Page 1

DIVA Revolution 195

User Guide

Page 2

About Avintage and French Corner Cellars

Avintage is the premium line of wine cabinets made by Frio Group, Europe’s leader in wine

cabinets. Located in France, Frio’s sole activity is the development and manufacturing of

wine cabinets. Frio is recognized for its expertise resulting from years of servicing wine

enthusiasts.

Created by a Winemaker, Avintage has developed a reputation as outstanding

manufacturer and has earned the loyalty of many wine collectors and lovers over the past

20 years. Exclusively built in Europe, Avintage offers superior quality wine cabinets with a

wide portfolio.

French Corner Cellars is the exclusive distributor of Avintage wine cabinets in the USA and

Canada. Already involved in wine activities, French Corner Cellars owners decided to

expand their services to provide means to preserve and serve wine in optimum conditions.

Located in the New York Capital region, French Corner Cellars serves private customers

as well as businesses wishing to enhance the potential of their wine collection. The quality

of our cabinets is also reflected in the range of services and the warranty we offer our

customers.

We thank you for your confidence and business. We trust you will enjoy your new Avintage

wine cabinet.

Page 3

USA

2

USA/CA&

Contents

Warning and Safety Instructions

3

- 4

&

Get to know your wine cooler 5

&

Before

use

6 - 7

&

Installation and start-up 8

&

Operation & functions 9 – 11

Defrosting and cleaning

12

Technical data 13-14

&

Reversible door 15 - 22

&

Accessories 23 - 24

Customer Care and Troubleshooting

25

&

Warranty and spare parts

26

&

Disposal

27

Page 4

USA

3

USA/CA&

Warning and safety instructions

&

Warnings and Safety Instructions mentioned in this guide are not meant to cover all possible

instructions and situations that may occur during the cabinet lifetime.

&

●Keep ventilation openings in the cabinet

or in the built-in structure clear of

obstruction.

●Do not use other mechanical devices or

other means to accelerate the defrosting

process than those recommended by the

manufacturer.

●Do not damage the refrigerant system

&

●Do not use electrical appliances inside

the refrigerated storage compartment,

unless they are of a type recommended

by the manufacturer.

●Do not connect the wine cellar to multiuse electrical adapters.

●Do not use your cellar outdoors. Do not

expose it to atmospheric agents.

(Humidity, moist, extreme temperatures

etc.).

●This cabinet is not intended nor designed

for use by children or people with

reduced physical, sensory or intellectual

capacities, or by people lacking

experience or knowledge unless they

are watched or have received

instructions on how to use the device by

a person responsible for their safety.

Before you dispose your old device:

- Take off the doors.

- Leave the shelves in place so that

children may not easily climb inside.

●Do not store explosive substances such

as aerosol cans with a flammable propellant in this cabinet.

●Do not operate the cabinet in the presence

of explosives and/or flammable fumes.

●Always keep the keys in a separate place

and out of reach of children. Keep

children away from the cellar. Do not let

them play with the device cabinet.

●Disconnect the cellar before performing

any servicing or cleaning operation

(disconnect the power plug cord or the

corresponding circuit breaker depending

on the model).

●In case liquid is accidentally spilled

(broken bottle or other) on the electrical

elements (motor or other), immediately

disconnect the power plug cord.

●Make sure that your electrical voltage

and power rates correspond to the indications on the name/data plate on your

wine cellar, which must be connected

to

a

grounded 3 prong electrical outlet. Repairs or incorrect connections will lead to

dangerous conditions. Have your electrical installation checked by a professional

if you are in doubt.

●To avoid any risk if the power cord is

damaged, have it replaced by an approved technical centre, the dealer, or an

authorized service representative.

●Never pull on the power cord. Never carry

the device by the cord and never pull on

the cord to disconnect it. Grip the plug

connected to the wall outlet and unplug.

●Place the power cable in a way to protect

it from any damage or risks of falling.

Page 5

USA

4

USA/CA&

&

●To avoid any risk of fire electric shock or

injury, do not dismount the cellar.

&

●To avoid any risk of fire, electric shock or

injury, do not immerse the power cord,

the plug or the device in water or any

other liquid.

●The power cable must not come in contact

with sharp edges, hot parts or any source

of heat.

●If your cellar is damaged (major shock) or

has suffered from any kind of incident

(over voltage due to lightning, flooding,

fire), it may prove dangerous. Disconnect

the power plug and have the device

checked by an approved professional

technician.

●An electrical device must only be repaired

by qualified personnel; unqualified repairs

may lead to serious dangers for the user.

●For safety reasons do not use an electrical extension cord.

