Page 1

VENTILATION SYSTEMS

INSTALLATION AND OPERATING

TECHNICAL MANUAL

FOR ADDITIONAL COPIES VISIT OUR WEB SITE AT

www.avtecind.com

AVTEC INDUSTRIES INC. 120 KENDALL POINT DR. OSWEGO, IL 60543-8898 630-851-4800

Page 2

TABLE OF CONTENTS

I. TYPES OF SYSTEMS 1

A. Baffle Filter . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

B. Modular Grease Extractors [Energy Aire] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

C. Auto Wash [Energy Aire] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

D. Airflow Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . 2

E. Fire Extinguishing Systems .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

II. INSTALLING THE VENTILATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2/3

III. CONTROL PANEL . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

A. Wall Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

IV. ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

A. VCW Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

B. PAWS Control Panel . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5/6/7

C. Damper and Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

D. Ventilator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

V. PLUMBING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

A. Hot Water Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

B. Cold Water Mist [optional] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

C. Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

D. Field Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

E. Detergent Pump and Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

F. Interconnecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

G. Detergent Flow Chart . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

VI. OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

A. VCW Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1. Adjustment . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2. Sequence Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3. Trouble-Shooting . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11/12

B. PAWS Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12/13

1. Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12/13

a. Fan Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

b. Fan Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

c. Wash Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

d. Wash Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. Trouble Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

a. Low Detergent Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

b. Supervised Valve [optional] . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3. Hood Plenum Fire Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

a. Automatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

b. Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4. Programming Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13/14

a . Setting The Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13/14

b. Setting The PAWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1. Single Wash Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2. Multi-Wash Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

c. Setting The Fire Delay . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

d. Reviewing The Daily Event Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

e. Changing The Daily Event Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

f. Repeating The Daily Event Schedule . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . 15

g. Holiday Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

h. Fan On During Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

i. Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

j. Last Command Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

k. Diagnostic Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

l. Detergent Pump and Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Page 3

VII. VENTILATOR FEATURES AND ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

A. Baffle Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

B. Modular Grease Extractors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

C. Auto Wash Grease Extractors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

D. Air Adjustment Baffle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

E. Fire Dampers . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. .. . . . . . . .. .. . 20

F. Air Make-Up [Supply] Plenums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .. . 20

G. Auto Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

H. Cold Water Mist [Optional] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

I. Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

VIII. PERIODIC MAINTENANCE . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

A. Baffle Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

B. Modular Grease Extractors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

C. Grease Trough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

D. Grease Collection Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

E. Hood Canopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

F. Detergent System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

G. Fusible Link Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

IX. PARTS LIST

A. PAWS Panel - Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

B. VCW Panel - Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

C. PAWS/VCW Panel - Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

D. EVAC Detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

E. Electro-Mechanical Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

F. Fusible Link Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

G. Hood Canopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25/26

X. OTHER DATA AND DRAWINGS

A. EVAC Cleaner Cut Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

B. Air Movement Recordings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

C. Calculating and Recording Air Movement Readings . . . . . . . . . . . . . . . . . . . . . . 29

D. Calculating and Recording Air Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

XI. WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 4

1

I. TYPES OF SYSTEMS

This manual covers three [3] of the basic types of

systems offered by AVTEC - Baffle Filter [AF],

Modular Grease Extractor [AX] and Auto Wash

Down [AW].

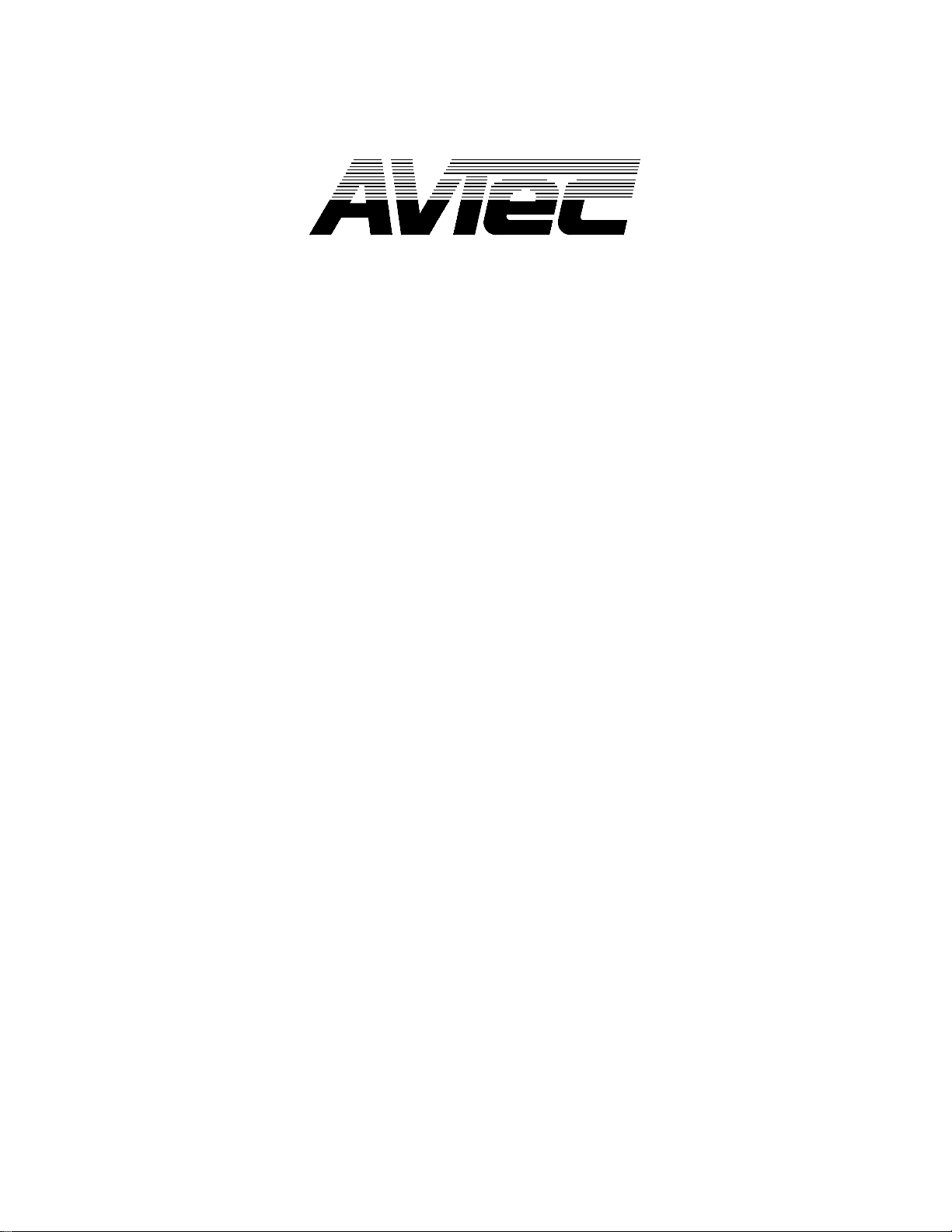

A.Baffle Filter [AF Series] [See fig. #1

]

Model AF ventilators are listed by Underwriters

Laboratories Inc. [UL] and are built in accordance

with the National Fire Protection Association

[NFPA] Standard No. 96 for use with UL Listed

fire extinguishing systems for duct hood

protection. They are available with or without an

automatic exhaust fire damper. They utilize UL

Classified removable baffle filters to extract

grease and provide a limited fire barrier. The

canopy contains an integral grease trough and

removable grease receptacle(s). Surface,

plenum and duct collar fire extinguis hing systems

may be factory supplied.

Vent Control Panels may be supplied with these

systems. See additional wiring diagrams for

options.

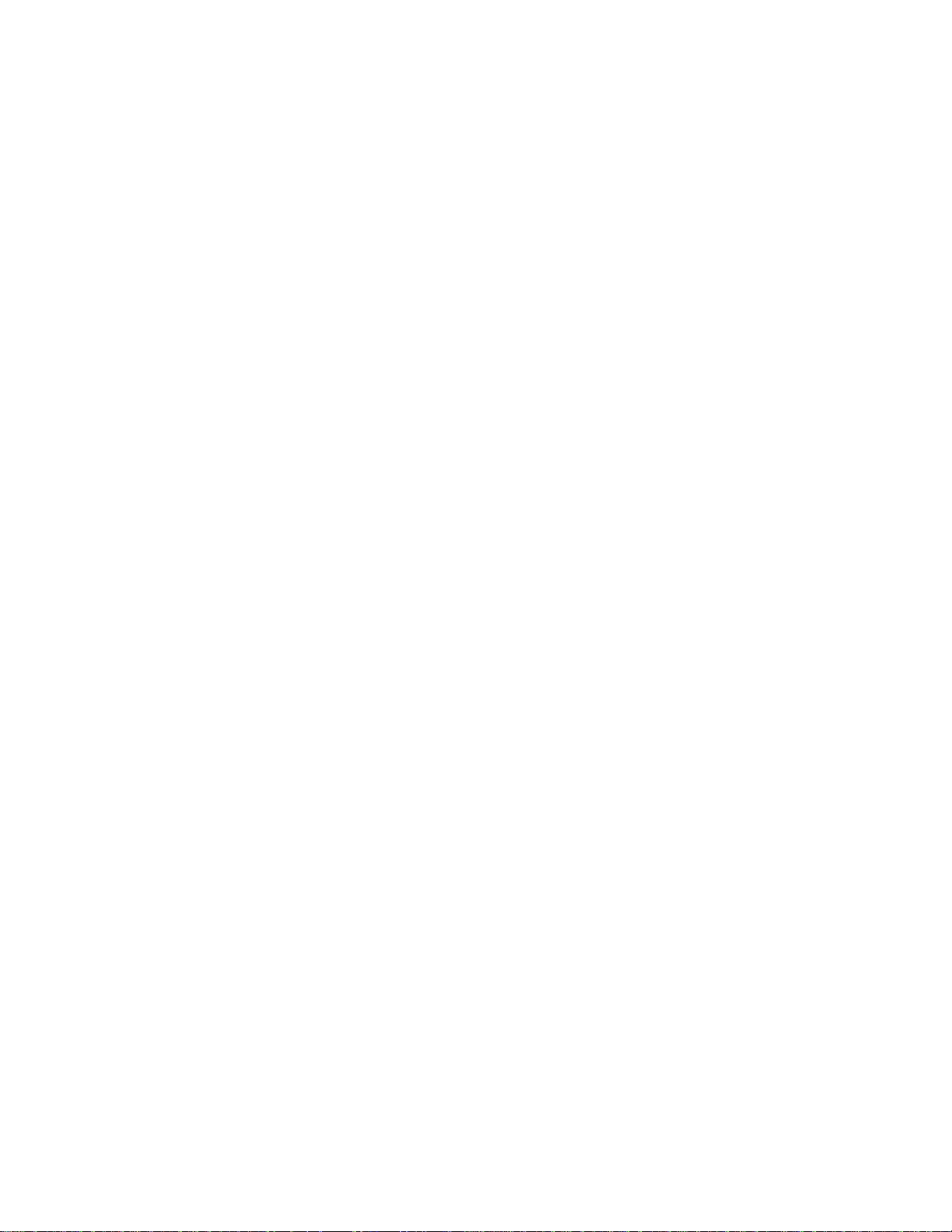

canopy contains an integral grease trough and

grease collection receptacle(s). Surface, plenum

and duct collar fire extinguishing systems are

required and may be factory supplied.

