Page 1

Water Wash Type

External Make-up Air Canopy

for Use Vver All Types of

Cooking Equipment

TAKU Premier Ventilation External MUA Water Wash Canopy model AWWO-P

Description:

The AWWO-P is UL 710 Listed for use over 400,

600 and 700ºF cooking surface temperatures. This

is an external make-up air canopy with an integral

self cleaning water wash exhaust plenum. Grease

extraction is accomplished through a built in 6-turn

exhaust plenum. Wash down is done through a series

of water spray nozzles spaced equally throughout the

length of the exhaust plenum. The perforated supply

air plenum can be shipped attached to the hood, or

shipped loose to suit on-site job specific requirements.

The front supply air plenum can provide up to 80%

make-up air.

AW water wash hoods are intended for use over all

types of commercial kitchen cooking appliances. This

model hood is suitable for heavy grease applications

for hotels, hospitals and institutions and is available in

either a wall or island style configuration.

Specifications:

Make-up air style Type I commercial kitchen ventilation canopy UL 710 Listed with an electro-mechanical fire damper in exhaust

collar. Exhaust fire damper assembly shall be activated by a fusible link rated at 350º F. Canopy is constructed of a minimum

18 gauge non-magnetic stainless steel on all surfaces. All exterior joints and seams shall be continuously welded liquid tight,

ground smooth, and polished to match the finish requirements. Construction to conform to NFPA 96 standards and shall meet UL

710 standards for operation. Canopy shall be complete with water wash grease extraction plenum, duct collar, exhaust plenum,

concealed wash nozzles, and wash plenum access doors. All water manifolds shall be square stainless steel tubing. Spray

nozzles shall be machined brass, 2” drain with fully welded threaded nipple located at either end or rear of the canopy. Canopy is

constructed using the standing seam method for optimum strength. Make up air is introduced to the kitchen via a fully insulated

ceiling mounted supply air plenum with stainless steel perforated discharge panels and with internal air diffusers to provide an

even flow of air across the length of the hood. Make up air collar(s) shall include air volume control damper. UL Listed globe style

incandescent light fixtures mounted on 36” center lines.

Standard Features: Optional Accessories:

•Non-magneticstainlesssteeldoublewallconstruction

•ULListedincandescentglobestylelightxturesmounted

on 36” centerlines

•6”Rearairspace

•ULListedwaterwashcontrolpanel–PAWSperspecs

•Pre-drilledhangerbrackets

•ULListed6-passwaterwashcartridgestylegrease

extractors

•Fullyweldeddrainstubspre-plumbedoutthebottomof

the extraction plenum

14” Wide utility cabinet mounted on end of hood

Electrical control panel

Pre-plumbed fire suppression

Insulated 3” air space for 0” clearance to combustibles

Stainless steel top enclosures

Fan/light switches

UL Listed recessed incandescent or recessed

fluorescent light fixtures

Stainless steel wall panel

Stainless steel side skirts

Continuous cold water mist to aid in grease extraction

Melink Intelli-Hood® system controls

Exhaust fan / cooking equipment interlock control

Sloped front design for low ceiling application

UL Listed exhaust volume damper available on

all models with (2) exhaust collars

UL Listed electro-mechanical manual reset fire damper

assembly with “fail safe” fusible link back up

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Avtec TAKU Premier Ventilation, Page 5a