●Always remove all bottles before moving

this cabinet.

●Frost formation on the interior evaporator

wall and upper parts is a natural phenomenon. Therefore, the cabinet should

be defrosted during normal cleaning or

maintenance.

●Please note that changes made by the

owner to the cabinet construction will

cancel all warranty and product liability.

●This cellar is designed to conserve exclusively wine. Do not store food!

●This wine cellar should not be recessed

or built in an endorsed cabinet; it’s designed for freestanding installation only.

●Do not splash or spray water from the

hose on or in the cabinet.

●The cabinet shall not be plugged to an

ungrounded electrical power.

●The cabinet is supplied with a UL listed,

3 wire power cord ready for connection

to a 120V, 60Hz supply.

Page 6

USA

5

USA/CA&

Get to know your wine cabinet

&

&

&

&

&

&

&

&

&

&

&

&

&

&

Light

Control panel

Charcoal filter

Wooden shelf

Sealing strip

Nameplate

Kick plate

Lock

Adjustable

feet

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

Page 7

USA

6

USA/CA&

&

Before use

At cabinet reception

Check that the cabinet and or box have not been damaged during transport. Do not

put in use if the cabinet has been damaged during transport.

Transport Damages must be reported to French Corner Cellars within 24 hours

of the delivery.

&

Remove the packaging. Clean the inside of the cabinet using warm water with a mild

detergent. Rinse with clean water and dry thoroughly (see cleaning instructions page

18). Use a soft cloth.

&

If the cabinet has been laid down during transport, or if it has been stored in cold

surroundings (colder than +41°F), it must be allowed to stabilize in an upright position

for at least twenty-four (24) hours before being

switched on.

The pieces on the rear of the cabinet ensure air

circulation by providing enough space for the

cabinet to operate normally. Fit the two caps

supplied with the cabinet as shown on the picture.

