Avdel 07265 Instruction Manual

07265

07265

Hydro-Pneumatic Power Tool

Instruction Manual

Original Instruction

3

Safety Rules 4

Specifications

Tool Specification 5

Tool Dimensions 5

Intent of Use

Tool Selection 6

Putting into Service

Air Supply 7

Operating Procedure 7

Accessories

Handling and Holster Kit 8

Pin Tail Deflector 8

Quick Connect Kit 9

Nose Assemblies

Fitting Instructions 10

Fitting Instructions for Maxlok®Nose Assemblies 10

Servicing Instructions 11

07285 Nose Assembly Components 11

Servicing the Tool

Daily 12

Weekly 12

Moly Lithium Grease EP 3753 Safety Data 12

Service Kit 12

Maintenance 13

Stem Catcher Unit 13

Piston Assembly 13

Trigger Assembly 14

Vacuum Stem Extraction Switch 14

Cabinet 14

Intensifier 14

Pilot Valve 15

Pressure Regulator and Filtering assembly 15

Air Pressure Indicator Assembly 15

Contents

LIMITED WARRANTY

Avdel makes the limited warranty that its products will be free of defects in workmanship and materials

which occur under normal operating conditions. This Limited Warranty is contingent upon: (1) the product

being installed, maintained and operated in accordance with product literature and instructions, and (2)

confirmation by Avdel of such defect, upon inspection and testing. Avdel makes the foregoing limited

warranty for a period of twelve (12) months following Avdel’s delivery of the product to the direct purchaser

from Avdel. In the event of any breach of the foregoing warranty, the sole remedy shall be to return the

defective Goods for replacement or refund for the purchase price at Avdel’s option. THE FOREGOING

EXPRESS LIMITED WARRANTY AND REMEDY ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES

AND REMEDIES. ANY IMPLIED WARRANTY AS TO QUALITY, FITNESS FOR PURPOSE, OR MERCHANTABILITY

ARE HEREBY SPECIFICALLY DISCLAIMED AND EXCLUDED BY AVDEL.

Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

General Assembly of Base Tool

General Assembly of Handle Tool 07285-03000 16

Parts List for 07285-03000 17

General Assembly of Cabinet 07265-03200 18

Parts List of Cabinet 07265-03200 19

General Assembly of Intensifier 07005-01650 20

Parts List of Intensifier 07005-01650 20

General Assembly of Valve 07005-00590 21

Parts List of Valve 07005-00590 21

Priming

Oil Details 22

Hyspin®VG32 Oil Safety Data 22

Priming Procedure 23

Fault Diagnosis

Symptom, Possible Cause and Remedy 24

4

Safety Rules

1 Do not use outside the design intent.

2 Do not use equipment with this tool/machine other than that recommended and supplied by Avdel UK Limited.

3 Any modification undertaken by the customer to the tool/machine, nose assemblies, accessories or any equipment supplied by

Avdel UK Limited or their representatives, shall be the customer’s entire responsibility. Avdel UK Limited will be pleased to advise

upon any proposed modification.

4 The tool/machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and

function by trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel UK

Limited procedures. Do not dismantle this tool/machine without prior reference to the maintenance instructions. Please contact

Avdel UK Limited with your training requirements.

5 The tool/machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the U.K. the “Health

and Safety at Work Act 1974” applies. Any question regarding the correct operation of the tool/machine and operator safety

should be directed to Avdel UK Limited.

6 The precautions to be observed when using this tool/machine must be explained by the customer to all operators.

7 Always disconnect the airline from the tool/machine inlet before attempting to adjust, fit or remove a nose assembly.

8 Do not operate a tool/machine that is directed towards any person(s) or the operator.

9 Always adopt a firm footing or a stable position before operating the tool/machine.

10 Ensure that vent holes do not become blocked or covered.

11 The operating pressure shall not exceed 7 bar.

12 Do not operate the tool if it is not fitted with a complete nose assembly unless specifically instructed otherwise.

13 Care shall be taken to ensure that spent stems are not allowed to create a hazard.

14 If the tool is fitted with a stem collector,it must be emptied when half full.

15 If the tool is fitted with a stem deflector, it should be rotated until the aperture is facing way from the operator and other

person(s) working in the vicinity.

