Page 1

MODEL NUMBER: D-24

ELECTRIC CLOTHES DRYER

OWNER’S MANUAL

CAUTION:

BEFORE USE, PLEASE READ AND FOLLOW ALL SAFETY RULES AND OPERATING

INSTRUCTIONS. SAVE THESE INSTRUCTIONS.

Avanti has a policy of continuous improvement on its products and reserves the right to

change materials and specifications without notice.

Avanti Products

www.avantiproducts.com

Page 2

Registration Card

Thank you for purchasing this fine Avanci product. Please fill out this card and return it

within 100 days of purchase and receive these important benefits:

Protect your product:

We will keep the model number and date of purchase of your new Avand

product on file to help you rfcfer to this information in the event of an insurance

claim such as fire or theft.

Promote better products:

We value your input. Your responses will help us develop products designed to

best meet vour future needs.

V-

, : V ^ ' *•- —

--------------- (detach here)

Avanti Registration Card

Name

Address

City

Area Code Phone Number

Did You Purchase An Additional Warranty:

□ Extended G Food Loss □ None

Reason For Choosing This Avanti Product:

Please indicate the most important factors

that influenced your decision to purchase

this product.

G Price

G Product Features

□ Avanti Reputation

G Product Quality

G Salesperson Recommendation

G Friend^Reiath/e Recommendation

"B Warranty

□ Other

-------------------------------------------

___________________

State

Zip

-------------------

Model#

Serial #

Date Purchased Store/Dealer Name

Occupation

As Your Primarv Residence. Do You:

□ Own

□ Rent

Your Aoe:

□ under 18 □ 18-25

G 31-35 □ 36-50

□ 26-30

□ over 50

Marital Status:

G Mamed u Single

Is This Product Used In The:

G Home □ Business

How Did You Learn About This Product:

G Advertising C Product Features

G In Store Demo G Personal Demo

G Other____________________________

Comments___________________

-

Page 3

HELP US HELP YOU...

Help Us Help You...

Read this guide carefully.

It is intended to help you operate and

maintain your new ^pliance properly.

Keep it handy to answer your questions.

If you don’t understand something or

your need more help, please call:

Write down the model and

serial numbers.

You'll find them on a plate located on

the back wall of the appliance.

Please write these numbers here:

Date of Purchase

AvantI Custonrier Service

800-220-5570

Model Number

Keep proof of original purchase date

(such as your sales slip) with this guide

to establish the warranty period.

Use these numbers in any correspondence or service calls concerning your appliance.

If you received a damaged appliance, immediately contact the dealer (or builder) that sold

you the appliance.

Save time and money. Before you call for service, check the Troubleshooting Guide.

It lists causes of minor operating problems that you can correct yourself.

Serial Number

IF YOU NEED SERVICE

We re proud of our service and want you

to be pleased. If for some reason you are

not happy with the service you receive,

here are some steps to follow for further

help.

FIRST, contact the people who serviced

your appliance. Explain why you are not

pleased. In most case.s. this will solve

the problem.

IVEXT. if you are srili not pleased, write

all the details, including your telephone

number, and send to:

Customer Service

Avanti Products

10880 NW 30 Street

Miami, FL 33172

Page 4

Table of Contents

-i-'

Registration Card

.........................................................................

Help Us Help You

Help us help you .................................................................................3

If you need service...............................................................................3

Safety Instructions

......

............................................................5,6

Installation Instructions

Installation instructions exhaust .............................................................7

Exhaust length calculation....................................................................8

Exhaust directions .............................................................................. 8

Special installation requirements ...........................................................9

Electrical power supply ........................................................................ 9

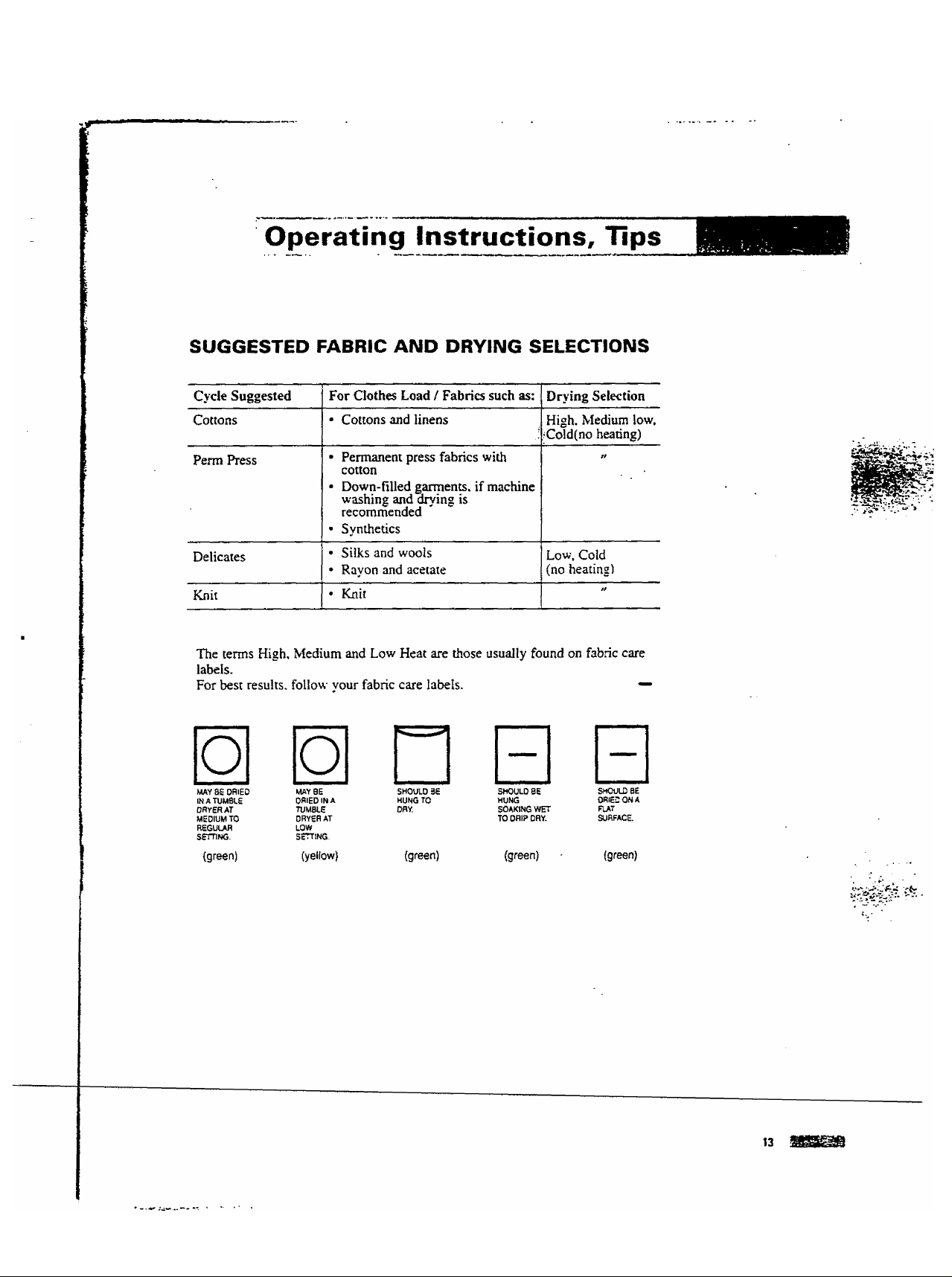

Operating Instructions, Tips

About the dryer control paneliD-24)

How to operate your dryer..................................................................11

Operating your dryer

How to load the clothes.......................................................................12

Suggested fabric and drying selections ................................................13

........................................-...

