Page 1

Document 464664

Model AX

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

Model AX

Standard Long Casing

Optional Short Casing

AX

Optional Vane Section

AX-S

Optional Roof Upblast

Table of Contents

Receiving, Unpacking Handling and Storage ........2

Removing from Storage ........................2

Lifting .......................................3

Effects of Installation on Performance .............3

Typical Installation .............................4

Operation and Unit Start-Up .....................4

Performance Adjustments

Field Performance Adjustments .................5

Adjusting Performance with a Variable

Frequency Drive ...........................5

Adjusting Performance through Blade

Pitch Adjustments ..........................5

Torque Specifications for Bushing and

Propeller Bolts ............................5

Maintenance .................................6

Parts List ....................................6

Maintenance Log ..............................7

Our Commitment ..............................8

AX-V

AX-U

General Safety Information

Only qualified personnel should install this unit.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

1. Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), the National

Fire Protection Agency (NFPA), where applicable.

Follow the Canadian Electric Code (CEC) in Canada.

2. The rotation of the propeller is critical. It must

be free to rotate without striking or rubbing any

stationary objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan propeller faster than the maximum

cataloged fan rpm. Adjustments to fan speed with

Variable Frequency Drives (VFD) may affect motor

load. If the fan RPM is changed, the motor current

should be checked to make sure it is not exceeding

the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

DANGER

Always disconnect power before working on or near a

unit. Lock and tag the disconnect switch or breaker to

prevent accidental power up.

CAUTION

When servicing the unit, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

®

Axial Fan

1

Page 2

Receiving

Upon receiving the product, check the bill of lading to

ensure all items were received. Inspect each crate for

shipping damage before accepting delivery. Notify the

carrier if any damage is noticed. The carrier will make

notification on the delivery receipt acknowledging any

damage to the product. All damage should be noted on

all the copies of the bill of lading which is countersigned

by the delivering carrier. A Carrier Inspection Report

should be filled out by the carrier upon arrival. If

damaged upon arrival, file claim with carrier. Any

physical damage to the unit after acceptance is not the

responsibility of Greenheck Fan Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative to

arrange for obtaining missing parts. Sometimes it is not

possible that all items for the unit be shipped together

due to availability of transportation and truck space.

Confirmation of shipment(s) must be limited to only

items on the bill of lading.

Handling

Handle in such a manner as to keep from scratching

or chipping the coating. Fans should not be lifted by

the motor shaft, motor housing or fan accessories.

Damaged finish may reduce ability of unit to resist

corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

INDOOR — The ideal environment for the storage of

units and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain, or snow. Temperatures

should be evenly maintained between 30°F (-1°C)

and 110°F (43°C) (wide temperature swings may

cause condensation and “sweating” of metal parts).

All accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To avoid

“sweating” of metal parts allow cold parts to reach room

temperature. To dry parts and packages, use a portable

electric heater. Leave coverings loose to permit air

circulation and to allow for periodic inspection.

The unit should be stored at least 3½ inches (89 mm)

off the floor on wooden blocks covered with moisture

proof paper or polyethylene sheathing. Aisles between

parts and along all walls should be provided to permit

air circulation and space for inspection.

OUTDOOR — Units designed for outdoor applications

may be stored outdoors, if absolutely necessary. Roads

or aisles for portable cranes and hauling equipment are

needed.

The fan should be placed on a level surface to prevent

water from leaking into the unit. The unit should be

elevated on an adequate number of wooden blocks so

that it is above water and snow levels and has enough

blocking to prevent it from settling into soft ground.

Locate parts far enough apart to permit air circulation,

sunlight, and space for periodic inspection. To minimize

water accumulation, place all unit parts on blocking

supports so that rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Inspection and Maintenance during Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan propeller by hand ten to fifteen

revolutions to distribute lubricant on motor. Every three

months, the fan motor should be energized. If paint

deterioration begins, consideration should be given to

touch-up or repainting. Fans with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lintfree cloths. Polish any remaining rust from surface

with crocus cloth or fine emery paper and oil. Do not

destroy the continuity of the surfaces. Wipe thoroughly

clean with Tectyl® 506 (Ashland Inc.) or the equivalent.

For hard to reach internal surfaces or for occasional

use, consider using Tectyl® 511M Rust Preventive or

WD-40

® or the equivalent.

REMOVING FROM STORAGE — As units are removed

from storage to be installed in their final location, they

should be protected and maintained in a similar fashion,

until the equipment goes into operation.