16 When using the tool, the wearing of safety glasses is required both by the operator and others in the vicinity to protect against

fastener ejection, should a fastener be placed ‘in air’. We recommend wearing gloves if there are sharp edges or corners on the

application.

17 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool which should

be kept dry and clean for best possible grip.

18 When carrying the tool from place to place keep hands away from the trigger/lever to avoid inadvertent start up.

19 Excessive contact with hydraulic fluid oil should be avoided. To minimize the possibility of rashes, care should be taken to wash

thoroughly.

20 C.O.S.H.H. data for all hydraulic oils and lubricants is available on request from your tool supplier.

This instruction manual must be read with particular attention to the following safety rules, by any person

installing, operating, or servicing this tool.

5

Dimensions shown in bold are in millimetres.

Other dimensions are in inches.

07265

B

A

6.5

160

1.35

34

5.15

130

500

19.7

400

15.75

250

9.85

5000

197

Air Pressure Minimum - Maximum 5-7 bar (72.5 - 101.5 psi)

Free Air Volume Required @ 5.5 bar 2.1 litres

Stroke Minimum 26.2mm (1.03in)

Pull Force @ 5.5 bar 12.47 KN

Cycle time Approximately 1.7 second

Noise Level 70 dB(A)

Pistol Weight 3.1 kg (6.82 lb)

Total Weight Pistol and Intensifier 37 kg (81.4 lb)

Vibration Less than 2.5 m/s2 (8.2 ft/s2)

Specifications

Tool Specification

Tool Dimensions

Features include an on/off switch for a vacuum facility and an adjustable air restrictor to control the amount of vacuum according to

which fastener is being used.

Spent stems are collected in a stem catcher.

The vacuum is also used to retain fastener in the nose tip prior to its installation.

6

The hydro-pneumatic 07265 tool is designed to place Avdel breakstem rivets at high speed making it ideal for batch or flow-line

assembly in a wide variety of applications throughout all industries.

The 07265 is of the remote intensifier or split tool concept, (see page 5).

Pistol Grip type head fitted with a stem catcher is the standard tool for which a stem deflector is available (see details page 9). It is also

possible to order the base tool only (part number 07265-00300) which will not be fitted with a nose assembly.

Steel

Al. Alloy

Al. Alloy

Al. Alloy

Al. Alloy

Al. Alloy

Al. Alloy

Al. Alloy

Al. Alloy

Al. Alloy

Steel

St. Steel

Al. Alloy

Steel

St. Steel

Al. Alloy

Steel

St. Steel

St. Steel

Al. Alloy

Al. Alloy

Steel

Al. Alloy

Steel

Al. Alloy

Steel

AVEX

®

Snap Head

TLR

®

AVSEAL

®

MONOBOLT

®

Protruding Head

& 100˚ csk

*

The nose tip actually

remains the same, it is

the nose casing that is

longer.

See nose assemblies on

page 10 for details.

AVINOX® BE61

AVTAINER

®

MAXLOK

®

Brazier Head

& 90˚ csk

HEMLOK

®

Protruding Head

3

/16"

3

/16"

1

/4"

8mm

9mm

10mm

3

/16"

1

/4"

3

/16"

3

/8"

3

/16"

1

/4"

1

/4"