.....................................................

...............................12

Care and Cleaning

Clean the filter before every dryer use ..................................................14

Care and cleaning ............................................................................. 14

Maximize your dryer efficiency by keeping

the exhaust duct clean....................................................................... .15

Cleaning lint from your dryer ............................................................... 15

2

10

^ - V... 'l;-^

Problem Solver

Questions? Use this problem solver.....................................................16

Your Avanti Products Warranty

What is covered limited one-year warranty

Limited 5 year warranty

What is not covered

......................................................................

............................

...........................................

:................................................17

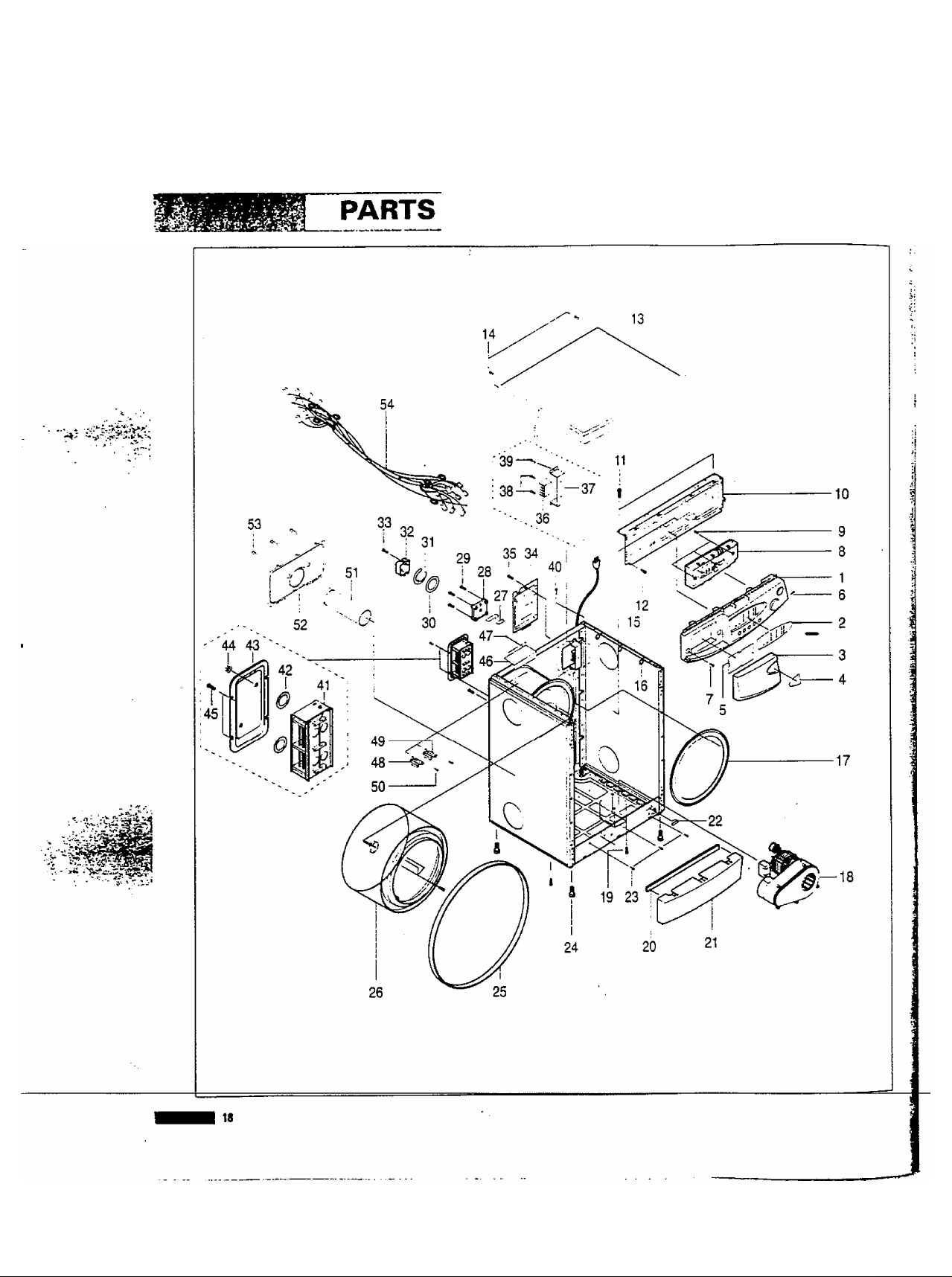

Parts Breakdown

Parts Breakdown/Parts List

Wiring Digram ...................................................................................23

-----

Schematic Diagram-......................................................................... 24

...........

................................................18"-22

17

17

Page 5

Safety instructions

Read all instructions before using this appliance

WARNING - It is extremeh important that you read and adhtre to the following

A

• Use this appliance only for its intended purpose as descr bed in this

Owner's Manual.

- This dryer must be properly installed and located in accordance with the

Installation Instructions before it is used.

- Properly ground to conform with Local Codes. Follow details in Installation

Instructions.

- Locate where the temperature is above SO^Fi lO^C.) for satisfactory

operation of the dr> er control system. Do not install or store the dryer

where it will be e.xposed to the weather.

- Connect CO a properly rated, protected and sized power supply circuit to

avoid electrical overload.

- Exhausting to the outside is STRONGLY RECOMMENDED to prevent

large amounts of moisture and lint from being blown into the room.

Carefully follow the Exhausting Details in the Installation Instructions.

- Do not repair or replace any part of the appliance or attempt any servicing

unless specifically recommended in this Owner’s Manual.

- ^"hen disconnecting this appliance pull by the plug rather than the cord to

avoid damage to the cord or junction of cord and plug. Make sure that the

cord is located so that it will not be stepped on. tripped over or otherwise

subjected to damage or stress.

“ This dryer is intended for use only with fabrics that have been washed with

water as a cleaning agent.

To Minimize the Possibility of a Fire Hazard

• Exhaust Duct - See Installation Instructions. Use only rigid metal or flexible metal

4” diameter ductwork for exhausting to the outside. USE OF PLASTIC OR

OTHER COMBUSTIBLE DUCTWORK CAN CAUSE A FIRE. FOIL OR

OTHER EASILY PL'NCTLTIED DUCTWORK CAN CAUSE A FIRE IF IT

COLL.APSES OR BECOMES OTHERWISE RESTRICTED IN USE OR

DURING LNSTALL-ATION.

• Do not use heat to dry articles containing rubber, plastic, or similar materials (such as

padded bra.*:, tennis shoes, galoshes, bath mats. rugs. bibs, pillows, baby pants, plastic

bags. etc. I as the;-e materials ma\ melt or bum. .Also, some rubber materials, when

heated, can under certain circum.-;tances produce tire by spontaneous combustion.

• Do not store items that ma\ bum or melt (such as clothing, paper material, plastics

or plastic containers, etc. i on top of the dryer during the operation.

• Garments labeled "Chy .Awa> from Heat" must not be put in your dry'er.

• Do not wash or dry articles that have been cleaned in. washed in. soaked in. or

sponed with combustible or explosive substances (such as wa.x. paint, gasoline

degreasers, dry-cleaning soKenLs, kerosene, etc.) which may ignite or explode. Do

not add these substances to the wash water. Do not use these substances around

your Wisher and/or dryer during operation.

• -Any anide on which )ou ha\e used a cleaning solvent, or which contains

Hammabie materials i such as cleaning cloths, mops, towels used in beauty salons.

restaurants or barber shop.s, etc. > must not tie placed in or near dTEiiyei until all

traces of these nammable liquids or solids and their fumes have been removed.