&

&

Setting up

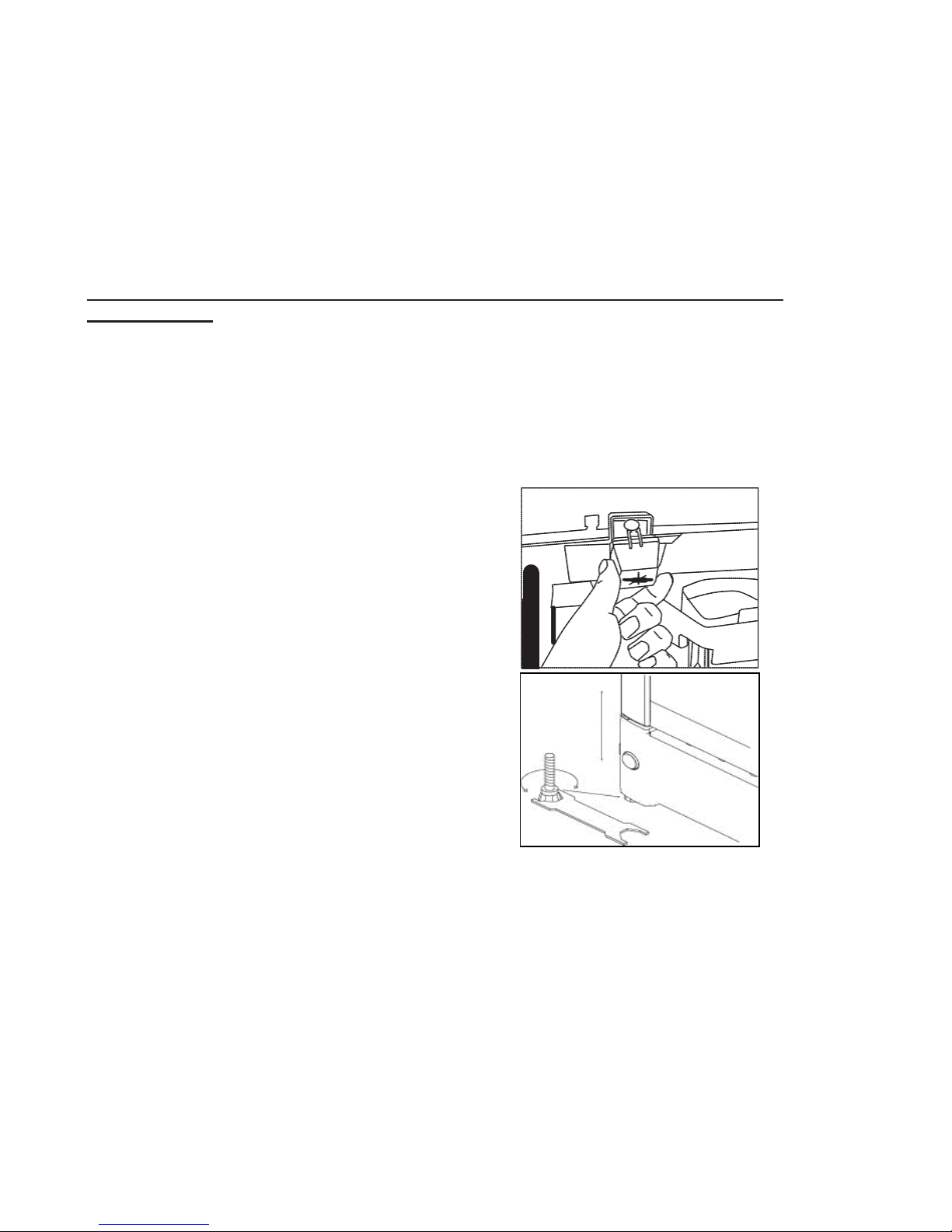

It’s important to have the cabinet leveled. It can

be adjusted by screwing or unscrewing the

adjustable feet at the front of the cabinet.

Use a spirit level to check that the cabinet is

absolutely level sideways.

&

&

Installing shelves

There are three different shelf models.

Fixed shelves

Place the shelf on top of the internal wall supports, and then slide it towards the back

of the cellar. Make certain the wedge is on the upper end of the shelf.

Display shelves

Use two sets of side supports per display shelf. The posterior part of the shelf sits on

the upper level, the front part of the shelf sits on the lower level supports, creating a

tilted shelf allowing bottles to be placed in an angled position.

Sliding Shelves

Place the 2 rails on the internal wall supports, with the wheels at the front.

Then insert the shelf between the rails, with the wheels on the back, in diagonal from

the top; once placed between the rails slide is towards the back.