Vent control panels may be supplied with these

systems. See additional wiring diagrams for

options.

Installation shall be in accordance with NFPA 96.

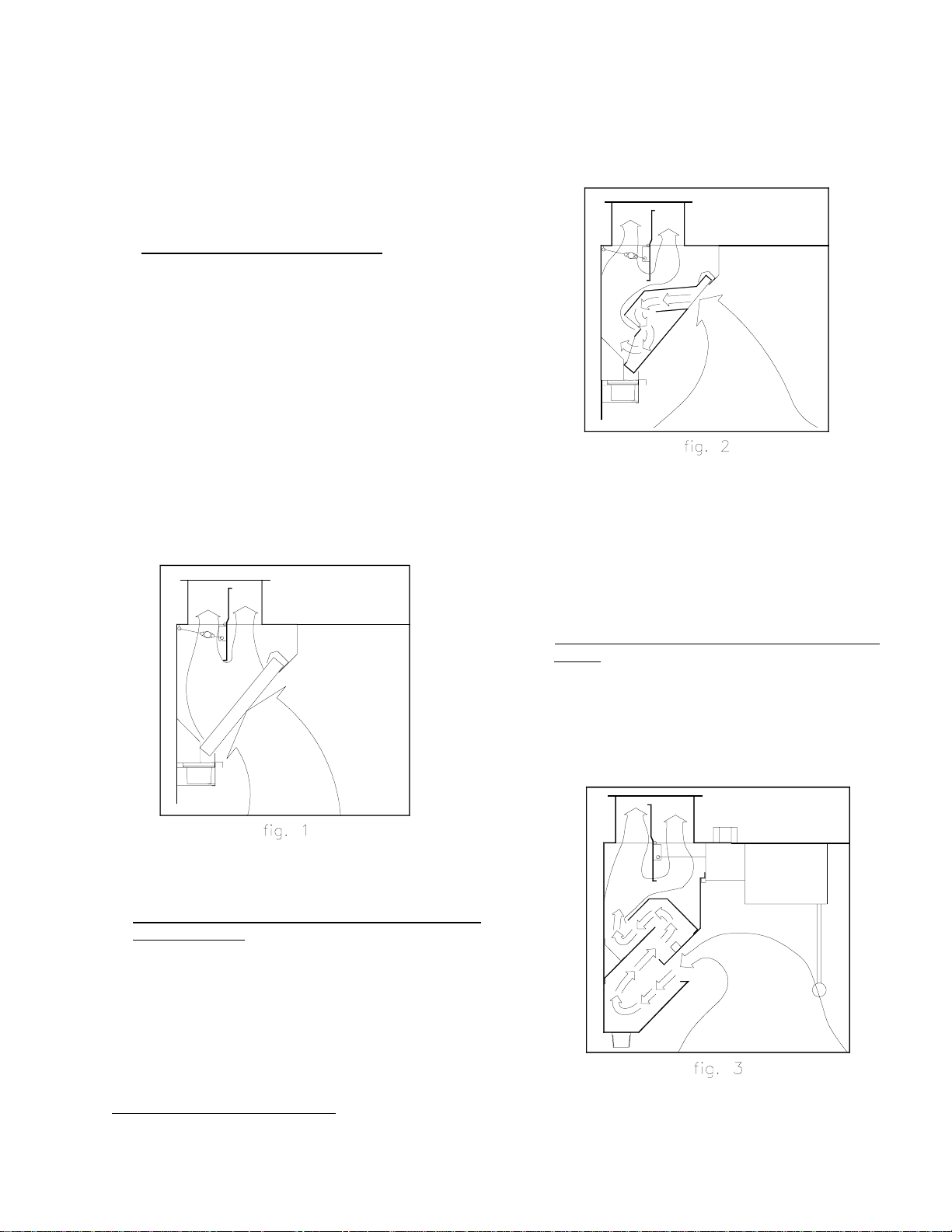

C.Auto Wash Down [AW Series] Energy Aire [see

fig. #3]

Model AW ventilators are listed by UL and built in

accordance with NFPA Standard No. 96 for use

with UL Listed fire extinguishing system s for duct

and hood protection. They are available with or

without an automatic exhaust fire damper.

Installation shall be in accordance with NFPA 96.

B.Modular Grease Extractors [AX Series] Energy

Aire [see fig. #2]

Model AX ventilators are listed by UL and built in

accordance with NFPA Standard No. 96 for use

with UL Listed fire extinguishing s ystems for duc t

and hood protection. They are available with or

without an automatic exhaust fire damper.

These models utilize high velocity removable

grease extractors. T his exclusive design extracts

up to 95%* of airborne grease c ontaminants. T he

1

*Data from independent tests not a part of UL test

procedure.

These systems utilize a high velocity grease

extractor. This exclusive design extracts up to

95%* of airborne grease contaminants. An

1

Page 5

integral water wash system cleans the inside of

the grease extraction cham ber either by manual

activation of the Wash Start button or by a

programmable tim er. T he duration of the wash is

electrically controlled. The wash system is also

activated by an electrical thermostat or a manual

switch in the event of a fire condition. A surface

fire extinguishing system is required and may be

factory supplied.

Auto Wash control panels are provided with these

systems. W iring diagrams are provided with this

manual.

Installation shall be in accordance with NFPA 96.

D.Airflow Requirements

Minimum exhaust airflow requirements and

maximum make-up airflow requirements [where

air is introduced directly inside the canopy] are

shown on the chart below. These flow rates were

established under laboratory conditions. Greater

exhaust airflows and/or reduced make-up airflows

may be required for complete capture.

Model No.

AFWO,AFBO 200 300 525

AFDO,AFWP

AFBP,AFDP

AFWE,AFDE

AFBE

AFWI,AFBI 250[175] N/R N/R

AFDI,AFWD

AFBD,AFDD

AFIO,AFIP 250 400 600

AFIE

AFII,AFID 300[150] N/R N/R

AXWO,AXBO 200 275 525

AXDO,AXWP

AXBP,AXDP

AXWE,AXDE

AXBE

AXWI,AXBI 250[175] N/R N/R

AXDI,AXWD

AXBD,AXDD

AXIO,AXIP 250 400 600

AXII 300[150] N/R N/R

AWWO,AWWP 194 270 *525

AWWE,AWDO

AWDP,AWDE

AWBO,AWBP

AWBE

AWWI,AWBI 250[190] 270[146] N/R

AWDI,AWWD

AWBD,AWDD

AWTE,AWTP 400 420 N/R

AWTO

N/R = Not Recommended

*=Manufacturer's test results not yet submitted to U.L. for capture tests.

Surface Equip. Surface Equip. Surface Equip.

CFM REQUIREMENTS

400°F Cooking 600°F Cooking 700°F Cooking

E.Fire Extinguishing Systems

There are two basic types of ventilator fire

extinguishing systems in use today:

Wet Chemical and Water Mist. Wet Chemical

Systems may be all or partially factory installed

[by the Fire System Manufacturer]; f inal hook up

and certification at job site is done by the Fire

System Manufacturer's local representative.

These systems must be periodially inspected,

and critical parts replaced. It is suggested that a

service contract be purchased from the local

representative. For further details refer to the

manufacturer's technical manual.

AVTEC manufactures and installs a water mist

fire extinguishing system, "MIST-A-FIRE", that

connects to the building fire sprinkler system

[must be "wet" type system]. Final connect of this

system must be done in the field by the sprinkler

contractor or authorized plumber. A

certification/inspection report is done by an

authorized AVTEC representative. Periodic

inspection is generally required, but replacement

of parts and periodic maintenance is virtually

eliminated. For further details, refer to the

AVTEC MIST-A-FIRE Installation and Operating

Technical Manual.

II. INSTALLING THE VENTILATOR

The ventilator is supplied with brackets to facilitate

the attachment of hanger r ods to the vent. Hanger

rods should be attached to all brackets to ensure

proper support.

A.Ascertain that the ceiling/roof str ucture is strong

enough to support the weight of the hood and

support system. T he approximate weight of the

hood is shown below:

45 lbs/linear ft. for hoods w/o AMU plenums.

55 lbs/linear ft. for hoods w/AMU plenums.

125 lbs for fire control cabinet.

B.Carefully uncrate the hood so as not to dent or

scratch the outer surface.

C.Position the hood on the floor in approximately

its final installed location.

D.Use 1/2" threaded rods to hang the hood. The

hanger rods should be approxim ately 1/2" closer

to the wall at the structural attachment location

than at the top of the hood. [see fig. #4] This

ensures that the hood is held tightly against the

wall.

Note! Do not remove

Support Brace until Ventilator

installation is complete. Upon completion of

installation, dispose of Support Brace and replace the

Acorn Nuts to their original locations.

Error! Not a valid link.

Fig 4

E.The hood should be hung so that the bottom of the

hood is 6'-6" above the finished floor unless otherwise

specified. Carefully lift the hood into position being

certain to avoid scratching the finished surfaces.

2

Page 6

Install 1/2" threaded rod from each bracket and the

structural support. Secure rods with heavy duty nuts.

[see fig. #5] Be sure that the hood is level.

Error! Not a valid link.

