Page 1

THE “AVO”

VALVE CHARACTERISTIC METER

WORKING INSTRUCTIONS

THIRD EDITION

PUBLISHED B Y

THE AUTOMATIC COIL WINDER & ELECTRICAL EQUIPMENT CO. LTD.

WINDER HOUSE, DOUGLAS STREE T, LONDON, S.W.l

Telephone: Victoria 3404-9

Page 2

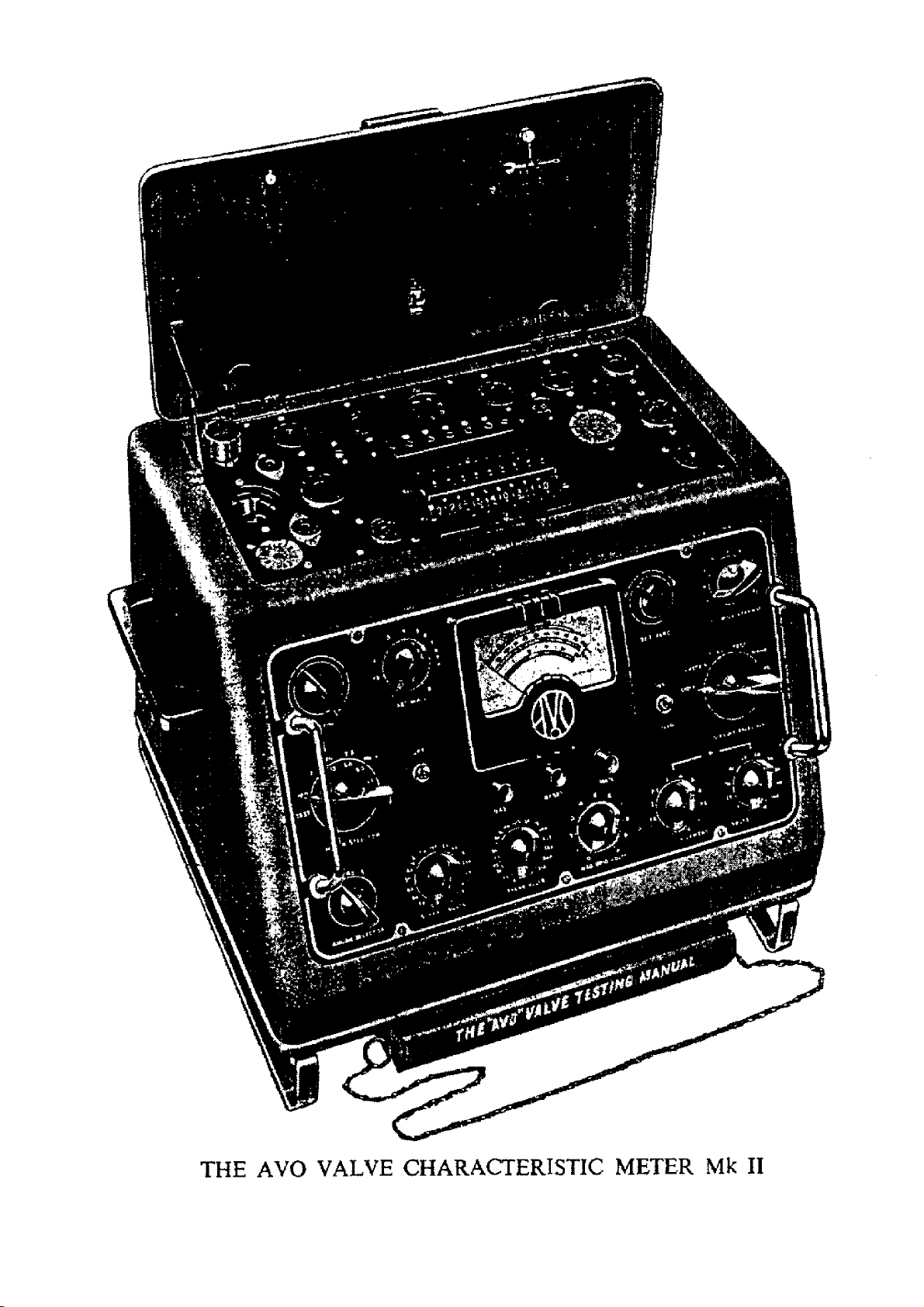

THE AVO VALVE CHARACTERISTIC METER Mk II

Page 3

F O R EWO R D

o r more than a quar ter of a century w e have be en engaged in the design and

manufacture of “AV O ” Electrical Mea surin g In struments. Throughout t hat tim e we

F

have consistently pio neer ed the design of modern multi-range instruments and have

kept abreast of and catered for the requir em ents of the e poch-makin g developments in

the fields of radio and electronics.

The success of our steadfast p olicy of main taining high st an dards of performanc e in

instruments of un excell ed accu rac y, and making such instruments avail able at rea sonable

cost, is reflected in the great respect and genu ine goodwill which “AVO ” pr od ucts enjoy

in every part of the World.

I t has been gra tifying t o note the very large number of instances where the satisfaction

obtaine d from t he perfor mance of one of our instruments has led to the aut omatic cho ice

of other instruments fro m the “AVO ” range. This process, ha ving continued ov er a long

period of years, has resulted in vir tual standardi sation on our products by numerous

Public Bodies, The Services, Railway Systems, and Pos t Office and Telegraph Undertaki ng s

throughout the worl d.

O ur design ers have thereby been encouraged to en sure that new instruments or

accessories for inclusion in the “AVO ” r ange fit in with existing “AVO ” apparatus and

serve to extend the usefulness of instruments already in use. Thus, the user who sta nda rdises

o n “AVO ” products will se ldom find h imself shor t of essential measuring equipment, for,

by means of s uitabl e accessories, his existing eq uipment ca n often be adapted to meet

unu sual demands .

It is with pleasure that we acknowledge that the unique po sition attained by “AVO ”

is due i n no small measure to the co-oper ation of so many users who stimula te our Research

and De velopment staffs from time to time wit h suggestions, criticisms, and even requests

fo r the pr od uction of ent irely new instrum ents or accessories. It is our desire to encou rage

and preserve this relationship between those who use “AVO ” I nstruments and those who

are respo nsible for th eir design a nd manufac ture, and correspondenc e is t herefore

welcomed, w hilst suggestions will receive prompt and sympathetic consideration.

3

Page 4

INDEX

For eword .. .. ..

Int rodu ction .............................................................

The Basic Method of characte ristic c h e c k in g

The Basic Method of checking diodes and re ctifie rs

Insulation Testing .. .. .. .. .: .. .. .. .. 8

T he Safety C ut-out.. ...................................................................................... 9

The Valve Panel and Selector S w itc h .......................................................................... 9

Pro cedure for setting up valve base connections .. ,, .. .. 10

Provision for new valve bases .......................................................................... 12

The prevent ion of Self oscillation of valves under test

Dia gram of Standard base pin conne ctions

Special pro cedure for valves ha ving internally connected pins .. . . . 14

The controls on the front panel, their functions and op erati ons

The Set 'v Control ...................................................................................... 16

The Electrod e Le aka ge S w itc h .......................................................................... 16

The Circuit Selector Switch .......................................................................... 16

T he Anode and Screen Voltage Switches

The Heater Voltage Switches .. .............................................................. 17

The N egative Grid Voltage Control .............................................................. 17

The Press Buttons ..

The Set Zero Control ...................................................................................... 17

The Meter Selector Switch...................................................................................... 18

The Set mA/V C o n tr o l ...................................................................................... 18

The Anode Selector S wit ch .......................................................................... 18

T he Sp ecial Ad ju stment Panel at the rea r o f the instrum ent .. .. . . .. 19

G eneral Procedure for testing a v a l v e .......................................................................... 19

Mains voltage adjustment and panel set up—cold and hot leakage tests—mutual

characteristic checks and gas tests—diode and rectifier tests made under load.

Instructions for test ing specific val ve ty pes .................................................. .. 22

Multiple diodes and rectifiers—double triodes and double pentodes—combined diode

and amplifying valves—frequency changers of heptode and hexode types—frequency

changers employing separate electrode assemblies.

The Use of the Link on th e Back P anel of the I nstr ument ..

Tuning Indica tors .. .. .. ...................................... .. . . 24

Gaseous Rectifiers .. .............................................................. .. .. 24

Cold Ca thode R ectifiers ...................................................................................... 24

Thyratrons .. .. .............................................................. .. ., 24

Neo n Indicators .. .. .. .. .. .. .. .. .. 25

General Precaution s to be obs erved when using the Valve Characterist ic Meter ., 25

N otes upon simple maintenance of instrument .. .. .. . . .. 26

Ci rcuit diagra m of Valve Ch ar acteristic M ete r

...................................... .......................... .. 3

.................................................

.................................................. 7

...................................... 7

...................................... 12

.......................... .. .. 13

.................................................. 17

.................................................

.......................... .......................... 27

..........................

...........................

..........................

5

15

17

24

The “ AVO Valve Data Manua l

This instrument will produce maximum information when used in conjunction with the Valve

Manufacturer’s Graphs and Technical Data, but to enable rapid checks to be made relative to a valve’s

general efficiency, the “ AVO” Valve Data Manual has been produced.

This instruction book refers throughout to the “AVO” Valve Data Manual, a copy of which should

always be kept with the instrument. New editions of this data manual will be published from time to time.

Watch our advertisements in the technical press for further announcements.

4

Page 5

Introduction

to

THE “AV O” VALV E CHARACTERISTIC METER

'T’he proble m of de signing a Valye Testing Instrument capable of giving a true and

A comprehensive pic ture of the state of any valve, has always been one of co nsiderable

magn itude, increasing in complexity as new valve types are brought into gen eral use.

For a quick general purpose test necessitating a minimum of time and technic al effort,

a mut ual conductan ce figure w ill give an adequ ate i dea of a valve’s usefulness, and the

original “AVO ” Valve Tester was design ed to tes t the efficiency of valves on t his basis.

Whilst a Valv e T ester must, of necessity, be accompani ed by a data book correlating

the results of the Tester wi th the cond ition of the valve in question, a purely empirical

figure, if u sed as a standard, will always give ri se to doubts in the mi nd of the operator.

Th e instrumen t should therefore , produce a figure which can be compared with so me

st andard quoted b y the valve ma nufactur er, if the opera tor is to use his in strument with

confidence. For this reas on the “A VO ” Valve Tester used the static ze ro bias mutual

conductanc e figure as a ba sis of comparison, this figu re being at that time almost universally

quoted by the valve manufacturer .

