Page 1

Installation — Chassis

Avaya Virtual Services Platform 9000

NN46250-304, 02.02

October 2011

3.1

Page 2

©

2011 Avaya Inc.

All Rights Reserved.

Notice

While reasonable efforts have been made to ensure that the

information in this document is complete and accurate at the time of

printing, Avaya assumes no liability for any errors. Avaya reserves the

right to make changes and corrections to the information in this

document without the obligation to notify any person or organization of

such changes.

Documentation disclaimer

“Documentation” means information published by Avaya in varying

mediums which may include product information, operating instructions

and performance specifications that Avaya generally makes available

to users of its products. Documentation does not include marketing

materials. Avaya shall not be responsible for any modifications,

additions, or deletions to the original published version of

documentation unless such modifications, additions, or deletions were

performed by Avaya. End User agrees to indemnify and hold harmless

Avaya, Avaya's agents, servants and employees against all claims,

lawsuits, demands and judgments arising out of, or in connection with,

subsequent modifications, additions or deletions to this documentation,

to the extent made by End User.

Link disclaimer

Avaya is not responsible for the contents or reliability of any linked Web

sites referenced within this site or documentation provided by Avaya.

Avaya is not responsible for the accuracy of any information, statement

or content provided on these sites and does not necessarily endorse

the products, services, or information described or offered within them.

Avaya does not guarantee that these links will work all the time and has

no control over the availability of the linked pages.

Warranty

Avaya provides a limited warranty on its Hardware and Software

(“Product(s)”). Refer to your sales agreement to establish the terms of

the limited warranty. In addition, Avaya’s standard warranty language,

as well as information regarding support for this Product while under

warranty is available to Avaya customers and other parties through the

Avaya Support Web site:

you acquired the Product(s) from an authorized Avaya reseller outside

of the United States and Canada, the warranty is provided to you by

said Avaya reseller and not by Avaya.

Licenses

THE SOFTWARE LICENSE TERMS AVAILABLE ON THE AVAYA

WEBSITE,

APPLICABLE TO ANYONE WHO DOWNLOADS, USES AND/OR

INSTALLS AVAYA SOFTWARE, PURCHASED FROM AVAYA INC.,

ANY AVAYA AFFILIATE, OR AN AUTHORIZED AVAYA RESELLER

(AS APPLICABLE) UNDER A COMMERCIAL AGREEMENT WITH

AVAYA OR AN AUTHORIZED AVAYA RESELLER. UNLESS

OTHERWISE AGREED TO BY AVAYA IN WRITING, AVAYA DOES

NOT EXTEND THIS LICENSE IF THE SOFTWARE WAS OBTAINED

FROM ANYONE OTHER THAN A V A Y A, AN A V A Y A AFFILIA TE OR AN

AVAYA AUTHORIZED RESELLER; AVAYA RESERVES THE RIGHT

TO TAKE LEGAL ACTION AGAINST YOU AND ANYONE ELSE

USING OR SELLING THE SOFTWARE WITHOUT A LICENSE. BY

INSTALLING, DOWNLOADING OR USING THE SOFTWARE, OR

AUTHORIZING OTHERS TO DO SO, YOU, ON BEHALF OF

YOURSELF AND THE ENTITY FOR WHOM YOU ARE INSTALLING,

DOWNLOADING OR USING THE SOFTWARE (HEREINAFTER

REFERRED TO INTERCHANGEABL Y AS “YOU” AND “END USER”),

AGREE TO THESE TERMS AND CONDITIONS AND CREATE A

BINDING CONTRACT BETWEEN YOU AND AVAYA INC. OR THE

APPLICABLE AVAYA AFFILIATE (“AVAYA”).

HTTP://SUPPORT.AVAYA.COM/LICENSEINFO/ ARE

http://support.avaya.com. Please note that if

Copyright

Except where expressly stated otherwise, no use should be made of

materials on this site, the Documentation, Software, or Hardware

provided by Avaya. All content on this site, the documentation and the

Product provided by Avaya including the selection, arrangement and

design of the content is owned either by Avaya or its licensors and is

protected by copyright and other intellectual property laws including the

sui generis rights relating to the protection of databases. You may not

modify, copy, reproduce, republish, upload, post, transmit or distribute

in any way any content, in whole or in part, including any code and

software unless expressly authorized by Avaya. Unauthorized

reproduction, transmission, dissemination, storage, and or use without

the express written consent of Avaya can be a criminal, as well as a

civil offense under the applicable law.

Third-party components

Certain software programs or portions thereof included in the Product

may contain software distributed under third party agreements (“Third

Party Components”), which may contain terms that expand or limit

rights to use certain portions of the Product (“Third Party Terms”).

Information regarding distributed Linux OS source code (for those

Products that have distributed the Linux OS source code), and

identifying the copyright holders of the Third Party Components and the

Third Party Terms that apply to them is available on the A vaya Support

Web site:

Trademarks

The trademarks, logos and service marks (“Marks”) displayed in this

site, the Documentation and Product(s) provided by Avaya are the

registered or unregistered Marks of Avaya, its affiliates, or other third

parties. Users are not permitted to use such Marks without prior written

consent from Avaya or such third party which may own the Mark.

Nothing contained in this site, the Documentation and Product(s)

should be construed as granting, by implication, estoppel, or otherwise,

any license or right in and to the Marks without the express written

permission of Avaya or the applicable third party.

Avaya is a registered trademark of Avaya Inc.

All non-Avaya trademarks are the property of their respective owners,

and “Linux” is a registered trademark of Linus Torvalds.

Downloading Documentation

For the most current versions of Documentation, see the Avaya

Support Web site:

Contact Avaya Support

Avaya provides a telephone number for you to use to report problems

or to ask questions about your Product. The support telephone number

is 1-800-242-2121 in the United States. For additional support

telephone numbers, see the Avaya W eb site:

http://support.avaya.com/Copyright.

http://support.avaya.com.

http://support.avaya.com.

2 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 3

Contents

Chapter 1: New in this release...........................................................................................

Chapter 2: Introduction......................................................................................................

Chapter 3: 9012 chassis installation fundamentals.........................................................

Virtual Services Platform 9000 9012 chassis............................................................................................

Power supplies..........................................................................................................................................

Cooling modules.......................................................................................................................................

Switch Fabric module................................................................................................................................

Control Processor module.........................................................................................................................

Site requirements......................................................................................................................................

Hardware requirements.............................................................................................................................

Successful installation verification.............................................................................................................

Chassis installation time requirements......................................................................................................

Chapter 4: 9012 chassis installation.................................................................................

Unpack the installation kit.........................................................................................................................

Install the installation shelf........................................................................................................................

Reduce the chassis weight.......................................................................................................................

Lift the chassis..........................................................................................................................................

Secure the chassis....................................................................................................................................

Assemble and install cable management brackets...................................................................................

Grounding the chassis..............................................................................................................................

Chapter 5: Chassis operations..........................................................................................

Determining the minimum number of AC power supplies.........................................................................

Powering up the system............................................................................................................................

Resetting the Avaya Virtual Services Platform 9000.................................................................................

Chapter 6: Part numbers....................................................................................................

Chapter 7: Technical specifications..................................................................................

Chassis weight..........................................................................................................................................

AC power supply.......................................................................................................................................

Component input power............................................................................................................................

Rack mount...............................................................................................................................................

Power supply selection.............................................................................................................................

Virtual Services Platform 9000 chassis specifications..............................................................................

Chapter 8: Regulatory Information and Safety Precautions...........................................

International Regulatory Statements of Conformity..................................................................................

National Electromagnetic Compliance (EMC) Statements of Compliance...............................................

National Safety Statements of Compliance..............................................................................................

Safety Messages.......................................................................................................................................

Chapter 9: Translations of safety messages....................................................................

Chapter 10: Customer service...........................................................................................

Getting technical documentation...............................................................................................................

Getting product training.............................................................................................................................

Getting help from a distributor or reseller..................................................................................................

Getting technical support from the Avaya Web site..................................................................................

Index.....................................................................................................................................

5

7

9

9

11

13

13

14

14

15

18

18

19

21

22

24

26

27

28

30

35

35

36

37

39

41

41

41

42

43

43

44

47

47

47

49

50

55

59

59

59

59

60

61

Installation — Chassis October 2011 3

Page 4

4 Installation — Chassis October 2011

Page 5

Chapter 1: New in this release

The following sections detail what's new in Avaya Virtual Services Platform 9000 Installation—Chassis

(NN46250–304) for release 3.1.

• Features on page 5

• Other changes on page 5

Features

There are no feature changes.

Other changes

See the following sections for information about changes that are not feature-related.

Switch Fabric modules

With Release 3.1, you must install a minimum of three Switch Fabric (SF) modules in the

chassis. For more information about SF module requirements, see Switch Fabric module on

page 13.

Compact Flash memory card

You must install the Compact Flash memory card in the CP module before you power on the

chassis. For more information about Compact Flash memory card requirements, see

Processor module on page 14.

The part number for the 2GB Compact Flash memory card is added to

page 39.

Hardware requirements on page 15 is updated. A Compact Flash memory card is not part

of the chassis shipping accessories.

Part numbers on

Control

Installation — Chassis October 2011 5

Page 6

New in this release

6 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 7

Chapter 2: Introduction

The Avaya Virtual Services Platform 9000 chassis provides the physical framework for the Avaya Virtual

Services Platform 9000 modules.