Page 8

USA

7

USA/CA&

&

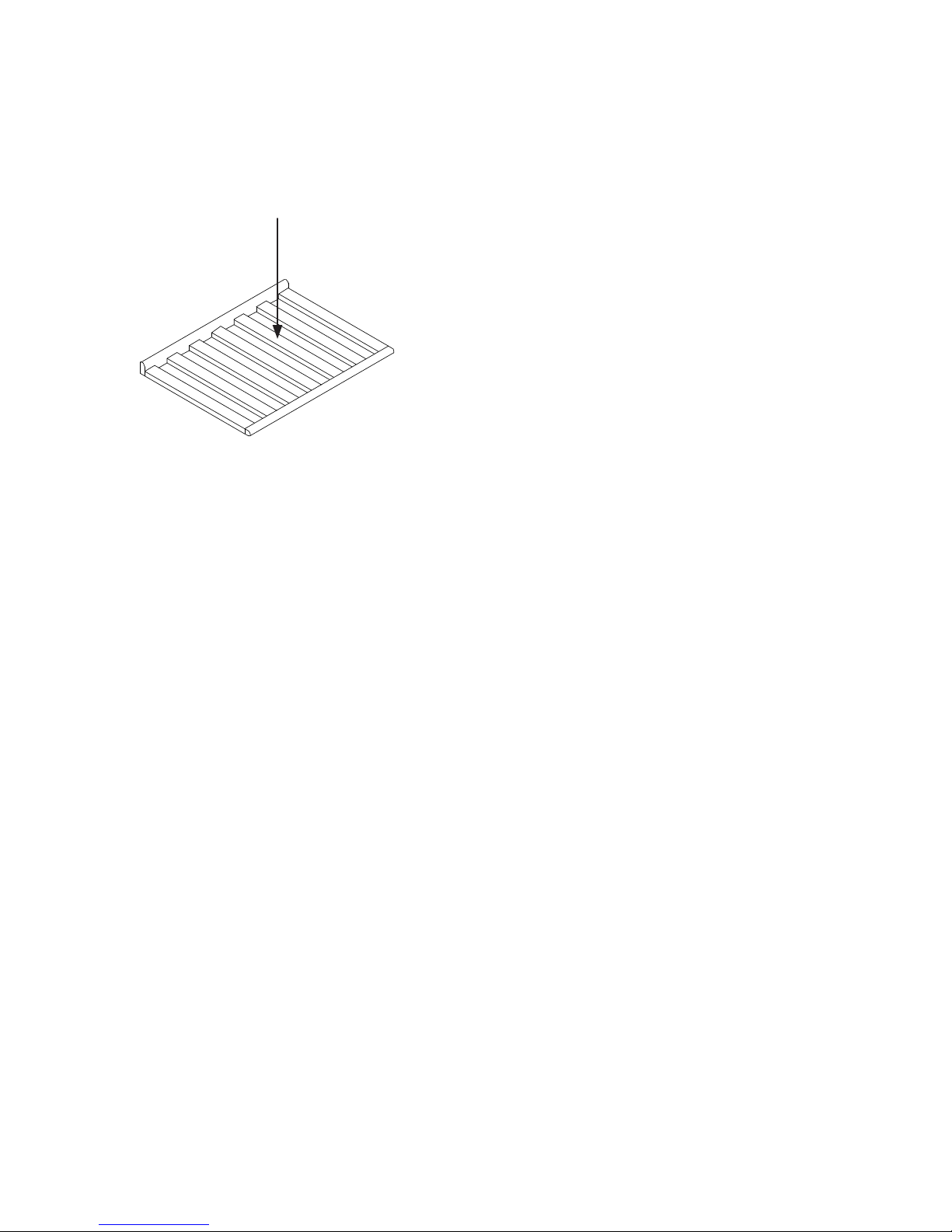

Max weight on the shelves (fig. 1)

&

Max. 85 kg./187 pounds

&

&

&

&

&

&

&

&

&

&

fig. 1

Page 9

USA

8

USA/CA&

&

Installation and start-up

Location

Make sure to measure the area where the DIVA Revolution 195 will be located and

ensure there is enough clearance on all sides (3 inches on the top of the cabinet, 1

inch on the sides and back).

For safety and operational reasons, the cabinet may not be installed outdoors. It

should be placed on a leveled surface in a dry, well-ventilated room (max. 75%

relative air humidity). Never place the cabinet close to sources of heat such as

ovens, stoves or radiators; and avoid placing it in direct sunlight.

&

Ambient temperature.

The winter function will guaranty the wine cabinet to operate at an ambient

temperature as low as 41ºF.

Installation

This wine cellar should not be recessed, nor should it be placed in an enclosed

cabinet. It is designed for free standing installation only.

Avoid risk of electrical shock:

- Plug into a grounded 3-prong outlet.

- Do not move the ground plug.

- Do not use and adapter

- Do not use and extension cord

Improper connection of the equipment grounding conductor may result in

electric shock. If you are in any doubt as to whether the appliance has been

properly grounded, have the appliance checked by a qualified electrician or

service technician.

&

Page 10

USA

9

USA/CA&

&

Operation & functions

&

&

&

&

&

&

&

&

&

&

&

&

&

&

Electronic control panel

The electronic control panel (above)

ensures that the temperatures set at the

top and at the bottom of the cabinet are

maintained. This is achieved by means of

an advanced control of the refrigeration

system, the heating element, and the fan.

The set temperature will be stored in the

event of power failure.

&

The electronic control has the following

functions:

• On/Off switch

• Light switch*

• Temperature setting

• Temperature indication

• Alarm for too high and too low

temperatures

• Door alarm

&

*The light may either be turned on

constantly or only when the door is open.

&

Temperature indication

The display shows the actual temperature.

The upper digits of the display indicate the

temperature at the top of the cabinet, and

the lower digits of the display indicate the

temperature at the bottom of the cabinet.

The temperature indicator is equipped with a

built-in filter, which simulates the actual

temperature in the bottles.

Consequently, the indicator does not

react on short-term fluctuations of the

air temperature (e.g. when opening

the door for a short period of time).

&

Temperature settings

The cabinet temperature is set by

selecting the low temperature for the

bottom of the cabinet and the high

temperature for upper part of the unit.

The pushed air system will then

establish 6 zones of temperature

distributed evenly between the two

selected temperature settings.

Temperature setting at the

top of the cabinet

Push SET1.The temperature at the top

of the cabinet may then be adjusted up

and down by means of the “up and

down” buttons. The temperature can be

adjusted from 46 to 72°F; however, the

top temperature cannot be set at a

lower temperature than SET2 (the

actual set point for the bottom

temperature sensor).

SE

SE

Page 11

USA

10

USA/CA&

&

Temperature setting at the bottom of the cabinet

Push SET2. The temperature at the bottom

of the cabinet may then be adjusted up and

down by means of the “up and down”

buttons. The temperature can be adjusted

from 40 to 72°F; however the bottom

temperature cannot be set at a higher

temperature than the actual set point of the

upper temperature SET1.

&

Alarm devices

The cabinet is equipped with 2 alarms: one

for the low temperature (bottom area) and

one for high temperature (upper area).

The alarm consists of a beeper and a

display warning.