In order to reproduce this stan dard correctly, it was also nec essary to reproduce the

stated values of DC anode and screen voltage, a matter of some considerable difficulty

when it is realised that for an y stated condition of anode and/ or screen volts the correspond

ing electrod e currents can vary over very wide limits, and in the case of valves of low

initial a no de current a nd high slope, the actuation of the control w hich pro duc es the

milliamp-per-vol t reading might eas ily double the anode cu rrent flowing. With D.C.

methods of testing t he inherent internal resistanc e of the rectifying circu its use d could be

such as to give regulation errors wh ich c ould cause results to be meaningless unless com

plicated thermionic stabilising circuits and a vast array of monitoring meters were used

in all voltage supply circuits. Such complications would not only re nder the Tester of

prohibitive price and size, but would considerabl y increase the complication of ope ration

for the non-technic al user .

The problem was overcome by th e intr oduction of the AC method of ope ration (Patent

No. 480752) by which m ean s the nec essary DC test conditions were correctly simul ated

and a true mutual co nductan ce figu re produced b y the application of AC voltages of

suitable amplitude t o all electrodes. This e normously simplified the power supply problem,

rendered regulation er ror s n egligible , and obvia ted the necessity forvoltagecircuitmonitoring.

The “AVO ” Valve Tester thus fulfilled normal testing needs for a long pe riod. Du ring

recent years, however , electronic tec hniqu es have bec ome much more precise and the

natu re and mul tiplicity of valve types have contin uo usly incre ased. T he zero bias mutual

co nduct ance figure is seldo m quoted by the valve manufacturers, who, usually, publis h t he

optimum wo rking point mutual conductance and voltage figures, and in a large number

of cases give full fa milies of curv es, from which, precise operatio n, under a variety o f

working conditions, can be judge d. To cater for present day requireme nts therefore, a

valve testin g d evice should n ot only be capable o f producing a working point mutu al

conductance figure at any reasonable val ue of anode, screen or grid voltage r ecomme nded

by the manufacturers, but should also be cap able, if necessary, of reprodu cing any one

of the mutual characteristics associ ated with the valve i n qu estion. The instrument thus

has to simulate the performance of a compr ehensive valve mea surin g s et-up of laboratory

5

Page 6

Page 7

type and yet, at the sam e tim e, be sufficiently cheap and s imp le to ca ter for the needs of

the comparatively inexp erienced rad io test assistant. It is obvious that the very much

wid er application of an instrument of this class, would render the regulation difficulties,

already r eferred to, much mo re critical.

Investiga tions were, therefore, put in hand t o see whether th e AC test method would

reproduce DC conditi ons n ot only in respect of the mutual conductance figure taken at

a singl e disc rete poi nt, but at all points o n ail characteristi cs fr om zero bias to c ut off.

In other words, it was necessary t o de termine whether the general funct ion for a DC stati c

valve characteristic

(Va + ^ V gl + μ 2ν ?2)

la = f ---------------------------------

Ra.

would hol d when la was measured in terms of DC current, but wh en Va, Vg2 an d, if

necessary, Vgl, were replaced by 50 cycle AC voltage s of suitable magnit ud e. It was

eventu ally fou nd that a complete co-relation between the se two sets of conditions was h eld

when the grid voltage took the form of a sin usoidal wave form with the positive half cycle

suppressed (in other words , rectified but completely unsmoothed AC), and th e following

relationships were maintai ned :—

Va RMS — 1*1 Va in dicated DC

Vg.2 RMS = 1 ·! Vg3 ind icated DC

Vgx ( mean un smoothed) = 0*52 Vgj indicated DC

la (mean DC) = 0*5 ind icated la

From the above c onditions, therefore, the re quired relationship s were obtaine d which

fo rmed the basis of oper ation of th e Valve Characteristic Met er (Pat ent No. 606707).

Such an in strument, whilst retaining the advantages of simplicity, size and reas onable

price, res ultan t upon the elimination of complicated regulated DC supply systems and

univ ersal mon itoring, woul d have the inherent regu latio n easily ob tained from a well-

designed AC transformer. It would enable a valve to be c heck ed at any point on any one

of i ts many mutual characteristics and if necessary would allow a full family of character

istics to be drawn.

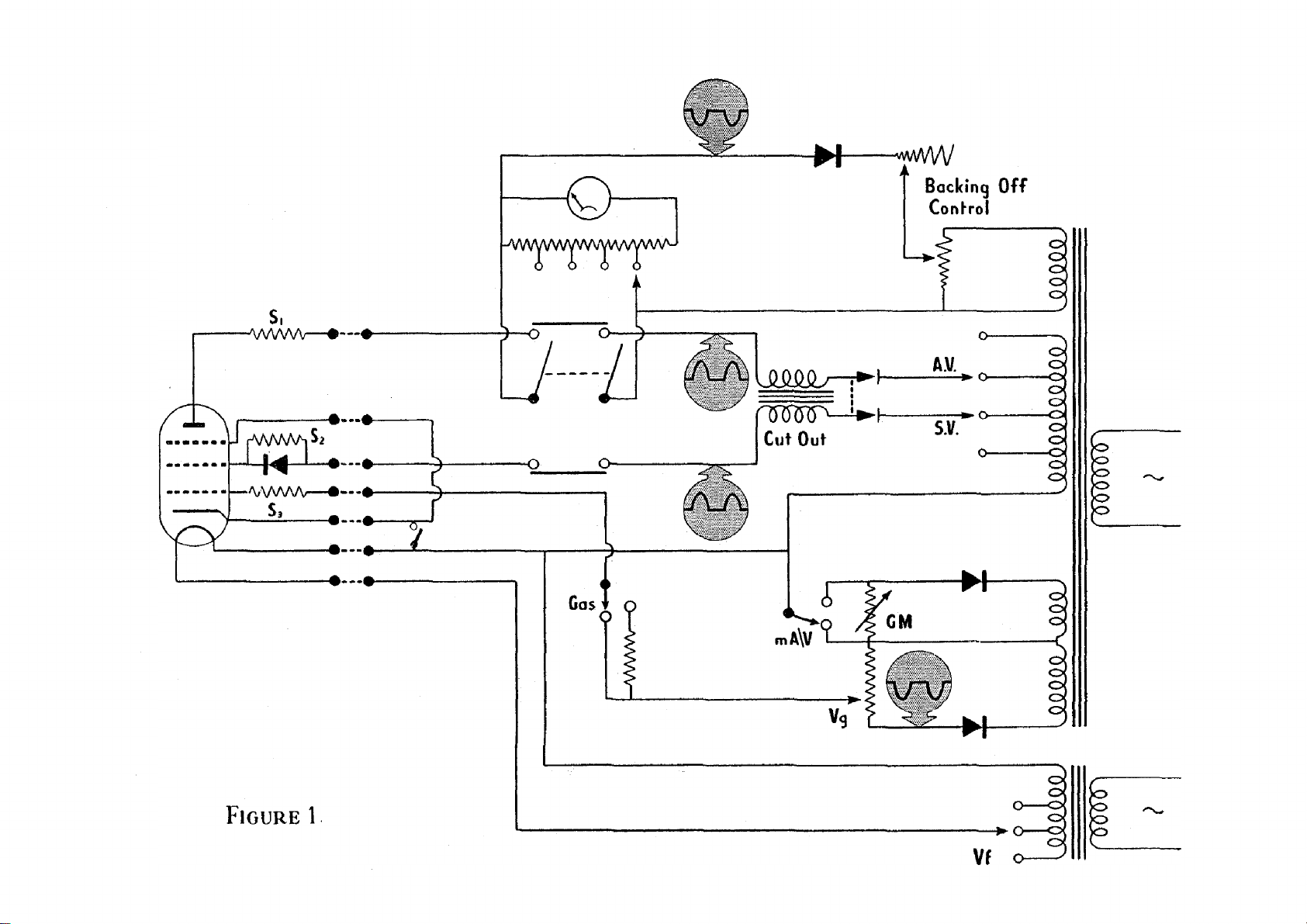

The basic method of characteristic checking

The fundamental circu it of operation of the instrument is shown in Figure 1 , the nature

of the wave forms present in the vario us parts of the circuit being indicate d thereon. As

in the origina l Valve Tester, the process of obtaining a direct readi ng mutual conductance

figure is simplified by the production of a backin g off circuit, whic h balances out the deflection

due to the standing anode current at the desired test condi tions prior t o the operation of

the mutual cond uctance button. Only the desire d figu re appears on the meter scale,

thus ena bling the meter to be set at a sufficiently sensitive range for preci se determ inati on

of mutual conductance. It will be noticed that the cu rrent flowing in this backing off

circuit is similar in wave form, but precisely opposite in direction to the an ode current,

thus eli minating any u nd esira ble rip ple that could otherwise bec ome appar ent when the

meter, after b acking off, was set to a sen sitive range.

