Page 1

Tray Trac™

Tray Assembly System

Modular Base Unit

Conveyors Tray Trac™ Conveyor Systems model TTM

Description:

The AVTEC Tray Trac™ is a unique tray assembly

system, designed for tray preparation for hospitals,

nursing homes, prisons and anywhere an assembly

line to prepare trays is required. The system

utilizes a series of tray carriers mounted to a drive

chain, rotating around a series of sprockets. The

system utilizes the “work facing approach to tray

assembly and thus eliminates the extraneous motion

of twisting and turning associated with straightline tray systems. The system utilizes consistent

spacing, easy recognition of tasks, limited range

of motion, and consistent delivery to increase tray

production. The Model TTM, modular-base unit,

utilizes AVTEC manufactured hot and or cold portable

units to standardize the tray line, allow flexibility, and

eliminate the need for many ancillary pieces.

Specifications:

Provide AVTEC UL listed, NSF approved, Tray Trac Assembly System, Model TTM, with table base, ______ long x ______ wide, with food

holding surface 30 ½” to 34 ½ “ above finished floor. Conveyor track length to be ________ long. Modular System shall contain non-refrigerated surfaces, mobile refrigerated units, mobile hot food well units, and other items as specified and shown on drawings.

System shall consist of a series of rotating removable tray carriers with UHMW polyethylene wear strips riding on a stainless steel track,

cantilevered above the finished floor and 12” above the food holding surfaces. Removable tray carriers shall attach to a closed-path steel

sprocket and chain located in a stainless steel housing. Top of drive housing shall be removable for access to all drive chain components.

Unit shall be constructed of stainless steel channel framing with exterior of 300 series, #4 finish stainless steel. Table top shall be 14 gauge,

with all side panels access doors and mullions 16 gauge stainless steel. Access doors to be hinged and provided with recessed handles.

Unit to be provided with adjustable leg assemblies with 4” adjustment. Unit to be complete with neoprene bumper guards on all sides and

stainless steel splash guards over work surfaces.

Power for drive to be provided by a (¾) (1) HP 120VDC motor with silicone controlled rectifier, solid state controls and automatic bearing

lubrication. Speed control and hour meter to be located inside access doors. Start /stop controls to be located at starter (and/or) checker

station of tray line. Unit to include main disconnect for drive mechanism and individual modular energy distribution systems.

Unit to be provided with UL listed, AVTEC Modular Energy Distribution System running on each side of base and as part of the individual

mobile sections, with main electrical disconnects. Modular system to house connection link plates consisting of point-of-use circuit breaker,

and matching electrical outlet or connection. Link plates on 12” centers and shall provide power for all ancillary equipment as shown on

drawing. Connection plates shall be interchangeable, with blank plates available for future connections.

KEC to determine size of crates that can be received at site and moved through building. If unit is to be shipped in sections, standard spline

joints will be supplied at field joints. Field welding, if required, is the responsibility of the KEC. Mandatory supervision of assembly and startup by factory authorized technician is required. Two weeks written notice of installation time required.

_______ Amps, 120/208/3F, _____ KW, 4-wire

_______ Amps, 120/208/3F, _____ KW, 4-wire

½” Hot and ½” cold water (Electrical) (Plumbing) services to terminate in (ceiling) (floor) by trades. Final connection by trades.