Prior to installing the unit and system components,

inspect the unit assembly to make sure it is in working

order.

1. Check all fasteners on the fan, propeller, motor base,

and accessories for tightness.

2. Rotate the fan propeller by hand and assure no parts

are rubbing.

3. Fans should not be lifted by the motor shaft, motor

housing or fan accessories.

2

Axial Fan

®

Page 3

Lifting Effects of Installation on

Performance

Any installation with inlet or discharge configurations

that deviate from these recommendations may result in

reduced fan performance. Restricted or unstable flow

at the fan inlet can cause pre-rotation of incoming air or

uneven loading of the fan propeller yielding large system

losses and increased sound levels. Free discharge or

turbulent flow in the discharge ductwork will also result

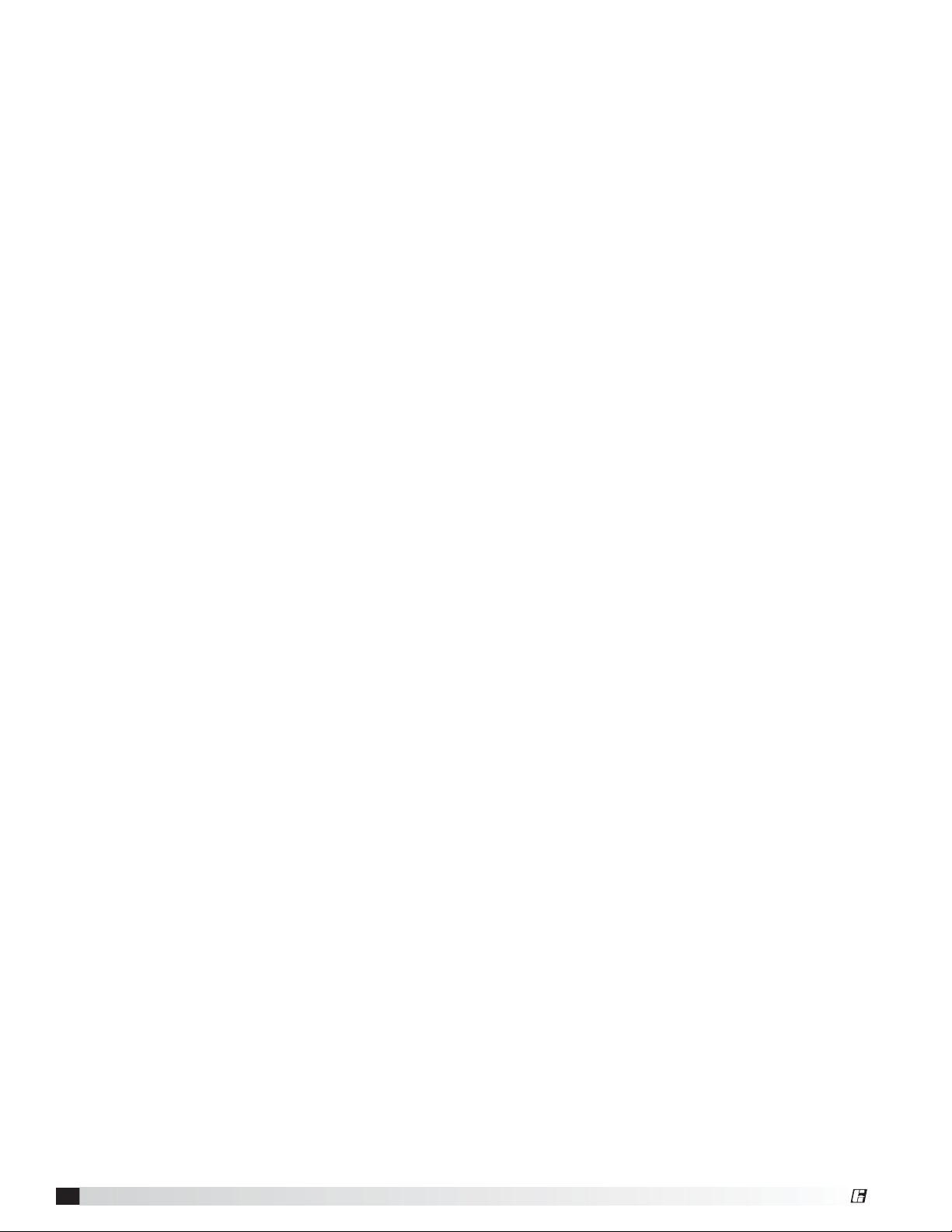

Standard

Long Casing

Optional

Vane Section

Fan models AX, AX-V or AX-S are to

be lifted using a minimum of four (4)

points on the fan housing or attach

two suitable chains/straps around

the entire fan housing, one near each

duct flange.