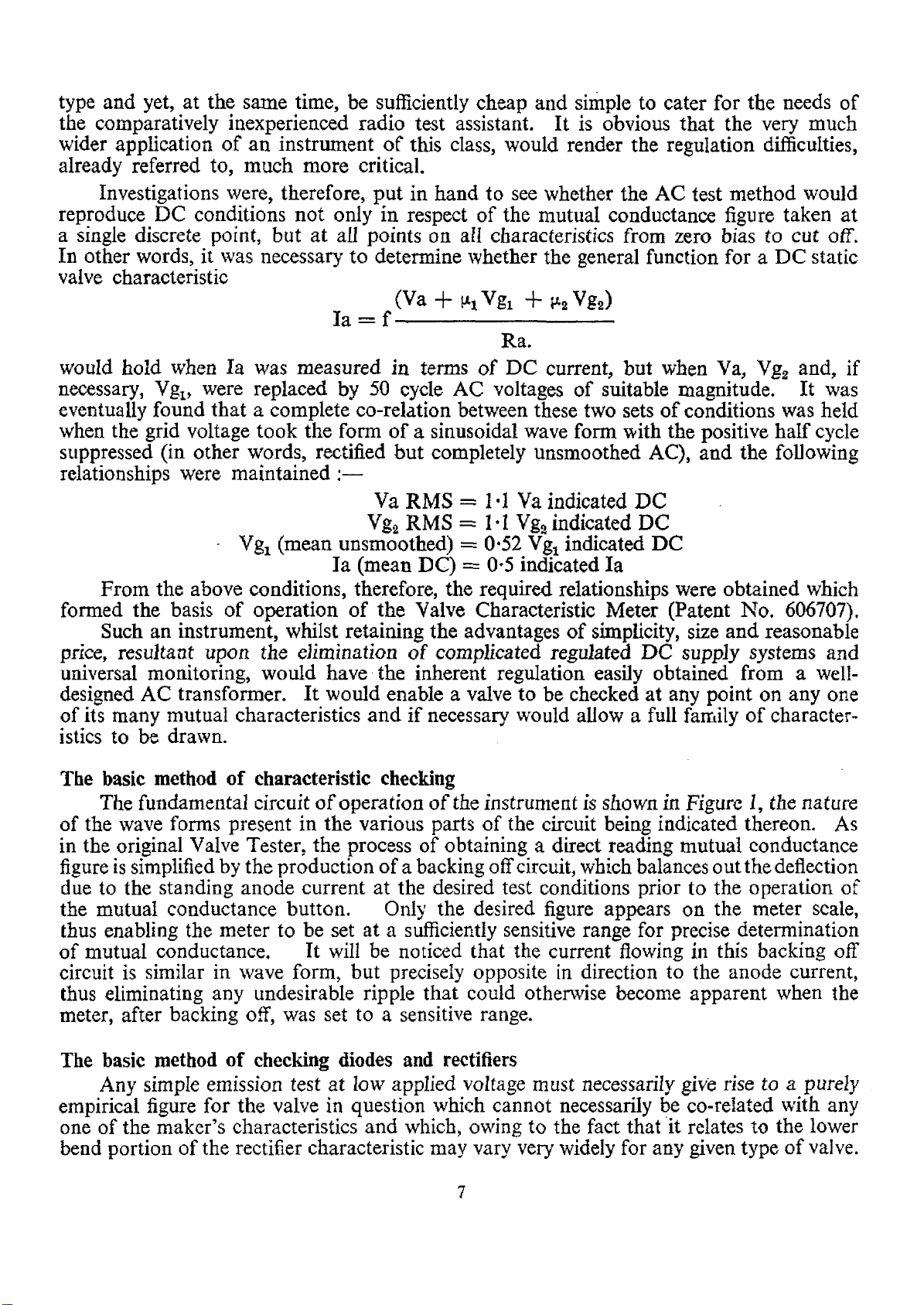

The basic method of checking diodes and rectifiers

Any simp le emission te st at lo w applied voltage must necessarily give rise to a purely

em pirical figure for the valve in question which cannot necessar ily be co-r eiated wi th any

one of the maker’s characte ristics and w hich, owing to th e f act that it relates to the lower

bend portion of the rectifier characteristic may vary very w idely for any given type of valve.

7

Page 8

The important function of a rectifying valve is that it will, under suitable reservoir load

conditions, produce sufficient curr ent to operate the apparatus which it is intended to supply.

This fundamental requirement,' therefore, is the basis of rectifier testing in the Valve

Characteristic Meter. A sufficiently high AC voltage is applied to operate the valve above

the bend in its characteristic, and to ensure that its internal voltage drop is negligible.

With a suitable reservoir condenser in circuit, the DC load is adjusted to correspond to a

number of DC current conditions, i.e. 5mA, 15mA, 30mA, 60mA and 120mA. The actual

current flowing in the load circuit is then indicated on a met er shunted to correspond with

the DC load required. The meter read ing will then indicate as a percentage, the comparative

efficiency of the valve on the basis of this required DC load. Each half of a full wave

rectifying valve is tested sepa rately thus enabling matching of two halves to be checked

and any tendency to pr oduce hum by part ial h alf waving to be indicated.

The pre-det ermined lo ad figures are chosen so that they not only give a sufficiently

wide range o f c urrents to cater fox the no rmal requirements of electronic appara tus, bu t

also correspond to the DC maximum emission figures usually quoted by manufacture rs

in th eir rectifyin g valve data. Signal diod e valves are similarly tested, but a lower AC

voltage is applied and comp arison is mad e with a single DC load figure of 1mA, this figure

being normally more tha n sufficient to cover the rectified signal current that would be

obtained. The basic operating circuit of the diode and rectifier system is shown in Figure 2.

Insula tion Testing

To cover all eventualities, three distinct forms of insulation measurement are catered

for in the Valve Characteristic Meter. Measurements are taken with DC applie d voltages,

and direct indication of the insulation value in megohms is shown on the meter scale.

As an initial test, prior t o the application of operating voltages to the valve, th e rotation of

a switch enables the insulation figure to be shown, which occurs between ea ch of the valve

electrodes taken i n order and all the others strapped together. The denominat ion of the

Fi gure 2

Page 9

elect rodes between which any bre ak down exists will thus be autom atically indicated and

fu rther , the continuity of the heater circuit is shown as a zero resistance at th e heater (H)

positio n of the switch.

Wi th d irectly heated valves it is not un common for electro de sagging to occur on the

appl ication of heater voltage, with the result that a breakdown occurs between heater and

an adjacent electrode. To show up thi s condition a test circui t is provided indi cating the

insulation resistance betw een t he heate r and cathode of a valve and all oth er e lectro des

strapped when heate r v olta ge has bee n applied.

Fin ally the very important factor of heater to cathode insulation when the heater is

hot c an be tested , the insulation again being shown directly in megohms, the usual cat hode

to heater connection b eing ope ned for this purpose an d the appl ied voltage being in such

a direction as to make the cat hode negative with respect to the heater, thus avoiding false

indic ations of i ns ulation r esi stance due to el ect rode emission.

Safety Cut -O ut

To preven t dam ag e to in ternal components of the Valve Charac teristic Meter, due to

inadvert en t o r delib erate shorting of the sup ply voltages, a safety cut-o ut is incorp orated,

op erative when da maging overlo ads of AC current are taken fro m either t he anode or screen

voltage sources. The cut-out takes th e form of a two circuit polarised elect ro-m agne tic

relay which has two windings incorporated in its ele ctro-m agn etic system, one as sociated

with the screen vol tage supply and one with the anode voltage supply . It will be appr eciated

that with the valve electrodes taking normal curre nt, half wave DC pulses only will flow

through these windings and the dir ection and magnitude of the windings are such that with

anode cu rrent only flowing, or alternatively, with a c onsiderab ly larger anode curr ent than

screen current flowing, the cut-o ut will be held in contact and the inst rument will work

normally. It is obvious, however, tha t if an internal valve sho rt occurs on any one of its

high voltage electrodes, or alternati vel y, if such a short is a pplied externally via the valve

holder sockets, or other part of the circuit, or further if any int ernal short occurs as sociated

with t he ano de or screen supply circuits, th en the current flowing i n these circuits will not

ta ke the form of un i-dir ectional pulses, but will be ordinary AC curren t.

In such circumsta nces, the effect of the first ha lf cycle of AC current in the reverse

direc tion fro m no rma l w ill be such as throw out t he c ut-ou t and thus break both anode

and screen sup ply circu its. The overload is, th erefore, removed from the supply system

and bur n out of transformers and associate parts is obviated. Note t hat this protection

does n ot apply in the ca se of a sho rt applie d to the heater voltage windings as these norm ally

pass sinusoidal AC current . Further, if for any reason w hen te sting a pentode the anode

circ uit should become disconnected (this can occur when the rolle r sw itch is wrongly

set up) then the nor mal result would be for a dam agin gly heavy rectified cur rent t o flow

In t he screen circuit; the rel ative direction and magnitude of the two windings on the

cut-out is then such that w hen the current in the screen circu it seriously exceeds the cur rent

in the anode circuit the cut-out is t hr own and damage both to va lve and circuit is obviated.

It must be stressed that this cut-out will not operate upon the passage of normal heavy

currents o f a DC nature occurring in the valve anode circuit, and it will not protect the

movement if the latter is wrongly set on a range not corresponding to the current passing.

This problem is dealt with by ensuring that the movement is always set to its maximum

current range when the probable magnitude of the current is unknown.

THE VALVE PAN EL AN D SELEC TOR S WITCH

The Valve Pane l com prises 18 valve holders of the fo llow ing types :—English—4/5

pin, 7 and 9 pin, 8 pin side contact, B7G. B8 A, B8B ( American Loc tal), B9G, Englis h Octal,

9

Page 10

B3G, 4 and 5 pin Hiv ac : A merican—4, 5,6 a nd sma ll 7 pin UX, m edium 7 pin UX, Octal,

and B9A. Provision is made by means of plug-in adaptors to cater for newly introduced

valve bases. These valve holders are all wired with th ei r corr esponding pins, ac cor din g

to the st andard pin numbering, in parallel, i.e. a ll pins n umb er one are wired togethe r, all

pins number two, and so on. T his wiring combination is associated with the well-k nown

“AVO ” Multi-Way Selector Switch whic h enables any one of the nine standa rd pin nu mbers

to be connect ed to any one of th e elect rode tes t circuits in t he Valve Characteristic M eter

pr op er, thus enabling any electrode combination to be set up for any n orma l valve hol der.

It will b e seen that the Selector Switch comprises nine thumb control r ollers, numb ered

from left to right 1— 9. This numberi ng a ppears on the moulded escutcheon immediately

behind t he rollers and corresp on ds to the valve pins in the order of their stan dard pin

numb ering. Thus valves with any number of base c onnections up t o nine c an be accom

modated. Further, to accommodate top cap and other external valve conne ctions a socket

panel is provide d wit h five sockets marked G l, S, A l, A2, D1 the markings corresponding

to the valve el ectrode conn ec tion which is made externally to the valve.

Rotat ion of the rollers by the fin ger rim provided will re veal that eac h roller can be

set in any one of ten positions, the setting in qu estion being indica ted in the window op ening

at the front of the e scu tcheon . The t en posi tio ns on the roller a re marked as under:—

1 2 3 4 5 6 7890

C Η - H + G S A A2 D1 D2 E

Th e numbers are provided for ease of memorising and noting base combin ations,

but the corresponding electrode denomin ations are shown by the l ett er ap pearing in the

escutcheon window immediat ely underneath the number, t hu s :—

corresponds to C athode.

(1)

(2)

C

H—

„ „ Heater normally Earthy, or conn ected to nega tive L.T.

in the case of a battery valve.

(3)

(4)

(5)

(6)

H4-

G

S

A

„ the other Heater connection or centre tap.

„ „ Control Grid.

„ „ Screen Grid or g2.

„ „ normal anode of single or multiple valve. I n the case of

an O scillat or mix er valve, A repre sents the Oscillator

anode.

(7)

A2

„ „ second anode of double valves, and in the case of

Os cillator mixer valves, the mixer anode.

(8)

D1

„ „ the first diode anode of ha lf and full wave signal diode

and rectifier valves , diode and rectifier/ampl ifier

co mbinati on s.