• Alarm for low temperature: beep

sound +“LtA” displayed on the

screen alternating with the current

temperature

• Alarm for high temperature:

beep sound +‘HtA” displayed on

the screen alternating with the

current temperature

&

The alarm temperature depends on the set

points. It is possible to manually configure

the temperature that will trigger the alarm.

&

The beep sound alarm can be cancelled by

pushing any random key on the thermostat

button. Push the on/off button to erase the

display alarm sign on the display, then again

for restarting the compressor.

&

Door alarm

When the door has been open for more

than 2 minutes, the door alarm is activated.

Child lock

The thermostat is equipped with a child

lock. This device function is activated by

pushing the “up and down” buttons

simultaneously. After approximately 3

seconds “Pof” flashes on the display.

Then the actual temperatures are

shown as usual. In addition, the set

temperatures can be shown by

pushing SET1 and SET2,

respectively.

&

The child lock function is cancelled

by pushing the “up and down”

buttons simultaneously. After approx.

3 seconds “Pon” flashes in the

display, and the temperature can be

set.

Light

To turn off the lights, press once .

Permanent lighting

To turn the lights on permanently,

press the light switch symbol twice.

To switch on the light press again the

light switch symbol .

Two-zone setting for

serving temperature

Typical serving temperature settings

for the top and bottom sections are

60°F and 43°F respectively. With

these settings, a suitable temperature

gradient will be achieved in the

cabinet for the storage of various

types of wine distributed from top to

bottom as follows:

• Heavy body red wines +60

to +66°F

• Rosé and light red wines

+54 to +60°F

• White wines +50 to +54°F

• Champagne and sparkling

wines +43 to +46°F

&

It is recommended to serve the wine

Page 12

USA

11

USA/CA&

&

at a temperature which is a few degrees

lower than the desired

drinking temperature, as the wine will be

warmed slightly when it is poured (into the

glass.)

Single-zone setting for longterm storage

For long-term wine storage preservation, the

top and bottom sections should both be set at

about 54°C. With identical settings for the top

(SET1) and bottom (SET 2) sections, the

controls will maintain an even temperature

throughout the cabinet. However, in case of

significant difference of temperature between

the room and the desired temperature in the

wine cabinet, there might be a slight

temperature gradient difference between the

top and bottom. The controls will maintain the

set temperature at the bottom of the cabinet,

and any deviation from the setting will

therefore occur at the top.&The difference will

vary from 1 to 7°C, depending on the ambient

temperature.

Switch from F° to C°

Press simultaneously Set1 + Down arrow for

3 sec, then press again simultaneously Set1

+ Down arrow for 7 sec; Hyi.1 appears on the

display; press 8 times the up arrow, F° .CF°

appears on the display; press Set 1, F° is

blinking, then press the down arrow to

change to C°; wait for 15 sec to exit the

setting mode.

Page 13

USA

12

USA/CA&

&

Defrosting and cleaning

Automatic defrosting.

The wine cooler is defrosting automatically. Defrost water runs through a pipe and is

collected in a tray above the compressor where the heat generated by the compressor

causes it to evaporate. The defrost water tray should be cleaned once a year.

&

Cleaning.

Before cleaning the cabinet, unplug it from the main power supply. The cabinet is best

cleaned using warm water (max. 150°F) with a little mild detergent. Never use aggressive

cleaning agents. Use a soft cloth. Rinse with clean water and dry thoroughly. The defrost

water channel, in which condensation from the evaporator runs, is located at the bottom of

the rear inside wall of the cabinet and must be kept clean. Add a few drops of disinfectant,

to the defrost water drain a couple of times a year, and clean the drain using a pipe cleaner

or similar. Never use sharp or pointed tools.

&

The sealing strip around the door must be cleaned regularly to prevent discoloration and

prolong service life. Use clean water. After cleaning the sealing strip, check that it continues

to provide a tight seal.

&

Dust collecting on the condenser on the rear of the cabinet, the compressor and in the

compressor compartment is best removed using a vacuum cleaner.

Page 14

USA

13

USA/CA&

&

Technical data

The DIVA Revolution 195 cabinet is the only one on the market to offer up to 6 zones of

temperature thanks to its pushed air technology. It is particularly appreciated by collectors,

restaurants and retailers as it offer the opportunity to serve any type of wine at the correct

temperature.