07265-00030

07265-00008

07265-00010

07265-00040

07265-00045

07265-00041

07265-00046

07265-00042

07265-00047

07265-00012

07265-00012

07265-00012

07265-00014

07265-00014

07265-00014

07265-00016

07265-00016

07265-00016

07265-00036

07265-00006

07265-00001

07265-00001

07265-00002

07265-00002

07265-00004

07265-00004

07381-04800

07498-02000

07498-01100

07340-08000

07498-08800

07340-08100

07498-08900

07340-08200

07498-09000

07498-04700

07498-04700

07498-04700

07498-04600

07498-04600

07498-04600

07498-00500 *

07498-00500 *

07498-00500 *

07347-03700

07498-00700

07610-02000

07610-02000

07610-02100

07610-02100

07612-02000

07612-02000

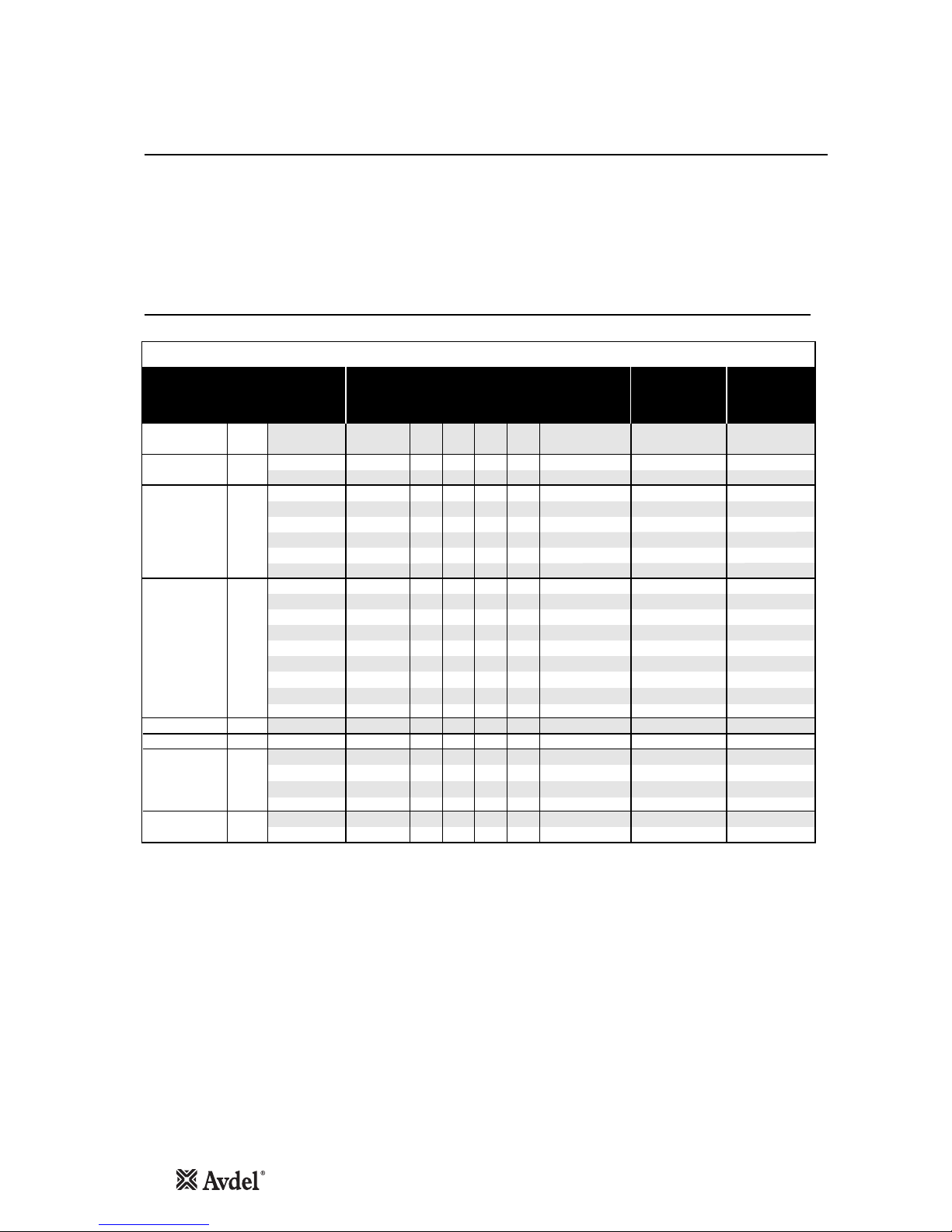

07265 TOOL SELECTION

FASTENER

NOSE (see drawing above for A & B)

MATERIAL/

DETAIL

Ø COMPLETE

TOOL PART Nº

NOSE ASSY

PART Nº

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

07265-02900

07265-02900

07265-02900

07265-02900

-

-

ADAPTOR

PART Nº

NAME &

HEAD

Standard

Standard

Standard

Standard

Extended

Standard

Extended

Standard

Extended

Standard

Standard

Standard

Standard

Standard

Standard

Extended *

Extended *

Extended *

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

.13

.16

.156

.22

.285

.22

.285

.22

.285

.16

.16

.16

.156

.156

.156

.156

.156

.156

.13

.16

.14

.14

.14

.14

.14

.14

A

(in)