(9)

D2

„ „ the second diode an ode of signal diode and rectifier

valves, diode and rectifier/amplifier combination s.

(0)

E

„ „ any earthed screen or screening electrod e not operating

und er applied voltage conditions nor normally connected

to cathod e.

Procedure for setting up valve base connections

The standard procedu re for s etting up a valve rea dy for test is as follows. From some

suitablesourc ei.e.“AVO” Valv eData Manual,Valve Manufacturer's Data Le aflet or publis hed

man ual of Valve Data, d etermin e the pin basing connections for the valve, in order of

thei r standa rd pin numberin g. Rota te the rollers of the Sel ector Switch until the set up

number or electrode letter combination appears in the window read ing from left to righ t

in order of the standa rd pin n umbering. I n the cas e of valves having less than nin e pins,

the fre e roll ers on the righ t o f the set up combinations correspo ndin g to non -existent valve

10

Page 11

electrode s should be set at 0(E) . Insert the valve in t he appropriat e valve holder. With

on e of the leads provided connec t any top cap or side connection on the valve to its

appropriat ely marked so cket, on th e Socket Panel immediat ely above t he Selector Switch.

Note that th e loctal valve holder having only eight normal ele ctrode s has its centre lug

connected to the n inth roller (correspo nding to pin No. 9) to accommodate valves which

have a cathode connection made to this lug.

The accompanying example s show how to co-relate the pin basing data and th e

equivalent set-up combination for a number of valves in common use.

Valve Type Set up Number Base Diagram

1. Osram MH4 in directly 6 4 2 3 10000

heated triode. A G H—- H-j- C E E E E

British 5-pin base.

2. Osram U50 full wave 0 2 080903 0

rectifier dire ctly heated. E H — E D1 E D 2 E H + E

Octal base.

3. Mullar d PenA 4 indir ect

ly he ate d output pen

0452 3 1600

E G S Η— H+ C A E E

tode .

British 7 pi n base.

4. American 6K8 indirec t

ly heated freque ncy

2

E

H-

7 5

A2 S

4 6 3 1

G A H + C

0

changer.

Octal base.

Top Cap Gl.

5. Mullard TDD2A b attery 6 8 2 3 90000

double diode triode. A D1 Η— H + D2 E E E E

British 5-pin base. Top Cap Gl.

6. Mullar d EF50 indirect- 2 5 6 1 0 1 4 0 3

ly heate d HF pentode. H— S AG3ECGEH4-

B9G base.

11

Page 12

Provision for New Valve Bases

To cover t he possibility of the introduction of new valve bases not provided for on the

standard panel and also the introduction of valves which may necessitate special conditions

asso ciated with standard valve holders, a plug- in adaptor is available which enables any

non-standard valve holder to be combine d in this adaptor and plugged int o the octal or

other suitab le base on the Valve Characteristic Panel . These a daptors are available

fo r bases not included on the Valve Pan el, and a lso w ith a blank valve holder m ounting

panel i n which can be mounted the user’s own valve h older if he require s any special

arrangement for which we have not catered.

The Prevention of Self Oscillation of valves under test

It will be realised that the length of wiring and its assoc iated capacity, co nnected

to t he grid and anode pins o f any one of the valve holders, ca n con stit ute a tun ed

line corres ponding to a high r esona nt frequency often of th e orde r of 100 megacycles per

seco nd or higher. A number of modern valves have sufficiently high slope to ove rcome

the inherent losses associated with su ch a tu ned line, and are, therefore, capable of bursting

int o os cillation at a frequency determined by the constants of their associated valve hold er

wiring when being tes ted at or near t hei r max imum wo rking slope. It is quite obvious

that in or der to test a valve some wirin g must exist between the valve holder and test

circuit. F urther, since a multiple test panel is desirable to obviate the necessity of a vast

numbe r of separate plu g-in units, the total amount of wiring asso ciated wit h any one valve

ho lder must be a considerable number of inches in length. It is almost impossible

to increase the effective resona nt frequency of the lines thus produced to such a high value

that no normal valve will oscil late therewith. The only altern ative is to render the line of

comparatively high loss a nd in extreme cases to st opper the valve in question righ t on top

of its anode and/or grid con nection. Unfo rtunately, however, since a very large n umbe r

of pin combinations have to be accommodated in any one valve holder the pres ence of

such a r esistan ce in say a heater or cathode ci rcuit could give complet ely erroneous results,

and this stopp ering system could there for e only be very sparsely used.

In c ertain circ umstances where a newly introduce d valve of high efficiency is likely

to be tested in any qua ntity and shows signs of oscil lation, the sepa rate valve hol der ada ptor

can be employed with considerabl e advantage . By this means a valve holder c an be

stoppe red to the maximu m ext ent necessary for the valve in question wit hout reference

to any ot her valves that may be incorporated therei n, as when the other types of valves

are likely to be used, the adaptor can be set a side and the valv e panel used normally. It

must be stressed that this oscillation is unlikely to occur where th e valve is teste d at anode

currents lower tha n normal, or at a point on its cu rve wh ich renders its mutual conductance

low. Were a purely empirical method of te sting employed in the Valve Characteristic

Meter, there fore, the proble m wrould in all probability not arise, but since every effort

has been made to actually test the valve under its correct operating conditions of current

and voltage, then it is on this account working at its normal efficiency and can, unless

special prec auti ons a re taken, give r ise to the oscillation trouble s to which we have

referred.

Whi lst discussing the prob lem of oscillation, mention should be made of the rectifier

(which will be seen in the circuit diagram) included in the screen circui t of pentode and

tetrode valves. This rectifier ha s been incorpor ated to obviate a difficulty which can a rise

in certain c ircumst ances when testi ng valves of the beam ^etrode type with a lternating

current app lied to their electrodes. A s the applied ele ctrode voltages approach ze ro

during a portion of their operativ e cycle, the focusing of the beam of such valves is to

some extent up set and the result can be that the screen circ uit begins to show an