There are many highly Hammabie items used in homes such as: acetone, denatured

alcohol, gasoline, kerosene, some household cleaners, some spot removers,

turpentines, waxes, wax removers and products containing petroleum distillates.

instructioR& FaOure to do so could cause boditv injuries and/or

proper^ damage due to fire

Page 6

Safety Instructions

• Clean the lint filter before eaeh load to prevent lint accumulation inside the

drver or in the room. DO NOT OPERATE THE DRYER WITHOLT THE

LINT FILTER IN PLACE.

• Keep the area around the exhaust opening, and around and underneath your

appliances free from the accumulation of combustible materials, such as lint,

paper, rags, chemicals, etc.

• Regularly inspect the exhaust duct to be sure it has not been crushed or

othewise restricted. ^

• The interior of the dryer cabinet and the e.xhaust duct connection inside the

dryer should be cleaned every 2 to 3 years, or more often if needed, by a

qualified service person.

To Minimize the Possibility of Injury

• Never reach into the dryer while the drum is moving. Before loading,

unloading or adding clothes, wait until the drum has completely stopped.

• Do not dry fiberglass articles in your dryer. Skin irritation could result from

the remaining glass panicles that may be picked up by clothing during

subsequent dryer uses.

• The laundry process can reduce the flame retardance of fabrics. To avoid such

a result, the garment manufacturer's core instructions should be followed very

carefully. “

• Close supervision is necessary if this appliance is used by or near children. Do

not allow children to play inside, on, or with this appliance or any discarded

appliance. Dispose of discarded appliances and shipping or packing materials

properly. Before discarding a dryer, or removing from service, remove the

door of the dryer compartment.

• Keep all laundry aids (such as detergents, bleaches, fabric softeners, etc.) out

of the reach of children, preferably in a locked cabinet. Observe all warnings

on container labels to avoid personal injury.

• Keep the floor around your appliances clean and dry to reduce the possibility

of slipping.

• To minimize the possibility of electric shock, unplug this appliance from the

power supply before attempting any maintenance or cleaning (except the

removal and cleaning of the lint filter).

• Do not tamper with the controls.

• Do not operate this appliance if it is damaged, malfunctioning, partially

disassembled, or has missing or broken parts, including a damaged cord or plug.

• .Never climb on or stand on the dryer top.

• DO NOT place items exposed to cooking oils in your dryer. Items

contaminated with cooking oils may contribute to a chemical reaction that

could cause a clothes load to catch fire.

• The plug must be reachable after installing the appliance.

^VE THESE INSTRUCTIONS

Page 7

Installation Instructions

INSTALLATION INSTRUCTIONS EXHAUST

Installation and ser\'ice must be pertbnned by a qualified installer, senice agency

IMPORTANT: Have your diyer installed properly.

A

NOTE: The WARNING and INIPORTANT instructions appearing in this manual are not meant

to cover all possible conditions and situations that may occur. It must be understood that

common sense, caution, and careiulness are faaors that CANNOT be Built into the dryer.

These factors MUST BE supplied by the person(s) installing, maintaining, or operating

the dryer.

Failure to install maintain, and/or operate this machine according to the manufacturer s instructions

may result in conditions which can produce bodily injury, electric shock and/or property damage.

This dryer comes ready for top

e.xhausting.

WARNINGS

• DO NOT USE NON .METALLIC

FLEXIBLE DUCT.

• Never use fle.xible duct inside the dryer.

• Do not terminate exhaust in a chimney,

range hood, gas vent, floor or attic. The

combination of lint and grease could

create a fire hazard or damages.

• Provide an access for inspection and

cleaning the exhaust system at least

once a vear.

EXHAUST LENGTH

The .\L\.XEva'M .ALLOWABLE length

of the exhaust system depends upon the

type of duct, number of turns, the type of

e.xhaust hood iwaJl capí, and all conditions

noted below. The maximum allowable

length for both rigid and flexible metal

duct is shown in the cable 1 (ne.xi page).

More than four nims is not

recommended.

EXHAUST SYSTEM CHECK LIST HOOD or WALL CAP

• Terminate in a manner to prevent back

drait'. or entry of bircL or other wildlife.

• Termination should present minimal

resistance to the exhaust air flow and

should require little or no maintenance

10 prevent dogging.

• Wall caps must be in.sialled at least .lOO

mm i. 12") abvive ground level or any

other abstraction with the ope.ning

pointed down,

•--If rtHif venL" or lou\ered plenums are

-----

rh.n aiKi hf> f^q(iiv:ilt>ni Ni a 100

mm 14") Jumpered w all cap in regard to

resistance to air flow, prevention of back

drafts and maintenance required to

prevent clogging.

SEPARATION OF TURNS

Separate all turns by at least lm(3ft) of

straight duct, including distance between

last turn and dampered wall cap. If two

turns must be closer than 1 m (3 ft.) deduct

3 m 110 ft.) from the maximum lengths

shown in the table for each occurrence.

TURNS OTHER THAN 90"

• One turn of 45^ or less may be ignored.

• Two 45'' turns should be treated as one

90°.

• Each turn over 45' should be treated as

one 90®,

SEALING OF JOINTS

• .All joints should be tight to avoid leaks.

The male end of each section of duct

must point away from the dryer.

• Do not assemble the duct work with

fastener that extend into the duct. They

will serve as a collection point for lint

• Duct joints can be made air and

moisture-tight by wrapping the

overlapped joints with duct tape.

INSULATION

• Duct work which mns through an

unheated area or is near an air

conditioning duct, should be insulated to

reduce condensation and lim build up

and be sloped down toward outdoors.

NOTE; .Never insiall screen m.side exhaust dua

WARNLNG: THE DR^ ER .MUST

E.mAUST TO THE OUTDOORS.