2.4

2.4

3.6

3.9

3.9

3.9

3.9

3.9

3.9

2.4

2.4

2.4

2.4

2.4

2.4

3.9

3.9

3.9

2.4

7.4

2.0

2.0

2.1

2.1

2.4

2.4

B

(in)

3.3

4.1

4.0

5.6

7.2

5.6

7.2

5.6

7.2

4.1

4.1

4.1

4.0

4.0

4.0

4.0

4.0

4.0

3.3

4.1

3.6

3.6

3.6

3.6

3.6

3.6

A

(mm)

61

61

99

99

99

99

99

99

99

61

61

61

61

61

61

99

99

99

61

188

51

51

53

53

61

61

B

(mm)

NOSE TIP

TYPE

Intent of Use

Tool Selection

7

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and

automatic filtering systems on the main air supply. These should be fitted within 3 metres of the tool (see diagram below) to ensure

maximum tool life and minimum tool maintenance.

Air supply hoses should have a minimum working effective pressure rating of 150% of the maximum pressure produced in the system or

10 bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and should be armoured where

operating conditions may result in hoses being damaged. All air hoses MUST have a minimum bore diameter of 6.4 millimetres or

1

/4 inch.

Read daily servicing details page 12.

8

6

4

2

0

10

1

2

14

16

TAKE OFF POINT

FROM MAIN SUPPLY

STOP COCK

(USED DURING MAINTENANCE

OF FILTER/REGULATOR

OR LUBRICATION UNITS)

MAIN SUPPLY

DRAIN POINT

PRESSURE REGULATOR

AND FILTER

(DRAIN DAILY)

LUBRICATOR

3

07265

Putting into Service

Air Supply

Operating Procedure

OPTION 2

• Ensure that the correct nose equipment is fitted.

• Connect the tool to the air supply.

• Insert the fastener stem into the nose of the tool.

• Insert the tool with the fastener squarely into the prepared hole

of the application.

• Fully operate the trigger. The tool cycle will ensure the fastener

is placed.

• Check that stems are projected into the stem catcher unit. If

not refer to the Vacuum Stem Extraction Valve paragraph on

page 14 in the Maintenance section.

OPTION 1

• Ensure that the correct nose equipment is fitted.

• Connect the tool to the air supply.

• Insert the fastener body squarely into the prepared hole of the

application.

• Apply the tool to the protuding fastener stem.

• Fully operate the trigger. The tool cycle will ensure the fastener

is placed.

• Check that stems are projected into the stem catcher unit. If

not refer to the Vacuum Stem Extraction Switch paragraph on

page 14 in the Maintenance section.