12

Page 13

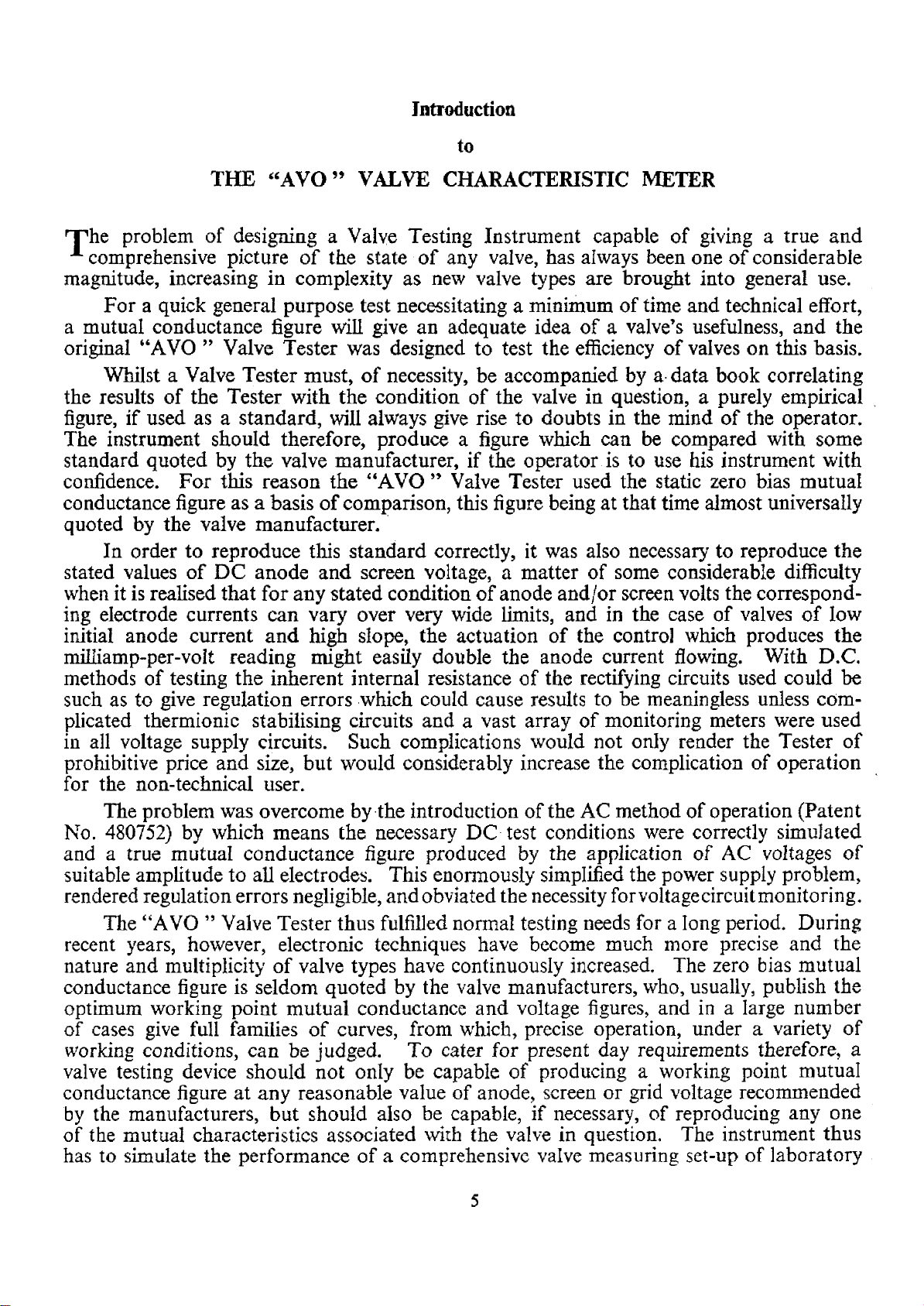

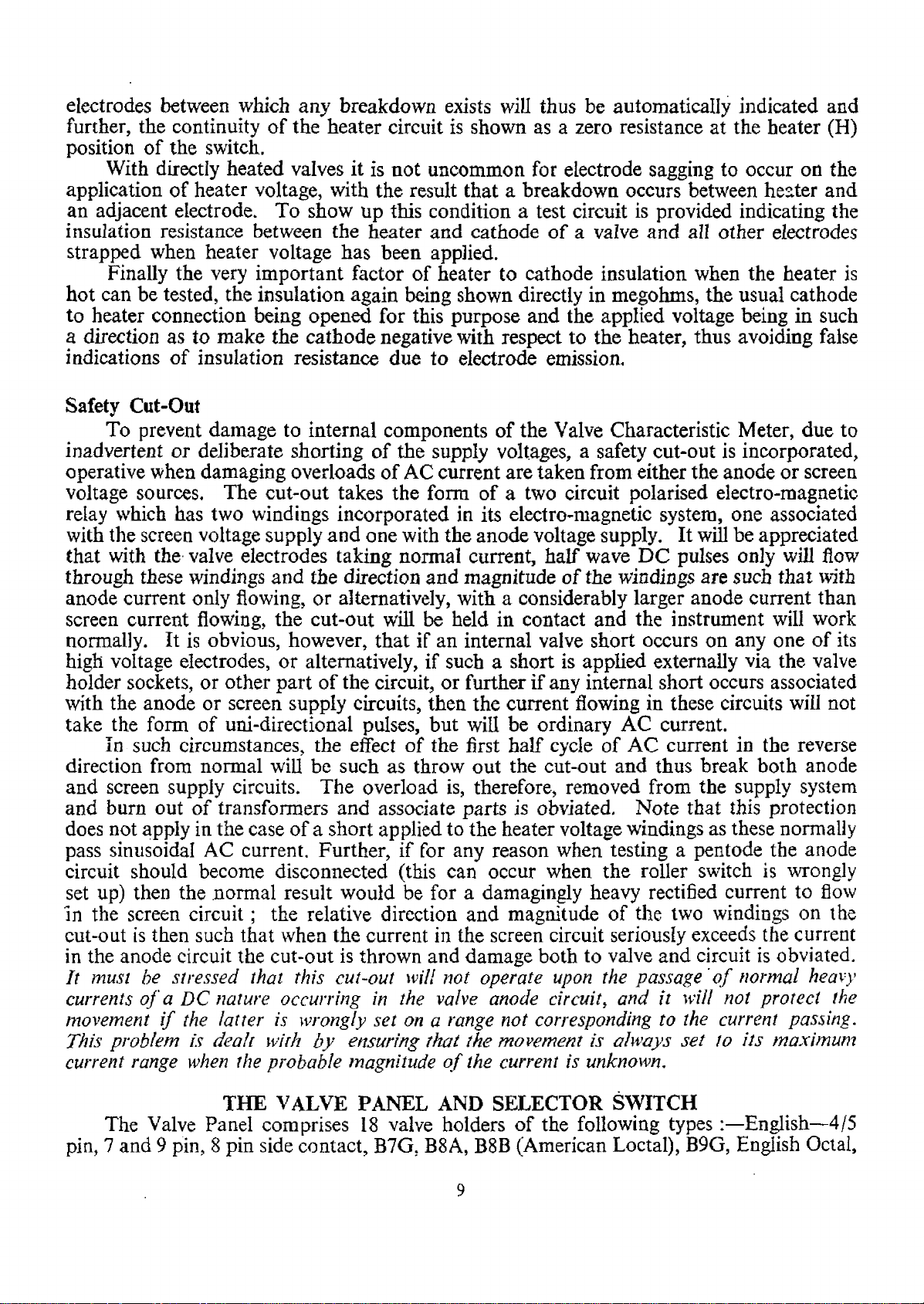

B RITI SH NINE PIN (B 9 ) BR ITIS H SEVEN PIN <B7>

INTERNATIONAL OCTAL ( A 0 8 ) AMERICAN SIX PIN (UX6> BRITISH 4 /5 PIN(BS&B4) AMERICAN FIVE PIN <UXS> BRITISH OCTAL (M 0 8>

B9C

‘ P'TYPE BASE (8 SC )

SUB MINIATURES PIN (M 8)

DIAG R A M OF STANDARD PI N CONN ECTIO NS

AMERICAN SMALL SEVEN PIN (S M 7)

HIVAC FOUR PIN < S M 4 ) HIVAC F IV E P I N (S MS)

AMERICAN FOUR PIN (UX4>

AMERICAN SEVEN P IN (U X7)

B 8A

AMERICAN LOC TAL (B8B)

B 7 0

B9A

(viewed from underside of base)

B 3 0

Page 14

emis sion in a reve rse di rection to normal screen current with the result that the a node

current rises and the curr ent t aken b y the scree n decreases rapidly and becomes neg ative.

Thi s can cause screen overheating and besides giving an unstable and erroneous impr ession

of the cond ition of the valve , can, if al lowed to c on tinue, damage the valve. To obvi ate

this conditio n, the ref ore, the rectif ier is i ncluded in such a manner that only its low fo rward

resistance is presented to th e screen passing c urre nt in t he normal direction, t hu s causing

a negligible variation to standard conditions, but t he reverse resistance of the rectifier

is o perative to limi t screen current of the op posite di re ctio n t o negligible propor tions

and thus prevent the condit ions st ated abo ve, fr om co mi ng into effect.

The problem of self oscillation has been a lmost c ompletel y eliminated in the

“ AVO ” Valve Characteristic Me ter Ma rk II by s to ppering the Roller Selec tor Switch,

and wirin g the Valve Holder Panel in conne ction loops of predetermined lengths, so

that any valve inse rted would tend to oscillate at a definite frequ ency dependent on the

loop lengths. T hese sepa rate inter -c onnection lo op s are then loaded so that oscillation

cannot occur when testing valves wi th conve nt ional characte ristics, irrespe ctive of the

Valve Hol der and pin combination used. In earlie r models, every attempt has been made

to reduc e t he poss ibility of oscill ation by the discreet use of st oppers where ver possible

and t he careful lay out of wiri ng i n cases wh ere it is known that high slope valves are

likely t o give rise to trouble of this nature.

Special procedure for Valves having Internally Connected Pins

The notes which follow relating to valves having internally connected pins do not apply

to the Valve Characteristic Meter Mark II and can be ignored. Here where * appears in the

Selector Switch number, denoting an internal connection, it is merely necessary to set the

appropriate Roller to e.g. U.81 where the Selector Switch reads **9 **8 230 set the Roller

Selector Switch to read 009 008 230 and test as a normal valve.

On certain valves of rec ent manufacture, particularly the miniature glass type employing

B7G, B8A, B9A, etc., b ases it has become the p ractice of m anufacturers to connect

internally certain of the valve electrodes to pin s which would otherwise b e blank and free

fro m any connection. Alt hough the manufacturer s specify the pins on which this is likely

to occur they rese rve the right to vary the nature of the internal connections from time to

time as prev ailing c ond itions might demand. This i n itself preven ts the inclusion of the

electrode thus inte rnally connect ed, in t he normal selector switch se t-up of the valve.

The pins on which this arrangement occurs however, cannot be connected to earth

(O) on the roller switch, for this may re sult in an elec trod e being sh orted to

earth with pos sible damage to the instru ment. Therefore, where this possibility is

kno wn to exist a symbol “ * ” a ppears in p lace of the relevant pin con nection in the

valve set up numbe r, (see “ AVO ” Valve Dat a Manual) to ensure t hat the preliminar y t est

for electr ode ins ulatio n is carefully carried out befo re normal test procedure is brought

into effect.

Where “ * ” a ppears in the set up numb er substitut e ^ whe n setting up the selector

switch. Before inserting valve, ensure that Ci rcuit Se lector switch is in position Ch eck (C)

and apply t he normal Electrode Leakage Test. This will enable th e unknown electrode

connection to be obtai ned as follows :—

(1) By ro tati ng the Electro de Leakage switch, a “ short ” will appear at th e position

“ C ” in ad dition to one or more other electrod e position s, depending on the number

of internal connections. If now t he rollers assoc iated with the valve pins designated

34

Page 15

^ “ * ” ( c m t^ie set UP) are rota te d, the short will be cleared when the roller(s)

electro de indica tion is the same as the elec trode t o which the pin(s) in qu estio n is

internally connect ed. Th e final set up which clears all short s will obviously be the

correct one for the valves and normal testing ca n thus proceed.

e.g. if set u p reads 41236*100

Set ro llers t o read 412361100

On proce eding as above, it is found that a short occurs on “ C ” and “ G ”

positions of Electr ode Leakage switch : On rota ting rol ler No. 6 to when the

set up reads 412364100, the indication of shorts will have bee n removed and normal

test procedure can be followed.

Thi s method will satisfactorily de al with all interna l ele ctrode connections

(A, S, G, etc.) with the exception of t he case where the int ernal connection is made

to a point on th e he at er (this may be eit her end or c entre tap).

(2) In such a case, a short will app ear at the “ C ” positi on of the Electrode Leak ag e

switch, but at no other electrode positio n (as “ H ” posi tion norm ally shows short

circuit denoting heater continuity). Rotating the correspondin g ro ller in this case

will merely change t he “ short ” i ndication to some other electrode designated by

the roller position.

Remove the valve from its socket and carry out a continuity test with an ordinary

ohm meter between the pin on which the unknown connection occurs and all standard

pins connected to he ater. The ohmmeter must be used on a low enough range to

distingu ish betw een “ shor t ” and the heater resistance. The point on the heater

(H —, H-f- or CT) showing zero resistance to the pin in question will now

determine the set up nu mber, and the ro ller must be rotated according ly.

E.g. If se t up is 41236*100

and on ohmmeter check, zero resistance is sho wn betw een pins 6 and 3, set up for

all tests will be 412362100.

It should be noted that if after switching to Ch eck (H ) the indicator lamps are

very dim, a nd valve heater does not li ght up, it is prob ab le that the valve filament

volt age is being shorted o ut, due to the wrong side of filame nt voltage be ing

connected to the int ernal connection pin, and this fault can be c leared by reversing

the heater conn ectio n to the pin marke d “ *. ”

(3) When no in dication of electrode leak age, other than normal he ater con tinuity ,

occurs at any position of Electrode Le akage switch, the pin(s) marked “ * ” have

not b een connecte d i nternally and normal pro cedure can be followed in testi ng the

valve, the roller position marked “ * ” b eing set a t

THE CONTROLS ON THE FRONT PANEL

THEIR FUNCTI ONS AND OPERATIONS

All the co ntr ols necessar y for car ry ing out the essentia l valve tes ting functions are

situated on the front panel of the ins trument, a nd by the ma nipu latio n of t hese controls

and the use of the valve panel already desc ribed , the following tests can be unde rtaken.

1. The direct in dication of insu lat ion resistance between electro des with the valve

cold. T his test will also indicate heater continuity .

2. The direc t ind icati on of insulatio n resistance between specific electrodes with th e

valve filament hot, including a sep arate tes t for the import ant func tion of cathode

to heater insu lation.

3. The measurement of mutual conductance directly in milliam ps/volt over a full

range of applied high tension and bias voltages.

15

Page 16

4. The compa rativ e indication of valve goodness on a coloured scale on the basis

of mutual co nductance reading.