This document provides the instructions to install the A vaya Virtual Services Platform 9000 chassis in an

equipment rack and describes how to power on the A vaya Virtual Services Platform 9000. This document

includes technical specifications for the chassis.

Before you install the Avaya Virtual Services Platform 9000 chassis, ensure that you install all network

wiring on the premises by using standard cable-system practices.

9012 chassis installation fundamentals on page 9

•

9012 chassis installation on page 19

•

• Chassis operations on page 35

• Part numbers on page 39

Technical specifications on page 41

•

• 9012 chassis installation fundamentals on page 9

Translations of safety messages on page 55

•

Installation — Chassis October 2011 7

Page 8

Introduction

8 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 9

Chapter 3: 9012 chassis installation

fundamentals

The A vaya Virtual Services Platform 9000 chassis consists of a sheet metal enclosure, a midplane, cooling

modules, and power supplies. The number of power supplies needed depends on the specific hardware

configuration and redundancy needs.

Virtual Services Platform 9000 9012 chassis on page 9

•

• Power supplies on page 11

• Cooling modules on page 13

Switch Fabric module on page 13

•

• Control Processor module on page 14

Site requirements on page 14

•

• Hardware requirements on page 15

• Successful installation verification on page 18

Chassis installation time requirements on page 18

•

Virtual Services Platform 9000 9012 chassis

The front of the Virtual Services Platform 9000 chassis has ten slots for interface modules and

two slots for Control Processor (CP) modules. Slots are numbered from top to bottom. The

front of the Virtual Services Platform 9000 chassis also has two bays for cooling modules and

six bays for power supplies. The following figure shows the front view of the chassis.

Installation — Chassis October 2011 9

Page 10

9012 chassis installation fundamentals

Figure 1: Virtual Services Platform 9000 chassis front view

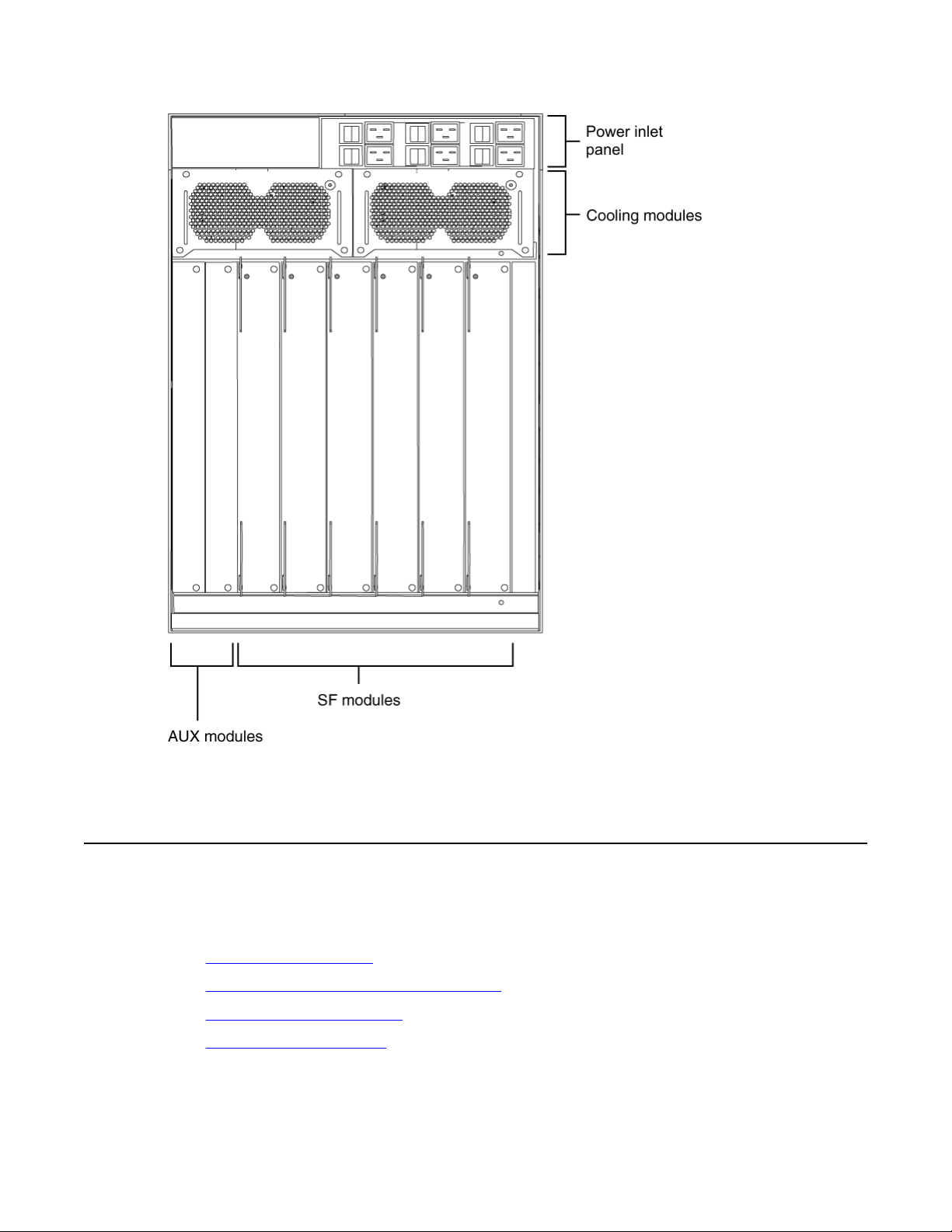

In the rear, the chassis has six slots for Switch Fabric (SF) modules and two auxiliary slots for

future use. Rear slots are numbered from right to left. The rear also has two bays for cooling

modules. There are six separate IEC 60320-C20 AC power inlets and six power switches which

connect the main AC power to their corresponding power supply bays. The following figure

shows the rear view of the chassis. The ground bonding location is located in the bottom right

part of the chassis.

10 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 11

Power supplies

Figure 2: Virtual Services Platform 9000 chassis rear view

Power supplies

This section describes the 9006 AC power supply, the power inlets and how to plan for feed

and power supply redundancy.

9006AC power supply on page 12

•

• Power supply and power inlet locations on page 12

• Power supply redundancy on page 12

Power feed redundancy on page 13

•

Installation — Chassis October 2011 11

Page 12

9012 chassis installation fundamentals

9006AC power supply

The Avaya Virtual Services Platform 9000 chassis has six bays for AC power supply

installation. Install the power supplies in the front of the chassis and plug the power plugs in

the corresponding power inlets at the back of the chassis.

To configure a Avaya Virtual Services Platform 9000 system, consider the total power

consumption to ensure proper system performance. The total input power consumption of the

components (modules and cooling modules) must not exceed the output power rating of the

power supply. For more information about the power consumption of each module, see

Component input power on page 42.

When the A vaya V irtual Services Platform 9000 operates in a redundant power configuration,

you can upgrade or replace power supplies while the chassis remains in operation.

For more information about power supply installation and electrical specifications, see Avaya

Virtual Services Platform 9000 Installation — AC Power Supply, NN46250-303.

Power supply and power inlet locations

In the front of the chassis, the power supply bays are numbered from left to right, so 1, 2, and

3 on the first row, and 4, 5, and 6 on the second row.

The power inlets in the back of chassis are numbered from left to right, so 3, 2, and 1 on the

first row, and 6, 5, and 4 on the second row (as viewed from the back).

For more information about grounding the Virtual Services Platform 9000 and related

precautions, see

Grounding the chassis on page 30.

Power supply redundancy

This section uses "n" to represent the number of power supplies required to operate the power

system without redundancy, and "m" to represent the number of redundant power supplies

required to improve the system availability. You can configure the Virtual Services Platform

9000 for n + n redundancy by means of distributing an "A" power feed to the "A" power shelf

(which comprises of AC power supplies 1, 2, and 3), and a "B" power feed to the "B" power

shelf (which comprises of AC power supplies 4, 5, and 6). Apply this power configuration

protection against simultaneous power supply and individual power feed failure. Use n + m

redundancy to ensure internal redundancy in the event of a power supply failure. Install an

additional power supply (additional to what you require to power your hardware configuration)

to provide n + m redundancy. If two separate power feeds are not available at the site power

distribution, you can only configure the system for n + m redundancy.

Use n + n redundancy to ensure redundancy in the event that an external failure occurs (for

example, an entire power feed within the building fails). To ensure n + n redundancy, you must

install power supplies to provide twice the power requirements of your hardware

configuration.

Important:

The system reserves the following power requirements:

• 80 Watts (W) each for the primary and secondary Control Processor (CP) modules

• 70 W each for the Switch Fabric (SF) modules located in slots 1 and 4

12 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 13

• 150 W each for the two IO fan trays

• 65 W each for the two SF fan trays

Cooling modules

Refer to

Component input power on page 42 for information on power consumption.

Power feed redundancy

Avaya recommends that you use two separate power feeds to plug the AC power supplies.

The power supplies in the 9012 chassis are divided in two shelves. The top shelf (shelf "A")

consists of power supplies 1, 2, and 3, while the bottom shelf (shelf "B") consists of power

supplies 4, 5, and 6. If you use n + n redundancy and plug the power supplies from the top

shelf in power feed "A", and the power supplies from the bottom shelf in power feed "B", this

gives you power feed redundancy. Each shelf can provide 3600 W or 6000 W, depending if

you use 100-120 V AC or 200-240 V AC. Ensure that each power supply connects to a

dedicated breaker.