TO PREVE.NT LARGE .AMOUNTS OF

LLVT AND MOISTU'RE FROM

ACCUMLTATING AND TO .M.AINT.ALN

DR'i'LNG EFFICIENCY.THIS M.ACHLNT

MUST BE EXHAUSTED UU1 DOORSr

Page 8

Installation Instructions

EXHAUST LENGTH CALCULATION

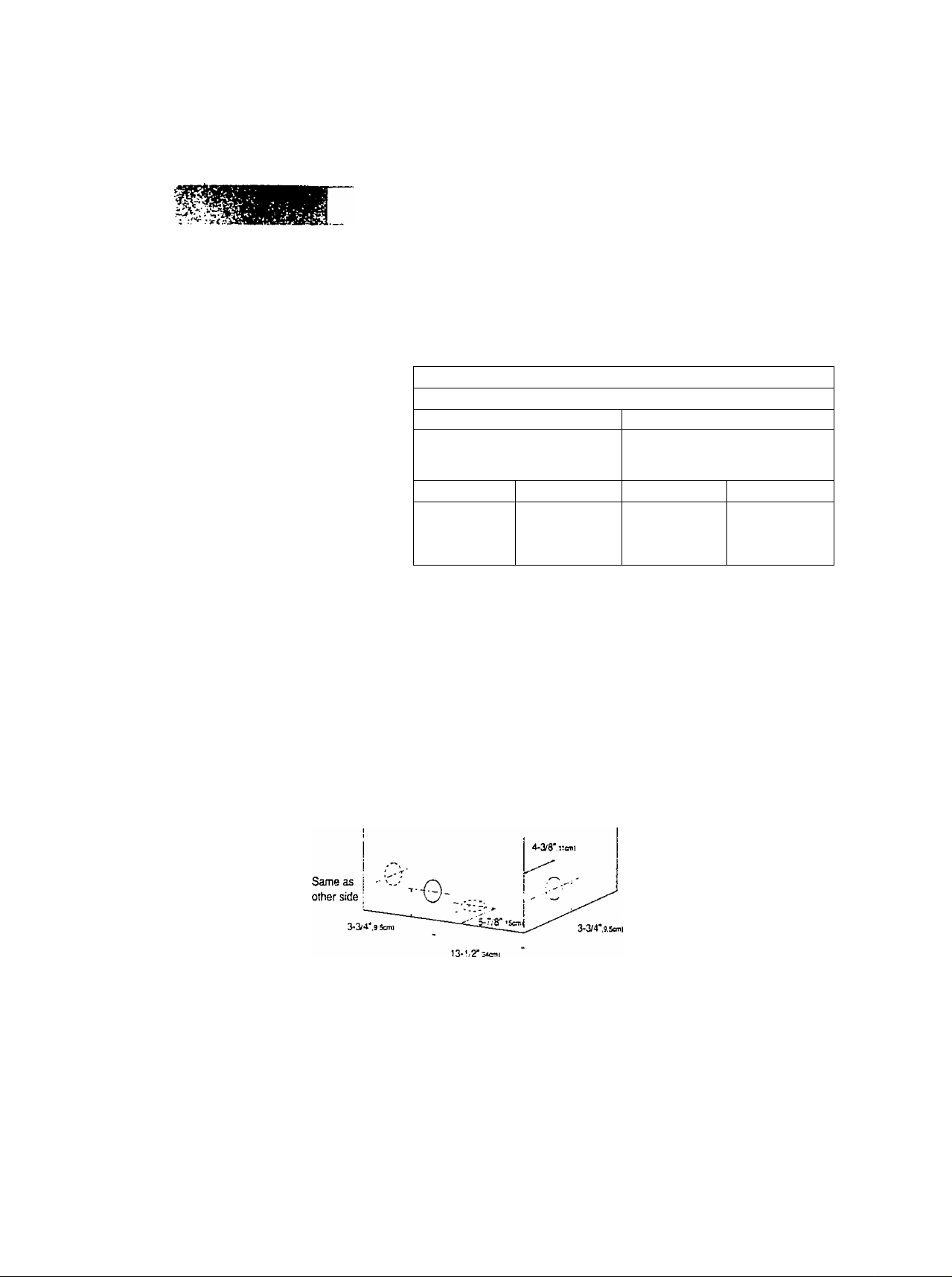

Table 1: RECOMMENDED MAXIMUM LENGTH

ELECTRIC DRYERS

Weather Hood Type

Recommended

L'se onlv for short run installations

No. of W

dlbowi

*-«a''n0.!6cmi

Rigid Metallic Rexibie*

14m(4brt.i

1 [m(38ft.)

9mi31 tt./

7miZ4t‘t. 1

9mi30ft.)

7Jmi25tt.)

bmtZOft.j

5 mi Ibft.t

Rigid Metallic Rexible*

1 lm{37ft.)

9m(30ft.)

6.5m(22ft.j

4.5m( 15ft.)

»-r2 [/2"(6.J5cml

7m(24ft.)

6m(20ft.)

4m{ 14ft.)

3mt 10ft. I

Do not use non metallic flexible duct.

EXHAUST DIRECTIONS

All dryers shipped from the factory are set up for rear exhausting. However

e.xhausting can be on the right or left side of the cabinet or the bottom of the

dryer.

• Remove access panel at back of dryer to gain access to internal ducts.

• Disconnect duct exhaust from blower housing.

• Remove desired knockout place (either right or left side).

• Attach a 90“ elbow duct to blower housing and facing desired opening.

• Reinstall rear access panel.

Left knockout

Blower.

i Bottom knockout

EXHAUST DUCT LOCATING DIMENSIONS

NOTE: Non-metallic ducts must never be used inside dryer cabinet.

Right knockout

Page 9

Installation Instructions

SPECIAL INSTALLATION REQUIREMENTS

ALCOVE OR CLOSET INSTALLATION

• VVARNCVG: To reduce the risk of fire, this drver ML'ST BE EXH-At STED TO THE

OLTDOORS. See EXRAUST IXFOILVLAflON section.

• Minimum clearances betv^ een diyer cabinet and adjacent wails or other surfaces are:

2” either side 3" from and rear

• Minimum vertical space from floor to overhead cabinets, ceilings, etc. is 52“( 132cm).

• Goset door must be louvered or othenvise ventilated and must contain a minimum of

60 sq. in. of open area equally distributed. If this closet contains both a washer and a

dryer, doors must contain a minimum of 120 sq. in. of open area equally distributed.

• No other fuel-burning appliance shall be installed in the same closet with the dryer.

MINIMUM CLEARANCES OTHER THAN ALCOVE OR CLOSET INSTALiATTONS.

• Minimum clearances to combustible surfaces: 2"clearance both sides and

3" rear.

MOBILE HOME INSTALLATION

• The dryer must be e.xhausted to the outdoors with the termination securely fastened to the

mobile home structure. (See EXH.\LST INFORMATfON section.)

• The exhaust ML'ST NOT be terminated beneath the mobile home.

• Provisions must be made for the introduction of outside air into the dryer. The free air

opiening shall not be less thji^SO cm* (12 in*)

• The exhaust duct material .ML’ST BE .METAL.

• The dryer must be attached to the floor following instructions a\ ailable from the dealer.

• Installation must comply with the current C.ANVCS.A Z240 MH series Mobile Home

Installation Codes.

NOTE: CO.N'SIDEILATIO.N .MUST BE GI\EN TO INST.UUING ANT) SERVICING THE

.■iJPLLAN'CE.

> C ^ri ■. Ijr-,

ELECTRICAL POWER SUPPLY

CALTION: .NEVER USE .AN EXTE.NS10N CORD WITH THIS APPLIANCE.

• This dryer must be connected to an individual circuit identical to the one specified on the

ratine plate of the loadine port, protected bv fuses or circuit breaker conformine to local

codes. THIS APPLIANCE .ML'ST BE PROPERLY GROL'NDED.

GROUNDING INSTRUCTIONS

• This appliance must be grounded. In the event of malfunction or breakdoun. grounding will

reduce the risk of eiectnc shock b> pro\ iding a path of least resistance for electric current.

The plug must be plugged into an appropriate outlet that Ls properl> installed and grounded

in accordance 'xith all local codes and ordinances.

WARNING:

• improper connection of the equipment grounding conductor can result in a risk of electric

shock. Check with a qualified electrician or ser\‘iceman if you are in doubt as to whether the

appliance i.s properly grounded,

• Do not modify the plug pro\ ided with the appliance - if it wilt not fit the outlet, have a

proper outlet installed a uualiiied electrician.

Note: If the electrical pi'wer •'Upply provided dtx;s not meet the specifica[iün^ listed below,

-------------

caiUüicea^cJ-elcctaáan.-----------------------------------------------------------------------------------------

Page 10

Operating instructions. Tips

WARNING - To mluce the risk of Rre, eiectric shix:k or Injun' to persois, read the

LMPORT.\.VrSAFET\' LNSTRL CTIONS before operating this appUance.

ABOUT THE DRYER CONTROL PANEL (D-24)

1. Display

2. Wrinkle Ease button

Press the button to turn Anti-crease indication lamp ON. Then, press the

button once more to turn the tamp OFF. You may make use of the button,

when doing anti-crease your laundry/.