5. The abilit y to plot com ple te sets of mutual characteristics Ta/Vgj, Ia/Va, Is/Vgj,

Is/Vs, etc., with a complete range of applied clectr ode voltages c orrespo nd ing to

D.C. opera ting cond itions.

6. The test ing of rectifiers under reservoir condenser cond itions with a full range of

D.C. loading.

7. The tes ting of signal diodes un der su itable D. C. load.

8. The testing of the separa te sections of multiple valves, the non-operative section

of the valve being maintained at reasonable workin g electrode voltages.

9. The indication of grid current and valve softness.

10. The possibility of testing valves with suitab le loads i nclud ed in the anod e or other

required electrode circuit, together with the abilit y to read the required electr ode

current on a separate meter of greater sensitivity if de sira ble, thus rendering the

instrument suitable for making tests on non -standard and specialised type s of

valves not catered f or in the normal ci rcuit arrang ements.

The separate fu nctions of the controls a vail able are as follows :—

The Set ^ Control.

This control enables minor adjus tments to be made to the input tapp ings on the mains

trans former after the coa rse mains tapping has been set.

The Electrode Leakage Switch

This switch serves t he dual purpose of putting the instrum ent in a condition f or the

initial setting of the Set ~ cont rol and also indicates the e lectro des, if any, between which

leaka ge occurs with the valve in a cold conditio n. It also serves to indicate heater contin uity.

The Circuit Selector Switch

This is a six position switc h enabling the instrument to be set up in readiness for the

type of test to be un de rtaken. All the ne cessary internal circuit co nnections are made to

satisfy the test conditions required, whilst internal test circuits, un nece ssary to the

measurements in quest ion are automatically removed from the valve.

On position Check (C) t he instrume nt is set up for the initial mains volta ge ad justment ,

also on the same posi tio n the Tester is suitably connected fo r the cold el ectr ode leakag e

test, to which we have already referr ed.

At the Check (H ) position of the switch, the valve is automaticall y t ested for electrode

leakage, with the heater hot, be tween the cathode and heater strapped, a nd all other

electrodes.

At po sition C/H. ins th e v alve is automatically tested for catho de to heater insulati on

with the valve hot.

Wit h the cir cuit selector turned t o Test all normal mu tual characteristics ar e measured

in con jun ction with t he electrode vol tage controls, the meter and an ode selector switches

and other relevan t controls. It will be noted that in the case of t he insula tion tests the

meter is automatically shu nted to the appro priate sensitivity and the insulation scale can

be r ead directly. On t he Tes t position of the Circuit Selector switch, however, the meter

rang e selec tor is brought into circuit , thus enabling the meter range to be suited to the

current measurement to be unde rtaken.

The switch setting Diode and Rec are for carry ing out reservoir load tests on diodes

and rectifiers, re spectively. In the case of the diode test the Meter Selector shou ld be set

to th e 1mA position, whilst when testing rectifiers the Meter Selector is set to a value , on the

inner scale, suit ed to the load on which it is desi red the rectifier should be tested.

16

Page 17

The Anode and Screen Voltage Switches

As their names imply these switches enable the requisite electrode voltages to be applied

to screens a nd anodes of valves fo r the purpose of carryi ng out mutua l characterist ic

measurements . They are normally ca librate d in the equivalent DC vo ltage settings and,

therefo re, no account nee d be taken of the actual value of AC voltage which appears at

the electrodes of the valve, which, as already explained, will differ fro m t he equiv alent DC

valu e marked at the switch position.

The Heater Voltage Switches

This dual switch combination is for adjustment of the heater voltage applie d to the

valve under test. To enable a very wide r ange of heater voltages to be o bt ai ned the settin gs

of the two switches are arrang ed to be additive. Thus, with the rig ht hand switch set at 0

all useful voltages betw een 1.1 a nd 16 can be applied to the valve by the left hand switch,

whilst with t he right hand switch at any figure above 0 the value indicated on the right

h and switch shou ld be added to the indicat ion of t he left hand switch. For example, with

the left hand switch set at 5 a nd the right han d switch a t 80, the heate r voltage applie d

to the valve will be 85.

The Negative Grid Voltage Control

A continuously variable co ntrol calibrated 0—10 and marked Neg Grid Vo lts

enables the initial negative bias at which a test is made, to be set at any value between

0 and — 10 volts, with the bias multiplier sw itch set at Vg x 1. With thi s switc h set at

Vg X 10 the bias range cov ered by th is control is increased to 0—I00V negative.

The Press Buttons

Immediately underneath the mov ement will be found a row of three bu ttons marked

respectively G as, Re- Set and mA/V. As their names imply these are for the indicati on

of grid current, the re-setting of t he automatic cut-out, and the direct reading of mutual

conducta nc e in mA/V after the initial valve test conditions have been set.

Th e mA/V button applies a small sup plemen tary change of grid bias in a positive

dir ect ion to the grid of the valve after the latt er has been correctly set up in ac cordance

with th e dat a given in the “ AVO ” Valve Data Manual or alternativel y, with the maker’s

characteristic details. The i nitial anode current having been obtained and the meter

indication bac ked off by the ba ck ing of f control, th e pressing of this button will cause a rise

in the ano de cur rent which will i ndicate on the appropriate meter scale the mutual con duct

ance of the valve directly in mA/V. This test also serves as a comparison test of valve

goodness in con junct ion with the coloured meter scale and Set mA/V. c ontrol.

A change in anode current consequent up on t he pressing of the Gas button

will indicate the p resence of grid current in the valve, the relative magnitude of which can

be assessed from a knowledge of the mutual c onductance of the valve and the c hang e in

current obtained.

When the presence of a damaging short causes the cut-out to operate, th e lamps

behin d the meter will be ex tinguishe d and voltages will be removed from anode and screen

circuits of the valve. After havi ng inv estigated and removed tin cause of the short th e

instrument may be put i nto operation again by the pressing of the Re-Set button, t he

correct condition being shown by the illum ination once ag ain appearing beh ind the meter

scale plate.

The Set Zero Cont rol enables an initia l anode curr ent reading for the valve to be backed

off prior to th e taking of mutual conductance readings, the direction of the co ntrol being

1 7

Page 18

such that an anti-clockwise movement of the knob will cause the meter nee dle to approach

zero.

The Meter Selector Sw itch is a combination switc h serving to shunt th e meter

sui tably to the cu rrent measurement to be undertaken and also to inser t the right va lue

of load when mak ing tests on rectifiers and diodes. It has two sets of calibrations, the

outer ring of figures marked 100, 25, 10, 2*5 and mA/V is for use when the curr ent selector

is at position Test, and serves to indicate the full scale deflection current for the move

ment in milliamps when takin g anode current figures, and similarly represents full scale

reading in mA/V wh en taking mutual conductance figures. The la st position ma rked

mA/V in dicates that the inst rument is correct ly switched fo r the use of the mA/V Control in

co njunction with the colour ed comparison scale on the meter.

The inner ring of figures marke d 120, 60, 30, 15, 5, 1 represe nt the load curre nt

ass ociated with the coloured scale when taki ng rectifier tests wi th the circui t selector on

Rec or Diode. Thus if the valve is rated at say 60 mA per ano de, the Meter

Sel ector Switch should be turned to “ 60 ” on t he inner ring of figures and the c omparative

goodness of the valve wit h reference to this basic figure will be shown on the coloured scale.

Note that when the Circuit Selector switch is set to Diode for testing s ignal diodes,

the Me ter Selecto r should always be turned to posi tion “ 1 ” and the coloure d scale

then o perates w ith reference to a load current at 1mA, a suita ble figure for sig nal diodes.

The 1mA sett ing of the Meter Selector do es not apply to rectifier load tests with t he Circuit

Sele ctor switch at Rec.

The S et mA/V Control, mark ed 1—15mA/V is for the rapid checking of the oper ative

good ness of a valve on the basis of mutual co nductance, after the valve has been set up

for nor mal tes t, and the anod e current backed off to zero. After t he Met er Selector is

turned to position mA/V, the mA/V Control should be turne d to the rated mutu al

conductance figure fo r the valve i n question. The pressing of the mA/V button will

iiow caus e the meter needle to rise and its position on the coloured scale will denot e o per ative

valve goodness.

The Anode Selector Switch marked Al5 A2, S, enable s sepa ra te tests to be m ad e on

multiple valves, and also makes possible the taking of Scr een (or ga) characteristic s. With

thi s s witch turned to “A ± ”, the figures of anode current and mutual condu ctance shown

on the me ter are relevant to the anode designat ed on the set up roll er by As s uch

the switch is in position f or measurem ents on all single e lectrode system valves (tr iodes,

pentodes, etc.). This position also serves for the first half of doub le valves (double triode s

etc.) and for the triode or pentode section of multiple diode valves (double-di od e-triode,

etc.). A sim ilar sett ing of this swi tch serves for the t riode or oscillator section of frequen cy

changers.

With the Anode Selecto r switch a t position “ Aa,” the indicator meter will sh ow ano de

current and mutual conduct ance associated wi th t he second an ode of double valves, the

mixer an ode of fr equency change rs and all anode systems a ssoc iated with the set u p

figure I In this condit ion the first ano de is not left fl oatin g, but h as the normal anode

volts s upplie d to it via a lim iting resistanc e.

With the Anode Selector s et to “ S ”, the current meter is inserted in the screen (ga)

circuit of valves and screen curre nt will thus be indicated. When making this test, anode

voltage is aut omati cally appli ed to all anodes in the valve. Note that in the case of a double

pentode valve, the current indicat ed will be the combined current of both screens.

When the Circuit Selecto r is swi tche d to position Rec and Diode, then pos itions

“ A t” and “ A ,” of the anode selector switch c orrespond to dio de anode 1,

and diode anode 2 respectively, i.e. : to the electrod es associated w ith the selector switch

number ® and *

1 8

Page 19

The Specia l A djustment Panel at the rear of In strument

This will b e uncovered by th e removable plate at the ba ck of th e instr ument and th e

following will be e xpose d to view,

(a) The coarse setting for the app lied 50/60 ~ mains voltage marked 100/115, 200/215,

220/230, 240/250, the setti ng being made by mea ns of th e plug on this small sub

board, to th e tappi ng mos t nearly corresponding t o the nominal mains voltage,

(b) The fuse holder cap which may be unscre wed re veal ing a small cartridge fuse whic h

may be thus easily replaced if blown. Th e co rrec t value for this fuse is 2.5 amp .

(c) The link shorting out two sock ets for the insertio n of resistance, meter or oth er load

in the anode circu it.