Cooling modules

The Avaya Virtual Services Platform 9000 chassis uses four cooling modules. Two cooling

modules at the front of the chassis cool the CP and interface modules. Two cooling modules

at the back of the chassis cool the SF modules.

You install the cooling modules for the interface and CP modules at the front of the chassis.

The cooling modules plug into the midplane. The cooling air flows from left to right, as viewed

from the front. A green LED indicates correct fan operation.

You install the cooling modules for the SF modules at the back of the chassis. The cooling air

flows from front to back to cool the SF and auxiliary modules.

See Avaya Virtual Services Platform 9000 Installation — Cooling Modules, NN46250-302 for

information about installing cooling modules.

Switch Fabric module

With Release 3.1, you must install a minimum of three SF modules in the chassis. Avaya

recommends that you install a minimum of four SF modules for redundancy. You must install

an SF module in slots SF1 and SF4; install a third SF module in one of the remaining slots.

Each SF module connects to the ten different interface module slots and the two CP module

slots simultaneously. You can install a maximum of six SF modules in each chassis in a 5 + 1

redundancy configuration.

The SF module slot numbers increment from right to left when you view the chassis from the

rear. The slot location determines the module function. Slots 1 and 4 provide the arbitration

and scheduling for traffic (and therefore, bandwidth management) from the interface modules

Installation — Chassis October 2011 13

Page 14

9012 chassis installation fundamentals

and provide redundancy when both slots are populated. The other slots provide additional

bandwidth.

Important:

Avaya recommends that you install SF modules in both Slot 1 and Slot 4 (to provide

redundancy). Y ou must have a functioning SF module in at least one of those slots for proper

operation of the interface modules.

Bandwidth is dependent on your hardware configuration.

Control Processor module

The 9080CP module performs the following tasks:

• runs all high level protocols, for example Border Gateway Protocol (BGP) and Open

Shortest Path First (OSPF)

• distributes the routing update

• manages and configures the interface and SF modules

• maintains and monitors the health of the chassis

• displays the status of the modules installed at the back of the chassis using LEDs

Important:

Y ou need to ensure that the external Compact Flash card is installed in the CP module before

you power on the chassis or enable the CP module.

See Avaya Virtual Services Platform 9000 Installation — Modules, NN46250-301 for

information about installing CP modules.

Site requirements

Ensure that the installation site meets the space requirements described in this section. For

more information about environmental and electrical requirements, see Technical

specifications on page 41.

The installation site must provide sufficient free space around the chassis to ensure proper

ventilation and service access.

You can install up to three Avaya Virtual Services Platform 9000 chassis in a single rack.

Although there are no space requirement between units, leave enough room between units to

remove and replace modules.

14 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 15

Hardware requirements

Important:

Chassis units should be installed from the bottom up to ensure racks do not become top

heavy and fall over.

Plan ahead to have three people present to lift the chassis. The chassis weighs in excess of

160 lb (73 kg) and requires a minimum of three people to lift. A mechanical lift should always

be used when one is available.

Use the following guidelines to plan front and rear access:

• For proper ventilation, Avaya recommends 36 inches (in.) (91 centimeters [cm]) of free

space in both the front and the back of the machine, and also 6 in. (15.2 cm) on each

side.

• Air inlet temperature to each chassis must be within the specified range.

Important:

To ensure efficient cooling, both the air intake (left side of the chassis) and air exhaust (right

side of the chassis) require a minimum of 6 in. (152.4 mm) of distance from any adjacent

equipment which would either obstruct air flow or provide preheated air to the intake side.

Each power supply must operate from a dedicated branch circuit. For n + n redundancy, you

must connect half the branch circuits on one power feed, and the other half of the branch

circuits on a separate power feed. On top of power supply redundancy , this also provides power

feed redundancy.

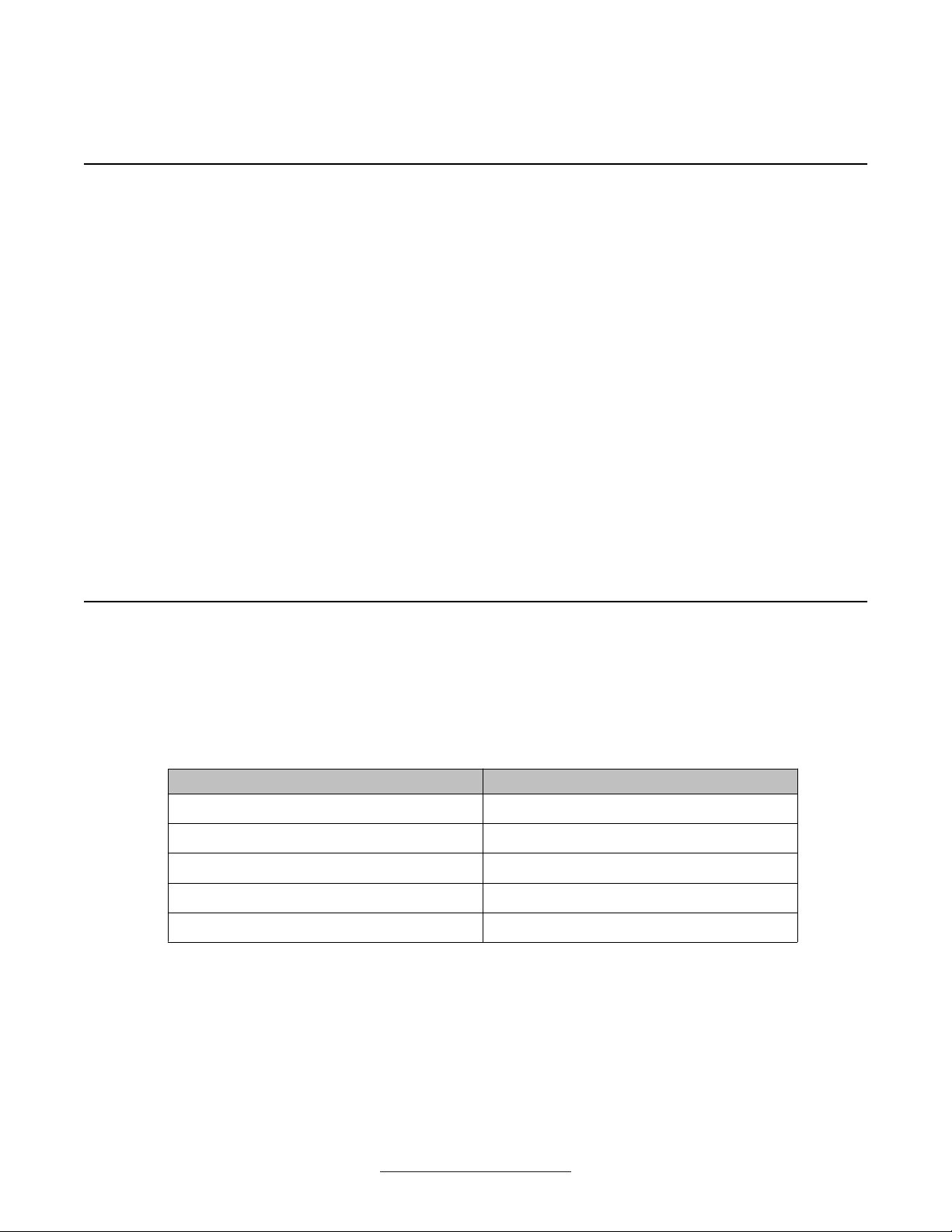

Hardware requirements

This section includes information about the hardware shipped with the A vaya V irtual Services

Platform 9000 chassis.

Shipped Assembly 9012 12 Slot Chassis hardware

In addition to the Avaya Virtual Services Platform 9000 chassis, your shipping container

contains several hardware accessories. Verify that the items in the shipping container match

those on the shipment packing list.

Use the following table as a checklist when you verify the contents of the shipping container.

Part numbers on page 39 for information about ordering replacement parts.