PP SPEC1009 Rev. D

Revised 05/09

Page 2

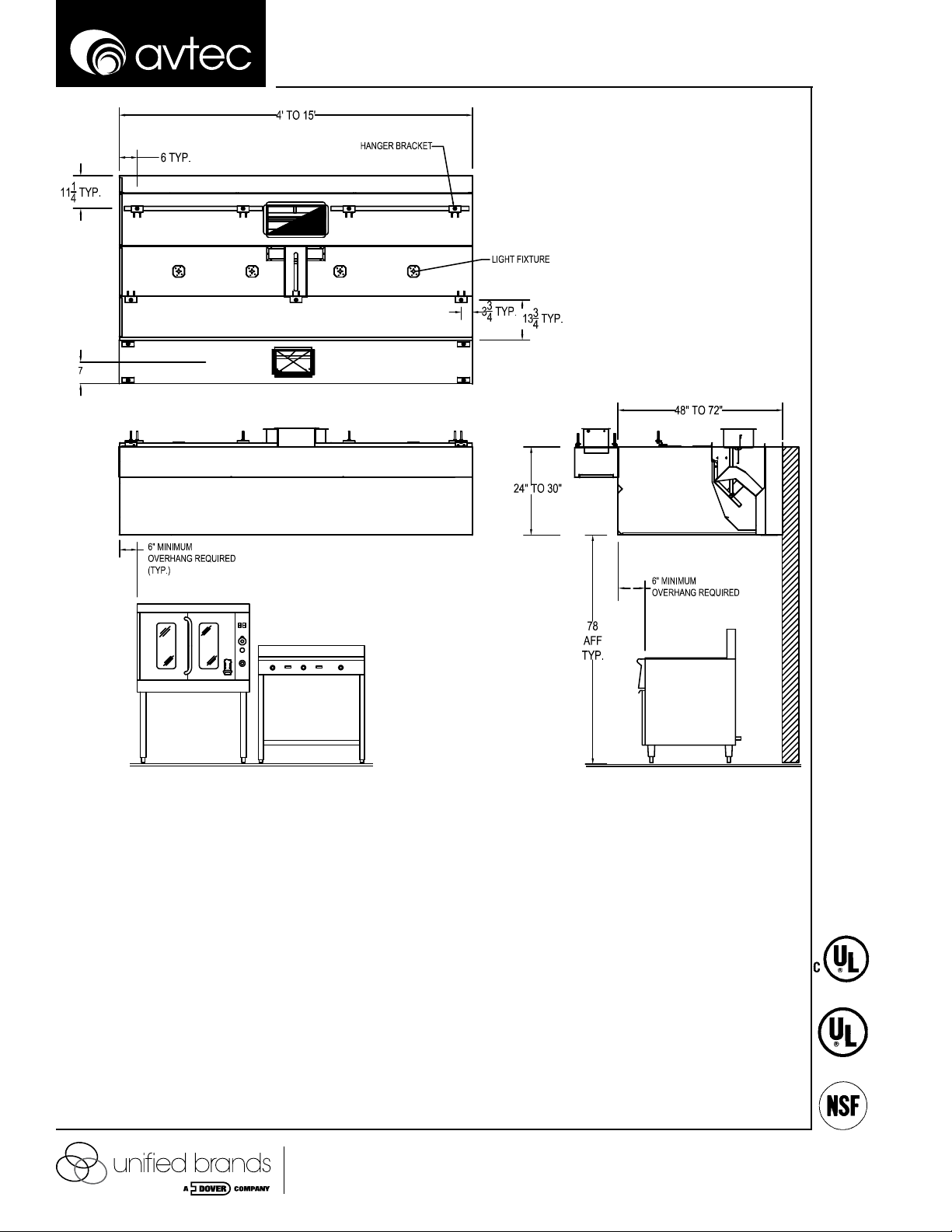

Model AWWO-P

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

UMC

IMC

NFPA-96

Page 3

Light Duty Temperature Cooking Equipment – 400°F

Light duty ranges, roasters, ovens, steamers, etc…

Medium Duty Temperature Cooking Equipment – 400-600°F

Rotisseries, ranges, grills, fryers, etc…

High Temperature Cooking Equipment – 600°F

Gas char-broilers, woks, upright broilers, etc...