3. Buzzer button

Press the button to turn End of Cycle indication lamp ON. When the cycle is

finished, buzzer makes sound. On the other hand, press the button once more

to turn End of Cycle indication lamp OFF.

4. Temperature button

Press the button to select dry temperature that you want. You may select

HIGH -* MEDIUM - LOW ^ COLD (no heating) in order, by pressing the

button continuously.

5. Fabrics button

Press the button to set temperature automatically for drying, depending upon

types of selected clothes. You may select COTTON — PERM PRESS -*■

DEDICATES KNIT in order, by pressing the button continuously. Al this

time, you may select temperature by pressing TEMP button. You may also

select HIGH, MEDIUM. LOW and COLD, etc by using COTTON and

PERM PRESS mode, or may select LOW and COLD mode by using

DEDICATES and KNIT mode.

6. Drying Time button

Press the button to set drying time and to make dry your laundry as you want.

You may select diying time (minutes) of 90 80 70 -* 60 -* 50 ^ 40

30 20 in order by pressing the button continuously.

7. Start/Pause button

Press the button to stan and pause the system.

8. Power button

Press the button one time to turn the system ON, and press it once more to

turn the system OFF. When the system turns ON for longer chan 10 minutes

without pressing any button, it automatically turns OFF.

Page 11

Operating Instructions, Tips

HOW TO OPERATE YOUR DRYER

To dry clothes using the Fabrics programs

1. Open the door and put the laundry in the dryer.

2. Egress the power button.

3. Choose the Fabrics program to the type of clothes you are drying.

You will see the indications light up on the control panel.

‘ 4. At this time you can control the temperature button.

5. Press the Start/Pause button and dry cycle will begin.

Prepare the laundry

- To prevent tangled bundles of laundry : Close zip fasteners : button-up bed

linen and pillow cases : tie-together loose tapes, e.g. aprons.

- Empty all pockets.

- Remove all metal objects {paper clips pins etc.)

- Untangle the laundry'.

.-wC i. ■ ■ .¡j \ ■

3-Wire System for Electric Dryers

1. Remove the cover of power supply connection.

2. Insert the power cord into the pjower cord hole, and connect with strain relief.

3. Connect each conductor on the terminal block following the sketch below.

Neutral! center conductor) to center terminal of terminal block.

Others to other terminaJs of terminal block.

4. Fix the cover of power supply connection.

Strain relief

mounting bracket

Power cord

Back of dryer

Cover of power supply

11

Page 12

Operating Instructions, Tips

OPERATING YOUR DRYER

Polyester Knits & Permanent Press Drying Tips

■ DO NOT OVERLOAD- Garments being dried or dewrinlckd should

tumble freely.

• REMOVE CLOTHES PROMPTLY- To help prevent wrinkling, remove

clothes from the dryer promptly at the end of the drying cycles.

• PLACE ON HANGERS- Permanent press and polyester knit garments

look best if placed on hangers after drying.

HOW TO LOAD THE CLOTHES

Don't overload your dryer. Crowded loads don't

dry efficiently and clothes may be unnecessarily

wrinkled.

HOW TO LOAD THE CLOTHES

As a general rule, sort clothes by surface texture, fabric, color and weight, as

you would for your washer.

Do not add fabric softener sheets once the load has become wann.

Do not overload. This wastes energy and caused wrinkling.

Do not dry the following items: fiberglass items, woolens, rubber- coated items,

plastics, items with plastic trim and foam-filled items.

Page 13

Page 14

Care and Cleaning

CLEAN THE FILTER BEFORE EVERY DRYER USE

Slide the grid out as shown

Clean the lint filter.

Put your moistened fingers '

at one comer of the filter

and wipe in a sideways

motion all the way across

to the other comer.

CLEAN LINT FILTER

AFTER EACH CYCLE

Do not operate the dryer without the grid in place.

PULL

Do not operate the dryer without the filter in place.

Periodically, remove ±e lint filter (it snaps in and out) and insert the suction

hose adapter from your vacuum cleaner into the opening.

Do the same through the rectangular opening at cop or bottom of the door and at

the louvers on the cabinet front.

CARE AND CLEANING

Dryer Exterior

Wipe off any spills or washing compounds. Wipe or dust with a damp cloth. Try

not to strike the surface with sharp objects.

Dryer control panel and finishes may be damaged by some laundry pre

treatment soil and stain remover products if such products are sprayed on or

have direct contact with the dryer.

Apply these pre-treatment products away from the dryer. The fabric may then be

washed and dried normally. Damage to your dryer caused by pre-treatment

products is not covered by your warranty.

Page 15

Care and Cleaning

MAXIMIZE YOUR DRYER EFFICIENCY BY KEEPING THE EXHAUST DUCT CLEAN.

1. Disconnect or Turn off

electrical power.

2. Disconnect duct from dryer.

3. Clean exhaust duct from end

where dryer is connected to the

exhaust hood using:

• the hose attachment of your

vacuum cleaner:

• a dust rag attached to a pole

(for straight stretches) or to a

draiajjleaning wire (for less

accessible turns).

4. Inspect exhaust hood. To minimize resistance to the exhaust air flow:

• flap must move freely (you may check with a mirror);

• flap should be fully open when dryer is on;

• ensure that no wildlife (birds, insects,...) have nested inside the duct.

CONNECTED

TO DRYER _

EXHAUST HOOD

/

ft)

Check turns in the exhaust

duct for any collected lint.

/

r

CLEANING LINT FROM YOUR DRYER

Combustible lint may collect on the inside of the drver cabinet. CLE.\N

EVERY 2 TO 3 YEARS OR MORE OFTEN DEPENDING ON I'SAGE.

Cleaning should be done by a qualified service person.

ALWAYS VERIFY PROPER OPERATION .AFTER SERVICING

15

Page 16

Problem Solver

QUESTIONS? USE THIS PROBLEM SOLVER

PROBLEM

DRYER WONT

START

CLOTHES TAKE TOO

LONG TO DRY

SHRINK.AGE,

GENERAL

WRINKLING

TO REMOVE

WRINKLES

i POSSIBLE CAUSE

• Dr\cr unplu^^sd. .Mokt; 'Ure pivwcr l'itiJ is pluggeJ in. j

• No po\sir :o ilrstfr. ChtiL'k fiist's jnd iimiuit breaktim !o muke sure dr. er is gciting

jurTint. Most ¿lectni.' Jners ust; IWH, j

• Controls impropcrls set. .Make 'ure amiroks are and that the Stan button is pressed.

Opsrmng the Jtn’f dunne operation >tops the dr\er. To restan. dose the door and

push the Stan button.

• Drser door is open. Close door securely - dryer will not run with door open.

• Circuit i.s overloaded. Do nor operate other appliances on the same electrical outlet

or circuit while the dryer is in operation.

• Controls Impropcrlv seL Check all comrois to make sure ihev are cotrectlv set for the

load you want to d^. See the How to Operate Your Dryer section. See the Care and

Cleaning section.

• Clogged iim tiller. Clean filter before every load. Periodically remove lint filter and ;

dean area under n with vacuum deancr. I

• Improper ducting. Make ^ure dryer is ducted in accordance with the Instoliation .

Instructions.

• Ob>tnicdon in e.chau.'.i ducting. Make 'ure ducting is clean and free of obstruction: |

make sure damper m oubide wall cap operates easily. If flexible ducting is used, be 1

sure It is not kinked and is properly installed according to the Installation

Instructions. i

• Blown fuses or tripped circuit breakers. Check household fuses or circuit breakers. *

Most electric dry cts use two. It is possible for one to be blown or tripped and the ^

dryer still tumble without heat

• Improper sotting. Do not mix heavy, haid-to-dty items with li^tweight articles,

• Large loads of moisture-holding fabrics, such as beach rowels, take a long dme to

remove moisture. i

• Too many items in dry er. Dry only one washer load at a dme. Do not combine

loads. ■

• Too few items in dryer. If drying only one aidde, add two more similar aitides. '

even if dry, to ensure proper tumbling.