See

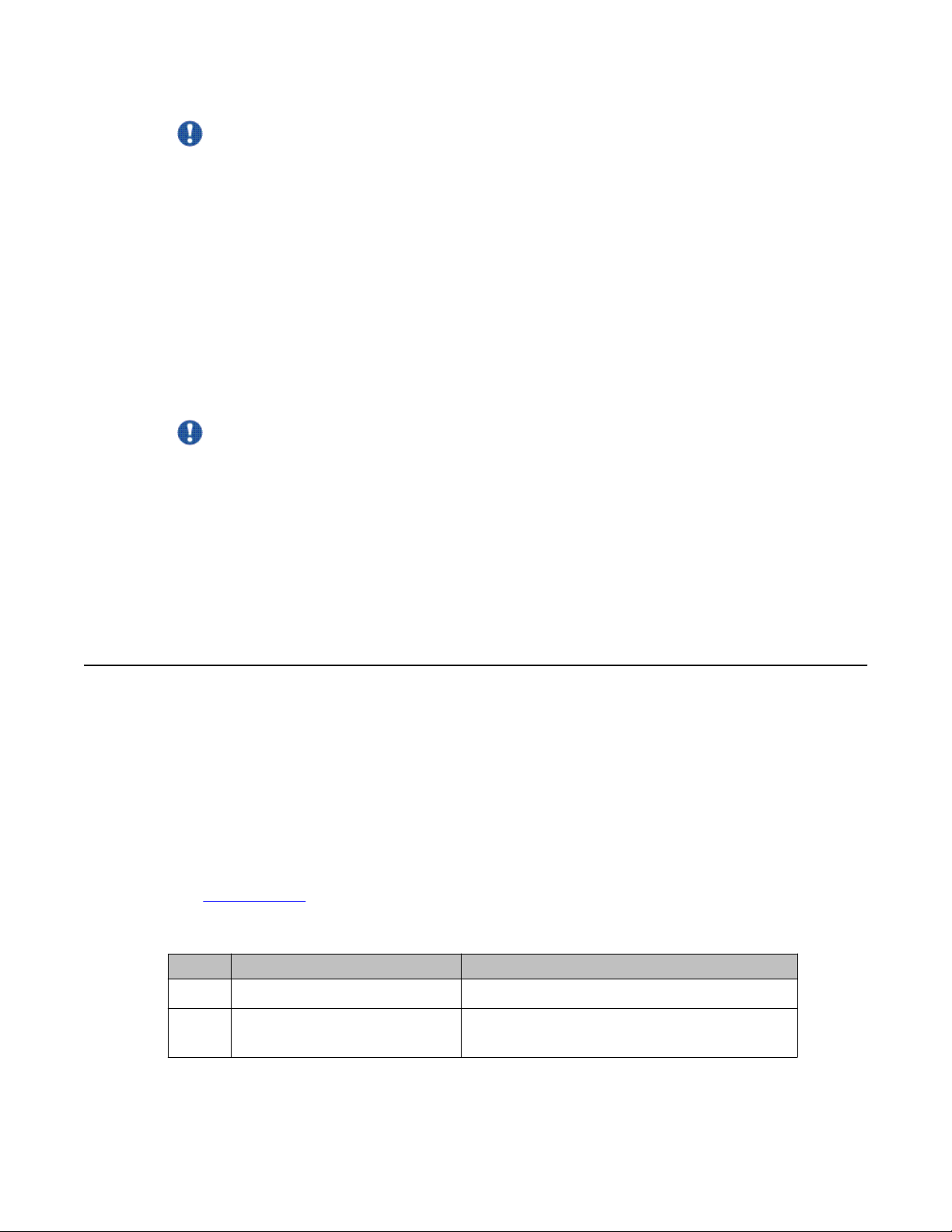

Table 1: 9012 chassis shipping accessories

Check

Accessory Usage

9012 chassis

Ten interface and Control

Processor (CP) filler panels

Installation — Chassis October 2011 15

Filler panels must be installed in unused slots.

Page 16

9012 chassis installation fundamentals

Check Accessory Usage

Four Switch Fabric (SF) filler

Filler panels must be installed in unused slots.

panels

Two Auxiliary card filler panels Filler panels must be installed in unused slots.

Regulatory label

Two SF fan trays

Two IO fan trays

One DB9 to DB9 connector

One accessory kit

One cable manager assembly

One generic label accessory kit

Screws and hardware: The hardware required to mount the chassis in

a rack depends on your rack type.

12 Phillips-head screws

12 clip nuts

4 Phillips-head screws

4 hex nuts

Mount the chassis to a rack rail.

Use the clip nuts, if necessary.

Mount the installation shelf to a rack rail.

Mount the installation shelf to a rack rail.

4 pan-head screws Install the cable management bracket.

Installation shelf Mount the Virtual Services Platform 9000

chassis in an equipment rack.

One left front cable

Manage network interface cables.

management bracket

Grounding kit hardware Connects the chassis to the ground of the

rack.

The following figure illustrates the accessories in the chassis shipping container.

16 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 17

Hardware requirements

Figure 3: Accessories of the chassis shipping container

Other equipment

You will require items not included in the Virtual Services Platform 9000 chassis accessory

package. The following sections describe these items. Before you install the Virtual Services

Platform 9000 hardware, ensure that you obtain all the cables, tools, and other equipment you

need.

To configure startup options and to monitor the results of startup diagnostics, you can attach

a PC, laptop, VT100 console or equivalent, such as a PC terminal emulator.

The hardware required to mount the Avaya Virtual Services Platform 9000 chassis in an

equipment rack depends on your equipment rack type.

You need a Phillips screwdriver to install the Virtual Services Platform 9000 chassis in a

standard rail-type equipment rack if using Avaya-supplied screws.

Install the device in standard EIA-310D 19-inch (in.) racks and ETSI 600-millimeter (mm) racks.

The chassis fits a standard 19-in. rack using the mounting brackets that ship with the unit. To

install the chassis in an ETSI 600-mm rack, you must provide mounting brackets to adapt the

chassis to the rack.

If the rack does not use threaded rail holes, you must use the supplied clip nuts with the clip

nut screws.

Avaya does not include the cables required for your network configuration in the Virtual

Services Platform 9000 chassis accessory package.

Installation — Chassis October 2011 17

Page 18

9012 chassis installation fundamentals

Successful installation verification

In a normal power-up sequence, the LEDs light as follows:

• After you apply power to the switch, the corresponding power supply AC power LEDs and

cooling module LED lights, and the Online LED for each interface module lights amber.

• Each interface module initiates a self-test during which the port and module LEDs display

various patterns to indicate the progress of the self-test.

• Upon successful completion of the self-test (within 5 to 15 minutes after you apply power,

depending on the module type), the interface module Online LED transitions from amber

to green.

If the LEDs on the modules light in this sequence, your installation is successful. Contact your

network administrator to verify that the Avaya Virtual Services Platform 9000 connects to the

network.

If the LEDs do not light in this sequence, contact your local Avaya Technical Solutions

Center.

Chassis installation time requirements

The following table lists the procedures you perform to install the Virtual Services Platform

9000 chassis and the estimated time you need to complete each procedure. Not all procedures

are required for every Virtual Services Platform 9000 system.

Table 2: Installation procedures and time requirements

Procedure Time requirement

Reducing the chassis weight 5 minutes

Attaching the mounting brackets 5 minutes

Mounting the chassis in a two-post rack 12–30 minutes

Installing the cable management brackets 5 minutes

Grounding the chassis 12 minutes

18 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 19

Chapter 4: 9012 chassis installation

About this task

This section describes how to install the Avaya Virtual Services Platform 9000 chassis.

Before you begin the installation of the Avaya Virtual Services Platform 9000 chassis, ensure you have

completed the following actions:

• Inspect all items for shipping damage. If you find items that are damaged, do not install the chassis.

Call the Avaya Technical Solutions Center in your area.

• Verify that the items in the shipping container match those on the shipment packing list.

• Verify that you have all other required hardware.

Warning:

The procedures in this task flow should be performed by trained service personnel only.

The following task flow shows you the sequence of procedures you perform to install the chassis. To link

to any procedure, select the procedure name in the list that follows the taskflow.

Installation — Chassis October 2011 19

Page 20

9012 chassis installation

Figure 4: 9012 chassis installation procedures

20 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 21

• Reduce the chassis weight on page 24

• Secure the chassis on page 27

• Assemble and install cable management brackets on page 28

Grounding the chassis on page 30

•

• Determining the minimum number of AC power supplies on page 35

Unpack the installation kit

Unpack the installation kit and remove the included equipment.

Unpack the installation kit

Note:

Extra screws and bolts are included to support a variety of installation options. You may not

need to use all of the hardware provided.

If the installation kit does not contain the above components, contact Avaya Support.

Installation — Chassis October 2011 21

Page 22

9012 chassis installation

Install the installation shelf

About this task

The installation shelf is an optional item used for installation of the chassis in a rack. You can

mount a chassis on top of another Virtual Services Platform 9000 chassis instead of using the

installation shelf.

Procedure

1. Use the rail guides provided at the top and bottom of the installation poster to identify

where you want the chassis bottom to rest, then mark that location and the location

of the rail guide holes on the front of the rack. Start at the bottom of the rack and

install subsequent chassis above it.

Note:

Folding or trimming off the margins of the poster will help with marking the

rack.

2. If the holes in the vertical supports require clip nuts, insert a clip nut in each of the

14 locations where you marked the holes. Clip nuts are included. If necessary , use

the clip nuts for your specific rack model.

22 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 23

Install the installation shelf

3. Place the installation shelf at the mark on the rack, inside the rails. Hold the

installation shelf in position, and then align the mounting rail with the two holes on

each side of the vertical rack support.

4. Insert a Phillips screw through each installation shelf mounting hole and into the

corresponding hole in the rack.

5. If using hex nuts, add a nut to each screw and tighten using a hex wrench.

6. Tighten each screw with a Phillips screwdriver.

Installation — Chassis October 2011 23

Page 24

9012 chassis installation

Reduce the chassis weight

About this task

Reduce the chassis weight to make the chassis easier to lift and to reduce the risk of personal

injury or equipment damage.

Procedure

1. Remove the 10 I/O filler modules from the front of the chassis.

2. Remove the 2 cooling modules from the front of the chassis.

24 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 25

Reduce the chassis weight

3. Unseat the I/O filler module by loosening the 2 captive screws, grasping the two

handles, and gently pulling the module out and away from the chassis.