Fig 5

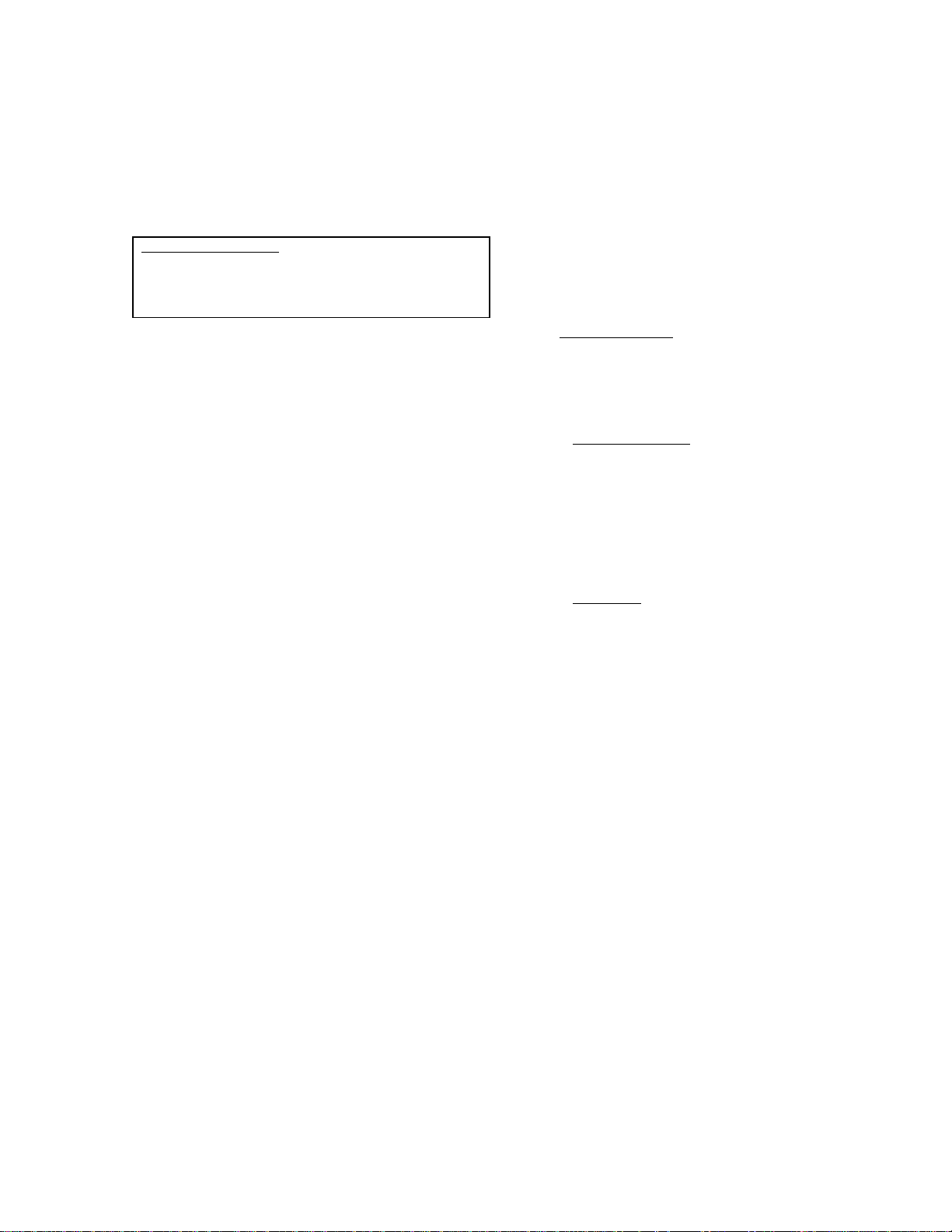

Tower Interface Detail

Place trim collar on tower. Position tower under hood.

Fully tighten trim collar retainer hardware after tower

and hood are aligned properly. See fig. A, B, and C

(next page).

F.The entire exhaust duct system must be con-

tinuously welded. This includes the connection

to the duct collar and the roof curb. All welds

must be liquid tight.

NOTE: Welds must not impede operation of

damper.

G.Connect the lights to the circuit breaker panel

through the light switch. All connections should

be in compliance with NFPA 70, National Electric

Code [NEC].

H. Install bulbs in the light fixture[s].

I.Install the grease filters [AF] or modules [AX].

J.Install the grease receptacles [AF or AX]

NOTE: A minim um of a three inch [3"] insulated

fire barrier and air space must be maintained

between the capture area skin of the ventilator

and any combustible surface, including wall and

ceiling. AVTEC ventilators normally have a 3" air

space; insulation is added when specified.

III.CONTROL PANEL [if provided]

Control panels are provided with all auto wash type

ventilators [Models AW- ] and are optional with the

baffle filter type [AF- ] and modular grease

extractor type [AX- ]. Control panels with Models

AF- and AX- do not have the auto wash plumbing

assembly compartments. Any control panel may

be provided with a integral MIST-A- FIRE

Extinguishing System alarm panel and sprinkler

assembly piping; refer to the MIST-A-FIRE

technical manual.

A.Wall Attachment

Control panel dimensions and connection detail

are shown on the enclosed shop drawing.

Panels may be surface mounted, partially

recessed or fully recessed as shown on fig. 6.

1.Surface Mounted

Drill four [4] holes in ventilator plumbing

compartment as required. Be careful not to

damage any components. Avoid drilling into

electrical compartments. Bolt to wall with

anchor bolts or other acceptable means.

Weight of control panel varies from 90 lbs. to

200 lbs.

2.Recessed

Cut hole in wall 1/2" greater than O/A

dimensions of control box [shown on shop

drawing]. Spacers or support angles may be

necessary to provide proper support. It is

recommended that panel be bolted to wall

similar to method used for surface mounted

above.

3

Page 7

4

Page 8

IV. ELECTRICAL CONNECTIONS

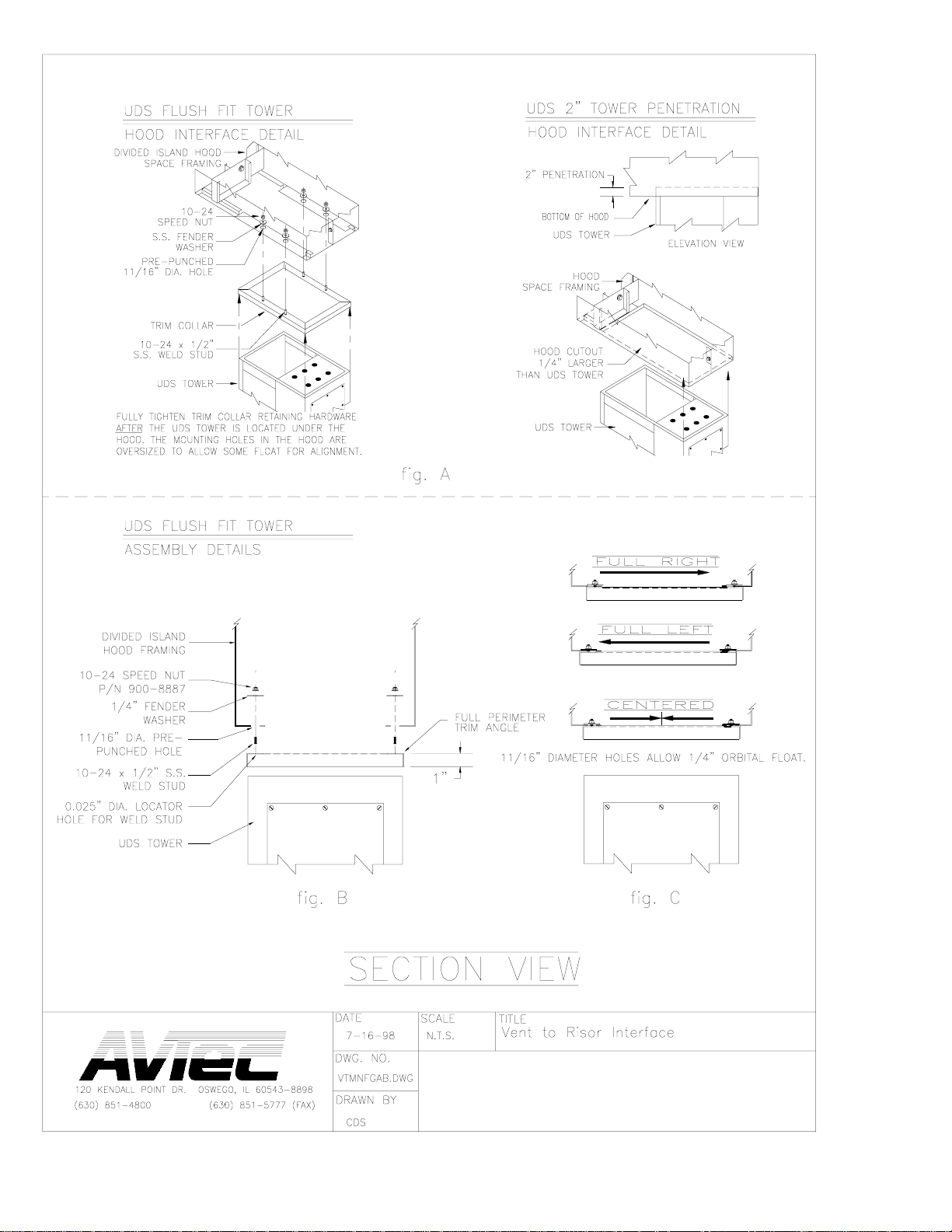

A.VCW Control Panel [Refer to fig. 7]

1.Typical field connection terminals for VCW

Control Panel are shown in fig. 7. For custom

features such as sequential wash, tim e delay,

etc. refer to AVTEC shop drawing in back of

this manual.

2.Terminals No. 1 and No. 2 are for the

120vac Power Supply. Terminal No. 1 is Hot

and Terminal No. 2 is Neutral.

3.Terminals No. 3 and No. 4 are 120vac

power for the W ater Solenoid and Detergent

Pump. These terminals are "hot" whenever

the Water W ash Solenoid and the Detergent

Pump is scheduled to be "ON" or when there

is a fire condition. Terminal No. 5 provides

power for a pump/prime switch with a

momentary closed/normally open contact.

This switch is helpful in checking the

performance of the pump as well as in

priming the pump.

