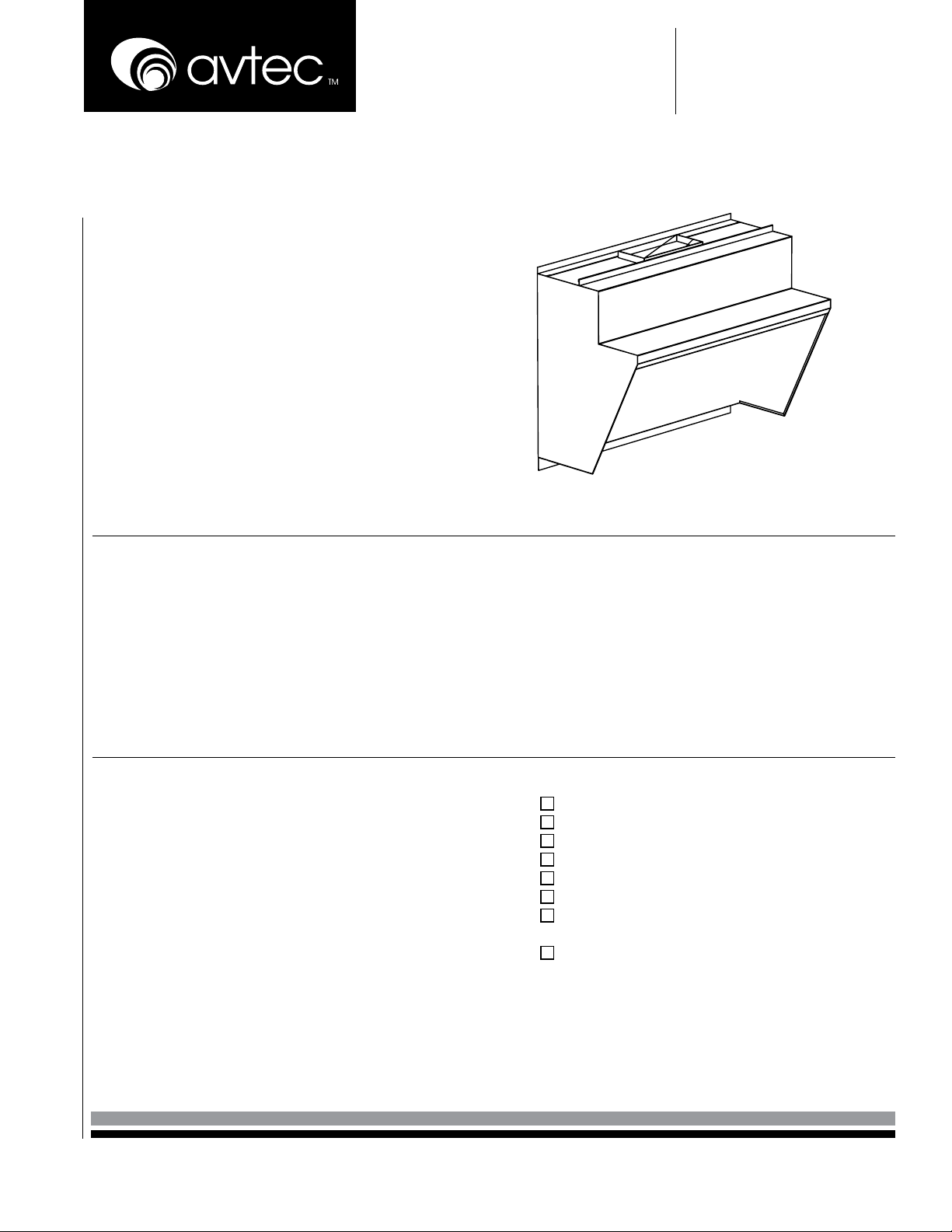

Exhaust Only V-Bank Island Canopy

for Light and Medium

Duty Cooking Equipment

CHINOOK Value Ventilation Exhaust Only Filter model VDV

Description:

This is a V-bank exhaust only single Island style

canopy.

This V-Bank island style canopy is best suited for use

over a single bank of cooking equipment. This hood

is recommended for use over light and medium duty

cooking appliances.

Specifications:

A single shell exhaust only Type I island canopy. The hood(s) shall be UL 710 Listed without (with) fire damper for 400 or 600

degree Fahrenheit rated cooking appliances. Canopy constructed of stainless steel on all exposed surfaces and aluminized steel

on all non-exposed surfaces. Canopy shall have all welded exterior joints and seams. Canopy construction shall conform to NFPA

96 standards. All exposed welds are to be ground and polished to match finish requirements. Canopy is to meet NSF standards

for construction and UL standards for operation. UL Listed aluminum baffle style grease filters to run full length of exhaust hood.

Grease trough(s) to be easily removable and sloped to removable grease cup(s). UL Listed globe type incandescent light fixtures

mounted on 36” center lines.

Standard Features: Optional Accessories:

• UL Listed aluminum grease filters

• UL Listed globe light(s)

• Removable grease trough & cup(s)

• Hanging brackets

• Exhaust and supply collars installed

• 1” Thick supply air plenum insulation

• Stainless steel construction where visible

All stainless steel construction

UL Listed stainless steel grease filters

14” Utility cabinet

Electrical control panel

Pre-plumbed fire suppression

Stainless steel top enclosures

Light and fan switches

Recessed fluorescent light fixtures

Recessed incandescent light fixtures

Stainless steel wall panel

Stainless steel side skirts

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Melink Intelli-Hood® control systems

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Avtec CHINOOK Value Ventilation, Page 2