4. Remove the cooling modules by pulling the retaining pin that holds it in place while

gently pulling the module’s handle to move it out and away from the chassis.

Installation — Chassis October 2011 25

Page 26

9012 chassis installation

Do not install additional components before mounting the chassis in the rack.

All unused slots should contain filler modules. Ensure filler modules removed to

reduce the chassis weight are reinstalled after chassis installation.

Lift the chassis

About this task

The chassis weighs in excess of 160 lb (73 kg) and requires a minimum of three people to lift.

Always use a mechanical lift when one is available.

Important:

Important:

26 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 27

Secure the chassis

Use the recessed handles at the top and bottom of the chassis sides to lift the chassis. From

the rear: Lift the chassis from the bottom only.

Important:

Reduce the weight of the chassis as much as possible before you lift it. Always use a

mechanical lift when one is available. Ensure you have at least three people to lift the

chassis. Use a third person to support the chassis from behind the rack, as you position the

chassis on the shelf and hold it in place. Take care to lift the chassis from the bottom.

Secure the chassis

About this task

Mount the Avaya Virtual Services Platform 9000 chassis in a standard two-post or four-post

equipment rack.

Procedure

1. Hold the Virtual Services Platform 9000 chassis in position and align the flanged

end of the chassis mounting bracket with the holes on either side of the vertical rack

support.

2. Ensure that the 7 hole pairs on either side of the rack vertical supports match

horizontally.

3. Insert 4 phillips screws through each hole on the mounting bracket in the 7 screw

positions in the flange and rack. If you‘ll be installing the optional I/O cable bracket

Installation — Chassis October 2011 27

Page 28

9012 chassis installation

4. Tighten each screw with a Phillips screwdriver.

then don’t insert screws into the top (1st), middle (4th) and bottom (7th) screw

positions of the left side flange and rack.

Assemble and install cable management brackets

About this task

This procedure is used to install the I/O and power cable brackets. Use these brackets to keep

cable clusters fastened and out of the way but still accessible for maintenance.

Important:

Do not attach any cables until after the bracket installation.

Procedure

1. Attach the three Z brackets to the vertical cable bracket as shown below using 6 of

the screws provided. Nuts are not required since the Z brackets are already

threaded on one side for connection to the I/O cable bracket using screws alone.

28 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 29

Assemble and install cable management brackets

2. Use 3 Phillips screws to fasten the I/O cable management assembly to the top,

middle and bottom screw positions of the left flange and rail.

3. Remove the two upper screws from the power cable receptacle panel on the rear

of the chassis.

4. Position the power cable bracket notches over the chassis positioning studs and

reuse the two screws you removed to fasten the power cable bracket as shown. Do

not attach any cables until after the bracket installation.

Installation — Chassis October 2011 29

Page 30

9012 chassis installation

Grounding the chassis

Before you begin

• Ensure you have a two-hole cable lug that fits over the grounding studs.

• Ensure you have a nut and a locking washer for the grounding stud.

• Ensure you have a 6-AWG green and yellow grounding wire long enough to connect to

the ground point.

• Ensure you have a 6 mm socket or nut driver.

About this task

Avaya recommends that you ground the A vaya V irtual Services Platform 9000 chassis before

you install power supplies or connect power and network cables to the system.

Procedure

1. Crimp the two hole lug onto the ground wire.

2. Attach the chassis ground cable to the grounding studs on the chassis. As shown

in the following figure, the studs are located on the bottom right part of the back of

the chassis.

30 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 31

Grounding the chassis

Job aid

3. Bond the chassis ground cable to the single point ground window.

The following figure shows an example of how to attach the chassis ground cable to the rack

grounding strip.

Installation — Chassis October 2011 31

Page 32

9012 chassis installation

Figure 5: Rack grounding strip example

32 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 33

Grounding the chassis

The following figure shows the ESD ground strap input location on the front of the chassis.

There are also two ESD ground strap input sites on the rear of the chassis.

Installation — Chassis October 2011 33

Page 34

9012 chassis installation

34 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 35

Chapter 5: Chassis operations

About this task

This section describes some of the routine tasks you perform to operate the Avaya Virtual Services

Platform 9000.

Determining the minimum number of AC power supplies on page 35

•

• Powering up the system on page 36

• Resetting the Avaya Virtual Services Platform 9000 on page 37

Determining the minimum number of AC power supplies

Before you begin

For more information about the power requirements for each module, see Component input

power on page 42.

Important:

The system reserves the following power requirements:

• 80 Watts (W) each for the primary and secondary Control Processor (CP) modules

• 70 W each for the Switch Fabric (SF) modules located in slots 1 and 4

• 150 W each for the two IO fan trays

• 65 W each for the two SF fan trays

•

About this task

Determine the minimum number of power supplies required to ensure there is enough power

to operate the installed components. You can install a maximum of six 9006AC power

supplies.

Procedure

1. Add the total input power consumption for all components (modules and cooling

modules assemblies).

2. Refer to the output power rating of the power supply based on the input

connection.

Installation — Chassis October 2011 35

Page 36

Chassis operations

Important:

If either the individual or the combined power requirements for the components

exceed the power supply rating, you need to add at least one additional power

supply to your configuration.

3. Consider your redundant power supply needs.

Powering up the system

Before you begin

• For more information about installing a 9006AC power supply , see Avaya Virtual Services

Platform 9000 Installation — Power Supply, NN46250-303.

• For more information about the power supply LEDs, see Avaya Virtual Services Platform

9000 Installation — Power Supply, NN46250-303.

Caution:

The AC power switches are double pole. The 9006AC power supply incorporates double

pole and neutral fusing.

About this task

Connect the power supplies and power up the system to start up the Avaya Virtual Services

Platform 9000.

Procedure

1. Determine power subsystem operating configuration based on module load

requirements and power redundancy needs.

2. Install the required power supplies in the power shelf bays.

3. Ensure the AC power switches are in the off position.

4. Determine the appropriate power cord based on the power supply operating power

and site requirements.

5. Connect the AC power cords to the AC power inlets and the power outlets.

6. For each power supply, turn on the corresponding power switch to the on

position.

If your chassis contains multiple power supplies, you can turn on the power supplies

simultaneously or one at a time. If you wait too long to turn on the additional power

supplies, one or more of the power supplies could stay or enter current limit based

on the system load condition until you power on a sufficient number of power

supplies to guarantee the system powers on.

36 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 37

Resetting the Avaya Virtual Services Platform 9000

7. Verify the AC power LEDs on each power supply illuminates green, and that the

service and fault LEDs are not illuminated.

8. Verify the cooling module LED on the CP modules illuminate green.

9. Verify that air flows from the cooling modules out through the vents of the chassis,

and that the power supply fans are operational.

The cooling module LED can illuminate red while the fans power to operational

speed.

10. If the power supply AC LEDs remain off indicating loss of AC power, the service or

fault LEDs are illuminated and you cannot feel air flow from the chassis vents, or

from each power supply, turn the power switch to the off position to diagnose the

problem or replace the failed power supply.

If the problem persists, contact the Avaya Technical Solutions Center.

Resetting the Avaya Virtual Services Platform 9000

About this task

Reset the Avaya Virtual Services Platform 9000 to restart the hardware without cycling

power.

Procedure

On the CP module, press Reset.

The following figure shows the location of the recessed Reset button.

Installation — Chassis October 2011 37

Page 38

Chassis operations

38 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 39

Chapter 6: Part numbers

The following table lists the Avaya Virtual Services Platform 9000 part numbers associated with the

hardware.

Products can be ordered with European Union Environmental Directive (EUED) Restriction of Hazardous

Substances (RoHS) (EUED RoHS) compliancy. EUED RoHS compliant products are designated with E5 or -E6 (for example EC1405A01-E6).

Table 3: Part numbers

Part number Item

EC1402001-E6 Shipped Assembly 9012 12 Slot Chassis

EC1405A01-E6 9006AC Power Supply

EC1404007-E6 9080CP CPU Module

EC1404001-E6 9024XL 24 SFP+ Module

EC1404002-E6 9048GB 48 SFP Module

EC1404003-E6 9048GT 48 10/100/1000 Module

EC1411001-E6 9012SC Side Fan Tray

EC1411002-E6 9012FC Fabric Fan Tray

EC1404006-E6 9090SF Switch fabric module

EC1411006-E6 Spare Front Module Filler Panel for 9012 12-Slot Chassis

EC1411007-E6 Spare Switch Fabric Filler Panel for 9012 12-Slot Chassis

EC1411008-E6 Spare Power Supply Filler Panel for 9012 12-Slot Chassis

EC1411009-E6 Spare Auxiliary Module Filler Panel for 9012 12-Slot Chassis

EC1411010-E6 2GB Compact Flash Memory Card for 9080CP Module

Installation — Chassis October 2011 39

Page 40

Part numbers

40 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 41

Chapter 7: Technical specifications

This section details the specifications for the Avaya Virtual Services Platform 9000.

• Chassis weight on page 41

• AC power supply on page 41

Component input power on page 42

•

• Power supply selection on page 43

• Virtual Services Platform 9000 chassis specifications on page 44

Chassis weight

The following table provides the chassis weight with each component.

Table 4: Chassis weight including components and cables

Chassis and components

Chassis and midplane 160 lb (73 kg)

Chassis, midplane, and cooling modules 183 lb (83 kg)

Chassis midplane, cooling modules, and full

length filler modules

AC power supply

This section provides power ratings for the AC power supply.