For flange mounted fans, attach

suitably sized chains or lifting straps

to two locations on the inlet and

outlet flanges as shown.

For fans with Universal Mounting

brackets, use brackets for lifting

connection points.

Optional

Short Casing

in system effect losses.

The most common inlet and discharge conditions which

affect fan performance are:

Inlet Duct Turns

1 Fan

Dia.

Turning

Vanes

Good Poor

Installation of a duct turn or elbow too close to the

fan inlet reduces fan performance because air is

loaded unevenly into the fan prop. To achieve full fan

performance there should be at least one to two fan

diameters between the turn or elbow and the fan inlet.

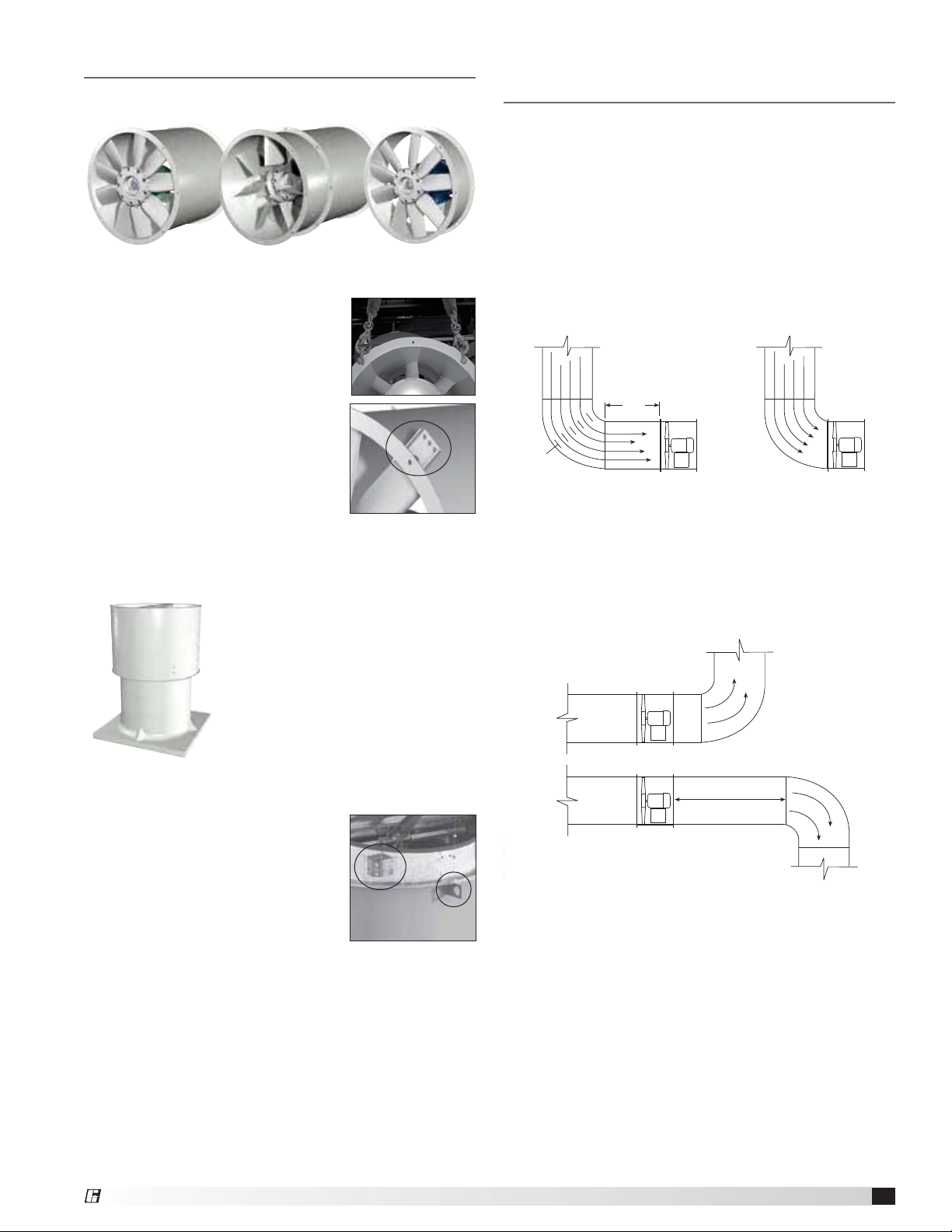

Optional

Roof Upblast

Fan model AX-U are to be lifted

using the four (4) windband gussets

located between the butterfly

damper section of the fan and the

exterior windband unless welded

lifting lugs are provided on fan

housing. Welded lifting lugs are

present on AX-113 thru AX-160.