• Some fabrics wiD shrink whether machine washed and tumble dried or washed bv ;

hand and drip dried: others may be safely washed but will shrink in a dryer. Follow

Gunnent Manufacnircrs’ Care Labels exactly. If in doubL do not machine wash or

tumble dry.

• Leaving clothes in dryer after tumbling stops. Remove clothes promptly and hang ]

them immediately. I

• Improper loads. .Avoid laundering heavy Permanent Press items, such as work 1

clothes, with lighter Permanent Press items, such as shirts or blouses. Do not wash

or dry Permanent Press with regular laundry.

• Failure to use fabric softener. Proper use of fabric softener will minimize wrinkling.

Try one or того of these suggestions

• Remmbte on Perm-Press setting,

' Rerinse and dry on Perma Press setting.

• If'uibuccessftil, renmibleon high heat for Ю-12 minutes and hang immedi^iy

• Iron carefully ;

• Send to dry cleaners for pressing

• Some wrinkles may remain which cannot be removed."

•NOT E:

If you follow good laundry procedures and Permanent Press clothes stiU

come out wrinkled the finish may not be good quality. .Also, in permanent press ■

synthetic/coiton blends the cotton ponton of the fabric can eventually wear away j

leaving only the symheoc. Since it's the cotton portion which is treated for Permanent f

Press, a loss or decrease of Permanent Press performance will result "Easy Care"

fabnes may eventually lose their finish and wrinkle even with proper care.

IF DRYER STILL DOES NOT OPER.ATE. C.ALL FOR SERVICE. GIV'E THE MODEL AND

SERIAL NL'NffiERS .AND DESCRIBE THE PROBLEMS YOU .ARE ENCOUNTERING.

j

Page 17

Your Avanti Products Warranty

WHAT IS COVERED

LIMITED ONE-YEAR WARRANTY

For one year from ihe date of purchase by the original owner. Avami Products will, at

its option, repair or replace any part of the appliance that proves to be defective in

material or workmanship under normal use. During this period Avanti Products will

provide all parts and labor necessary to correct such defects free of charge, so long as

the appliance has been installed and operated in accordance with the written

instructions in this manual. In rental or commercial use. the warranty period is 90 days.

Staph your sales receipt here. Proof of original purchase date is needed to

obtain service under warranty.

LIMITED 5 YEAR WARRANTY

After one year and until five years from date of purchase. Avanti will furnish a

replacement drum, which is defective in material or workmanship.

You will be charsed for labor.

WHAT IS NOT COVERED

• Incidental or consequential damages.

• Service calls to;

• Correct the installation of your dryer.

• Instruction on how to use your dryer.

• Replace house fuses or incorrect house wiring or plumbing.

• Repairs performed by unauthorized servicers.

• Repairs when your dryer is used in other than normal, single-family household use.

• Service calls that are related to external problems, such as abuse, misuse,

inadequate electrical power, accidents, fire, floods, or acts of God.

• Failure of the product if it is used for other than its intended purpose.

• Pickup and delisery. Your dryer is designed to be repaired in the home.

• Repairs caused by unauthorized modifications made to the appliance.

• This warranty does not apply outside the Continental L'.S.A..

17

Page 18

BREAKDOWN

Page 19

PARTS LIST

No.; Code No. ; Description

j OC97-01091R

DC6iC0013Y

DC6^C0055A

I

DC6d-iX)036F

! DC63^1iaA

I OC60-20030A

7 i0C6O20054C

8 MF-024JW-00

Q

DC60-20W9A

Oai-30344A

10

11

600&001240

CXH)-20060A

U

DC97-00851D

13

14

DC60-300158

DC9WXX)95A

15i

le! DC6140081A

171 DC97-01428A

18;

191 DC60-10019B

20; OC63O0108A

21 j DC61-10672A

22 DC6S00136A

231 0060-200100

241 DC61-00214A

25 DC6&O0121A

26; DC97-014248

27 i DC61-00215A

28. DC6&C0062A

29 DC60-20054C

30' X60-60003A

31 i 6044^1042

32; DC6S<XX)45A

33; DC60-20054C

34 i 0C63<XX)49A

OC60-20060A

3716-001155

DC61-00222A

DD60-20010D

DC60-20060A

DC60-10023A

41

DC47-00005D

6031-001253

42

OC63-00059A

45

DC60-50019A

DC6i>20060A

! ““

i 48

DC61-00300A

! 47

DC60-20060A

; 48

OG47-00002C

6002-000588

I 50

DC62^XX)60A

; 51

DC63-00050A

: 52

j 53 O C6 0 20060A

X9&C0224A ' ASSY-WIRE HARNESS : SDF-50V1.MUU

ASSY-PANEL con™. | O24;\VANTVDRYE№0EM

INLAY-PANEL

PANEL-ORAWER

INLAY-DETERGENT

COVER-DRAWER

SCREW TAPPING

SCREW TAPPING

ASSY-PCB PARTS

SCREW TAPPING

FRAME-PLATE(U)

SCREW-SPECIAL

SCREWTAPPING

ASSY-COVER TOP

SCREW-SPECIAL

ASSY-PAINTFRAME

HOLDER-WIRE

ASSY-OASKETPAD

ASSY-MOTOR DUCT

SCREW MACHINE

SPONGE-PLATE

COVER-FRONT(L)

CAP^OWER PLATE

SCREW TAPPING

LEG

B&T-TRANSMISSION

ASSY-DRUM

PLATE-SPRING

3USH-SHAFT

SCREW TAPPING

WASHER-PULSATOP

RING-E

COVER-BUSHING

SCREW TAPPING

COVER-POWER CORD | DV500aJ.SECCP.T0.6.-.-,DRYEaSCREW TAPPING j Tl-i.^2D4.L8.FE.FZY

TERMINAL-BLOCK | NON SOLDER.6P,-,600V,30A

BPACKET-TERMINALaLQCK; EGI.T0.5.SDF-50V1.-.DRYER,SCREW TAPPING j TH.-r2.D4.L122PC2(NTR),SCREW TAPPING | TH.-2D4.L8.FE.FZY

SCREW MACHINE ; Tn.*.04.L10ZPC2.TAP-TTTE

HEATER ;lRCAaV5OOeJ.MICA2OOOW.aA23OV,-.L17O.W0O.-.FOR

’WASHER-PLAIN ST3304.-.ID6,5.0D17.8.T2.0PASS

COVER-HEATER ; OV50C8J.SECCP.T0.6.-.-.DRYEaNL~F.ANGE : -.M4,-,MSWR10.SCREWTAPPING ‘ TH.-ZOA.LS.FE.FZY

BRACKET-HEATER : OV5008J.EGI.-,-.T0.6.-.-.DHYER

SCREW TAPPING ! T1-|.*2.04.L8.FE.FZY

THERMOSTAT ^SDF-V501.-250V.16A.145.-.-.-.-.-7ENTAN

SCREW-TAPPING ' TH.*2.M4.L6,ZPC(YEL),MSWR10

DUCT-OUTLET 'DV50C8J.G1.T0.5.0D100.L350.ID97.DRYER

COVER-SACK DV5008J.SECCP.T0.5.-.-.DRYEa-

-^EWRAPPiNG

Specification

D-24.PC.-.-.LGRY,-AVANTVDRYER

! D-24ABS(Hfr0760).PEARL_WHT(W9737),DF[YEFVAVAN

j D-24.PC.-,-.DGRY.-AVANTM0RYER^

D-24/DRYER.EGI.T0.5.-.-.UL

! FH.-.1,04.L12.NTR.iTH.-.1.D4.L12.FEF2Y.;D-24

' SCM4302.PH.-^.D4.L12.-,-.-.-

EGI.NTR.SWF-P12

SM10C.-.TH.-h,M5.LiaZPC{YEL),1

TH.-h2.D4.LS,FE,FZY

DV5006JC>RYEaWOODWVHT(W9737yTAPE

FlANGE,PH,-t-.D4.L122nFe(Ya),-

DV5008J,DRYERWHT

NYLON66,-,DAWH-2NC.NTR(PI18S)