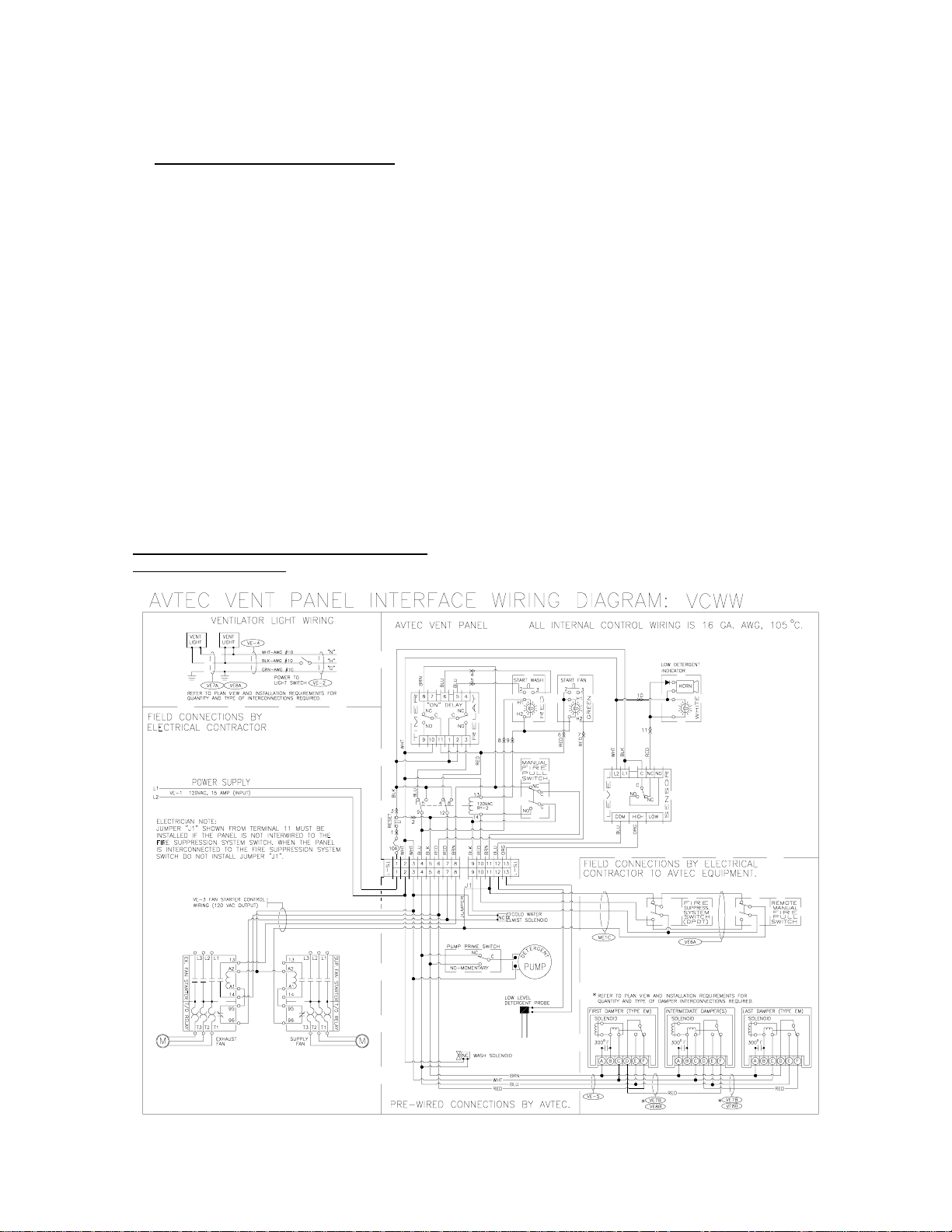

B.Programmable Automatic Wash Sequence

[PAWS] Control Panel

1.Typical Field Connections for the PAWS

Control Panel are shown on [figs. 10, 11, and

12]. Note that all options and connections may

not be included on your system.

2.Terminal Block #1 [TB-1] has three [3]

terminals and is located on the right-hand side of

the Input/Output [I/O] Board. Terminal #1

[uppermost] is for the Hot lead of the power

supply and is protected by a fuse located within

the panel. Terminal #2 [center] is for the Neutral

lead of the power supply. Terminal #3

[lowermost] is used to ground the Input/Output

Board to the Control Panel Housing.

Terminal No. 4 is Hot and Terminals No. 2 & 3

are Neutral.

3.Terminals No. 3 and No. 6 carry 120vac

whenever the fans are scheduled to be ON.

They are used to activate the fan contactor[s]. In

the event of a fire situation, power is removed

from Terminal 5 which provides power for

Terminal No. 6. Terminal No. 6 is the Hot lead

and Terminal No. 3 is Neutral.

Fig. 7

5

Page 9

4.Terminal Block #2 [TB-2] has three [3] pairs of

terminals and is located at the upper right corner

of the Input/Output Board. The first pair of

terminals are for the number one wash valve

solenoid. This will be the only wash output

active in a P-10-__ or P-15-__ Control Panel.

The second pair of terminals are f or the number

two wash valve solenoid. The third pair of

terminals are for the number three wash valve

solenoid.

5.Terminal Block #3 [TB-3] has three [3] pairs of

terminals. It will not be present on P- 10-__ or P15-__ Control Panels. The firs t pair of terminals

are for wash valve solenoid number four. The

second pair of term inals are for the number five

wash valve solenoid. The third pair of terminals

are for the number six wash valve solenoid.

6.Terminal Block #4 [TB-4] has three [3] pairs of

terminals. It will not be present on P- 10-__ or P15-__ Control Panels. The firs t pair of terminals

are for the number seven wash valve solenoid.

The second pair of term inals are for the number

eight wash valve solenoid.

7.Terminal Block #5 [TB-5] has three [3] pairs of

terminals. T he first pair provides power for the

detergent pump. The second pair provides

power for the PAW S Alarm/Trouble horn. [The

third pair provides power for the vent fan

contactors. [see figs. #8a & 8b]

Note that the maximum output is one-and-onehalf [1-1/2] amperes. If the total inrush current

for all contactors will exceed this limit, an

intermediate relay must be used.

8.Terminal Block #9 [TB-9] has three [3] pairs of

terminals and is located at the lower left corner of

the Input/Output Board. The first pair of

terminals are for connection to the optional

supervised shut-off valve. If the panel is not

equipped with this option, a jumper wire must be

installed. The second pair of terminals are for

connection to the Manual Fire Switch. T he third

pair of terminals are for connection to the

automatic fire switch contacts terminals are for

connection to the automatic fire switch contacts.

Fig 8a

Fig 8b

6

Page 10

9.Terminal Block #11 [TB-11] has three [3] pairs of

terminals. The first pair of terminals are low voltage

connections for the detergent low level probe. The

probe should be installed in the detergent container

so that it does not protrude above the top of the

detergent pump inlet strainer. [fig. #9] This is

intended to prevent cavitation of the pump and will

advise when the tank needs to be refilled. The probe

rods may be cut to facilitate a neat and effective

installation.

Fig 9

10.Terminal Bloc k #12 [TB-12] has three [3] pairs

of terminals. The first pair of terminals are for

connection to the optional battery.

7

Page 11

Terminal Block Designation

B. PAWS Cont rol Panel

TB-1 1-Line Hot

2-Line Neutral Incoming Power Supply 120vac, 15 amps, 60 Hz

3-Mech. Ground

TB-2 1-Switched Hot

2-Neutral Wash Solenoid #1, 120vac , 1.5 amps max

3-Switched Hot

4-Neutral Wash Solenoid #2, 120vac , 1.5amps max

5-Switched Hot

6-Neutral Wash Solenoid #3, 120vac , 1.5amps max

TB-3 1-Switched Hot

2-Neutral Wash Solenoid #4 120vac, 1.5amps max

3-Switched Hot

4-Neutral Wash Solenoid #5 120vac, 1.5amps max

5-Switched Hot

6-Neutral Wash Solenoid #6 120vac, 1.5amps max

TB-4 1-Switched Hot

2-Neutral Wash Solenoid #7 120vac, 1.5amps max

3-Switched Hot

4-Neutral Wash Solenoid #8 120vac, 1.5amps max

TB-5 1-Switched Hot

2-Neutral Detergent Pump, 120vac, 1.5apms max

3-Switched Hot

4-Neutral PAWS Alarm Horn, 120vac, 1.5amps max

5-Switched Hot

6-Neutral Fan Contractor, 120vac, 1.5amps max

TB-6 1-Switched Hot

2-Neutral Spare Output [PAW ] 120vac 1.5amps max

*3-Switched Hot

*4-Neutral Spare Output [MAF II] 120vac, 1.5amps max

5-Neutral Auxillary

6-Hot Power Tap 120vac, 120amps max

TB-7 *1-NC

*2-C Trouble Dry Contacts [MAF II ] 1.5amps @ 28vdc/120vac

*3-NO

*4-NC

*5-C Trouble Dry Contacts [MAF II ] 1.5amps @ 28vdc/120vac

*6-NO

TB-8 *1-NC

*2-C Fire Dry Contacts [MAF II ] 1.5amps @ 28vdc/120vac

*3-NO

*4-NC

*5-C Fire Dry Contacts [MAF II ] 1.5amps @ 28vdc/120vac

*6-NO

TB-9 1-Line Hot PAWS Supervised ]

2-Switched Hot Valve Switch |

3-Line Hot PAWS Manual | 120vac, 25 milliamps

4-Switched Hot Fire Pull Switch |

5-Line Hot PAWS Automatic |

6-Switched Hot Fire Switch ]

TB-10 *1-Line Hot MAF II Water ]

*2-Switched Hot Flow Switch |

*3-Line Hot MAF II Water | 12vdc, 25 milliamps

*4-Switched Hot Press ure S witch |

*5-Line Hot MAF II Supervised |

*6-Switched Hot Valve Switch ]

TB-11 1-Detergent

2-Probe 20vdc, 2 milliamps

*3-Positve

*4-Negative MAF II Horn, 12vdc, 1.5am ps

TB-12 1-Positve

2-Negative Battery, 12v, 5A Hours

3-Positve Auxillary

4-Negative Power Tap

*See “Mist-A-Fire Technical Manual” (fig. 10)

[For authorized sevice techinician use only]

8

Page 12

C.Dampers & Detectors [AW & optional AX

Models] [Fig. 13]

Terminal block in the damper housing is prewired to a junction box above. The wires are

colorcoded; refer to field interconnection wiring

diagram. [Refer to enc losed contr ol panel wiring

diagram]. Interconnection may be required

between damper housings.

Fig. 13

D.Ventilator Lights

A 120vac supply circuit must be supplied thru a

ventilator light switch to the ventilator. The light

switch may be supplied by AVTEC in the control

panel or on the hood. Interconnection may be

required between light fixtures.

V.PLUMBING CONNECTIONS

[AW Models] [Refer to fig. 14]

The connections listed below are shown on page

8.

A.Hot Water Wash

140° hot water is needed to properly clean the

extractor cham ber. Supply is connected to the

control panel inlet. Control panel outlet is

connected to the ventilator inlet[s].

NOTE: A vacuum break er and check valve m ust

be installed at least 6" above the ventilator inlet

to prevent back-up of detergent water into f resh

water supply.

B.Cold Water Mist [Optional]

Cold water supply is connected to the control

panel inlet. Control panel outlet is connected to

the ventilator inlet[s].

C.Drain[s]

The drain pipe is connec ted at one or both ends

of the ventilator and run to an air gap assem bly,

hub & funnel or open floor drain to act as an

anti-siphoning device. An air gap assembly is

recommended f o r the most sanitary and positive

connection. The air gap should be the same

size on the inlet end and one pipe size larger on

the outlet to avoid splash over.