The DIVA Revolution 195 has the following features:

• 110/120 V / 60 Hz. UL / c UL compliance

• Maximum capacity: 195 bottles*

• Typical capacity in 5 shelves configuration: 165 bottles

• Typical capacity in full shelves configuration: 105 bottles

• Possibility to control simultaneously up to six temperature zones

• Winter function (Security Variation System)

• Anti-vibration system

• 1 active charcoal filter

• Constant hygrometry (from 60% to 75%)

• Temperature range: from 40°F (5°C) to 72°F (22°C)

• Pushed air technology

• Temperature digital display

• 2 digital hygro/thermometers

• 1 full glazed UV-proof door with LED light integrated on the sides

• Varnished case black colour

• LED internal light

• Back wheels and adjustable front feet

• Power indicator

• Reversible door with integrated handle

• Removable skirting

• Visual & acoustic temperature alarm

• Compressor security

• Security lock

• Energy consumption: 0.59 kWh/24h

• Sound level: 42 db

• Gas: R134A

• Climatic category: SN – ST (5-38°C)

• Category: 2

• Gencod: 5703540148328

Product dimensions and weight

Packaging: 24.6 x 26.4 x 75.6in (62.5 x 67 x 192cm) – 202lbs (92kg)

Cabinet: 23.4 x 23.4 x 73.8in (59.5 x 59.5 x 185cm) – 192lbs (87kg)

*Maximum capacity for Bordeaux bottles stored on 3 shelves

Page 15

USA

14

USA/CA&

&

The technical marking and Serial Number of the cabinet can be seen from the plate located

on the back of the cabinet (below).

&

Important: Wiring and connections in power supply systems must respect all applicable

domestic electrical codes. Consult these codes lengths and sizes prior to cabinet

installation.

&

Power supply: (Grounded through 3 wire

power supply cord) 115V ac, 60 Hz Single

Phase.

&

Maximum fuse size 10Amps.

&

This cabinet is equipped with a three- prong (ANSI type 5-15P grounded) plug for your

protection against shock hazards. The cabinet should be plugged in to properly grounded

three-prong power outlet.

&

Do not under any circumstances cut or remove the round grounding prong from the cabinet

plug power cord.

&

Do not under any circumstances use extension cords.

CLASS 1 LED PRODUCT

&

Page 16

USA

15

USA/CA&

Reversible door

Follow the instructions carefully.

NOTE: Before you start, the unit needs to be disconnected from the main grid.

We recommend that the change of door side is done by a technician. It is advised to have two

persons to perform this operation.

Equipment needed:

• 4 mm Allen key;

• Flat-headed screwdriver

•

Torx 20 (TX20) screwdriver

&

&

&

1. Open the door, unscrew the two screws

fixing the bottom cover (Torx20). Do not

remove the cover yet.

&

&

&

&

&

&

&

&

&

&

&

2. Place the cabinet on its back (preferably on a soft foundation).

&

&

&

&

&

&

&

&

&

&

&

&

3. Loosen the upper hinge and remove it (4

mm Allen key).

Page 17

USA

16

USA/CA&

&

&

&

&

4. Dismount the bottom cover (the built-in

snap function in each side can be

unsnapped with the flat-headed screwdriver).

&

&

&

&

&

&

&

&

&

5. Place the bottom cover with glass front

down, on an additional support, so the

wires are not stretched.

&

&

&

&

&

&

&

6. The door LED wires have to be dismounted from the connector on the

bottom cover (pure black & black / white

stripe wires). Push the top release down

to free the wire ends. (Note: the pure

black wire is + and corresponds to the

red wire on opposite side. The black /

white stripe wire is 0 (neutral) and corresponds to the black wire on the opposite

side – this is important when the wires

are to be mounted later).

&

7. To reverse the bottom glass, the brackets

need to be removed. Loosen the screw

and the bracket.

.

NOTE: Now the glass is loose.

Page 18

USA

17

USA/CA&

&

&

&

8. Lift the bottom sheet metal part and turn

the glass so the lock hole fits the other

ends round Ø hole concentric. Place the

sheet metal part on the glass again, and

mount the brackets onto the plastic profile in each end again. Don’t over tighten

the screws.

Note: The nut has to fit into the centre

groove.

&

&

&

&

&

9. The door has to be moved up from the

hinge.

&

&

&

&

&

&

&

&

&

&

10. Unscrew the lock pin (using the flat-headed

screwdriver) and remove it.

&

&

&

&

&

&

&

&

&

11. Pull up the lock cylinder and refit

both lock cylinder and lock pin on

opposite side.

Page 19

USA

16

USA/CA&

&

&

&

&

&

12. Pull the LED wires gently out of the bot-

tom hinge pin.

&

&

&

&

&

&

&

&

&

13. Dismount the bottom hinge pin and fit it

on the opposite side.

Note: The socket must also be moved.