The following table lists the input power specifications.

Table 5: AC input power specifications

Parameter

Input current 13.3 A (100 V AC) - 11.2 A

288 lb (131 kg)

Specification at input

voltage 100-120 V AC

(120 V AC)

Weight

Specification at input

voltage 200-240 V AC

11.8 A (200 V AC) – 9.9 A

(240 V AC)

Operating frequency range 47–63 Hz 47-63 Hz

Installation — Chassis October 2011 41

Page 42

Technical specifications

Parameter Specification at input

voltage 100-120 V AC

Input volt-ampere (VA) 1445 VA 2325 VA

Efficiency 85% minimum, 90% typical 88% minimum, 93% typical

Input power consumption 1416 W 2277 W

Heat dissipation (thermal

output)

Hold-up time (See note 1.) 25 ms 20 ms

Note 1: Measurementstarts at zero crossing of the AC voltage. Measurement made at

fullload and voltage is allowed to decay to 44 VDC.

724 British Thermal Unit

(BTU)/hour

Specification at input

voltage 200-240 V AC

933 BTU/hour

The following table lists the DC output power specifications.

Table 6: DC output power specifications

Parameter Specification at input voltage

100–120 V AC

Maximum main output power 1200 W 2000 W

Maximum main output current 22 A 37 A

Specification at

input voltage 200–

240 V AC

Auxiliary output voltage / power 5 V DC / 3.75 W 5 V DC / 3.75 W

Output voltage set-point 54 V DC 54 V DC

Mean time between failures (See

note 1.)

Note 1:Per telcordia SR-332, 25 C, full load, method 1, case III

Component input power

The following table provides input power specifications for the Virtual Services Platform 9000

components.

Important:

The system reserves the following power requirements:

• 80 Watts (W) each for the primary and secondary Control Processor (CP) modules

• 70 W each for the Switch Fabric (SF) modules located in slots 1 and 4

• 150 W each for the two IO fan trays

400 000 hours 400 000 hours

42 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 43

• 65 W each for the two SF fan trays

•

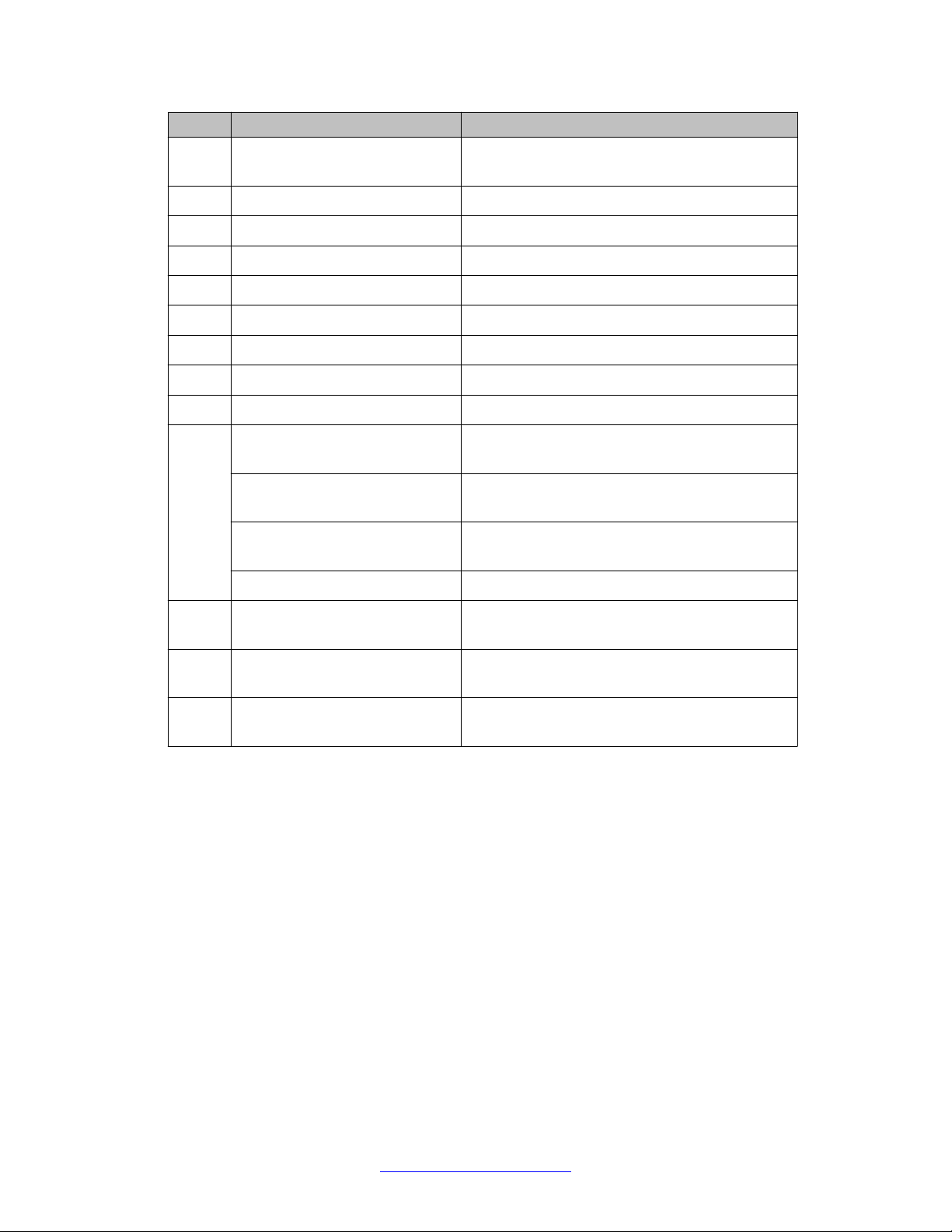

Table 7: Component input power

Component Total input power (watts) Thermal output rating (BTU/

Rack mount

hour)

9080CP Central

Processor Module

9090SF Switch Fabric

Module, slots 1 and 4.

9090SF Switch Fabric

Module, slots 2, 3, 5, and

6.

9012FC Fabric Fan Tray

(Maximum fan speed)

9012SC Side Fan Tray

(Maximum fan speed)

9048GT interface module 350 1194

9048GB interface module 340 1160

9024XL interface module 575 1962

Rack mount

80 273

70 239

50 170

65 222

150 512

Y ou can install a maximum of three Avaya Virtual Services Platform 9000 chassis in a standard

19 in. wide 7 ft. tall rack.

Important:

Chassis units should be installed from the bottom up to ensure racks do not become top

heavy and fall over.

Power supply selection

Power management identifies the available power in the chassis, called the power budget, and

determines if enough power is available to operate the installed components. For more

information about the power management feature and configuration instructions, see Avaya

Virtual Services Platform 9000 Administration, NN46250-600

Installation — Chassis October 2011 43

Page 44

Technical specifications

Virtual Services Platform 9000 chassis specifications

This section provides physical, environmental, and electrical specifications for the Avaya

Virtual Services Platform 9000 chassis and includes the following topics:

Physical specifications on page 44

•

• Network Equipment Building Standard on page 44

Environmental specifications on page 44

•

• Maximum airflow on page 45

International regulatory requirements on page 45

•

Physical specifications

The following physical specifications apply to the Avaya Virtual Services Platform 9000

chassis.

Table 8: 9012 chassis physical specifications

Parameter Specification

Height 24.375 in. (61.91 cm)

Rack units (RU) 14

Width 17.5 in. (44.45 cm)

Depth 32.5 in. (82.55 cm) plus cable

management system

Weight Chassis and midplane 160 lb (73 kg)

Chassis and midplane, and cooling

modules

Chassis and midplane, cooling modules,

and full length filler modules

183 lb (83 kg)

288 lb (131 kg)

Network Equipment Building Standard

The Virtual Services Platform 9000 chassis does not comply with Network Equipment Building

Standard (NEBS) Level 3 as specified in SR3580.

Environmental specifications

The following environmental specifications apply to the Virtual Services Platform 9000

chassis.

44 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 45

Virtual Services Platform 9000 chassis specifications

Table 9: 9012 chassis environmental specifications

Parameter Specification

Operating temperature 0C to 40C (32F to 104F)

Storage temperature – 25C to 70C (– 13F to 158F)

Operating humidity 10% to 90%

Storage humidity 0 to 90%

Operating altitude 0 ft to 10 000 ft

Storage altitude 0 ft to 10 000 ft

Maximum airflow

The maximum airflow specification for the Virtual Services Platform 9000 chassis is 500

linear ft/min for side-to-side airflow in the front of the chassis, and 350 linear ft/min for front-toback airflow for modules installed at the rear of the chassis.

International regulatory requirements

The Virtual Services Platform 9000 chassis conforms to the following international regulatory

requirements:

Electromagnetic emissions on page 45

•

Electromagnetic immunity on page 45

•

• Safety agency certification on page 46

Electromagnetic emissions

The Virtual Services Platform 9000 chassis conforms to the following electromagnetic

emissions standards.