OV5008J.GASKET-FELT/REAR

i D-24240V/60HZ

j RH.^,M5.L12.STS430.SEAL-LOCK

i DV5008J.Pl>rOAM.T13.W15.L440.GRY,DRYERaATE(

i SWF-Pl2.PP(BJ-730).-.-,WHT{W9737),-,I DV5006JEPOM.-,-.8LACK.DRYEFM-!AflDNESS_60,' ■m.^2,D4.L122PC2(NTR).-

DV5008JABS{VE0856).5V.WH[TE(W9737),-,DRYER

DV500eJ,RUB8ERL1975.RBNFORCED,DRYEFVDAYCO

OV50C8J,DRYERSTS “

SK5.T0.3.SDF-50V1 .DRYER

i P0M(TS-22).1D13.2.0D18.6.DRYER/WHT

iTH.-,1.D4.L12.FEFZY.: -.ID132.0D24T1.5.SBHG.STS304

: I010.0D20,T1.BLX.SK5

i DV5008J/DRYER.PPfTB54),-.-,WHT{W9711},-.i TH.-!-.1.D4.U2.FE FZY.-

-----

---------------------------------------------------

Qty Remartts

PANEL

PANa-ORAWER

PANa-ORAWER

PANa+FRAME

PANa-fORAWER

CPANa-PCB

PLATE(U)

FFtAME-PLATE(U)

COVER-TDP+FRAME

FRAME

MOTOR-hFRAME

PLATE-LOWER

LOWER-PLATE

DUCT-FFOVT-tPRAME

BUSH+FRAME

F/SHAFT

F-SHAFT

COVER-BUSH

OPOWER-PRAME

TERMINAL-BLOCK

&K-THER+FRAME

EARTH-WIRE

HEATER

HEATER-fCOVER+lEATER

.OHEATER-ifRAME

&K-HEATER

DUCT-INLET

THERMOSTAT

^BACKHFRAME-

19

Page 20

V.. ...

PARTS BREAKDOWN

'. -1 ■ ■■>

No. CocleNo.

1

DC61-00210A

3 0C63O0138A CAP-LAMP

4 OC6M0154A

5 DC664X»70A

DC9WX)096A

S

7

DC6020060A

DC54-X129A

3

9 DC97-01429A

DC6a60097A

10

It 6002-000445 SCREW-TAPPING

12 OC63-00108B

DC82-0CO69A

13

14

DC634X)062A

DC6300063A

15

16

DC61-00305A

17

DD60-20010D

18 6002-000445

19

-20- pDC60-3Qi4QB

-

Description

SUPPORT-DRUM

PA£W?ASKEr

BUSH-SUPPORT DRUM

ASSY-PAiNT FRONT

SCREW TAPPING

DOOR-aW

ASSY-GUIDE LP/ER

CAP-FRONT FRAME

SPONGE-PLATE

DUCT-FRONT DV5008J.PPfm54M}-,-.-,-.WHT/DRYEfl 1

SPONGE-DUCT DC5008J.PE-FOAM,T6.W6,L660,GRY.DRYER/FRONT

SPONGE-DUCT

RXER-HINGE

SCREW TAPPING

SCREW-TAPPING

ASSY-DOOR

■iTPFW TAPPINR

Specification

DV5008J,PP{TH54M).WHT(W9711-.DRYER 1

O-24.SlUCON.-,-.NTR,DRYERHAR0N£SS_65.P£-FELI-.-,SDF-50V1 .DRYER(FRONT)

POM(FL204)3>+TEFRON,-.-.DV5008vVWHT

DV5008JC1RYER,FRAME-FRONT,WHT 1

TH,+,2,D4.L3.FE.FZY 8

-,-.-.-.-,SDF-50Vl .-.WHT.DC24V(PUSHS(W)

DV5008J.DRYERff^P+SKS

DV5008J.PPfTB54),-,-.WHT(W9711).ORYER.-,

TH.-(-.2S.M4l18,NTR.STS304 4

OV5008J.PU-FOAM.T13,W35J.440.GRY,DRYER/FRONT

OV5008JroRYER.PU-FOAM,T13.W10.l435,BUCK.REAR

-.DV5008J.PP(TBS4VWHT(W9711),-,-.DRYER

T>l,+,2.D4.L12ZPC2(NTR),-

TR.+.2S.M4.LI8,iVTR,STS304

OV5008J.DRYER/WHT

FH.4..1.D4.120.STS304.-.-.-

Q'ty Remarks

1

1

4

FRAME-FRONT

1

4

2

SUPPORT-OFRAME-r

1

FRAME-FRONT

DUCT-FRONT

2

DUCT-FRONT

1

DUCT-FRONT

2

DUCT-F+FIXER-HINGE

2

DUCT-F+FRAME-F

2

1

HINGE+FRONT-FRAME

4

Page 21

PARTS BREAKDOWN

No.

Code No.

1

DC62-00064A

2 DC62-00064B SEAL-DOOR

DC63^)0096A COVER-HINGE

3

4

DC63-00046A COVER-DOOR DV5008J.PP(TH54M).-.-.\WHT(W9711 ).DRYER.DCS4-00099A

: 5

6

6002-001139

7

DC66-00112A

8 IX60-20030A

9 OC63-00058A

10 DC64^00096A

11

DC97-01490A

12 DC60-20030A SCREW TAPPING

13 rc97-0l427A ASSY-FILTER

l_U_

15 X83-Q0057A

[description Specification Qty Reniarks

SEAL-DOOR

DOOR-FRONT

SCREW-TAPPING

LEVER-DOOR

SCREW TAPPING

COVER-SCREW

HANDLE-DOOR

ASSY-HINGE

FILTER

COVER-FILTER

PVC.GRY,DRYER,L1189.T0.5.W9 1

PVC.GRY,DRY£R.L805.T0.5.W9 1

DV5008JPPrrB54),..-.WHT{W9711 ),DRYER,-

EGI.T0.6.-.-,-.SOF-50V1.-.-.ORYER 1

FH.T.1.M3.L16,BLK,SWRCH18A

OV5008J.POM(Fl2(W3).T3.-.-,-,WHT(W9711),DRYER

FH.-,1.04,L12,NTR,DV5008J.PP(TB54}.-.-,WKT(W9711 }.DRYER.DV5008Jj^6S(VE0856).-.-PEAflL_WHT{W9737).5V.-,DRYER

DV5008J.3TS430/2T 2

FH.-,1.D4112.NTR.OV5008J.ORYER/VWT/PP(TB54}

PPfTB54j,NYLON MESH,DV5008J/DRYEfl,WHT(W9711)

OV5008JPP(TB54).-,-,WHTiW97lif.UHYtH.-

2

1

4 COVER-DOOR+OOOR-F

DOOR

2

LEVER-DOOR

2

2

COVER-DOOR

1

4

HINGE+COVER-DOOR

1

—i

----

c.

i

2t

Page 22

-i.-

f.