&

&

&

&

&

&

&

&

&

&

&

&

14. Turn the door, so the glass side is down

(Note: Place something between the

glass and the other surface to prevent

scratching the glass).

Then loosen the gasket on the low end of

the door by pulling.

15. Pull the LED wires up and out.

&

Page 20

USA

18

USA/CA&

&

&

&

&

&

&

16. Replace the wires into the plastic

groove and lead them to the other side.

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

17. Push the wires through the oblong hole

and through the new hinge hole. This

can be a bit tricky so try to mount only

one wire first.

&

&

&

&

&

&

18. (2 pictures) Then tape the second wire

end to first wire and pull them both fully

through (remove tape subsequently).

&

&

Page 21

USA

19

USA/CA&

&

19. Make sure the wires are fitted into the

plastic groove and mount the gasket. It’s

important to check that the sealing strip

provides a tight seal all the way round.

If it does not, carefully heat the strip all the

way round using a hair dryer. Then ease the

strip slightly outwards so that it forms a tight

seal against the cabinet. Be careful not to

heat the strip so much that it melts!

20. Dismount the door hinge socket and

mount it on opposite side.

&

&

&

&

&

&

&

&

&

21. Pull the wire through the socket before

mounting it into the door hinge hole.

22.Reverse the door again and leave a space

to the bottom hinge.

Page 22

USA

20

USA/CA&

&

&

&

&

23. Pull the two wires through the bottom

hinge pin…

&

&

&

&

&

&

&

&

&

&

&

&

24.… and through the wire hole in the pla-

stic column.

&

&

&

&

&

&

&

&

&

&

25. Remount the wires (see under # 6)

and make sure that they are firmly

secured.

&

&

&

&

&

&

&

&

&

&

&

&

26.Push the door back in place over the

hinge pin and pull the wires simultaneously so the wires do not get stuck.

Page 23

USA

21

&

&

&

&

&

27.Dismount the top door socket

and mount it on opposite side.

&

&

&

&

&

&

&

&

&

&

&

&

28.Dismount the plastic caps on the top

of the cabinet and mount them on

opposite side.

&

&

&

&

&

&

&

&

&

&

29.Make sure that the door is aligned

with the cabinet before mounting

the top hinge.

&

&

30. Remount the bottom front cover. Place

the unit vertically again and mount the

two screws (see under # 1).

&

Page 24

USA

22

&

Restarting the cabinet after reversing the door

Before connecting the Wine Cabinet to the power source, let it stand upright for

approximately 24 hours.

This will reduce the possibility of a malfunction in the cooling system caused by handling

during transportation.

Note: If the door LEDs are not working but

the top LED in the cabinet is functioning, the

door wires are most likely not mounted correctly into the connector. (See under # & 25)

Page 25

USA

23

&

Accessories

Shelves

Stationary wooden shelf

Made of unscented oak to prevent any odor transmission to the wine.

Dimension: 20.66 x 17.3in (52.5 x 44.0cm)

Reference: CLAVIP01

Sliding shelves

Made of unscented oak to prevent any odor transmission to the wine.

Dimension: 20.66 x 17.3in (52.5 x 44.0cm)

Reference: CLAVIP06

Display shelf

Made of unscented oak to prevent any odor transmission to the wine.

Dimension: 20.66 x 9.00in (52.0 x 23.0cm)

Reference: CLAVIP02

Page 26

USA

24

&

Thermometer/Hygrometer

Thermometer/hygrometer with digital display to clip on a shelf.

Reference: THYG01

Note: Switch F° to C° with the button on the back of the unit.

Filter

Carbon filter to be placed in the wine cabinet.

Reference: FCA-01

Labels

Labels to clip on the shelves.

Reference: RET1

Page 27

USA

25

&

Customer care and troubleshooting

Customer Care number: 855-WNECORK (855-963-2675)

Before calling for service

Before calling French Corner Cellars Customer Care, refer to the Troubleshooting Guide below.

Check the household fuse or circuit breaker to see if it has been blown or tripped and that the

electrical connection to the cabinet has not been disconnected.

A power outage may also have caused a disruption in service.

Troubleshooting

Fault

Possible cause

Remedy

The cabinet is not

working.

The cabinet is switched off.

&

Power failure; the fuse is blown;

The cabinet is not plugged in

correctly.

Press the on/off switch.

&

Reset the fuse.

Check that power is connected.

Water collects in

the bottom of the

cabinet.

The defrost water pipe is

blocked.

Clean the defrost water channel

and the drain hole on the rear wall

of the cabinet.

Vibration or

bothersome noise.

The cabinet is not

levelled.

The cabinet is resting against

other kitchen elements.