D. Field Joints

Interconnection between field joints on AW

Hood attach with 2” elbows and expandable

coupler. [Refer to fig. 11]

E.Detergent Pump and Tank

Detergent pump tubing [plastic, copper or

stainless steel] must be provided from the

detergent pump outlet to an injection point

between the vacuum breaker/check valve and

the ventilator inlet. For larger installations

multiple pumps are used. Normally the

detergent pump and tank are located in the

control panel, and tubing from the detergent

pump to the detergent tank is factory connected.

In the application when the detergent pump and

tank are located in a remote area, tubing is

provided for connection from the pump to the

tank.

Pumps may be pre-wired in control panel or

Energy Distribution System, or located rem otely.

Detergent tank must always be located within 5

ft. of the pump.

F.Interconnecting

Depending on specifications, some ventilator

sections may require interconnection of hot

water, cold water or drains. See shop drawing

in back of this manual for detail.

Error! Not a valid link.

Fig. 11

9

Page 13

10

Page 14

VI. OPERATION

A. VCW Control Panel [Refer to fig. 16]

1.Adjustment

The component layout is shown below. The

only adjustment necessary is for the auto wash

timer relay. Refer to Sec. VII. G, page 18 for

function explanation. Normally three minutes is

used for ovens, s team equipm ent and light duty

ranges, and five minutes is used for fryers,

griddles, etc. A longer wash may be required

for charbroilers.

2.Sequence Of Operation

Press "START" Button to turn f an[s ] ON. When

the time com es to shut down the fan[s] [either

at the end of the day or the end of the cooking

period] press the "STOP" Button. If the system

is equipped with auto wash, the fans will shut

OFF and the auto wash and detergent pump

will come ON. At the end of the W ash Cycle,

the auto wash solenoid closes.

If the fans are OF F you can advance directly to

the Auto Wash [T im e- Delay] Period by pressing

the "STOP" Button.

In the event of a fir e condition, the f ans will shut

OFF [if they were ON] and the Auto W ash will

come ON [if the unit is so equipped]. The unit

will remain in this condition until the

thermoswitch resets itself and then the panel

will return to its mode of operation before the

fire condition occurred.

NOTE: If a fire condition occurs during the

timed auto wash/time-delay period, the timers

will continue to time down. For example, if the

fire were to occur after 5 minutes of a 30

minute time-delay period and lasted for 15

minutes before the fire switch [manual] or

thermoswitch [auto] was activated, then the

fan[s] would com e on for 10 m inutes, then shut

OFF.

3.Trouble- Shooting [VCW]

a.Fans won't activate when start button is

pushed.

1.Check the wiring to the fan contactor and

verify that it is wired according to the

VCW panel schematic.

2.Check the inter-wiring between the VCW

panel and the electro-mechanical

dampers located on the ventilator hoods.

If the wiring is correct proceed to step c.

3.Check terminals No. 1 and No. 2 with a

voltmeter. 120vac should be present at

all times. If voltage is present, proceed

to step 6.

4.No voltage present. Check wiring to

ensure terminals No. 1 and No. 2 have

been connected to a proper 120vac

power source.

5.Check that all related fuses ar e intact and

that the circuit breaker in main circuit

breaker panel is "ON".

6.Check the fire switch pull station

[optional] for proper wiring and also

check that it is properly closed and

latched.

7.Check the dampers on all interconnected

ventilator hoods for a fire condition.

8.In a normal condition damper terminals A

& C will have 120vac. In a fire condition

terminals B & C will have 120vac.

a.If terminals B & C have 120vac fans will

not operate. Voltage present at these

terminals indicates that the

thermoswitches in the duct have

closed. These thermoswitches

automatically reset after cooling to a

temperature below 300°F.

If the thermoswitch does not reset after

cooling, replace it with a new

thermoswitch.

b.Check for 120vac at terminals No. 2 &

No. 5. This voltage should be present

at all times. If voltage is present

proceed to step 8c. If voltage is not

present refer to step 8.a as listed

above.

c.While pushing the "START" Button,

terminals No. 3 and No. 7 will have 120

11

Page 15

vac as long as the "START" Button is

depressed.

d.Once the "Start" Button is released,

power[120vac] will be present at

terminals No. 2 & No. 6. If no power is

present after releasing start button

verify that the fan contactor has been

wired as shown on VCW Panel

Electrical Schematic.

e.Voltage present at terminals No. 2 &

No. 6 after pushing "START" Button,

fans won't operate. This condition

indicates that the control wiring is

operating properly, therefore the

problem must be in the f an motor itself

or the power supply wiring to fan thru

the normally open contactor or the f an

contactor.

b.Auto Wash Solenoid does not open.

4.Check all the damper s on the ventilator to

verify that none of the dampers have

been activated into the fire condition.

5.Check condition of solenoid for damage

or debris.

d.Solenoid coil activates but no water flow is

present.

1.Check water pressure gauge. If water

pressure of 25 psig or more is present

proceed to steps 2 & 3. If no water

pressure is present proc eed to steps 4 &

5.

2.Check solenoid valve for damage or

debris.

3.Check for water line blockage and verify

all spray nozzles are clear.

4.Check all water supply valves to verify

they are open.

5.Check and clean all line wye strainers.

1.Check that fuse is intact.

2.Check terminals No. 1 and No. 2 with volt

meter.

a.If 120vac proceed to step 2d.

b.If no voltage, check fus e and wiring to

panel.

c.Check panel circuit breaker and verify

that it is "ON",

d.Press "Stop" button in completely and

hold for one [1] full second.

e.Check terminals No. 3 and No. 4 with

volt meter.

i.If 120vac is present, check wiring to

water solenoid. Check voltage at

solenoid coil. If 120vac is present,

replace coil. If no voltage, refer to

step 2.b.

ii.Check the timer r elay inside the VCW

Panel to verify that power is going thru

the contacts and that the coil is

engaging. If relay doesn't function

properly, replace the relay, If relay

functions properly proceed to step 4.

iii.Check wiring against schematic to

verify that is correct. Check condition

of wires and connections to verif y that

they are not loose or damaged.

c. Auto Wash Solenoid will not close.

1.Check term inals No. 3 & No. 4 f or voltage

[120vac]. If no voltage is present

proceed to step e.

2.Check the wiring to the fire switch pull

station to see that it has been wired to

the correct contacts.

3.Check the fire switch pull station

[optional] to verify it has not been pulled.

B. PAWS Control Panel

1. Manual Operation

[Refer to fig. 17]

The Programm able Automatic W ash Sequence

[PAWS] Panel is designed to control the

operation of the ventilator exhaust and air

make-up fans and wash the grease extraction

plenum with a hot water/detergent solution.

The fan operation and wash sequence can be

12

Page 16

started and stopped manually or programmed

or automatic operation.

a. Fan Start

The exhaust and air make-up fans can be

started manually by pressing "FAN ON/WASH

OFF" on the PAWS panel. If the wash cycle is

in progress it will stop immediately and the fans

will start. The PAW S disp lay will indicate "FAN

ON/WASH OFF".

b. Fan Stop

The exhaust and air make-up fans can be

stopped manually by pressing "FAN

OFF/WASH OFF" on the PAWS panel. The

fans will stop im mediately. The PAW S display

will indicate "FAN OFF/WASH OFF".

c. Wash Start

The wash cycle can be started manually by

pressing "FAN OFF/W ASH ON'' on the PAWS

panel. If the fans are on, they will stop

immediately. The display will indicate "W ASH

1" and the total time [in hours and minutes]

remaining until the wash cycle ends.

d. Wash Stop

The wash cycle can be stopped manually by

pressing "FAN OFF/WASH OFF" on the PAWS

panel. The wash cycle will stop immediately.

The PAW S display will read "FAN OFF/W ASH

OFF".

2. Trouble Conditions

a. Low Detergent Indicator

If the detergent level drops below the bottom of

the detergent probe, the PAW S panel horn will

sound and the display will flash "DETERGENT

LOW". T he horn can be silenced by pressing

the "VFC Horn Silence" s witch, but the trouble

condition will continue to be displayed. The

detergent pump will not operate until the

detergent tank is refilled. The fan and wash

cycles will continue to operate normally,

however, the display will continue to flash

"LOW DETERGENT". When the detergent

tank is refilled, the trouble condition will

automatically clear itself after appr oximately 10

seconds.

b. Supervised Water Valve [optional]

If your PAWS panel is equipped with the

optional supervised valve, the PAWS panel

horn will sound and the display will flash

"PLENUM WASH AND FIRE CYCLES LOST"

when the valve is closed. The horn can be

silenced by pressing the "VFC Horn Silence"

switch, but the trouble condition will continue to

be displayed. The fan will operate normally,

hot water will not flow during the wash cycle

and the display will continue to flash "PLENUM

WASH AND FIRE CYCLES LOST ". When the

valve is opened, the alarm condition will

automatically clear itself. In the event that the

detergent level drops below the probe and the

optional supervised valve is closed at the sam e

time, the horn will sound and the display will

alternate between "DETERGENT LOW" and

"PLENUM WASH AND FIRE CYCLES LOST".

The horn can be silenced by pressing the "VFC

Horn Silence " switch.

3. Hood Plenum Fire Protection

a. Automatic Operation

In the event of a fire in and/or under the

ventilator, the fans will turn off and the plenum

wash will be activated when the temperature at

the duct collar exceeds 300°F. The display will

read "AUTO FIRE CYCLE FAN OFF/WASH

ON" and the PAWS panel alarm will sound.

The alarm cannot be silenced. When the

temperature at the duct collar drops below 300

°F, the PAWS panel will enter the fire delay

cycle. During the fire delay cycle the fan will

remain off and the hood plenum wash will

remain on for a programmable period of time

then automatically return to normal operation.

The fire delay cycle can be terminated by

pressing "FAN OFF/WASH OFF" on the PAWS

panel. [See Sec. 4.b.2.c for setting Fire Delay

Cycle Duration].

b. Manual Operation

The PAWS panel may be equipped with the

optional "Manual Fire Switch". Pulling the

"Manual Fire Switch" will turn on the exhaust

fan(s) and activate the plenum hood wash to

act as a fire barrier. The display will read

"MAN'L FIRE CYCLE FAN ON/WASH ON" and

the PAW S panel alarm will sound. The alarm

cannot be silenced. After the "Manual Fire

Switch" is reset, the PAW S panel will enter the

fire delay cycle. During the fire delay cycle the

exhaust fan will remain on f or a programm able

period of time then automatically return to

normal operation. The f ire delay cycle can be

terminated by pressing "FAN OFF/WASH OFF"

on the PAW S panel. [See Sec. 4.3 for setting

Fire Delay Cycle duration].

4. Programming Instructions [Refer to fig. 17A

& 17B]

a. Setting the Clock

13

Page 17

The PAW S Control Panel is equipped with an

integral clock which can be used to

automatically operate the fan and wash cycles.

To set the time press "RETURN CLOCK" once.