8

1

2

3

4

5

5

7

8

6

9

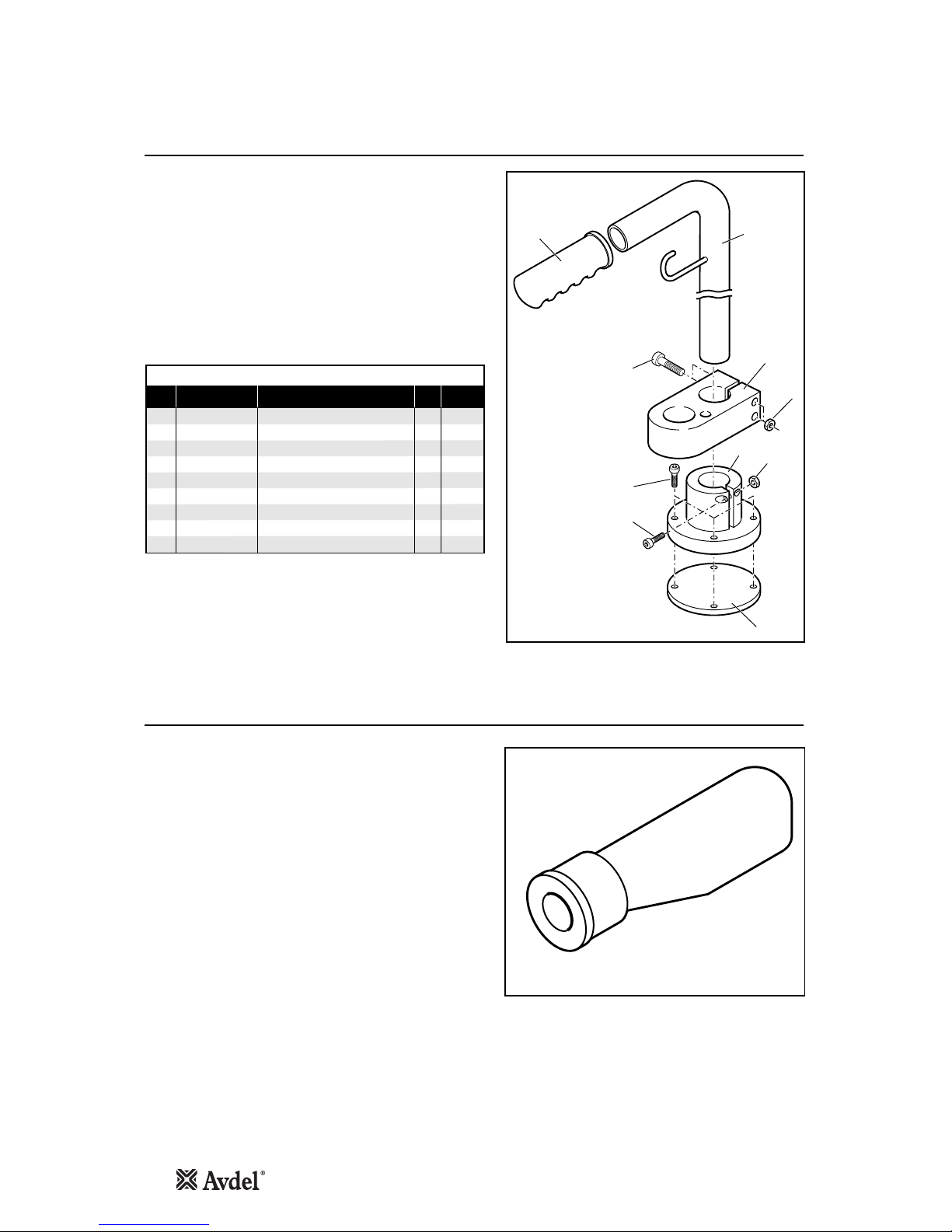

Handling and Holster Kit

Accessories

07265-09500 PARTS LIST

ITEM PART Nº DESCRIPTION QTY SPARES

1 07265-09501 RUBBER HANDLE 1 2 07265-09502 TUBE WITH HOOK 1 3 07265-09504 M5 BOLTS 2 4 07265-09503 HOLSTER 1 5 07265-09505 M5 NUTS 3 6 07265-09508 BASE 1 7 07265-09507 M5 BOLT 4 8 07265-09506 M5 BOLT 1 9 07265-09509 PLATE 1 -

This kit enables an easier handling of the cabinet around the

workplace and allows the tool pistol to be stored in a convenient

position.

Pin Tail Deflector

Pin Tail Deflector Part No 07220-00215

Item numbers in bold refer to the general assembly and parts list

on pages 16 and 17.

• To replace the stem catcher with a pin tail deflector remove stem

catcher end cap 38 and silencer 39.

• Unscrew screws 36 and remove stem catcher assembly together

with end cover 40.

• Unscrew screws 15 and remove adaptor 14.

• Push pin tail deflector onto the boss on stop cover 13.