PP SPEC1026 Rev. C

Revised 05/09

Page 4

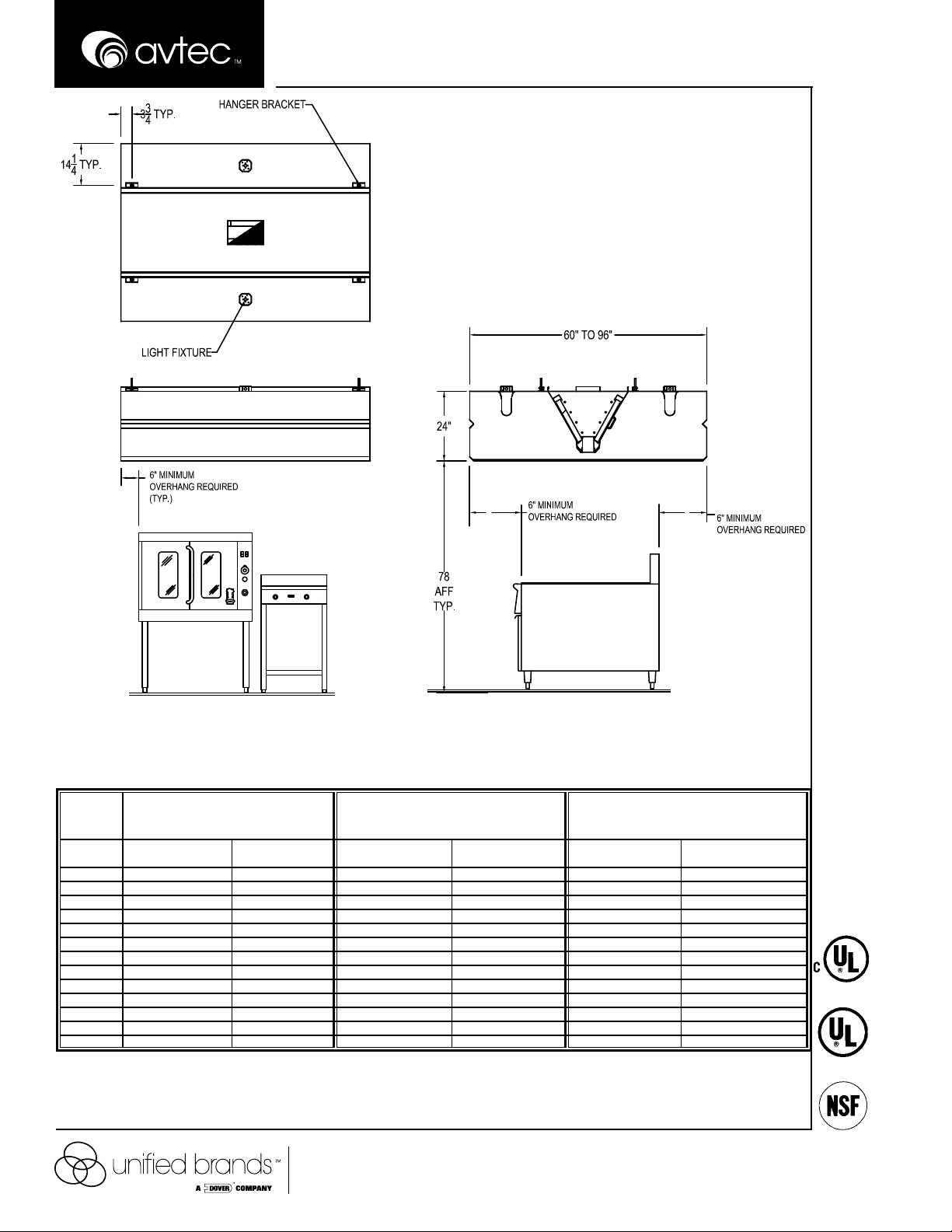

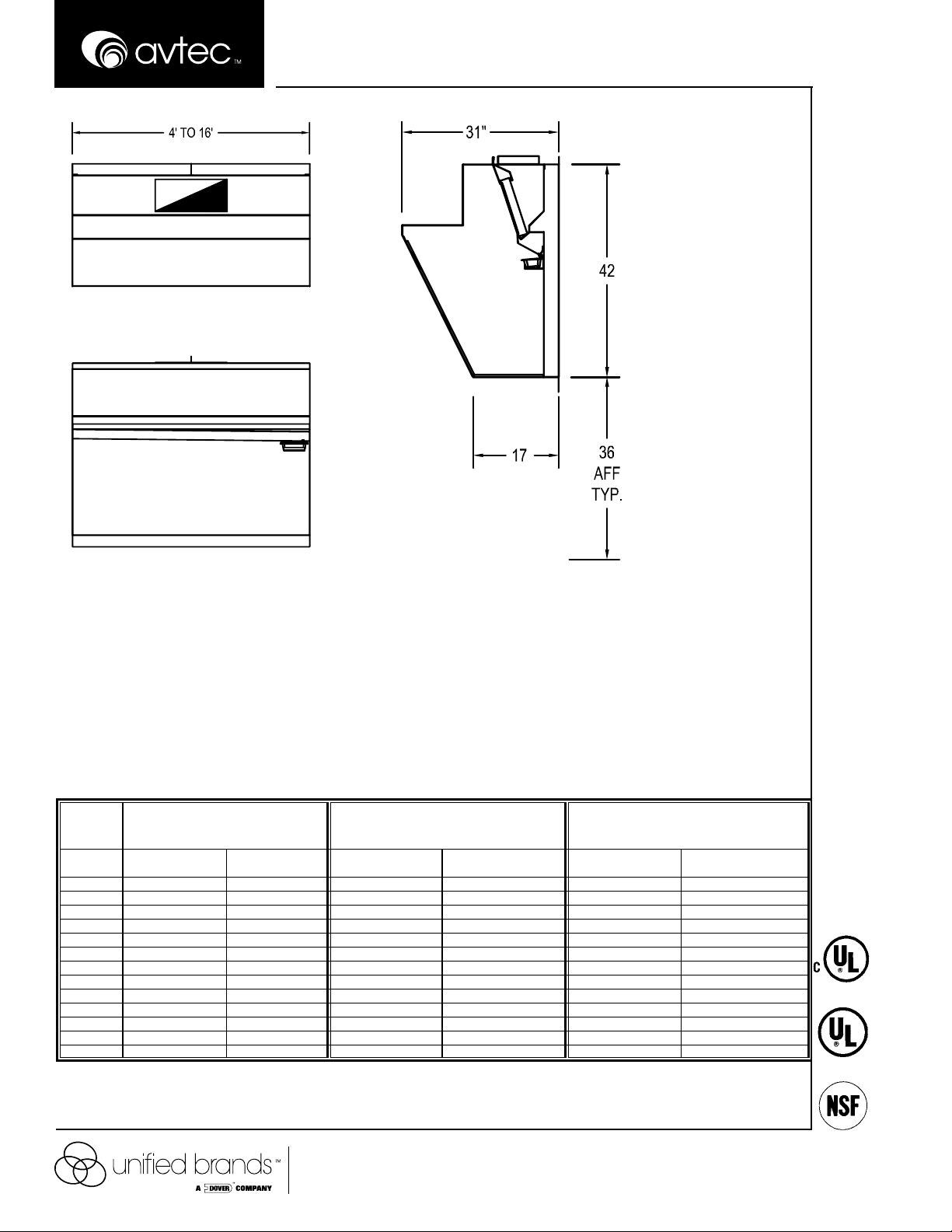

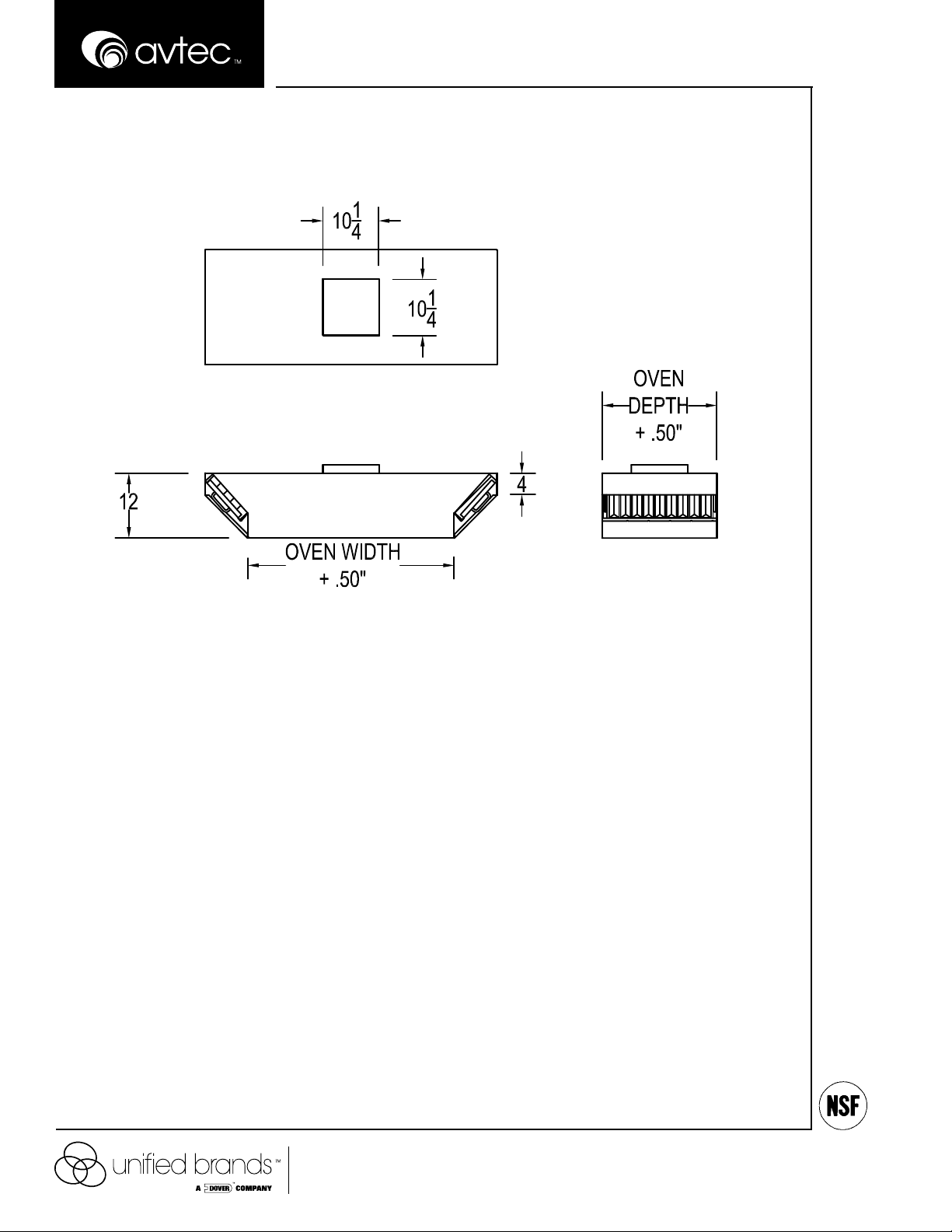

Model VDV

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1400 10 x 12 1800 12 x 14 2000 12 x 16

5’-0” 1750 12 x 14 2250 12 x 16 2500 12 x 18

6’-0” 2100 12 x 16 2700 12 x 20 3000 12 x 22

7’-0” 2450 12 x 18 3150 12 x 24 3500 12 x 26

8’-0” 2800 12 x 22 3600 12 x 28 4000 12 x 30

9’-0” 3150 12 x 24 4050 12 x 30 4500 12 x 34

10’-0” 3500 12 x 26 4500 12 x 34 5000 12 x 38

11’-0” 3850 12 x 28 4950 12 x 38 5500 12 x 42

12’-0” 4200 12 x 32 5400 2 12 x 20 6000 2-12 x 22

13’-0 4550 2-12 x 18 5850 2 -12 x 22 6500 2-12 x 24

14’-0” 4900 2-12 x 18 6300 2 -12 x 24 7000 2-12 x 26

15’-0” 5250 2-12 x 20 6750 2 -12 x 26 7500 2-12 x 28

16’-0” 5600 2-12 x 22 7200 2 - 12 x 28 8000 2-12 x 30

Note: Greater exhaust air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with two exhaust collars have them located on ¼ hood length lines unless otherwise

specified. Canopy is to have a minimum 6” overhang on all exposed sides and the front and rear leading edge of the hood to the perimeter of the cooking

equipment surface.

CFM @

.75 SP

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

400-600 Medium Duty

Cooking Equipment

Exhaust CFM

Duct Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

CFM @

1.00” SP

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

CFM @

1.25”SP

Exhaust CFM

Duct Collar

NFPA-96

Page 5

Exhaust Only Wall Mount

Ventilator for Light and Medium

Duty Cooking Equipment

CHINOOK Value Ventilation

Description:

The Avtec Model VNW is an exhaust only wall mount

ventilator. The VNW is mounted a maximum of 36”

above the cooking equipment resulting in lower

exhaust rates. The VNW is supplied with integral

stainless steel side curtains and back wall.

The model VNW ventilator is UL Listed for use Over

400 or 600°F commercial cooking appliances. Due

to the close proximity of the ventilator to the cooking

surface, no 6” front or side over hang is required with

this model.

Specifications:

This Commercial Kitchen Ventilator is of Type I construction and suitable for use with light and medium duty cooking appliances.