&

Containers or bottles inside the

cabinet are rattling against one

another.

Level the cabinet using the

adjustable feet at the front of the

cabinet.

Move the cabinet away from the

kitchen elements.

Move containers and/or bottles

apart.

Compressor runs

continuously.

High room temperature.

Ensure adequate ventilation.

P1 is shown on

the display.

The upper sensor is

disconnected or shortcircuited.

Call for service. The

temperature within the entire

cabinet is maintained at the

higher of the two set points

(SET1 or SET2) until the fault

has been corrected.

P2 is shown on

the display.

The lower sensor is

disconnected or short-circuited.

Call for service. The

temperature in the cabinet is

maintained at the higher of the

two set points until the fault has

been corrected.

Page 28

USA

26

&

Warranty and spare parts

Warranty disclaimer

Faults and damage caused directly or indirectly by incorrect operation, misuse,

insufficient maintenance, incorrect cabinet building installation or main power

connection, fire, accident, lightening, voltage variation or other electrical

interference, including defective fuses or faults in main power installations will not

be covered by the warranty.

&

Repairs performed by other than approved service centers, and any other faults and

damage that the manufacturer can substantiate are caused by reasons other than

manufacturing or material faults, are not covered by the warranty.

&

Please note that changes to the construction of the cabinet or changes to the

component equipment of the cabinet will invalidate warranty and product liability,

and the cabinet cannot be used lawfully. The approval stated on rating plate will also

be invalidated.

&

Transport damage discovered by the buyer is primarily a matter to be settled

between the buyer and the distributor, i.e. the distributor must ensure that such

complaints are resolved to the buyer’s satisfaction.

&

Before calling for technical assistance, please check whether you are able to rectify

the defect yourself. If your request for assistance is unwarranted, e.g. if the cabinet

has failed a result of a blown fuse or incorrect operation, you will be charged the

cost incurred by your call for technical assistance.

&

Spare parts

When ordering spare parts, please state the type, serial number and production

numbers of your cabinet. This information is given on the rating plate and inside

the user guide. The rating plate contains various technical information, including

type and serial numbers.

Page 29

USA

27

&

Disposal

The symbol on the product, or on the documents accompanying the product,

indicates that this cabinet may not be treated as household waste. Instead it shall be

handed over to the applicable collection point for the recycling of electrical and

electronic equipment.

&

Environmental regulations on disposal must also be observed. When disposing of the

cabinet you should contact your local authority technical department who will inform

you of how collection and recycling of such units takes place in your area.

You should check with your electric utility company to see if a bounty program is

offered in your area. Since some bounty programs have required specifications for

appliances (e.g., must be in working condition, of a minimum vintage and/or

dimension), you may also need to confirm that your appliance is acceptable.

If a bounty program is not available, you can contact your municipal department of

public works to inquire about the procedures for collecting and disposing of

refrigerated appliances in your neighborhood. Typically, for refrigerators/freezers,

municipalities require you to make an appointment for bulky item collection, which

may be provided at no additional cost. Some municipalities charge a fee for

refrigerated appliance collection or require you to haul items to a transfer station or

dump. (Your municipality can direct you to a solid waste contractor for more

information.) Other municipalities may require the refrigerant to be recovered from

appliances before they will accept it for pick-up. In such cases owners would need

to hire a technician with certified recovery equipment to remove the refrigerant prior

to disposal.

By ensuring that this product is disposed of correctly, you will help prevent potential

negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product.

Disposal must be carried out in accordance with local environmental regulations for

waste disposal.

For more detailed information about treatment and recycling of this product, please

contact your local city office, your household waste disposal service or the store

where you purchased the product.

When disposing of a refrigerated appliance, try to inquire about the disposal practices

of the entity removing your unit to ensure that it will be disposed of responsibly. If you

learn about illegal or suspect activities (e.g., refrigerant venting), you can file a report

easily and anonymously by visiting EPA's Office of Enforcement and Compliance

Assurance website.

NOTE: Do not attempt to remove refrigerant or compressors yourself. Improperly

handled refrigerant may result in physical harm. Only properly trained individuals

using EPA-approved refrigerant recovery equipment should attempt to remove

refrigerant from appliances.

Page 30

USA

28

&

&

&

&

&

&

US115 Volts- 60 Hz Version

&

&

Reserving the right to alter specifications without prior notice. Please refer to

our websites to obtain the most recent product specifications, technical and

warranty information

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

www.frenchcornercellars.com

76 Clinton Street

Saratoga Springs, NY 12866

United States of America

1613 Heritage Way

Oakville

ON L6M 2Z5

Canada

Loading...

Loading...