A spreader bar is recommended

to prevent damage to the damper

section when lifting.

Discharge Duct Turns

Poor

3 Diameters of

Straight Duct

Good

Fan performance is reduced when duct turns are made

immediately off the fan discharge. To achieve cataloged

fan performance, there should be at least three

equivalent fan diameters of straight ductwork between

the fan discharge and any duct turns.

®

Axial Fan

3

Page 4

Typical Installations

Operation and Unit Start-Up

The examples shown below are common installations

of the different housing options with and without

optional Universal Mounting Brackets. Before beginning

installations, reference the airflow direction as indicated

by the direction decal

attached to the fan. Note

that airflow for AX units

with straightening vanes is

opposite of the standard AX

Airflow

Direction Decal

long casing design.

Units with Flange Mounting

• Upblast, Downblast or Horizontal

Airflow Airflow

Airflow

Units with Universal Mounting Brackets (Optional)

• Vertical, Ceiling Mount with Isolators,

Downblast or Upblast

Airflow Airflow

Electrical Connections

Before electrical connections are made, the supply

voltage, phase and ampere capacity must be checked

for compatibility with the fan motor. In addition, the

supply wiring must be properly fused and conform to

local and national electrical codes.

The supply wires are then connected to an optional

safety disconnect switch, to the optional wiring pigtail,

or directly to the motor junction box.

Pre-Start-Up Checks

1. Check all fasteners for tightness. Fasteners may

come loose during transit or handling at the jobsite.

This includes motor bolts, mounting brackets, and

bushing bolts attaching the propeller to the motor

shaft.

2. Propeller rotation should be in the same direction

as the rotation decal affixed to the unit. For 3-phase

installations, fan rotation can be reversed by simply

interchanging any two

of the three electrical

leads. For single phase

installations, follow the

wiring diagram located on

the motor.

Propeller Rotation

Decal

• Horizontal, Floor or Ceiling Mount with Isolators

Airflow Airflow

Roof Upblast on a Roof Curb

Airflow

Wall Mounted (Short Casing)

Airflow

4

Axial Fan

Optional

Inlet Bell

®

Page 5

Performance Adjustments

Field Performance Adjustments

The performance of an AX fan can be adjusted through

the use of a variable speed drive (VFD) or adjusting

the fan pitch. Both can be effectively used for final air

balancing. Note that any change, increase or decrease

in fan speed (RPM) or blade pitch, can represent a

substantial increase in power required from the motor.

Check motor load amperage and compare to nameplate

rating when changing the fan speed or blade pitch.

Adjusting Performance with a Variable Frequency

Drive (VFD)

Before wiring a VFD, determine that the motor is

compatible with this type of equipment. Connecting a

VFD to a non-compatible motor may reduce the life of

the motor. Additionally, it is important to properly ground

fans being wired with a VFD. For more information

on these subjects, refer to Greenheck document “Are

Bearing Currents Causing Your Motor Failures?” located

at www.greenheck.com. Click on Library, Application

Articles, and use the keyword “VFD”. Greenheck is not

responsible for improper wiring of a VFD or for potential

motor damage as a result of operating a fan over its

maximum operating frequency.

Adjusting Performance through Blade Pitch

Adjustments

The blade pitch can be adjusted without removing the

propeller from the fan casing. Steps to adjust the blade

pitch are as follows:

1. Determine the new blade pitch required with your

local Greenheck representative. Verify that the

motor has sufficient capacity to handle the new

power requirements.

2. Disconnect and lock out all power to the fan to

prevent accidental start-up.

3. Gain access to the propeller side of the fan. This

may require removing the fan from the existing duct

system or dismantling ductwork to gain access.

4. Loosen the blades to the point where they can be

rotated in the hub. Hub and blade fastening vary by

fan size. Hub styles and bolt torque requirements

are provided. Do NOT pound on the blades to

adjust the pitch. They should be snug, but movable

by hand.