A single shell, exhaust only wall mount ventilator constructed of stainless steel on all exposed surfaces and aluminized steel on

all non-exposed surfaces. Ventilator shall have all welded exterior joints and seams. Ventilator construction shall conform to

NFPA-96 standards. All exposed welds are to be ground and polished to match finish requirements. Ventilator is to meet NSF

standards for construction and UL 710 standards for operation. Grease trough(s) to be easily removable and sloped to removable

grease cup(s). UL Listed baffle style aluminum grease filters to run the full length of ventilator.

Exhaust Only Filter

model VNW

Standard Features: Optional Accessories:

• Stainless steel construction on all non-exposed surfaces

• UL Listed aluminum grease filters

• 3” Rear air space

• Removable grease trough & cup(s)

• Fixed location hanger brackets

• Exhaust collar installed

• Stainless steel side and back panels

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

All stainless steel construction

UL Listed stainless steel grease filters

Electrical control panel

Pre-plumbed fire suppression

UL Listed insulated 3” air space for top, back, or ends

Stainless steel top enclosures

Fan Switches

Melink Intelli-Hood® system controls

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Exhaust fan/cooking equipment interlock control

Avtec CHINOOK Value Ventilation, Page 3

PP SPEC1027 Rev. D

Revised 08/10

Page 6

Model VNW

CENTERLINE

8.0

30" - 42"

1.5

23.5

59.5

4' - 16'

36.0

AFF

TYP.

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 900 8 x 10 1100 8 x 12 1200 8 x 14

5’-0” 1125 8 x 12 1375 8 x 16 1500 8 x 16

6’-0” 1350 8 x 16 1650 8 x 18 1800 8 x 20

7’-0” 1575 8 x 18 1925 8 x 22 2100 8 x 24

8’-0” 1800 8 x 20 2200 8 x 24 2400 8 x 28

9’-0” 2025 8 x 22 2475 8 x 28 2700 8 x 30

10’-0” 2250 8 x 26 2750 8 x 30 3000 8 x 34

11’-0” 2475 8 x 28 3025 8 x 34 3300 8 x 38

12’-0” 2700 8 x 30 3300 8 x 38 3600 8 x 40

13’-0 2925 2-8 x 16 3575 2-8 x 20 3900 2-8 x 22

14’-0” 3150 2-8 x 18 3850 2-8 x 22 4200 2-8 x 24

15’-0” 3375 2-8 x 20 4125 2-8 x 24 4500 2-8 x 26

16’-0” 3600 2-8 x 20 4400 2- 8 x 24 4800 2-8 x 28

Note: Greater exhaust air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with two collars have them located on ¼ hood length lines. Non-Canopy hoods do not

require a 6” overhang on the sides and a front under-hang of up to 12” is permitted.

CFM @

.50 SP

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

Duct Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

CFM @

.75” SP

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

CFM @

1.00”SP

Exhaust CFM

Duct Collar

NFPA-96

Page 7

Exhaust Only Back Shelf Ventilator

for Light and Medium Duty

Cooking Equipment

CHINOOK Value Ventilation

Description:

This is a low profile, exhaust only ventilator designed

to mount either on the wall or on a Randell 20000

series equipment stand. A plate shelf is built into the

front of this model for plate and condiment storage.

This unit is UL 710 Listed and intended for use over

400 and 600°F cooking appliances. This model

is recommended for 24” and 30” deep cooking

equipment and most counter top cooking appliances.

Ovens and broilers are not recommended for use

under this model.

Specifications:

An exhaust only single shell back shelf ventilator constructed of stainless steel on all exposed surfaces and aluminized steel on

all non-exposed surfaces. Ventilator shall have all welded exterior joints and seams. Ventilator construction shall conform to

NFPA 96 standards. All exposed welds are to be ground and polished to match finish requirements. Ventilator is to meet NSF

standards for construction and UL standards for operation. Grease trough(s) to be easily removable and sloped to removable

grease cup(s). UL Listed baffle style aluminum grease filters to run the entire length of ventilator.

Exhaust Only Filter

model VNP

Standard Features: Optional Accessories:

• UL Listed aluminum grease filters

• 3” Rear air space

• Removable grease trough & cup(s)

• Exhaust collar installed

• Stainless steel construction where visible

• Built in plate shelf

• Wall or base mount design

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

All stainless steel construction

UL Listed stainless steel grease filters

Insulated 3” air space

Pre-plumbed fire suppression

Stainless steel top enclosures

Melink Intelli-Hood® system controls

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Exhaust fan/cooking equipment interlock control

Avtec CHINOOK Value Ventilation, Page 4

PP SPEC1028 Rev. D

Revised 09/10

Page 8

Model VNP

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 500 6 x 8 600 8 x 8 800 8 x 9

5’-0” 625 8 x 8 750 8 x 8 1000 8 x 12

6’-0” 750 8 x 8 900 8 x 10 1200 8 x 14

7’-0” 875 8 x 10 1050 8 x 12 1400 8 x 16

8’-0” 1000 8 x 12 1200 8 x 14 1600 8 x 20

9’-0” 1125 8 x 12 1350 8 x 16 1800 8 x 20

10’-0” 1250 8 x 14 1500 8 x 16 2000 8 x 24

11’-0” 1375 8 x 16 1650 8 x 18 2200 8 x 24

12’-0” 1500 8 x 16 1800 8 x 20 2400 8 x 28

13’-0 1625 2-8 x 10 1950 2-8 x 10 2600 2-8 x 14

14’-0” 1750 2-8 x 10 2100 2-8 x 12 2800 2-8 x 16

15’-0” 1875 2-8 x 12 2250 2-8 x 12 3000 2-8 x 18

16’-0” 2000 2-8 x 12 2400 2- 8 x 14 3200 2-8 x 20

Note: Greater exhaust and/or lesser supply air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with two collars have them located on ¼ hood length lines unless otherwise specified.

Note: Non-Canopy hoods do not require a 6” overhang on the sides and a front under-hang of up to 6” is permitted.

CFM @

.50 SP

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

Duct Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

CFM @

.75” SP

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

Exhaust CFM

CFM @

1.00”SP

Duct Collar

NFPA-96

Page 9

Direct Draw Cap Style Hood

for Deck Oven

CHINOOK Value Ventilation

Description:

This Avtec cap style exhaust only canopy is designed

to mount directly on top of any deck style oven. The

flue for gas ovens discharges directly into the hood.

An adjustable damper allows for proper flue exhaust

adjustment.

The cap style hood is designed for all deck style

baking ovens, electric, gas, or convection. Includes

a warming pocket below the filters. For use in Type II

applications only.

Specifications:

This is a single shell cap style canopy of Type II construction and suitable for use with all types of deck ovens. Canopy is

constructed of stainless steel on all exposed surfaces and aluminized steel on all non-exposed surfaces. Canopy is complete

with UL Listed baffle type aluminum grease filters. Canopy shall be constructed using the standing seam method for optimum

strength. An adjustable air volume control damper shall be provided for gas ovens with flues. The hood shall overhang the front

edge of the oven by 18”. A pizza warming pocket is to be supplied directly below the UL Listed filters.

Exhaust Only Filter

model VPO

Standard Features: Optional Accessories:

• Stainless steel construction on all exposed surfaces

• Specifically designed per oven model

• Warming pocket for hot pizza storage

• Type II construction

• Exhaust collar installed

• UL Listed aluminum grease filters

• Adjustable damper for flue gases

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

All stainless steel construction

UL Listed stainless steel grease filters

Type 1 all welded hood construction

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Avtec CHINOOK Value Ventilation, Page 5

PP SPEC1029 Rev. B

Revised 03/08

Page 10

Model VPO

Hood size is based on make and model of oven. Consult factory for specific exhaust CFM and collar size.

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 11

Direct Draw Cap Style Exhaust

Only Canopy for Conveyor Ovens

CHINOOK Value Ventilation

Description:

This is an exhaust only close proximity cap style

conveyor oven canopy specifically designed for

maximum capture with minimum exhaust. Canopy

is mounted above the oven so that the oven can be

rolled in and out for ease of cleaning and service.

This model is intended for use with all makes and

models of electric and gas conveyor ovens. The VCP

is designed as a Type I grease hood.

Specifications:

A single shell, direct draw cap style canopy specifically designed to ventilate conveyor ovens. The canopy is constructed of

stainless steel on all exposed surfaces and aluminized steel on all non-exposed surfaces. Canopy is to meet NSF standards for

construction and UL 710 standards for operation. Canopy shall have fluid welded exterior joints and seams. Canopy construction

shall conform to NFPA 96 standards. All exposed welds are to be ground and polished to match finish requirements. Hanging

brackets provided to hang hood one half inch above the oven. A clean out door shall be located in the bottom center of the

canopy. Round or square duct is available upon request. UL Listed aluminum baffle style grease filters are located over both the

loading and landing ends of the oven and shall be easily removable for cleaning.

Exhaust Only Filter

model VCP

Standard Features: Optional Accessories:

• Stainless steel construction on all visible surfaces

• UL Listed aluminum grease filters

• Canopy designed to match oven model

• Hanging brackets

• Exhaust collar provided

• Removable grease trough(s) & cup(s)

• Type 1 all welded hood construction

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

All stainless steel construction

UL Listed stainless steel grease filters

Avtec CHINOOK Value Ventilation, Page 6

PP SPEC1030 Rev. C

Revised 05/09

Page 12

Model VCP

Hood size is based on make and model of oven. Consult factory for specific exhaust CFM and collar size.