Extra-Heavy Temperature Cooking Equipment – 700°F

Solid fuel broilers

Model AWWO-P

400 Degree Light Duty

Cooking Equipment

Exhaust CFM

Length

4’-0” 1000 8 x 12 1200 8 x 14 1400 8 x 16 2100 8 x 24

5’-0” 1250 8 x 14 1500 8 x 16 1750 8 x 20 2625 10 x 24

6’-0” 1500 8 x 16 1800 8 x 20 2100 8 x 24 3150 10 x 28

7’-0” 1750 8 x 20 2100 8 x 24 2450 8 x 28 3675 10 x 34

8’-0” 2000 8 x 22 2400 8 x 28 2800 10 x 24 4200 12 x 32

9’-0” 2250 8 x 26 2700 10 x 24 3150 10 x 28 4725 12 x 36

10’-0” 2500 8 x 28 3000 10 x 28 3500 12 x 26 5250 12 x 40

11’-0” 2750 10 x 24 3300 12 x 24 3850 12 x 30 5775 12 x 44

12’-0” 3000 10 x 28 3600 12 x 28 4200 12 x 32 6300 2-12 x 24

13’-0 3250 12 x 24 3900 12 x 30 4550 12 x 34 6825 2- 12 x 26

14’-0” 3500 12 x 26 4200 12 x 32 4900 12 x 36 7350 2- 12 x 28

15’-0” 3750 12 x 28 4500 12 x 34 5250 12 x 40 7875 2- 12 x 30

16’-0” 4000 2-10 x 18 4800 2- 10 x 22 5600 2-10 x 24 8400 2- 12 x 32

Length

4’-0” 800 12 x 12 960 10 x 20 1120 10 x 20 1680 12 x 24

5’-0” 1000 10 x 20 1200 10 x 20 1400 10 x 30 2100 12 x 24

6’-0” 1200 10 x 20 1440 10 x 30 1680 12 x 24 2520 10 x 40

7’-0” 1400 10 x 30 1680 12 x 24 1960 10 x 40 2940 10 x 40

8’-0” 1600 12 x 24 1920 10 x 40 2240 2-10 x 20 3360 2-10 x 30

9’-0” 1800 10 x 40 2160 10 x 40 2520 2-10 x 20 3780 2-10 x 40

10’-0” 2000 10 x 40 2400 2-10 x 20 2800 2-10 x 30 4200 2-10 x 40

11’-0” 2200 2-10 x 20 2640 2-10 x 30 3080 2-10 x 30 4620 2-10 x 40

12’-0” 2400 2-10 x 20 2880 2-10 x 30 3360 2-12 x 24 5040 2-10 x 40

13’-0 2600 2-10 x 30 3120 2-12 x 24 3640 2-10 x 40 5460 2-10 x 40

14’-0” 2800 2-10 x 30 3360 2-12 x 24 3920 2-10 x 40 5880 2-10 x 40

15’-0” 3000 2-12 x 24 3600 2-10 x 40 4200 2-10 x 40 6300 2-10 x 40

16’-0” 3200 2-12 x 24 3840 2-10 x 40 4480 2-10 x 40 6720 2-10 x 40

Note: Greater exhaust and/or lesser supply air flow rates may be required for each specific installation to obtain complete vapor and smoke removal.

Note: Hoods over 15’-0”in length require two exhaust duct collars. Exhaust collar sizing is based on an average range of 1600FPM. Duct collars are located

on centerline of canopy, unless otherwise specified. Hoods with double collars have them located on ¼ hood length lines unless otherwise specified.

Canopy is to have a minimum 6” overhang on all exposed sides and the front leading edge to the perimeter of the cooking surface.

CFM @

1.30 SP

CFM @

.25 SP

Duct Collar

Light Duty

Supply CFM

Duct Collar

400-600 Degree Medium Duty

Cooking Equipment

Exhaust CFM

CFM @

1.65” SP

CFM @

.385” SP

Medium Duty

Duct Collar

Supply CFM

Duct Collar

600 Degree Heavy Duty

Cooking Equipment

Exhaust CFM

CFM @

1.75”SP

CFM @

.50”SP

Supply CFM

Duct Collar

Heavy Duty

Duct Collar

700 Degree Extra-Heavy

Duty Cooking Equipment

Exhaust CFM

CFM @

1.90”SP

Extra-Heavy Duty

CFM @

. 65”SP

Duct Collar

Supply CFM

Duct Collar

UMC

IMC

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

NFPA-96

Page 5b

Loading...

Loading...