The display will read "SET DAY AND TIME

SELECTED" and then change to "SET DAY

AND TIME" as well as the day and time. Press

"CHANGE CLEAR" and the day and time will

begin to flash. Press "DAY+" and/or "DAY-" to

set the correct day. Press "HOUR+" and/or

"HOUR-" to set the correct hour. Note if "AM"

or "PM" is displayed correctly. Press

"MINUTE+" and/or "MINUTE-" to set the

correct minutes. When you are satisfied that

the day and time are correctly displayed, press

"SAVE ENTER". The display changes to the

Normal Display. If no key is pressed f or thirty

[30] seconds, the display will automatically

return to Normal Display.

b. Setting the PAWS

1. Single Wash Models

The wash can be programm ed to run for up to

fifteen [15] minutes. It is followed by a recovery

period of from zero [0] minutes up to two [2]

hours. This period c an be used in installations

which require that the fans automatically turn

on for a period of time af ter the wash cycle is

complete.

To review the PAWS, press "PAWS". The

display will indicate "PAWS MODE

SELECTED" for about three [3] seconds then

change to indicate the total PAWS duration

[wash and recovery periods] in hours and

minutes, and the duration of the wash period in

minutes. Press "NEXT" to dis play the duration

of the recovery period. Press "NEXT" to

display the duration of the fire delay cycle.

To change the duration of a segment, press

"NEXT" or "LAST" until the appropriate

segment is displayed, then press "CHANGE

CLEAR". When the display flashes, press

"MINUTE+" or "MINUTE-" until the duration is

displayed, then press "SAVE ENTER" to retain

that time. The total PAWS duration is

automatically updated.

To change the duration of an additional

segment, repeat the above procedure.

When all segments have been set, press

"RETURN CLOCK" to return to Normal Display.

If no key is pressed for thir ty [30] seconds, the

panel will automatically return to Normal

Display.

2. Multi-Wash Models

[P-10__ & P-15__]

[P-20-__ & P-25-___]

As many as eight [8] hood sections can be

programmed to wash in s equence. [The total

number of washes and outputs is determined

prior to shipment and set at the f actory]. Each

section can be programmed to wash for a

different period of time, up to fifteen [15]

minutes per section.

There are also up to eight [8] recovery periods

which can be programmed for different

durations from zero [0] minutes up to two [2]

hours per segment. T he recovery periods can

be used to allow the water heater to recover

between wash segments in installations with a

limited hot water supply. It can also be used in

installations which require that the fans

automatically turn on for a period of time after

the final wash period.

To review PAW S, press "PAWS". The dis play

will indicate "PAWS MODE SELECTED" for

about three [3] seconds then change to indicate

the total PAWS duration [PAW S and recovery

periods] in hours and minutes, and the duration

of the first wash period in minutes. Press

"NEXT" to display the duration of the first

recovery period. Continue to press "NEXT" to

review the remaining wash and recovery

segments.

To change the duration of a wash or recovery

segment, press "NEXT" or "LAST" until the

appropriate segment is displayed, then press

"CHANGE CLEAR". When the display flashes,

press "MINUTE+" or "MINUTE-" until the

desired duration is displayed, then press

"SAVE ENTER" to retain that time. The total

PAWS duration is automatically updated.

To change additional segments, repeat the

above procedure.

When all segments have been set, press

"RETURN CLOCK" to return to Normal Display.

If no key is pressed for thir ty [30] seconds, the

panel will automatically return to Normal

Display.

c. Setting The Fire Delay

To change the duration of the fire delay cycle

press "PAWS" to enter the PAWS Review

mode. Press "NEXT" to review all of the

PAWS segments. After the final PAWS

segment, press "NEXT" again and the display

will read "FIRE DELAY" and its duration. Press

"CHANGE CLEAR" and the display will begin to

flash. Press "MINUTE+" and/or "MINUTE-"

until the correct duration is displayed. Press

14

Page 18

"SAVE ENTER" to retain that time. Press

"RETURN CLOCK" to return to Normal Display.

d. Reviewing The Daily Event Schedule

The Daily Event Schedule is a program which

will automatically turn the fans on and off

and/or initiate the PAWS up to four [4] times

each day. Each day may be different from

another or it may be programmed to stay off for

the entire day. To review the Daily Event

Schedule, press "CHECK". The display will

show "CHECK MODE SELECTED" and then

indicate the first program m ed event of that day.

If there are no events program med for that day,

it will display the next programmed event. If

there are entries in the Daily Event Schedule,

press "NEXT" to see the next event and/or

press "LAST" to see the previous event. Press

"RETURN CLOCK" to return to Normal Display.

If no key is pressed for thirty [30] seconds the

display will automatically change to Normal

Display.

e. Changing The Daily Event Schedule

In order to make initial entires in the Daily

Event Schedule or change existing entries,

press "PROGRAM DAY". The display will

show "PROGRAM MODE SELECTED" then

ask which day's events are to be changed.

Press "DAY+" and/or "DAY-" to select the

desired day, then press "SAVE ENTER". If no

events are programm ed to occur that day, the

display will indicate "FAN ON UNPROG". If

events are programmed for the day selected,

that day's first event will be displayed. If an

event other than the one being displayed is to

be entered or changed, press "NEXT" until the

correct event is displayed. Press "CHANGE

CLEAR".

NOTE: WHEN AN EVENT IS CHANGED, ALL

EVENTS WHICH ARE SCHEDULED TO OCCUR

ON THAT DAY AFTER THE EVENT BEING

CHANGED ARE ERASED.

The time will begin to flash. Press "HOUR+"

and/or "HOUR-" to select the desired hour.

Press "MINUTE+" and/or "MINUTE-" to select

the desired minute. W hen the correct time is

displayed, press "SAVE ENTER". Press

"NEXT" to access the next event.

NOTE: A "FAN ON" EVENT MUST BE FOL LOWED

BY A "FAN OFF" EVENT.

Repeat the programming procedure indicated

above. When you have completed

programming the events for that day, press

"RETURN CLOCK" to return to Normal Display.

If no key is pressed for thir ty [30] seconds, the

display will automatically return for Normal

Display.

To program Daily Event Schedules for

additional days, particularly if they are different

from the schedule already program med, repeat

the previous steps.

f. Repeating The Daily Event Schedule

If you wish to repeat the Daily Event Schedule

from one day to another, press "REPEAT

DAY". The display will show "REPEAT MODE

SELECTED", then ask which day's Daily Event

Schedule is to be repeated. Select the

intended day by pressing "DAY+" and/or "DAY-

". When the proper day is displayed, press

"SAVE ENTER". The display will then ask on

which day that Daily Event Schedule is to be

repeated. Press "DAY+" and/or "DAY-" until

the proper day is displayed, then press "SAVE

ENTER". The display will acknowledge that the

schedule has been copied, then return to the

starting Repeat Day display. Continue as

outlined above to repeat additional Daily Event

Schedules.

NOTE: IF A DAY HAS ALREADY BEEN

PROGRAMMED FOR A DAILY EVENT SCHEDULE,

THE ORIGINAL WILL BE ERASED AND

REPLACED BY THE REPEAT SCHEDULE.

When you are finished repeating Daily Event

Schedules, press "RETURN CLOCK" to return

to Normal Display. If no key is pressed for

thirty [30] seconds, the display will return to

Normal Display, automatically.

g. Holiday Feature

To temporarily suspend a programmed Daily

Event Schedule for a particular day during the

upcoming seven [7] day period, press

"HOLIDAY". The display will show the status of

the current day. Select the day's Daily Event

Schedule which you wish to suspend [make a

Holiday] by pressing "DAY+" and/or "DAY-".

Press "CHANGE CLEAR" to make that day a

holiday. Press "DAY+" and/or "DAY-" to select

additional Holidays press "RETURN CLOCK" to

return to Normal Display. If no key is pressed

for thirty [30] seconds, the display will

automatically return to Normal Display. After

the Holiday passes, the Daily Event Schedule

will resume norm ally. The Manual Controls will

operate normally during a Holiday.

15

Page 19

h. Fan On During Recovery

The operator can choose to have the fan on

during PAWS recovery periods or remain off.

To have the fan come on dur ing re cover y, push

down the right side of switch number one of the

selector switch. To have the fan remain off

during recovery, push down the left side of

switch number one of the s elector switch. [see

fig. 19]

i. Power Loss

In the event of a power loss the clock stops but

the PAWS and the Daily Event Schedule are

retained for up to six [6] months.

j. Last Command Indicator

In the Normal Display, the last digit of the top

row indicates the last command put into the

microprocessor.

The letters used are:

L = Power Loss

C = Clock or Program Change

P = Programmed Daily Event

Schedule Command

M = Manual fan or PAWS Command

H = Holiday in progress

LAST

DAY OF AM/PM COMMAND

WEEK TIME INDICATOR INDICATOR

FRI 06:45 PM M

FAN OFF/WASH OFF

PAWS NORMAL DISPLAY

fig. 17B

PAWS

Programming Keypad

k. Diagnostic LED Indicators

Because of the use of s olid state relay circuits,

a conventional voltmeter m ay not give reliable

readings as regards to the operation of the

various inputs and outputs. To aid in

troubleshooting, diagnostic LED indicators

have been built into the left-hand side of the

Input/Output Board.

They are shown below.

D-1 Green

Illuminates when the number one wash

output is energized.

D-2 Green

Illuminates when the number two wash

output is energized.

D-3 Green

Illuminates when the number three wash

output is energized.

D-4 Green

Illuminates when the number four wash

output is energized.

D-5 Green

Illuminates when the number five wash

output is energized.

D-6 Green

Illuminates when the number six wash

output is energized.

D-7 Green

Illuminates when the number seven wash

output is energuzed.

D-8 Green

Illuminates when the number eight wash

output is energized.

D-9 Green

Illumintates when the detergent pump

output is energized.

D-10 Green

Illuminates when the PAWS Alarm Horn

output is energized.

D-11 Green

Illuminates when the ventilator fan

output is energized.

D-18 Red

Illuminates when the manual pull station

circuit is in the normal postion.

D-20 Green

Illuminates when the PAWS supervised

valve is open.

D-21 Red

Illumintes when the ventilator automatic fire

detection circuit is activated.

D-32 Red

Glows when the battery circuit is charging.

D-35 Red

Glows when the detergent level is low.

16

Page 20

17

Page 21

l. Detergent Pump and Tank

Terminals No. 23 and 24 of AVTEC terminal

strip supply 120vac power to the detergent

pump during the Wash Cycle[s]. The pump

does not run during the Fire Cycle nor when

the detergent level is below the bottom of the

probe.