5. Use the blade pitch protractor found on

Greenheck’s website (www.greenheck.com) to

adjust the pitch. Follow the directions stated on the

guide for determining blade pitch.

6. Adjust one blade to the desired pitch angle and

remove the protractor sheet.

7. Use a marker to trace the profile of the blade on the

fan housing.

8. Adjust the remaining blades to the traced profile.

9. Retighten the hub to the torque specs detailed

below per hub size.

10. Reinstall the fan or any duct pieces that were

removed.

11. Review the Operation and Start-Up procedures

listed earlier in this manual.

12. After start-up, make a final check of the fan amps

to ensure the motor is not overloaded.

Torque Specifications for Bushings and Propeller

Bolts

HUB SIZE: 160 mm

Bushing bolts 9 ft-lb / 12.2 N-m

Propeller bolts 7 ft-lb / 9.5 N-m

HUB SIZE: 190 mm

Bushing bolts 16 ft-lb / 21.7 N-m

Propeller bolts 7 ft-lb / 9.5 N-m

HUB SIZE: 275 mm

Bushing bolts 16 ft-lb / 21.7 N-m

Propeller bolts 21 ft-lb / 28.5 N-m

HUB SIZE: 400 mm

Bushing bolts 27 ft-lb / 36.6 N-m

Propeller bolts 40 ft-lb / 54.2 N-m

HUB SIZE: 533 mm

Bushing bolts 40 ft-lb / 54.2 N-m

Blade Nuts 125 ft-lb / 169.5 N-m

®

Axial Fan

5

Page 6

Maintenance

Parts List

Once the unit has been put into operation, a routine

maintenance schedule should be set up to accomplish

the following:

1. Lubrication of motor.

2. Propeller, housing, and bolts on the entire fan should

be checked for tightness.

3. Any dirt accumulation on the propeller or in the

housing should be removed to prevent unbalance

and possible damage.

4. Inspection of fan propeller and housing looking for

fatigue, corrosion, or wear.

When performing any service to the fan, disconnect the

electrical supply and secure fan propeller.

Motors

Motor maintenance is generally limited to cleaning

and lubrication. Cleaning should be limited to exterior

surfaces only. Removing dust and grease buildup on

the motor housing assists proper motor cooling. Never

wash-down motor with high pressure spray.

Greasing of motors is only intended when fittings are

provided. Many motors are permanently lubricated for

life and require no further lubrication. Motors supplied

with grease fittings should be greased in accordance

with the motor manufacturer’s recommendations.

Each fan bears a manufacturer’s nameplate with model

number and serial number embossed. This information,

in addition to the shown parts diagram, will assist

the local Greenheck representative and the factory in

providing service and replacement parts.

Nameplates are mounted in an area which is clearly

visible, usually near the fan outlet. The exact tag

location may differ with fan model and size.

Propeller

(hub and blades)

Motor

(behind propeller)

Casing

Mounting Brackets

(optional)

Windband

Butterfly Dampers

Fasteners and Set Screws

A periodic inspection should include checking all

fasteners and bolts for tightness. Particular attention

should be paid to the bushing attaching the propeller to

the motor shaft and the motor to its mounting fixture.

Removal of Dust and Dirt

Dirt clogs cooling openings on the motor housing,

contaminates bearing lubricant, and collects on the

propeller causing severe imbalance if left unchecked.

The exterior surface of the motor and propeller should

be thoroughly cleaned periodically. Use caution and do

not allow water or solvents to enter the motor. Under no

circumstances should motors be sprayed with steam or

water.

Windband Gussets

Propeller

Motor

Casing

Curb Cap

6

Axial Fan

®

Page 7

Maintenance Log

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

®

Axial Fan

7

Page 8

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Specific Greenheck product warranties are located on greenheck.com within the product area tabs and in the

Library under Warranties.

Greenheck’s High Performance Axial Fan catalog, Model AX,

provides additional information describing the equipment, fan

performance, available accessories, and specification data.

®

Phone: 715.359.6171 • Fax: 715.355.2399 • Parts: 800.355.5354 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

464664 • AX, Rev. 2, December 2013 Copyright 2013 © Greenheck Fan Corporation

8

AMCA Publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans, provides

additional safety information. This publication can be obtained

from AMCA International, Inc. at www.amca.org.

Loading...

Loading...