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

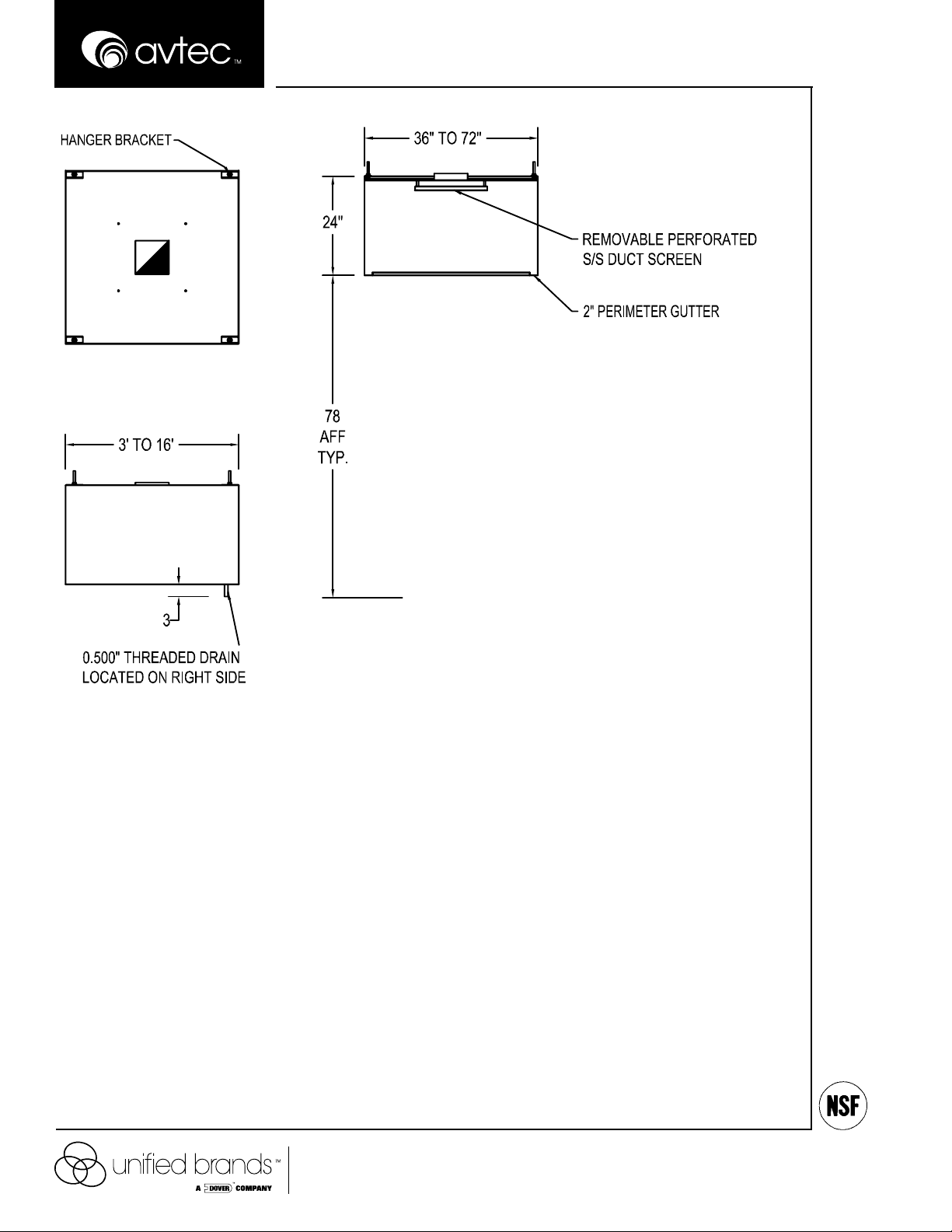

Page 13

Exhaust Only

Condensate Hood

CHINOOK Value Ventilation

Description:

This exhaust only condensate canopy designed to

ventilate steam producing cooking equipment.

This model hood is recommended to be installed over

automatic dishwashers and steam or heat producing

cooking equipment this hood is for use in Type II

applications only.

Specifications:

This is a single shell exhaust only Type II canopy. Hood shall be constructed of all stainless steel. Hood shall have a 2” wide

perimeter gutter with a ½” diameter drain located in one corner and a 3” stainless steel nipple. Hood shall also contain a

stainless steel perforated duct protector.

Exhaust Only Filter

model VDW

Standard Features: Optional Accessories:

• All 300 series stainless steel construction

• Hanging brackets

• Perimeter gutter with drain

• Perforated stainless steel duct protector

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

400 Series stainless steel construction

UL Listed incandescent globe lights

Stainless steel top enclosures

Light switch

Light and fan switch

Stainless steel wall panel

Avtec CHINOOK Value Ventilation, Page 7

PP SPEC1031 Rev. C

Revised 06/08

Page 14

Model VDW

Hood size is based on make and model of oven. Consult factory for specific exhaust CFM and collar size.

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 15

Exhaust Make Up Air Canopy

for All Types of

Cooking Equipment

CHINOOK Value Ventilation

Description:

This low volume exhaust only canopy is UL 710 Listed

for use over 400, 600 and 700°F cooking surface

temperatures. The perforated supply air plenum can

be shipped attached to the hood, or shipped loose to

suit on-site job specific requirements. The front supply

air plenum can provide up to 80% make-up air.

This hood is intended for use over all types

of commercial cooking appliances. This model

is recommended for all projects where energy

consumption is a factor or when adequate make-up air

is not available from the heating and cooling system.

Specifications:

Single shell canopy constructed of stainless steel on all exposed surfaces and aluminized steel on all non-exposed surfaces.

Canopy shall be constructed using the standing seam method for optimum strength. Canopy shall have all welded exterior joints

and seams. Canopy construction shall conform to NFPA-96 standards. All exposed welds are to be ground smooth and polished

to match the finish requirements. Canopy is to meet NSF standards for construction and UL 710 standards for operation. Grease

trough(s) to be easily removable and sloped to removable grease cup(s). Canopy comes complete with UL Listed globe style

incandescent light fixtures mounted on 36” center lines. Make-up air is introduced to the kitchen via a fully insulated ceiling

mounted supply air plenum with stainless steel perforated discharge panels and with internal air diffusers to provide an even flow

of air across the length of the hood. Make-up air collar(s) shall include air volume control damper. UL Listed baffle style aluminum

grease filters shall run the entire length of the canopy and be easily removable for cleaning.

External MUA Filter

model VDD-P

Standard Features: Optional Accessories:

• Stainless steel construction on all exposed surfaces

• UL Listed aluminum grease filters

• UL Listed globe style incandescent light fixtures mounted

on 48” center lines

• 3“ rear air space

• Removable grease trough & cup(s)

• Fixed location hanger brackets

• Exhaust collar installed

• Insulated ceiling mounted supply air plenum

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

UL Listed stainless steel grease filters

14” Utility cabinet (mounted on end of canopy)

Insulated 3” air space

Electrical control panel

Pre-plumbed fire suppression

Stainless steel top enclosures

Light and fan switch

Recessed incandescent and fluorescent light fixtures

Stainless steel wall panel

Stainless steel side skirts

Melink Intelli-Hood® control systems

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Sloped front design for low ceiling applications

Avtec CHINOOK Value Ventilation, Page 8a

PP SPEC1032 Rev. D

Revised 05/09

Page 16

Model VDD-P

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 17

Model VDD-P

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

Extra-Heavy Temperature Cooking Equipment – 700°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1000 8 x 12 1200 8 x 14 1400 8 x 16 2100 8 x 24

5’-0” 1250 8 x 14 1500 8 x 16 1750 8 x 20 2625 10 x 24

6’-0” 1500 8 x 16 1800 8 x 20 2100 8 x 24 3150 10 x 28

7’-0” 1750 8 x 20 2100 8 x 24 2450 8 x 28 3675 10 x 34

8’-0” 2000 8 x 22 2400 8 x 28 2800 10 x 24 4200 12 x 32

9’-0” 2250 8 x 26 2700 10 x 24 3150 10 x 28 4725 12 x 36

10’-0” 2500 8 x 28 3000 10 x 28 3500 12 x 26 5250 12 x 40

11’-0” 2750 10 x 24 3300 12 x 24 3850 12 x 30 5775 12 x 44

12’-0” 3000 10 x 28 3600 12 x 28 4200 12 x 32 6300 2-12 x 24

13’-0 3250 12 x 24 3900 12 x 30 4550 12 x 34 6825 2- 12 x 26

14’-0” 3500 12 x 26 4200 12 x 32 4900 12 x 36 7350 2- 12 x 28

15’-0” 3750 12 x 28 4500 12 x 34 5250 12 x 40 7875 2- 12 x 30

16’-0” 4000 2-10 x 18 4800 2- 10 x 22 5600 2-10 x 24 8400 2- 12 x 32

Length

4’-0” 800 12 x 12 960 10 x 20 1120 10 x 20 1680 12 x 24

5’-0” 1000 10 x 20 1200 10 x 20 1400 10 x 30 2100 12 x 24

6’-0” 1200 10 x 20 1440 10 x 30 1680 12 x 24 2520 10 x 40

7’-0” 1400 10 x 30 1680 12 x 24 1960 10 x 40 2940 10 x 40

8’-0” 1600 12 x 24 1920 10 x 40 2240 2-10 x 20 3360 2-10 x 30

9’-0” 1800 10 x 40 2160 10 x 40 2520 2-10 x 20 3780 2-10 x 40

10’-0” 2000 10 x 40 2400 2-10 x 20 2800 2-10 x 30 4200 2-10 x 40

11’-0” 2200 2-10 x 20 2640 2-10 x 30 3080 2-10 x 30 4620 2-10 x 40

12’-0” 2400 2-10 x 20 2880 2-10 x 30 3360 2-12 x 24 5040 2-10 x 40

13’-0 2600 2-10 x 30 3120 2-12 x 24 3640 2-10 x 40 5460 2-10 x 40

14’-0” 2800 2-10 x 30 3360 2-12 x 24 3920 2-10 x 40 5880 2-10 x 40

15’-0” 3000 2-12 x 24 3600 2-10 x 40 4200 2-10 x 40 6300 2-10 x 40

16’-0” 3200 2-12 x 24 3840 2-10 x 40 4480 2-10 x 40 6720 2-10 x 40

Note: Greater exhaust and/or lesser supply air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 15’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with double collars have them located on ¼ hood length lines unless otherwise

specified. Canopy is to have a minimum 6” overhang on all exposed sides and the front leading edge to the perimeter of the cooking surface.