9

Quick Connect Kit

1

23

4

1

5

6

*14

*157 *16

8

9

10

11

9

13

12

2

6

5

Accessories

1 07265-03206 NUT 4 -

2 07265-03269 CONNECTION 4 -

3 07265-03295 AIR HOSE EXTENSION 2 -

4 07265-09296 OIL HOSE EXTENSION 1 -

5 07265-03204 WASHER 4 -

6 07265-03205 SCREW 4 -

7 07265-03297 TRAY 1 -

8 07265-03258 NIPPLE1-

9 07265-03259 WASHER 2 -

10 07265-02056 QUICK FITTING NIPPLE1-

11 07265-02055 QUICK FITTING COUPLER1 -

12 07265-03272 WASHER 2 -

13 07265-03221 CONNECTOR 2 -

*14 07265-03290 RUBBER RING 1 -

*15 07265-03291 SPACER WASHER 1 -

*16 07265-03292 CLAMP 1 -

ITEM PART N… DESCRIPTION QTY SPARES

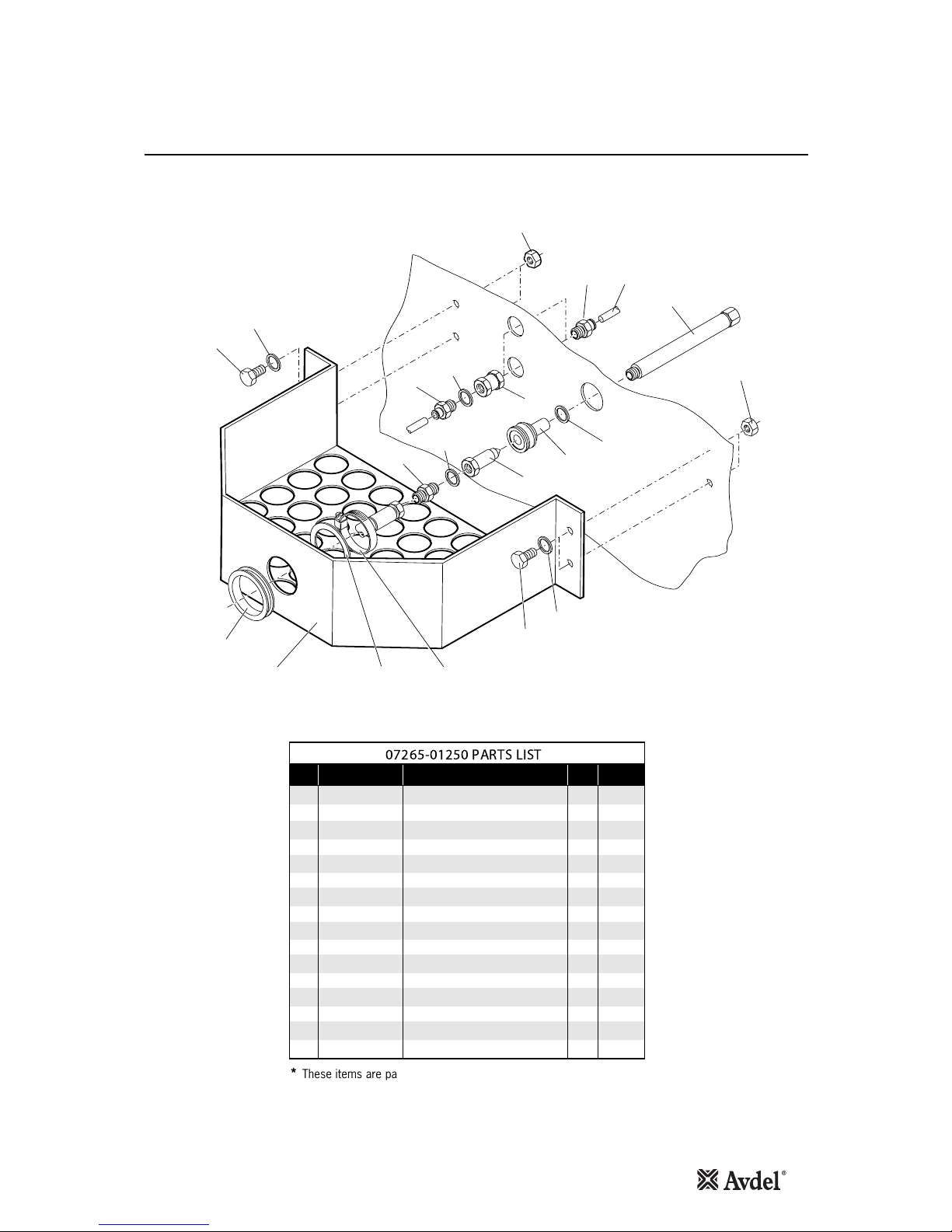

07265-01250 PARTS LIST

* These items are part of the Base Tool and are not part of the Quick

Connect Kit

This kit enables rapid connection of the handle and hose to the cabinet.

Loading...

Loading...