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Avtec Conveyors, Page 15a

PP SPEC1065 Rev. A

Revised 11/07

Page 2

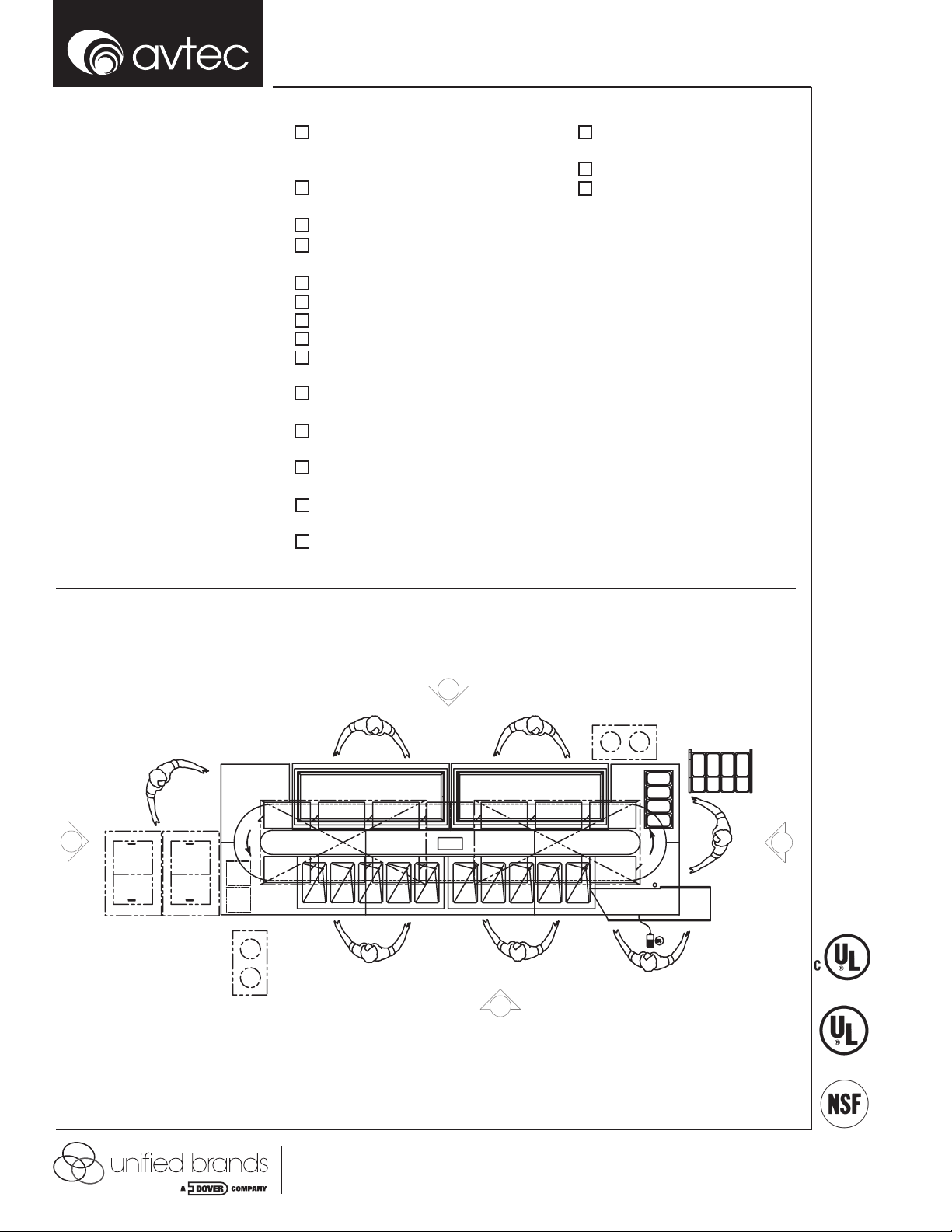

ELEVATION VIEW

ELEVATION VIEW

B

D

• Chain link drive with removable tray

carriers – no conveyor belt service

problems

• Cantilevered tray carrier design

saves floor space

• Tray carriers easily removable

for cleaning

• Operator is facing tray line during

operation – no turning or extraneous

motions

• Tray interval remains constant

• Checker unload station allows

continuous operation-no stoppage

on the line for checking

• Uniform work surface containing

hot and cold units

• Menu cards easily readable at 45%

angle towards operator

• AVTEC Modular EDS allows for

powering ancillary equipment w/one

electrical service for entire system

• Allows for easy relocation or adding

of electrical connection

Optional Accessories:Standard Features:

Integral Starter Station: Side mounted 2 tier, 6

bin with: 3 extra bins in table top

and top shelf

End mounted over trac, 2-tier,

10 bin w/top shelf

Mounted under trac, 5-bin

____” x ____” cutout for tray dispenser

( to be verified )

Tray Unload Station, 5 ft. (5 ft. std.)

____(Qty) Portable 6-well (Cold)(Hot) Food Units

____(Qty) Portable 5 well (Cold)(Hot) Food Units

____(Qty) Portable 4 well (Cold)(Hot) Food Units

____(Qty) Portable Cold Top Units3 Bun Pan size

____(Qty) Foot Operated Momentary

Stop Switch(es)

____(Qty)Angle Double Side Over shelf,

38”d x ____ft. lg.

S/S Fluorescent Work Light Fixtures

(over table base)

S/S Fluorescent Work Light Fixtures

(over tray carrier)

Checker Audio Call System w/ microphone

& 2 speakers

Model TTM

Timer/Programmer, 7-Day,

single channel

Door Locks (2)

Heavy duty casters, in lieu of legs

Top View

C

PLAN VIEW

B

D

A

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 3

Front & Side Views

ELEVATION VIEW

ELEVATION VIEW

B

B

C

D

ELEVATION VIEW

PLAN VIEW

ELEVATION VIEW

A

B

B

D

D

Model TTM

ELEVATION VIEW

ELEVATION VIEW

B

A

ELEVATION VIEW

C

ELEVATION VIEW

D

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

Page 15b

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 4

Tray Trac Application Data

*Maximum No. of Hot Food Wells

OA Length Trac Length Overshelf Length Single Double

12’ 11’ 2” 9’ 6 8

15’ 13’ 5” 11’ 3” 8 10

17’ 15’ 8” 13’ 6” 9 12

19’ 17’ 11” 15’ 9” 10 14

21’ 20’ 2” 18’ 13 16

24’ 22’ 5” 20’ 3” 15 18

26’ 24’ 8” 22’ 6” 17 22

28’ 26’ 11” 24’ 9” 19 24

30’ 29’ 2” 27’ 21 26

33’ 31’ 5” 29’ 3” 23 28

*If used with integral unload station. Add 3” in width if “double” hot food wells are used.

Model TTM

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...