GENERAL PROCEDURE FOR T ESTING A VALVE

1. After hav ing set the coarse mains voltage plug at the rear of the instrument

to su it the supply voltage, connect mai ns lead to supply noting that red and black leads

are live and neutra l. The green or yellow lead is the Earth connect ion. Switch on and note

that illumi nation appears behind the trans parent meter scale. The va lve to be te sted

should not be inserte d at this stage.

2. Turn the Cir cuit Selector switch to position Che ck (C) and Electrode Leakage

switch to position “ ^ .” The instrument needle sh ould now rise and assume a position

near the black region of the ins ulat io n scale denoting zero ohms. Rotate t he Set -v co ntrol

until the meter needle assumes its nearest point to the red line in the middl e of th is black

scale markin g. With a correct se ttings of the init ial mains volt age adjustment rotation

of the Set -v co ntrol s hould ena ble the needle to b e moved on either side of the red arrow.

If this is no t the c ase and rotation of the Set ^ co ntrol does not enable the needle to reach

its sett ing mark from e ither direction , t hen the initi al mains set ting should be moved to

the next appropriate tapping. This tap ping sho ul d be hig her than the one chosen if the

needle always appears to t he righ t of the red mark and lower if to the left.

3. Having set up the accuracy of the ins trument to conform to th e applied main s

voltage, refer to t he “AVO” Valve Dat a Manu al, or alternativel y to th e maker’s characteristi c

d ata for the valve a nd se t up the appropriate valve holde r connecti ons on the Valve P anel

sele ctor switch as already e xplained.

Set t he heat er voltag e switch to its correct value for the valve and insert it in the

appropriate valve holder, with out moving the Circuit Selector swi tch from its position

Check (C). Rotate t he Electrode Leakage switch throug h its various el ectrode posit ions

star ting with the ext reme co unter clockwise position marked “ H ”, At posit ion “ H ”

the meter should show a short, thus indicating heater continuit y. Thereafter any r eading

obtained on the i nsu lation scale of the meter will show an elect rode insulation bre akdown

correspon ding to the electrode indicated by the Electrod e leakage switch setting. (Th us

a r eading on th e meter of 1 meg ohm when the Electro de Leakage switch is set to position

“ Gi ” and position “ S ” will indic ate that a cold insulation breakdown of 1 megohm is

occurring between the grid and screen elec trodes of the valve.) It will be noted that

whe rever el ectrode l eakage occurs, indication of this will be sh own at two positions of the

Electrode Leakage s witch, because, obviously, le akage must oc cur betwee n two points.

In the case of br eakdo wn to heater fro m any other electrode, such l eakage indicat ion will

only occur at on e switch setting subse quent to the initial se lector setting, which should

automatically s how zero ohms to deno te heater c ontinuity.

4. Having ensured that no col d leakage path of an y magnit ude is present in the valve

to be tested tu rn t he Cir cuit Selector switch to Ch eck (H ). Allow a few mom en ts for the valve

1 9

Page 20

heater to warm up and note if any meter deflection oc curs. Such a deflection would denote

in megohms th e amoun t of in sul ation breakdown that occurs between cathode and hea ter

strapped and all other electrodes of the valve when h eater volt age is applied. Note tha t if,

for any reason, the Circuit Sele ctor switch is turned ba ck to Check (C) there will,

in all probability, be an indication of an appar ent cold ele ctrode in sulation breakdown

between a number of the valve elec trodes. This need n ot b e the caus e and the read ing

will be found generally to disa ppear after a few moments. Th e rea so n f or such an indication

is o bvious when it is realised that the va lve cathode h as been heated durin g the Check (H )

test. When returning to the Check (C) position, therefore, the cathode is hot and still

emitting. What app ea rs to be a temporary electrode breakdo wn, therefore, is in fact t he

indication of emiss ion which disappears as the he at er or cathode cools.

5. Turn Circuit Selec tor switch to C/H. ins when any cath ode to heater insulation

br eakdown which occurs w ith the heater hot will be shown on the insulation resistance

scale of the meter. No set rule for the rejection of a valve on th is score can b'e laid dow n,

but it will be realised tha t in many circuits w here an appr eciable potential exists between

heater and c athode such as, for instance, in c athode fol lower circuits or DC valve ampli fiers,

the presence of a heater to cathode breakdown of the order of megohms can often give

rise to quite serious trouble. Heater to cathode ins ulation breakdown, eit her permanent

or variable, can also give rise to noise in v alve ampl ifier circuits. If, on t he other hand, the

value of cathode to heater circ uit resis tance is onl y of the order of a few hundr ed ohms,

as for insta nce where ca thode biasing is used with high slope valves, then a cathode to

heater insu lat ion breakdown of th e order o f fracti ons of a megohm need not give rise to

any serious tro uble.

6. The next test normal ly to be made upon the valve is the measurement of some

or all of its mutual characteristics. This ma y ta ke the form of the complete plott ing of

on e or all of its cha racteristics , or the measurement of its mutual conductanc e, or the

compa rative te sting of the valve on th e basis o f its mutual conductan ce. All t hese require

the manipulation of the main volta ge and meter co ntrols and, before s uc h a test is under

taken and the Circuit Selector sw itch turned to position Test, one should be assured that

all the requisite controls ar e correctly set. This applies to the sett ing of the anode, screen

and grid voltage controls, the Meter Selector and the Anode Selector switches. In particular,

where the probable anode current of the valve is unknown, the Meter Selector should be set

to 100 mA to avoid damage to the movement, if the current flowing is such as to be considerably

higher than that catered for by the lower meter range positions. I t is always perfectly

simple an d safe to s et th e Meter Selector at successively lower full scale curr ent

deflectio ns to cater for a valve, the anode current of which is less than that whi ch can be

appro priately read on a higher r ange. If the reverse procedure is adopted, however, then

it is quite possible tha t a damaging current may have passed through the meter circuit

before the latte r is set to a suitable high range. The procedure for taki ng the n ecessary

valve measureme nts is then almo st sel f expl anator y.

Where only a measurement of m utual conducta nce is re quired then t he data for this

can be tak en from the “AVO” Valve Data Manual. Th e el ectrode vol tage settings sh ould

be mad e as indicate d an d consequent upon such settings an initial anode current will be

shown on the meter wh ich has been finally set to a suitable range. This anode current rea d

ing s hould normally be compared with t he anode c urrent reading shown in the t ables, as it

will give an initial ind ication of the valve “ goodness ”. Quite obviously if a valve shows

an anode current rea ding considerably below that which is appropriate for the applied

electrode v oltages, then its emission is much lower than would normally be expe cted and

in normal c ircumstances the valve will not function at full efficiency. Mo re particularly

20

Page 21

does this apply in the case of valves used either as o scillators or output valves, for in both

condit ions the valve has to deliver an appreciable power which cannot obviously be up to

standard if the emiss ion is low. At the s ame time care should be taken not to jump to

false concl usi ons on this basis when testing valves of very high slope and short grid base,

where i t m ay be possible to double the valv e anod e curr ent for a change in bias of some

‘25V, and a very slight variation in the va lve characte ristics may give rise to an erroneous

impr ession of the valve’s “ goo dness ” on the score of a node current. Afte r having

obt ained th e ini tial anode current re ad ing and obtained therefrom such information as is

desirable, this anode curre nt indication may now be ba cked off to zero by the Se t Zero

control an d the Meter Selector sw itch re-set to a range appr opriate to the exp ected reading

of mutual conductance. By pressing the mA/V button the mutual conductance of the valve

will then be directly indicated on the meter, the reading in mil liamps obtaine d being

indicative of the mutual co nductance in mA/V.

Alternatively, wher e it is not necessarily required to obtain a precise readin g of mutual

conduct an ce , but merely a gauge of the valv e’s goodness fa ctor on the basis of mu tual

conductance, then af te r backing off to ze ro the Meter Se lector s hould be set t o position

mA/V and the Set mA/V control set to a value correspondin g to the standard mutual

condu ctance reading for t he valve. On pressing t he mA/V butt on t he com par ative

goodness of the valve will then be show n on th e colou red scale which is divided in three

coloured ba nds. A ll valves coming within th e green portio n can be take n as satisfactory.

Valves in the red po rt ion are suitable for rejection, whilst the small intermediate band

betwe en the gr een and red portion s denotes a valve which, wh ilst not entirel y unsatisf actory,

is not by an y means working at its full rated efficiency. Subs equent acti on on the valves

whose test figures come wi thin this band will obviously ha ve t o be rela ted to the particular

requiremen t of the moment.

W here more comprehe nsi ve tests of the valve are required, to assis t in the solution

of development or more intricate tes t probl ems, th e plotting of one or a family of mutual

ch aracteristics can oft en give a much more complete answer. This may readi ly be under

taken with the Valve Chara cteri sti c Meter and is performed with the Circuit Sele ctor in

its position Test. The man ipulati on of the co ntrols subsequent to the o btaining of

the in itial ano de current readings is not of course re quired, it being merely necessar y to

plot the value of the appropriate elec trode curr ents as re ad from the mete r, against the

settings of the associated el ectrode volt age switches. I aj\g x curves will be taken at a

pre-determined setting of anod e and/or screen volts, the readin g of the anode current

obt ained b eing pl ot te d a ga inst the settings on the variable grid bias control. Similarly

Ia/Va curves will require a fixed set ting of grid bias, anode current being plotted agai nst

the settin gs of t he ano de voltage switch.

Where either m utual conductance characteristic curves are requi red for the screen

or g2 of th e valve in q ue stion, then the Anode Selector sw itch should be set to positi on

“ S ”, the me ter current shown will be an indication of the screen (or g^ current and all

the above instruct ions can be related thereto.

Remarks in relati on to the tests describe d abov e as applied to multiple or special type s

of valve, will be fou nd in subsequent test notes .

7. Where a valve is suspected of passin g too mu ch gr id current, a measure of the

magnitude of grid curr ent at th e desired conditions of applied electrode voltag e may be

made a fter having measured the mu tual conductance of the valve in question. After hav ing

set the val ve up and backed off the anode current to z ero as for mA/V test, the button

marked Ga s should be pressed. Any grid curr ent flowing will set up a DC grid voltage

across the 100,000 Ω r esistance introduced into circui t. This will result in a change in

21

Page 22

anode current (usua lly forward) depend en t upon the polari ty of the voltage d eveloped across

the resistor. The value of the grid current flowing will then be calculated from t he formula

A la X 10

Ig (μΑ) =

---------------where Ala is the a node current change, a nd g is the mutual

g

condu ctance in mA/V. The dire ction of anode curr ent change will denote the nature of

th e grid current flowing.