To start the flow of detergent, press the Pump

Prime Switch while the PAW S panel is not in a

wash cycle [no pressure on the outlet side of

the pump]. Hold the Pump Prim e Switch until

there is no air in the suction line of the pum p or

in the pump head itself. Once there is a solid

column of detergent from the tank through the

pump, no further action [except to fill the

detergent tank] should be required.

Detergent pumps are factory preset according to the

chart in fig. no. 15. This is a generalized guide;

settings may vary depending on water temperature

and pressure, detergent type and concentration,

grease load and PAWS duration.

VII. VENTILATOR FEATURES AND ACCESSORIES

A. Baffle Filter Ventilators [AF Models]

These type of ventilators have removable filters

which extracts and collects grease in a

receptacle.

1.Filter Installation [Refer to fig. 20]

Grease extractor f ilters are installed by sliding

them into the upper slot and then lowering

them into the grease trough slot as shown in

the drawing below.

Terminals No. 21 and 22 of AVTEC terminal

strip are low voltage [20vdc, 2ma] connections

for the detergent level probe. The probe

should be installed in the detergent container

so that it is above the top of the detergent

pump inlet strainer. It

is intended to prevent air from entering the

pump and notify the operator when it is tim e to

refill or replace the detergent tank . The probe

rods may be cut to facilitate a neat and

effective installation. [See fig. no. 9]

fig. 20

The filters are removed for cleaning by

reversing the procedure.

NOTE: The filters must be installed with the

baffles running vertically and with the handles

facing toward the capture area.

2.Grease Receptacles

Grease receptacles are located at one each

of each ventilator section. These must be

cleaned out periodically. The frequency of

this cleaning is dependent upon the type of

equipment used beneath the ventilator and

the duration of its use.

It is suggested that initially the grease

receptacles be emptied daily.

B. Modular Grease Extractors [AX Models]

These type ventilators have removable

extractor modules which extracts grease

contaminants which collects in a grease

receptacle at each end of the ventilator

section.

1. Grease Extractor Module Installation

18

Page 22

[Refer to fig. 21]

Grease extractor modules are installed

by sliding the top [narrow] part of the

module into the upper retaining slot and

then lowering the bottom part of the

module into the grease trough slot.

fig. 21

NOTE: Handle faces towards capture area.

2. Grease Receptacles

Grease receptacles are located at each

end of each ventilator section. These

must be cleaned out periodically. The

frequency of this cleaning is dependent

upon the type of equipment used beneath

the ventilator and the duration of its use.

It is suggested that initially the grease

receptacles be emptied daily.

C. Auto Wash Grease Extractors [AW

Models]

These type ventilators have an automatic

wash cycle which requires only occasional

wiping down of inside grease extractor.

1. Grease Extraction Chamber

The front panel is hinged to facilitate

access to the nozzles and grease

extraction baffles.

[Refer to fig.22]

ventilator section to hold the front panel

open.

2. Spray Nozzles

Spray nozzles for hot water wash and

cold water mist are protected from

clogging by wye-strainers located in the

plumbing enclosure. However, scale and

contaminants will acc umulate in time and

these will require occasional cleaning to

assure proper wash down and spray

distribution. A paper clip or other pointed

object should be used to scrape

contaminants from the nozzles.

D. Air Adjustment Baffle [Refer to fig. 23]

Some grease extractor models may be

equipped with air adjustment baffles at the

exhaust intake slot. These baffles may be

adjusted to increase or decrease the intake

slot, according to the cfm desired or required

for varying pieces of cooking equipment

underneath. The length of the baffles varies

according to project design specifications and

conditions. The standard opening of nominal 3"

yields approximately 250 cfm/linear ft. and is

used for most c ooking appliances. Air flow may

be reduced to a low as 150 cfm/linear ft. for

ovens, steamers, etc. depending on local job

conditions. Adjusting the slot to nominal 1-3/4"

opening will yield approximately 150 cfm/linear

ft.

The Thrift Island Series ventilators uses only

one grease extraction cham ber and is designed

for 250-270 cfm/linear ft. on the cooking side

and 150 cfm/linear ft. on the oven/steamer side.

These units are provided with air adjustment

baffles to "fine-tune" the balance of air from

each side, and to change air velocity as job

conditions dictate.

fig. 22

To open, turn all front panel latches

clockwise to the open [unlatched] position

and swing the bottom of the front panel out.

"Kickstands" are provided at eac h end of the

fig. 23

19

Page 23

To adjust air intake slot, turn nuts to loosen,

move air adjustment baffles up or down until

the desired slot opening is obtained, and tighten

nuts.

E. Fire Dampers

1. Fusible Link Type

Some ducts are protected by fire dampers

which are activated by a fusible link rated at

360°F exhaust and 286°F supply When this

temperature is exceeded, the fusible link

melts allowing the fire damper to fall closed.

This linkage should be inspected and the

fusible links r eplaced annually. Fusible links

in the exhaust duct collar are readily

accessible by removing the baffle filters

[Models AF] or grease extractor modules

[Models AX]. [Refer to fig. 20 and 24] An

access plate is provided for access [supply]

duct collar for all models.

F. After the tem perature has dropped below

300°F, the damper can be res et and opened

by pushing the damper reset arm toward the

plenum until it latches.

If the fusible link has melted, it must be

replaced before the damper c an be reset. An

access plate is provided.

When the dam per is c losed m anually or if the

fusible link melts and causes the damper to

close, the fan and auto wash down are not

affected.

When the damper closes due to ac tivation of

the thermoswitch, the fan[s] will shut OFF and

the auto wash will actuate.

F. Air Make-Up [Supply] Plenums

Ventilators may be supplied with four [4]

different Air-Make-up plenums. Air is

controlled by grill registers or a special E-Z

Breeze perforated panel.

1. Grill Registers [Refer to fig. 25]

Grill registers are located for external

discharge or both internal and external

discharge. Internal register have fixed

louvers for proper "Short Cycle" of air.

External registers have four-way louvers for

adjusting direction of air flow to suit job

requirements. Grill registers have opposing

blade dampers located on the rear of the

fig. 24

Electro-Mechanical Type [Refer to fig. 24]

Some ducts are protected by fire dampers

which are activated by heat sensitive

thermoswitches located near the duct inlet.

These switches close electrically at

temperatures above 300° F and activate a

solenoid which releases the damper, and

energizes a relay which activates the plenum

auto wash/fire extinguishing spray and

deactivates the fan. In the event of a loss of

power, the damper assem bly also contains a

fusible link, set at 360°F.

The damper can be manually closed by

pulling down on the red knob at the end of the

damper reset arm and allowing it to swing

away from the plenum.

If the damper has been activated by

excessive temperature, it cannot be reset

until the temperature has dropped below 300°

register. The airflow may be adjusted by

turning the damper adjustment screwhead

located just behind the louvers as shown in

fig. 25.

fig. 25

2. E-Z Breeze [Refer to fig. 26]

The E-Z Breeze plenum is specially designed

to slow the velocity of the supply air to

minimize the energy costs incurred for

tempering the air. The f ront perforated panel

is removable for cleaning. Screws are

provided to secure the panel in place after

cleaning.

20

Page 24

3. Slot-Type Internal Air Make-Up

Hoods provided with "Short-Cycle" type air

make-up only are supplied with a slot which is

designed to direct the air along the top of the

hood and into the exhaust plenum inlet. T he

volume of air can be regulated through the

use of a combination balancing damper and

fire damper located on top of the air m ak e-up

plenum. [Refer to fig. 24]

G.Auto Wash

Plenum wash down is a feature of the Energy

Aire Ventilator which eliminates the need to

frequently clean the grease extraction area.

The wash down cycle normally occurs

immediately after the cooking period and

does not occur while the fans are ON. A

water/detergent mixture is sprayed from a

series of nozzles to remove accumulated

grease and grime which flows out through the

drain. A vacuum breaker/check valve must

be installed upstream of the detergent

injection point [and a minimum of 6" higher

than the ventilator inlet] to prevent detergent

from backflowing into the building water

supply. [Refer to fig. 14]. Hot water should

be at 120°F and pressure must be between

20 psig and 40 psig flow. The duration of the

wash down cycle is adjustable and will vary

depending of length of cooking cycle, type of

cooking equipment used, concentration of

detergent, water pressure and temperature,

among other cons iderations. See Sec. VI, b.,

"Setting the PAWS", for instructions.

**Note: See Page 28 cut sheet for detergent

information.

H.Cold Water Mist [Optional]

To aid in extracting particulates from the

exhausted air and to aid in cooling the

exhaust, a cold water m ist option is available.

This is especially useful with charbroilers.

Cold water mist is a fine spray within the

fig. 26

plenum area which runs whenever the fans

are ON. This com- plements the baffle

system on Energy Aire Systems and does not

replace the wash down feature. Water

pressure should be between 30-40 psig flow.

I. Lights

VIII. PERIODIC MAINTENANCE

A.Baffle Filters

Filters should be removed and c leaned at least

weekly, depending on hours of operation.

Filters may be cleaned by soaking in a strong

detergent solution, or running thru a

dishwasher. W hen r eplacing, m ak e sur e filter s

and handles are running vertically, and filters

are seated properly, refer to Sec. VII, A.1, pg.

15.

B.Modular Grease Extractors

Modules should be removed and cleaned at

least weekly, depending on hours of operation.

Modules may be cleaned with a brush and a

strong detergent solution, or run thru the

dishwasher. When replacing modules, make

sure they are seated properly, refer to Sec. VII,

B.1, pg. 16.

C.Grease Trough

Should be checked weekly for grease build up,

and cleaned with strong detergent, if

necessary.

21

1. Surface Mounted - Incandescent

To replace the bulb unscrew the globe.

Fixture will accept bulbs up to a maximum of

100 watts. Screw the bulb into the socket

and then proceed to screw the globe tightly

in position. Be sure that the inner silicone

gasket is in place before installing the globe

2. Recessed - Incandescent

To replace the bulb, loosen screws which

retain diffuser panel. Diffuser panel is

attached to housing with a cable to prevent it

from falling or becoming lost. Fixture will

accept bulbs up to a maximum of 150 watts.

3. Recessed - Fluorescent

To replace bulbs, unscrew diffuser panel.

The diffuser is attached to a housing with a

cable to prevent it from falling or being lost.

Two [2] bulbs are required for each fixture.

Fixture Size

[nominal] Bulb Size

24" [2] F20T12TS

36" [2] F30T12RS

48" [2] F40T12RS

Page 25

D. Grease Collection Receptacle

Should be emptied at least once a day, and

cleaned daily with a strong detergent.

E. Hood Canopy

1. Inside hood canopy should be wiped

down as needed. The area at the exhaus t

intake openings should be wiped down daily.

2. Inspect inside of extraction chamber at

least monthly, to insure proper c leaning and

that the trough is free of foreign matter.

F. Detergent System

1. Detergent tank should be checked at

least weekly; and cleaned every six months.