CFM @

.625 SP

CFM @

.25 SP

Duct Collar

Light Duty

Supply CFM

Duct Collar

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

Solid fuel broilers)

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

.75” SP

CFM @

.385” SP

Medium Duty

Duct Collar

Supply CFM

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

CFM @

1.00”SP

CFM @

.50”SP

Exhaust CFM

Duct Collar

Heavy Duty

Supply CFM

Duct Collar

700 Degree Extra-Heavy

Duty Cooking Equipment

Exhaust CFM

CFM @

1.25”SP

Extra-Heavy Duty

CFM @

. 65”SP

Duct Collar

Supply CFM

Duct Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 8b

Page 18

Page 19

External Make-up Air Canopy

for All Types of

Cooking Equipment

CHINOOK Value Ventilation

Description:

The VPF model is UL 710 Listed for use over 400, 600

and 700°F cooking surface temperatures. This is a

double shell canopy which discharges make-up air

through a perforated panel located along the entire

length of the canopy front face.

This hood is intended for use over all types of

commercial kitchen appliances. This model is

recommended for all projects where up to 80% of the

required make-up air can be supplied directly into the

room.

Specifications:

Provide a double shell fully compensating Type I wall canopy. Canopy constructed of stainless steel on all exposed surfaces and

aluminized steel on all non-exposed surfaces. Canopy shall have all welded exterior joints and seams. Canopy construction shall

conform to NFPA 96 standards. All exposed welds are to be ground and polished to match finish requirements. Canopy is to meet

NSF standards for construction and UL standards for operation. The make-up air diffusers shall be perforated stainless steel panels

with 70% net open area. The hood supply plenum shall be lined with 1” thick foil backed fiberglass insulation for prevention of

condensation. The supply air shall pass through a perforated metal baffle for even air flow from the room. A UL Listed air volume

damper in the supply collar shall be supplied by the factory and may be installed in the field if required. Grease trough(s) to be

easily removable and sloped to removable grease cup(s). UL Listed baffle style aluminum grease filters shall run the entire length

of the canopy and be easily removable for cleaning. UL Listed globe style incandescent light fixtures mounted on 36” center lines.

External MUA Filter

model VPF

Standard Features: Optional Accessories:

• Stainless steel construction where visible

• UL Listed aluminum grease filters

• UL Listed globe style incandescent light fixtures

mounted on 48” center lines

• 3” Rear air space

• Removable grease trough & cup(s)

• Hanging brackets

• 1” Thick supply air plenum insulation

• Air volume damper in supply collar

• Front face perforated stainless steel panels

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

All stainless steel construction

UL Listed stainless steel grease filters

14” Utility cabinet (mounted on end of canopy)

Insulated 3” air space for zero clearance to combustibles

Electrical control panel

Pre-plumbed fire suppression

Stainless steel top enclosures

Light and fan switch

Recessed incandescent and fluorescent light fixtures

Stainless steel wall panel

Stainless steel side skirts

Melink Intelli-Hood® control systems

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Avtec CHINOOK Value Ventilation, Page 9a

PP SPEC1033 Rev. D

Revised 05/09

Page 20

Model VPF

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 21

Model VPF

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

Extra-Heavy Temperature Cooking Equipment – 700°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1000 8 x 12 1200 8 x 14 1400 8 x 16 2100 8 x 24

5’-0” 1250 8 x 14 1500 8 x 16 1750 8 x 20 2625 10 x 22

6’-0” 1500 8 x 16 1800 8 x 20 2100 8 x 24 3150 10 x 28

7’-0” 1750 8 x 20 2100 8 x 24 2450 8 x 28 3675 12 x 28

8’-0” 2000 8 x 22 2400 8 x 28 2800 10 x 24 4200 12 x 32

9’-0” 2250 8 x 26 2700 10 x 24 3150 10 x 28 4725 12 x 36

10’-0” 2500 8 x 28 3000 10 x 28 3500 12 x 26 5250 12 x 40

11’-0” 2750 10 x 24 3300 12 x 24 3850 12 x 30 5775 12 x 44

12’-0” 3000 2-10 x 14 3600 2-12 x 14 4200 2-12 x 16 6300 2-12 x 24

13’-0 3250 2-10 x 16 3900 2-12 x 14 4550 2-12 x 16 6825 2- 12 x 26

14’-0” 3500 2-10 x 16 4200 2- 12 x 16 4900 2-12 x 18 7350 2- 12 x 28

15’-0” 3750 2-10 x 18 4500 2- 12 x 16 5250 2-12 x 20 7875 2- 12 x 30

16’-0” 4000 2-10 x 18 4800 2- 12 x 18 5600 2-12 x 22 8400 2- 12 x 32

Length

4’-0” 800 12 x 12 960 12 x 18 1120 10 x 20 1280 10 x 30

5’-0” 1000 12 x 18 1200 12 x 18 1400 10 x 30 1600 12 x 24

6’-0” 1200 10 x 20 1440 12 x 24 1680 12 x 24 1920 10 x 30

7’-0” 1400 12 x 24 1680 12 x 24 1960 10 x 30 2240 10 x 40

8’-0” 1600 12 x 24 1920 10 x 30 2240 10 x 40 2560 10 x 40

9’-0” 1800 10 x 30 2160 10 x 40 2520 10 x 40 2880 2-10 x 30

10’-0” 2000 10 x 40 2400 10 x 40 2800 2-10 x 30 3200 2-12 x 24

11’-0” 2200 2-10 x 20 2640 2-12 x 24 3080 2-10 x 30 3520 2-10 x 40

12’-0” 2400 2-10 x 20 2880 2-12 x 24 3360 2-10 x 30 3840 2-10 x 40

13’-0 2600 2-10 x 20 3120 2-12 x 24 3640 2-10 x 40 4160 2-10 x 40

14’-0” 2800 2-10 x 30 3360 2-10 x 30 3920 2-10 x 40 4480 2-10 x 40

15’-0” 3000 2-12 x 24 3600 2-10 x 30 4200 2-10 x 40 4800 2- 10 x 40

16’-0” 3200 2-12 x 24 3840 2- 10 x 40 4480 2-10 x 40 5120 2- 10 x 40

Note: Greater exhaust and/or lesser supply air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with two collars have them located on ¼ hood length lines unless otherwise specified.

Canopy is to have a minimum 6” overhang on all exposed sides and front leading edge to the perimeter of the cooking equipment surface.

CFM @

.625 SP

CFM @

.25 SP

Duct Collar

Low Duty

Supply CFM

Duct Collar

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

Solid fuel broilers)

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

.75” SP

CFM @

.385” SP

Medium Duty

Duct Collar

Supply CFM

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

CFM @

1.00”SP

CFM @

.50”SP

Exhaust CFM

Duct Collar

Heavy Duty

Supply CFM

Duct Collar

700 Degree Extra-Heavy

Duty Cooking Equipment

Exhaust CFM

CFM @

1.25”SP

Extra-Heavy Duty

CFM @

. 65”SP

Duct Collar

Supply CFM

Duct Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 9b

Page 22

Page 23

Perforated Front Face Make-up Air

Island Canopy for Light and Medium

Duty Cooking Equipment

CHINOOK Value Ventilation

Description:

This is a double shell island style canopy which discharges make-up air through a perforated panel located along the entire length of the front face.

The VPV model hood is UL 710 Listed for use over 400

and 600°F cooking appliances. This V-Bank island

style canopy is best suited for use over a single bank

of cooking equipment. This hood is recommended for

use over light and medium duty cooking appliances.

Specifications:

Provide a double shell fully compensating Type I island canopy. The hood(s) shall be UL 710 Listed for use over 400 or 600 degree Fahrenheit cooking appliances. Canopy constructed of stainless steel on all exposed surfaces and aluminized steel on all

non-exposed surfaces. Canopy shall have all welded exterior joints and seams. Canopy construction shall conform to NFPA 96

standards. All exposed welds are to be ground and polished to match the finish requirements. Canopy is to meet NSF standards

for construction and UL standards for operation. The make-up air diffusers shall be perforated stainless steel panels with 70%

net open area. The hood supply plenum shall be lined with 1” thick foil backed insulation. The supply air shall pass through a

perforated metal baffle for even air flow into the room. A UL Listed air volume damper in the supply collar shall be supplied by

the factory and may be installed in the field if required. Grease trough(s) to be easily removable and sloped to removable grease

cup(s). UL Listed baffle style grease filters running the full length of canopy. UL Listed globe type incandescent light fixtures

mounted on 36” center lines.