S. The testing of rectifying valves should rea lly be associated wi th the requirements

of the circuit in which these val ves ar e to work, although in most cases, in the data for the

valve in question a figure is quo te d denoting the standard emis sion to be expected for a

valve of the type under test. Th e proce dure for car rying o ut the test is again str aightfor

ward. All initi al tests should have been ca rr ied o ut as for amplifying valves, but instead

of set ting Circuit S electo r t o Te st fo r the measurement of mutual characteristics, the circuit

selector should be set to position Rec after having turned the M et er Selector to a load

current range appropriate to the valve. This load current, it will be reali sed, appl ies

to one anode only. The setting of load current can eith er be determined fr om th e

tabulated data as alread y mention ed, or alternatively can be related to the tota l current

that t he valve is required to deliver. Th us in a piece of apparatus where the total HT

current dra wn is say 50mA , then a rectifier load current setting of “ 60 ” will be an adequate

test for the valve emission (assuming half wave rectifi cation.)

Alternatively, if the valve is a new one, the maker’s rating for maximum load curr ent

can be used as the basis for the settin g of the meter range switch. It will be realised that

since each half of a ful l wave valve is tested independently, then the setti ng of the r ange

switch should ind icate half the total valu e of current t hat the valve would be exp ected to

deli ver in a full wave ci rcuit. For instance a valve rated at a ma ximum c urrent of 120mA

w ould be tested with each anod e at the “ 60 ” po sition on the Meter Selector. No further

manipulation of the electrode voltag e co ntro ls is r eq uired. T he heat er voltage is already

set whils t anode, grid and screen v oltage control s are completely d is-associated from the

test circuit by the s etting of the Circuit Selector swit ch to Rec, aU appropria te volta ge and

ci rcuit connections also being automatically made. Having, therefore, correctly set

up th e valve as explained, the i ndication of the meter needle on the coloured scale will

show the oper ative goodness of the va lve in relation to the stand ar d load current chose n.

Sim ilar remarks app ly to the te sting of signal di ode valves, with the exception that

the se are al ways tested wit h t he Met er Selec tor at “ 1 ” and the Circuit Selector at posit ion

Diode.

INS TRUCTIONS FOR TESTING SPECIFI C VALVE TY PE S

The function of a valve, as distinct from its manufac turer’s type number is indic ated

by a symb ol in the form of letters appearing at the extreme right of the test data ; thus a

half wave re ctifi er would have t he letter “ R ” i n the function column, whilst a full wave

rectifier would be designat ed by “ RR ” . Similarly, diode valves will be shown by the

letter “ D ” the number of diode eleme nts being indicated by the numbe r of “ Ds ”, th us

** DDD ” refer to a triple diode.

Th e testing of multiple diodes or rectifiers is carried out in the manner already explained,

the An ode Selecto r swit ch being used to select the di ode or rectifier element, the emissio n

figure for which , being indicated on the m eter. It will be reali sed t hat wh en dealing with

diodes or rectifiers A x and A2 positions of the se lec tor switch represen t d io de or rectifier

anodes 1 and 2 respectively and correspond t o figures S and 9 in the set up figure.

22

Page 23

In the case of t riple diodes since only two an ode systems are no rm ally catered for ,

a special procedure is adop ted in the set up figure. At t he position in the set up number

representing t he third d iod e th e symbol f is included, the first an d second diodes being

indicated by 8 an d 9 respectively in the n ormal way. The valve should now be tested

normally with the selector switc h set to 0 whe re the f appears in the set u p n umber. This

will give emission figures for di odes 1 and 2. Now rot ate the Selector Switch rollers so

that the two ro llers origina lly set at 8 and 9 are now set to 0 and set up the position f as 8

on the s elector switch. A fu rther test w ith the ano de selector switch at Ax will thus give

the emission of the third diode , e.g., AAB1 will be indicated in t he data as 0231|0980.

T o test diodes 1 and 2 the set up on the roller sw itch will be 023100980 and diodes 1 and 2

will be test ed in the normal manner. Fo r o btaining the emission figure for the third diode

the Selector Switch w ill be altered to 023180000 and the Anode Selector to posit ion A v

Double Trio des or Double Pentodes will be indicated by the le tters “ TT ” or “ PP ”

in the type column and will be tested in the nor mal way for ea ch half of the valve, selection

being made by th e rotat ion of the Anode Selector switch to o r A2 co rresponding to set

u p figures 6 and 7.

Combined Diode and Amplifying Valv es will be represente d in the type columns by

“ DT ” and “ DDT ” for diode triodes and double d io de t riode s, whilst “ DP ” and

“ DDP ” indicate diode pentodes and double d iode pento des. The tes ting of such valves

is automatic* the amp lifying section being test ed first with the C ircuit Selector switch at

position Test and the Anode Selector at posit ion “ A t ” whilst t he rotation of the Ci rcuit

Selector s witch to the Diode position will automatically set the instrument in readin ess for

testi ng one or both the diode s wit h the ano de selector at A 1 or A2 respective ly, with the

Meter Selector set to “ 1”.

Fre quency Changers of the Hep tode, Hexode class employing the normal oscillator

section as a phantom ca thode for the mixer section are not very satis factorily tes ted i n two

Sections, as the nature of the valve construction is such that each sect ion is dependent on

the other for its correct operatio n. For te st pur poses t herefor e, thi s va lve is shown con

nected as an HF pentode for w hich, where possibl e, ano de current a nd/or mutual con

ductance figures are given. Such valves are indic at ed by the letters “ H ” in the type

column.

An exc epti on to this class of valve is t he Oc tode designated by “ 0 ” in the type colum n

which, as will be seen from the data, is tested as if it had two s eparate elect rode assemblies,

separate data bein g g iven f or each. In th is case the osc illator section is te sted wit h anode

sel ector at A 1 and the mixer sect ion at A2.

A s a further test to ensur e the pro babili ty of such a valve oscill ating satisfactorily, an

indication of failin g e mis sion will poss ibly give the most use ful results . It will be realised

that when a valve is up to s tandard its cathode will develop its full emission at the rated

heater voltage for the valve, and any change in the cathode tempe ra ture will not resul t in

a correspond ing change in the emiss ion. If, however, the cathode’s emission is failing, then

an in creas e or d ecrease in the Cathode temperature will resul t in a noticeable change in the

em ission for the valve. When a valve is oscill ating it tends to run in to the positive grid region,

and thus makes use of the full emiss ion ca pabilities of th e cathode. Any failing emission will

limit its ut ility in this res pect. As a subseque nt test, therefore, on a valve designed to be

used as an o scillator, it is helpful to not e the anode current at the rated test figures with

the normal heater vol tage applie d and then decrease the heater vol tage by about 10 to

15 % (t he next tapp ing on the selector sw itch) for a short period. In the case of a valve

with fai ling emission this will result in an excessive decreas e in the anode current con

siderabl y greater than the per centage decrease in heater vo lts. Such a result would suggest

that the valve will not oscillate ve ry satisfactoril y. A negligible or small decrease in anode

23

Page 24

current (or of the same or der as the heater volts cha nge ) will show that the valve is

developi ng its full emission at the rated heater voltage, and pro vided that the cir cuit

conditions are right it should oscil late normall y.

Frequency Changers employing separ ate electro de assemblies for oscillat or and mixer

functions are designated by “ TH ” (Triode Hex ode) “ TP ” ( Triod e Pe ntode). The separat e

sections of this valve are not interd ependent, as in the case of th e phantom cathode types,

and they can thus be tested in. two separat e s ections as a pentode or triod e respectively.

This arra ngement is catere d for in the set -up figures given, 6 correspondi ng to the triode

section and teste d with th e Anode Selector at Aj whils t 7 in t he set up figure corresponds

to the mixer sectio n which is tested with the Anode Selector at Aa. The f igures to be expected

from both halv es of the valve are given in the table s wh ere available, but it is often informa

tive to apply a test for f ailing ca thode emission to the trio de or os cillator section in the

man ner alr ea dy descr ibed .

In the case of normal triode s and pentodes (incl ud ing beam tetrodes) the test procedur e

for which has already been fully outlined, the type column will show the symbol “ T ”

and “ P ” respectively.

THE USE OF THE LINK ON THE BACK PANEL OF THE INSTRUMENT .

This link is to enable a lo ad to be inserted i nto the a node cir cuit of the valve under

test when an an ode current or mutua l cond uctanc e test is b eing perfor med on the

electrode c ircuit in question. It thus ena bles dynamic figur es for the valve or ele ctrode

system concerned to be obtained, the procedure bein g to remove the shorting link and

ins ert across t he sockets a resistance or other load which it is desired to include in circuit.

Tuning i ndicators (Magic Eye s) are tested with the contr ol s set a cc ording to the figures

given in the se parate data table, using the screen swit ch f or obtaining target voltage and

inser ting the ano de load, sh own in columns marked “ Ra ” by means of the link at the rear

of the instrument. At the approx imat e bias given in the table the tr io de section should be

at cut-of f and the “ eye ” fulJy closed. On varying the grid bias t o zer o the “ eye ” s hould

open fully and th e value of anode current sho uld be appro ximately that app earin g

in the t able. In the ca se of d ouble sensitivity indicators giving multiple im ages

responding to different sensitivities, two sets of data (where possib le) are given, the first

set referrin g to th e more s ensitive indication.

Gaseous Rectifiers

These also necessitate the use of the link, as s uch valves would normally pass a

dama ging current if tested wit hout suita ble limiting load in the an ode circuit. They are,

therefore, teste d not on the re ctifie r or di ode test circui t, but with t he selec tor switch turned

to Test, anode voltage and representative anode current figures bei ng given in the

Val ve Data c olumns. The value of load r esistance (of su itable watta ge) which must be

in cluded across the li nk , befor e the valve is tested, is shown in K Ω in the“ mA/V ” column

(which would not normally apply to a rectifier'valve). Fall wa ve examples of th is class

of valve are of course tested at anode selector switch positions Aj and A 2.

Cold Cathode Recti fiers designate d by the symbol “ CCR ” can be tested in a similar

manner, the anode v oltage, approximate anode cur rent, and load resistance being given

in the data columns as above.

Thyratrons c an be checked by comp arison if set up as a normal triode, with a limiting

resistance included in the link, th e control ratio being indicated by a comparison between

the peak v alue of the ap plied anode volt age, and the se tting of the grid bia s control which

will prevent the valve striki ng and passing anode current. It must be emphasised, howeve r,

that the main v alue of suc h a test is in comparison only, as the hold off grid bia s value

24

Page 25

shown on the gri d bias co ntrol is only approximately half that of the bias which would