Always keep cover on tight to prevent

spillage and evaporation.

2. A colloid type detergent, is recommended

due to its non-caustic, non-toxic,

biodegradable characteristics. It will not

damage the rubber or synthetic parts of the

pumping system. AVTEC recommends

using EVAC Detergent. Available thru your

local Service Agents or call Factory. See

page 28 for more information.

3. All fittings should be checked for air

tightness at least monthly.

4. Foot check valve should be cleaned every

six months.

G. Fusible Link Replacement

1. Blade Type

Exhaust damper fusible links are rated at

350°F [P/N 306-0000] and Air Make-up

damper fusible links are rated at 286°F [P/N

306-0005]. Fusible links shall be replac ed at

least annually per NFPA 96, 8-2.1.2. New

"S" hooks [P/N 306-0002] should be used

whenever the fusible links are replaced.

[Refer to fig. 27]

Cable tension can be adjusted by moving the

eye-bolts in and out to ensure that the

damper is fully open.

fig. 27

2. Curtain Type

When make-up air is brought directly into

the capture area a fire dam per is required at

the duct collar. The curtain damper is

equipped with a 212°F fusible link [P/N 3060006]. Fusible links shall be replaced at

least annually per NFPA 96, 8-2.1.2. New

clover hooks [P/N 306-0007] should be

installed whenever the fusible links are

replaced. These links are replaced by

unfolding the retaining strap and removing

the clover hook and fusible link as a unit.

Be careful to hold the curtain damper in

place as a spring will try to pull it closed.

[Refer to fig. 28]

fig. 28

22

Page 26

IX. PARTS LIST

A. PAWS PANEL - ELECTRICAL

ITEM NO. AVTEC PART NO. DESCRIPTION

1 112-0301 Fuse Block Bracket

2 200-1018 Terminal Brass Screws

3 200-1019 Terminal Trac

4 200-1020 End Stop for 200-1018

5 206-0005 Fuse [SC-15]

6 206-0112 Fuse Block [Holder]

7 407-1252 Low Level Sensor [Detergent] PC Board

8 407-1300 Flush Toggle Switch

9 407-1417 Pull Station [Yellow]

10 412-0300 Sonalert Horn

11 412-0322 PAWS Assembly Model P10 & P20

12 412-0323 Output Term for Converting MAF/PAWS Assembly

13 412-0324 Output Relay for Converting MAF/PAWS Assembly

14 412-0330 PAWS Faceplate w/slot Silkscreen/Acrylic

15 490-0331 PAWS Faceplate no slot Silkscreen/Acrylic

16 490-1172 Detergent Probe Cut to Length

B. VCW PANEL - ELECTRICAL

ITEM NO. AVTEC PART NO. DESCRIPTION

1 200-1026 Terminal Block Section

2 200-1028 Terminal Section End Stop

3 405-1140 Push Button w/Black Cap, Start Fan

4 405-1141 Push Button w/Red Cap, Start Wash

5 405-1142 Normally Open Contact Block

[For part no. 405-1140 & 405-1141]

6 407-1300 Light Switch [20a]

7 407-1307 Time Delay Timer [5 hr]

8 407-1414 Agastat Timer Relay

9 407-1417 Fire Switch [Pull Station]

10 407-1420 Relay Socket [For part no. 407-1421]

11 407-1421 Omnetics Timer Relay

C. PAWS/VCW PANEL - PLUMBING

ITEM NO. AVTEC PART NO. DESCRIPTION

1 131-0108 5 gal. Detergent Tank

2 131-0112 2 gal. Detergent Tank

3 407-1101 1/2" Water Solenoid

4 407-1102 3/4" Water Solenoid

5 407-1103 1" Water Solenoid

6 407-1104 1-1/4" Water Solenoid

7 407-1105 1-1/2" Water Solenoid

8 600-0302 1/2" Ball Valve

9 600-0303 3/4" Ball Valve

10 600-0304 1" Ball Valve

11 600-0305 1-1/4" Ball Valve

12 600-0306 1-1/2" Ball Valve

13 600-0453 3/4" Supervised Shut-Off Valve [Water]

14 600-0454 1" Supervised Shut-Off Valve [Water]

15 600-0455 1-1/4" Supervised Shut-Off Valve [Water]

23

Page 27

16 600-0456 1-1/2" Supervised Shut-Off Valve [Water]

17 600-1100 1/2" Check Valve, Br.

18 600-1101 3/4" Check Valve, Br.

19 600-1102 1" Check Valve, Br.

20 600-1103 3/8" Check Valve, Br.

21 600-1104 1/4" Check Valve, Br.

22 600-1105 1-1/4" Check Valve, Br.

23 600-1107 1-1/2" Check Valve, Br.

24 601-0051 1/2" Wye [Line] Strainer, B.I.

25 601-0052 3/4" Wye [Line] Strainer, B.I.

26 601-0053 1" Wye [Line] Strainer, B.I.

27 601-0054 1-1/4" Wye [Line] Strainer, B.I.

28 601-0055 1-1/2" Wye [Line] Strainer, B.I.

29 601-0103 1/2" Shock Arrestor

30 601-0153 1/2" Press/Temp. Gauge

31 601-0212 1/2" Vacuum Breaker, Br.

32 601-0213 3/4" Vacuum Breaker, Br.

33 601-0214 1" Vacuum Breaker, Br.

34 601-0215 1-1/4" Vacuum Breaker, Br.

35 601-0216 1-1/2" Vacuum Breaker, Br.

36 602-1403 3/4" Pressure Reducing Valve

37 602-1404 1" Pressure Reducing Valve

38 602-1405 1-1/4" Pressure Reducing Valve

39 602-1406 1-1/2" Pressure Reducing Valve, Br.

40 602-2000 Single Head Diaphragm Pump [Detergent]

41 602-2009 Foot Valve

42 602-2014 Check Anti-Syphon Valve

D. EVAC DETERGENT

ITEM NO. PART NO. DESCRIPTION

1 602-3001 EVAC 1 Gallon

2 602-3005 EVAC 5 Gallon

3 602-3030 EVAC 30 Gallon

4 602-3055 EVAC 55 Gallon

E. ELECTRO - MECHANICAL DAMPER

ITEM NO. AVTEC PART NO. DESCRIPTION

1 119-0406 1-1/2" S/S Spring

2 119-0600 Damper Spring [Right]

3 119-0601 Damper Spring [Left]

4 119-0603 Solenoid Return Spring

5 129-0202 Red Knob [Damper]

6 200-1026 Terminal Section

7 200-1028 Terminal Section End Stop

8 407-1283 Fire Relay [Damper]

9 407-1282 Damper Solenoid

10 407-1419

11 411-0226 Electro-Mechanical Damper Instruction [Label]

12 205-0001 Convolution Boot

13 190-0404 AW Damper Linkage Assembly Complete

14 306-0000

15 306-0003 Stainless Steel Cable

16 306-0004 Crimp Sleeve (For S.S. Cable)

300°F, Normally Open Thermoswitch

350°F, Fusible Link

24

Page 28

17 144-0901 Small Linkage (Between 306-0000 and 144-0902)

18 144-0902 Large LInkage

F. FUSIBLE LINK DAMPER

ITEM NO. AVTEC PART NO. DESCRIPTION

1 120-7000 10" x 10" Balancing Damper

2 120-7001 16" x 10" Balancing Damper

3 120-7002 20" x 10" Balancing Damper

4 120-7003 30" x 10" Balancing Damper

5 120-7004 40" x 10" Balancing Damper

6 120-7100 10" x 10" Combo Balancing and Fire Damper

7 120-7101 16" x 10" Combo Balancing and Fire Damper

8 120-7102 20" x 10" Combo Balancing and Fire Damper

9 120-7103 30" x 10" Combo Balancing and Fire Damper

10 120-7104 40" x 10" Combo Balancing and Fire Damper

11 306-0000

12 306-0001 Eye Bolt 3/16" x 2" - 10 - 24

13 306-0002 "S" Hook

14 306-0003 Stainless Steel Cable

15 306-0004 Crimp Sleeve [for S/S Cable]

16 306-0005

17 306-0006

18 306-0007 Clover Hook [Curtain Damper]

Fusible Link 350°F

Fusible Link 286°F

Fusible Link 212°F

G. HOOD CANOPY

ITEM NO. AVTEC PART NO. DESCRIPTION

1 119-0211 Paddle Latch

2 119-0413 "Vice Action" Panel Latch

3 190-0380 16" x 16" S/S Filter

4 190-0383 20" x 25" S/S Filter

5 190-0398 20" x 20" S/S Filter

6 190-0400 20" x 20" Aluminum Filter

7 190-0401 16" x 16" Aluminum Filter

8 190-0405 Hanger Bracket [Ventilator]

9 190-0410 16" x 20" S/S Filter

10 190-0412 16" x 20" Aluminum Filter

11 190-0413 20" x 16" Aluminum Filter

12 190-0416 20" x 25" Aluminum Filter

13 190-0832 20" x 16" S/S Filter

14 412-0103 Incandescent Work Light Globe

15 412-0104 Incandescent Work Light Cage

16 412-0105 Incandescent Work Light Base

17 412-0115 3'-0" Fluorescent Work Light

18 412-0116 4'-0" Fluorescent Work Light

19 412-0117 2'-0" Fluorescent Work Light

20 412-0118 Recessed Incandescent Work Light

21 608-0410 Spray Nozzle, Br. No. 1/8 B-0.5-0.5W

[Cold Water Mist]

22 608-0412 Spray Nozzle, Br. No. 1/8 GG-2.8W ]Water

23 608-0413 Spray Nozzle, Br. No. 1/8 GGA-1.5W ]Wash

24 609-0050 2” Expandable Coupler

25

Page 29

25 609-0051 2” PVC XMPT Adapter

26 609-0052 2” Male PVC Fitting

26

Page 30

Cleaner/Degreaser

For Exhaust Ventilator Auto-wash Cleaner

Cleaner/Degreaser

Advantages

UNIQUE, POWERFUL CLEANING FORMULA

• Tough enough to break down the worst oil and

grease in your water wash system…leaving it

Super Clean!

• Reduces the need for using environmentally

harmful chemicals

• Non-caustic and non-abrasive

• Concentrated formula gives you more cleaning

power for your money!

• Compatible with bio-enzyme wastewater treatment

products like TDW Grease Treatment

• Exclusive factory detergent pump warranty

Formulas at your fingertips

In order to achieve maximum economy in the

maintenance of your water-wash system,

Cleaner/Degreaser

some suggested dilutions:

COOKING TYPE DILUTION SUGGESTED

Medium daily cooking

Heavy daily cooking

(No Charbroilers/solid

fuel use)

Heavy daily cooking