Table 10: 9012 chassis electromagnetic emissions

Parameter

United States FCC CFR47 Part 15, Subpart B, Class A

Canada ICES-003, Issue-4, Class A

Europe EN 55022:2006/ A1:2007 Class A; EN

61000-3-2/A14, EN 300 386 v1.3.3,

EN55024:1998/A1:2001/A2:2003, EN

61000-3-3:1995:A1:2001/A2:2005

Australia/New Zealand AS/NZS CISPR 22:2006, Class A

Japan VCCI-V3/97.04, Class A

Specification

Electromagnetic immunity

The Virtual Services Platform 9000 chassis conforms to the following electromagnetic immunity

standards.

Installation — Chassis October 2011 45

Page 46

Technical specifications

Table 11: 9012 chassis electromagnetic immunity

Global basis for certification CISPR 24:1997

Europe EN 55024:1998

Safety agency certification

The Virtual Services Platform 9000 chassis conforms to the following safety agency

standards.

Table 12: 9012 chassis safety agency certification

Global basis for certification IEC 60950-1 current edition with all CB member

US ULIEC 60950-1

Canada CSA 22.2 No. IEC 60950-1

Parameter Specification

Parameter Specification

deviations

Europe ENIEC 60950-1 (CE Marking)

Australia/New Zealand AS/NZS IEC 60950-1

46 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 47

Chapter 8: Regulatory Information and

Safety Precautions

Read the information in this section to learn about regulatory conformities and compliances.

International Regulatory Statements of Conformity

This is to certify that the Avaya Virtual Services Platform 9000 chassis and components

installed within the chassis were evaluated to the international regulatory standards for

electromagnetic compliance (EMC) and safety and were found to have met the requirements

for the following international standards:

• EMC—Electromagnetic Emissions—CISPR 22, Class A

• EMC—Electromagnetic Immunity—CISPR 24

• Electrical Safety—IEC 60950, with CB member national deviations

Further, the equipment has been certified as compliant with the national standards as detailed

in the following sections.

National Electromagnetic Compliance (EMC) Statements of Compliance

FCC Statement (USA only)

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the Federal Communications Commission (FCC) rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy . If it is not installed and used in accordance with the instruction manual,

it may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case users will be required to

take whatever measures may be necessary to correct the interference at their own expense.

Installation — Chassis October 2011 47

Page 48

Regulatory Information and Safety Precautions

ICES Statement (Canada only)

Canadian Department of Communications Radio Interference Regulations

This digital apparatus (Virtual Services Platform 9000 chassis and installed components) does

not exceed the Class A limits for radio-noise emissions from digital apparatus as set out in the

Radio Interference Regulations of the Canadian Department of Communications.

Règlement sur le brouillage radioélectrique du ministère des Communications

Cet appareil numérique (Virtual Services Platform 9000 chassis) respecte les limites de bruits

radioélectriques visant les appareils numériques de classe A prescrites dans le Règlement sur

le brouillage radioélectrique du ministère des Communications du Canada.

CE Marking Statement (Europe only)

EN 55 022 Statements

This is to certify that the Virtual Services Platform 9000 chassis and components installed

within the chassis are shielded against the generation of radio interference in accordance with

the application of Council Directive 2004/108/EC. Conformity is declared by the application of

EN 55 022 Class A (CISPR 22).

Caution:

This device is a Class A product. Operation of this equipment in a residential area is likely

to cause harmful interference, in which case users are required to take appropriate

measures necessary to correct the interference at their own expense.

EN 55 024 Statement

This is to certify that the Virtual Services Platform 9000 chassis is shielded against the

susceptibility to radio interference in accordance with the application of Council Directive

2004/108/EC. Conformity is declared by the application of EN 55 024 (CISPR 24).

EN 300386 Statement

The Virtual Services Platform 9000 chassis complies with the requirements of EN 300386

V1.3.3 for emissions and for immunity for a Class A device intended for use in either

Telecommunications centre or locations other than telecommunications centres given the

performance criteria as specified by the manufacturer.

EC Declaration of Conformity

This product conforms to the provisions of the R&TTE Directive 1999/5/EC.

European Union and European Free Trade Association (EFTA) Notice

All products labeled with the CE marking comply with R&TTE Directive (1999/5/

EEC) which includes the Electromagnetic Compliance (EMC) Directive

(2004/108/EC) and the Low Voltage Directive (2006/95/EC) issued by the

Commission of the European Community.

48 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 49

National Safety Statements of Compliance

Compliance with these directives implies conformity to the following European Norms (ENs).

The equivalent international standards are listed in parenthesis.

• EN 55022 (CISPR 22)–Electromagnetic Interference

• EN 55024 (IEC 61000-4-2, -3, -4, -5, -6, -8, -11)–Electromagnetic Immunity

• EN 61000-3-2 (IEC 610000-3-2)–Power Line Harmonics

• EN 61000-3-3 (IEC 610000-3-3)–Power Line Flicker

VCCI Statement (Japan/Nippon only)

This is a Class A product based on the standard of the Voluntary Control Council for

Interference (VCCI) for information technology equipment. If this equipment is used in a

domestic environment, radio disturbance may arise. When such trouble occurs, the user may

be required to take corrective actions.

National Safety Statements of Compliance

CE Marking Statement (Europe only)

EN 60 950 Statement

This is to certify that the Virtual Services Platform 9000 chassis and components installed

within the chassis are in compliance with the requirements of EN 60 950 in accordance with

the Low Voltage Directive. Additional national differences for all European Union countries

have been evaluated for compliance. Some components installed within the Virtual Services

Platform 9000 chassis may use a nickel-metal hydride (NiMH) and/or lithium-ion battery. The

NiMH and lithium-ion batteries are long-life batteries, and it is very possible that you will never

need to replace them. However, should you need to replace them, refer to the individual

component manual for directions on replacement and disposal of the battery.

Installation — Chassis October 2011 49

Page 50

Regulatory Information and Safety Precautions

Denan Statement (Japan/Nippon only)

Safety Messages

This section describes the different precautionary notices used in this document. This section

also contains precautionary notices that you must read for safe operation of the A vaya V irtual

Services Platform 9000.

Notices

Notice paragraphs alert you about issues that require your attention. The following sections

describe the types of notices. For a list of safety messages used in this guide and their

translations, see the Translations of safety messages chapter.

Attention Notice

Important:

An attention notice provides important information regarding the installation and operation

of Avaya products.

Caution ESD Notice

Electrostatic alert:

ESD

ESD notices provide information about how to avoid discharge of static electricity and

subsequent damage to Avaya products.

Electrostatic alert:

ESD (décharge électrostatique)

La mention ESD fournit des informations sur les moyens de prévenir une décharge

électrostatique et d'éviter d'endommager les produits Avaya.

50 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 51

Safety Messages

Electrostatic alert:

ACHTUNG ESD

ESD-Hinweise bieten Information dazu, wie man die Entladung von statischer Elektrizität

und Folgeschäden an Avaya-Produkten verhindert.

Electrostatic alert:

PRECAUCIÓN ESD (Descarga electrostática)

El aviso de ESD brinda información acerca de cómo evitar una descarga de electricidad

estática y el daño posterior a los productos Avaya.

Electrostatic alert:

CUIDADO ESD

Os avisos do ESD oferecem informações sobre como evitar descarga de eletricidade

estática e os conseqüentes danos aos produtos da Avaya.

Electrostatic alert:

ATTENZIONE ESD

Le indicazioni ESD forniscono informazioni per evitare scariche di elettricità statica e i danni

correlati per i prodotti Avaya.

Caution Notice

Caution:

Caution notices provide information about how to avoid possible service disruption or

damage to Avaya products.

Caution:

ATTENTION

La mention Attention fournit des informations sur les moyens de prévenir une perturbation

possible du service et d'éviter d'endommager les produits Avaya.

Caution:

ACHTUNG

Achtungshinweise bieten Informationen dazu, wie man mögliche Dienstunterbrechungen

oder Schäden an Avaya-Produkten verhindert.

Caution:

PRECAUCIÓN

Los avisos de Precaución brindan información acerca de cómo evitar posibles

interrupciones del servicio o el daño a los productos Avaya.

Installation — Chassis October 2011 51

Page 52

Regulatory Information and Safety Precautions

Caution:

CUIDADO

Os avisos de cuidado oferecem informações sobre como evitar possíveis interrupções do

serviço ou danos aos produtos da Avaya.

Caution:

ATTENZIONE

Le indicazioni di attenzione forniscono informazioni per evitare possibili interruzioni del

servizio o danni ai prodotti Avaya.

Warning Notice

Warning:

Warning notices provide information about how to avoid personal injury when working with

Avaya products.

Warning:

AVERTISSEMENT

La mention Avertissement fournit des informations sur les moyens de prévenir les risques

de blessure lors de la manipulation de produits Avaya.

Warning:

WARNUNG

Warnhinweise bieten Informationen dazu, wie man Personenschäden bei der Arbeit mit

Avaya-Produkten verhindert.

Warning:

ADVERTENCIA

Los avisos de Advertencia brindan información acerca de cómo prevenir las lesiones a

personas al trabajar con productos Avaya.

Warning:

AVISO

Os avisos oferecem informações sobre como evitar ferimentos ao trabalhar com os produtos

da Avaya.

Warning:

AVVISO

Le indicazioni di avviso forniscono informazioni per evitare danni alle persone durante

l'utilizzo dei prodotti Avaya.

52 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 53

Safety Messages

Danger High Voltage Notice

Voltage:

Danger—High Voltage notices provide information about how to avoid a situation or

condition that can cause serious personal injury or death from high voltage or electric

shock.