External MUA Filter model VPV

Standard Features: Optional Accessories:

• UL Listed aluminum grease filters

• UL Listed globe light fixtures on 48” centers

• Removable grease trough & cup(s)

• Hanging brackets

• Exhaust and supply collars installed

• 1” Thick supply air plenum insulation

• Stainless steel construction where visible

• UL Listed fire damper in supply collar

• Air volume damper in supply collar

• Front face perforated stainless steel panels

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

All stainless steel construction

UL Listed stainless steel grease filters

14” Utility cabinet

Electrical control panel

Pre-plumbed fire suppression

Stainless steel top enclosures

Light and fan switch

Recessed fluorescent light fixtures

Stainless steel wall panel

Stainless steel side skirts

Fire damper in supply air collar

Melink Intelli-Hood® control systems

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Avtec CHINOOK Value Ventilation, Page 10a

PP SPEC1034 Rev. D

Revised 05/09

Page 24

Model VPV

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 25

Model VPV

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1400 10 x 12 1800 12 x 14 2000 12 x 16

5’-0” 1750 12 x 14 2250 12 x 16 2500 12 x 18

6’-0” 2100 12 x 16 2700 12 x 20 3000 12 x 22

7’-0” 2450 12 x 18 3150 12 x 24 3500 12 x 26

8’-0” 2800 12 x 22 3600 12 x 28 4000 12 x 30

9’-0” 3150 12 x 24 4050 12 x 30 4500 12 x 34

10’-0” 3500 12 x 26 4500 12 x 34 5000 12 x 38

11’-0” 3850 12 x 28 4950 12 x 38 5500 12 x 42

12’-0” 4200 12 x 32 5400 2 12 x 20 6000 2-12 x 22

13’-0 4550 2-12 x 18 5850 2 -12 x 22 6500 2-12 x 24

14’-0” 4900 2-12 x 18 6300 2 -12 x 24 7000 2-12 x 26

15’-0” 5250 2-12 x 20 6750 2 -12 x 26 7500 2-12 x 28

16’-0” 5600 2-12 x 22 7200 2 - 12 x 28 8000 2-12 x 30

Length

4’-0” 1120 2-8 x 24 1440 2-12 x 12 1600 2-12 x 12

5’-0” 1400 2-12 x 12 1800 2-10 x 16 2000 2-10 x 20

6’-0” 1680 2-12 x 12 2160 2-10 x 20 2400 2-10 x 20

7’-0” 1960 2-10 x 20 2520 2-10 x 20 2800 2-12 x 24

8’-0” 2240 2-10 x 20 2880 2-10 x 30 3200 2-12 x 24

9’-0” 2520 2-12 x 18 3240 2-10 x 30 3600 2-10 x 30

10’-0” 2800 2-12 x 24 3600 2-10 x 30 4000 2-10 x 40

11’-0” 3080 2-12 x 24 3960 2-10 x 40 4400 2-10 x 40

12’-0” 3360 2-10 x 30 4320 2-10 x 40 4800 4-10 x 40

13’-0 3640 2-10 x 30 4680 2-10 x 40 5200 4-10 x 20

14’-0” 3920 2-10 x 40 5040 4-10 x 20 5600 4-10 x 30

15’-0” 4200 2-10 x 40 5400 4-10 x 30 6000 4-10 x 40

16’-0” 4480 2-10 x 40 5760 4-10 x 30 6400 4-10 x 40

Note: Greater exhaust and/or lesser supply air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with two collars have them located on ¼ hood length line. Canopy is to have a

minimum 6” overhang on all exposed sides, front and rear leading edge of hood to the perimeter of the cooking equipment surface.

CFM @

.75 SP

CFM @

.50 SP

Duct Collar

Light Duty

Supply CFM

Duct Collar

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

400-600 Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

1.00” SP

CFM @

.75” SP

Medium Duty

Duct Collar

Supply CFM

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

Exhaust CFM

CFM @

1.25”SP

Heavy Duty

Supply CFM

CFM @

.875”SP

Duct Collar

Duct Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 10b

Page 26

Page 27

External Make-up Air Canopy for

All Types of Cooking Equipment

CHINOOK Value Ventilation

Description:

The VFF model is UL 710 Listed for use over 400, 600,

and 700°F cooking surface temperatures. This is a

double shell canopy which discharges make-up air

through double deflection adjustable face diffusers.

Up to 80% of the required make-up air can be supplied

directly into the room.

This canopy is intended for use over all types of

commercial kitchen cooking appliances. This model

is available in both a wall mount or double island style

configuration.

Specifications:

Provide a double shell fully compensating Type I wall canopy. The hood(s) shall be UL 710 Listed with or without a fire damper in the

exhaust collar. Canopy constructed of stainless steel on all exposed surfaces and aluminized steel on all non-exposed surfaces. Canopy

shall have all welded exterior joints and seams. Canopy construction shall conform to NFPA 96 standards. All exposed welds are to be

ground and polished to match finish requirements. Canopy is to meet NSF standards for construction and UL standards for operation.

The make-up air shall pass through a perforated metal baffle for even air flow out of diffusers. The hood supply plenum shall be lined

with 1” thick foil backed fiberglass insulation for prevention of condensation. A UL Listed air volume control damper in the supply collar

shall be supplied by the factory and may be installed in the field if required. Grease trough(s) to be easily removable and sloped to removable grease cup(s). UL Listed baffle style aluminum grease filters to run the entire length of the canopy and to be easily removable

for cleaning. UL Listed globe style incandescent light fixtures mounted on 36” center lines.

External MUA Filter

model VFF

Standard Features: Optional Accessories:

• Stainless steel construction where visible

• UL Listed aluminum grease filters

• UL Listed globe style incandescent light

fixtures mounted on 48” center lines

• Removable grease trough & cup(s)

• Built in 3” rear air space

• Hanging brackets

• 1” Thick supply air plenum insulation

• Air volume damper in supply collar

• Front face double deflection diffusers

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

All stainless steel construction

UL Listed stainless steel grease filters

14” Utility cabinet (mounted on the end of hood)

Electrical control panel

Pre-plumbed fire suppression

Insulated 3” air space for zero clearance to combustibles

Stainless steel top enclosures

Light and fan switch

Recessed incandescent and fluorescent light fixtures

Stainless steel wall panel

Stainless steel side skirts

Melink Intelli-Hood® control systems

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Avtec CHINOOK Value Ventilation, Page 11a

PP SPEC1035 Rev. D

Revised 05/09

Page 28

Model VFF

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 29

Model VFF

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

Extra-Heavy Temperature Cooking Equipment – 700°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1000 8 x 12 1200 8 x 14 1400 8 x 16 2100 8 x 24

5’-0” 1250 8 x 14 1500 8 x 16 1750 8 x 20 2625 10 x 22

6’-0” 1500 8 x 16 1800 8 x 20 2100 8 x 24 3150 10 x 28

7’-0” 1750 8 x 20 2100 8 x 24 2450 8 x 28 3675 12 x 28

8’-0” 2000 8 x 22 2400 8 x 28 2800 10 x 24 4200 12 x 32

9’-0” 2250 8 x 26 2700 10 x 24 3150 10 x 28 4725 12 x 36

10’-0” 2500 8 x 28 3000 10 x 28 3500 12 x 26 5250 12 x 40

11’-0” 2750 10 x 24 3300 12 x 24 3850 12 x 30 5775 12 x 44

12’-0” 3000 2-10 x 14 3600 2-12 x 14 4200 2-12 x 16 6300 2-12 x 24

13’-0 3250 2-10 x 16 3900 2-12 x 14 4550 2-12 x 16 6825 2- 12 x 26

14’-0” 3500 2-10 x 16 4200 2- 12 x 16 4900 2-12 x 18 7350 2- 12 x 28

15’-0” 3750 2-10 x 18 4500 2- 12 x 16 5250 2-12 x 20 7875 2- 12 x 30

16’-0” 4000 2-10 x 18 4800 2- 12 x 18 5600 2-12 x 22 8400 2- 12 x 32

Length

4’-0” 800 12 x 12 960 12 x 18 1120 10 x 20 1280 10 x 30

5’-0” 1000 12 x 18 1200 12 x 18 1400 10 x 30 1600 12 x 24

6’-0” 1200 10 x 20 1440 12 x 24 1680 12 x 24 1920 10 x 30

7’-0” 1400 12 x 24 1680 12 x 24 1960 10 x 30 2240 10 x 40

8’-0” 1600 12 x 24 1920 10 x 30 2240 10 x 40 2560 10 x 40

9’-0” 1800 10 x 30 2160 10 x 40 2520 10 x 40 2880 2-10 x 30

10’-0” 2000 10 x 40 2400 10 x 40 2800 2-10 x 30 3200 2-12 x 24

11’-0” 2200 2-10 x 20 2640 2-12 x 24 3080 2-10 x 30 3520 2-10 x 40

12’-0” 2400 2-10 x 20 2880 2-12 x 24 3360 2-10 x 30 3840 2-10 x 40

13’-0 2600 2-10 x 20 3120 2-12 x 24 3640 2-10 x 40 4160 2-10 x 40

14’-0” 2800 2-10 x 30 3360 2-10 x 30 3920 2-10 x 40 4480 2-10 x 40

15’-0” 3000 2-12 x 24 3600 2-10 x 30 4200 2-10 x 40 4800 2- 10 x 40

16’-0” 3200 2-12 x 24 3840 2- 10 x 40 4480 2-10 x 40 5120 2- 10 x 40

Note: Greater exhaust and/or lesser supply air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with two collars have them located on ¼ hood length lines unless otherwise specified.

Canopy is to have a minimum 6” overhang on all exposed sides and front leading edge to the perimeter of the cooking equipment surface.