PARTS BREAKDOWN

i: 16

No. Code No.

DC63-OOOS6A

1

2

DD60-20010D

OC60-5014SA

3

4

OC664X)063A FAN

DC62-00056A

5

DC60-20060A

5

rc90-10128H

7

OD60-20010D

3

DC31-00024A

9

10

DC61-00218A

11

DC60-20060A

0C614W304A

12

DC66-00111A

13

14

OC61-00244A

OC60-10003A SCREW MACHINE

15

DC61-00302A

16

DC6W30077A

17

DC61-00306A

18

DC61-00217A

19

DC61-00301A

20

DC60-20060A

21

00

DC62-000700

D060-200100

23

24

0061^(0081 A

Description Specification

COVER-DUCT FAN

SCREW TAPPING TH.^.2.D4.L12.ZPC2(NTR).NUT-HEX

DUCT-FAN

SCREW TAPPING

ASSY-THERMISTOR KS-PJT.RUBBERADD

SCREW TAPPING

MOTOR-DRYER

RXER-MOTOR

SCREW TAPPING

CUSHION-MOTOR

BUSH-MOTOR

SUPPORT-MOTOR

BRACKET-IDLER

HCtlEfl-BELT

SPRING-TENSIONER

BRACKET-MOTOR

SUPPORT-BRACKH MOTOR

SCREW TAPPING

CONDENSER-M.F

SCREW TAPPING

HOLDER-WIRE

Q’ty

SDF-50V1 ,PPfTH54M),-,-,VmT,DRYER,-

SM20C(NYLON),M8.-,-.2PC3{YEL),-.HEX.SQ-PROviECT

PP(A353),DRYER.NTR

OV5008J.PP(TH54M)/WHT-,-,.,-.DRYER

TH,+,2,D4.L8.FE.FZY 3

TH,h2.D4.L12.ZPC2(NTR).iC-14240SSWA,DRYER,-.60H2.-.-.3000.-.240V.B.-.2POLE

EGI, T1.SDF-50V1 .DRYER,-.TH.+,2.D4,L8,FE.FZY 2

-.0V5008J.CR.-.-.DRYER

POM(FL20-03),ID40.0D62.DV5008J(DRYER)

EGl.Tl .0.SDF-50V1DRYER, 2

-.-.M4.L6.FZY.DV5008J.Gl(HOTGI),-.-.T2.0,-,-,DRYER

0V5008J.POM{FL2O03).-.-,WHT,-.DRYER

0V5008J,HDSW-C,*'2.0.-.L68,18,0016.7,-.NTR,-,-

EGl.Tl .6.SDF-50V1 .-.DRYER,-.-,-,-

DV5008J.EGI.-.-.T0.6.L112,Wl0,DRYEfi

TH.>,2.04.L8,FE.FZY 4

A8S,L74,W35.-.DRYER(450VAC'6MFO}

TH.-r.2.D4,L12.ZPC2(NTR},- 1

NYLON66,-.DAWH-2NC,NTR(PI18.5)

Remarks

-

1

COVER-DUCT+DUCT

3

1

FAN

1

-

1

•

DUCT*MOTQR

1

DUCT-FAN

■mERMIS+DUCT

1

1

2

FiXER+BUSH-MOTOR

2

2

6 SUPPORT-MOTOR

1

1

1

1

2

Brt<-SUPPOflT-MOTOR

1 -

CONDENSOR

1

a/K-MOTOR

Page 23

WIRING DIAGRAM

23 V

Page 24

T. ■*' *** '

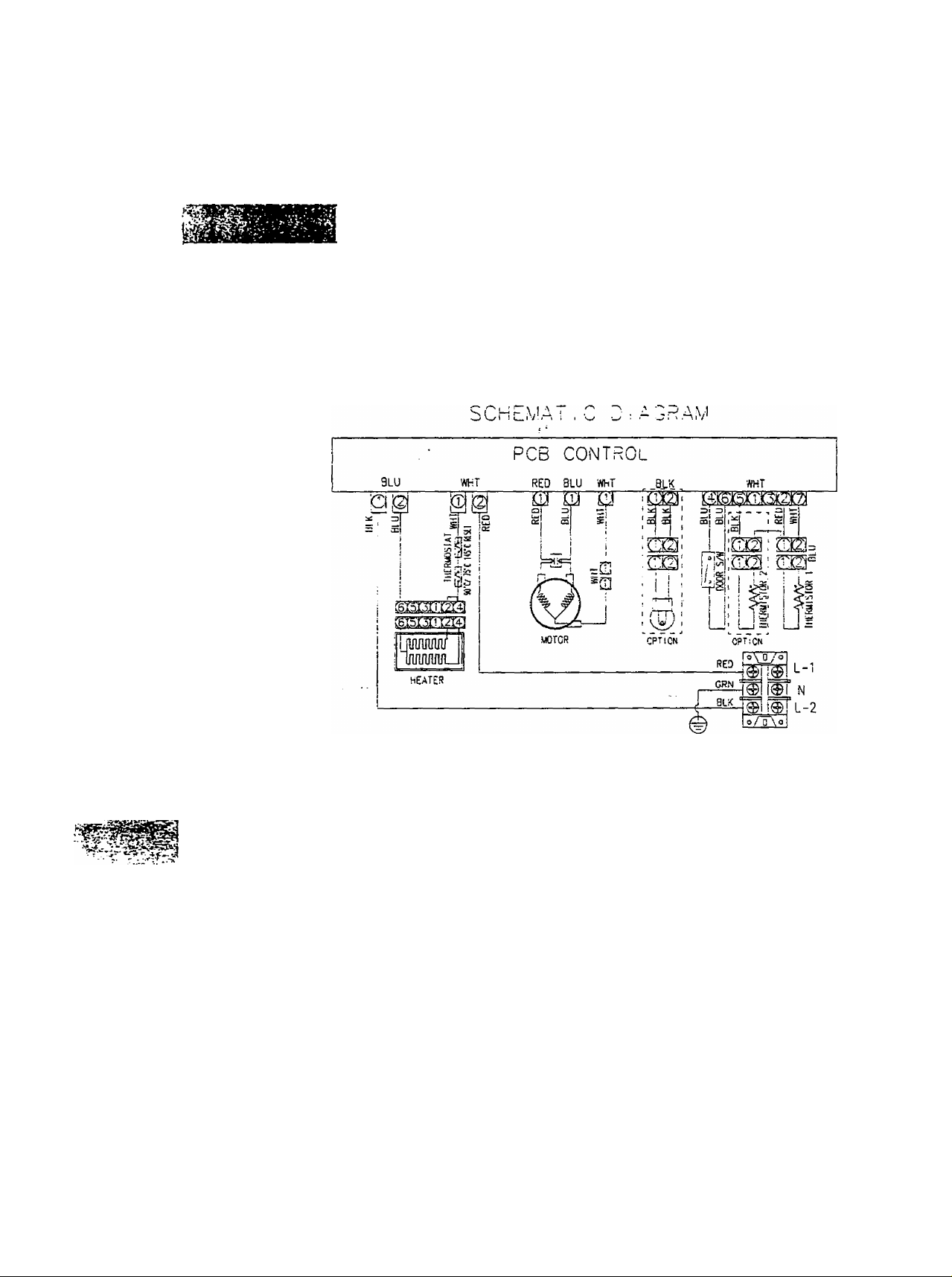

SCHEMATIC DIAGRAM

i/wwara

DC58-0C551A

Loading...

Loading...