Voltage:

La mention Danger—Tension élevée fournit des informations sur les moyens de prévenir

une situation ou une condition qui pourrait entraîner un risque de blessure grave ou mortelle

à la suite d'une tension élevée ou d'un choc électrique.

Voltage:

GEFAHR

Hinweise mit „Vorsicht – Hochspannung“ bieten Informationen dazu, wie man Situationen

oder Umstände verhindert, die zu schweren Personenschäden oder Tod durch

Hochspannung oder Stromschlag führen können.

Voltage:

PELIGRO

Los avisos de Peligro-Alto voltaje brindan información acerca de cómo evitar una situación

o condición que cause graves lesiones a personas o la muerte, a causa de una electrocución

o de una descarga de alto voltaje.

Voltage:

PERIGO

Avisos de Perigo—Alta Tensão oferecem informações sobre como evitar uma situação ou

condição que possa causar graves ferimentos ou morte devido a alta tensão ou choques

elétricos.

Voltage:

PERICOLO

Le indicazioni Pericolo—Alta tensione forniscono informazioni per evitare situazioni o

condizioni che potrebbero causare gravi danni alle persone o il decesso a causa dell'alta

tensione o di scosse elettriche.

Danger Notice

Danger:

Danger notices provide information about how to avoid a situation or condition that can

cause serious personal injury or death.

Installation — Chassis October 2011 53

Page 54

Regulatory Information and Safety Precautions

Danger:

La mention Danger fournit des informations sur les moyens de prévenir une situation ou une

condition qui pourrait entraîner un risque de blessure grave ou mortelle.

Danger:

GEFAHR

Gefahrenhinweise stellen Informationen darüber bereit, wie man Situationen oder

Umständen verhindert, die zu schweren Personenschäden oder Tod führen können.

Danger:

PELIGRO

Los avisos de Peligro brindan información acerca de cómo evitar una situación o condición

que pueda causar lesiones personales graves o la muerte.

Danger:

PERIGO

Avisos de perigo oferecem informações sobre como evitar uma situação ou condição que

possa causar graves ferimentos ou morte.

Danger:

PERICOLO

Le indicazioni di pericolo forniscono informazioni per evitare situazioni o condizioni che

potrebbero causare gravi danni alle persone o il decesso.

54 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 55

Chapter 9: T ranslations of safety messages

This section contains translations of precautionary notices that you must read and follow for safe operation

of the Avaya Virtual Services Platform 9000.

Class A device caution statement

Caution:

This device is a Class A product. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case users are required to take appropriate measures necessary to

correct the interference at their own expense.

Caution:

ATTENTION

Le périphérique est un produit de Classe A. Le fonctionnement de cet équipement dans une zone

résidentielle risque de causer des interférences nuisibles, auquel cas l'utilisateur devra y remédier à

ses propres frais.

Caution:

ACHTUNG

Dies ist ein Gerät der Klasse A. Bei Einsatz des Geräts in W ohngebieten kann es Störungen des Radiound Fernsehempfangs verursachen. In diesem Fall muss der Benutzer alle notwendigen Maßnahmen

ergreifen, die möglicherweise nötig sind, um die Störungen auf eigene Rechnung zu beheben.

Caution:

PRECAUCIÓN

Este es un producto clase A. El uso de este equipo en áreas residenciales puede causar interferencias

nocivas, en cuyo caso, se requerirá que los usuarios tomen cualquier medida necesaria para corregir

la interferencia por cuenta propia.

Caution:

CUIDADO

Este dispositivo é um produto Classe A. Operar este equipamento em uma área residencial

provavelmente causará interferência prejudicial; neste caso, espera-se que os usuários tomem as

medidas necessárias para corrigir a interferência por sua própria conta.

Caution:

ATTENZIONE

Installation — Chassis October 2011 55

Page 56

Translations of safety messages

Questo dispositivo è un prodotto di Classe A. Il funzionamento di questo apparecchio in aree

residenziali potrebbe causare interferenze dannose, nel cui caso agli utenti verrà richiesto di adottare

tutte le misure necessarie per porre rimedio alle interferenze a proprie spese.

Electrostatic discharge caution statement

Electrostatic alert:

ESD

To prevent damage from electrostatic discharge, always wear an antistatic wrist strap connected to an

electrostatic discharge (ESD) jack when performing maintenance on this product. Ensure that the wrist

strap makes contact with your skin.

Electrostatic alert:

ATTENTION ESD (décharge électrostatique)

Pour prévenir tout dommage dû à une décharge électrostatique, vous devez toujours porter un un

bracelet antistatique connecté à une prise pour décharge électrostatique (ESD) lors de l'exécution

d'opérations de maintenance sur ce produit. Assurez-vous que le bracelet antistatique est en contact

avec votre peau.

Electrostatic alert:

ACHTUNG ESD

Um Schäden durch elektrostatische Entladung zu verhindern, tragen Sie bei der Instandhaltung dieses

Produkts immer ein antistatisches Band am Handgelenk, das mit einer ESD-Buchse verbunden ist.

Stellen Sie sicher, dass das Band am Handgelenk Kontakt zur Haut hat.

Electrostatic alert:

PRECAUCIÓN ESD (Descarga electrostática)

Para prevenir el daño producido por una descarga electrostática, use siempre una pulsera antiestática

conectada a un enchufe de descarga electrostática (ESD) al realizar el mantenimiento de este

producto. Asegúrese de que la pulsera antiestática haga contacto con su piel.

Electrostatic alert:

CUIDADO ESD

Para evitar danos com descarga eletrostática, sempre use uma pulseira antiestática que esteja

conectada a uma tomada de descarga eletrostática (ESD) quando estiver realizando a manutenção

deste produto. Certifique-se de que a pulseira esteja em contato com sua pele.

Electrostatic alert:

ATTENZIONE ESD

Per evitare danni derivanti da scariche elettrostatiche, indossare sempre un polsino antistatico collegato

a una presa di scarico elettrostatico (ESD) durante la manutenzione del prodotto. Accertarsi che il

polsino sia a contatto con la pelle.

56 Installation — Chassis October 2011

Comments? infodev@avaya.com

Page 57

Laser fiber optic warning statement

Warning:

Risk of eye injury by laser

Fiber optic equipment can emit laser or infrared light that can injure your eyes. Never look into an optical

fiber or connector port. Always assume that fiber optic cables are connected to a light source.

Warning:

AVERTISSEMENT

Risques de blessure oculaire par lumière laser

L'équipement de fibres optiques peut émettre une lumière laser ou infrarouge nuisible à vos yeux. Ne

regardez jamais en direction de fibres optiques ou d'un port connecteur. Supposez toujours que les

câbles de fibres optiques sont connectés à une source de lumière.

Warning:

WARNUNG

Risiko einer Augenverletzung durch Laser

Glasfasergeräte können Laserstrahlen oder ultraviolettes Licht aussenden, das Ihre Augen verletzen

kann. Schauen Sie nie direkt in einen Glasfaserleiter oder Verbindungsanschluss. Gehen Sie immer

davon aus, dass Glasfaserkabel mit einer Lichtquelle verbunden sind.

Warning:

ADVERTENCIA

Riesgo de lesión en los ojos por láser

El equipo de fibra óptica puede emitir una luz láser o infrarroja que dañe sus ojos. Nunca mire un puerto

de fibra óptica o conector. Siempre asuma que los cables de fibra óptica están conectados a una fuente

de luz.

Warning:

AVISO

O laser pode causar ferimentos no olho

O equipamento de fibra ótica pode emitir laser ou luz infravermelha que pode causar danos a sua vista.

Nunca olhe para dentro da fibra ótica ou da porta do conector. Tenha sempre em mente que os cabos

de fibra ótica estão ligados a uma fonte de luz.

Warning:

AVVISO

Rischio di ustioni agli occhi dovute al laser

Installation — Chassis October 2011 57

Page 58

Translations of safety messages

Le apparecchiature con fibre ottiche possono emettere raggi laser o infrarossi in grado di provocare

ferite agli occhi. Non guardare mai all'interno di una porta di connessione o una fibra ottica. Tenere

sempre presente che i cavi a fibra ottica sono collegati a una sorgente luminosa.

Lifting 9012 chassis warning statement

Warning:

Risk of personal injury

It requires three people to lift the Virtual Services Platform 9000 chassis. To make the chassis lighter,

remove the modules and power supplies before you lift it.

Warning:

AVERTISSEMENT

Risques de blessure corporelle

Trois personnes sont nécessaires pour soulever le châssis VSP. Pour alléger le châssis, retirez les

modules et les alimentations avant de le soulever.

Warning:

WARNUNG

Verletzungsrisiko

Es sind 3 Personen notwendig, um das Chassis des VSP anzuheben. Entfernen Sie vor dem Anheben

die Module und die Netzteile, um so das Gewicht des Chassis zu reduzieren.

Warning:

ADVERTENCIA

Riesgo de lesiones

Se necesitan tres personas para levantar el chasis de VSP. Para alivianar el peso, retire los módulos

y las fuentes de alimentación antes de levantarlo.

Warning:

AVISO

Risco de ferimento

Para erguer o chassi VSP, são necessárias três pessoas. Para erguer o chassi, remova os módulos e

as fontes de alimentação antes de erguê-lo.

Warning:

AVVISO

Rischio di lesioni personali