CFM @

.625 SP

CFM @

.25 SP

Duct Collar

Low Duty

Supply CFM

Duct Collar

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

Solid fuel broilers)

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

.75” SP

CFM @

.385” SP

Medium Duty

Duct Collar

Supply CFM

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

CFM @

1.00”SP

CFM @

.50”SP

Exhaust CFM

Duct Collar

Heavy Duty

Supply CFM

Duct Collar

700 Degree Extra-Heavy

Duty Cooking Equipment

Exhaust CFM

CFM @

1.25”SP

Extra-Heavy Duty

CFM @

. 65”SP

Duct Collar

Supply CFM

Duct Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 11b

Page 30

Page 31

Single Island Style External Make-up

Air Canopy for Light and

Medium Duty Cooking Equipment

CHINOOK Value Ventilation External MUA Filter model VFV

Description:

This island style canopy is UL 710 Listed over 400

and 600°F cooking surface temperatures. This

external make-up air island style canopy is designed

to reduce exhausting large quantities of air from the

conditioned space. Up to 80% of the required makeup air can be supplied directly into the room via the

front face diffusers.

This V-Bank island style canopy is intended for use

over light and medium duty commercial kitchen

cooking appliances and is best suited for use over a

single bank of cooking equipment.

Specifications:

Hood shall be a double shell fully compensating Type I island canopy. Canopy to be constructed of stainless steel on all exposed

surfaces and aluminized steel on all non-exposed surfaces. Canopy shall have all welded exterior joints and seams. Canopy construction shall conform to NFPA 96 standards. All exposed welds are to be ground and polished to match the finish requirements.

Canopy is to meet NSF standards for construction and UL standards for operation. The make-up air diffusers shall be aluminum

with horizontal and vertical adjustable vanes. The hood supply plenum shall be lined with 1” thick foil backed fiberglass insulation

for prevention of condensation. The supply air shall pass through a perforated metal baffle for even air flow from the room. A UL

Listed fire damper and air volume damper in the supply collar shall be supplied by the factory and may be installed in the field if

required. Grease trough(s) to be easily removable and sloped to removable grease cup(s). UL Listed aluminum baffle style grease

filters located the entire length of the hood and shall be easily removable for cleaning. UL Listed globe style incandescent light

fixtures mounted on 36” center lines.

Standard Features: Optional Accessories:

• UL Listed aluminum grease filters

• UL Listed globe light(s)

• Removable grease trough & cup(s)

• Hanging brackets

• Exhaust and supply collars installed

• 1” Thick supply air plenum insulation

• Stainless steel construction where visible

• UL Listed fire damper in supply collar

• Air volume damper in supply collar

• Front face perforated stainless steel panels

All stainless steel construction

UL Listed stainless steel grease filters

14” Utility cabinet

Electrical control panel

Pre-plumbed fire suppression

Stainless steel top enclosures

Light and fan switches

Recessed fluorescent light fixtures

Recessed incandescent light fixtures

Stainless Steel wall panel

Stainless Steel side skirts

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Melink Intelli-Hood® control systems

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Avtec CHINOOK Value Ventilation, Page 12a

PP SPEC1036 Rev. D

Revised 05/09

Page 32

Model VFV

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 33

Model VFV

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1400 10 x 12 1800 12 x 14 2000 12 x 16

5’-0” 1750 12 x 14 2250 12 x 16 2500 12 x 18

6’-0” 2100 12 x 16 2700 12 x 20 3000 12 x 22

7’-0” 2450 12 x 18 3150 12 x 24 3500 12 x 26

8’-0” 2800 12 x 22 3600 12 x 28 4000 12 x 30

9’-0” 3150 12 x 24 4050 12 x 30 4500 12 x 34

10’-0” 3500 12 x 26 4500 12 x 34 5000 12 x 38

11’-0” 3850 12 x 28 4950 12 x 38 5500 12 x 42

12’-0” 4200 12 x 32 5400 2 12 x 20 6000 2-12 x 22

13’-0 4550 2-12 x 18 5850 2 -12 x 22 6500 2-12 x 24

14’-0” 4900 2-12 x 18 6300 2 -12 x 24 7000 2-12 x 26

15’-0” 5250 2-12 x 20 6750 2 -12 x 26 7500 2-12 x 28

16’-0” 5600 2-12 x 22 7200 2 - 12 x 28 8000 2-12 x 30

Length

4’-0” 1120 2-8 x 24 1440 2-12 x 12 1600 2-12 x 12

5’-0” 1400 2-12 x 12 1800 2-10 x 16 2000 2-10 x 20

6’-0” 1680 2-12 x 12 2160 2-10 x 20 2400 2-10 x 20

7’-0” 1960 2-10 x 20 2520 2-10 x 20 2800 2-12 x 24

8’-0” 2240 2-10 x 20 2880 2-10 x 30 3200 2-12 x 24

9’-0” 2520 2-12 x 18 3240 2-10 x 30 3600 2-10 x 30

10’-0” 2800 2-12 x 24 3600 2-10 x 30 4000 2-10 x 40

11’-0” 3080 2-12 x 24 3960 2-10 x 40 4400 2-10 x 40

12’-0” 3360 2-10 x 30 4320 2-10 x 40 4800 4-10 x 40

13’-0 3640 2-10 x 30 4680 2-10 x 40 5200 4-10 x 20

14’-0” 3920 2-10 x 40 5040 4-10 x 20 5600 4-10 x 30

15’-0” 4200 2-10 x 40 5400 4-10 x 30 6000 4-10 x 40

16’-0” 4480 2-10 x 40 5760 4-10 x 30 6400 4-10 x 40

Note: Greater exhaust and/or lesser supply air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with two collars have them located on ¼ hood length line. Canopy is to have a

minimum 6” overhang on all exposed sides, front and rear leading edge of hood to the perimeter of the cooking equipment surface.

CFM @

.75 SP

CFM @

.50 SP

Duct Collar

Light Duty

Supply CFM

Duct Collar

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

400-600 Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

1.00” SP

CFM @

.75” SP

Medium Duty

Duct Collar

Supply CFM

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

Exhaust CFM

CFM @

1.25”SP

Heavy Duty

Supply CFM

CFM @

.875”SP

Duct Collar

Duct Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

NFPA-96

Page 12b

Page 34

Page 35

Internal Make-up Air Canopy for

Light And Medium

Duty Cooking Equipment

CHINOOK Value Ventilation

Description:

This internal make-up air canopy is designed to

reduce exhausting large quantities of air from the

conditioned space. Non-tempered make-up air is

introduced under the hood reducing the amount of

conditioned air removed from the building.

The VID model is UL 710 Listed for use over 400

and 600°F commercial cooking appliances. This

model is recommended for all projects where energy

consumption is a factor or when adequate makeup air is not available from the heating and cooling

system.

Specifications:

A double shell, internal make-up air canopy constructed of stainless steel on all exposed surfaces and aluminized steel on all

non-exposed surfaces. Canopy shall have all welded exterior joints and seams. Canopy construction shall conform to NFPA 96

standards. All exposed welds are to be ground and polished to match finish requirements. Canopy is to meet NSF standards for

construction and UL standards for operation. Grease trough(s) to be easily removable and sloped to removable grease cup(s).

The internal make-up air louver shall be an extruded aluminum diffuser with 15 degree non-adjustable vanes spaced ½” apart.

The hood supply plenum shall be lined with 1” thick foil backed insulation for prevention of condensation. The supply air shall

pass through two perforated metal baffles for even air flow out of the louvers. A UL Listed fire damper and air volume damper

in the supply collar shall be supplied by the factory and may be installed in the field if required. Canopy to be complete with UL

Listed removable baffle style aluminum grease filters. Canopy complete with UL Listed globe type incandescent light fixtures

mounted on 36” centers.

Internal MUA Filter

model VID

Standard Features: Optional Accessories:

• Stainless steel construction where visible

• UL Listed aluminum grease filters

• UL Listed globe light fixtures mounted on 48” centers

• 3” rear air space

• Removable grease trough & cup(s)

• Hanging brackets

• 1” thick supply air plenum insulation

• Extruded aluminum interior linear diffuser

• UL Listed fire damper in supply collar

• Air volume damper in supply collar

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

UL Listed stainless steel grease filters

14” Utility cabinet

Insulated 3” air space

Electrical Control Panel

Pre-plumbed fire suppression

Stainless steel top enclosures

Light and fan switch

Recessed fluorescent light fixtures

Stainless steel wall panel

Stainless steel side skirts

Melink Intelli-Hood® system controls

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Avtec CHINOOK Value Ventilation, Page 13

PP SPEC1037 Rev. D

Revised 05/09

Page 36

Model VID

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1100 8 x 14 1300 8 x 14 1400 10 x 12 800 12 x 12

5’-0” 1375 8 x 16 1625 8 x 18 1750 10 x 16 1000 10 x 16

6’-0” 1650 8 x 18 1950 10 x 18 2100 10 x 18 1200 12 x 18

7’-0” 1925 8 x 22 2275 10 x 20 2450 10 x 22 1400 12 x 24

8’-0” 2200 8 x 24 2600 10 x 24 2800 10 x 24 1600 12 x 24

9’-0” 2475 10 x 22 2925 12 x 22 3150 12 x 22 1800 10 x 30

10’-0” 2750 10 x 24 3250 12 x 24 3500 12 x 26 2000 10 x 40

11’-0” 3025 10 x 28 3575 12 x 26 3850 12 x 28 2200 2-10 x 20

12’-0” 3300 12 x 30 3900 12 x 30 4200 12 x 30 2400 2-10 x 20

13’-0 3575 2-10 x 16 4225 2-10 x 20 4550 2-10 x 20 2600 2-10 x 30

14’-0” 3850 2-10 x 18 4550 2-10 x 20 4900 2-10 x 22 2800 2-10 x 30

15’-0” 4125 2-10 x 18 4875 2-12 x 18 5250 2-12 x 20 3000 2-10 x 30

16’-0” 4400 2-10 x 20 5200 2- 12 x 20 5600 2-12 x 22 3200 2- 10 x 30

Note: Greater exhaust and/or lesser supply air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with double collars have them located on ¼” lines hood length lines. Canopy is to

have a minimum 6” overhang on all exposed sides and front leading edge of canopy to the perimeter of the cooking equipment surface.

CFM @

.625 SP

Duct Collar

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

.75” SP

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

Exhaust CFM

CFM @

1.00”SP

Duct Collar

CFM @

.375”SP

Supply CFM

Duct Collar

NFPA-96

Page 37

Internal Make-up Air Canopy

for Light to Medium Duty

Cooking Equipment

CHINOOK Value Ventilation

Description:

This internal make-up air canopy is designed to

reduce exhausting large quantities of air from the

conditioned space. The model VIS is UL 710 Listed

for use over 400 and 600°F cooking appliances.

This model is recommended for all projects where

energy consumption is a factor or when adequate

make-up air is not available from the heating and

cooling system.

Specifications:

A double shell, internal make-up air canopy of Type I construction. Canopy shall be constructed of stainless steel on all exposed

surfaces and aluminized steel on all non-exposed surfaces. Canopy shall have all welded exterior joints and seams and

construction shall conform to NFPA 96 standards. All exposed welds are to be ground and polished to match finish requirements.

Canopy is to meet NSF standards for construction and UL standards for operation. The internal make-up air shall be introduced

inside the hood through a full length internal slot. The hood supply plenum shall be lined with 1” thick foil backed insulation for

prevention of condensation. A UL Listed fire damper and air volume damper in the supply collar shall be supplied by the factory

and may be installed in the field if required. Grease trough(s) to be easily removable and sloped to removable grease cup(s). UL

Listed removable baffle style aluminum grease filters running the full length of canopy. Canopy to come complete with UL Listed

globe style incandescent light fixtures mounted on 36” centers.

Internal MUA Filter

model VIS

Standard Features: Optional Accessories:

• Stainless steel construction where visible

• UL Listed globe light fixtures on 48” centers

• 3” Rear air space

• Removable grease trough & cup(s)

• Exhaust and supply collars installed

• Fixed location hanging brackets

• 1” Thick supply air plenum insulation

• UL Listed aluminum baffle grease filters

• UL Listed fire damper in supply collar

• Air volume damper in supply collar

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

All stainless steel construction

UL Listed stainless steel grease filters

14” Utility cabinet

Insulated 3” air space

Electrical control panel

Pre-plumbed fire suppression

Stainless steel top enclosures

Light and fan switch

Recessed fluorescent light fixtures

Recessed incandescent light fixtures

Stainless steel wall panel

Stainless steel side skirts

Melink Intelli-Hood® system controls

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Avtec CHINOOK Value Ventilation, Page 14

PP SPEC1038 Rev. D

Revised 05/09

Page 38

Model VIS

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1100 8 x 14 1300 8 x 14 1400 10 x 12 800 12 x 12

5’-0” 1375 8 x 16 1625 8 x 18 1750 10 x 16 1000 10 x 16

6’-0” 1650 8 x 18 1950 10 x 18 2100 10 x 18 1200 12 x 18

7’-0” 1925 8 x 22 2275 10 x 20 2450 10 x 22 1400 12 x 24

8’-0” 2200 8 x 24 2600 10 x 24 2800 10 x 24 1600 12 x 24

9’-0” 2475 10 x 22 2925 12 x 22 3150 12 x 22 1800 10 x 30

10’-0” 2750 10 x 24 3250 12 x 24 3500 12 x 26 2000 10 x 40

11’-0” 3025 10 x 28 3575 12 x 26 3850 12 x 28 2200 2-10 x 20

12’-0” 3300 12 x 30 3900 12 x 30 4200 12 x 30 2400 2-10 x 20

13’-0 3575 2-10 x 16 4225 2-10 x 20 4550 2-10 x 20 2600 2-10 x 30

14’-0” 3850 2-10 x 18 4550 2-10 x 20 4900 2-10 x 22 2800 2-10 x 30

15’-0” 4125 2-10 x 18 4875 2-12 x 18 5250 2-12 x 20 3000 2-10 x 30

16’-0” 4400 2-10 x 20 5200 2- 12 x 20 5600 2-12 x 22 3200 2- 10 x 30

Note: Greater exhaust and/or lesser supply air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with double collars have them located on ¼” lines hood length lines. Canopy is to have

a minimum 6” overhang on all exposed sides and front leading edge of canopy to the perimeter of the cooking equipment surface.

CFM @

.625 SP

Duct Collar

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

.75” SP

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

Exhaust CFM

CFM @

1.00”SP

Duct Collar

CFM @

.375”SP

Supply CFM

Duct Collar

NFPA-96

Page 39

Internal Make-up Air Canopy

for Light and Medium Duty

Cooking Equipment

CHINOOK Value Ventilation

Description:

This internal make-up air canopy is designed to

reduce exhausting large quantities of air from the

conditioned space. Non-tempered make-up air is

introduced under the hood reducing the amount of

conditioned air removed from the building.

The VAD hood model is suitable for use over 400

and 600°F commercial cooking appliances. This

model is recommended for all projects where energy

consumption is a factor or when adequate makeup air is not available from the heating and cooling

system.

Specifications:

A double shell, internal make-up air canopy of Type I construction. Canopy shall be constructed of stainless steel on all exposed

surfaces and aluminized steel on all non-exposed surfaces. Canopy shall have all welded exterior joints and seams and shall conform to NFPA 96 standards. All exposed welds are to be ground and polished to match the finish requirements. Canopy is to meet

NSF standards for construction and UL 710 standards for operation. The internal make-up air louver shall be an extruded aluminum

diffuser with 15 degree non-adjustable vanes spaced ½” apart. Exhaust hood shall have an integral capture curtain on front of

the canopy to aid in the containment of heart, smoke, and grease laden vapors directional louvers to be the same as interior fresh

air louvers. The hood supply plenum shall be lined with a 1” thick UL Listed foil backed insulation for prevention of condensation.

The supply air shall pass through two perforated metal baffles for even air flow out of the louvers. A UL Listed fire damper and air

volume damper in the supply collar shall be supplied by the factory and may be installed in the field if required. Canopy shall be

supplied with UL Listed baffle type removable aluminum grease filters. Canopy is complete with UL Listed globe type incandescent

light fixtures mounted on 36” centers. Grease troughs shall be easily removable and sloped to a removable grease cup.

Internal MUA Filter

model VAD

Standard Features: Optional Accessories:

• Stainless steel construction where visible

• UL Listed aluminum grease filters

• UL Listed globe light fixtures mounted on 48” centers

• 3” Rear air space

• Removable grease trough & cup(s)

• Hanging brackets

• 1” Thick supply air plenum insulation

• Extruded aluminum interior linear diffuser

• UL Listed fire damper in supply collar

• Air volume damper in supply collar

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

All stainless steel construction

UL Listed stainless steel grease filters

14” Utility cabinet

Insulated 3” air space

Electrical control panel

Pre-plumbed fire suppression

Stainless steel top enclosures

Light and fan switch

Recessed fluorescent light fixtures

Stainless steel wall panel

Stainless steel side skirts

Melink Intelli-Hood® system controls

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

all units with (2) exhaust collars

Avtec CHINOOK Value Ventilation, Page 15

PP SPEC1039 Rev. D

Revised 05/09

Page 40

Model VAD

Light Duty Temperature Cooking Equipment – 400°F (

Medium Duty Temperature Cooking Equipment – 400-600°F (

Heavy Duty Temperature Cooking Equipment – 600°F (

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1100 8 x 14 1300 8 x 14 1400 10 x 12 800 12 x 12

5’-0” 1375 8 x 16 1625 8 x 18 1750 10 x 16 1000 10 x 16

6’-0” 1650 8 x 18 1950 10 x 18 2100 10 x 18 1200 12 x 18

7’-0” 1925 8 x 22 2275 10 x 20 2450 10 x 22 1400 12 x 24

8’-0” 2200 8 x 24 2600 10 x 24 2800 10 x 24 1600 12 x 24

9’-0” 2475 10 x 22 2925 12 x 22 3150 12 x 22 1800 10 x 30

10’-0” 2750 10 x 24 3250 12 x 24 3500 12 x 26 2000 10 x 40

11’-0” 3025 10 x 28 3575 12 x 26 3850 12 x 28 2200 2-10 x 20

12’-0” 3300 12 x 30 3900 12 x 30 4200 12 x 30 2400 2-10 x 20

13’-0 3575 2-10 x 16 4225 2-10 x 20 4550 2-10 x 20 2600 2-10 x 30

14’-0” 3850 2-10 x 18 4550 2-10 x 20 4900 2-10 x 22 2800 2-10 x 30

15’-0” 4125 2-10 x 18 4875 2-12 x 18 5250 2-12 x 20 3000 2-10 x 30

16’-0” 4400 2-10 x 20 5200 2- 12 x 20 5600 2-12 x 22 3200 2- 10 x 30

Note: Greater exhaust and/or lesser supply air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 12’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600FPM. Duct collars are

located on centerline of canopy, unless otherwise specified. Hoods with double collars have them located on ¼” lines. Canopy is to have a minimum 6”

overhang on all exposed sides and front leading edge of canopy to the perimeter of cooking equipment surface.

CFM @

.625 SP

Duct Collar

Light duty ranges, roasters, ovens, steamers, etc.)

Rotisseries, ranges, grills, fryers, etc.)

Gas char-broilers, woks, upright broilers, etc.)

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

.75” SP